The Influence of Electrostatic Spraying with Waist-Shaped Charging Devices on the Distribution of Long-Range Air-Assisted Spray in Greenhouses

Abstract

:1. Introduction

2. Materials and Methods

2.1. CMR Test

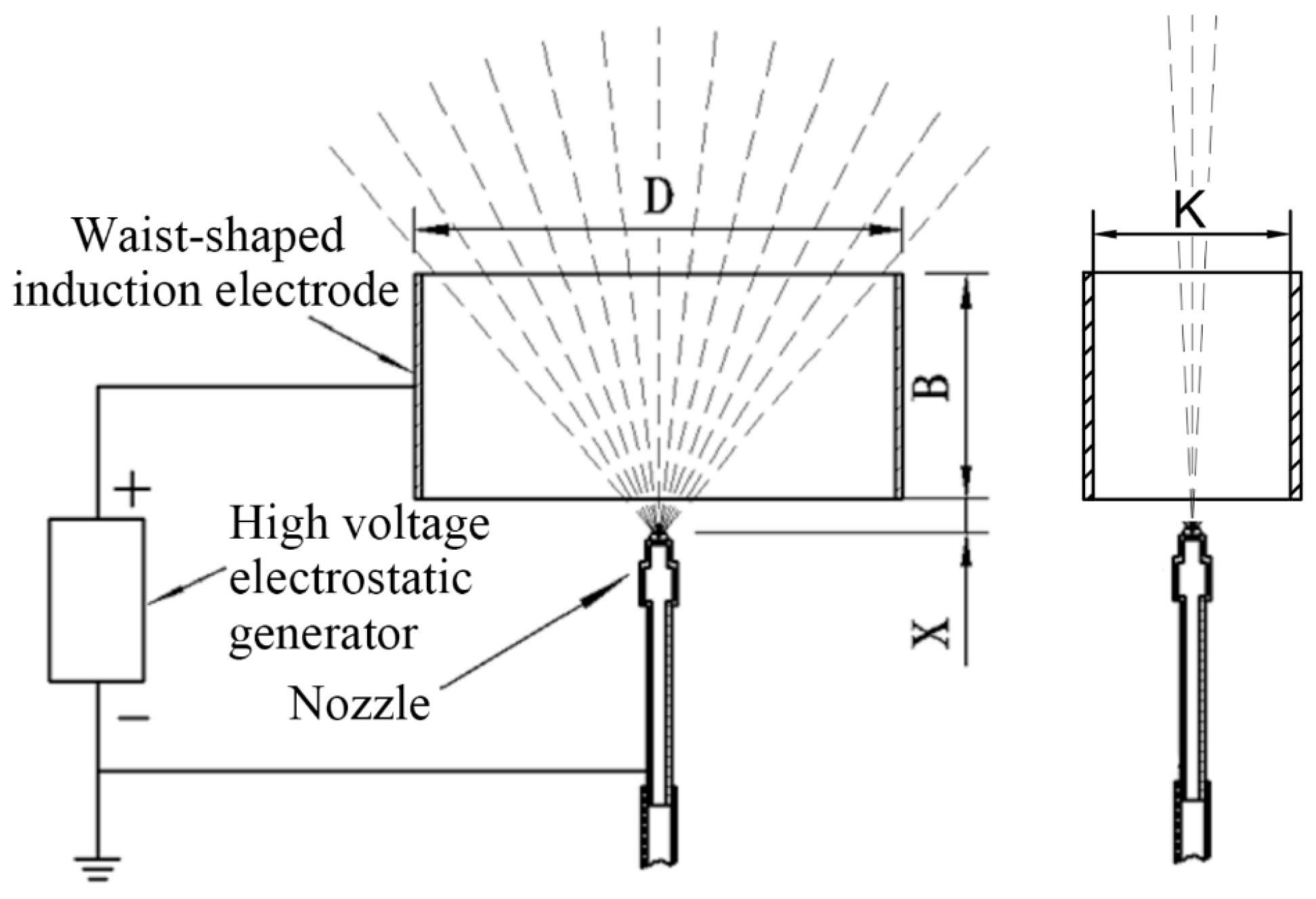

2.1.1. Structure of Waist-Shape Charging Device

