Abstract

The fundamentals of the design and operation of self-priming pumps, as indispensable equipment in industry, have been the focus of research in the field of fluid mechanics. This paper begins with a comprehensive background on self-priming pumps and gas-liquid two-phase flow, and it outlines recent advances in the field. Self-priming pumps within the gas-liquid two-phase flow state and the spatial and temporal evolution of the transient characteristics of self-priming pumps determine the self-priming pump self-absorption performance. Through mastery of the self-absorption mechanism, high-performance self-absorption pump products can be formed to provide theoretical support for the development of products. In current research, numerical simulation has become an important tool for analyzing and predicting the behavior of gas-liquid two-phase flow in self-priming pumps. This paper reviews existing numerical models of gas-liquid two-phase flow and categorizes them. Reviewing these models not only provides us with a comprehensive understanding of the existing research but also offers possible directions for future research. The complexity of gas–liquid interactions and their impact on pump performance is analyzed. Through these detailed discussions, we are able to identify the challenges in the simulation process and summarize what has been achieved. In order to further improve the accuracy and reliability of simulations, this paper introduces the latest simulation techniques and research methodologies, which provide new perspectives for a deeper understanding of gas-liquid two-phase flow. In addition, this paper investigates a variety of factors which affect the operating efficiency of self-priming pumps, including the design parameters, fluid properties, and operating conditions. Comprehensive consideration of these factors is crucial for optimizing pump performance. Finally, this paper summarizes the current research results and identifies the main findings and deficiencies. Based on this, the need to improve the accuracy of numerical simulations and to study the design parameters in depth to improve pump performance is emphasized.

1. Introduction

As a kind of fluid machine, the self-suction pump has been widely used in the fields of energy, electricity, petroleum, national defense, and municipal administration, among others [1]. Currently, self-priming performance and vibration level have become important evaluation indicators for self-priming pumps. The self-suction process of the self-priming pump includes gas-liquid mixing, gas-liquid separation, and recirculation of the self-priming circulating fluid [2]. Gas-liquid two-phase flow is the central phenomenon of many industrial applications in chemical, petroleum, energy, and environmental protection. Whereas self-priming pumps play an important role in multiphase flow systems, the gas-liquid mixing process in self-priming pumps forms a complex two-phase flow structure. The internal flow dynamics, especially the shear layer between the liquid jet at the impeller discharge and the returning liquid in the return orifice, accelerates the formation and expansion of gas-liquid mixing and cavitation flow, which accelerates the dissolution and expulsion of the gas and radically affects the self-priming properties [3]. The internal flow characteristics of a self-priming pump are critical to its overall performance. The dynamics of the gas-liquid two-phase flow directly affects the pump’s suction capacity and operating efficiency. During the design and optimization of self-priming pumps, the complexity of two-phase flow must be fully considered, including the interaction at the gas–liquid interface, the generation and shedding of bubbles, and the resulting turbulence effects. In addition, the design of the internal structure of the self-priming pump, such as the geometry of the impeller, the layout of the inlet and outlet, and the design of the separator, need to be optimized according to the theoretical study of two-phase flow and experimental data. Numerical simulation techniques allow in-depth study of the flow dynamics inside a self-priming pump to predict and improve gas-liquid mixing and separation. In addition, experimental studies are essential. Observing actual flow conditions through visualization techniques can verify the accuracy of numerical simulations and provide intuitive feedback for design.

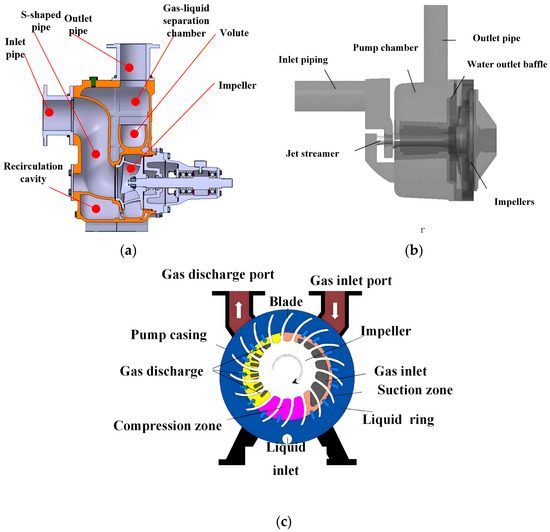

According to their working principle, self-priming pumps are mainly divided into three types: gas-liquid mixed type (internal mixing type and external mixing type), liquid ring type, and jet type. Figure 1 below shows three classic self-priming pumps. Gas-liquid mixed self-priming centrifugal pumps are the most widely used ones. After the pump is started, the water inside the pump is fully mixed with the gas inhaled from the inlet pipe under the rotation of the impeller, forming a gas-liquid mixture which is discharged into a gas-liquid separating compartment. The gas is discharged from the upper part of the gas-liquid separation chamber, while the liquid flows back to the volute through the reflux channel under the effect of gravity, which promotes gas-liquid remixing until there is no gas in the pump, thus completing the self-priming process and making the pump operate normally. The gas-liquid mixture and separation process in the self-priming pump is crucial to ensuring its operational efficiency. In this review, we have chosen to focus on two-phase gas-liquid flow in self-priming pumps because pumps, as the core equipment for transporting fluids, have a direct impact on the performance of the entire industrial system in terms of efficiency and reliability. Especially in self-suction pumps, the complexity of gas-liquid two-phase flow has a decisive impact on the pump’s self-suction performance and operational efficiency. Therefore, this review aims to demonstrate the applicability and variability of multiphase flow models, as well as their potential applications in pump design and optimization of pump properties, through an in-depth analysis of gas-liquid two-phase flow in self-priming pumps, which follows a review of the literature.

Figure 1.

Three types of self-priming pumps: (a) gas-liquid mixing self-priming pump [4]; (b) jet self-priming pump [5]; and (c) liquid ring self-priming pump [6].

2. Numerical Model of Gas-Liquid Two-Phase Flow and Its Application in Pumps

Gas-liquid two-phase flow in a pump can be divided into two typical states: cavitation and gas-liquid mixed transport. Cavitation occurs when a liquid passes through a low-pressure region and rapidly changes to a gaseous state, forming bubbles, and these bubbles rapidly rupture in the high-pressure region. This process may not only increase the noise and vibration of the pump but also reduce the performance of the pump and even cause damage to the pump vane and other components. In the gas-liquid mixing and transportation process, the gas forms bubbles or elastic flows in the pump, and periodic changes in these flow patterns can lead to instability of the flow in the pump, which can cause dramatic fluctuations in the pump flow, head, and efficiency [7,8]. For numerical simulation of gas-liquid two-phase flow, the traditional single-phase flow calculation method is no longer applicable due to the complex fluid interactions, interface dynamics, and material exchange involved. Therefore, constructing accurate gas-liquid two-phase flow models is the key to achieving accurate simulation of the flow characteristics in pumps, which helps to deeply understand the dynamic behavior of gas-liquid mixing and their mixing mechanism. Through these models, the performance of the pump can be predicted and controlled more effectively, and then the design and operation of the pump can be optimized to improve its stability and efficiency [9,10,11,12].

2.1. Numerical Model for Simulating Gas-Liquid Two-Phase Flow

From the point of view of the composition of the fluid medium in fluid mechanics, the flow state can be divided into single-phase flow and multiphase flow. Single-phase flow refers to the fluid only being in a liquid or gas phase, where the fluid parameters (density, viscosity, flow velocity) are relatively clear and distinct and the flow follows the conservation of mechanical energy. This can be based on the Navier–Stokes equations to set up a simplified turbulence model for the solution, where the numerical simulation results are stable and highly accurate. Multiphase flow refers to the simultaneous existence of two or more than two kinds of material mixture flow, where fluid flow characteristics are complex, variable, and affected by a variety of factors, such as the phase content or interphase forces. In addition, there will be further complex interphase interactions, such as mass transfer, heat transfer, or phase transition. This paper focuses on the flow characteristics of gas-liquid two-phase flow in a self-priming pump, and thus it mainly focuses on the numerical simulation model of gas-liquid two-phase flow for further introduction.

