Characterization of Material Extrusion-Printed Amorphous Poly(Ether Ketone Ketone) (PEKK) Parts

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection

2.2. MEX Printing Parameter Selection

2.3. Thermal Treatment

2.4. Sample Characterization

3. Results and Discussion

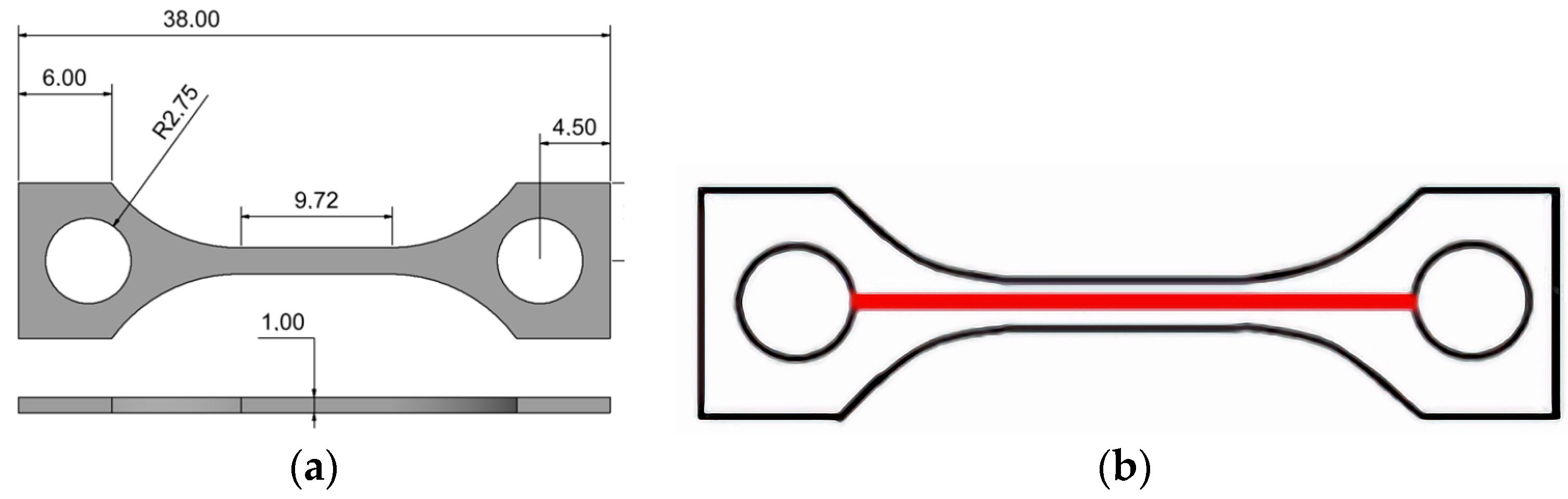

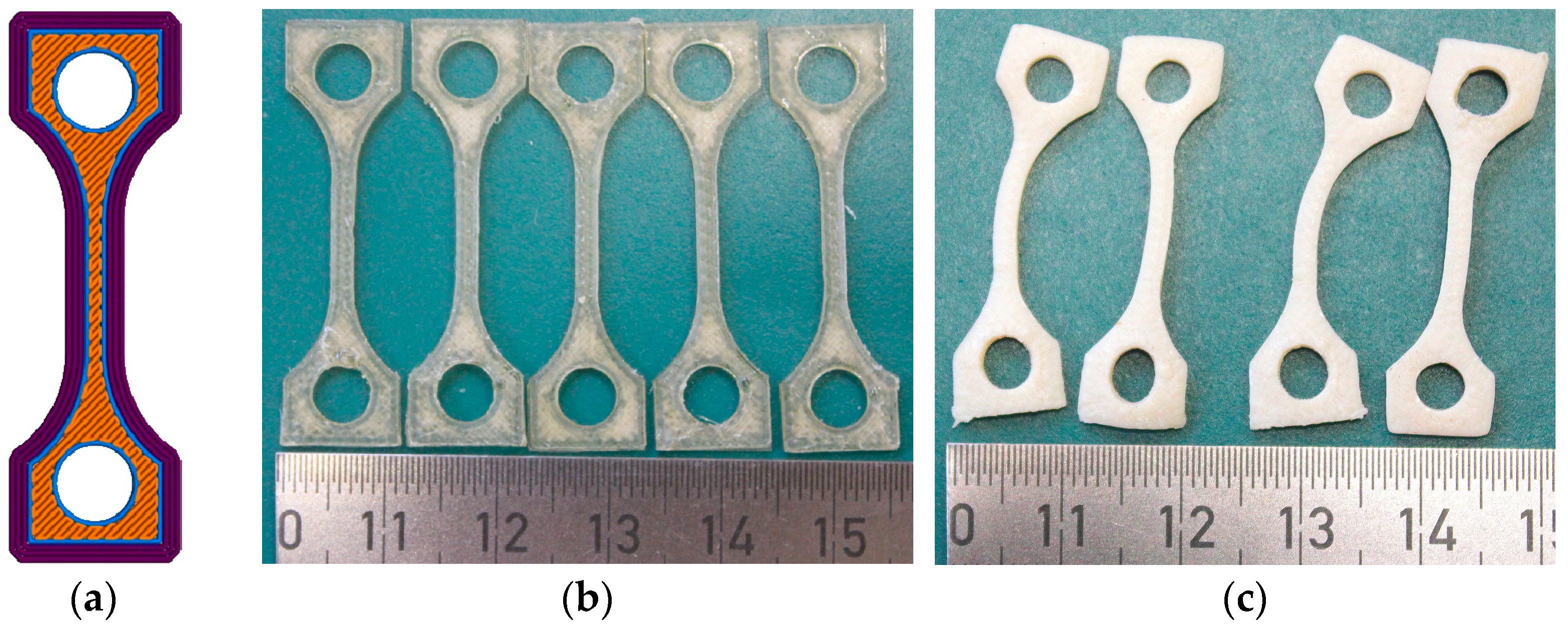

3.1. MEX Printing of Tensile Test Specimens

3.2. Printed Sample Characterization

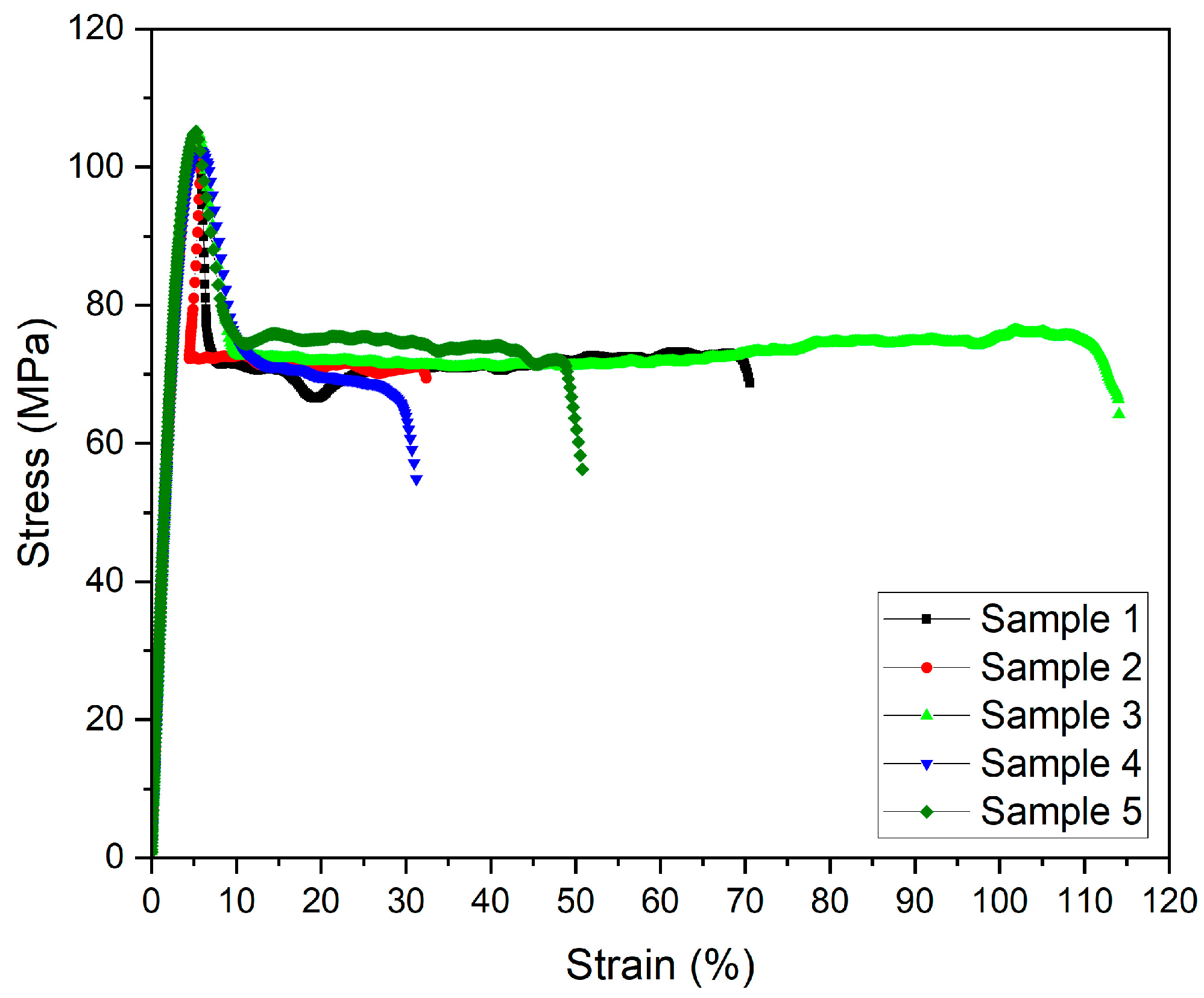

3.2.1. Mechanical Testing

3.2.2. Surface Roughness

- Rmax: The maximum difference between the valley and peak.

- Rz: The maximum peak-to-valley height of the measured profile line.

- Ra: The average deviation from the mean or center line.

- Rq: The average root mean square deviation from the mean line.

3.2.3. Thermal Conductivity

3.3. MEX Printing as a Rapid Tooling Method

4. Conclusions and Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fakirov, S. Fundamentals of Polymer Science for Engineers; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2017; pp. 353–355. ISBN 978-3-527-34131-3. [Google Scholar]

