Advanced Machining of Joint Implant UHMWPE Inserts

Abstract

:1. Introduction

2. Materials and Methods

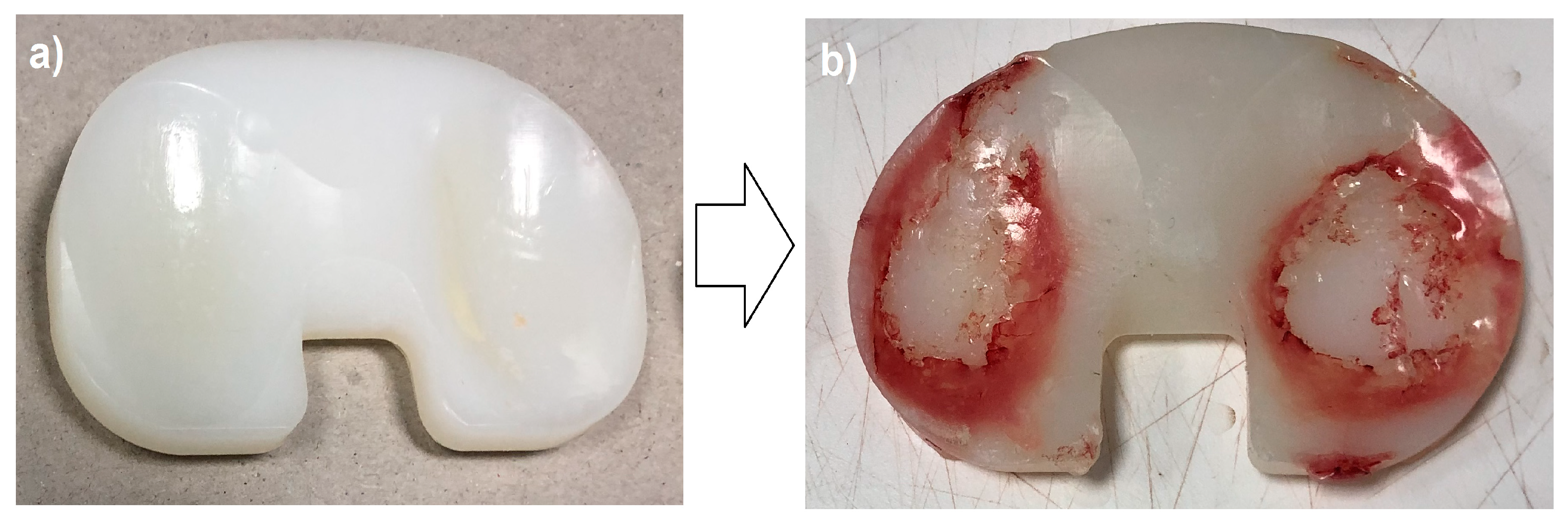

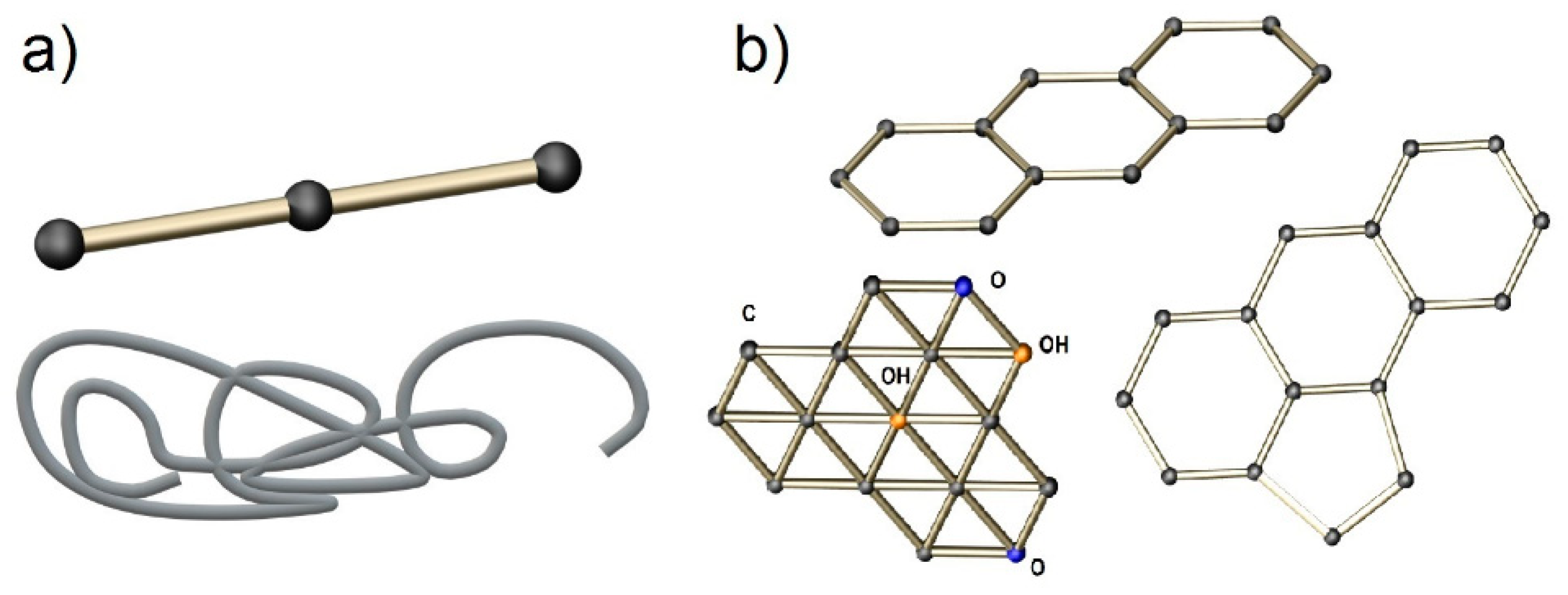

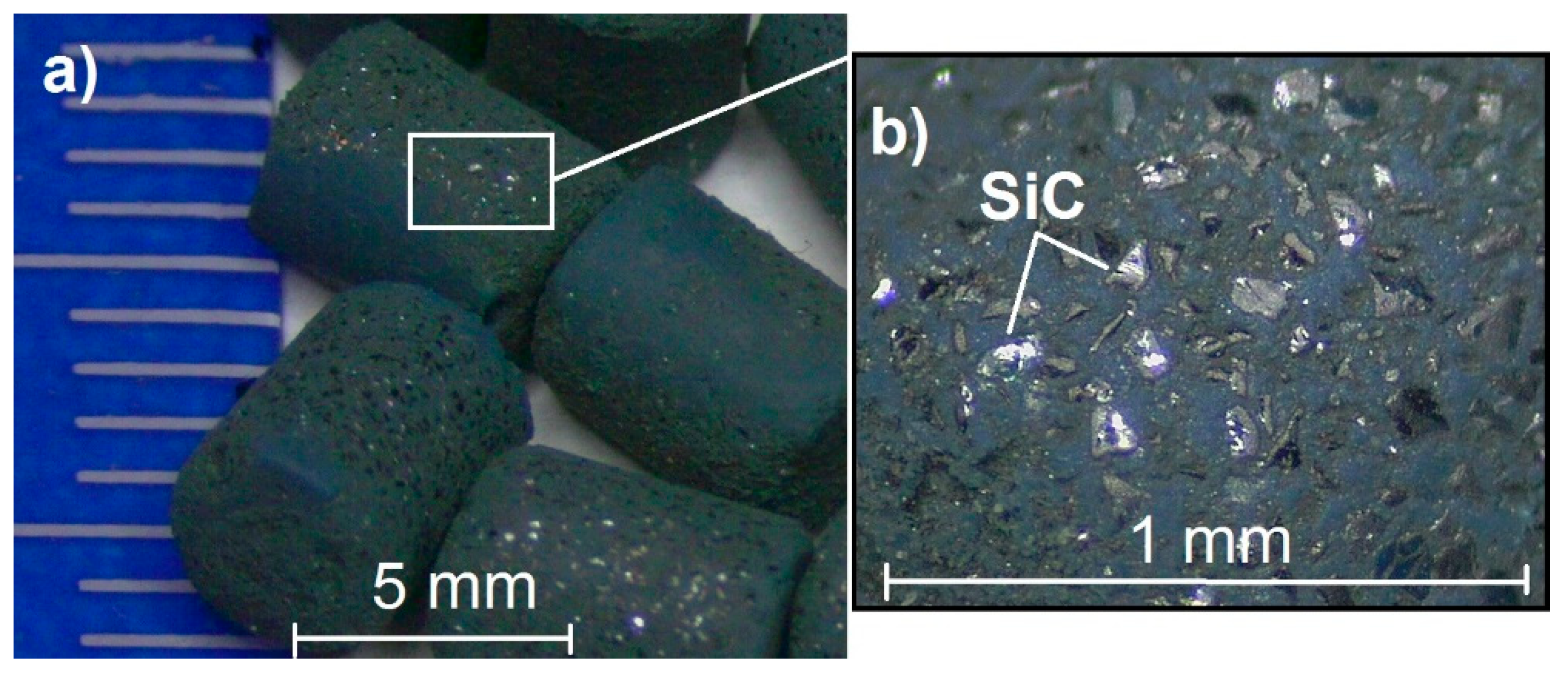

2.1. Material and Design of Joint Inserts

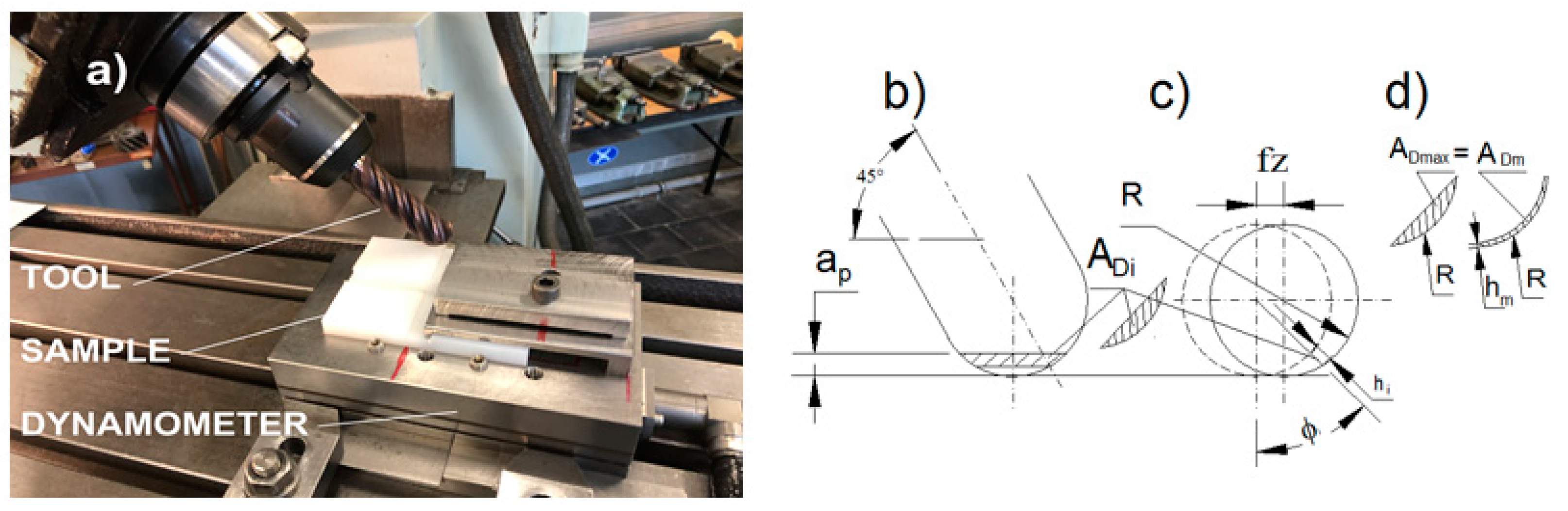

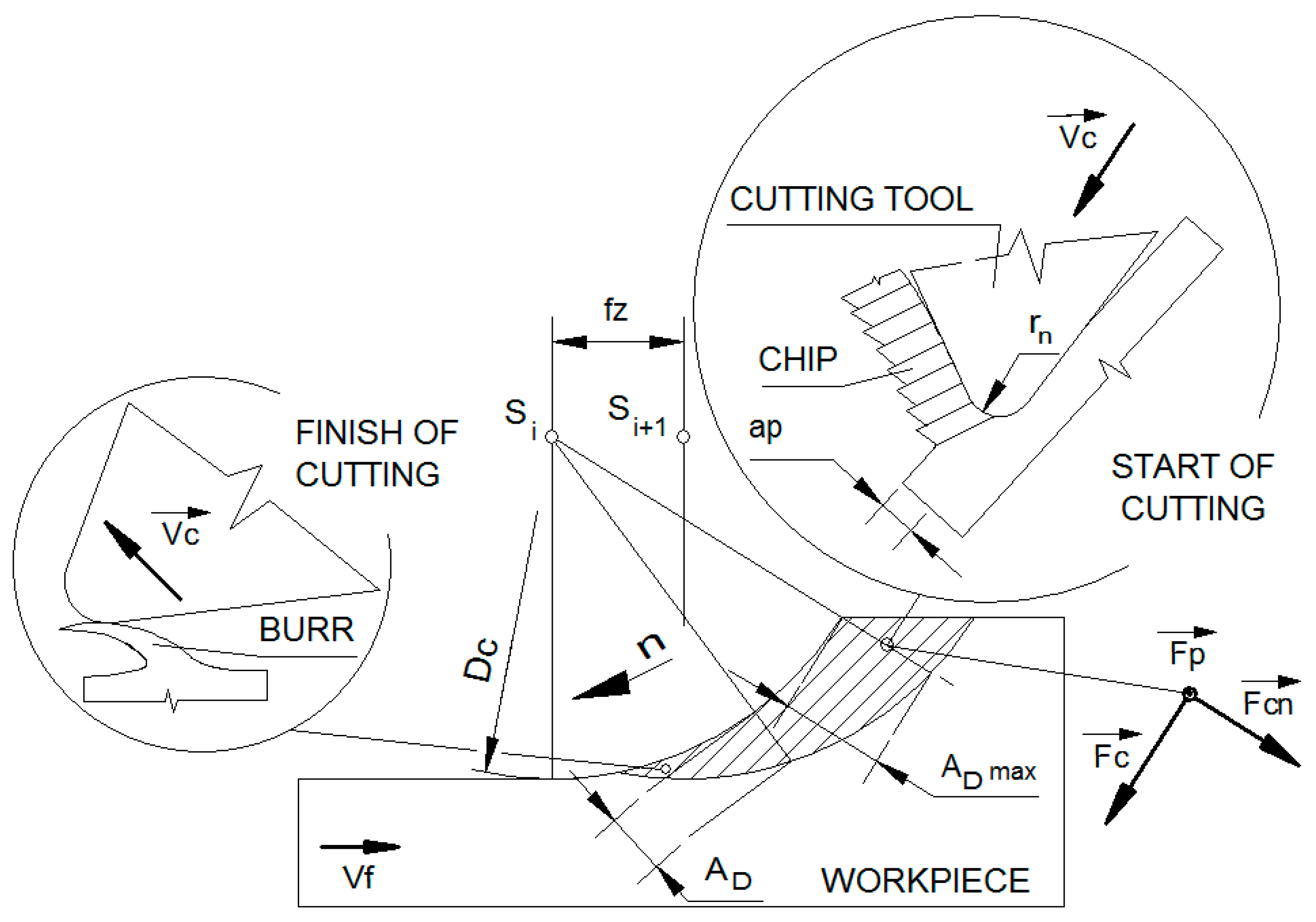

2.2. Machining Tests

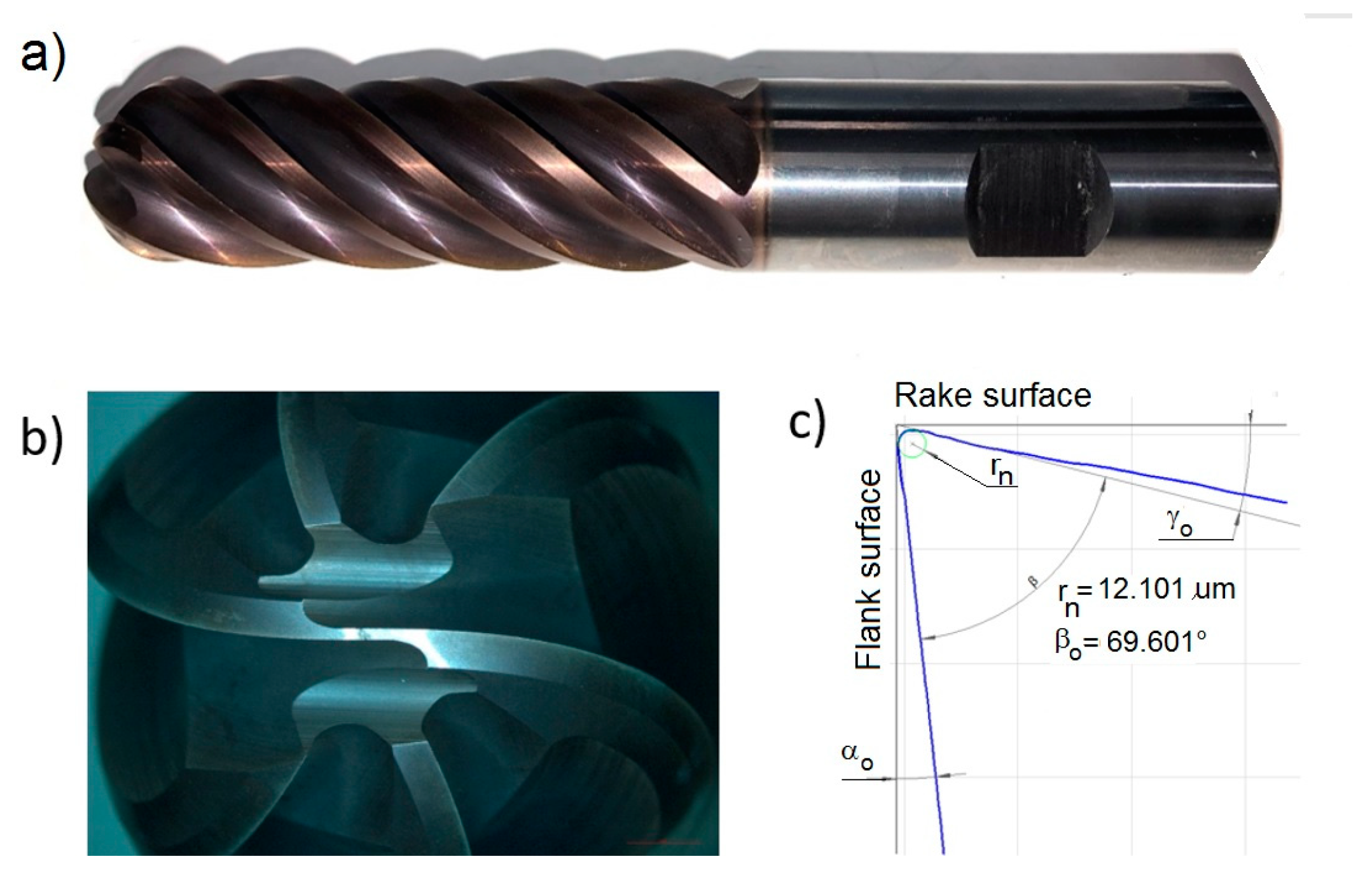

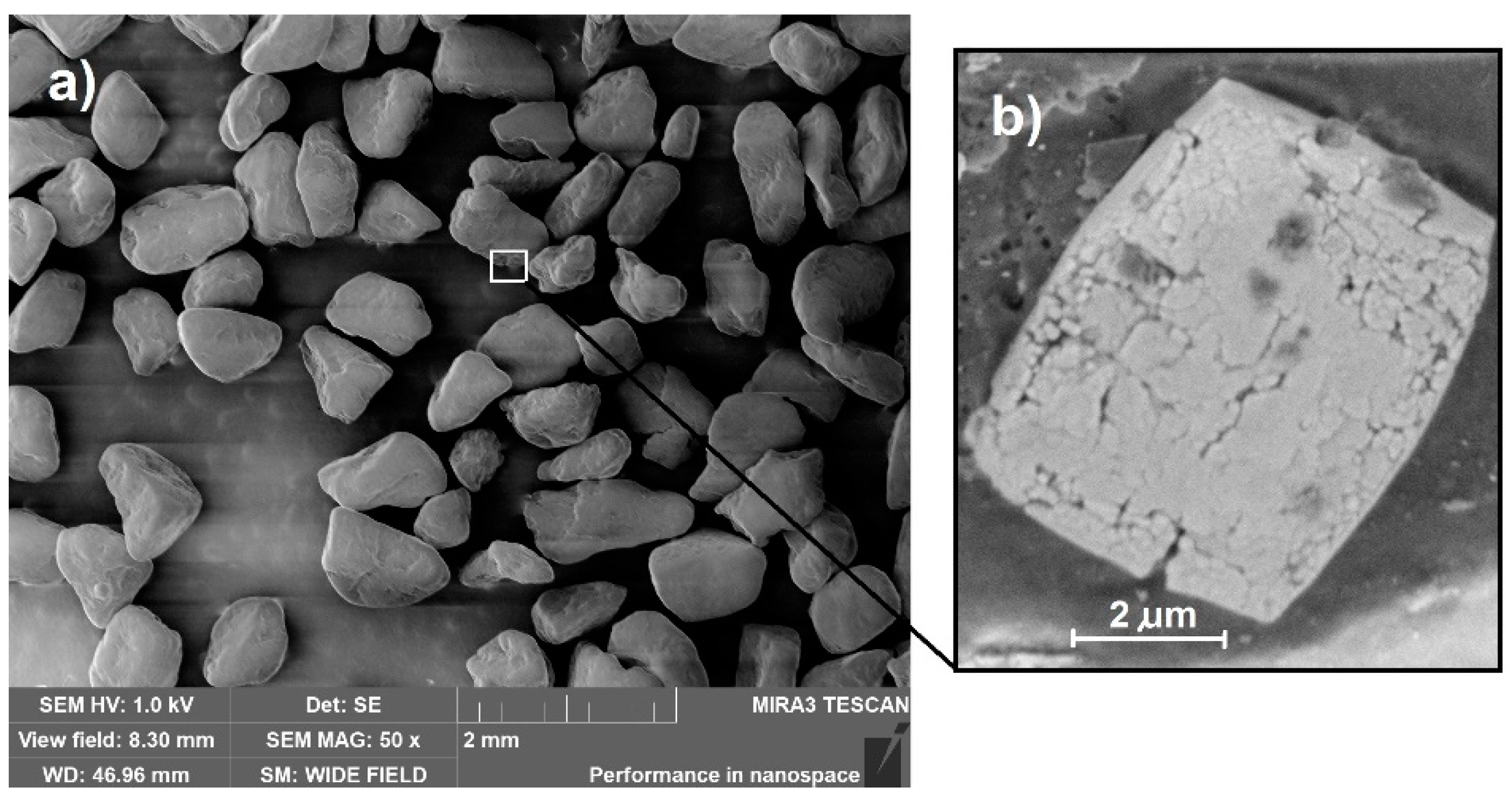

New Cutting Tool

2.3. Tribological Tests

3. Results

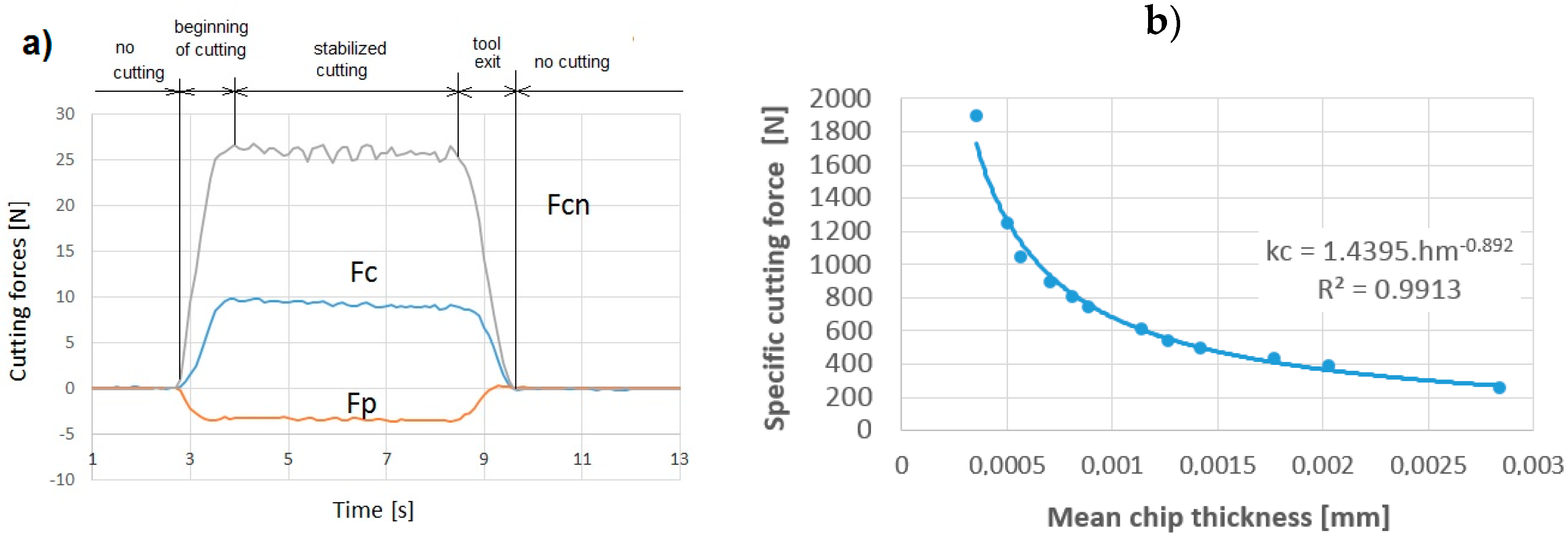

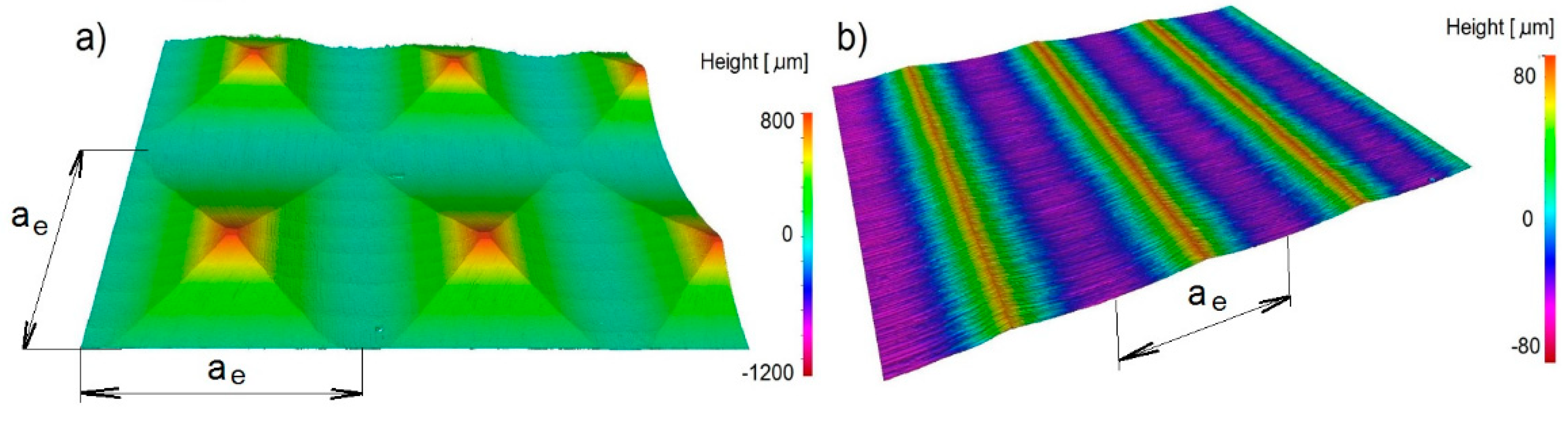

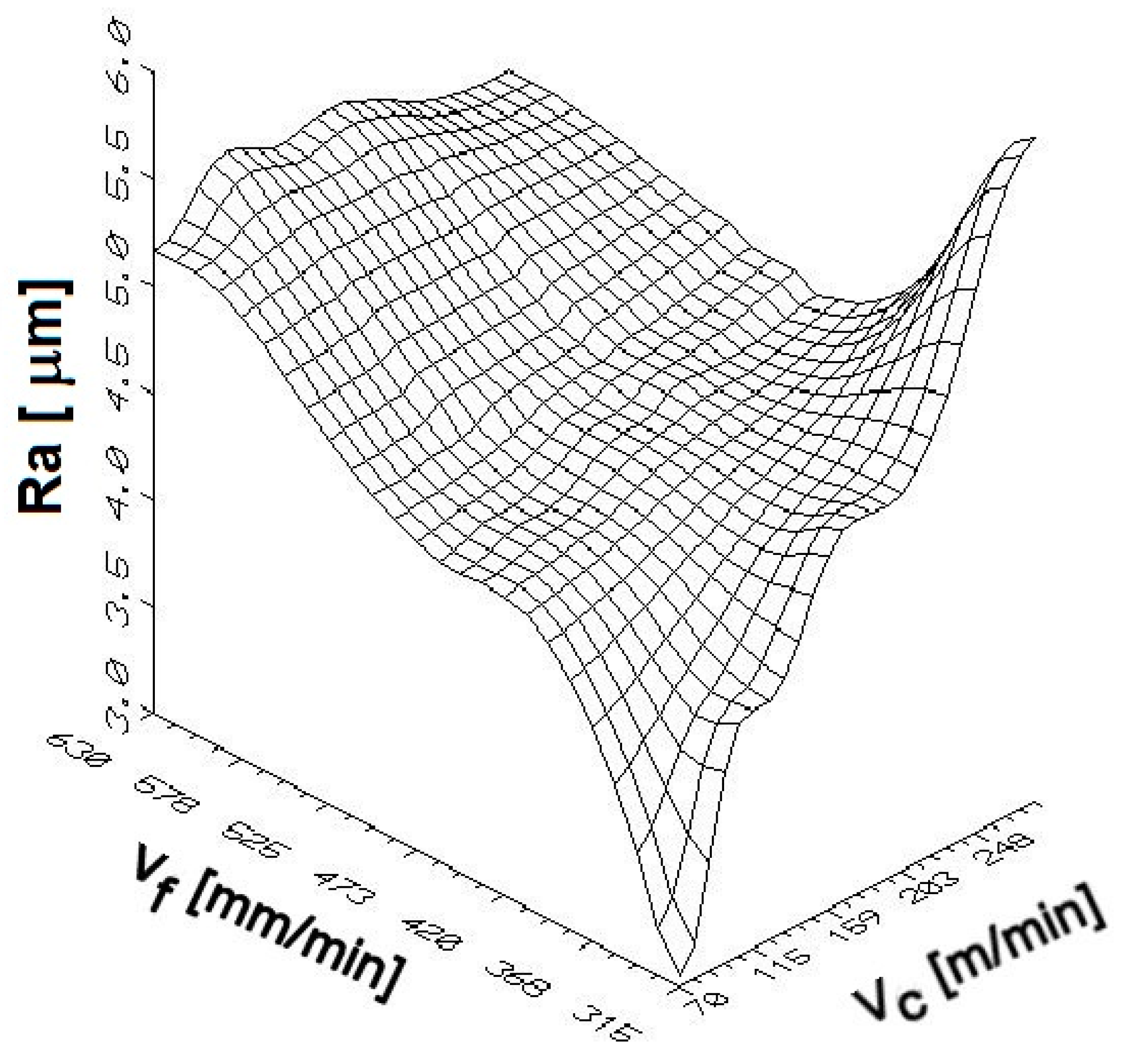

