Abstract

Soybean–maize intercropping involves the simultaneous planting of maize and soybean. Compound planting sprayers are equipped with a dual-spraying system, particularly for herbicide application, where isolation between crops is essential. To isolate the spraying, it is necessary to select appropriate nozzles that minimize the interference between spray boundaries while ensuring spray uniformity. This study focuses on soybean–maize intercropping systems and investigates the variation patterns of spray boundary under different nozzle arrangement types. Eccentric nozzles (i.e., spray pattern is asymmetric fan-shaped) and fan-shaped nozzles (i.e., spray pattern is symmetric fan-shaped) were evaluated at a working pressure of 0.3 MPa. The results showed that the eccentric nozzle achieved a coefficient of variation (CV) of 0.57 and a compactness of 0.43, while the fan-shaped nozzle had a CV of 0.50 and a compactness of 0.52. This indicates the eccentric nozzle maintains uniformity with a narrower boundary. In addition, this validation was conducted at 0.4 MPa, having similar observations. In soybean–maize intercropping, the maize row width ranges from 40 to 80 cm and where the maize plants exceed 2 m in height, two-eccentric nozzles are required, tested at spacing intervals of 50 cm, 70 cm, and 90 cm. At 0.3 MPa, the CV reached its minimum value (0.3) at a spacing of 70 cm. Additionally, the spray volume on the eccentric nozzle side decreased as the spacing increased. The soybean row width ranges from 160 to 240 cm, requiring eccentric nozzles on both sides and a fan-shaped nozzle in the middle. The spacing between the eccentric and fan-shaped nozzles is chosen to be 50, 70, and 90 cm. A combination of eccentric and fan-shaped nozzles was tested at the same spacing intervals. The results showed that the CV consistently decreased with increasing spacing, and the spray volume on the eccentric nozzle side also declined. Overall, the optimal nozzle configuration for maize zones is two eccentric nozzles at a spacing of 70 cm, while for soybean zones, combining an eccentric nozzle with a fan-shaped nozzle at a spacing of 90 cm effectively ensures both spray uniformity and boundary compactness when variation in windspeed and direction are ignored.

1. Introduction

Soybean–maize intercropping involves planting soybean and maize in alternating strips within the same field and growth period. Farmers who use an intercropping system can improve land use efficiency by 20–30% [1]. The intercropping pattern typically adopts a wide–narrow row arrangement in the field, which helps to mitigate the shading effect of maize on soybean by leveraging the border effect, thereby improving soybean light exposure, enhancing light energy utilization, and achieving a dual harvest in one growing season. This approach effectively mitigates land-use competition between soybean and maize. In 2021, China’s soybean import volume accounted for 85.5% of the country’s total soybean demand. The soybean–maize intercropping model has been selected as a key national agricultural technology for 12 consecutive years, with a planned total area of 50 million hectares by 2025. Maize, a monocot, and soybean, a dicot, require different herbicide treatments during early weed control. Selective foliar-applied herbicides are formulated to target either monocotyledonous or dicotyledonous weeds and are typically safe only for crops of the non-target group. Herbicide drift across crop strips can cause severe phytotoxicity in soybeans, depending upon herbicide selection and possible weed resistance, making precise droplet control essential [2].

Research on soybean–maize intercropping in China has shown that planting 4–6 rows of soybeans alongside 2–3 rows of maize achieves optimal yield performance [3]. Typically, the row spacing within maize and soybean strips is approximately 40 cm, while the spacing between maize and soybean strips ranges from 60 to 70 cm. No-till seeding is commonly practiced with soybean–maize agriculture in the Huang-Huai Hai region of China. Post-emergence herbicides are generally applied at critical growth stages: the 3–5 leaf stage for maize, the 2–3 compound leaf stage for soybean, and the 2–5 leaf stage for weeds [4]. To address the challenges of this intercropping system, several researchers have developed strip-spraying boom sprayers. Henan Agricultural University designed a small, electric self-propelled boom sprayer with a dual-variable spraying system [5]. Weikex Company in Shandong developed a soybean–maize intercropping sprayer featuring multiple functions such as isolation curtains, adjustable spacing, adjustable nozzle height (both vertically and laterally), and adjustable wheel track and chassis height [6]. Most studies have focused on physical methods to isolate spray drift, with limited attention given to the impact of nozzle types on spray boundary performance. The type of nozzle and the operating parameters have a direct impact on both spray uniformity and droplet drift [7,8].

Different nozzle types vary in their ability to achieve uniform spray distribution [9]. For different crops, selecting appropriate nozzle types is crucial. The conventional flat-fan nozzle is widely used in field pesticide applications [10,11], with the 110° flat-fan nozzle being particularly common due to its excellent droplet distribution characteristics [12]. While most researchers have studied spray coverage, drift rate, and uniformity [13], few have specifically investigated nozzle performance at the boundary areas of soybean and maize strips. Conventional flat-fan nozzles often struggle to provide uniform spray coverage at these boundaries. The height difference and spatial distribution between soybean and maize crops make it difficult for flat-fan nozzles to ensure consistent application, often resulting in insufficient coverage or excessive overlap at the edges, reducing pest control efficacy. Due to differences in crop height and leaf area index, a single spray pattern is insufficient to meet the precise spraying needs of both crops. At the soybean strip boundary, where flat-fan spray patterns taper off, droplet size and volume are reduced, increasing the risk of drift unless a selection of flat-fan nozzle yielding coarse drop generation are used. Meanwhile, the taller maize plants pose additional challenges, as conventional flat-fan nozzles have limited penetration, making it difficult for the spray to effectively reach the lower and middle portions of the maize canopy. This study improves penetration by using side spraying with eccentric nozzles and explores combinations of different types of nozzles.

In intercropping systems, crop strip width influences nozzle arrangement. For soybean–maize intercropping, a combination of conventional flat-fan nozzles and eccentric nozzles is commonly used. During weed control operations with boom sprayers, the nozzle spacing is typically 50 cm, and the nozzle height is 50 cm above the top of the plant canopy [14]. Nuyttens et al. [15,16,17] conducted extensive research on nozzle atomization technology, examining the effects of nozzle type, size, and pressure on droplet size and velocity. Edwards et al. [18] demonstrated that factors such as nozzle model and spray pressure significantly influence spray uniformity. Eccentric nozzles, designed to optimize liquid flow trajectory and spray angle, enhance target coverage. Although widely applied in irrigation and sprinkling systems, their use in field spraying operations remains limited. The combination of different nozzle types also provides a basis for prescription map generation. Prescription map technology is fundamental to variable-rate pesticide application, where determining the appropriate pesticide dosage relies heavily on crop growth conditions and density. Pietro Mattivi et al. [19] identified and mapped weed spatial distribution in traditional cropping systems. By dividing the field into grid units and calculating the weed coverage percentage for each unit, they generated effective prescription maps which is now common practice for UAV applications having appropriate sensing equipment. Yang Li et al. [20] employed the Normalized Difference Vegetation Index (NDVI) to assess variations in pesticide demand across different field areas. The overlapping spray zones between adjacent nozzles pose additional challenges for prescription map division. Research on the spray width and flow distribution of various nozzle combinations contributes valuable insights for refining grid-based prescription mapping techniques.

This study investigates the nozzle arrangement of a sprayer for intercropping systems, selecting different combinations of nozzles based on the characteristics of the soybean and maize rows. This study examines the impact of various nozzle spacings on the uniformity of spray distribution for different nozzle combinations. In light of the pesticide interference characteristics in soybean–maize intercropping, this research explores the spray edge distribution characteristics of different nozzle combinations and quantitatively studies the edge spray behavior to minimize interference between the edge sprays.