- Pelin, G.; Sonmez, M.; Pelin, C.E. The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review. Polymers 2024, 16, 1055. [Google Scholar] [CrossRef] [PubMed]

- Medesi, A.J.; Nötzel, D.; Wohlgemuth, J.; Franzreb, M.; Hanemann, T. Ceramic Injection Moulding using 3D-Printed Mould Inserts. Ceram. Mod. Technol. 2019, 1, 104–110. [Google Scholar] [CrossRef]

- Available online: https://www.kern.de/de/kunststofflexikon (accessed on 2 December 2024).

- Available online: https://www.sciencedirect.com/topics/materials-science/high-performance-polymer (accessed on 2 December 2024).

- Leach, D.; Bai, J.M. High Performance Thermoplastic Polymers and Composites (paper P156). In Proceedings of the SAMPE Conference, Long Beach, CA, USA, 1–5 May 2005. [Google Scholar]

- Parker, D.; Bussink, J.; van de Grampel, H.T.; Wheatley, G.W.; Dorf, E.-U.; Ostlinning, E.; Reinking, K. Polymers, High-Temperature. In Ullmann’s Encyclopedia of Industrial Chemistry 2005; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2000; pp. 1–26. [Google Scholar] [CrossRef]

- de Leon, A.C.; da Silva, Í.G.M.; Pangilinan, K.D.; Chen, Q.; Caldona, E.B.; Advincula, R.C. High performance polymers for oil and gas applications. React. Funct. Polym. 2021, 162, 104878. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Wang, R.; Wang, Q.; Wen, M.; Wang, J.; Sheng, L.; Zheng, Y.; Xi, T. A Review on 3D Printing Processes in Pharmaceutical Engineering and Tissue Engineering: Applications, Trends and Challenges. Adv. Mater. Technol. 2024, 10, 2400620. [Google Scholar] [CrossRef]

- Pugliese, R.; Beltrami, B.; Regondi, S.; Lunetta, C. Polymeric biomaterials for 3D printing in medicine: An overview. Ann. 3d Print. Med. 2021, 2, 100011. [Google Scholar] [CrossRef]

- Hanemann, T.; Klein, A.; Baumgaertner, S.; Jung, J.; Wilhelm, D.; Antusch, S. Material extrusion 3D printing of PEEK-based composites. Polymers 2023, 15, 3412. [Google Scholar] [CrossRef] [PubMed]