The morphology of the gas phase in gas-liquid two-phase flow will change significantly with an increase in the gas phase content. With a low gas phase content, the gas is distributed in the form of small discrete bubbles in a continuous liquid phase, where the bubbles are independent of each other and the liquid phase flow has a small impact. With an increase in the gas phase content, the bubbles begin to merge to form larger bubble clusters or gas clusters. At this time, the continuity of the liquid phase is affected to some extent but still maintains a continuous flow. A further increase in the gas phase content will make the gas phase a continuous phase, and in extreme cases, the liquid phase is dispersed into tiny droplets and entrapped in the gas phase movement. In order to accurately simulate the actual operating conditions of fluid machinery under different gas-liquid two-phase flow regimes or accurately capture the interface between the gas-liquid two-phase motion, three main numerical simulation models, namely the mixture model, Euler–Euler model, and VOF model, are proposed based on the different volumes, behaviors, and continuity of bubbles under different gas phase contents. Their advantages and disadvantages are shown in Table 1, and the main difficulty lies in capturing the gas-liquid two-phase interface.

Table 1.

Advantages and disadvantages of common gas-liquid two-phase flow models.

Among these models, is the time, ρ is the density of the fluid, is the velocity of the fluid phase, μ is the coefficient of dynamic viscosity of the fluid, g is the acceleration of gravity, F is the volume force, is the drift velocity, is the apparent density of the phase particles, is the volume fraction of the kth phase, is the Magnus force on the kth particle, represents the elative coordinates in the x and y directions, respectively, is the velocity of the particle phase, is the effective kinetic viscosity coefficient of the fluid, S is the source term, and τ is the bubble transient acceleration time.

The mixture model is a numerical model commonly used to describe gas-liquid two-phase flow which is built on the assumption of macroscopic mixing of the two phases (i.e., the two fluids share the same flow region and speed field). The model simplifies the calculations mainly by defining the properties of the mixture, such as the density and viscosity. By using relatively simple physical relationships, the mixture model can effectively simulate the interaction and mass transfer between different phases. This model is suitable for simulating the case of two-phase flow with a uniform distribution, such as the flow of gas-liquid mixtures in pipelines. Due to its simplified treatment of interphase interfaces, the mixture model is more computationally efficient than the multifluid model and is particularly suitable for rapid prediction and analysis in engineering applications. However, due to its rough treatment of the interphase interfaces and local interphase interactions, it may have some limitations in complex flow problems, where the behavior of the interphase interfaces needs to be accurately described. A study by El-Batsh et al. [13] focused on the application of a hybrid model, which they utilized to predict and analyze the corrosion problem in specific regions of a pipeline. Through their study, they found that the hybrid model was not only able to accurately predict the two-phase flow characteristics within the pipeline but also able to determine the location in the pipeline where corrosion occurred in a relatively short period of time. This finding demonstrates the effectiveness of the hybrid model in predicting pipeline corrosion and provides an efficient analytical tool for pipeline maintenance and safe operation. Liu et al. [14], among others, used the mixture multiphase flow model combined with the Simple-C algorithm in the self-priming process of a pump’s gas-liquid two-phase distribution in an in-depth study. The study revealed, to a certain extent, the changing law of a flow field inside an internal mixed self-priming pump in the self-priming process, providing valuable reference information for self-priming pump design. In addition, the study further explored the effects of the return valve, gas-liquid separation chamber, and liquid storage chamber on the pump efficiency. The findings show that the return valve has the greatest influence on the pump efficiency, while the gas-liquid separation chamber and the liquid storage chamber have relatively small influences. These findings are important for optimizing the performance and increasing the efficiency of self-priming pumps.

With the development of numerical simulation technology and the increasing demand for engineering and scientific computation, the mixture model is not good at calculating complex two-phase flow simulations, and thus the Euler–Euler model became the public’s choice. The Euler–Euler approach treats each phase of fluid as a continuous medium which can penetrate each other by introducing the concept of volume fraction. Each phase of the fluid has its own independent physical properties, such as pressure, temperature, and velocity fields, allowing them to overlap and interact with each other in the computational domain. The advantage of this approach is that it is able to significantly reduce the computational cost compared with the Euler–Lagrange method while maintaining a certain level of accuracy. Due to its computational efficiency and applicability, the Euler–Euler method has been widely used in the field of multiphase flows. Shi et al. [15] used the Euler–Euler model to numerically internalize the motion of bubbles in a mixing tank. They extended the turbulence and drag model to improve the simulation accuracy of individual bubble phenomena by utilizing the closure relations verified in pipe and bubble column flows. The results show that the improved model can accurately predict the distribution and flow characteristics of bubbles in a stirred tank. In the digital simulation of gas-liquid two-phase flow in self-priming pumps, the liquid phase is usually portrayed using the Euler method, while the gas phase, as a dispersed phase, can be simulated with the Euler or Lagrangian method.

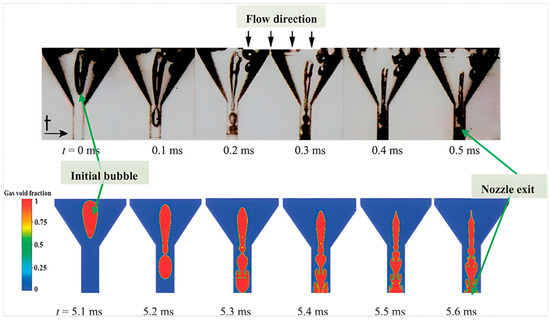

The mixture model is crude in its treatment of interphase interfaces and local interphase interactions, and the Euler–Euler model is deficient in capturing the shape and evolution of the interphase interfaces. Thus, to effectively characterize the interphase interfaces of multiphase flows, Hirt and Nichols [16] proposed the VOF model in 1985, which utilizes interfacial reconstruction techniques and convective algorithms for tracing the free interfaces of multiphase flows. It is well known for its ability to accurately capture free surfaces and handle complex topological changes. The method is based on the continuity equation of the volume fraction and tracks the volume fraction of each phase. For numerical implementation, the VOF method needs to be combined with an appropriate interpolation scheme to compute the volume fractions at the mesh interfaces and employ, for example, geometric reconstruction or higher-order reconstruction techniques to specify the positions of the interfaces. The advantage of this approach is that it is able to handle complex geometrical changes, including interface breaks and mergers. However, the VOF method may encounter challenges in numerical stability and interface trapping when dealing with high-speed flows or flows with large density ratios. Based on this, researchers have developed models such as FLAIR [17] and CICSAM [18]. These models can capture the interphase interface, but interface reconstruction is complicated, and the discontinuity of volume fractions in neighboring grid cells makes the interface easy to break. In the area of numerical simulation of two-phase flow associated with a high gas phase content and bubbly flow, Sengia et al. [19] investigated the influence of the cylinder size on gas-liquid mixing efficiency in an oscillating cylinder. They utilized the VOF method to capture the gas–liquid interface in determining the mixing time. Zhao et al. [20] also numerically simulated the gas-liquid two-phase flow in a Pierce–Smith converter using the VOF model and Fluent software. They used the Press implicit split operator algorithm for better convergence during the solution process. They found that increasing the gas flow rate promotes circulation but significantly increases the wall shear stress, and the numerical simulation results were in high accord with the experimental data. Sun et al. [21] used numerical simulation to study the gas-liquid two-phase flow characteristics at a bubble spray outlet. In their study, they used commercial software and the VOF model and compared their findings with the experimental results. The results show that the numerical simulation results were in good agreement with the results of the experiments and could reflect the change rule of a two-phase flow pattern over time. In the process of flow pattern change, turbulence and bubble face tension in the flow field are the main reasons for a change in bubble morphology. When there is a large pressure gradient in the flow field, the bubble may be stretched and broken in two. The experimental and simulation results were highly similar, as shown in Figure 2.