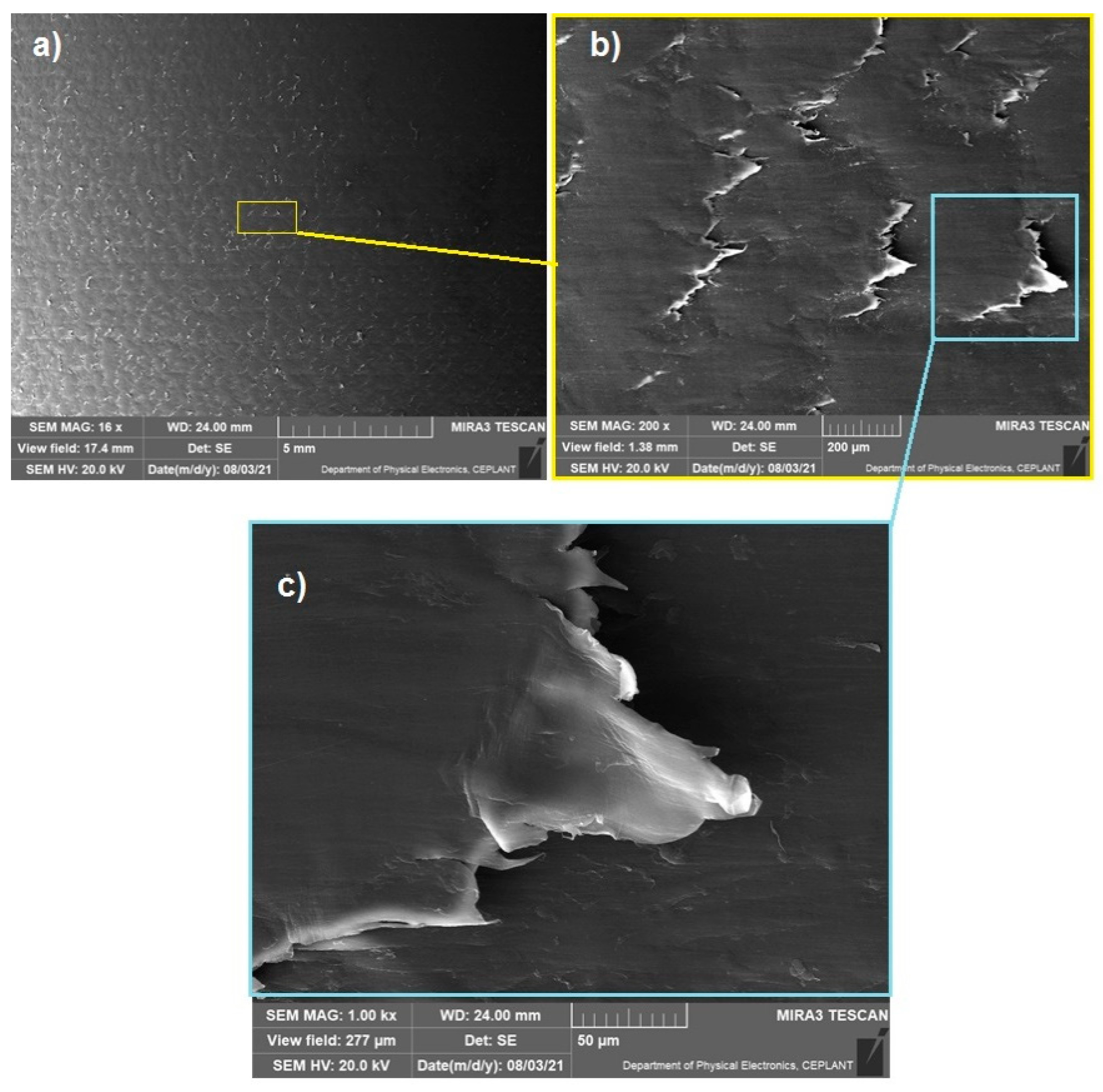

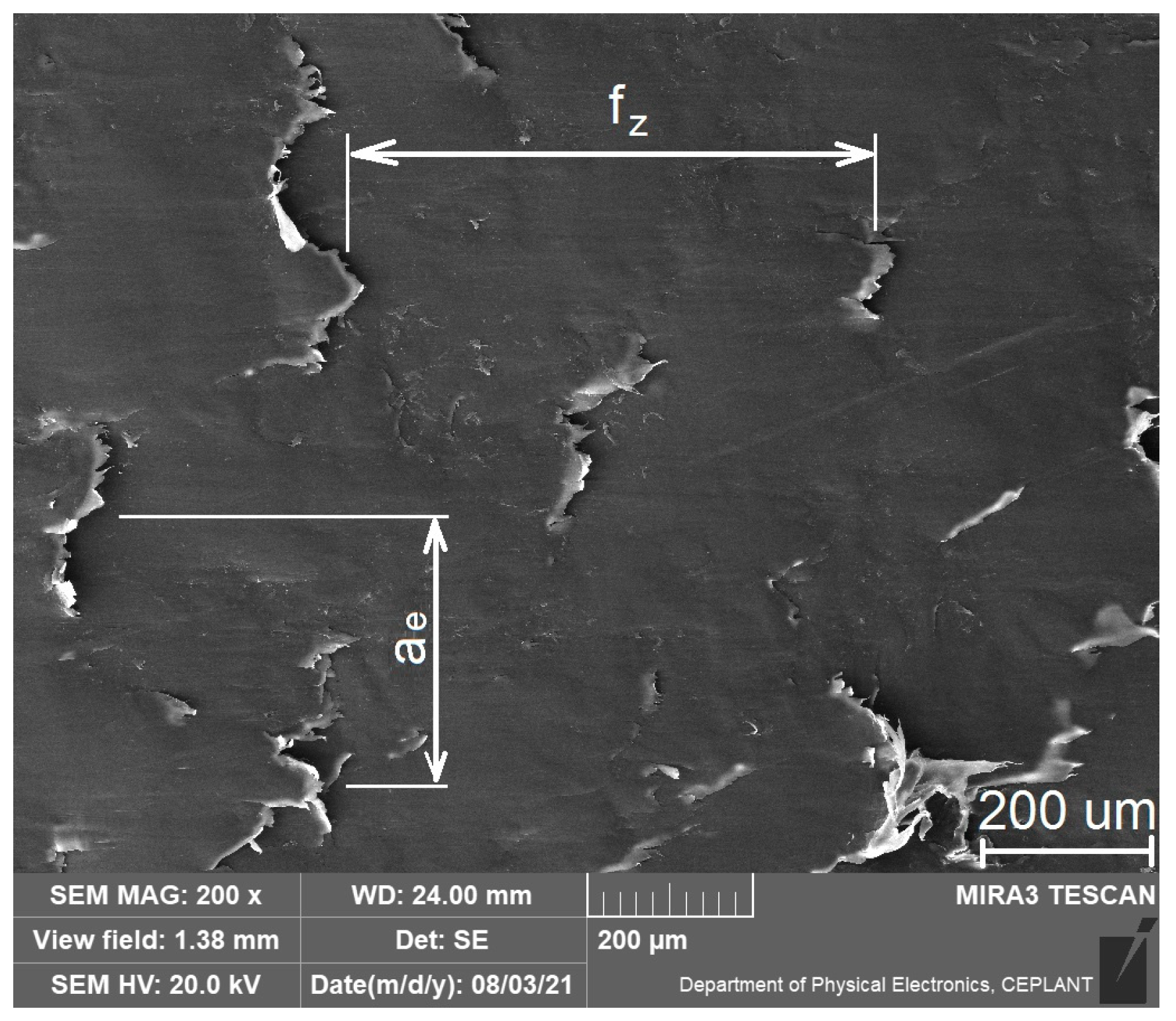

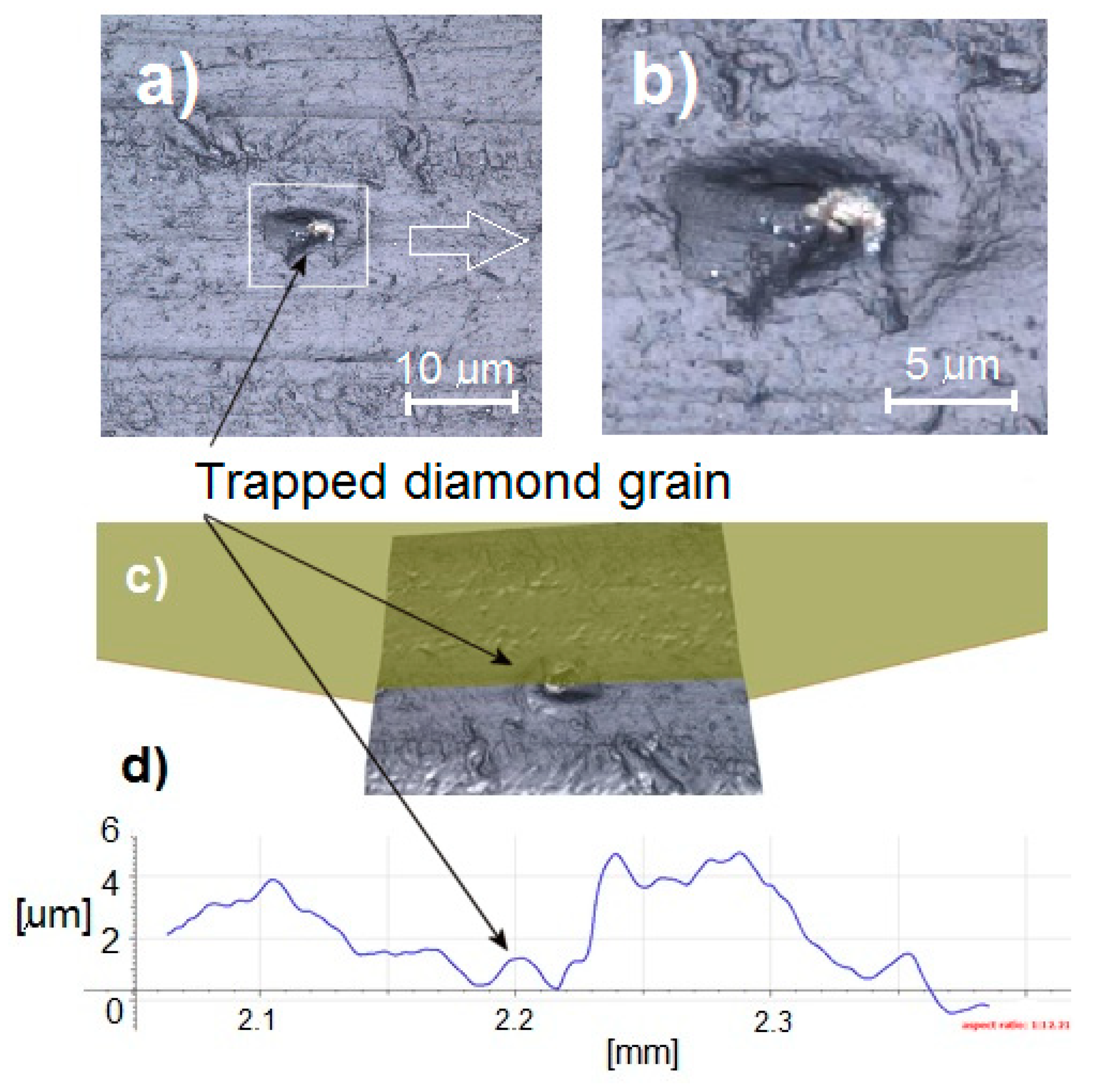

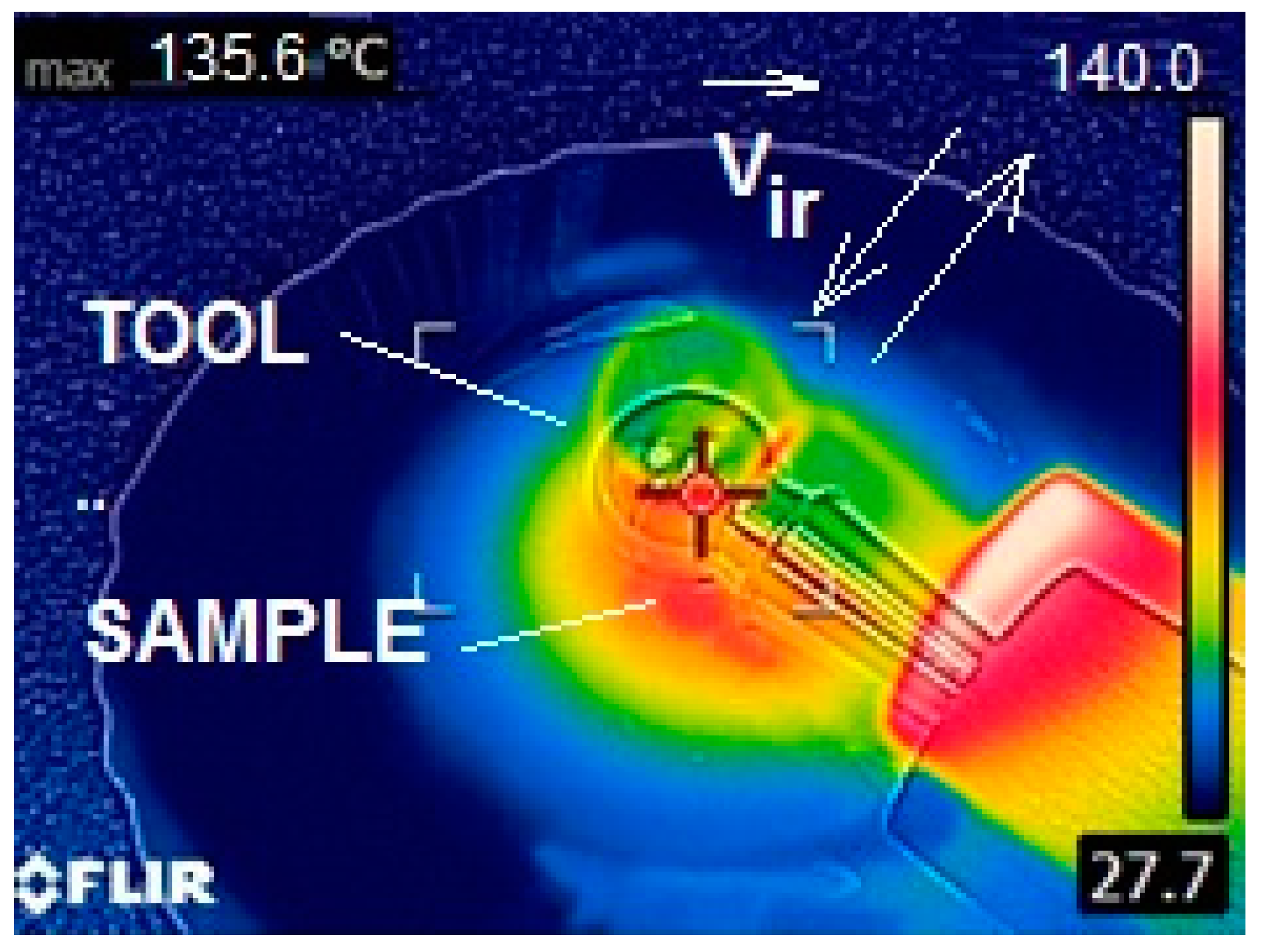

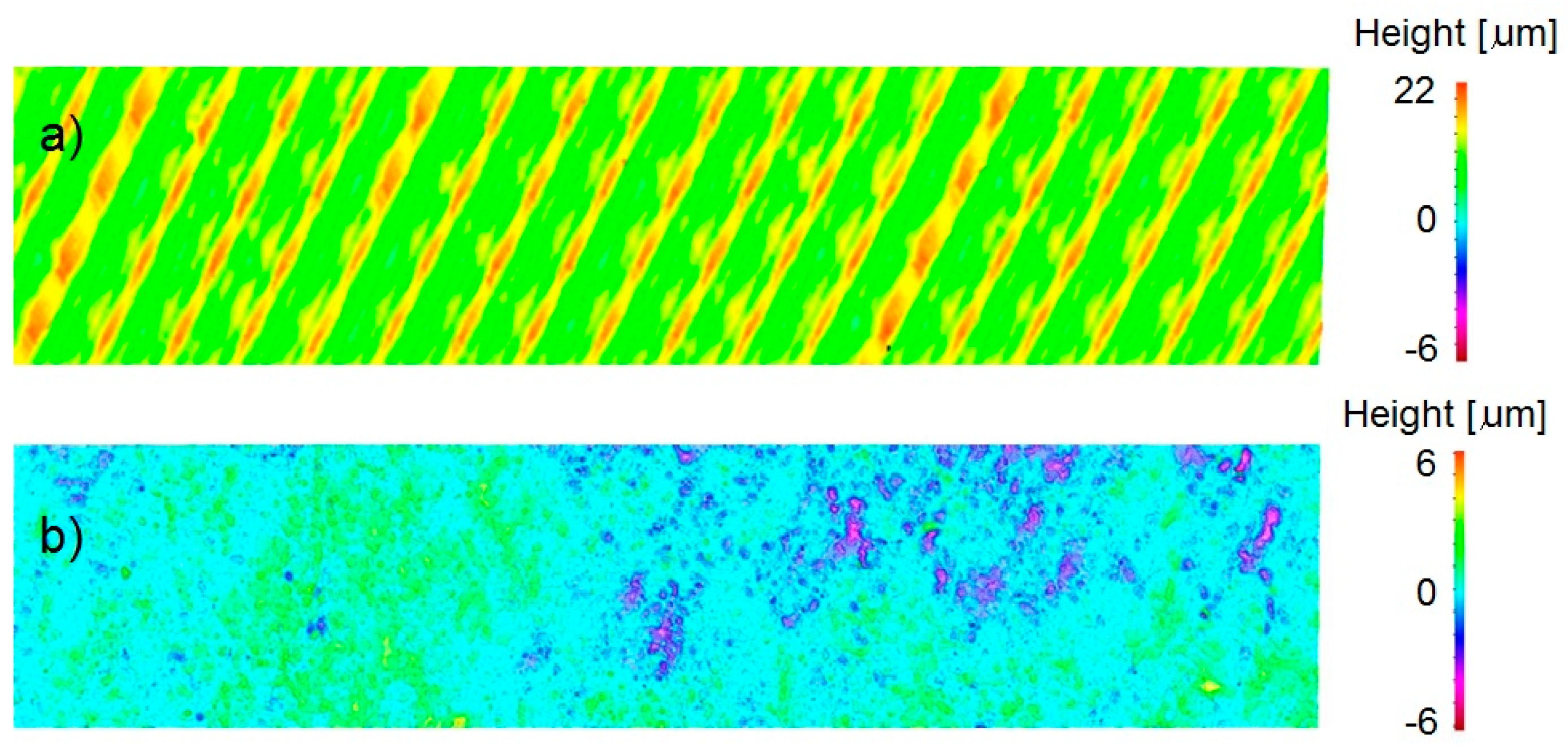

3.1. Results of Machining Tests

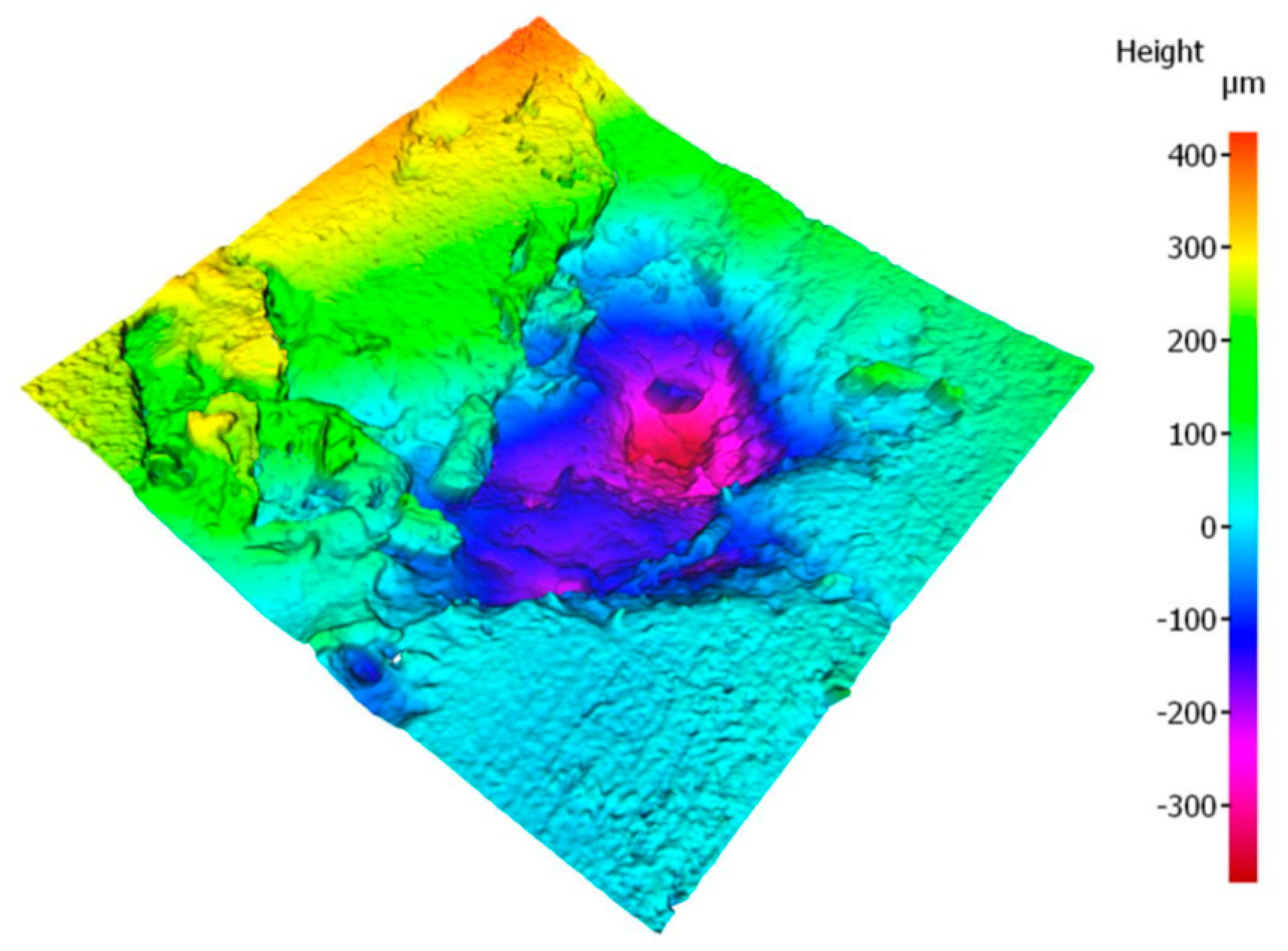

3.2. Results of Tribological Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Statistics 2021: Monitoring Health for the SDGs, Sustainable Development Goals; World Health Organization: Geneva, Switzerland, 2021; ISBN 978-92-4-002705-3.

- Píška, M.; Bučková, K. On the analysis of Ti6Al4V-ELI powder material, electron beam technology and machining on quality of machined implant surfaces. In