- Hanemann, T.; Klein, A.; Baumgaertner, S.; Wilhelm, D.; Antusch, S. Evaluation of Material Extrusion Printed PEEK Mold Inserts for Usage in Ceramic Injection Molding. J. Manuf. Mater. Process. 2024, 8, 156. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Lesiak, P.; Walkowiak, K.; Irska, I.; Miadlicki, K.; Krolikowski, M.; Piesowicz, E.; Figiel, P. The Mechanical, Thermal, and Biological Properties of Materials Intended for Dental Implants: A Comparison of Three Types of Poly(aryl-ether-ketones) (PEEK and PEKK). Polymers 2023, 15, 3706. [Google Scholar] [CrossRef] [PubMed]

- Yap, T.; Heathman, N.; Phillips, T.; Beaman, J.; Tehrani, M. Additive Manufacturing of Polyaryletherketone (PAEK) polymers and their composites. Compos. Part B Eng. 2023, 266, 111019. [Google Scholar] [CrossRef]

- Doyle, L.; Pérez-Ferrero, X.; García-Molleja, J.; Losada, R.; Romero-Rodríguez, P.; Fernández-Blázquez, J.P. Fused Filament Fabrication of Slow-Crystallizing Polyaryletherketones: Crystallinity and Mechanical Properties Linked to Processing and Post-Treatment Parameters. Polymers 2024, 16, 3354. [Google Scholar] [CrossRef] [PubMed]

- Maloney, A.; Major, I.; Gately, N.; Devine, D.M. Effects of 3D printing parameters on the flexural properties of semi-crystalline PEKK. Mater. Today Commun. 2025, 42, 111152. [Google Scholar] [CrossRef]

- Quiroga Cortés, L.; Caussé, N.; Dantras, E.; Lonjon, A.; Lacabanne, C. Morphology and dynamical mechanical properties of poly ether ketone ketone (PEKK) with meta phenyl links. J. Appl. Polym. Sci. 2016, 133, 43396. [Google Scholar] [CrossRef]

- Lepoivre, A.; Boyard, N.; Levy, A.; Sobotka, V. Methodology to assess interlayer quality in the material extrusion process: A temperature and adhesion prediction on a high performance polymer. Addit. Manuf. 2022, 60, 103167. [Google Scholar] [CrossRef]

- Gama, L.T.; Duque, T.M.; Ozcan, M.; Philippi, A.G.; Mezzomo, L.A.M.; Goncalves, T.M.S.V. Adhesion to high-performance polymers applied in dentistry: A systematic review. Dent. Mater. 2020, 36, e93–e108. [Google Scholar] [CrossRef] [PubMed]

- Rodzen, K.; O’Donnell, E.; Hasson, F.; McIlhagger, A.; Meenan, B.J.; Ullah, J.; Strachota, B.; Strachota, A.; Duffy, S.; Boyd, A. Advanced 3D Printing of Polyetherketoneketone Hydroxyapatite Composites via Fused Filament Fabrication with Increased Interlayer Connection. Materials 2024, 17, 17133161. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.O.; Pyo, J.Y.; On, S.W.; Seo, J.Y.; Choi, J.Y. The Biocompatibility and the Effect of Titanium and PEKK on the Osseointegration of Customized Facial Implants. Materials 2024, 17, 4435. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Liu, T.; Yin, Z.; Liu, X.; Tan, Y.; Zhao, Y.; Yu, H. Bio-functional hydroxyapatite-coated 3D porous polyetherketoneketone scaffold for enhanced osteogenesis and osteointegration in orthopedic applications. Regen. Biomater. 2024, 11, rbae023. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.R.; Chen, C.; Hua, Y.W.; Xu, X.Y.; Song, P.; Wang, R.Y.; Wang, C.X. A comparative quantitative assessment of 3D-printed PEKK and PEEK thin meshes in customized alveolar bone augmentation. BMC Oral Health 2024, 24, 1304. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.S.; Binduhayyim, R.I.H.; Kuruniyan, M.S.; Heboyan, A. DFT-based investigation of polyetherketoneketone materials for surface modification for dental implants. Eur. J. Med. Res. 2024, 29, 436. [Google Scholar] [CrossRef] [PubMed]

- Kimya PEKK-A 3D Filament. Available online: https://www.kimya.fr/de/produkt/filament-3d-pekk-a (accessed on 28 October 2024).

- Kepstan PEKK Polymers. Available online: https://hpp.arkema.com/en/product-families/kepstan-pekk-polymers/ (accessed on 10 February 2025).

