Improved Energy Storage Performance of Composite Films Based on Linear/Ferroelectric Polarization Characteristics

Abstract

1. Introduction

2. Experimental Section

2.1. Raw Materials

2.2. Preparation of the Bilayer Films

2.3. Structural Characterization and Performance Testing

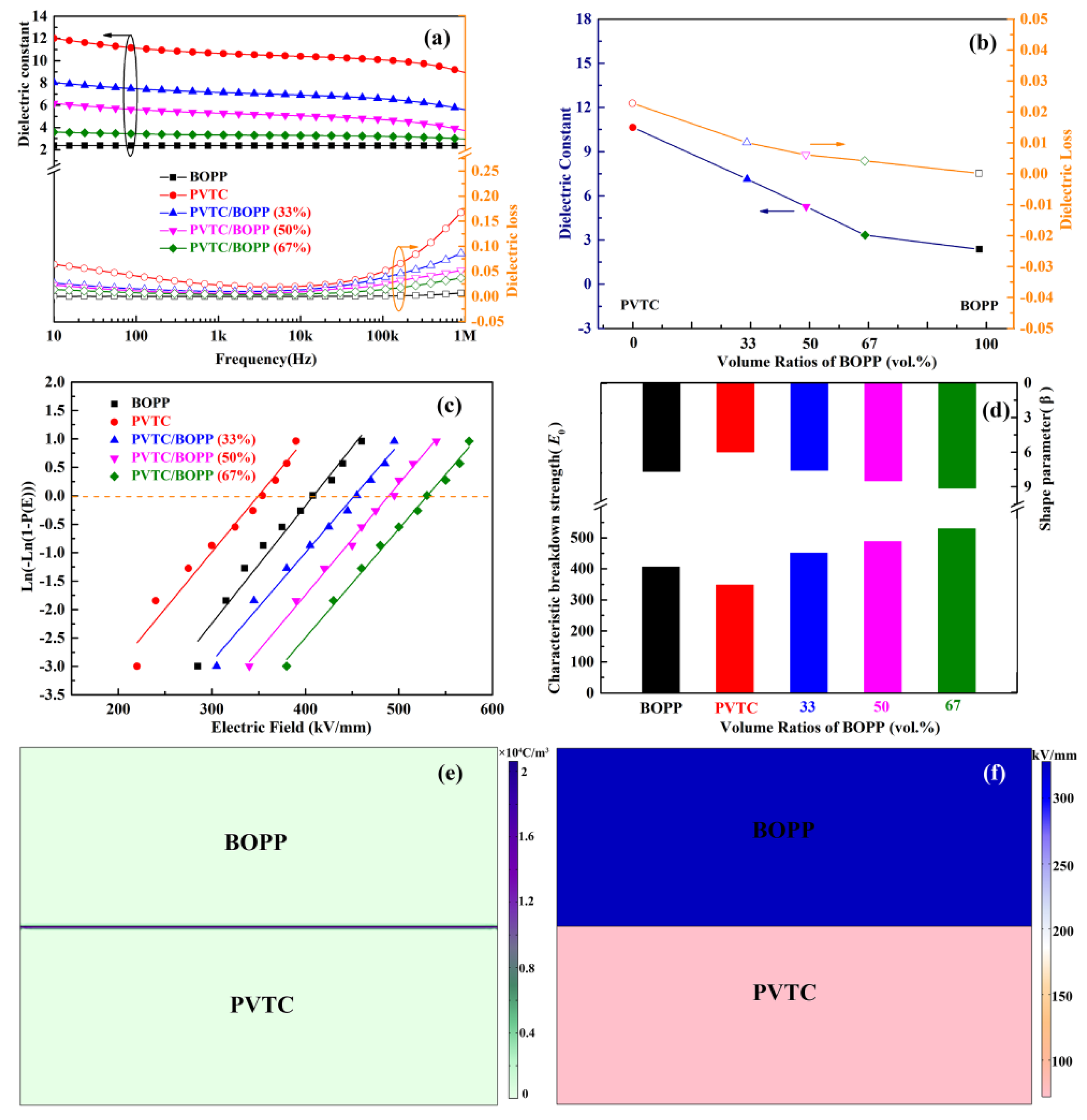

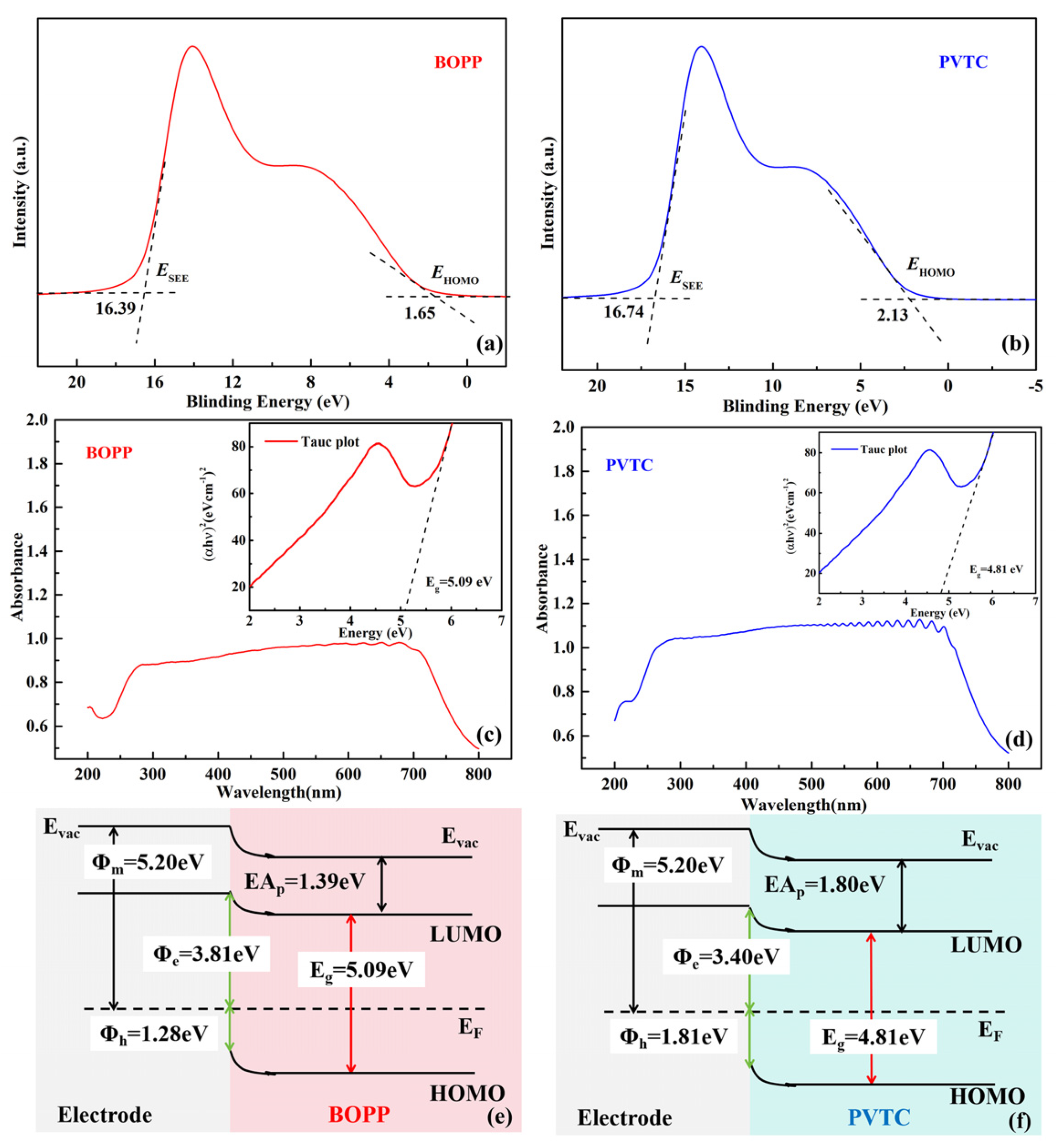

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Pei, J.; Yin, L.; Zhong, S.; Dang, Z. Suppressing the loss of polymer-based dielectrics for high power energy storage. Adv. Mater. 2023, 35, 2203623. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Huang, X. Dielectric polymers for emerging energy applications. Sci. Bull. 2023, 68, 1478–1483. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Matthew, R.; Zhang, S.; Zhang, G.; Li, H.; Aman, H.; Chen, L.; Jackson, T.; Wang, Q. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Zha, J.; Tian, Y.; Zheng, M.; Wan, B.; Yang, X.; Chen, G. High-temperature energy storage polyimide dielectric materials: Polymer multiple-structure design. Mater. Today Energy 2023, 31, 101217. [Google Scholar] [CrossRef]

