Values for the Mechanical Properties of Wheat, Maize and Wood Pellets for Use in Silo Load Calculations Involving Numerical Methods

Abstract

:1. Introduction

2. Materials and Methods

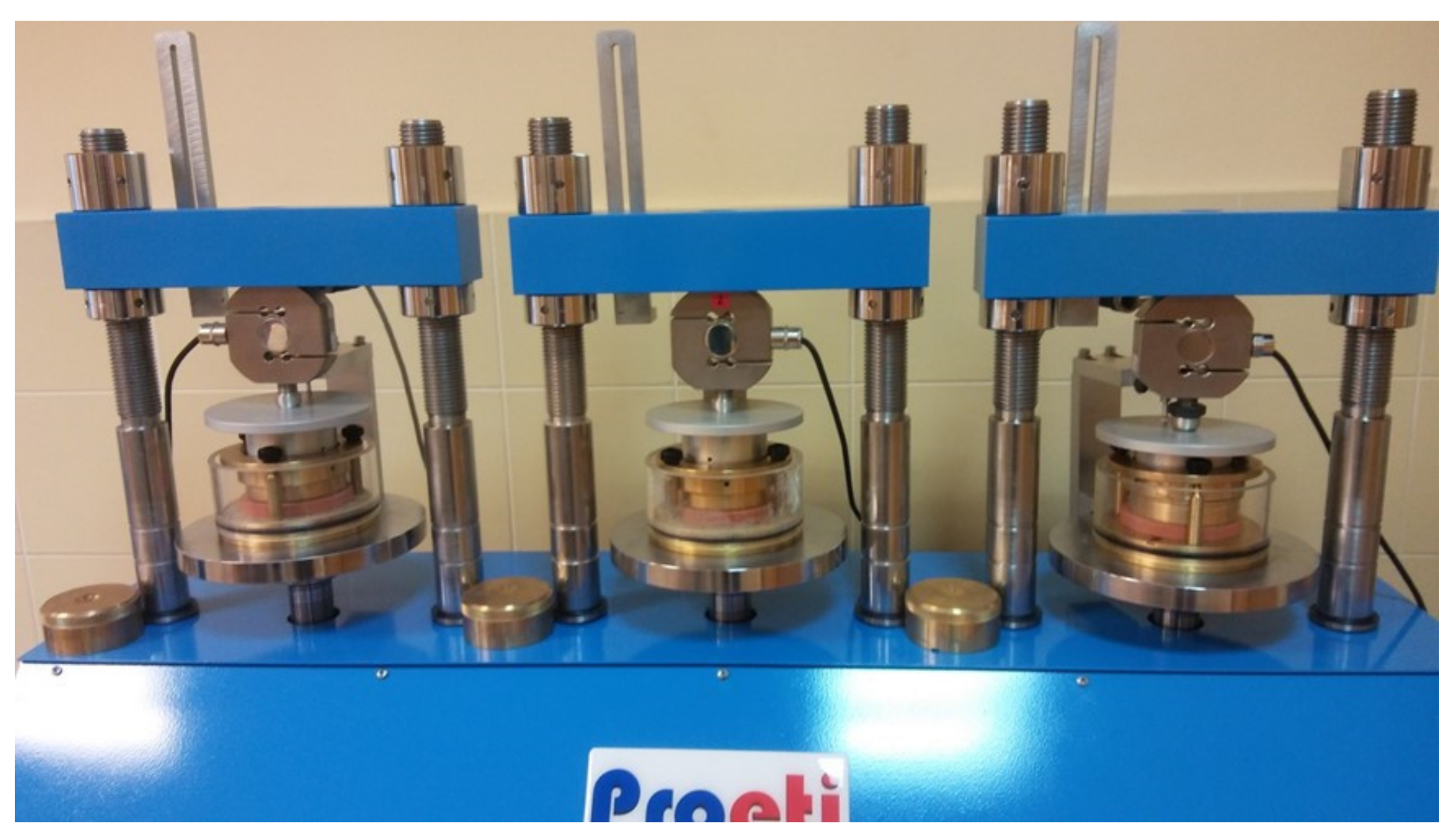

2.1. Direct Shear Assays

- Ψ = Dilatancy angle;

- Δεv = Increment of the vertical deformation at a time range (mm);

- ΔεH = Horizontal displacement variation at a time range (mm);

- h0 = Initial height of the sample (mm);

- L = Initial length of the sample (mm).

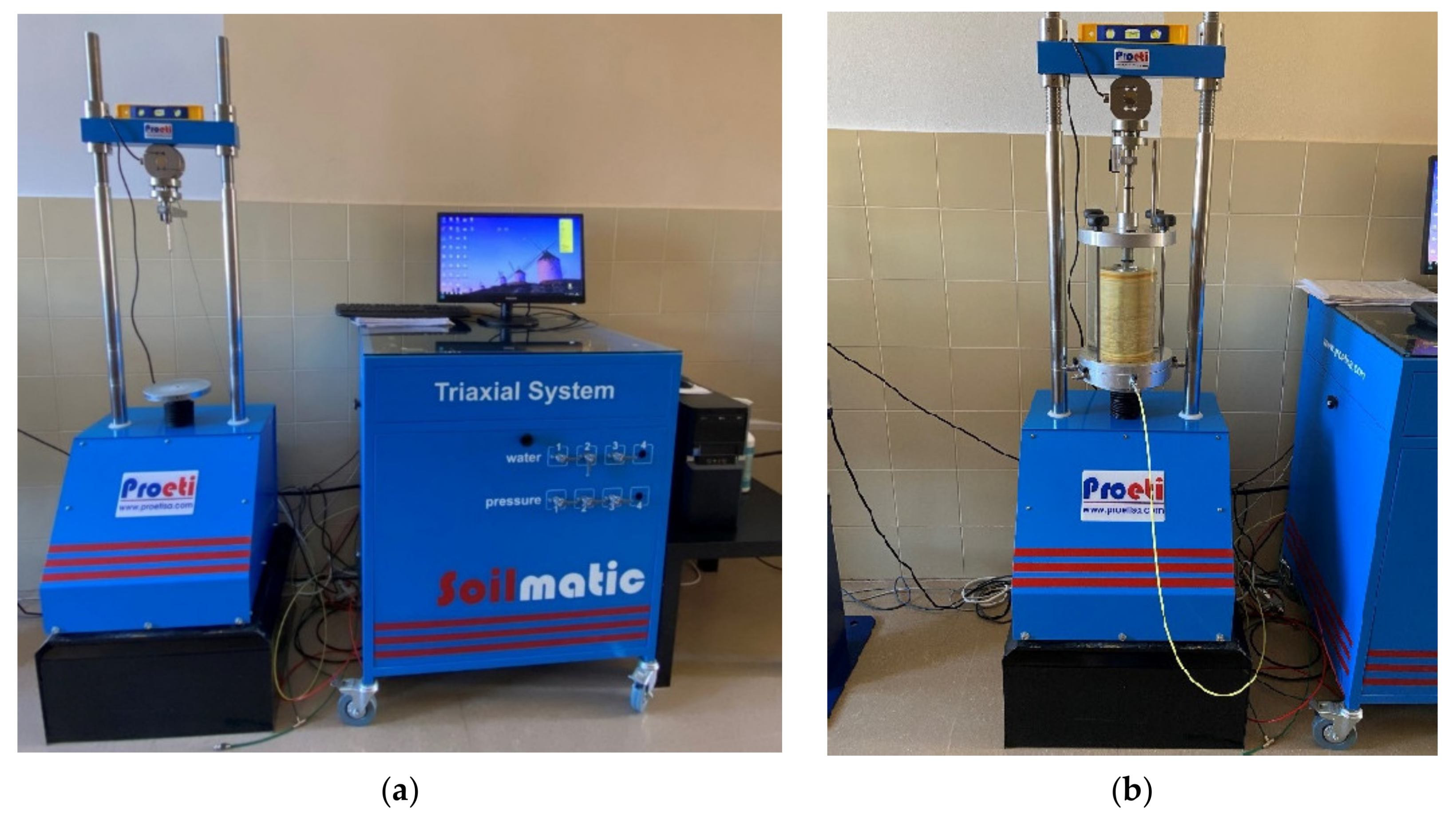

2.2. Triaxial Tests

- σm = The action of the latex membrane used to surround the sample (kPa);