2. Materials and Methods

2.1. Experimental Design

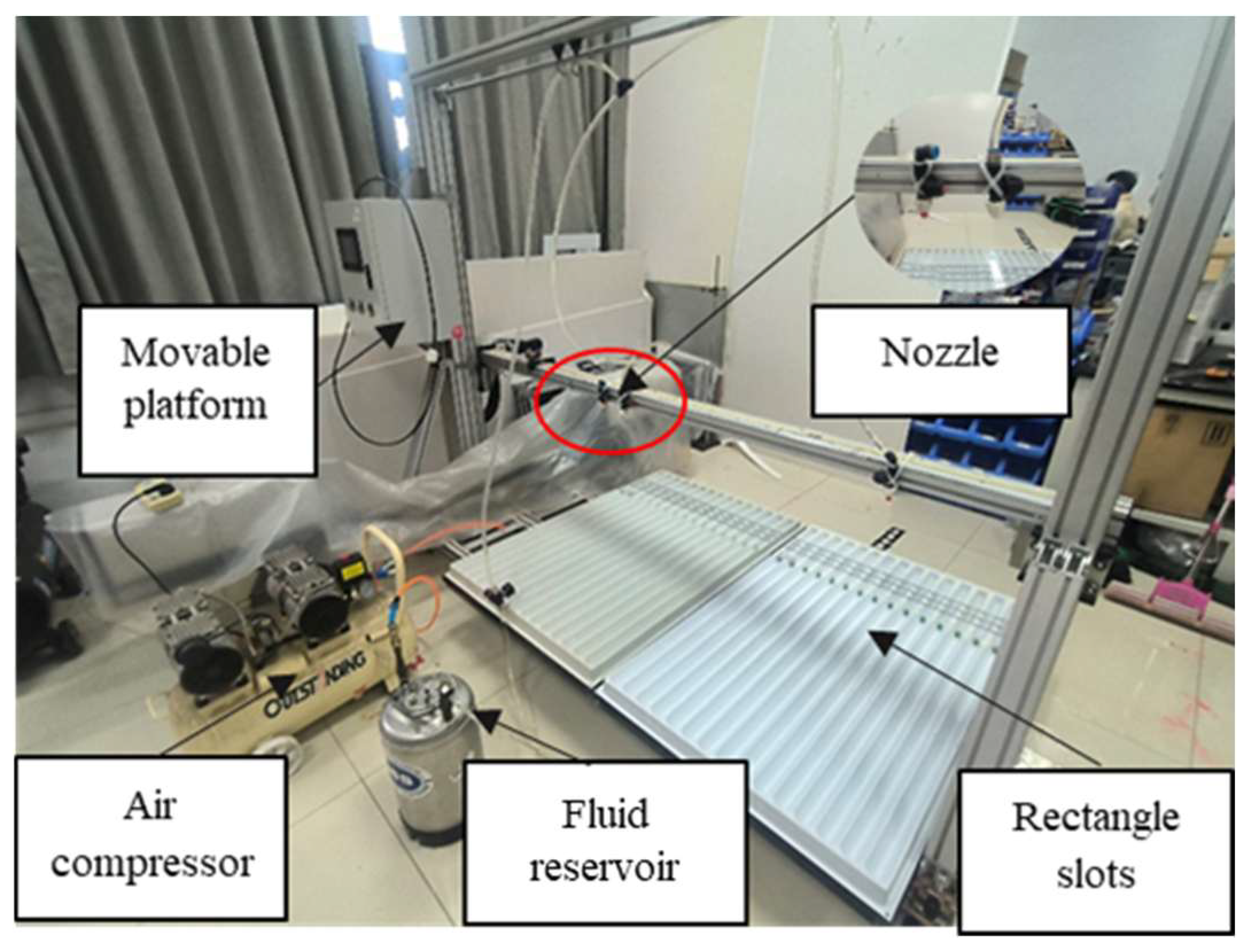

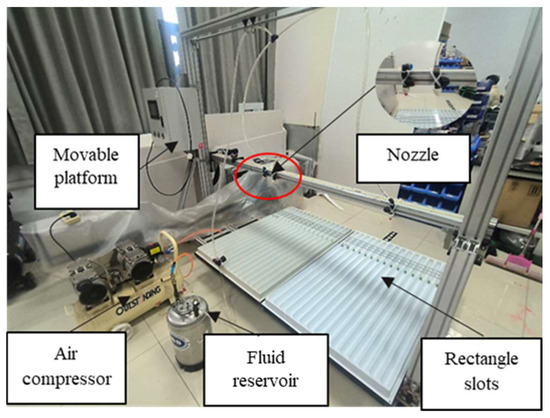

A spray volume analyzer provides insights into the droplet distribution for different nozzle combinations. The spray distribution pattern reflects the performance of the sprayer and its droplet coverage under optimal field conditions. The spray volume distribution testing platform consisted of a spraying system, an adjustable mobile rack, and a spray analyzer, as shown in Figure 1. The spraying system’s pressure was supplied by an air compressor combined with a pressure stabilizing tank to ensure a more stable pressure output than a conventional pump. The pressure was regulated using a gas control valve, with testing conducted at 0.3 MPa and 0.4 MPa. The adjustable mobile rack allowed movement in both vertical and horizontal directions, facilitating nozzle combination experiments. The spray volume analyzer featured continuous grooves with a total length of 120 cm and a width of 150 cm, with each groove being 5 cm wide, it enabled the continuous collection of spray at various locations across the grooves. After each experiment, water collected in each groove was transferred to a measuring cylinder for volume assessment. Tap water was used as the test liquid, and two types of nozzles, flat-fan nozzles and eccentric nozzles, were employed, both manufactured by Lechler. The nozzles were mounted on an adjustable spray rack, enabling flexible height and position adjustments to accommodate different nozzle types and spacing configurations.

Figure 1.

Spray volume analyzer test.

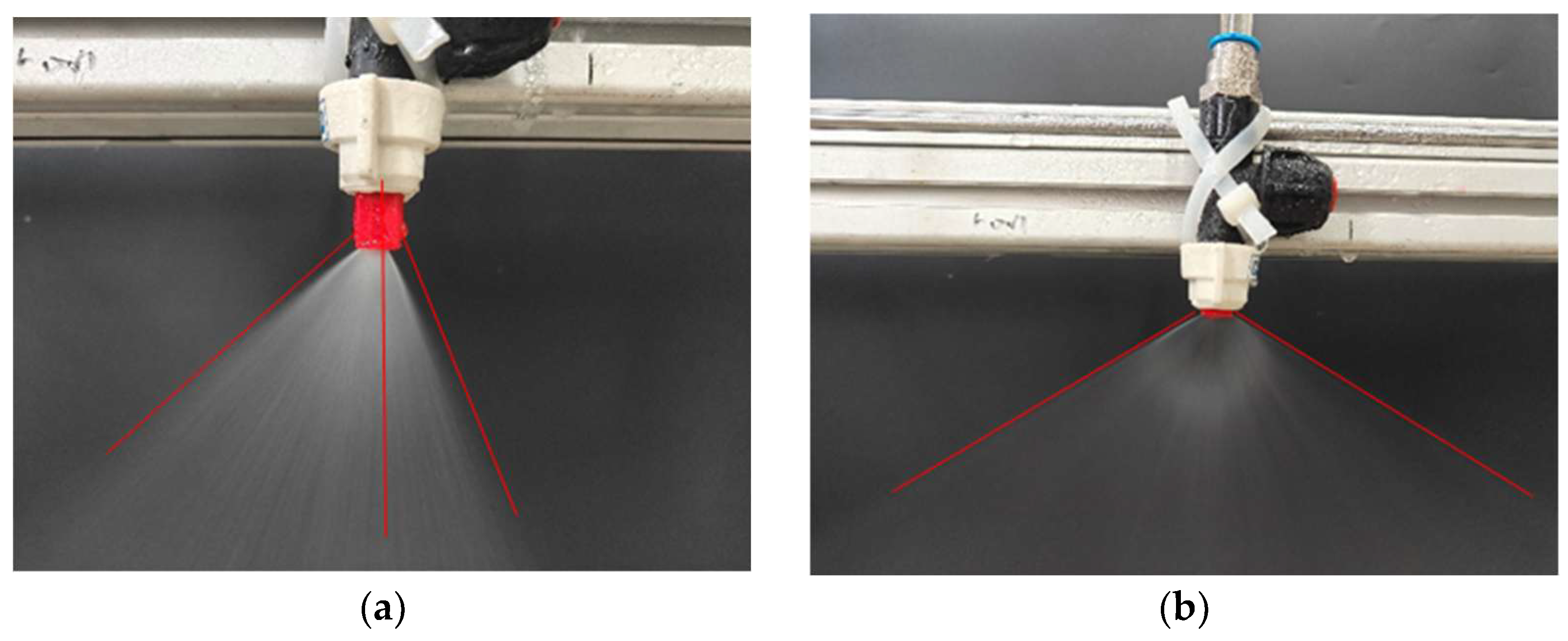

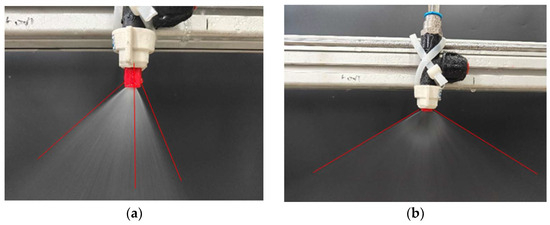

2.2. Single Nozzle Spray Distribution and Spray Angle Determination

This study selected two commonly used nozzles for field spraying: the LU 110-04 flat-fan nozzle and the IDKS 80-04 eccentric flat-fan nozzle (Lechler GmbH, Metzingen, Germany). To assess nozzle flow rates, individual nozzle tests were conducted by collecting spray volume using a measuring cylinder (bkman, Changsha, China). The results showed that the IDKS 80-04 nozzle had a flow rate of 1200 mL/min at a spray pressure of 0.3 MPa and 1360 mL/min at 0.4 MPa. The LU 110-04 flat-fan nozzle exhibited a flow rate of 1410 mL/min at 0.3 MPa and 1680 mL/min at 0.4 MPa. Spray angles were analyzed by photographing the spray patterns and measuring the angles using Image-Pro Plus 6.0 image processing software (Meyer Instruments, Silver Spring, MD, USA). For the eccentric nozzle, the spray angle was 73° at 0.3 MPa and 75° at 0.4 MPa. For the LU 110-04 flat-fan nozzle, the spray angle was 111° at 0.3 MPa and 115° at 0.4 MPa, as shown in Figure 2.

Figure 2.

Measurement of spray angles: (a) eccentric nozzle and (b) flat-fan nozzle.