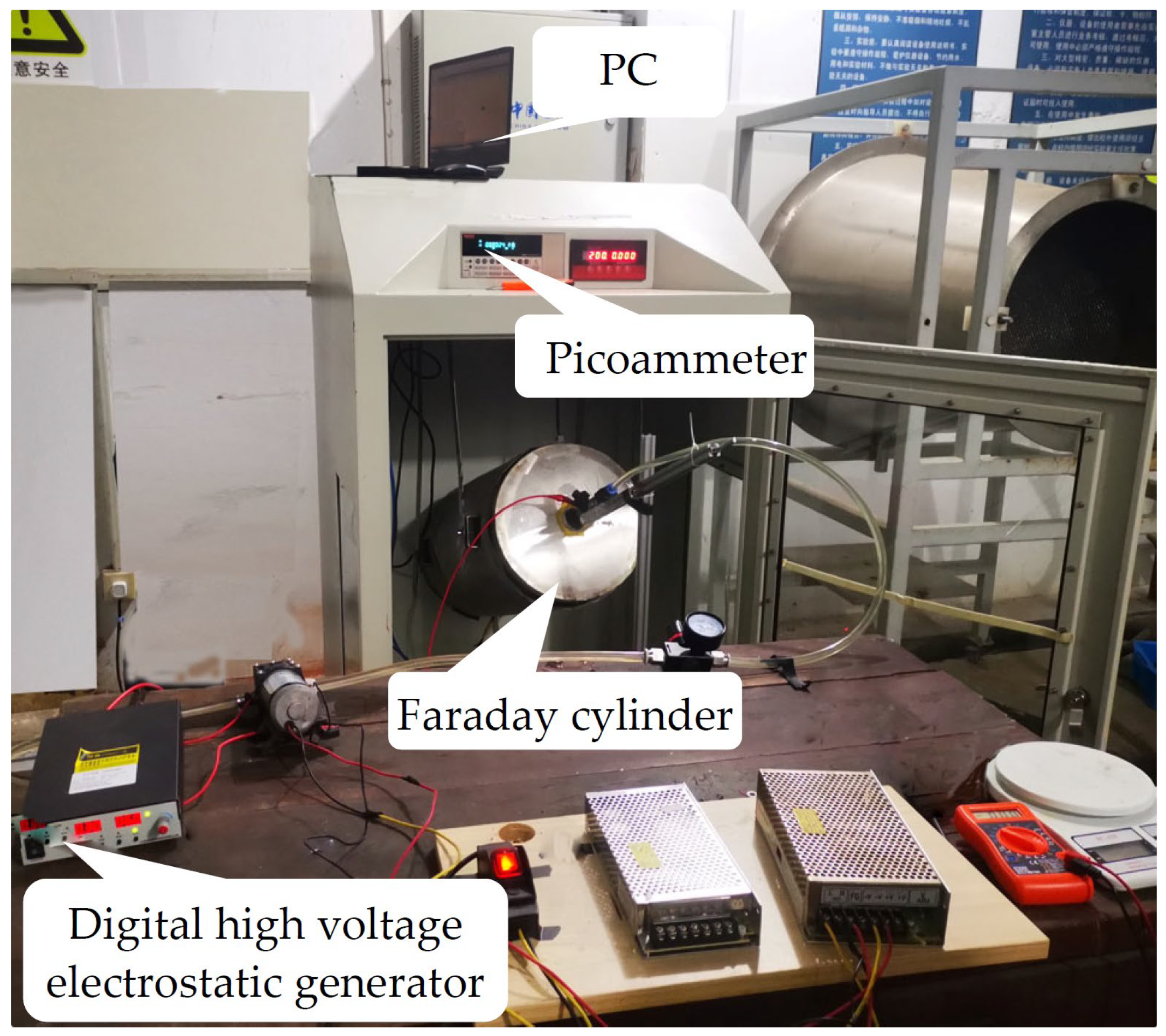

2.1.2. CMR Measurement

2.2. Field Test

2.2.1. Autonomous Air-Assisted Sprayer

2.2.2. Test Greenhouse and Crop

2.2.3. Test Zone and Sample Layout

2.2.4. Data Processing

3. Results and Discussion