Figure 2.

Comparison of experimental and numerical simulations.

Bubbles are the main form of the gas phase in the gas-liquid two-phase mixing and transport process, and the capture of bubbles involves the key forces shown in Table 2.

Table 2.

Information on the forces acting on bubbles.

In summary, while there has been some advancement in constructing and numerically simulating multiphase flow models, research on numerical simulations of gas-liquid two-phase flow in self-priming pumps remains at an early stage.

2.2. Numerical Simulation of Gas-Liquid Two-Phase Flow in a Pump

Numerical simulation of centrifugal pumps can be divided into steady state numerical simulation and transient numerical simulation, mainly to capture the external performance characteristics of centrifugal pumps under different operating conditions or the internal pressure fluctuation situation during the operation of centrifugal pumps. In the numerical simulation process, the rotating impeller fluid domain and the stationary volute fluid domain are separated for modeling, and the impeller fluid domain is set as a rotating domain based on the multi-rotating coordinate system method. The data transfer problem between the rotating and stationary fluid domains is handled using the frozen rotor method (steady state simulation) or the sliding mesh method (transient simulation) [22]. Numerical simulation methods for gas-liquid two-phase flow are extensively employed in pump research [23,24]. Currently, extensive research has been conducted by numerous scholars on this topic.

Frurya [25] proposed a one-dimensional, incompressible two-fluid model based on the pump impeller geometry, gas content, and two-phase velocity slip. Minemura et al. [26], building upon Frurya’s model, additionally incorporated considerations for fluid viscosity and gas phase compressibility. They addressed the deflection of the flow angle at the impeller outlet, the sudden expansion of the flow channel section, and the effects of uniform two-phase mixing. Their calculations focused on a low specific speed radial-flow two-phase pump, yielding results which closely correlated with the experimental data. This progress has significantly advanced the development of one-dimensional calculation methods for centrifugal pumps. Lee et al. [27] also conducted a comprehensive experimental study on the gas-liquid two-phase flow performance of the nuclear main pump under high-pressure conditions. They obtained experimental data correlating the local gas volume fraction with the mass flow rate at the pump suction inlet, thereby providing valuable insights. The inlet temperature and initial conditions were the main factors affecting the performance of the nuclear main pump. Poullikkas [28], based on considering the additional losses caused by the standard two-phase lift of the pump and the gas phase pressure, related the pump geometry, phase separation, density changes, and condensation and compressibility of the gas phase and proposed a method based on an improved model of the two-phase flow head calculation method for nuclear main pump water loss accidents with the dimensional control volume, and a nuclear main pump two-phase flow performance calculation model was developed. Poullikkas [29] used high-speed video monitoring technology to detect water loss. The internal flow of the main pump under accident conditions was studied, and the flow process of bubbles entering the impeller channel in the water loss accident was determined. The gas phase distribution rules under small, medium, and high flow rates were given, which promoted the development of mathematical models based on the control volume method of rotating machinery.

The aforementioned studies on vapor-liquid two-phase flow in a nuclear main pump exclusively employed experimental methods to investigate this phenomenon. As such, they provided only a macroscopic perspective of the gas content within a nuclear main pump during water loss accidents. Regarding the influence of external characteristics, no theoretical analysis or numerical simulation has been conducted to give reasons for the differences in these external characteristics, nor has the internal law of the two-phase flow inside a nuclear main pump been analyzed microscopically. Hazra et al. [30] used a Reynolds time-averaged equation and mixing length model to simulate the continuous phase and the Lagrangian method to simulate the dispersed phase, and they studied the sparse two-phase flow in a pump. They found that during pump operation, air bubbles and solid particles were carried out from the pump chamber, especially larger solid particles, which tended to collect in the low-pressure area near the pump casing or the shaft. Caridad et al. [31] employed numerical simulation technology to analyze the stress experienced by bubbles within the centrifugal pump impeller. It was found that larger bubbles took up more space in the impeller, interfering with the normal flow of the liquid and thus reducing the efficiency of the pump. Gao et al. [32] formulated a transient flow mathematical model to simulate the idle rotation of a nuclear main pump. They systematically analyzed various operational scenarios, including a constant speed and flow rate as well as zero speed and flow rate conditions. It was shown that when the pump was operated at extremely low flow rates close to the stopping condition, a large gap appeared between the actual measured pump performance (experimental values) and the theoretically calculated pump performance (calculated values). Barrios et al. [33] developed a model based on the size of a stagnant bubble and the bubble resistance coefficient, pointed out the bubble size measurement method and influencing factors, proposed that the resistance coefficient varies with the rotation speed and Reynolds number, and gave a detailed analysis of a submersible electric pump’s numerically simulated gas-liquid two-phase flow. Lu et al. [34] utilized the Euler model to analyze the three-dimensional viscous flow of vapor-liquid two-phase flow within the impeller of a centrifugal pump. They noted that the gas concentration near the impeller disc in the flow channel was low, the suction force on the side of the wheel cover and the pressure near the surface were low, and the pressure gradient changed directions. The bubbles in this area are easy to condense, resulting in a higher gas content. Yu et al. [35] assumed the existence of bubble flow inside a hybrid pump impeller. The two-phase three-dimensional turbulent field inside the pump impeller was numerically calculated, and the distribution characteristics of the flow field under the water-air mixing condition were analyzed. Xie et al. [36] conducted tests to study the impact of liquid mixture transport on cavitation performance. They used the clean water cavitation test as a benchmark to analyze how changes in two key factors (gas content and total gas-liquid mixing flow velocity at the test operating point) affect cavitation performance. It was found that the pump’s ability to resist cavitation when handling liquids containing air decreases as the air content increases. Pumps work best with air-liquid mixing when they are operated at a standard flow rate of 5 cubic meters per hour and the air content is kept below 0.42 cubic meters per hour. Ma et al. [37] numerically simulated the flow field of a vane-type gas-liquid mixed pump with varying numbers of guide vane blades and different gas contents. They obtained the pressure field and velocity distribution of the pump impeller and guide vanes under different operating conditions. The gas content rate and relative head curved under the condition. Studies have shown that when there are more air bubbles in a pump, the pump works less efficiently and has less of an ability to lift liquids. It was found that the pump’s best overall efficiency was achieved when the number of guide vane blades was 13.

3. Research on Gas-Liquid Numerical Simulation Method of Self-Priming Process

Unlike typical numerical simulations of two-phase flow in centrifugal pumps, simulating a self-priming pump involves an extremely complex two-phase flow situation. This simulation encompasses free surfaces, a high gas phase content, and strong rotational flow fields interacting with one another. This process not only requires accurate treatment of the changing dynamics of the gas-liquid Interface but must also take into account the effects of phenomena such as bubble generation, merging, and collapse. In addition, self-priming pumps have obvious unsteady characteristics during the start-up phase. Numerical simulation of the self-priming process is concerned with the internal gas-liquid two-phase spatial and temporal change law, and the transient numerical simulation method must be used. General self-priming process research directly sets the impeller speed for stable operation of the rotational speed, with a lack of starting the impeller speed at 0 and increasing to the stable speed of the transition process of consideration so that gas is discharged at a high speed in the numerical simulation of the start of the instantaneous pump. This results significant error in the self-priming process of the exhaust velocity simulation, and therefore the self-priming time of judgment for the self-priming pump simulation is far less than that of the experimental situation.