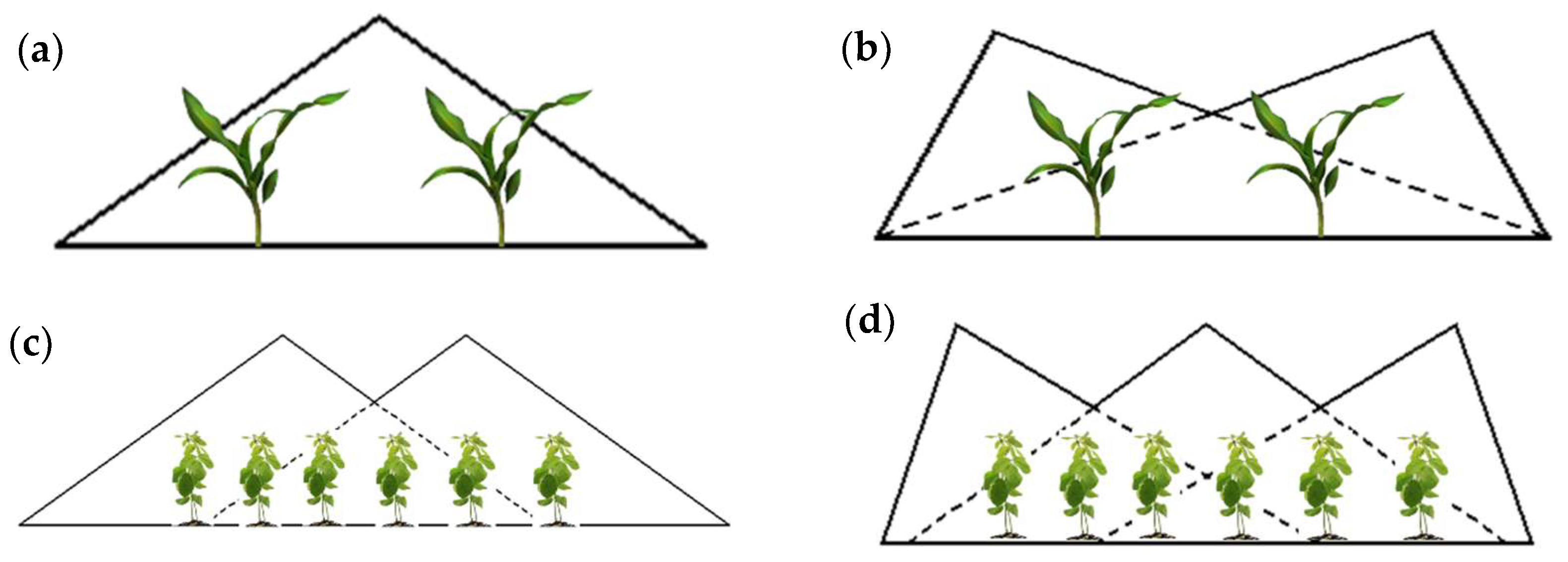

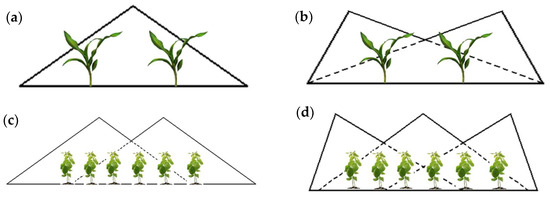

2.3. Combination of Eccentric Nozzles and Fan-Shaped Nozzles

In soybean–maize intercropping systems, herbicide droplets are prone to cross-boundary drift. Placing eccentric nozzles at the edges of soybean and maize strips can effectively reduce droplet drift. The nozzle arrangement should be adjusted based on the width of the soybean and maize strips. Typically, maize strips consist of 2–3 rows with 40 cm row spacing. With a row spacing of 40 cm, and considering the width and height of the maize rows, as well as the relatively tall maize plants, side spraying with eccentric nozzles is required. For such configurations, either two eccentric nozzles or one flat-fan nozzle can be used. Soybean strips generally include 4–6 rows with a total width of 160–240 cm, requiring either two eccentric nozzles on both sides with one flat-fan nozzle in the middle or two flat-fan nozzles, resulting in four possible nozzle arrangements, as shown in Figure 3. Based on field practices, a flat-fan nozzle height of 50 cm above the target with a standard spacing of 50 cm ensures uniform spray distribution and reduces drift. Three spacing configurations of 50 cm, 70 cm, and 90 cm were selected for the experiments considering the spray angle characteristics of the eccentric nozzle, see Table 1.

Figure 3.

Nozzle arrangement in soybean and corn strips: (a) flat-fan nozzle; (b) eccentric nozzle and eccentric nozzle; (c) flat-fan nozzle and flat-fan nozzle; and (d) eccentric nozzle and flat-fan nozzle.

Table 1.

Experimental design and measurement parameters.

3. Results

3.1. Spray Uniformity

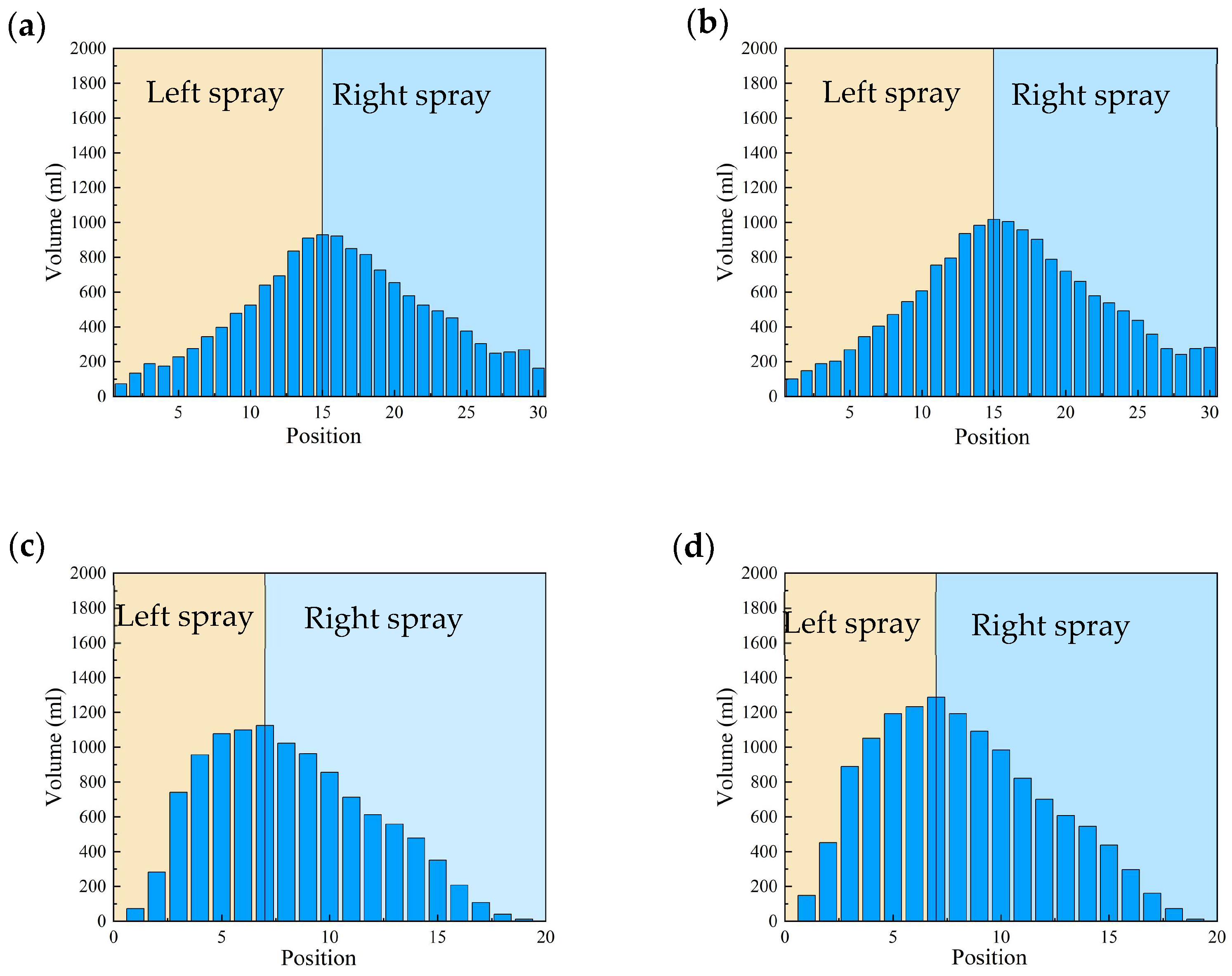

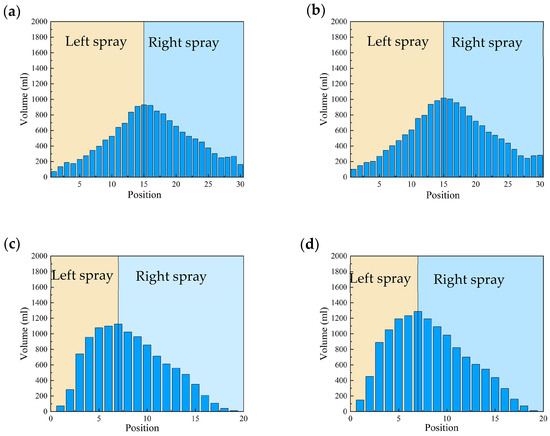

Spray uniformity is a key parameter that reflects the even distribution of pesticide deposition on crops [21]. The boundary of the spray field between two adjacent nozzles plays a crucial role to achieve uniform spraying along the boom direction. Additionally, the nozzle spacing is a key factor in determining droplet deposition [22,23,24]. A spray uniformity test was first conducted using both flat-fan and eccentric nozzles. The tests were performed at two common pressures: 0.3 MPa and 0.4 MPa. The results show that the flat-fan nozzle exhibits a trend of higher deposition in the center and lower on the sides, with a nearly symmetrical distribution. In contrast, the eccentric nozzle also shows a trend of higher deposition in the center and lower on the sides, but the distribution is asymmetric, as shown in Figure 4.

Figure 4.

Single nozzle spray volume distribution: (a) flat-fan nozzle at 0.3 MPa; (b) flat-fan nozzle at 0.4 MPa; (c) eccentric nozzle at 0.3 MPa; and (d) eccentric nozzle at 0.4 MPa.