- Dehghani-Sanij, A.; Tharumalingam, E.; Dusseault, M.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Cong, X.; Wang, Q.; Yi, H.; Li, S.; Zhang, C.; Zhang, T.; Wang, X.; Chi, Q. Enhanced energy storage performance of polyethersulfone-based dielectric composite via regulating heat treatment and filling phase. J. Alloy. Compd. 2023, 960, 170539. [Google Scholar] [CrossRef]

- Tang, H.; Sodano, H. Ultra-high energy density nanocomposite capacitors with fast discharge using Ba0.2Sr0.8TiO3 nanowires. Nano Lett. 2013, 13, 1373–1379. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Shen, Y.; Zhang, Q.; Gu, L.; Hu, Y.; Du, J.; Lin, Y.; Nan, C. Ultrahigh energy density of polymer nanocomposites containing BaTiO3@TiO2 nanofibers by atomic-scale interface engineering. Adv. Mater. 2015, 27, 819–824. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, X.; Thakur, Y.; Lu, B.; Zhang, Q.; Runt, J.; Zhang, Q. A highly scalable dielectric metamaterial with superior capacitor performance over a broad temperature. Sci. Adv. 2020, 6, eaax6622. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, J.; Yuan, Q.; Niu, Y.; Bai, Y.; Wang, H. Significantly enhanced breakdown strength and energy density in sandwich-structured barium titanate/poly (vinylidene fluoride) nanocomposites. Adv. Mater. 2015, 27, 6658–6663. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Hu, P.; Yu, J.; Fan, M.; Ji, X.; Sun, B.; Shen, Y. Topologically distributed one-dimensional TiO2 nanofillers maximize the dielectric energy density in a P(VDF-HFP) nanocomposite. J. Mater. Chem. A 2020, 8, 18244–18253. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, J.; Zhang, Q.; Yang, H.; Shen, D.; Zhou, F. Enhanced dielectric performance of P(VDF-HFP) composites filled with Ni@polydopamine@BaTiO3 nanowires. Colloids Surf. A Physicochem. Eng. Asp. 2019, 576, 55–62. [Google Scholar] [CrossRef]

- Li, H.; Yao, B.; Zhou, Y.; Xu, W.; Ren, L.; Ai, D.; Wang, Q. Bilayer-structured polymer nanocomposites exhibiting high breakdown strength and energy density via interfacial barrier design. ACS Appl. Energy Mater. 2020, 3, 8055–8063. [Google Scholar] [CrossRef]

- Bai, H.; Zhu, K.; Wang, Z.; Shen, B.; Zhai, J. 2D fillers highly boost the discharge energy density of polymer-based nanocomposites with trilayered architecture. Adv. Funct. Mater. 2021, 31, 2102646. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, Y.; Ji, Q.; Wei, S.; Du, P.; Luo, L.; Li, W. Significant enhancement of energy storage performances by regulating the dielectric contrast between adjacent layers in the heterostructural composites. ACS Appl. Energy Mater. 2020, 3, 3015–3023. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Li, H.; Ren, L.; Dong, L.; Xiong, C.; Wang, Q. Largely enhanced energy storage performance of sandwich-structured polymer nanocomposites with synergistic inorganic nanowires. Ceram. Int. 2019, 45, 8216–8221. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, Q.; Deng, Q.; Xu, Z. High-energy density in Si-based layered nanoceramic/polymer composites based on gradient design of ceramic bandgaps. Ceram. Int. 2019, 45, 16600–16607. [Google Scholar] [CrossRef]