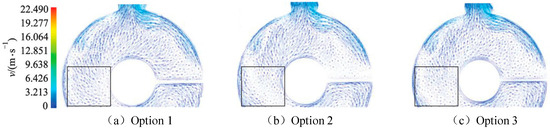

Huang et al. [38] investigated the behavior of gas-liquid two-phase flow transients in a self-priming centrifugal pump after initiation, where the intake pipe was filled with air at start-up. Calculations showed that the gas-liquid two-phase stream in the self-absorbing pump varied over time, and the amount of gas suctioned and discharged by the pump was mainly concentrated in the early stage of start-up. The pressure inside the pump was low when the impeller was suctioned. After entering the stable stage, the pressure inside the pump increased. Yu [39] and Liu [40] investigated the gas-liquid two-phase interaction forces for gas cylinder flow in multiphase flow pumps. A large number of analytical studies examined the resistance, lift, virtual mass force, and tropical dispersion force in the interphase forces of vapor-liquid two-phase flow. The results show that the turbulent dispersion force in the gas-liquid two-phase flow was almost negligible. Drag was the main factor affecting the state of gas-liquid two-phase flow in the impeller, outer edge, and pump outlet sections of the pump. Zhu et al. [41,42,43] investigated changes in flow regimes and bubble dynamics models for gas-liquid two-phase flow in an electric pump. Through a comparison of numerical simulation results between the Euler–Euler two-phase flow model and the VOF model, they concluded that the Euler–Euler multiphase flow model better suits the numerical simulation of flow patterns and bubble motion in centrifugal pumps. Yan [44] utilized the Euler–Euler non-uniform two-phase flow model, while Chen [45] employed the discrete particle population balance model (PBM). They conducted studies on multi-stage gas-liquid mixed pumps and submersible electric pumps, respectively. The bubble distribution within the pumps was studied. Lu et al. [46] investigated the same type of self-priming pump using a Euler multiphase flow model, examining the impeller inlet, all parts of the vortex casing, the inlet of the gas-liquid separation room, and the return port. The results showed that the intermediate stage of self-priming of the self-priming pump accounted for the largest proportion in the whole self-suction process, and the duration of self-priming in the numerical simulations showed a certain delay compared with the experimental results. Zhu et al. [5] studied the influence of adding a baffle to the guide vane on the self-priming performance of a jet self-priming pump. Euler–Euler multiphase flow models were used for digital simulation, and the simulation results were compared with the experimental outcomes. The findings indicate that the baffle plate significantly affected the performance of the self-priming pump, and the presence of the baffle plate effectively prevented gas-liquid two-phase circulating flow in the pump chamber, reduced the residence time of the gas in the pump chamber, and facilitated the discharge of the gas to the pump outlet. The baffle plate exists in the optimal position so that the gas-liquid separation inside the pump is most efficient, as shown in Figure 3.

Figure 3.

Velocity vectors of gas phase in pump chamber [5].

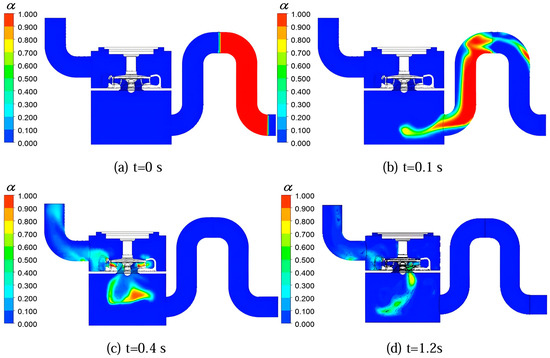

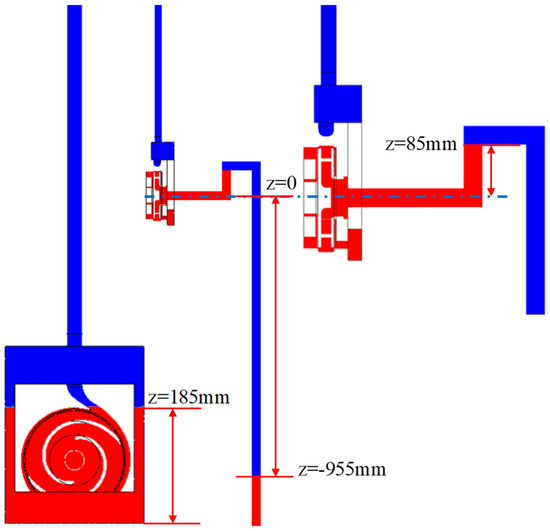

Wang et al. [47,48,49] analyzed the self-priming process of a multistage self-priming sprinkler pump via numerical simulation and compared the results with experimental data. During the numerical simulation, weakly constrained boundary conditions (pressure inlet and free outflow) were used for the first time to capture the rising law of the liquid level in the pump during each stage of the self-priming process. The results show that the self-priming process of the pump could be divided into three stages, among which the middle stage took the longest time and had the greatest influence on the overall self-priming time. The study also compared the rising law of the liquid level in the outlet pipe with the numerical simulation results, and the accuracy of the numerical simulation technique was confirmed by the error being no more than 6%. Su et al. [50] carried out a dynamic numerical simulation of gas-liquid two-phase flow inside a pump and investigated the distribution law of the gas content, pressure, and flow rate as well as the flow characteristics of the self-priming pump. Their results show that the gas phase tends to concentrate at the suction surface of the vanes of the impeller. In Figure 4, α = 1 means gas, and α = 0 means liquid.

Figure 4.

Gas-liquid two-phase distribution in the center section of a pump [50].

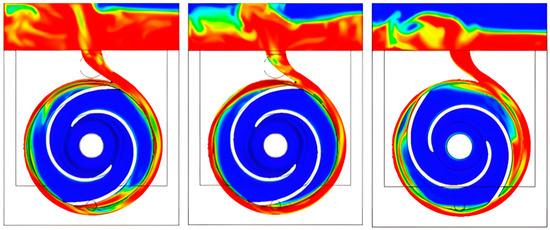

Liu et al. [14,51] numerically simulated the gas-liquid two-phase flow during the self-absorption process of an internally-mixed self-absorbing pump using a multiphase flow model. They discussed the motion of the gas-liquid two-phase medium inside the pump by analyzing the pressure and speed distributions in the flow field and the distribution of the gas phase under different gas content conditions. To some extent, they revealed the internal flow dynamics in the self-priming process of an internal mixing self-priming pump. Qian [52] numerically simulated the transient self-priming process of a centrifugal pump and compared it with experimental measurements using a Euler–Euler two-fluid model with flexible boundary conditions implemented to take into account the change in the pump impeller’s speed during start-up of a self-priming pump, in combination with the motor rotational speed and the actual operating boundary conditions of the self-priming pump. The results show that the errors between the numerical simulation results and the experimental results for the external performance parameters of the pump ranged from 1% to 3.5%, indicating that the inlet pipe, outlet pipe, and water rise mode of the pump were consistent. During the self-priming process of a self-priming pump, the complexity of the gas-liquid two-phase flow, the asymmetric reflux caused by the lateral flow velocity of the fluid, and the bubble mass entering the diffusion section or impeller cavity due to the tongue shunt effect all contribute to the formation of the pump cycle. These flow characteristics directly affect the pump’s self-priming efficiency and stability, though visualization of the gas-liquid two-phase cloud diagram can lead to a clearer understanding of this process (see Figure 5 and Figure 6 below).