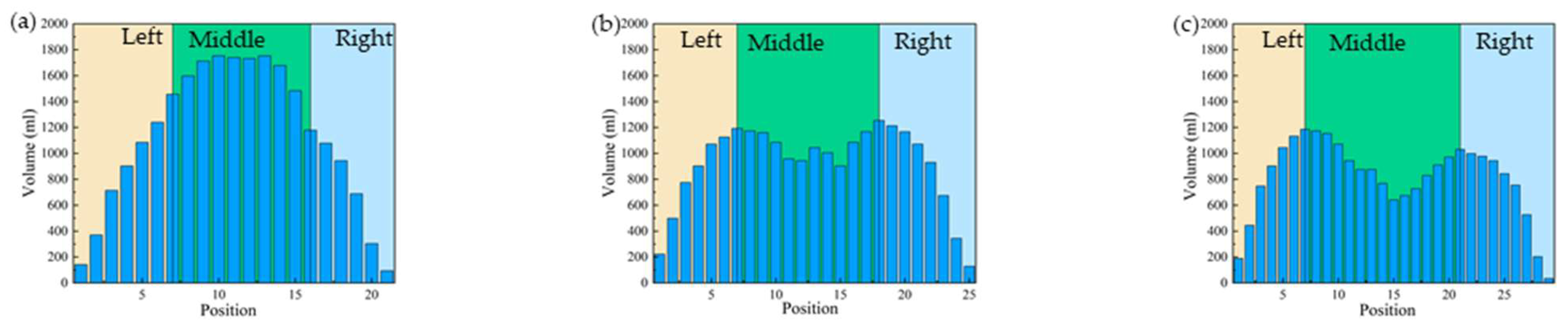

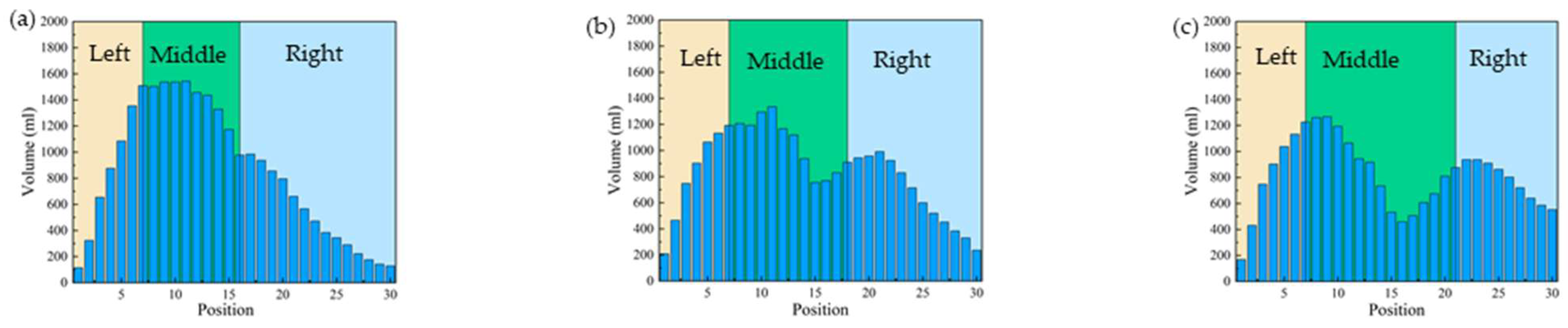

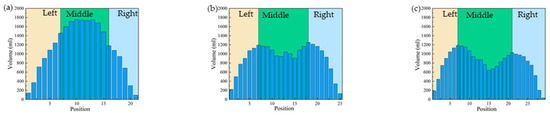

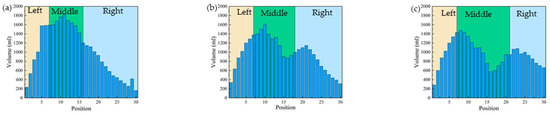

Experiments were conducted on two combinations: eccentric nozzles paired with flat-fan nozzles, and eccentric nozzles paired with eccentric nozzles, Figure 5, Figure 6, Figure 7 and Figure 8. The nozzle spacing was varied to study the changes in spray distribution. The droplet distribution shows a single peak when the spacing between to excentric nozzles is 50 cm, Figure 5. As the nozzle spacing increases, the peak value gradually decreases and splits into two peaks, with the distribution range expanding. From Figure 6, it can be seen that the combination of a flat-fan nozzle and an eccentric nozzle at a 50 cm spacing also exhibits a single peak, which decreases and splits into two peaks as the nozzle spacing increases. Moreover, the peak value of the eccentric nozzle is higher than that of the flat-fan nozzle. When the pressure is increased to 0.4 MPa, the distribution pattern remains consistent with that observed at 0.3 MPa.

Figure 5.

Spray distribution of eccentric nozzle and eccentric nozzle at 0.3 MPa: (a) nozzle spacing: 50 cm; (b) nozzle spacing: 70 cm; and (c) nozzle spacing: 90 cm.

Figure 6.

Spray distribution of eccentric nozzle and flat-fan nozzle at 0.3 MPa: (a) nozzle spacing: 50 cm; (b) nozzle spacing: 70 cm; and (c) nozzle spacing: 90 cm.

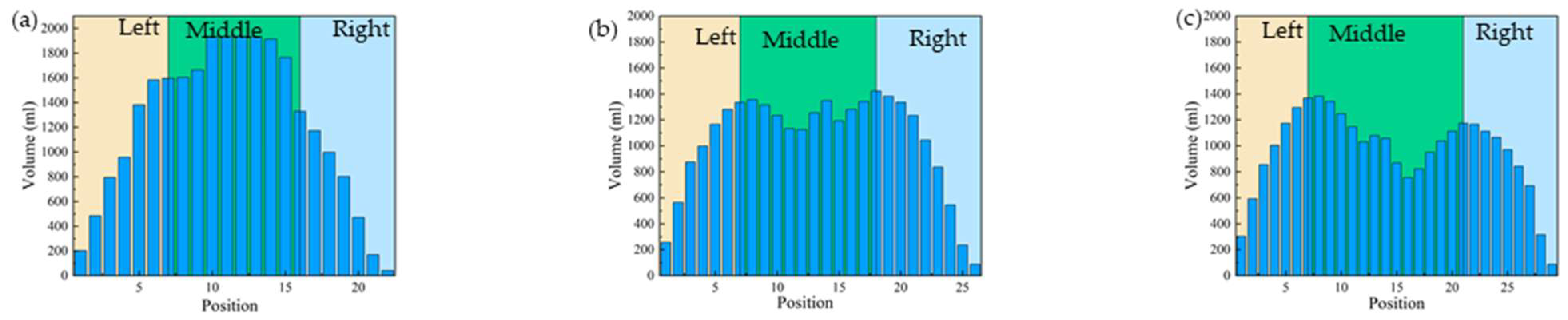

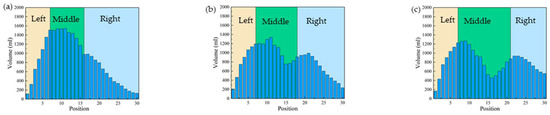

Figure 7.

Spray distribution of eccentric nozzle and eccentric nozzle at 0.4 MPa: (a) nozzle spacing: 50 cm; (b) nozzle spacing: 70 cm; and (c) nozzle spacing: 90 cm.

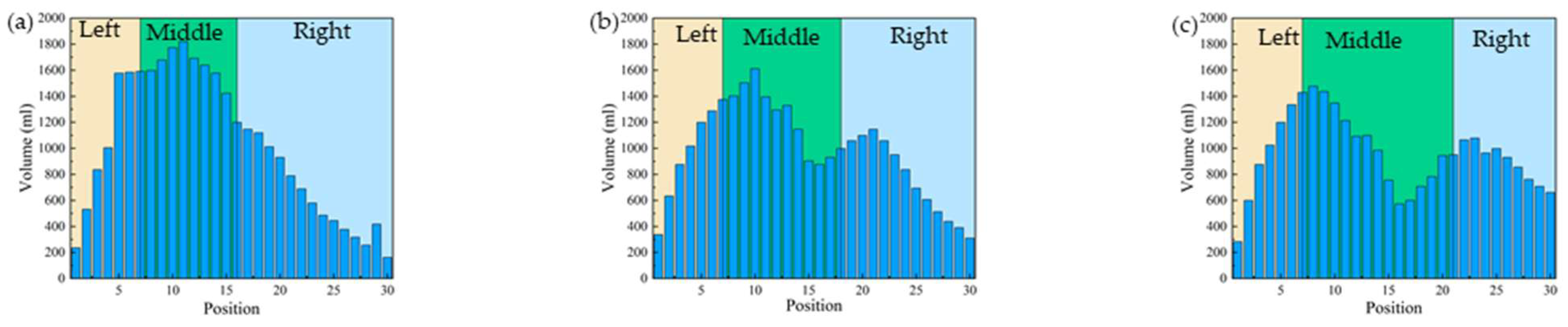

Figure 8.

Spray distribution of eccentric nozzle and flat-fan nozzle at 0.4 MPa: (a) nozzle spacing: 50 cm; (b) nozzle spacing: 70 cm; and (c) nozzle spacing: 90 cm.

The flowrate for the two eccentric nozzles increased as the pressure increased. As the nozzle spacing increased, the initial single peak gradually evolved into two distinct peaks, as shown in Figure 7. At a pressure of 0.4 MPa and a nozzle spacing of 50 cm, the peak value increased, and the peak region broadened, indicating an expanded overlap between the spray patterns of the eccentric nozzle and the flat-fan nozzle. When the nozzle spacing increased to 90 cm, the difference between the two peaks increased to 398 mL, as shown in Figure 8.

3.2. Coefficient of Variation of Spray Distribution

Due to the differences in the two nozzle combinations, the coefficient of variation is chosen to describe the spray uniformity. The coefficient of variation is a dimensionless statistic that represents the ratio of the standard deviation to the mean, used to measure the relative dispersion of the spray volume [25]. The formula is as follows:

where σ is the standard deviation of the dataset (L/min), and μ the mean of the dataset (L/min).