- Feng, Y.; Xue, J.; Zhang, T.; Chi, Q.; Li, J.; Chen, Q.; Wang, J.; Chen, L. Double-gradients design of polymer nanocomposites with high energy density. Energy Storage Mater. 2022, 44, 73–81. [Google Scholar] [CrossRef]

- Wang, L.; Luo, H.; Zhou, X.; Yuan, X.; Zhou, K.; Zhang, D. Sandwich-structured all-organic composites with high breakdown strength and high dielectric constant for film capacitor. Compos. Part A: Appl. Sci. Manuf. 2019, 117, 369–376. [Google Scholar] [CrossRef]

- Daljeet, K.; Naveen, K.; Gagan, A.; Ranvir, S.; Charu, M. Enhancement of energy storage in nanocomposite thin films: Investigating PVDF-ZnO and PVDF-TZO for improved dielectric and ferroelectric characteristics. Phys. Scr. 2024, 99, 036101. [Google Scholar]

- Uwa, O.; Abimbola, P.; Olawale, M. Carbon nanotubes enhancement of tribological and nanomechanical properties of PVDF-BN nanocomposites. Polym. Bull. 2024. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Feng, Y.; Zhang, T.; Chen, Q.; Chi, Q.; Liu, L.; Wang, X.; Lei, Q. Energy storage enhancement of P(VDF-TrFE-CFE)-based composites with double shell structured BZCT nanofibers of parallel and orthogonal configurations. Nano Energy 2019, 66, 104195. [Google Scholar] [CrossRef]

- Wang, X.; An, Z.; Zhuo, M. Energy storage performance and dielectric properties of surface fluorinated BOPP films. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1950–1957. [Google Scholar] [CrossRef]

- Chi, Q.; Wang, T.; Zhang, C.; Yu, H.; Zhao, X.; Yang, X.; Lei, Q.; Zhao, H.; Zhang, T. Significantly improved high-temperature energy storage performance of commercial BOPP films by utilizing ultraviolet grafting modification. iEnergy 2022, 1, 374–382. [Google Scholar] [CrossRef]

- Yu, Y.; Li, J.; Xie, Z.; Gong, X.; Gao, G.; Wang, J.; Li, J. Characterizing piezoelectric properties of PVDF film under extreme loadings. Smart Mater. Struct. 2024, 33, 015026. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Y.; Jiang, J.; Lv, C.; Fu, H.; Xie, M. A flexible piezoelectric PVDF/MXene pressure sensor for roughness discrimination. IEEE Sens. J. 2024, 24, 7176–7184. [Google Scholar] [CrossRef]

- Adel, M.; Abdulrahman, I.; Hosam, H.; Penchal, R.; Mohamed, M.; Essam, A.; Waleed, H.; Teresa, D. Enhanced corrosion resistance and surface wettability of PVDF/ZnO and PVDF/TiO2 composite coatings: A comparative study. Coatings 2023, 13, 1729. [Google Scholar] [CrossRef]

- Zhang, T.; Liang, S.; Yu, H.; Zhang, C.; Tang, C.; Li, H.; Chi, Q. Improved high-temperature energy storage density at low-electric field in BOPP/PVDF multilayer films. J. Appl. Polym. Sci. 2023, 140, e54729. [Google Scholar] [CrossRef]

- Wang, D.; Yang, J.; Li, L.; Wang, X.; Yang, X.; Zhao, X.; Zhao, H.; Li, L.; Liu, H. Effect of shear action on structural and electrical insulation properties of polypropylene. Energies 2023, 16, 1421. [Google Scholar] [CrossRef]