- tm = The thickness of the membrane when not under stress (mm);

- Em = The Young’s modulus of the membrane, measured under stress (kPa);

- Dm = The initial internal diameter of the membrane (mm);

- εvm = The vertical deformation of the membrane (mm).

2.3. Oedometric Assays

2.4. Determination of the Apparent Specific Weight

2.5. Determination of the Moisture Content

3. Results

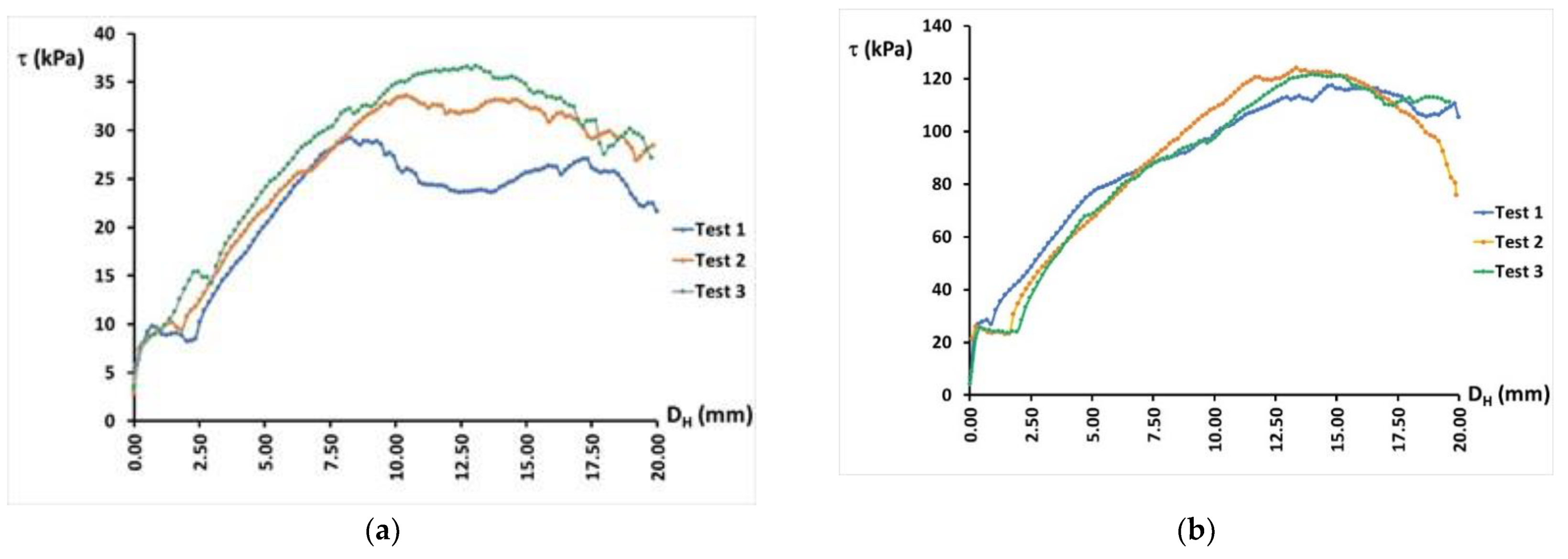

3.1. Direct Shear Assays

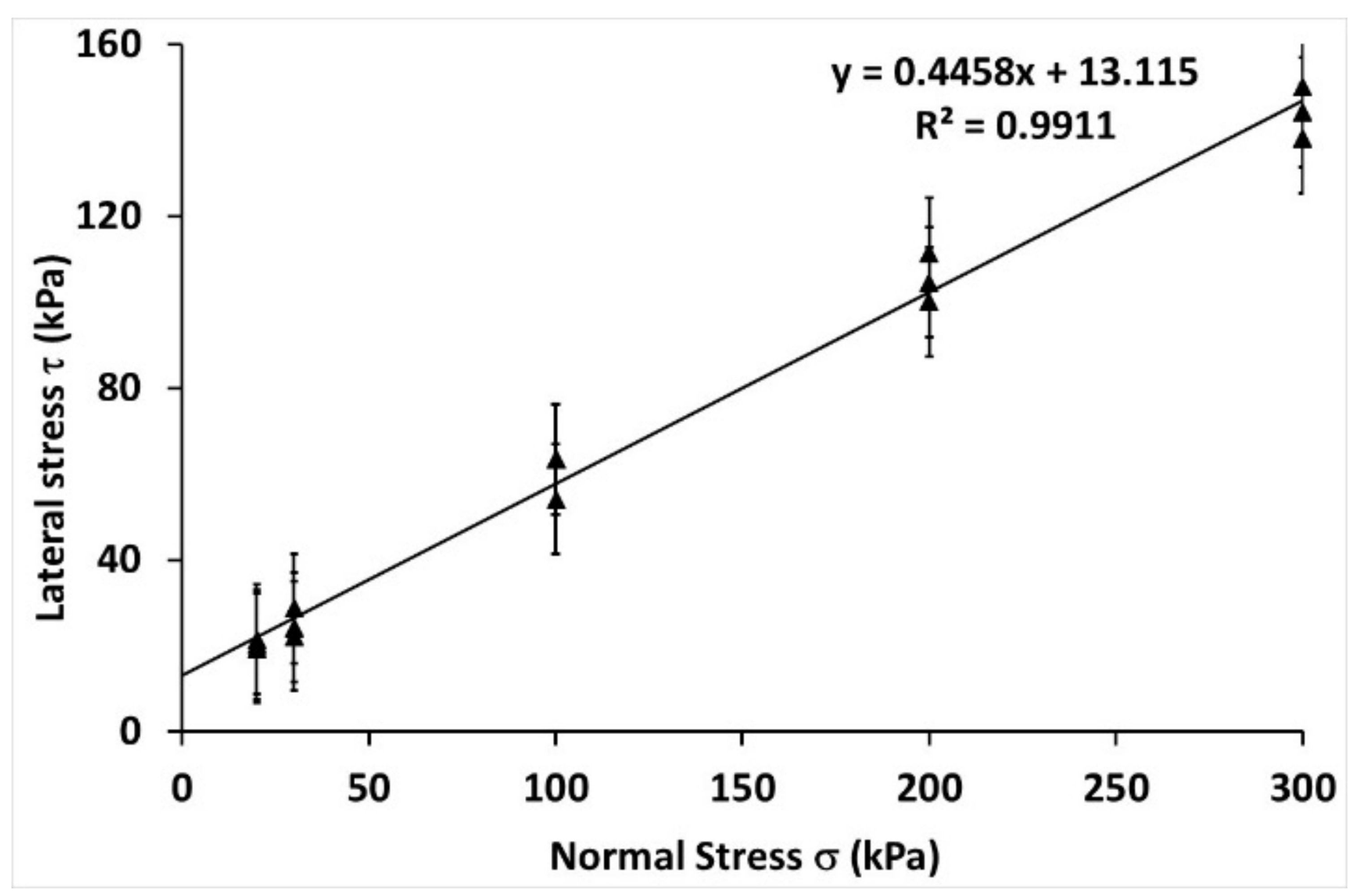

3.1.1. Internal Angle of Friction and Apparent Cohesion

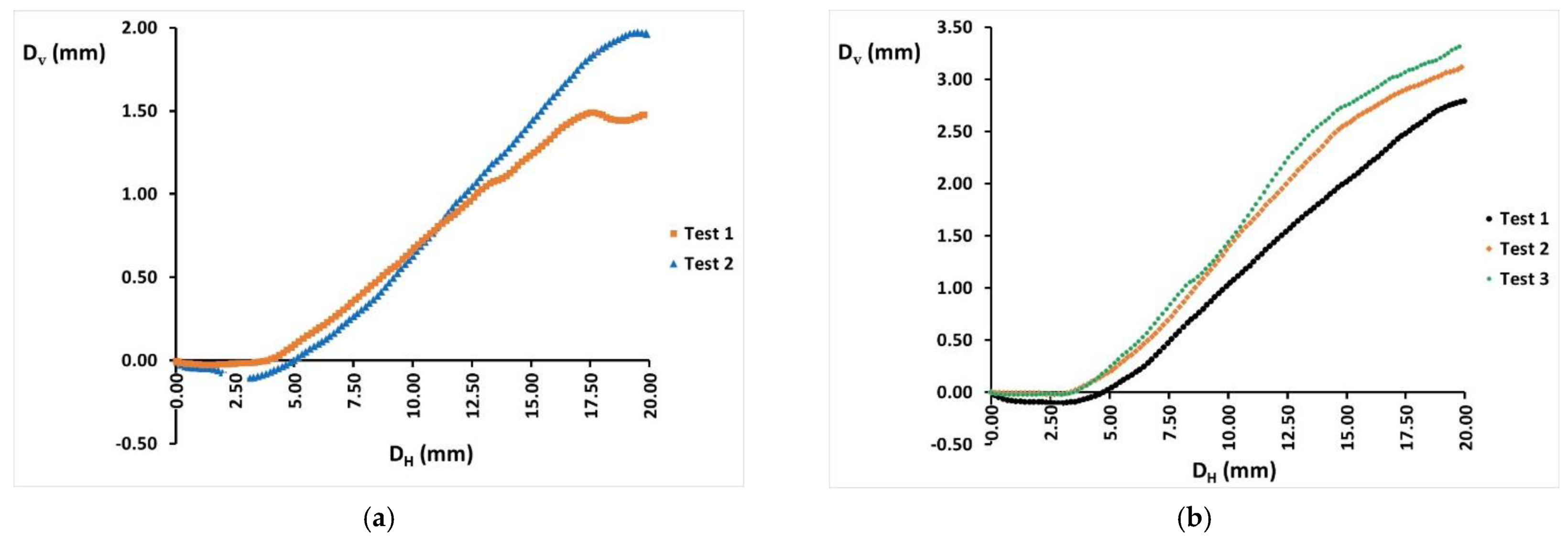

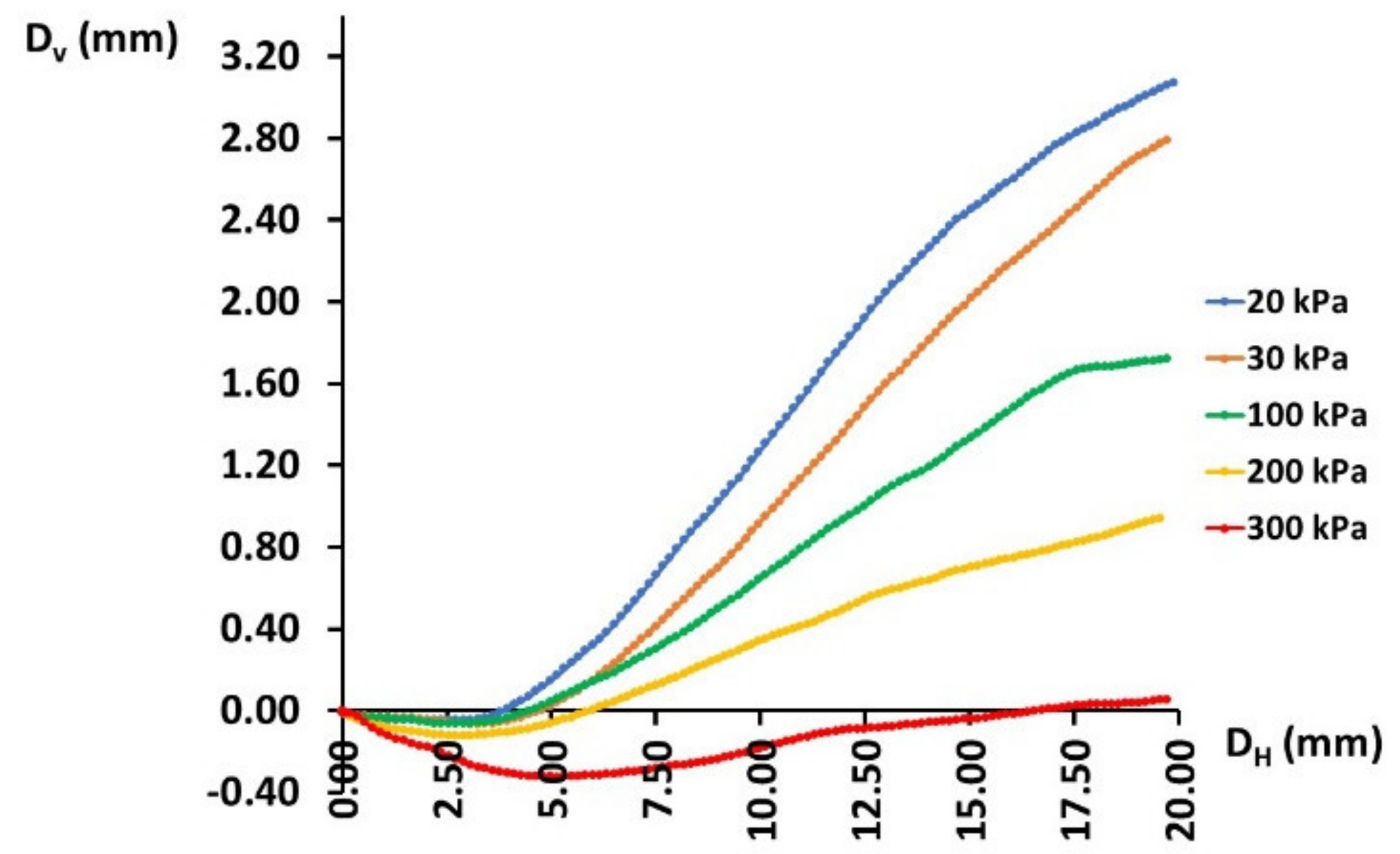

3.1.2. Dilatancy Angle

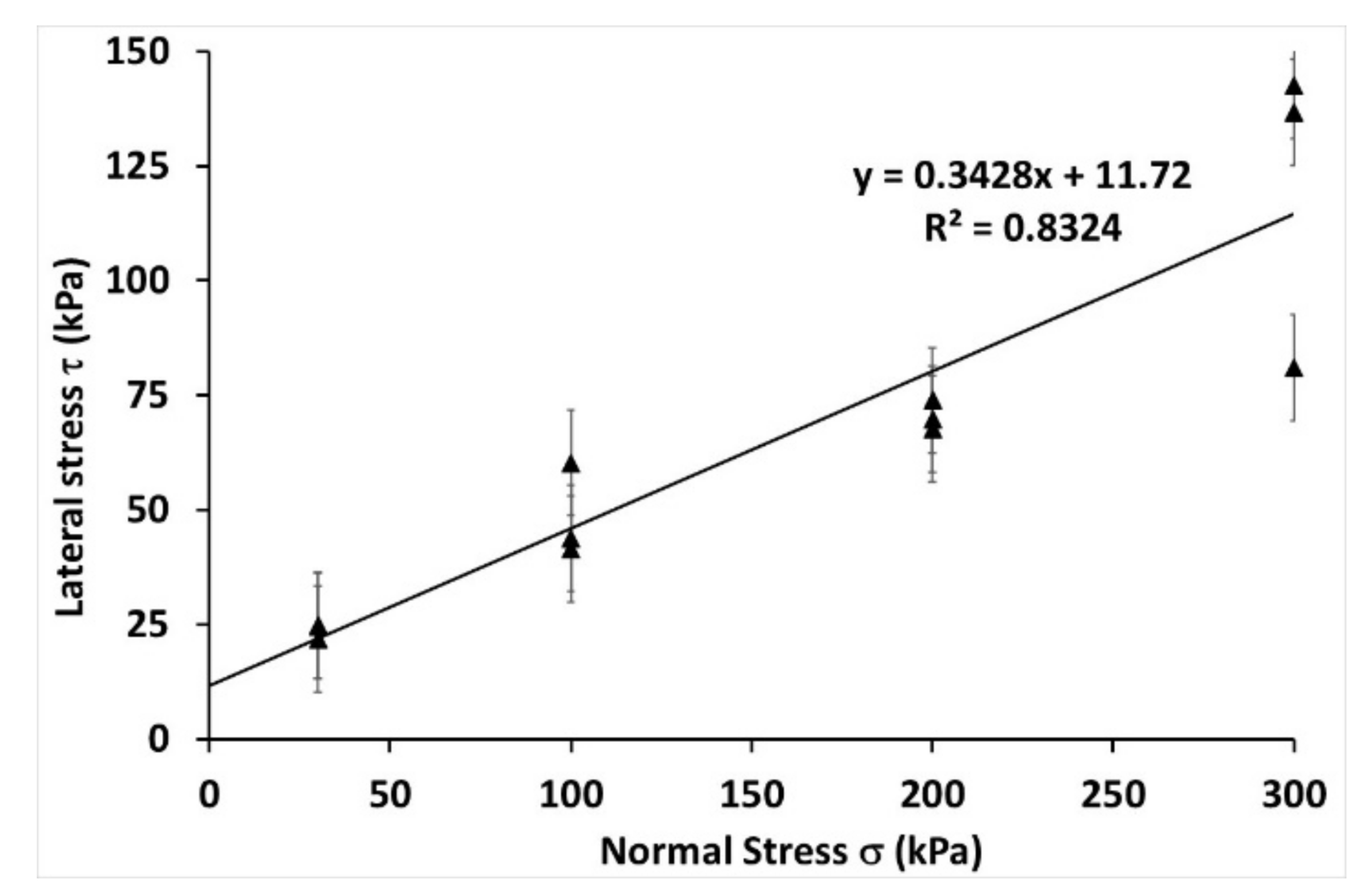

3.1.3. Particle–Wall Coefficient of Friction

3.2. Triaxial Tests