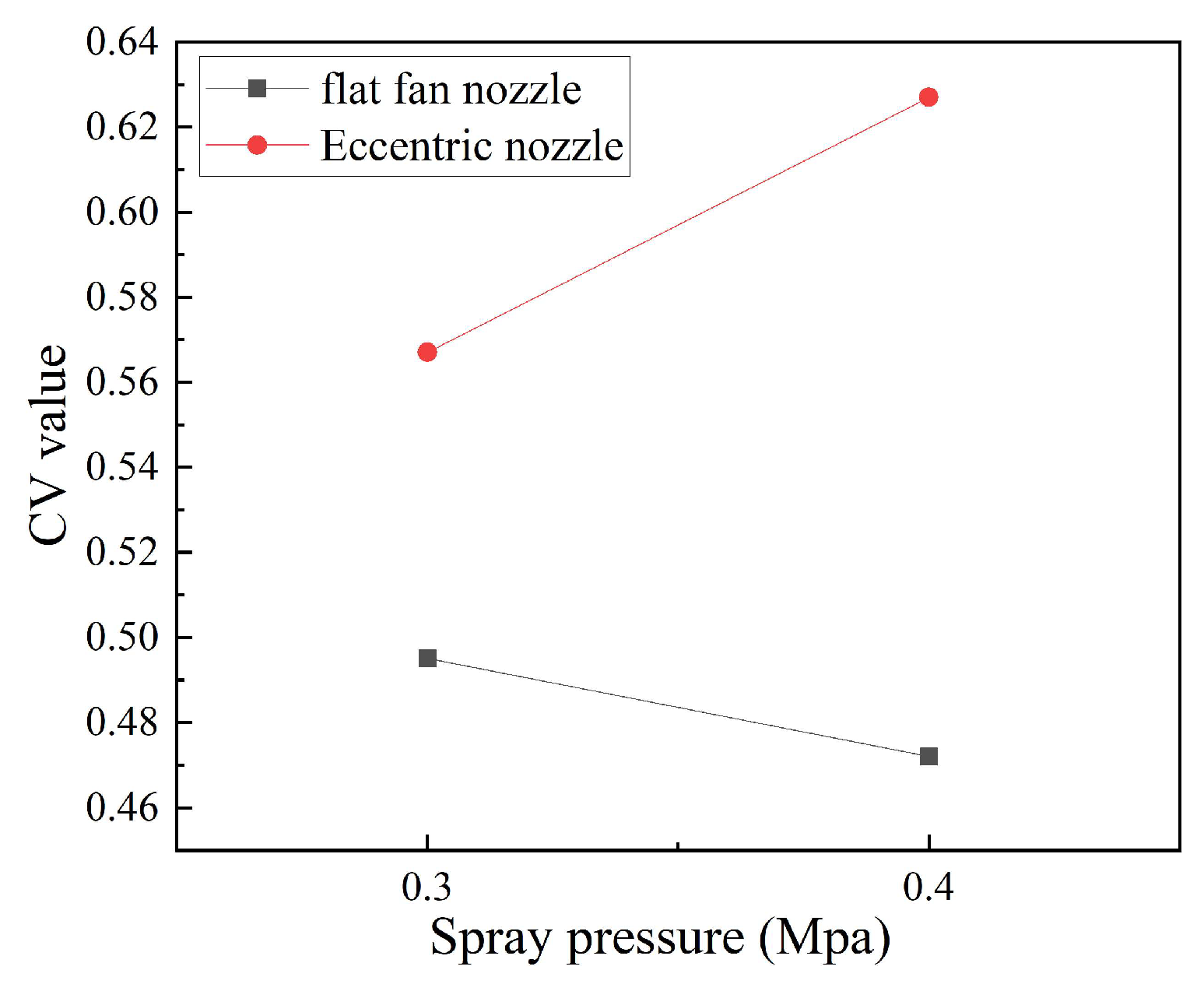

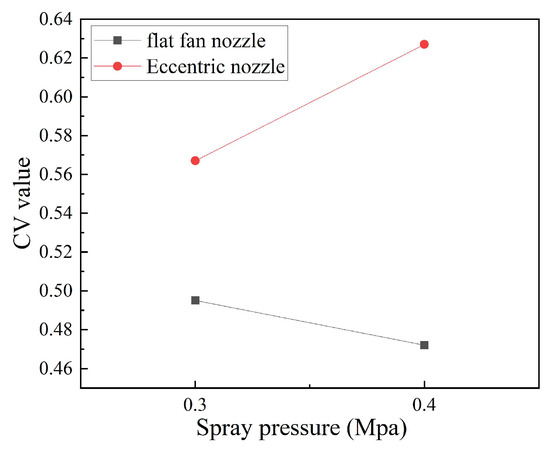

The coefficient of variation (CV) reflects the spray uniformity of a nozzle. As shown in Figure 9, the CV of the eccentric nozzle is significantly higher than that of the fan-shaped nozzle, indicating a greater variability in the spray distribution of the eccentric nozzle. When the spray pressure increases from 0.3 MPa to 0.4 MPa, the difference in CV between the two nozzle types becomes more pronounced. This suggests that the spray output at the edges of the eccentric nozzle exhibits greater fluctuation, allowing it to reach peak spray volume over a shorter distance from the edge. Such characteristics make the eccentric nozzle more suitable for placement at the boundaries of soybean and maize rows, helping to reduce cross-contamination of pesticides between the two crop zones.

Figure 9.

Coefficient of Variation of Eccentric Nozzle and Flat-Fan Nozzle.

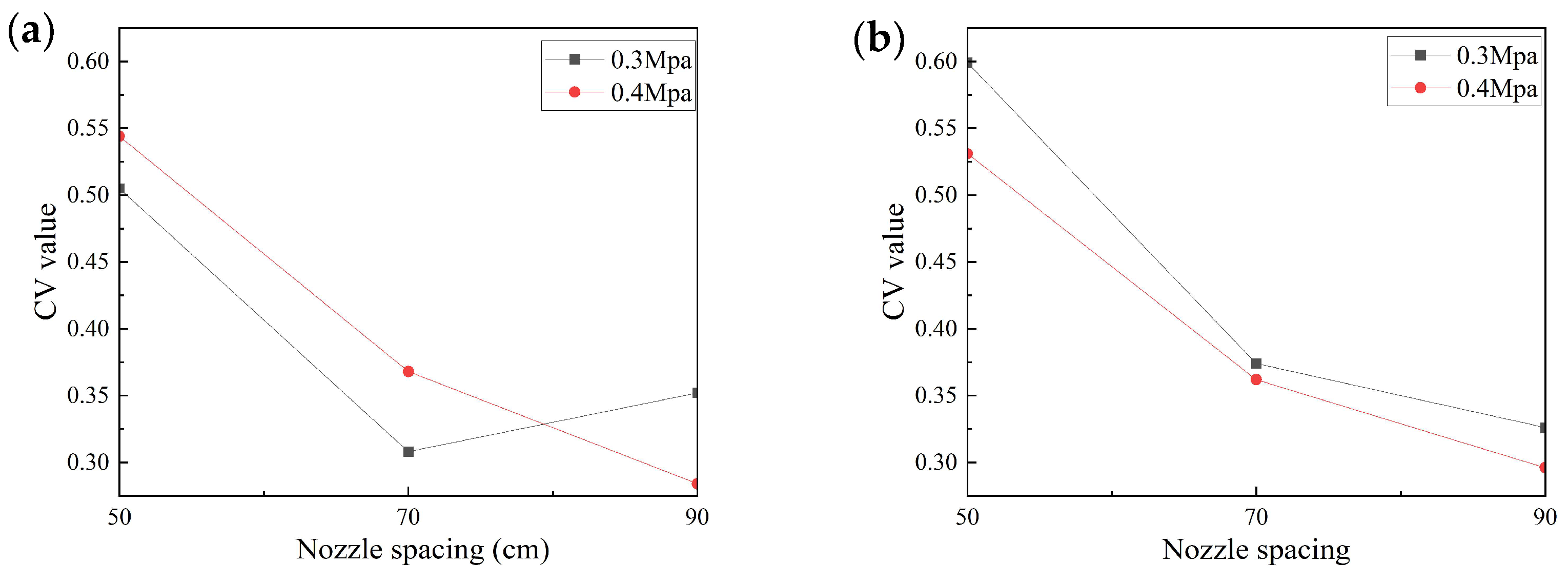

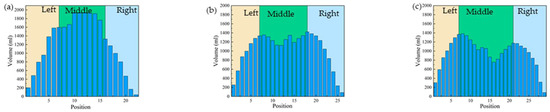

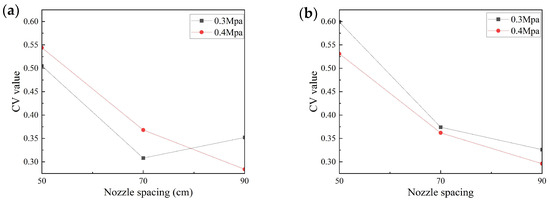

The coefficient of variation for two combinations, eccentric nozzle paired with eccentric nozzle and eccentric nozzle paired with flat-fan nozzle, was statistically analyzed. It was found that as the nozzle spacing increased, the spray coefficient of variation decreased. However, at 0.3 MPa, when the spacing between the eccentric nozzles increased from 70 cm to 90 cm, the coefficient of variation increased; at 0.3 MPa, the spray angle of the nozzles is relatively small. When the nozzle spacing increases to 90 cm, the overlap between adjacent spray patterns becomes insufficient, leading to an increase in the coefficient of variation. Changes in nozzle spacing alter the overlap in edge spray regions, which in turn affects the spray uniformity as reflected by the variation in the coefficient of variation. The coefficient of variation for the combination of two eccentric nozzles was lower than that of a single eccentric nozzle, improving the uniformity. After the spacing increased to 70 cm, the coefficient of variation for the combination of two eccentric nozzles was also lower than that of the flat-fan nozzle. When the eccentric nozzle and flat-fan nozzle were combined, the spray uniformity at a spacing of 70 cm showed a lower coefficient of variation than the flat-fan nozzle, as shown in Figure 10.

Figure 10.

Coefficient of variation: (a) eccentric nozzle and eccentric nozzle, and (b) eccentric nozzle and flat-fan nozzle.

3.3. Spray Deposition Distribution at the Edge of the Spray Band

This study primarily focuses on the spray boundary, specifically the side with the smaller spray angle of the eccentric nozzle. The spray deposition density at the edge of the spray band represents the deposition amount at the boundary. Spray deposition density is typically expressed as the spray mass per unit area and is commonly used to evaluate the uniformity and effectiveness of the spray. This paper mainly presents the statistical analysis of the spray volume and spray width on the side of the eccentric nozzle [26], The deposition density at the edge of the spray band is given as follows:

where D is the deposition density at the edge of the spray band (kg/m2), M is deposition mass within the spray band edge area (kg), and A is the area at the edge of the spray band (m2).