- Gao, M.; Yang, J.; Zhao, H.; He, H.; Hu, M.; Xie, S. Preparation methods of polypropylene/nano-silica/styrene-ethylene-butylene-styrene composite and its effect on electrical properties. Polymers 2019, 11, 797. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Gao, Y.; Yu, C.; Gao, C.; Zhang, Y.; Li, E. Experimental study of the dielectric properties of energy-containing materials at variable temperatures. Rev. Sci. Instrum. 2023, 94, 035113. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Yan, W.; Zhang, Y.; Cui, Y.; Zhang, T.; Tang, C.; Liu, X.; Chi, Q. Enhanced energy storage performance of doped modified PC/PVDF coblended flexible composite films. ACS Appl. Electron. Mater. 2023, 5, 3817–3829. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Y.; Cheng, S.; Hu, J.; He, J.; Li, Q. Polymer nanocomposites with high energy density utilizing oriented nanosheets and high-dielectric-constant nanoparticles. Materials 2021, 14, 4780. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhang, T.; Zhang, C.; Feng, Y.; Zhang, Y.; Zhang, Y.; Chi, Q.; Wang, X.; Lei, Q. Improved energy storage performance of P(VDF-TrFE-CFE) multilayer films by utilizing inorganic functional layers. ACS Appl. Energy Mater. 2021, 4, 11726–11734. [Google Scholar] [CrossRef]

- Zhang, C.; Tong, X.; Liu, Z.; Zhang, Y.; Zhang, T.; Tang, C.; Liu, X.; Chi, Q. Enhancement of energy storage performance of PMMA/PVDF composites by changing the crystalline phase through heat treatment. Polymers 2023, 15, 2486. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wang, H.; Zhang, T.; Zhang, Y.; Zhang, Y.; Tang, C. Significantly enhanced energy storage density and efficiency of sandwich polymer-based composite via doped MgO and TiO2 nanofillers. J. Mater. Sci. 2023, 58, 12724–12735. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, C.; Zhang, T.; Feng, Y.; Zhang, Y.; Chi, Q.; Wang, X.; Lei, Q. Improved energy storage performances of solution-processable ferroelectric polymer by modulating of microscopic and mesoscopic structure. Compos. Part B 2020, 199, 108312. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, L.; Zhang, C.; Feng, Y.; Wang, J.; Shen, Z.; Chen, Q.; Lei, Q.; Chi, Q. Polymer dielectric films exhibiting superior high-temperature capacitive performance by utilizing an inorganic insulation interlayer. Mater. Horiz. 2022, 9, 1273–1282. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Q.; Dang, B.; Yang, Y.; Shao, T.; Li, H.; Hu, J.; Zeng, R.; He, J.; Wang, Q. A scalable, high-throughput, and environmentally benign approach to polymer dielectrics exhibiting significantly improved capacitive performance at high temperatures. Adv. Mater. 2018, 30, 1805672. [Google Scholar] [CrossRef]

- Tong, J.; Song, Z.; Kim, D.; Chen, X.; Chen, C.; Axel, F.; Paul, F.; Matthew, O.; Sean, P.; Obadiah, G.; et al. Carrier lifetimes of >1 ms in Sn-Pb perovskites enable efficient all-perovskite tandem solar cells. Science 2019, 364, 475–479. [Google Scholar] [CrossRef]

- Tong, J.; Jiang, Q.; Andrew, J.; Axel, F.; Wang, X.; Hao, J.; Sean, P.; Amy, E.; Steven, P.; Li, C.; et al. Carrier control in Sn-Pb perovskites via 2D cation engineering for all-perovskite tandem solar cells with improved efficiency and stability. Nat. Energy 2022, 7, 642–651. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, L.; Ruan, J.; Zhang, C.; Chi, Q. Improved high-temperature energy storage performance of PEI dielectric films by introducing an SiO2 insulating layer. Macromol. Mater. Eng. 2021, 306, 2100514. [Google Scholar] [CrossRef]

- Li, L.; Dong, J.; Hu, R.; Chen, X.; Niu, Y.; Wang, H. Wide-bandgap fluorides/polyimide composites with enhanced energy storage properties at high temperatures. Chem. Eng. J. 2022, 435, 135059. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, H.; Young, J.; Zhang, C.; Feng, Y.; Chen, Q.; Lee, K.; Chi, Q. Significantly improved high-temperature energy storage performance of BOPP films by coating nanoscale inorganic layer. Energy Environ. Mater. 2022, 7, e12549. [Google Scholar] [CrossRef]

- Liu, G.; Lei, Q.; Feng, Y.; Zhang, C.; Zhang, T.; Chen, Q.; Chi, Q. High-temperature energy storage dielectric with inhibition of carrier injection/migration based on band structure regulation. InfoMat 2023, 5, e12368. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, P.; Huang, X. Poly(vinylidene fluoride) terpolymer and poly(methyl methacrylate) composite films with superior energy storage performance for electrostatic capacitor application. Compos. Sci. Technol. 2019, 179, 115–124. [Google Scholar] [CrossRef]