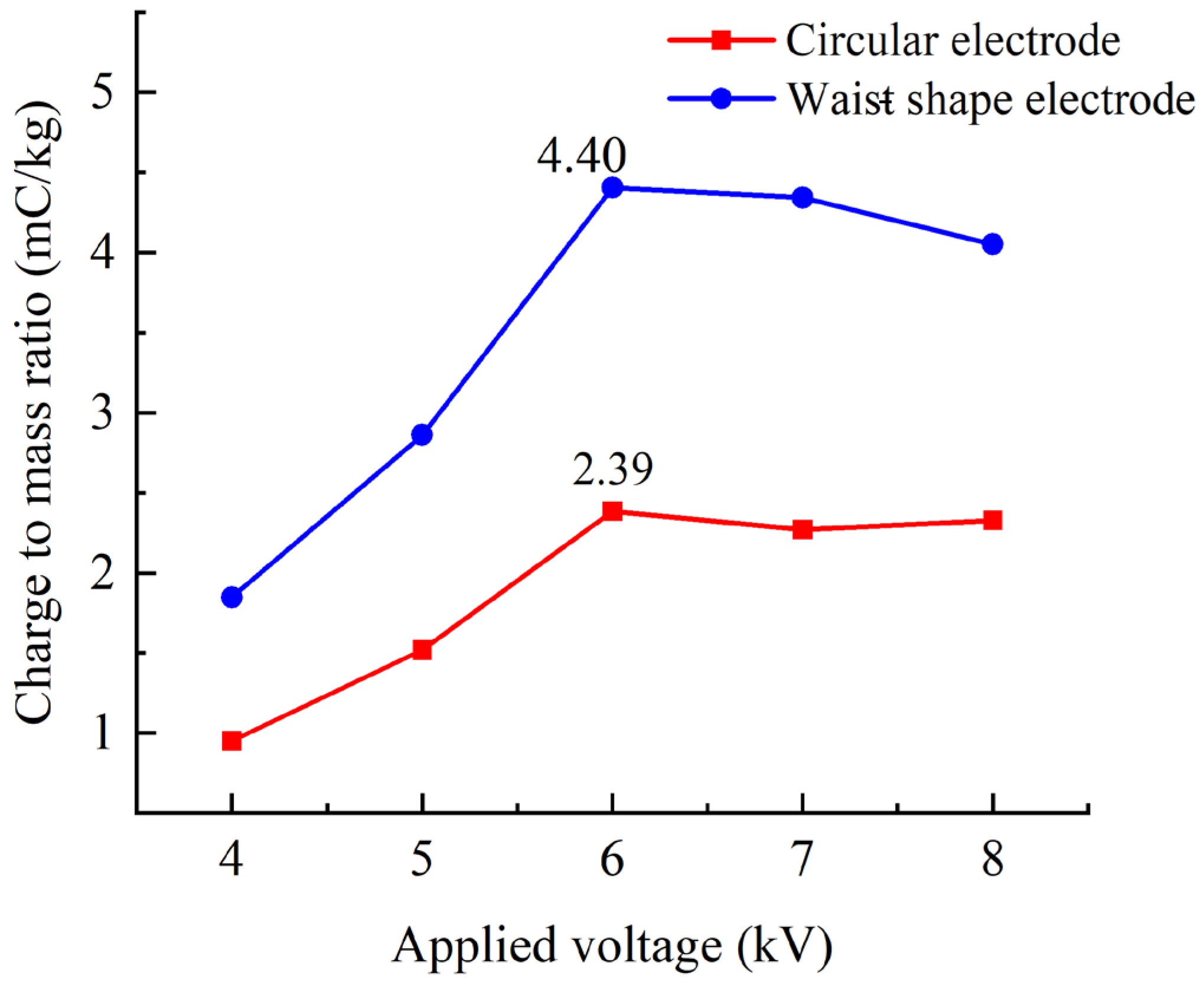

3.1. Effect of Voltage on Charging Capacity

3.2. Differences in the Overall Performance

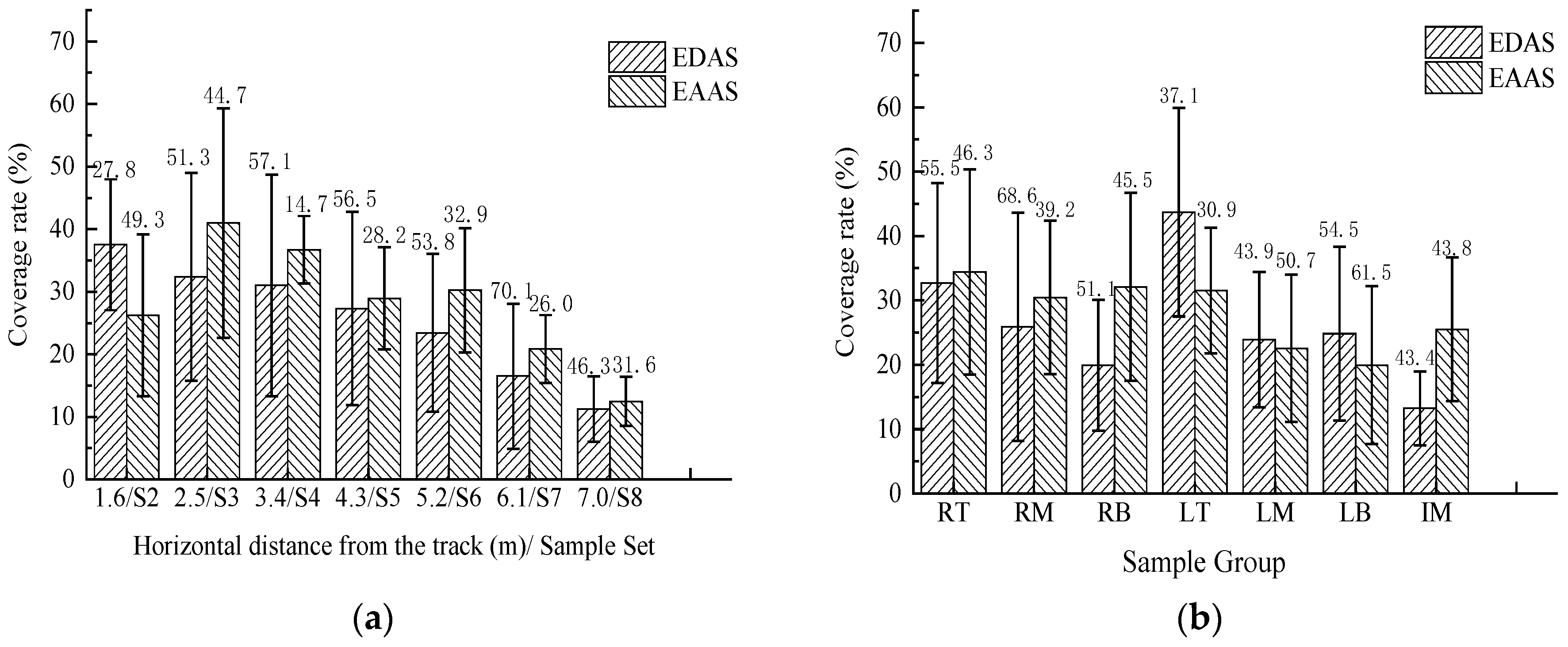

3.3. Effect of Electrostatic Spray on Axial Coverage and Distribution Uniformity

3.4. Effect of Electrostatic Spray on Radial Coverage and Distribution Uniformity

3.5. Effect of Electrostatic Spray on Penetration

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Law, S.E.; Bowen, H.D. Charging Liquid Spray by Electrostatic Induction. Trans. ASAE 1966, 9, 501–506. [Google Scholar] [CrossRef]