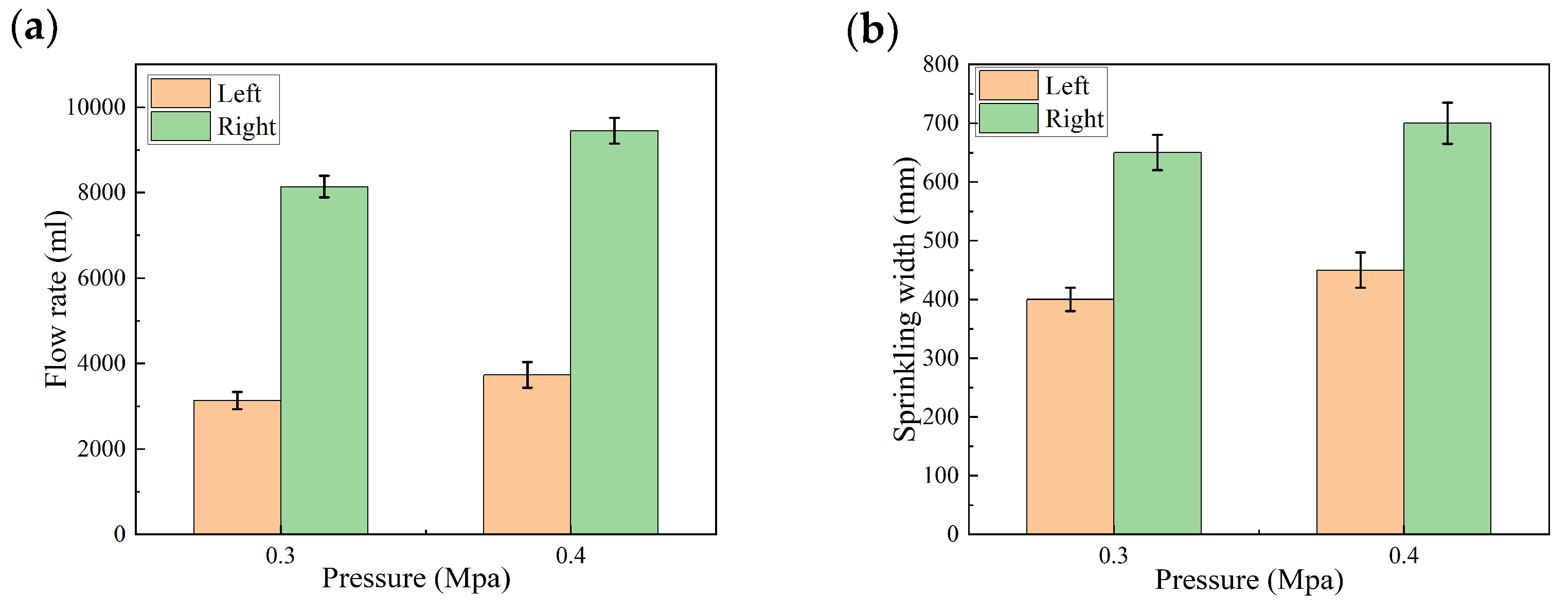

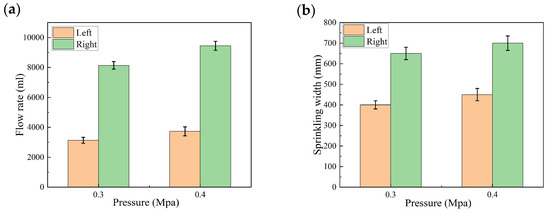

The spray volume on both sides of the nozzle was statistically analyzed. The spray volume on the right side of the eccentric nozzle is 2.6 times that on the left side, with the spray width 1.6 times greater, when the pressure is 0.3 MPa. At 0.4 MPa, the spray volume on the right side is 2.5 times that on the left side, with the spray width being 1.5 times greater. At a pressure of 0.3 MPa, the configuration shown in Figure 11b exhibits a narrower spray width, while Figure 11a shows a reduced flow rate, both of which indicate enhanced suitability for boundary spraying applications.

Figure 11.

Spray volume and spray width on both sides of the eccentric nozzle: (a) spray volume, and (b) spray width.

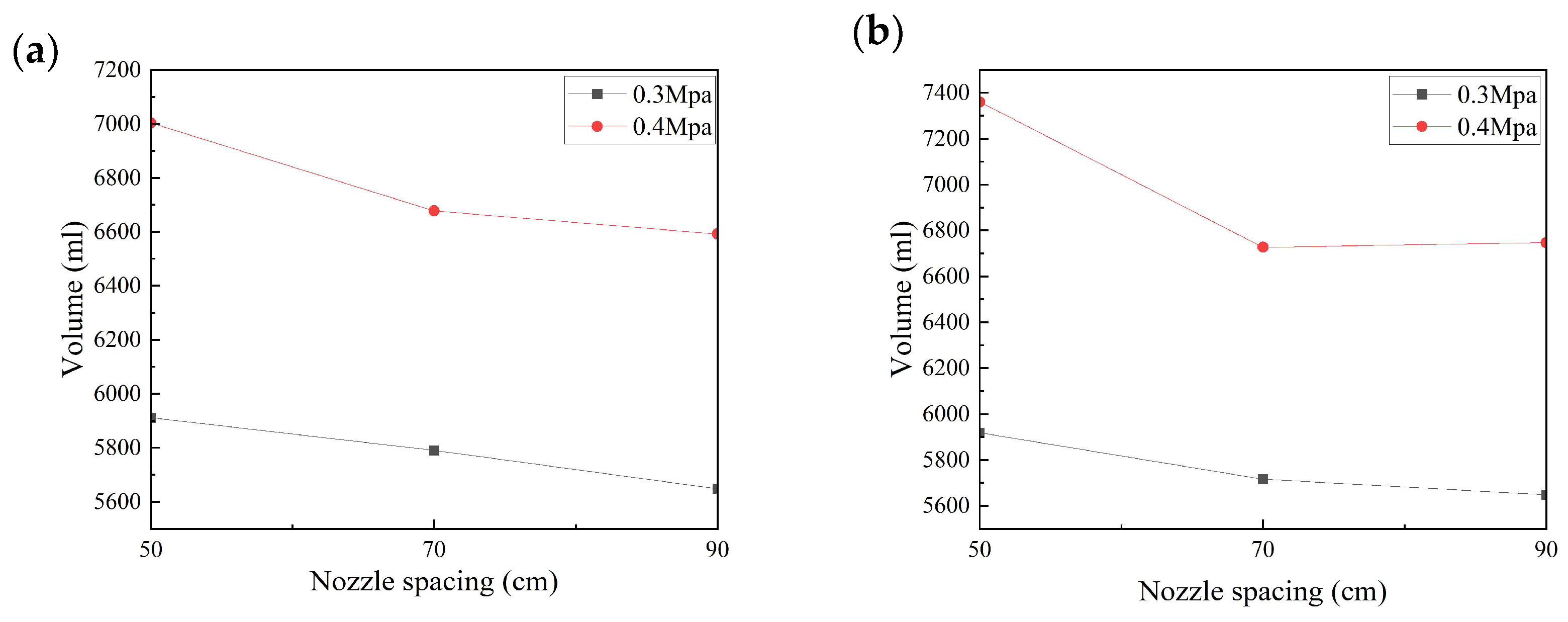

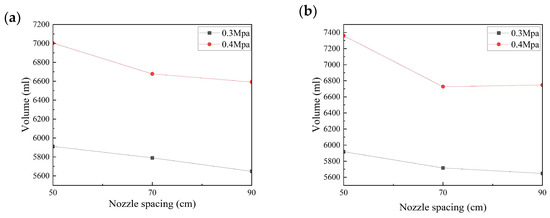

The interaction between the left-side flow rate of an eccentric nozzle and the adjacent nozzle whether eccentric or fan shaped varies with nozzle spacing. Exploring these effects under different configurations can offer theoretical support for optimizing spray uniformity in intercropping applications. As the nozzle spacing increased, the flow rate on the left side decreased for both nozzle combinations. At 0.3 MPa, the deviation in flow rate on the left side was within 1.5%. At 0.4 MPa, the deviation increased to between 2.3% and 5%. This indicates that the combination of eccentric nozzles and flat-fan nozzles has a smaller effect on the spray volume on the left side compared to the combination of two eccentric nozzles, as shown in Figure 12. The results indicate that when the off-center nozzle is positioned at the edge, adding either an additional off center or flat-fan nozzle on the right side does not affect the spray distribution on the left edge of the off-center nozzle. Therefore, the off-center nozzle is suitable for use as an edge nozzle.

Figure 12.

Spray volume on the left side of the nozzle: (a) spray volume on the left side of the nozzle, and (b) eccentric nozzle and flat-fan nozzle.

3.4. Spray Boundary Compactness

The edges of the soybean and corn strips are the boundary areas of the spray. The boundary formed by the eccentric nozzle and flat-fan nozzle is crucial for spray uniformity and spray width [27]. The compactness of the spray boundary can be used to describe the extent of the spray boundary. Compactness is defined as the ratio of the boundary area to the area of its circumscribed circle. A smaller P and a larger A indicate a more compact and concentrated boundary. A higher compactness value signifies a more concentrated spray boundary.

where A is the area of the spray boundary (m2), and P is the perimeter of the spray boundary (m).