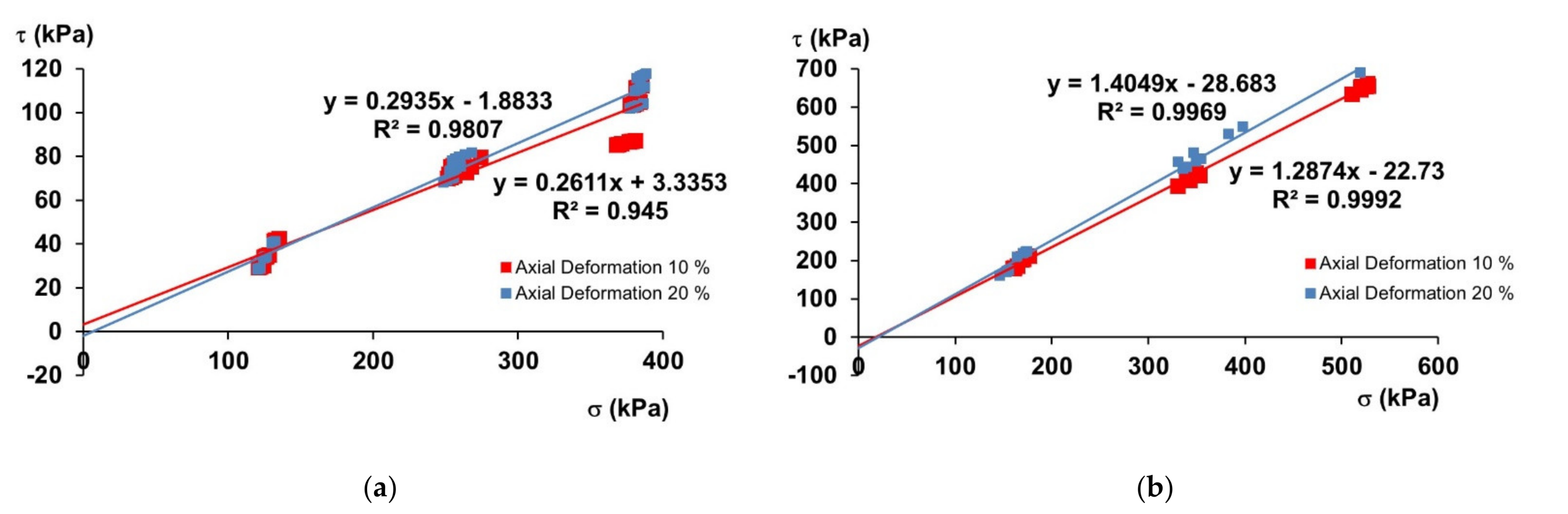

3.2.1. Free Lateral Deformation

3.2.2. K0 Assays

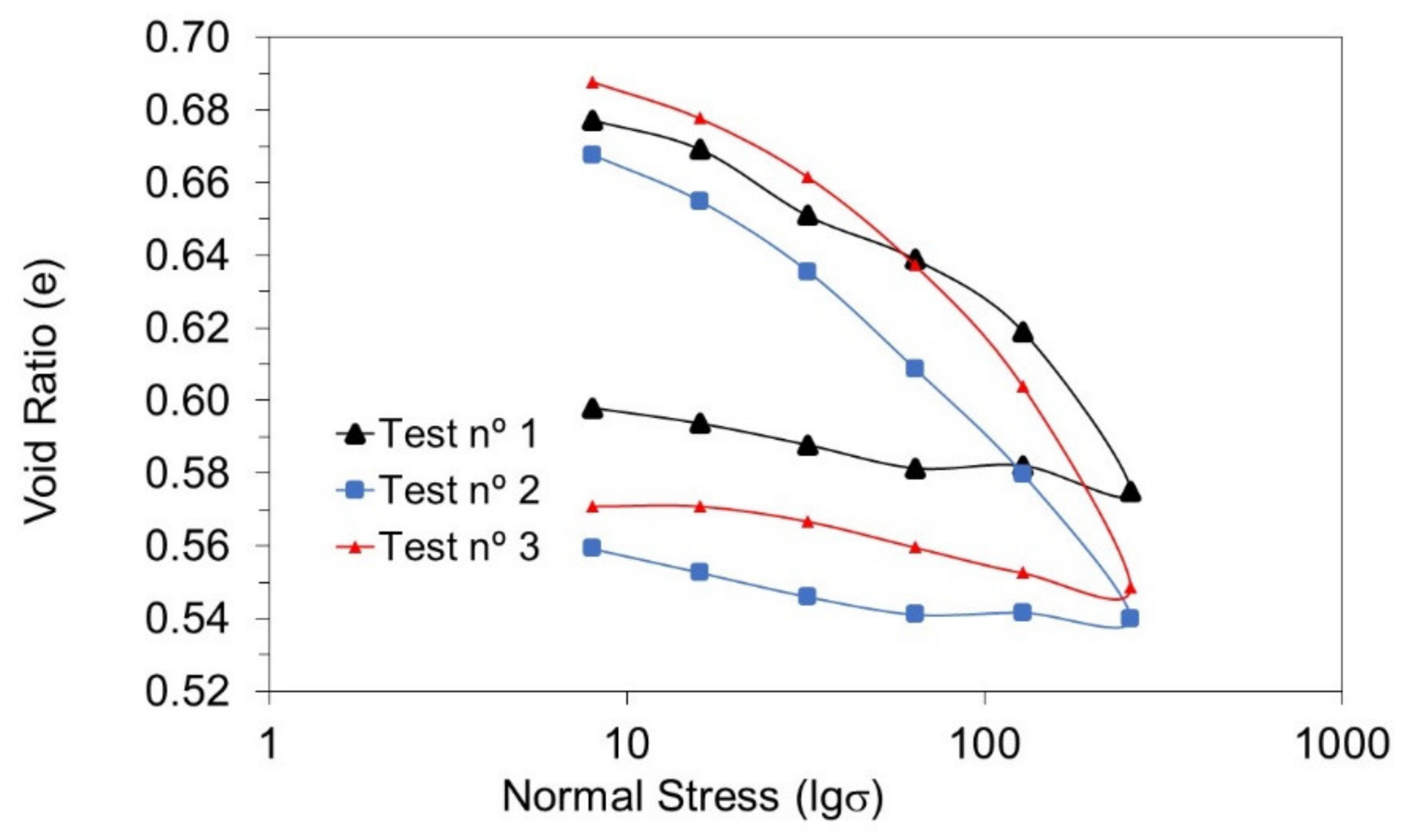

3.3. Oedometric Assays

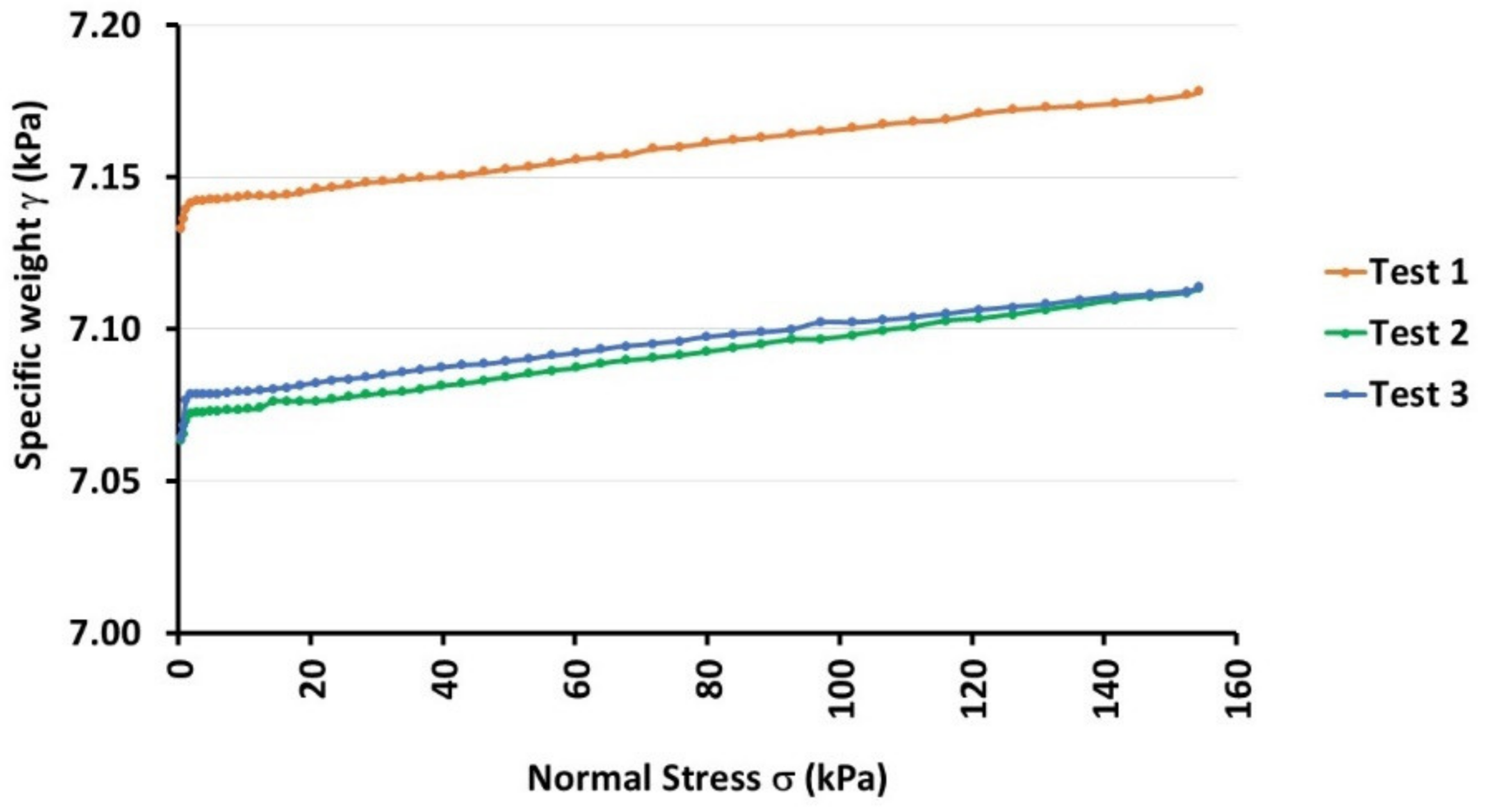

3.4. Determination of the Apparent Specific Weight

3.5. Determination of the Moisture Content

4. Discussion

4.1. Direct Shear Assays

4.1.1. Internal Angle of Friction and Apparent Cohesion

4.1.2. Dilatancy Angle

4.1.3. Particle–Wall Coefficient of Friction

4.2. Triaxial Tests

4.2.1. Free Lateral Deformation Assays

4.2.2. K0 Assays

4.3. Oedometric Assays

4.4. Apparent Specific Weight

4.5. Moisture Content

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Janssen, H. Versuche Über Getreidebruck in Silozellen. Z. Des Ver. Dtsch. Ing. 1895, 39, 1045–1049. [Google Scholar]