Proceedings of the European Advanced Material Congress, Stockholm, Sweden, 20–23 August 2018; VBRI Press: Stockholm, Sweden, 2018; pp. 257–258, ISBN 978-91-88252-12-8. [Google Scholar]

- Píška, M.; Bučková, K. On the machining of Ti-6Al-4V ELI alloy made with EBM technology for implants. In Proceedings of the UTIS 9th International Congress on Machining Congress Proceedings, Antalya, Türkiye, 8–11 November 2018; UTIS Royal Seginus: Antalya, Türkiye, 2018; pp. 242–247. [Google Scholar]

- Píška, M.; Bučková, K. Advanced knee implants for the third millenium. J. Mater. Sci. Eng. 2019, 8, 20–21. [Google Scholar]

- Píška, M.; Bučková, K. Analysis of machined electron beam treated Ti6Al4V-ELI implant surfaces. Adv. Mater. Lett. 2019, 10, 381–385. [Google Scholar] [CrossRef]

- Píška, M.; Bučková, K. On the SLM and EBM of Ti-6Al-4V ELI Alloy for Advanced Knee Arthroplasty; Bone Research Society and British Orthopaedic Research Society: Cardiff, Wales, 2019; p. 92. [Google Scholar]

- Píška, M.; Bučková, K. A Set for Application of Joint Implant. Czech Patent No 309024, 2021. [Google Scholar]

- Katti, K.S. Biomaterials in total joint replacement. Colloids Surf. B Biointerfaces 2004, 9, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M. UHMWPE Biomaterials Handbook-Ultra-High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices, 