- He, X.; Zeng, A.; Liu, Y.; Song, J. Precision Orchard Sprayer Based on Automatically Infrared Target Detecting and Electrostatic Spraying Techniques. Int. J. Agric. Biol. Eng. 2011, 4, 35–40. [Google Scholar]

- Neto, J.G.; Da Cunha, J.P.A.R.; Almeida, V.V.; Al Ves, G.S. Spray Deposition on Coffee Leaves from Airblast Sprayers with and without Electrostatic Charge. Biosci. J. 2015, 31, 1296–1303. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Pérez-Alonso, J.; Martínez-Carricondo, P.; Carvajal-Ramírez, F.; Agüera-Vega, F. Evaluation of Electrostatic Spraying Equipment in a Greenhouse Pepper Crop. Horticulturae 2022, 8, 541. [Google Scholar] [CrossRef]

- Tavares, R.M.; Cunha, J.P.; Alves, T.C.; Bueno, M.R.; Silva, S.M.; Zandonadi, C.H. Electrostatic Spraying in the Chemical Control of Triozoida Limbata (Enderlein) (Hemiptera: Triozidae) in Guava Trees (Psidium Guajava L.). Pest. Manag. Sci. 2017, 73, 1148–1153. [Google Scholar] [CrossRef]

- Patel, M.K.; Praveen, B.; Sahoo, H.K.; Patel, B.; Kumar, A.; Singh, M.; Nayak, M.K.; Rajan, P. An Advance Air-Induced Air-Assisted Electrostatic Nozzle with Enhanced Performance. Comput. Electron. Agric. 2017, 135, 280–288. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E. Spray deposition in “Tendone” Vineyards When Using a Pneumatic Electrostatic Sprayer. Crop Prot. 2015, 68, 1–11. [Google Scholar] [CrossRef]

- Salcedo, R.; Llop, J.; Campos, J.; Costas, M.; Gallart, M.; Ortega, P.; Gil, E. Evaluation of Leaf Deposit Quality Between Electrostatic and Conventional Multi-Row Sprayers in a Trellised Vineyard. Crop Prot. 2020, 127, 104964. [Google Scholar] [CrossRef]

- Mishra, P.K.; Singh, M.; Sharma, A.; Sharma, K.; Mahal, A.K. Studies on Effectiveness of Electrostatic Spraying for Cotton Crop. AMA Agric. Mech. Asia Afr. Lat. Am. 2015, 46, 17–22. [Google Scholar]

- Joseph, S.V.; Bolda, M. Evaluating the Potential Utility of an Electrostatic Sprayer and a Tractor-Mounted Vacuum Machine for Lygus Hesperus (Hemiptera: Miridae) Management in California’s Coastal Strawberry. Crop Prot. 2018, 113, 104–111. [Google Scholar] [CrossRef]

- Wei, Z.; Yongrui, H.; Xin, L.; Qi, L.; Xiaoming, F.; Bo, Z.; Haiyang, W.; Yingqian, W. Wind Tunnel Experimental Study on Droplet Drift Reduction by a Conical Electrostatic Nozzle for Pesticide Spraying. Int. J. Agric. Biol. Eng. 2017, 10, 87–94. [Google Scholar]

- Hoffmann, W.C.; Farooq, M.; Walker, T.W.; Fritz, B.; Szumlas, D.; Quinn, B.; Bernier, U.; Hogsette, J.; Lan, Y.; Huang, Y.; et al. Canopy Penetration and Deposition of Barrier Sprays from Electrostatic and Conventional Sprayers. J. Am. Mosq. Control Assoc. 2009, 25, 323–331. [Google Scholar] [CrossRef] [PubMed]