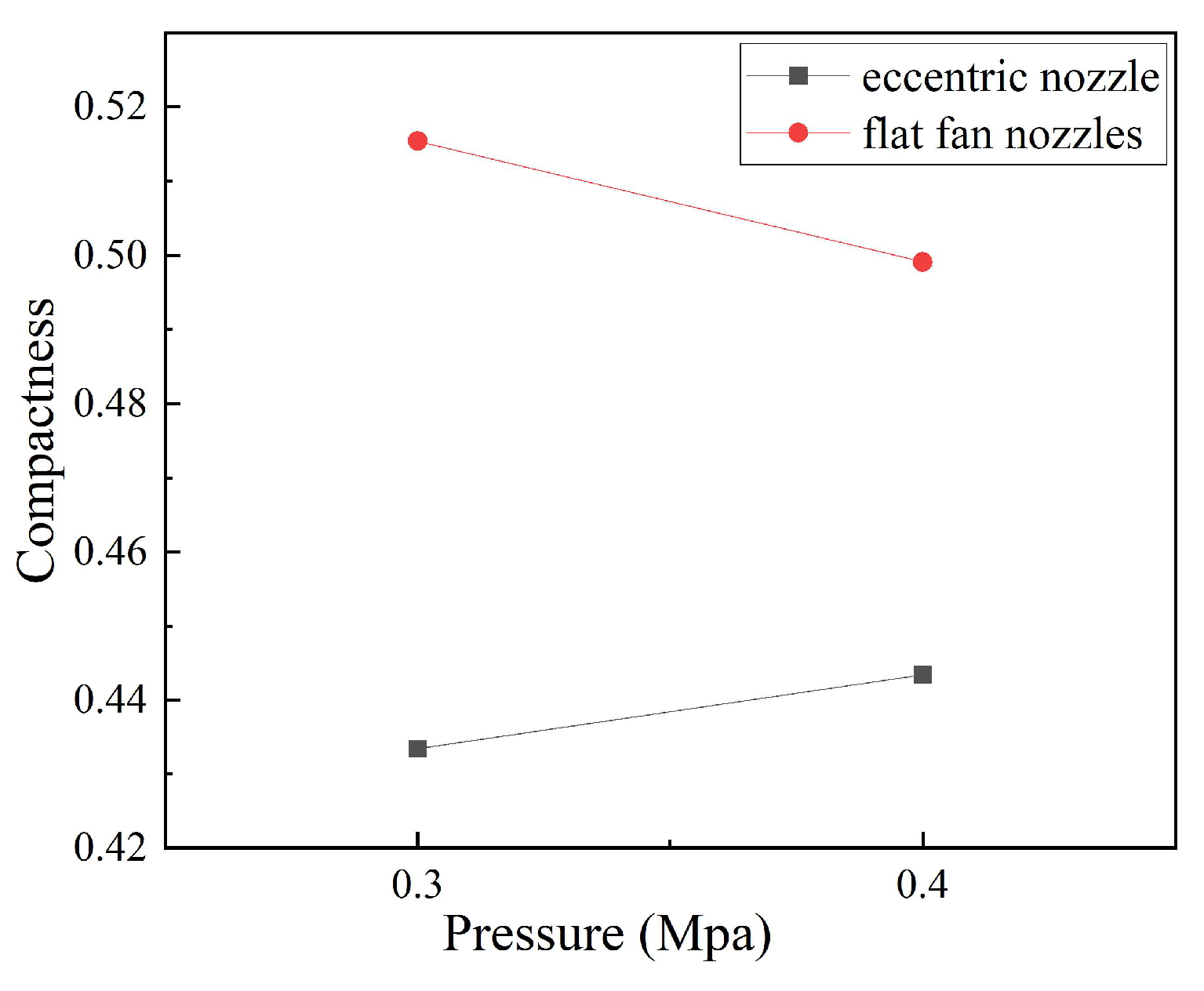

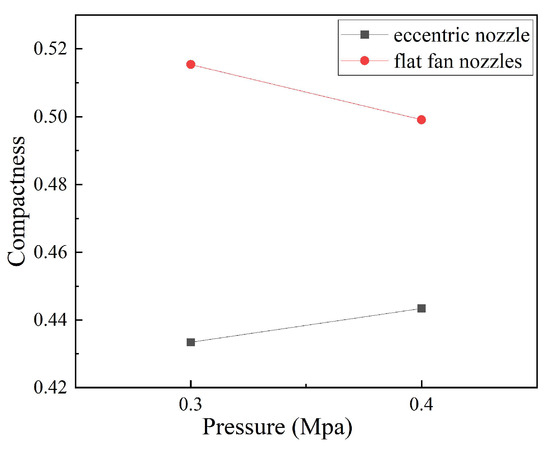

The compactness of the eccentric nozzle and flat-fan nozzle was studied. At both 0.3 MPa and 0.4 MPa, the compactness of the eccentric nozzle was much lower than that of the flat-fan nozzle. At 0.3 MPa, the compactness of the eccentric nozzle was 18.9% lower than that of the flat-fan nozzle, and at 0.4 MPa, it was 12.5% lower, as shown in Figure 13, The above results indicate that eccentric nozzles are more suitable for edge spraying than fan-shaped nozzles, owing to their shorter spray width.

Figure 13.

Compactness of Eccentric Nozzle and Flat-Fan Nozzle.

4. Discussion

This study proposes different nozzle combination strategies for sprayers used in intercropping systems and evaluates spray boundary performance using the coefficient of variation (CV) and compactness metrics. Intercropping typically involves combinations of legumes and gramineous crops, or root crops with upright crops, with soybean–maize intercropping being the most widely adopted configuration [1]. To accommodate different crop characteristics, appropriate nozzle types and arrangements must be selected. Tall crops require an increased spray–leaf contact angle, to increase the deposition density of spray droplets, while densely planted crops demand higher spray penetration, to improve droplet deposition on the underside or lower layers of the crop canopy. Meanwhile, it is essential to ensure that the spray boundaries do not interfere with one another. Spray performance is commonly assessed using parameters such as uniformity, deposition, and penetration [28]. Uniformity encompasses both the evenness of spray volume and droplet distribution; deposition is measured at various parts of the plant; and penetration is evaluated based on droplet deposition at the lower canopy. Spray uniformity is typically analyzed in controlled laboratory conditions using droplet analyzers and laser particle sizers. In contrast, deposition and penetration are assessed by placing water-sensitive papers at different positions within the plant canopy to determine spatial distribution of droplet deposition key indicators of spray effectiveness.

Field experiments are inherently more complex than laboratory tests, particularly in intercropping systems, as environmental wind and machine movement significantly influence outcomes [29,30]. Currently, in soybean–maize intercropping sprayers, spray isolation is often achieved through physical shielding over the soybean rows. However, crosswinds inside the shielded areas can increase spray drift [31]. Due to the height of maize plants, side spraying is generally required. The eccentric nozzle proposed in this study is well-suited for such applications, as it facilitates side spraying while minimizing pesticide drift into adjacent soybean rows.

Unlike monoculture cropping, intercropping systems require tailored nozzle types and operational parameters to address varying crop characteristics. Future advancements in intelligent spraying should focus on the spray width and volume output of different nozzle types under field conditions. The independent control of each nozzle will be essential to precisely meet prescription maps and ensure accurate pesticide application [32]. The strategic combination of different nozzle types allows for adaptation to various crop structures, ensuring not only spray uniformity but also the precise delivery of pesticides within targeted areas thereby achieving optimal pest control efficacy [33]. Field management robots have become a prominent research focus in recent years. In uncertain operational environments, they are capable of performing more complex tasks. One such application involves optimizing spray system parameters for different crop types, enabling the adjustment of spraying configurations to suit a variety of crops [34].

5. Conclusions

The intercropping of soybean and corn in China has reached an area of 20 million acres, and the planted area is increasing year by year. However, the application of pesticides is mainly still reliant on manual methods. This study addresses the issue of separate pesticide application in intercropping systems by investigating different nozzle layouts. This study aims to reduce the interaction of pesticide application between the soybean and corn zones while ensuring uniformity of the spray distribution. By quantifying key indicators, the optimal nozzle combinations and spacing are identified. In the corn zone, a combination of eccentric nozzles is used, while in the soybean zone, a combination of eccentric and fan-shaped nozzles is adopted. The edge spray volume and spray width of both combinations are experimentally analyzed. This research also provides insights for other intercropping systems by introducing the compactness index to quantify edge spray distribution.

This study investigates the nozzle arrangement for sprayers used in soybean–maize intercropping systems. By employing a droplet analyzer, various combinations of eccentric and fan-shaped nozzles were tested to evaluate their spray distribution patterns under controlled laboratory experimentation. Experiments were conducted at a spraying pressure of 0.3 MPa and a nozzle height of 50 cm, with additional validation at 0.4 MPa.

- (1)

- First, the spray volume and spray width of eccentric and fan-shaped nozzles were examined. At 0.3 MPa, the spray volume on the right side of the eccentric nozzle was 2.6 times that of the left side, and the spray width was 1.6 times greater. The coefficient of variation (CV) for the eccentric nozzle was 0.57, and the compactness was 0.43. In contrast, the fan-shaped nozzle exhibited a CV of 0.5. At both 0.3 MPa and 0.4 MPa, the spray compactness of the eccentric nozzle was significantly lower than that of the fan-shaped nozzle 18.9% lower at 0.3 MPa and 12.5% lower at 0.4 MPa indicating the eccentric nozzle is more suitable for edge spraying.

- (2)

- Based on the width of the maize rows and plant height, a combination of two eccentric nozzles was selected. The configuration with 70 cm spacing yielded the lowest CV of 0.3, ensuring spray uniformity (investigated for spacing of 50, 70, and 90 cm). The influence of one eccentric nozzle on the flow rate to the left side of the adjacent nozzle was also analyzed, showing a difference of less than 1.5%, indicating that dual eccentric nozzles can achieve both edge compactness and uniform spray coverage.

- (3)

- For the soybean rows, a combination of eccentric and fan-shaped nozzles was selected. Among the three nozzle spacings (50 cm, 70 cm, and 90 cm), a spacing of 90 cm achieved the lowest CV of 0.33, ensuring uniform spray distribution. Additionally, the influence of the fan-shaped nozzle on the left-side flow of the eccentric nozzle was examined, with a flow rate difference within 1.5%, confirming that the combination ensures both internal uniformity and edge compactness within the soybean band.

This research highlights that in intercropping pesticide application, isolation should not rely solely on structural shields, which may have limited use under field conditions to reduce pesticide waste. Future studies should focus on the development of variable-rate spray actuators and investigate the influence of nozzle parameters on spray performance, providing theoretical support for variable pesticide application in different crops.