3rd ed.; Drexel University: Philadelphia, PA, USA; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Malito, G.L.; Arevalo, S.; Adam, K.; Stephen, S.; Anuj, B.; Lisa, P. Material properties of ultra-high molecular weight polyethylene: Comparison of tension, compression, nanomechanics and microstructure across clinical formulations. J. Mech. Behav. Biomed. Mater. 2018, 83, 9–19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panayotov, I.V.; Orti, V.; Cuisinier, F.; Yachouh, J. Polyetheretherketone (PEEK) for medical applications. J. Mater. Sci. Mater. Med. 2016, 27, 118. [Google Scholar] [CrossRef]

- Mckeen, L.W. Fatigue and Tribological Properties of Plastics and Elastomers, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Zaribaf, F.P. Medical-grade ultra-high molecular weight polyethylene: Past, current and future. Mater. Sci. Technol. 2018, 34, 1940–1953. [Google Scholar] [CrossRef]

- Katarzyna, G.; Sylwester, G. The effect of gamma radiation on molecular stability and mechanical properties of biodegradable polyurethanes for medical applications. Polym. Degrad. Stab. 2003, 79, 465–474. [Google Scholar]

- Ducháček, V. Polymery: Výroba, Vlastnosti, Zpracování, Použití, 2nd ed.; VSCHT: Prague, Czech Republic, 2006; ISBN 80-708-0617-6. (In Czech) [Google Scholar]

- ASTM F648-21, 10th ed.; Standard Specification for Ultra-High-Molecular-Weight Polyethylene Powder and Fabricated Form for Surgical Implants; ASTM international: West Conshohocken, PA, USA, 2021.

- ISO 5834-2:2019; DIN ISO 5834-1 Implants for Surgery-Ultra-High-Molecular-Weight Polyethylene-Part 1: Moulded Forms. ISO: Geneva, Switzerland, 2019.

- ISO 5834-2:2019; DIN ISO 5834-2 Implants for Surgery-Ultra-High-Molecular-Weight Polyethylene-Part 2: Moulded Forms. ISO: Geneva, Switzerland, 2019.

- ISO 5834-1:2019; DIN ISO 5834-1 Implants for Surgery-Ultra-High-Molecular-Weight Polyethylene-Part 3: Powder Form. ISO: Geneva, Switzerland, 2019.