- Sun, S.; Shi, Z.; Sun, L.; Liang, L.; Dastan, D.; He, B.; Wang, H.; Huang, M.; Fan, R. Achieving concurrent high energy density and efficiency in all polymer layered paraelectric/ferroelectric composites via introducing a moderate layer. ACS Appl. Mater. Interfaces 2021, 13, 27522–27532. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, Y.; Wang, L.; Yuan, Q.; Chen, J.; Niu, Y.; Xu, X.; Wang, Q.; Wang, H. Gradient-layered polymer nanocomposites with significantly improved insulation performance for dielectric energy storage. Energy Storage Mater. 2020, 24, 626–634. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, J.; Wang, L.; Yuan, Q.; Niu, Y.; Chen, J.; Wang, Q.; Wang, H. Compositional tailoring effect on electric field distribution for significantly enhanced breakdown strength and restrained conductive loss in sandwich-structured ceramic/polymer nanocomposites. J. Mater. Chem. A 2017, 5, 4710–4718. [Google Scholar] [CrossRef]

- Cui, Y.; Zhang, T.; Feng, Y.; Zhang, C.; Chi, Q.; Zhang, Y.; Chen, Q.; Wang, X.; Lei, Q. Excellent energy storage density and efficiency in blend polymer-based composites by design of coreshell structured inorganic fibers and sandwich structured films. Composites Part B 2019, 177, 107429. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, Q.; Zhang, L.; Zhu, Y.; Guo, X.; Fan, P.; Zhang, H. Ultrahigh discharged energy density in polymer nanocomposites by designing linear/ferroelectric bilayer heterostructure. Nano Energy 2018, 54, 437–446. [Google Scholar] [CrossRef]

- Marwat, M.; Xie, B.; Zhu, Y.; Fan, P.; Ma, W.; Liu, H.; Ashtar, M.; Xiao, J.; Salamon, D.; Samater, C.; et al. Largely enhanced discharge energy density in linear polymer nanocomposites by designing a sandwich structure. Compos. Part A 2019, 121, 115–122. [Google Scholar] [CrossRef]

- Pan, Z.; Yao, L.; Zhai, J.; Wang, H.; Shen, B. Ultrafast discharge and enhanced energy density of polymer nanocomposites loaded with 0.5(Ba0.7Ca0.3)TiO3-0.5Ba(Zr0.2Ti0.8)O3 one-dimensional nanofibers. ACS Appl. Mater. Interfaces 2017, 9, 14337–14346. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.; Liu, L.; Chi, Q.; Zhang, C.; Chen, Q.; Cui, Y.; Wang, X.; Lei, Q. Sandwich-structured PVDF-based composite incorporated with Hybrid Fe3O4@BN nanosheets for excellent dielectric properties and energy storage performance. J. Phys. Chem. C 2018, 122, 1500–1512. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Shen, L.; Liu, G.; Cui, Y.; Yan, S. Improved Energy Storage Performance of Composite Films Based on Linear/Ferroelectric Polarization Characteristics. Polymers 2024, 16, 1058. https://doi.org/10.3390/polym16081058

Chen C, Shen L, Liu G, Cui Y, Yan S. Improved Energy Storage Performance of Composite Films Based on Linear/Ferroelectric Polarization Characteristics. Polymers. 2024; 16(8):1058. https://doi.org/10.3390/polym16081058

Chicago/Turabian StyleChen, Chen, Lifang Shen, Guang Liu, Yang Cui, and Shubin Yan. 2024. "Improved Energy Storage Performance of Composite Films Based on Linear/Ferroelectric Polarization Characteristics" Polymers 16, no. 8: 1058. https://doi.org/10.3390/polym16081058

APA StyleChen, C., Shen, L., Liu, G., Cui, Y., & Yan, S. (2024). Improved Energy Storage Performance of Composite Films Based on Linear/Ferroelectric Polarization Characteristics. Polymers, 16(8), 1058. https://doi.org/10.3390/polym16081058