Author Contributions

W.Z.: investigation, methodology, data curation, formal analysis, writing—original draft, and writing—review and editing; W.Y. and Y.L.: investigation, writing—original draft, and data curation; X.D. and X.W.: supervision and project administration; W.J.: investigation, writing—original draft, conceptualization, supervision, funding acquisition, and project administration; G.W. and M.O.: investigation, writing-original draft, conceptualization, supervision, and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Plan of China (grant number: 2023YFD2000503) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (grant number: PAPD-2023-87).

Data Availability Statement

The data presented in this study are available within the article.

Acknowledgments

The authors thank the Faculty of Agricultural Equipment of Jiangsu University for its facilities and support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- MacLaren, C.; Waswa, W.; Aliyu, K.T.; Claessens, L.; Mead, A.; Schöb, C.; Vanlauwe, B.; Storkey, J. Predicting intercrop competition, facilitation, and productivity from simple functional traits. Field Crops Res. 2023, 297, 108926. [Google Scholar] [CrossRef]

- Antonelli, C.R.; Cabral, E.; Berejnoi, D.E.; Priotto, J.; Gomez, M.D. Plot and border effects on herbicide-resistant weed seed consumption by rodents in corn and soybean crops of central Argentina. Agric. Ecosyst. Environ. 2025, 378, 109320. [Google Scholar] [CrossRef]

- Egli, D.B. Yield improvement and yield components: A comparison of corn and soybean. Crop Sci. 2023, 63, 1019–1029. [Google Scholar] [CrossRef]

- Gannett, M.A.; Butler-Jones, A.L.; DiTommaso, A.; Sparks, J.P.; Kao-Kniffin, J. Soil C: N impacts on soil biological health and consequences on weed control in soybean and corn systems. Weed Sci. 2024, 72, 402–421. [Google Scholar] [CrossRef]

- Shang, Z. Design and Experimental Study on Small Electric Self-Propelled Striping Boom Sprayer. Master’s Thesis, HeNan Agricultural University, Zhengzhou, China, 2021. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, B. Shandong Vikes provides precision plant protection machinery for corn and soybean compound planting. Farm Mach. 2022, 32. [Google Scholar] [CrossRef]

- Chen, R.; Li, H.; Wang, J.; Chen, C. Effects of plate structure and nozzle diameter on hydraulic performance of fixed spray plate sprinklers at low working pressures. Trans. ASABE 2021, 64, 231–242. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, J.; Li, H.; Hua, L.; Yong, Y. Droplet distribution characteristics of impact sprinklers with circular and noncircular nozzles: Effect of nozzle aspect ratios and equivalent diameters. Biosyst. Eng. 2021, 212, 200–214. [Google Scholar] [CrossRef]

- Issaka, Z.; Li, H.; Jiang, Y.; Tang, P.; Chen, C.; Fordjour, A. Comparative evaluation on performance characteristics of an impact sprinkler with nozzle-dispersion devices and rotary plate sprinkler. Appl. Eng. Agric. 2020, 36, 321–329. [Google Scholar] [CrossRef]

- Wei, Z.; Zhu, H.; Zhang, Z.; Salcedo, R.; Duan, D. Droplet size spectrum, activation pressure, and flow rate discharged from PWM flat-fan nozzles. Trans. ASABE 2021, 64, 313–325. [Google Scholar] [CrossRef]

- Villermaux, E. Fragmentation. Annu. Rev. Fluid Mech. 2007, 39, 419–446. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, M.; Sun, W.; Chen, B. The Type Choice of Nozzle in Sprayer Design. J. Agric. Mech. Res. 2005, 151–153. [Google Scholar] [CrossRef]

- Qin, W.; Xue, X.; Cui, L.; Zhou, Q.; Xu, Z.; Chang, F. Optimization and test for spraying parameters of cotton defoliant sprayer. Int. J. Agric. Biol. Eng. 2016, 9, 63–72. [Google Scholar] [CrossRef]

- Griesang, F.; Spadoni, A.B.D.; Ferreira, P.H.U.; Ferreira, M.d.C. Effect of working pressure and spacing of nozzles on the quality of spraying distribution. Crop Prot. 2022, 151, 105818. [Google Scholar] [CrossRef]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. PDPA laser-based characterization of agricultural Spray nozzles. Agric. Eng. Int. CIGR Ejournal 2006, VIII. Available online: https://ecommons.cornell.edu/server/api/core/bitstreams/51495db3-214a-4c81-9a6d-b2e9d71c7cb6/content (accessed on 1 June 2024).

- Nuyttens, D.; De Schampheleire, M.; Verboven, P.; Brusselman, E.; Dekeyser, D. Droplet size and velocity characteristics of agricultural sprays. Trans. ASABE 2009, 52, 1471–1480. [Google Scholar] [CrossRef]

- Nuyttens, D.; De Schampheleire, M.; Baetens, K.; Brusselman, E.; Dekeyser, D.; Verboven, P. Drift from field crop sprayers using an integrated approach: Results of a five-year study. Trans. ASABE 2011, 54, 403–408. [Google Scholar] [CrossRef]

- Edwards, C.J.; Ripper, W.E. Droplet Size, Rates of Application and the Avoidance of Spray Drift. 1954. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/19551102521 (accessed on 1 June 2024).

- Mattivi, P.; Pappalardo, S.E.; Nikolić, N.; Mandolesi, L.; Persichetti, A.; De Marchi, M.; Masin, R. Can Commercial Low-Cost Drones and Open-Source GIS Technologies Be Suitable for Semi-Automatic Weed Mapping for Smart Farming? A Case Study in NE Italy. Remote Sens. 2021, 13, 1869. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Xue, X.; Liu, X.; Xu, Y.; Liu, X. Efficiency-first spraying mission arrangement optimization with multiple UAVs in heterogeneous farmland with varying pesticide requirements. Inf. Process. Agric. 2024, 11, 237–248. [Google Scholar] [CrossRef]

- Gong, C.; Li, D.; Kang, C.; Wang, Y. Visualisation of the evolution of perforations in oil-based emulsion sheets formed by flat-fan spray nozzles. Biosyst. Eng. 2021, 207, 68–80. [Google Scholar] [CrossRef]

- Cao, Y.; Xi, T.; Xu, L.; Qiu, W.; Guo, H.; Lv, X.; Li, C. Computational fluid dynamics simulation experimental verification and analysis of droplets deposition behaviour on vibrating pear leaves. Plant Methods 2022, 18, 80. [Google Scholar] [CrossRef]

- He, L.; Ding, L.; Li, B.; Mu, W.; Li, P.; Liu, F. Optimization strategy to inhibit droplets rebound on pathogen-modified hydrophobic surfaces. ACS Appl. Mater. Interfaces 2021, 13, 38018–38028. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Ding, L.; Zhang, P.; Li, B.; Mu, W.; Liu, F. Impact of the equilibrium relationship between deposition and wettability behavior on the high-efficiency utilization of pesticides. Pest Manag. Sci. 2021, 77, 2485–2493. [Google Scholar] [CrossRef]

- Huang, X.; Wang, W.; Li, Z.; Wang, Q.; Zhu, C.; Chen, L. Design method and experiment of machinery for combined application of seed, fertilizer and herbicide. Int. J. Agric. Biol. Eng. 2019, 12, 63–71. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, C.; Zhang, M.; Zhang, C.; Zou, W.; Zhao, C. Staggered-phase spray control: A method for eliminating the inhomogeneity of deposition in low-frequency pulse-width modulation (PWM) variable spray. Agriculture 2024, 14, 465. [Google Scholar] [CrossRef]

- Liu, J.; Abbas, I.; Noor, R.S. Development of deep learning-based variable Rate agrochemical spraying system for targeted weeds control in strawberry crop. Agronomy 2021, 11, 1480. [Google Scholar] [CrossRef]

- Dengeru, Y.; Ramasamy, K.; Allimuthu, S.; Balakrishnan, S.; Kumar, A.P.M.; Kannan, B.; Karuppasami, K.M. Study on spray deposition and drift characteristics of UAV agricultural sprayer for application of insecticide in redgram crop (Cajanus cajan L. Millsp.). Agronomy 2022, 12, 3196. [Google Scholar] [CrossRef]

- Gao, Z.-M.; Hu, W.; Dong, X.-Y.; Zhao, X.-Y.; Wang, S.; Chen, J.; Qiu, B.-J. Motion behavior of droplets on curved leaf surfaces driven by airflow. Front. Plant Sci. 2024, 15, 1450831. [Google Scholar] [CrossRef] [PubMed]

- Martin, D.E.; Perine, J.W.; Grant, S.; Abi-Akar, F.; Henry, J.L.; Latheef, M.A. Spray deposition and drift as influenced by wind speed and spray nozzles from a remotely piloted aerial application system. Drones 2025, 9, 66. [Google Scholar] [CrossRef]

- Wang, G.; Liu, M.; Ou, M.; Jia, W.; Jiang, L.; Li, Z.; Dong, X.; Huang, Y.; Zhang, T. Anti-drift performance of a hoods spray system for soybean (Glycine max (L.) Merr.)-maize (Zea mays L.) strip intercropping. Crop Prot. 2024, 181, 106689. [Google Scholar] [CrossRef]

- Wang, A.; Li, W.; Men, X.; Gao, B.; Xu, Y.; Wei, X. Vegetation detection based on spectral information and development of a low-cost vegetation sensor for selective spraying. Pest Manag. Sci. 2022, 78, 2467–2476. [Google Scholar] [CrossRef]

- Hua, L.; Jiang, Y.; Li, H.; Qin, L. Effects of different nozzle orifice shapes on water droplet characteristics for sprinkler irrigation. Horticulturae 2022, 8, 538. [Google Scholar] [CrossRef]

- Jiang, Y.; Issaka, Z.; Li, H.; Tang, P.; Chen, C. Range formula based on angle of dispersion and nozzle configuration from an impact sprinkler. Int. J. Agric. Biol. Eng. 2019, 12, 97–105. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).