Figure 5.

Initialization of self-priming pump fluid domain [52].

Figure 6.

Gas-liquid two-phase flow in different self-priming stages [52].

While previous researchers have extensively explored the mixing and distribution of gas-liquid two-phase flow in centrifugal pumps during the self-priming process, they have not successfully quantified the gas-liquid mixing process numerically. Current simulation methods fail to capture the dynamic changes in the gas–liquid interface or the flow state of the mixed fluid within the pump. Although existing numerical simulations partly reveal the pattern of liquid level rising during self-priming, there remains a significant gap between the experimental and numerical results in predicting the self-priming time. The authors suggest that future efforts should focus on refining numerical simulation methods for self-priming processes, capturing evolving flow patterns of the two-phase flow in a pump, revealing internal flow field distributions during self-priming, and improving the accuracy of predictions of the self-priming time.

4. Research on Factors Affecting the Performance of Self-Priming Pumps

The examination of how structural parameters affect the operational effectiveness of centrifugal pumps with self-priming capabilities remains a persistent field of study. Globally, numerous studies have focused on the diverse configurations and structures of self-priming pump models. Pioneering researchers predominantly utilized experimental approaches to assess how the structural parameters of self-priming pumps affect their performance. Shepard et al. [53] repeatedly distilled the pivotal parameters and principal challenges associated with self-priming pump designs.

Since the dawn of the 21st century, advancements in computational fluid dynamics (CFD) technology and numerical simulation techniques have paved the way for in-depth studies on how structural parameters influence the performance of self-priming pumps. CFD provides a comprehensive model of the fluid motion and force changes within a pump, thereby creating a basis for in-depth micro-scale examination of such equipment. A review of the literature indicates that micro-scale simulation research on self-priming pumps commenced in 1991, when Li et al. [54] presented a numerical simulation for examining bubble dynamics within a self-priming pump which incorporates external mixing. Their study postulated four fundamental assumptions and, based on these, concluded that the bubble diameter influences the motion trajectory, and an increased impeller rotation speed correlates with a faster gas-liquid separation rate.

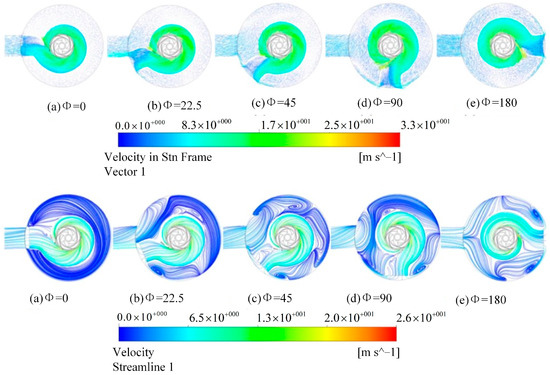

Sun et al. [55,56] carried out a computational analysis to study the fluid dynamics within the axial guide vane system of a self-priming pump. By analyzing the flow and velocity distributions in Figure 7, it was found that the hydraulic performance and efficiency of the pump may be adversely affected when the Φ value is high due to the vortex and the impact effect of the fluids. This gives us a better understanding of the specific effects of different mounting angles on the pump performance and optimizes the pump design accordingly to achieve higher efficiency and better hydraulic performance. This is an important guide for the design improvement and performance enhancement of self-priming pumps.

Figure 7.

Streamline and velocity distribution diagram [55,56].

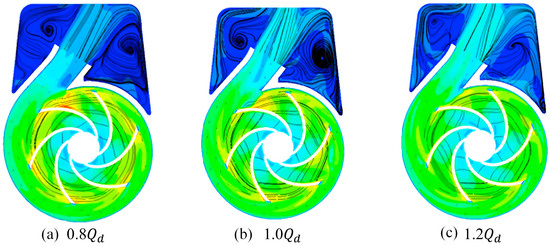

Li et al. [57] explored the effects of baffle plates on the efficiency of self-venting irrigation pumps when subjected to dual-phase gas-liquid flow scenarios. They found that the introduction of partition plates effectively diminished the internal circulation velocity within the pump compartment and reduces the gas concentration ratio at the jet nozzle, which in turn enhanced the self-priming capability. Following the implementation of partition plates, the self-priming height for the original model increased significantly from 4.5 m to 8.2 m. In another study, Liu et al. [58] analyzed the behavior of pressure fluctuations within the flow field of vortex self-priming pumps and observed the alterations in the noise patterns in vortex pumps featuring non-uniformly arranged blades during conditions of reduced flow rates. Wang et al. [59,60] examined the distribution of dual-phase gas-liquid flow in pumps designed for multistage self-priming. As shown in Figure 8, the existence of a worm shell tongue leads to uneven velocity distribution in the impeller channel, and the velocity is higher in the area near the worm shell tongue. At the same time, the structural characteristics of the gas-liquid separation chamber lead to a vortex being generated when the liquid hits the wall, and these factors work together to become one of the reasons for the low efficiency of self-priming pumps.

Figure 8.

Absolute velocity distribution inside the volute and gas-liquid separation chamber under different flow rate conditions [59,60].

Chang et al. [61,62] carried out a study on energy loss in an innovative self-priming pump by applying the theory of entropy fields. Their research revealed that the internal turbulence and viscous resistance within the fluid are the predominant sources of energy loss. Furthermore, they examined the energy loss across various blade thickness distribution patterns and identified an optimal blade thickness configuration. Mou et al. [63,64,65] employed numerical simulation techniques to investigate the transient flow properties within self-priming pumps, with a particular focus on scenarios involving the transport of solid particles.

Wu et al. [66] aimed to evaluate how the shape of the blades affects the efficiency of self-priming pumps. In a separate investigation, Zhou et al. [67] examined the short-term behavior of flows at the reflow orifice. Chang et al. [68] developed an innovative self-priming mechanism by altering the shape of the impeller’s entry and the pump’s discharge, which significantly improved the pump’s self-priming performance. Additionally, Zhang et al. [69] analyzed the fluctuating hydraulic efficiency of a pump during initial operation in a range of rotational velocities.

In recent years, to thoroughly explore the mechanisms of gas-liquid two-phase flow within pumps, many scholars have focused on the lifecycle and dynamic characteristics of cavitation bubbles at the microscopic level, encompassing their formation, growth, and explosive collapse. This research has provided new insights into and contributions to the understanding of pump cavitation and bubble dynamics [70,71,72,73,74,75,76]. Notably, most numerical simulation studies cited in this paper are complemented by experimental validation, highlighting the foundational and enduring importance of experimental methods in self-priming pump research. The combination of microscopic-level investigation, numerical simulation, and experimental validation has collectively advanced the progress and development of this research field.

Previous investigations have delved into the multitude of factors influencing the operational efficiency of self-priming pumps, identifying the most critical among them and establishing a hierarchy of significance for each. Theoretical analyses, numerical simulations, and experimental approaches have been employed to elucidate the micro-level mechanisms through which structural parameters impact pump performance, correlating variations in these parameters with the observed performance trends. Despite this, a complete grasp of the fundamental concepts which dictate how particular design aspects, like the dimensions and location of the reflow opening, affect the efficiency of self-priming remains out of reach. The impact of these design details on a pump’s ability to prime itself has yet to be clearly understood. Furthermore, experimental data have not yet yielded a straightforward and easily understood representation of a pump’s internal dual-phase flow dynamics. As a result, further in-depth research is necessary to thoroughly understand how structural attributes impact the flow patterns and functional properties of self-priming pumps.