- Bucklin, R.A.; Thompson, S.A.; Ross, I.J.; Biggs, R.H. Apparent Dynamic Coefficient of Friction of Corn on Galvanized Steel Bin Wall Material. Trans. Am. Soc. Agric. Eng. 1993, 36, 1915–1918. [Google Scholar] [CrossRef]

- Bucklin, R.A.; Molenda, M.; Bridges, T.C.; Ross, I.J. Slip-Stick Frictional Behavior of Wheat on Galvanized Steel. Trans. Am. Soc. Agric. Eng. 1996, 39, 649–653. [Google Scholar] [CrossRef]

- Degoutte, G. Caractérisation En Laboratoire Des Propriétés Physiques et Mécaniques Des Matiéres Ensilées. Constr. Métallique 1989, 2, 91–95. [Google Scholar]

- Lebègue, Y.; Boudakian, A. Bases Des Règles « Silos » Du SNBATI—Essais Sur Les Produits et Principes Des Formules « Silos ». Ann. ITBTP 1989, 476, 69–113. [Google Scholar]

- Molenda, M.; Stasiak, M.; Moya, M.; Ramirez, A.; Horabik, J.; Ayuga, F. Testing Mechanical Properties of Food Powders in Two Laboratories—Degree of Consistency of Results. Int. Agrophys. 2006, 20, 37–45. [Google Scholar]

- Molenda, M.; Thompson, S.A.; Ross, I.J. Friction of Wheat on Corrugated and Smooth Galvanized Steel Surfaces. J. Agric. Eng. Res. 2000, 77, 209–219. [Google Scholar] [CrossRef]

- Moysey, E.; Lambert, E.; Wang, Z. Flow Rates of Grains and Oilseeds through Sharp-Edged Orificesitle. Trans. Am. Soc. Agric. Eng. 1988, 31, 226–231. [Google Scholar] [CrossRef]

- Ramírez, A.; Moya, M.; Ayuga, F. Determination of the Mechanical Properties of Powdered Agricultural Products and Sugar. Part. Part. Syst. Charact. 2010, 26, 220–230. [Google Scholar] [CrossRef]

- Thompson, S.A.; McNeill, S.G.; Ross, I.J.; Bridges, T.C. Packing Factors of Whole Grains in Storage Structures. Trans. Am. Soc. Agric. Eng. 1987, 3, 215–221. [Google Scholar] [CrossRef]

- Thompson, S.A.; Bucklin, R.A.; Batich, C.D. Variation in the Apparent Coefficient of Friction of Wheat on Galvanized Steel. Trans. Am. Soc. Agric. Eng. 1988, 31, 1518–1524. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Puri, V.M.; Manbeck, H.B. Physical Properties Effect on Stress-Strain Behavior of Wheat En Masse—Part II. Constitutive Elastoplastic Parameter Dependence on Initial Bulk Density and Moisture Content. Trans. Am. Soc. Agric. Eng. 1989, 32, 203–209. [Google Scholar] [CrossRef]

- Zhang, Q.; Britton, M.G.; Kieper, R.J. Interactions between Wheat and a Corrugated Steel Surface. Trans. Am. Soc. Agric. Eng. 1994, 37, 951–956. [Google Scholar] [CrossRef]

- Jofriet, J.C.; Lelievre, B.; Fwa, T.F. Friction Model for Finite Element Analyses of Silos. Trans. Am. Soc. Agric. Eng. 1977, 20, 735–740. [Google Scholar] [CrossRef]

- Ooi, J.Y.; Chen, J.F.; Lohnes, R.A.; Rotter, J.M. Prediction of Static Wall Pressures in Coal Silos. Constr. Build. Mater. 1996, 10, 109–116. [Google Scholar] [CrossRef]

- Ayuga, F.; Guaita, M.; Aguado, P. Static and Dynamic Silo Loads Using Finite Element Models. J. Agric. Eng. Res. 2001, 78, 299–308. [Google Scholar] [CrossRef]

- Vidal, P.; Gallego, E.; Guaita, M.; Ayuga, F. Simulation of the Filling Pressures of Cylindrical Steel Silos with Concentric and Eccentric Hoppers Using 3-Dimensional Finite Element Models. Trans ASABE 2006, 49, 1881–1895. [Google Scholar] [CrossRef]

- Holst, J.; Doerich, C.; Rotter, J. Accurate Determination of the Plastic Collapse Loads of Shells When Using Finite Element Analyses; Elsevier: Oxford, UK, 2005; ISBN 9780080446370. [Google Scholar]

- Rotter, J.M.; Holst, J.M.F.G.; Ooi, J.Y.; Sanad, A.M. Silo Pressure Predictions Using Discrete-Element and Finite-Element Analyses. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1998, 356, 2685–2712. [Google Scholar] [CrossRef]

- Höhner, D.; Wirtz, S.; Scherer, V. Experimental and Numerical Investigation on the Influence of Particle Shape and Shape Approximation on Hopper Discharge Using the Discrete Element Method. Powder Technol. 2013, 235, 614–627. [Google Scholar] [CrossRef]

- Zheng, Z.; Zang, M.; Chen, S.; Zhao, C. An Improved 3D DEM-FEM Contact Detection Algorithm for the Interaction Simulations between Particles and Structures. Powder Technol. 2017, 305, 308–322. [Google Scholar] [CrossRef]

- Weinhart, T.; Labra, C.; Luding, S.; Ooi, J.Y. Influence of Coarse-Graining Parameters on the Analysis of DEM Simulations of Silo Flow. Powder Technol. 2016, 293, 138–148. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Mao, H. DEM Investigation of the Effect of Intermediate Principle Stress on Particle Breakage of Granular Materials. Comput. Geotech. 2017, 84, 58–67. [Google Scholar] [CrossRef]

- González-Montellano, C.; Ayuga, F.; Ooi, J.Y. Discrete Element Modelling of Grain Flow in a Planar Silo: Influence of Simulation Parameters. Granul. Matter 2011, 13, 149–158. [Google Scholar] [CrossRef]

- González-Montellano, C.; Gallego, E.; Ramírez-Gómez, A.; Ayuga, F. Three-Dimensional Discrete Element Models for Simulating the Filling and Emptying of Silos: Analysis of Numerical Results. Comput. Chem. Eng. 2012, 40, 22–32. [Google Scholar] [CrossRef]

- Bagherzadeh Kh., A.; Mirghasemi, A.A.; Mohammadi, S. Numerical Simulation of Particle Breakage of Angular Particles Using Combined DEM and FEM. Powder Technol. 2011, 205, 15–29. [Google Scholar] [CrossRef]