- Available online: https://apiumtec.com (accessed on 18 December 2024).

- DIN EN ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- DIN EN ISO 4287; Surface Texture: Profile Method. ISO: Geneva, Switzerland, 2010.

| ITEM | PEEK 1 | PEKK 2 |

|---|---|---|

| Density (g/cm3) | 1.32 | 1.26 |

| Moisture absorption (%) | 0.03 | 0.29 |

| Flexural modulus (MPa) | 3.6 (xy); 3.7 (xz) | 2.6 (xy); 2.2 (xz) |

| Elongation at break (%) | 19.1 (xy); 16.1 (xz) | 5.6 (xy); 4.0 (xz) |

| Tensile strength (MPa) | 98.3 (xy); 93.7 (xz) | 92.1 (xy); 76.9 (xz) |

| Young’s modulus (GPa) | 4.0 (xy); 3.7 (xz) | 3.0 (xy); 2.7 (xz) |

| Glass transition temperature (°C) | 143 | 159 |

| Melting temperature (°C) | 343 | 308 |

| Heat deflection temperature (°C) | 162 (HDT-A) | 139 (HDT-A) |

| Thermal conductivity (W/(m K)) | 0.25 | 0.21 |

| ITEM | PEKK (Vendors’ Recommendation 1) | PEKK (Own Parameters) |

|---|---|---|

| Extruder temperature (°C) | 370–380 | 375 |

| Printing speed (mm/s) | 20–40 | 30 |

| Infill orientation (°) | 45 | 45 |

| ITEM | Specification |

|---|---|

| x,y-resolution (mm) | 0.5 |

| z-resolution (mm) | 0.1 |

| Smallest layer height (mm) | 0.1 |

| Smallest wall thickness (mm) (@0.4 mm nozzle) | 0.5 |

| Reproducibility (mm) | 0.1 |

| Standard nozzle diameter (mm) | 0.4 |

| Filament diameter (mm) | 1.75 |

| Max. temperature of built platform (°C) | 160 |

| Max. printhead temperature (°C) | 540 |

| Material | Young’s Modulus (GPa) | Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation at Max. Force (%) | Ultimate Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|

| PEKK | 3.5 ± 0.2 | 59.4 ± 5.4 | 104 ± 1.2 | 5.4 ± 0.2 | 63 ± 6.9 | 61 ± 36 |

| Material | Rmax (µm) | Rz (µm) | Ra (µm) | Rq (µm) |

|---|---|---|---|---|

| PEKK | 79.7 ± 17.6 | 62.7 ± 19.2 | 9.0 ± 0.6 | 11.7 ± 1.1 |

| PEEK [8] | 141 | 122 | 16 | n.a. |

| ITEM | PEEK | PEKK |

|---|---|---|

| Nozzle diameter (mm) | 0.4 | 0.4 |

| Extruder temperature (°C) | 430 | 360 |

| Printing speed (mm/s) | 10 | 10 |

| Infill orientation (°) | 45 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanemann, T.; Klein, A.; Baumgärtner, S.; Jung, J.; Wilhelm, D.; Antusch, S. Characterization of Material Extrusion-Printed Amorphous Poly(Ether Ketone Ketone) (PEKK) Parts. Polymers 2025, 17, 1069. https://doi.org/10.3390/polym17081069

Hanemann T, Klein A, Baumgärtner S, Jung J, Wilhelm D, Antusch S. Characterization of Material Extrusion-Printed Amorphous Poly(Ether Ketone Ketone) (PEKK) Parts. Polymers. 2025; 17(8):1069. https://doi.org/10.3390/polym17081069

Chicago/Turabian StyleHanemann, Thomas, Alexander Klein, Siegfried Baumgärtner, Judith Jung, David Wilhelm, and Steffen Antusch. 2025. "Characterization of Material Extrusion-Printed Amorphous Poly(Ether Ketone Ketone) (PEKK) Parts" Polymers 17, no. 8: 1069. https://doi.org/10.3390/polym17081069

APA StyleHanemann, T., Klein, A., Baumgärtner, S., Jung, J., Wilhelm, D., & Antusch, S. (2025). Characterization of Material Extrusion-Printed Amorphous Poly(Ether Ketone Ketone) (PEKK) Parts. Polymers, 17(8), 1069. https://doi.org/10.3390/polym17081069