5. Conclusions and Prospects

5.1. Conclusions

This paper reviewed the research progress of gas-liquid two-phase flow numerical simulation for self-priming pumps and analyzed in depth the working principle of self-priming pumps, the numerical model of gas-liquid two-phase flow, the simulation method of the self-priming process, as well as the key factors affecting the self-priming pump properties, finding the following:

(1). As for the importance and working principle of self-priming pumps, self-priming pumps are widely used in many industrial fields because of their self-priming performance. The self-priming procedure includes key aspects such as gas-liquid mixing, separation, and recirculation, which have a decisive impact on the function of the pump.

(2). Regarding numerical modeling of gas-liquid two-phase flow, this article provides an overview of the current state of the art in the numerical modeling of gas-liquid two-phase flow in self-priming pumps, with special emphasis on the importance of multiphase flow modeling in the simulation process. The development of numerical simulation techniques has enabled researchers to analyze in detail the flow properties inside a self-priming pump at the microscopic level, including the gas-liquid mixing, separation, and recirculation processes.

For example, the Euler–Euler model has been widely used due to its advantages in dealing with interphase interactions and dynamic changes at the phase interface. In addition, this paper discussed the application of phase transition models, VOF models, level set methods, and coupled methods in gas-liquid two-phase flow simulation, which have unique advantages in capturing free surfaces, dealing with complex topological changes, and simulating interphase mass transfer and thermodynamic nonequilibrium phenomena.

(3). Concerning the complexity of simulating the self-absorption process, the self-absorption process of a self-priming pump is one of its core functions, involving the pump mixing gas and liquid during the initial start-up phase and the gradual removal of gas and water in order to achieve normal delivery. This paper reviewed numerical simulation studies of the self-priming process of self-priming pumps, emphasizing the complexity and challenge of simulating this process. For example, self-priming pumps have significant non-stationary characteristics during the start-up phase, requiring a numerical model which accurately describes the transient process.

(4). For research on the factors influencing the properties of self-priming pumps, this review examined the current status and progress of research on the factors influencing the properties of self-priming pumps, revealing the far-reaching effects which the internal structural design, operating conditions, and other factors have on the properties of self-priming pumps. Through numerical simulations, researchers are able to analyze the gas-liquid two-phase flow inside a self-priming pump at the microscopic level, thus gaining insight into how these factors jointly affect the self-suction pump’s performance. The close integration of digital simulation and experimentation not only deepens the understanding of the flow phenomena inside the self-priming pump but also provides powerful data support and intuitive feedback for optimization of the design.

5.2. Outlook

Although existing numerical simulation methods have achieved certain success, further improvements are still needed to improve the accuracy and reliability of simulations, especially in predicting the self-priming time. Future research will likely combine more advanced computing technology and artificial intelligence algorithms to achieve more accurate simulation and analysis of the internal flow of self-priming pumps. At the same time, studies on the factors influencing the performance of self-priming pumps have highlighted the significant impact of structural parameters on a pump’s behavior. Structural characteristics, including the design of the return hole, the shape of the impeller, and the installation angle of the guide vanes, have been shown to directly affect self-priming performance. Through a combination of experiments and numerical simulations, researchers can more accurately evaluate the effects of these parameters on a pump’s performance and propose optimized design solutions accordingly. However, current research has not fully revealed the mechanism of all influencing factors, the understanding of the changing laws of the complex internal flow field in particular needing to be deepened. Future research will continue to explore the optimal configuration of structural parameters while combining visualization techniques and numerical simulation methods to achieve the goal of improving the performance and efficiency of self-priming pumps. In summary, the study of gas-liquid two-phase flow in self-priming pumps is a multidisciplinary field involving fluid mechanics, thermodynamics, materials science, mechanical engineering, and other disciplines. Along with calculation technology and experimental technology development, the understanding of the gas-liquid two-phase flow inside a self-priming pump will be more in depth so as to promote the progress and application of self-priming pump technology.

Author Contributions

Conceptualization and theoretical foundation, C.X. and H.Q.; methodology and research, H.Z. and H.Q.; writing—manuscript preparation, H.Z. and H.Q.; writing—review and editing, Z.D.; professional supervision and guidance, C.X., S.Z. and P.Z.; project administration and funding acquisition, C.X. and H.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key R&D Program of Zhejiang (grant number 2022C02035); Key Science and Technology Program of Ministry of Water Resources of the PRC (grant number SKS-2022053); and Zhejiang Provincial Natural Science Foundation (grant numbers LTGG24E060001 and LGG22F030024).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, W.; Yang, S.; Wu, D.; Mou, J. Effect of particle mass concentration on erosion characteristics of self-priming pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6782–6797. [Google Scholar] [CrossRef]

- Qian, H.; Mou, J.; Wu, D.; Ren, Y.; Zheng, S.; Zhu, Z. Experimental investigation on the gas-liquid flow patterns in a centrifugal pump during self-priming process. AIP Adv. 2020, 10, 010101. [Google Scholar] [CrossRef]

- Xiao, L.; Long, X. Cavitating flow in annular jet pumps. Int. J. Multiph. Flow 2015, 71, 116–132. [Google Scholar] [CrossRef]

- Qian, H.; Wu, D.; Xiang, C.; Jiang, J.; Zhu, Z.; Zhou, P.; Mou, J. A Visualized Experimental Study on the Influence of Reflux Hole on the Double Blades Self-Priming Pump Performance. Energies 2022, 15, 4617. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, Y.; Wang, Q.; Tang, H.; Yu, H. Influence of outlet baffle on the self-priming performance of a jet self-priming pump. J. Drain. Mach. Eng. 2020, 38, 469–475. (In Chinese) [Google Scholar]

- Zhang, Y.; Zhou, F.; Li, J.; Kang, J.; Zhang, Q. Application and research of new energy-efficiency technology for liquid ring vacuum pump based on turbulent drag reduction theory. Vacuum 2020, 172, 109076. [Google Scholar] [CrossRef]

- Verde, W.M.; Biazussi, J.L.; Sassim, N.A.; Bannwart, A.C. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers. Exp. Therm. Fluid Sci. 2017, 85, 37–51. [Google Scholar] [CrossRef]

- Mansour, M.; Wunderlich, B.; Thévenin, D. Effect of tip clearance gap and inducer on the transport of two-phase air-water flows by centrifugal pumps. Exp. Therm. Fluid Sci. 2018, 99, 487–509. [Google Scholar] [CrossRef]

- Suh, J.W.; Kim, J.W.; Choi, Y.S.; Kim, J.H.; Joo, W.G.; Lee, K.Y. Development of numerical Eulerian-Eulerian models for simulating multiphase pumps. J. Pet. Sci. Eng. 2018, 162, 588–601. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, L. Energy performance and pressure fluctuation of a multiphase pump with different gas volume fractions. Energies 2018, 11, 1216. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Cai, S.J.; Li, Y.J. Optimization design of multiphase pump impeller based on combined genetic algorithm and boundary vortex flux diagnosis. J. Hydrodyn. Ser. B 2017, 29, 1023–1034. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H.Q. A review of experiments and modeling of gas-liquid flow in electrical submersible pumps. Energies 2018, 11, 180. [Google Scholar] [CrossRef]

- El-Batsh, H.M.; Doheim, M.A.; Hassan, A.F. On the application of mixture model for two-phase flow induced corrosion in a complex pipeline configuration. Appl. Math. Model. 2012, 36, 5686–5699. [Google Scholar] [CrossRef]

- Liu, J.R.; Su, Q.Q.; Xu, Y.G.; Zhou, X.; Zhang, Y.X. Numerical analysis of the internal flow field in a jet self-priming irrigation pump. J. Drain. Mach. 2009, 27, 347–351. (In Chinese) [Google Scholar]