- Salcedo, R.; Sánchez, E.; Zhu, H.; Fàbregas, X.; García-Ruiz, F.; Gil, E. Evaluation of an Electrostatic Spray Charge System Implemented in Three Conventional Orchard Sprayers Used on a Commercial Apple Trees Plantation. Crop Prot. 2023, 167, 106212. [Google Scholar] [CrossRef]

- Khatawkar, D.S.; Dhalin, D.; James, P.S.; Subhagan, S.R. Electrostatic Induction Spray-Charging System (Embedded Electrode) for Knapsack Mist-Blower. Curr. J. Appl. Sci. Technol. 2020, 39, 80–91. [Google Scholar] [CrossRef]

- Miranda-Fuentes, A.; Marucco, P.; González-Sánchez, E.J.; Gil, E.; Grella, M.; Balsari, P. Developing Strategies to Reduce Spray Drift in Pneumatic Spraying in Vineyards: Assessment of the Parameters Affecting Droplet Size in Pneumatic Spraying. Sci. Total Environ. 2018, 616–617, 805–815. [Google Scholar] [CrossRef]

- Xue, X.; Zeng, K.; Li, N.; Luo, Q.; Ji, Y.; Li, Z.; Lyu, S.; Song, S. Parameters Optimization and Performance Evaluation Model of Air-Assisted Electrostatic Sprayer for Citrus Orchards. Agriculture 2023, 13, 1498. [Google Scholar] [CrossRef]

- Moon, J.; Lee, D.; Kang, T.; Yon, K. A Capacitive Type of Electrostatic Spraying Nozzle. J. Electrost. 2003, 57, 363–379. [Google Scholar] [CrossRef]

- Patel, M.K.; Sahoo, H.K.; Nayak, M.K.; Ghanshyam, C. Plausibility of Variable Coverage High Range Spraying: Experimental Studies of an Externally Air-Assisted Electrostatic Nozzle. Comput. Electron. Agric. 2016, 127, 641–651. [Google Scholar] [CrossRef]

- Dai, S.; Zhang, J.; Jia, W.; Ou, M.; Zhou, H.; Dong, X.; Chen, H.; Wang, M.; Chen, Y.; Yang, S. Experimental Study on the Droplet Size and Charge-to-Mass Ratio of an Air-Assisted Electrostatic Nozzle. Agriculture 2022, 12, 889. [Google Scholar] [CrossRef]

- Wang, J.F.; Zhang, S.C.; Zuo, Z.W. Experimental Study of Influence Rules on Spray Charged Characteristics in the Induction Charging Process. High Volt. Eng. 2017, 43, 514–519. [Google Scholar] [CrossRef]

- Lan, Y.B.; Zhang, H.Y.; Wen, S.; Li, S. Analysis and Experiment on Atomization Characteristics and Spray Deposition of Electrostatic Nozzle. Trans. of the CSAE 2018, 49, 130–139. [Google Scholar] [CrossRef]

- Mamidi, V.R.; Ghanshyam, C.; Patel, M.K.; Kapur, P. Electrostatic Hand Pressure Swirl Nozzle for Small Crop Growers. Int. J. Appl. Sci. Technol. Res. Excell. 2012, 2, 164–168. [Google Scholar]

- Qi, L.; Miller, P.C.H.; Fu, Z. The Classification of the Drift Risk of Sprays Produced by Spinning Discs Based on Wind Tunnel Measurements. Biosyst. Eng. 2008, 100, 38–43. [Google Scholar] [CrossRef]

- Patel, M.K.; Ghanshyam, C.; Mamidi, V.R.; Kapur, P. Performance and Characterization of Different Material Electrodes in Electrostatic Pesticide Spraying Nozzle System. Int. J. Appl. Sci. Technol. Res. Excell. 2012, 2, 158–163. [Google Scholar] [CrossRef]