- Zhang, Q.; Britton, M.G. A Micromechanics Model for Predicting Dynamic Loads during Discharge in Bulk Solids Storage Structures. Can. Biosyst. Eng. Le Genie Des Biosyst. Au Can. 2003, 45, 5.21–5.27. [Google Scholar]

- Kobyłka, R.; Molenda, M. DEM Modelling of Silo Load Asymmetry Due to Eccentric Filling and Discharge. Powder Technol. 2013, 233, 65–71. [Google Scholar] [CrossRef]

- Couto, A.; Ruiz, A.; Aguado, P.J. Experimental Study of the Pressures Exerted by Wheat Stored in Slender Cylindrical Silos, Varying the Flow Rate of Material during Discharge. Comparison with Eurocode 1 Part 4. Powder Technol. 2013, 237, 450–467. [Google Scholar] [CrossRef]

- Gallego, E.; Ruiz, A.; Aguado, P.J. Simulation of Silo Filling and Discharge Using ANSYS and Comparison with Experimental Data. Comput. Electron. Agric. 2015, 118, 281–289. [Google Scholar] [CrossRef]

- Wang, X.; Liang, C.; Guo, X.; Chen, Y.; Liu, D.; Ma, J.; Chen, X.; An, H. Experimental Study on the Dynamic Characteristics of Wall Normal Stresses during Silo Discharge. Powder Technol. 2020, 363, 509–518. [Google Scholar] [CrossRef]

- Ruiz, A.; Couto, A.; Aguado, P.J. Design and Instrumentation of a Mid-Size Test Station for Measuring Static and Dynamic Pressures in Silos under Different Conditions—Part II: Construction and Validation. Comput. Electron. Agric. 2012, 85, 174–187. [Google Scholar] [CrossRef]

- Wójcik, M.; Tejchman, J.; Enstad, G.G. Confined Granular Flow in Silos with Inserts—Full-Scale Experiments. Powder Technol. 2012, 222, 15–36. [Google Scholar] [CrossRef] [Green Version]

- Wójcik, M.; Sondej, M.; Rejowski, K.; Tejchman, J. Full-Scale Experiments on Wheat Flow in Steel Silo Composed of Corrugated Walls and Columns. Powder Technol. 2017, 311, 537–555. [Google Scholar] [CrossRef]

- Moya, M.; Guaita, M.; Aguado, P.; Ayuga, F. Mechanical Properties of Granular Agricultural Materials, Part 2. Trans. ASABE 2006, 49, 479–489. [Google Scholar] [CrossRef]

- Moya, M.; Aguado, P.J.; Ayuga, F. Mechanical Properties of Some Granular Agricultural Materials Used in Silo Design. Int. Agrophys. 2013, 27, 181–193. [Google Scholar] [CrossRef]

- Zeng, C.; Wang, Y. The Shear Strength and Dilatancy Behavior of Wheat Stored in Silos. Complexity 2019, 2019, 1547616. [Google Scholar] [CrossRef] [Green Version]

- Moya, M.; Ayuga, F.; Guaita, M.; Aguado, P.J. Mechanical Properties of Granular Agricultural Materials. Trans. ASAE 2002, 45, 1569–1577. [Google Scholar] [CrossRef]

- UNE-EN ISO 17892-10; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 10: Direct Shear Tests. Asociación Española de Normalización: Madrid, Spain, 2018.

- UNE-EN-1991-4: 2011/AC; Eurocode 1: Actions on Structures—Part 4: Silos and Tanks. [Eurocódigo 1: Acciones En Estructuras. Parte 4: Silos y Depósitos]. Asociación Española de Normalización: Madrid, Spain, 2013.

- Härtl, J.; Ooi, J.Y. Numerical Investigation of Particle Shape and Particle Friction on Limiting Bulk Friction in Direct Shear Tests and Comparison with Experiments. Powder Technol. 2011, 212, 231–239. [Google Scholar] [CrossRef]

- UNE-EN ISO 17892-8; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 8: Unconsolidated Undrained Triaxial Test. Asociación Española de Normalización: Madrid, Spain, 2018.

- UNE-EN ISO 17892-5; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 5: Incremental Loading Oedometer Test. Asociación Española de Normalización: Madrid, Spain, 2017.

- UNE-EN ISO 17892-2; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 2: Determination of Bulk Density. Asociación Española de Normalización: Madrid, Spain, 2014.

- UNE-EN ISO 17892-1; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 1: Determination of Water Content. Asociación Española de Normalización: Madrid, Spain, 2015.

- UNE-EN ISO 18134-2; Solid Biofuels. Determination of Moisture Content. Oven Dry Method—Part 2: Total Moisture. Simplified Method. Asociación Española de Normalización: Madrid, Spain, 2017.

- Molenda, M.; Horabik, J. Mechanical Properties of Granular Agro-Materials and Food Powders for Industrial Practice. Part I: Characterization of Mechanical Properties of Particulate Solids for Storage and Handling; Horabik, J., Laskowski, J., Eds.; Institute of Agrophysics Polish Academy of Science: Lublin, Poland, 2005. [Google Scholar]

- Horabik, J.; Molenda, M.; Ross, I.J. Comparison of Load Distribution in Two Similar Grain Bins. Trans. ASAE 1995, 38, 1875–1879. [Google Scholar] [CrossRef]

- Gallego, E.; Fuentes, J.M.; Ruiz, Á.; Hernández-Rodrigo, G.; Aguado, P.; Ayuga, F. Determination of Mechanical Properties for Wood Pellets Used in DEM Simulations. Int. Agrophys. 2020, 34, 485–494. [Google Scholar] [CrossRef]

- Wu, M.R.; Schott, D.L.; Lodewijks, G. Physical Properties of Solid Biomass. Biomass Bioenergy 2011, 35, 2093–2105. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Specific Energy Consumption and Quality of Wood Pellets Produced Using High-Moisture Lodgepole Pine Grind in a Flat Die Pellet Mill. Chem. Eng. Res. Des. 2016, 110, 82–97. [Google Scholar] [CrossRef] [Green Version]

- Kruszelnicka, W. Study of Selected Physical-Mechanical Properties of Corn Grains Important from the Point of View of Mechanical Processing Systems Designing. Materials 2021, 14, 1467. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Gu, H.; Wang, Y. Stress-Strain Response of Sheared Wheat Granular Material Stored in Silos Using Triaxial Compression Tests. Int. Agrophys. 2020, 34, 103–114. [Google Scholar] [CrossRef]

- Thompson, S.A.; Galili, N.; Williams, R.A. Floor and Wall Pressures in a Full-Scale Corrugated Grain Bin during Unloading. Trans. ASAE 1998, 41, 1799–1805. [Google Scholar]

- Shan, Y. Structural Loads in a Model Grain Bin during Drying of Stored Grain with Near-Ambient Air. Master’s Thesis, University of Manitoba, Winnipeg, MB, Canada, 1996. [Google Scholar]

- Cheng, X.; Zhang, Q.; Shi, C.; Yan, X. Model for the Prediction of Grain Density and Pressure Distribution in Hopper-Bottom Silos. Biosyst. Eng. 2017, 163, 159–166. [Google Scholar] [CrossRef]