- Shi, P.; Rzehak, R. Bubbly flow in stirred tanks: Euler-Euler/RANS modeling. Chem. Eng. Sci. 2018, 190, 419–435. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Ashgriz, N.; Poo, J.Y. FLAIR: Flux line-segment model for advection and interface reconstruction. J. Comput. Phys. 1991, 93, 449–468. [Google Scholar] [CrossRef]

- Ubbink, O.; Issa, R. A method for capturing sharp fluid interfaces on arbitrary meshes. J. Comput. Phys. 1999, 153, 26–50. [Google Scholar] [CrossRef]

- Sengupta, J.; James, A.; Singh, R.; Bale, S. Size effect of oscillating columns on mixing: A CFD study. Eur. J. Mech.-B/Fluids 2019, 77, 230–238. [Google Scholar] [CrossRef]

- Zhao, H.L.; Zhao, X.; Mu, L.Z.; Zhang, L.F.; Yang, L.Q. Gas-liquid mass transfer and flow phenomena in a Peirce-Smith converter: A numerical model study. Int. J. Miner. Metall. Mater. 2019, 26, 1092–1104. [Google Scholar] [CrossRef]

- Sun, C.; Ning, Z.; Qiao, X.; Lv, M.; Fu, J.; Zhao, J.; Wang, X. Numerical simulation of gas–liquid flow behavior in the nozzle exit region of an effervescent atomizer. Int. J. Spray Combust. Dyn. 2019, 11, 175682771882159. [Google Scholar] [CrossRef]

- Ciappi, L.; Stebel, M.; Smolka, J.; Cappietti, L.; Manfrida, G. Analytical and computational fluid dynamics models of Wells turbines for oscillating water column systems. J. Energy Resour. Technol. 2022, 144, 050903. [Google Scholar] [CrossRef]

- Jiang, Q.; Heng, Y.; Liu, X.; Zhang, W.; Bois, G.; Si, Q. A review of design considerations of centrifugal pump capability for handling inlet gas-liquid two-phase flows. Energies 2019, 12, 1078. [Google Scholar] [CrossRef]

- Xiuli, W.; Yonggang, L.; Rongsheng, Z.; Qiang, F.; Weiyuan, Z. Study of non-linear cavitation on flow characteristics inside the centrifugal pump. J. Balk. Tribol. Assoc. 2016, 22, 2828. [Google Scholar]

- Furuya, O. An analytical model for prediction of two-phase (noncondensable) flow pump performance. J. Fluids Eng. 1985, 107, 139–147. [Google Scholar] [CrossRef]

- Minemura, K.; Uchiyama, T.; Shoda, S.; Egashira, K. Prediction of air-water two-phase flow performance of a centrifug-al pump based on one-dimensional two-fluid model. J. Fluids Eng. ASME 1998, 120, 327–334. [Google Scholar] [CrossRef]

- Chan, A.M.C.; Kawaji, M.; Nakamura, H.; Kukita, Y. Experimental study of two-phase pump performance using a full size nuclear reactor pump. Nucl. Eng. Des. 1999, 193, 159–172. [Google Scholar] [CrossRef]

- Poullikkas, A. Two phase flow performance of nuclear reactor cooling pumps. Prog. Nucl. Energy 2000, 36, 123–130. [Google Scholar] [CrossRef]

- Poullikkas, A. Effects of two-phase liquid-gas flow on the performance of nuclear reactor cooling pumps. Prog. Nucl. Energy 2003, 42, 3–10. [Google Scholar] [CrossRef]

- Hazra, S.B.; Steiner, K. Computation of dilute two-phase flow in a pump. J. Comput. Appl. Math. 2007, 203, 444–460. [Google Scholar] [CrossRef]

- Caridad, J.; Asuaje, M.; Kenyery, F.; Tremante, A.; Aguillón, O. Characterization of a centrifugal pump impeller under two-phase flow conditions. J. Pet. Sci. Eng. 2008, 63, 18–22. [Google Scholar] [CrossRef]

- Gao, H.; Gao, F.; Zhao, X.; Chen, J.; Cao, X. Transient flow analysis in reactor coolant pump systems during flow coastdown period. Nucl. Eng. Des. 2011, 241, 509–514. [Google Scholar] [CrossRef]

- Barrios, L.; Prado, M.G. Modeling two-phase flow inside an electrical submersible pump stage. J. Energy Resour. Technol. December 2011, 133(4), 042902. [Google Scholar] [CrossRef]

- Lu, J.L.; Xi, G.; Qi, D.T. Numerical study of three-dimensional gas-liquid two-phase flow in a centrifugal pump impeller. J. Eng. Thermophys. 2003, 24, 237–240. (In Chinese) [Google Scholar]

- Yu, Z.Y.; Cao, S.L.; Wang, G.Y. Numerical calculation of gas-liquid two-phase flow in a blade-type mixed transport pump. J. Eng. Thermophys. 2007, 28, 46–48. (In Chinese) [Google Scholar] [CrossRef]

- Xie, P.; Zhu, Z.C. Experimental analysis of cavitation in a low specific speed centrifugal vortex pump. J. Hydraul. Eng. 2009, 40, 1506–1511. (In Chinese) [Google Scholar]

- Ma, X.J.; Li, X.K.; Wang, N.; Zhou, G.W. Influence of guide vane blade number on the performance of gas-liquid mixed transport pump. J. Lanzhou Univ. Technol. 2012, 38, 51–55. (In Chinese) [Google Scholar]

- Huang, S.; Yue, L.; Guo, J.; Wang, L. Unsteady numerical simulation of gas-liquid two-phase flow during the self-priming process of a centrifugal pump. Sci. Technol. Guide 2013, 31, 36–40. (In Chinese) [Google Scholar]

- Yu, Z.; Zhu, B.; Cao, S. Interphase force analysis for air-water bubbly flow in a multiphase rotodynamic pump. Eng. Comput. 2015, 32, 2166–2180. [Google Scholar] [CrossRef]

- Liu, M.; Cao, S.; Cao, S. Numerical analysis for interphase forces of gas-liquid flow in a multiphase pump. Eng. Comput. 2018, 35, 2386–2402. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, J.; Cao, G.; Zhao, Q.; Peng, J.; Zhu, H.; Zhang, H.Q. Modeling flow pattern transitions in electrical submersible pump under gassy flow conditions. J. Pet. Sci. Eng. 2019, 180, 471–484. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.Q. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments. J. Pet. Sci. Eng. 2019, 173, 339–350. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H.Q. Mechanistic modeling and numerical simulation of in-situ gas void fraction inside ESP impeller. J. Nat. Gas Sci. Eng. 2016, 36, 144–154. [Google Scholar] [CrossRef]

- Yan, S.; Sun, S.; Luo, X.; Chen, S.; Li, C.; Feng, J. Numerical investigation on bubble distribution of a multistage centrifugal pump based on a population balance model. Energies 2020, 13, 908. [Google Scholar] [CrossRef]

- Chen, Y.; Patil, A.; Chen, Y.; Bai, C.; Wang, Y.; Morrison, G. Numerical study on the first stage head degradation in an electrical submersible pump with population balance model. J. Energy Resour. Technol. 2019, 141, 022003. [Google Scholar] [CrossRef]

- Lu, T.Q.; Li, H.; Zhan, L.C. Numerical calculation and visualization experimental study on self-priming process of pump. J. Drain. Irrig. Mach. Eng. 2016, 34, 11. (In Chinese) [Google Scholar]

- Wang, C.; Shi, W.D.; Li, W.; Zhang, D.S.; Jiang, X.P. Numerical calculation and verification of the self-priming process of a self-priming irrigation pump. Trans. Chin. Soc. Agric. Eng. 2016, 32, 16. (In Chinese) [Google Scholar]