- Patel, M.K.; Ghanshyam, C.; Kapur, P. Characterization of Electrode Material for Electrostatic Spray Charging: Theoretical and Engineering Practices. J. Electrost. 2013, 71, 55–60. [Google Scholar] [CrossRef]

- Ma, X.; Guo, L.; Wen, Z.; Wei, Y.; Xiao, R.; Zeng, H. Atomization characteristics of multi-nozzle electrostatic spray and field experiment. Trans. Chin. Soc. Agric. Eng. 2020, 36, 73–82. [Google Scholar] [CrossRef]

- Jia, W.; Hu, H.; Chen, L.; Chen, Z.; Wei, X. Performance experiment on spray atomization and droplets deposition of wind-curtain electrostatic boom spray. Trans. Chin. Soc. Agric. Eng. 2015, 31, 53–59. [Google Scholar]

- Jyoti, B.; Mani, I.; Kumar, A.; Khura, T.K. Studies on Chargeability Parameters of Charged Spray Droplets for Chemical Application in Agriculture. Indian J. Agric. Sci. 2020, 90, 1245–1249. [Google Scholar] [CrossRef]

- Maynagh, B.M.; Ghobadian, B.; Jahannama, M.R.; Hashjin, T.T. Effect of Electrostatic Induction Parameters on Droplets Charging for Agricultural Application. J. Agric. Sci. Technol. 2009, 11, 249–257. [Google Scholar]

- Rincon, V.J.; Paez, F.C.; Sanchez-Hermosilla, J. Potential Dermal Exposure to Operators Applying Pesticide on Greenhouse Crops Using Low-Cost Equipment. Sci. Total Environ. 2018, 630, 1181–1187. [Google Scholar] [CrossRef]

- Cang, T.; Sun, C.; Zhao, H.; Tang, T.; Zhang, C.; Yu, R.; Wang, X.; Wang, Q.; Dai, F.; Zhao, X. Residue Behavior and Risk Assessment of Imidacloprid Applied on Greenhouse-Cultivated Strawberries under Different Application Conditions. Environ. Sci. Pollut. Res. 2018, 25, 5024–5032. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yuan, J.; Liu, X.; Niu, Z.; Chen, B.; Liu, X. Spraying Strategy Optimization with Genetic Algorithm for Autonomous Air-Assisted Sprayer in Chinese Heliogreenhouses. Comput. Electron. Agric. 2019, 156, 84–95. [Google Scholar] [CrossRef]

- Lin, J.; Ma, J.; Liu, K.; Huang, X.; Xiao, L.; Ahmed, S.; Dong, X.; Qiu, B. Development and Test of an Autonomous Air-Assisted Sprayer Based on Single Hanging Track for Solar Greenhouse. Crop Prot. 2021, 142, 105502. [Google Scholar] [CrossRef]

- Yang, Z.; Niu, M.; Li, J.; Xu, X.; Xu, J.; Chen, Z. Design and experiment of an electrostatic sprayer with on-line mixing system for orchard. Trans. Chin. Soc. Agric. Eng. 2015, 31, 60–67. [Google Scholar]

- Brentjes, A.; Jansen, B.; Pozarlik, A.K. Spray Characteristics of an Air-Assisted Electrostatic Atomiser. J. Electrost. 2022, 115, 103654. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, D. High Voltage Insulation Technology, 3rd ed.; China Electric Power Press: Beijing, China, 2015. [Google Scholar]

- Xie, C.; He, X.; Song, J.; Andreas, H. Comparative research of two kinds of flat fan nozzle atomization process. Trans. Chin. Soc. Agric. Eng. 2013, 29, 25–30. [Google Scholar]

- Lin, J.; Cai, J.; Xiao, L.; Liu, K.; Chen, J.; Ma, J.; Qiu, B. An Angle Correction Method Based on the Influence of Angle and Travel Speed on Deposition in the Air-Assisted Spray. Crop Prot. 2024, 175, 106444. [Google Scholar] [CrossRef]