- Reimbert, M.; Reimbert, A. Silos.Theory and Practice; Lavoisier: Paris, France, 1987; ISBN 9782852063655. [Google Scholar]

- European Pellet Council (EPC). Handbook ENplus. Quality Certification Scheme for Wood Pellets. Spanish Version. Part 3: Quality Requirements. [Manual ENplus. Esquema de Certificación de Calidad Para Pellets de Madera. Versión Para España. Parte 3: Requisitos de Calidad]; European Biomass Association: Brussels, Belgium, 2015. [Google Scholar]

| Material | Internal Angle of Friction (ϕ) | Apparent Cohesion (C, kPa) |

|---|---|---|

| Wheat | 24.0 ± 0. 6 | 13.12 ± 30.19 |

| Maize | 29.0 ± 0.9 | 13.99 ± 26.25 |

| Wood pellets | 40.7 ± 1.2 | 23.02 ± 27.89 |

| Material | Dilatancy Angle (ψ) | ||||

|---|---|---|---|---|---|

| 20 kPa | 30 kPa | 100 kPa | 200 kPa | 300 kPa | |

| Wheat | 19.7 ± 7.2 | 13.7 ± 1.0 | 7.4 ± 1.7 | 6.0 ± 2.1 | 4.2 ± 1.2 |

| Maize | 33.6 ± 2.3 | 31.9 ± 4.3 | 15.3 ± 2.6 | 14.3 ± 1.4 | 8.8 ± 0.6 |

| Wood pellets | 36.4 ± 4.8 | 33.2 ± 3.2 | 22.8 ± 3.4 | 15.7 ± 2.5 | 10.4 ± 1.2 |

| Material | Particle–Wall Coefficient of Friction (μ) |

|---|---|

| Wheat | 0.29 ± 0.01 |

| Maize | 0.34 ± 0.04 |

| Wood pellets | 0.52 ± 0.06 |

| Material | Internal Angle of Friction (ϕ) | Apparent Cohesion (C, kPa) | ||

|---|---|---|---|---|

| Axial Deformation | ||||

| 10% | 20% | 10% | 20% | |

| Wheat | 14.6 ± 0.5 | 16.4 ± 0.3 | 3.34 ± 13.20 | −1.88 ± 6.54 |

| Maize | 46.7 ± 0.1 | 47.6 ± 0.3 | −10.11 ± 9.55 | −13.29 ± 12.26 |

| Wood pellets | 50.5 ± 2.1 | 54.6 ± 0.3 | −22.73 ± 1.66 | −28.68 ± 20.66 |

| Material | Poisson’s Ratio (ν) | ||

|---|---|---|---|

| 100 kPa | 200 kPa | 300 kPa | |

| Wheat | 0.39 ± 0.01 | 0.38 ± 0.00 | 0.37 ± 0.01 |

| Maize | 0.18 ± 0.04 | 0.15 ± 0.02 | 0.14 ± 0.01 |

| Wood pellets | 0.13 ± 0.01 | 0.12 ± 0.01 | 0.12 ± 0.02 |

| Normal Stress (kPa) | Material | |||

|---|---|---|---|---|

| Wheat | Maize | Wood Pellets | ||

| Loading cycle | 8 | 1405 ± 290.6 | 1350 ± 148.5 | 1067 ± 363.2 |

| 16 | 977 ± 87.9 | 1793 ± 172.5 | 1146 ± 418.5 | |

| 32 | 1418 ± 137.5 | 2331 ± 530.5 | 1265 ± 185.3 | |

| 64 | 2620 ± 352.3 | 3476 ± 511.8 | 2549 ± 1480.5 | |

| 128 | 4321 ± 733.3 | 4714 ± 511.5 | 3446 ± 1650.0 | |

| 256 | 8693 ± 1629.2 | 7319 ± 355.4 | 4739 ± 257.4 | |

| Unloading cycle | 128 | 51,720 ± 1011.2 | 44,476 ± 10172.6 | 27,495 ± 215.7 |

| 64 | 18,883 ± 997.7 | 22,349 ± 3268.1 | 13,404 ± 38.2 | |

| 32 | 14,677 ± 1793.9 | 20,518 ± 16780.7 | 9674 ± 2031.3 | |

| 16 | 8767 ± 208.6 | 6047 ± 804.1 | 3868 ± 379.7 | |

| 8 | 3476 ± 72.8 | 3660 ± 1200.7 | 2363 ± 754.5 | |

| Material | Apparent Specific Weight γ (kN/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Normal Stress (kPa) | ||||||||

| 0 | 25 | 50 | 75 | 100 | 125 | 150 | 200 | |

| Wheat | 7.98 ± 0.10 | 8.02 ± 0.08 | 8.03 ± 0.08 | 8.03 ± 0.08 | 8.03 ± 0.08 | 8.04 ± 0.08 | 8.04 ± 0.08 | 8.05 ± 0.08 |

| Maize | 7.47 ± 0.04 | 7.51 ± 0.05 | 7.51 ± 0.06 | 7.52 ± 0.05 | 7.52 ± 0.05 | 7.53 ± 0.06 | 7.53 ± 0.06 | 7.55 ± 0.06 |

| Wood pellets | 7.08 ± 0.04 | 7.10 ± 0.04 | 7.11 ± 0.03 | 7.12 ± 0.04 | 7.12 ± 0.04 | 7.13 ± 0.03 | 7.13 ± 0.04 | ---- |

| Material | Moisture Content (%) |

|---|---|

| Wheat | 9.78 |

| Maize | 12.77 |

| Wood pellets | 6.38 |

| Material | ϕ (°) | C (kPa) | Ψ (°) | μ Steel | ν | E (kPa) | γap (kN/m3) | H (%) |

|---|---|---|---|---|---|---|---|---|

| Wheat | 19.3 | 6.6 | 19.7 | 0.29 | 0.39 | 37,350 | 8.03 | 9.78 |

| Maize | 38.8 | 7.0 | 33.6 | 0.34 | 0.18 | 34,800 | 7.52 | 12.77 |

| Wood pellets | 47.7 | 11.5 | 36.4 | 0.52 | 0.13 | 21,330 | 7.12 | 6.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moya, M.; Sánchez, D.; Villar-García, J.R. Values for the Mechanical Properties of Wheat, Maize and Wood Pellets for Use in Silo Load Calculations Involving Numerical Methods. Agronomy 2022, 12, 1261. https://doi.org/10.3390/agronomy12061261

Moya M, Sánchez D, Villar-García JR. Values for the Mechanical Properties of Wheat, Maize and Wood Pellets for Use in Silo Load Calculations Involving Numerical Methods. Agronomy. 2022; 12(6):1261. https://doi.org/10.3390/agronomy12061261

Chicago/Turabian StyleMoya, Manuel, David Sánchez, and José Ramón Villar-García. 2022. "Values for the Mechanical Properties of Wheat, Maize and Wood Pellets for Use in Silo Load Calculations Involving Numerical Methods" Agronomy 12, no. 6: 1261. https://doi.org/10.3390/agronomy12061261

APA StyleMoya, M., Sánchez, D., & Villar-García, J. R. (2022). Values for the Mechanical Properties of Wheat, Maize and Wood Pellets for Use in Silo Load Calculations Involving Numerical Methods. Agronomy, 12(6), 1261. https://doi.org/10.3390/agronomy12061261