- Wang, C.; He, X.; Zhang, D.; Hu, B.; Shi, W. Numerical and experimental study of the self-priming process of a multistage self-priming centrifugal pump. Int. J. Energy Res. 2019, 43, 4074–4092. [Google Scholar] [CrossRef]

- Wang, C.; Hu, B.; Zhu, Y.; Wang, X.; Luo, C.; Cheng, L. Numerical study on the gas-water two-phase flow in the self-priming process of self-priming centrifugal pump. Processes 2019, 7, 330. [Google Scholar] [CrossRef]

- Huang, S.; Su, X.; Guo, J.; Yue, L. Unsteady numerical simulation for gas–liquid two-phase flow in self-priming process of centrifugal pump. Energy Convers. Manag. 2014, 85, 694–700. [Google Scholar] [CrossRef]

- Liu, J.R.; Su, Q.Q. Numerical simulation analysis of gas-liquid two-phase flow in a self-priming pump. J. Agric. Mach. 2009, 40, 73–76. (In Chinese) [Google Scholar]

- Qian, H. Transient Flow Characteristics and Self-Priming Performance Influence Mechanism of Gas-Liquid Two-Phase Flow during the Self-Priming Process of a Centrifugal Pump; Zhejiang University of Technology: Hangzhou, China, 2020. (In Chinese) [Google Scholar]

- Shepard, J. Self-priming pumps: An overview. World Pumps 2003, 444, 21–22. [Google Scholar]

- Fan, Z.L.; Li, W.G. Motion of bubbles in an external mixed self-priming pump. Pump Technol. 1991, 4, 9–11. (In Chinese) [Google Scholar]

- Sun, Y.B.; Chen, T.; Wu, D.Z.; Wang, L.Q. Numerical study on matching structures improvement of vertical self-priming pump. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 072003. [Google Scholar] [CrossRef]

- Sun, Y.B.; Chen, T.; Yang, S.; Wu, D.Z.; Wang, L.Q. Analysis of hydraulic performance and internal structure improvement of vertical self-priming pump. J. Zhejiang Univ. Eng. Sci. 2013, 2, 332–338. (In Chinese) [Google Scholar]

- Li, G.; Wang, Y.; Yin, G.; Cui, Y.; Liang, Q. Investigation of the self-priming process of self-priming pump under gas-liquid two-phase condition. In Proceedings of the Fluids Engineering Division Summer Meeting, Chicago, IL, USA, 3–7 August 2014. [Google Scholar] [CrossRef]

- Liu, Z.C.; Kong, F.Y.; Wang, Y.; Xie, S.F.; Zhao, L.F. Influence of non-uniform blade distribution on pressure pulsation in vortex self-priming pump. J. Drain. Irrig. Mach. Eng. 2017, 35, 2. (In Chinese) [Google Scholar] [CrossRef]

- Kai, W.; Zixu, Z.; Linglin, J.; Liu, H.; Li, Y. Research on unsteady performance of a two-stage self-priming centrifugal pump. J. Vibroeng. 2017, 19, 1732–1744. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Jiang, L.; Liu, H.; Li, Y. Effects of impeller trim on performance of two-stage self-priming centrifugal pump. Adv. Mech. Eng. 2017, 9, 168781401769249. [Google Scholar] [CrossRef]

- Chang, H.; Li, W.; Shi, W.; Liu, J. Effect of blade profile with different thickness distribution on the pressure characteristics of novel self-priming pump. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 518. [Google Scholar] [CrossRef]

- Chang, H.; Shi, W.; Li, W.; Liu, J. Energy Loss Analysis of Novel Self-Priming Pump Based on the Entropy Production Theory. J. Therm. Sci. 2019, 28, 306–318. [Google Scholar] [CrossRef]

- Mou, J.G.; Wang, H.S.; Wu, D.H.; Ren, Y.; Shi, Z.Z.; Jian, J.; Zhao, L.P. Unsteady study of solid-liquid two-phase flow in a sewage self-priming pump. J. Zhejiang Univ. Technol. 2018, 46, 633–638. (In Chinese) [Google Scholar]

- Mou, J.G.; Wang, H.S.; Wu, D.H.; Ren, Y.; Shi, Z.Z.; Jian, J.; Zhao, L.P. Study on the flow and distribution of solid particles in a sewage self-priming pump. J. Hydropower 2018, 37, 48–57. (In Chinese) [Google Scholar]

- Mou, J.G.; Wu, Z.X.; Zhou, P.J.; Gu, Y.Q.; Wu, D.H.; Ren, Y. Transient flow characteristics inside the volute of a self-priming centrifugal pump. J. Shanghai Jiao Tong Univ. 2018, 4, 461–468. [Google Scholar]

- Wu, D.; Zhu, Z.; Ren, Y.; Gu, Y.; Zhou, P. Influence of blade profile on energy loss of sewage self-priming pump. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 470. [Google Scholar] [CrossRef]

- Zhou, P.; Wu, Z.; Mou, J.; Wu, D.; Zheng, S.; Gu, Y. Effect of reflux hole on the transient flow characteristics of the self-priming sewage centrifugal pump. J. Appl. Fluid Mech. 2019, 12, 689–699. [Google Scholar] [CrossRef]

- Chang, H.; Shi, W.; Li, W.; Wang, C.; Zhou, L.; Liu, J.; Yang, Y.; Ramesh, K.A. Experimental Optimization of Jet Self-Priming Centrifugal Pump Based on Orthogonal Design and Grey-Correlational Method. J. Therm. Sci. 2020, 29, 241–250. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Zhu, Z.C.; Zhao, Y.J.; Wu, J.; Zhou, F.L. Comparative Experiments on a Self-priming Pump Delivering Water Medium During Rapid and Slow Starting Periods. Iran. J. Sci. Technol. Trans. Mech. Eng. 2021, 45, 1007–1019. [Google Scholar] [CrossRef]

- Wen, H.; Yao, Z.; Zhong, Q.; Tian, Y.; Sun, Y.; Wang, F. Energy partitioning in laser-induced millimeter-sized spherical cavitation up to the fourth oscillation. Ultrason. Sonochem. 2023, 95, 106391. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Yao, Z.; Wen, H.; Zhong, Q.; Wang, F. Cavitation bubble collapse in a vicinity of a rigid wall with a gas entrapping hole. Phys. Fluids 2022, 34, 7. [Google Scholar] [CrossRef]

- Zi, D.; He, D.Q.; Yao, Z.F.; Wang, F.J.; Zhong, Q.; Lyu, P. Investigations of the dynamical behaviors of a millimeter-scale cavitation bubble near the rigid wall. J. Hydrodyn. 2023, 35, 1064–1076. [Google Scholar] [CrossRef]

- Supponen, O.; Obreschkow, D.; Kobel, P.; Farhat, M. Luminescence from cavitation bubbles deformed in uniform pressure gradients. Phys. Rev. E 2017, 96, 033114. [Google Scholar] [CrossRef] [PubMed]

- Preso, D.B.; Fuster, A.B.; Sieber, D.; Obreschkow, D.; Farhat, M. Vapor compression and energy dissipation in a collapsing laser-induced bubble. Phys. Fluids 2024, 36, 033601. [Google Scholar] [CrossRef]

- Zhang, S.; Yao, Z.; Wu, H.; Zhong, Q.; Tao, R.; Wang, F. A new turbulent viscosity correction model with URANS solver for unsteady turbulent cavitation flow computations. J. Fluids Eng. 2022, 144, 9. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, P.; Zhou, C.; Zhou, W.; Li, J. Analysis of cavitation-induced vibration characteristics of a vortex pump based on adaptive optimal kernel time-frequency representation. J. Appl. Fluid Mech. 2024, 17, 3. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).