- Zhou, L.F.; Zhang, L.; Xue, X.Y.; Chen, C. Research progress and application status of electrostatic pesticide spray technology. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–11. [Google Scholar] [CrossRef]

- Junior, R.G.M.; Teixeira, M.M.; Vieira, L.B.; Ferreira, L.R.; de Alvarenga, C.B. Development of an Electronic Device for Attraction Drops of the Electrostatic Spraying in Citric Plants. Biosci. J. 2011, 27, 798–804. [Google Scholar]

- Mamidi, V.R.; Ghanshyam, C.; Kumar, P.M.; Kapur, P. Electrostatic Hand Pressure Knapsack Spray System with Enhanced Performance for Small Scale Farms. J. Electrost. 2013, 71, 785–790. [Google Scholar] [CrossRef]

- Law, S.E.; Bowen, H.D. Theoretically Predicted Interactions of Surface Charge and Evaporation on Airborne Pesticide Droplets. Trans. ASAE 1975, 18, 40–45. [Google Scholar] [CrossRef]

| Components | Type | Parameters |

|---|---|---|

| Digital high-voltage electrostatic generator | TCM6000iN (Teslaman Ltd., Dalian, China) | 0–30 kV |

| Picoammeter | Keithley 6485 (Tektronix China Ltd., Shanghai, China) | 10 fA–20 mA |

| Digital electronic scales | LQ-A10001 (Licheng China Ltd., Shanghai, China) | 0.1–1000 g |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Horizontal traveling stroke SH (m) | 1.4 | Average traveling velocity (m/s) | 0.30 |

| Vertical lifting stroke SV (m) | 1.5 | Average lift velocity (m/s) | 0.35 |

| Pressure P (Mpa) | 0.3 | Flow rate (L/min) | 1.56 |

| Items | Value | Items | Value |

|---|---|---|---|

| Wide line spacing (m) | 0.85 | Average number of leaves (Ps) | 187.4 |

| Narrow line spacing (m) | 0.55 | Average leaf area (cm2) | 112.3 |

| Plant spacing (m) | 0.45 | Leaf area index LAI | 7.47 |

| Plants per row Np (Ps) | 30 | Relative humidity (%) | 66–75 |

| Average plant height (m) | 2.16 | Operating temperature (°C) | 26–31.2 |

| Spray Pattern | CaO (%) | CVO (%) | |

|---|---|---|---|

| Before correction | EDAS | 27.7 | 62.6 |

| EAAS | 28.1 | 48.3 | |

| After correction | EDAS | 25.6 | 62.0 |

| EAAS | 28.4 | 48.0 |

| Spray Pattern | CVaS (%) | CVaG (%) |

|---|---|---|

| EDAS | 33.4 | 33.7 |

| EAAS | 31.4 | 17.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Cai, J.; Ouyang, J.; Xiao, L.; Qiu, B. The Influence of Electrostatic Spraying with Waist-Shaped Charging Devices on the Distribution of Long-Range Air-Assisted Spray in Greenhouses. Agronomy 2024, 14, 2278. https://doi.org/10.3390/agronomy14102278

Lin J, Cai J, Ouyang J, Xiao L, Qiu B. The Influence of Electrostatic Spraying with Waist-Shaped Charging Devices on the Distribution of Long-Range Air-Assisted Spray in Greenhouses. Agronomy. 2024; 14(10):2278. https://doi.org/10.3390/agronomy14102278

Chicago/Turabian StyleLin, Jinlong, Jinping Cai, Jingyi Ouyang, Liping Xiao, and Baijing Qiu. 2024. "The Influence of Electrostatic Spraying with Waist-Shaped Charging Devices on the Distribution of Long-Range Air-Assisted Spray in Greenhouses" Agronomy 14, no. 10: 2278. https://doi.org/10.3390/agronomy14102278