- Axinte, D.; Guo, Y.; Liao, Z.; Shih, A.J.; M’Saoubi, R.; Sugita, N. Machining of biocompatible materials—Recent advances. CIRP Ann. 2019, 68, 629–652. [Google Scholar] [CrossRef]

- Aldwell, B.; Hanley, R.; O’Donnell, G.E. Characterising the Machining of Biomedical Grade Polymers. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1237–1251. [Google Scholar] [CrossRef] [Green Version]

- Kousuke, S.; Narita, H. Study on Ball End Milling of Inclined Surfaces for Ultra High Molecular Weight Polyethylene. Int. J. Autom. Technol. 2017, 11, 948–957. [Google Scholar]

- Wright, T.M.; Rimnac, C.M.; Stulberg, S.D.; Mintz, L.; Tsao, A.K.; Klein, R.W.; McCrae, C. Wear of Polyethylene in Total Joint Replacements Observations From Retrieved PCA Knee Implants. Clin. Orthop. Relat. Res. 1992, 214, 124–134. [Google Scholar] [CrossRef]

- Mohsen, M.; Suh, N. Wear Particles of Polyethylene in Biological Systems. Tribol. Trans. 1996, 39, 843–848. [Google Scholar]

- Howling, G.I.; Barnett, P.I.; Tipper, J.L.; Stone, M.H.; Fisher, J.; Ingham, E. Quantitative characterization of polyethylene debris isolated from periprosthetic tissue in early failure knee implants and early and late failure Charnley hip implants. J. Biomed. Mater. Res. 2001, 58, 415–420. [Google Scholar] [CrossRef] [PubMed]

- Tulp, N.J.A. Polyethylene delamination in the PCA total knee. Material analysis in two failed cases. Acta Orthop. Scand. 2009, 63, 263–266. [Google Scholar]

- Evans, D.C.; Lancaster, J.K. The Wear of Polymers; Wear; Elsevier: Amsterdam, The Netherlands, 1979; Volume 13, pp. 85–139. [Google Scholar]

- Abdelbary, A. Wear of Polymers and Composites, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Wilches, L.V.; Uribe, J.A.; Toro, A. Wear of materials used for artificial joints in total hip replacements. Wear 2008, 265, 143–149. [Google Scholar] [CrossRef]

- Mishra, V.; Singh, G.; Yadav, C.B.; Karar, V.; Prakash, C.; Singh, S. Precision machining of biopolymers: A brief review of the literature and case story on diamond turning. J. Thermoplast. Compos. Mater. 2021, 34, 557–578. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 2nd ed.; Oxford University Press: Oxford, UK, 2005; ISBN 0-19-514206-3. [Google Scholar]

- Fisher, J.; Dowson, D.; Hamdzah, H.; Lee, H.L. The effect of sliding velocity on the friction and wear of UHMWPE for use in total artificial joints. Wear 1994, 175, 219–225. [Google Scholar] [CrossRef]

- Song, J.; Liu, P.; Cremens, M.; Bonutti, P. Effects of machining on tribological behavior of ultra high molecular weight polyethylene (UHMWPE) under dry reciprocating sliding. Wear 1999, 225–229, 716–723. [Google Scholar] [CrossRef]

- Gabriel, M.C.; Mendes, L.B.; Carvalho, B.d.; Pinheiro, L.A.; Capocchi, J.D.T.; Kubaski, E.T.; Cintho, O.M. High-energy mechanical milling of ultra-high molecular weight polyethylene (UHMWPE). In Proceedings of the Seventh International Latin American Conference on Powder Technology, Atibaia, SP, Brazil, 8–10 November 2010; pp. 342–346. [Google Scholar]

- Pereira, O.; Gonzáles, H.; Calleja, A.; Rodrigues, A.; Urbikaín, G.; López de Lacalle, L.N. Manufacturing of human knee by cryogenic machining: Walking towards cleaner processes. Procedia Manuf. 2019, 41, 257–263. [Google Scholar] [CrossRef]

- Gómez-Escudero, G.; Jimeno Beitia, A.; Martínez de Pissón Caruncho, G.; López de Lacalle, L.N.; González-Barrio, H.; Pereira Neto, O.; Calleja-Ochoa, A. A reliable clean process for five-axis milling of knee prostheses. Int. J. Adv. Manuf. Technol. 2021, 115, 1605–1620. [Google Scholar] [CrossRef]

| PMMA | PEEK | PUR | PP | UHMWPE | |

|---|---|---|---|---|---|

| Molar mass [g/mol] | 1.3 × 104 −2.2 × 105 | 1.4 × 104 −1.0 × 105 | 7 × 103 −1.2 × 104 | 1 × 105 −6 × 105 | 3 × 106 −6 × 106 |

| Density [kg/m3] | 1180 | 1320 | 15–600 | 900–910 | 941–965 |

| Crystallinity [%] | 0 | 16–47 | 0–13 | 60–75 | 39–75 |

| Flow temperature Tf [°C] | 1.6 | 334 | 141–150 | 176 | 135 |

| Tensile modulus [MPa] | 1800–3100 | 3000–4000 | 6 | 1325 | 655–1077 |

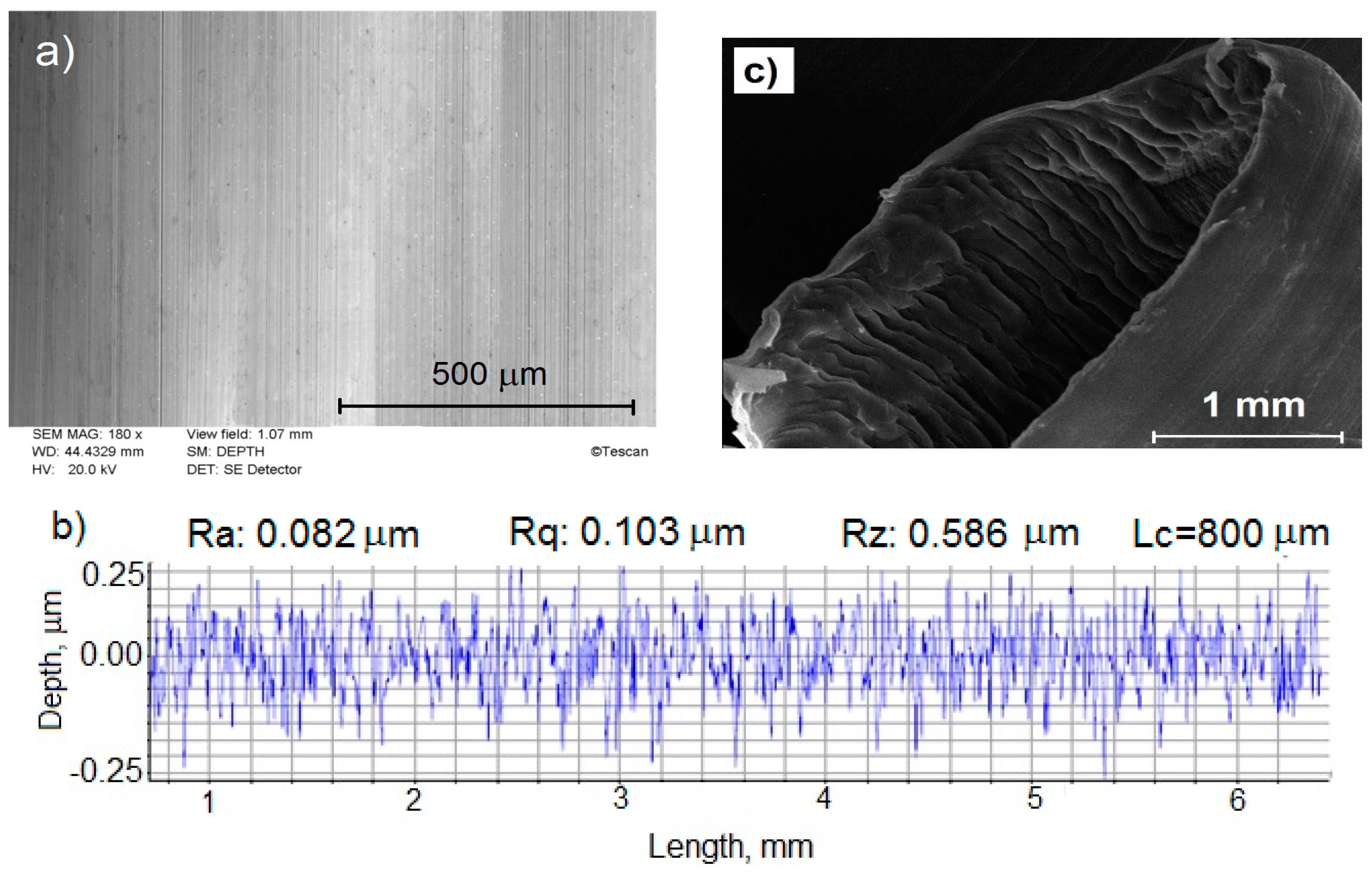

| Ra [μm] | Rz [μm] | Sa [μm] | |

|---|---|---|---|

| Surface after milling | 2.49–2.61 | 18.68–19.84 | 3.63–3.68 |

| Ironing (flat contact) | 1.29–1.36 | 9.21–9.72 | 1.37–1.42 |

| Ironing (cylindrical contact) | 1.70–1.86 | 12.29–13.45 | 3.27–3.41 |

| Ironing (ball contact) | 1.93–2.02 | 14.17–14.84 | 2.58–2.72 |

| Thrust Force [N] | Feed Speed [mm/min] | |||

|---|---|---|---|---|

| 200 | 800 | 1400 | 2000 | |

| 20 | 0.074 | 0.080 | 0.082 | 0.080 |

| 25 | 0.085 | 0.089 | 0.093 | 0.094 |

| 100 | 0.080 | 0.096 | 0.103 | 0.094 |

| 300 | 0.088 | 0.098 | 0.097 | 0.099 |

| Mean ± SD | 0.082 ± 0.006 | 0.091 ± 0.008 | 0.093 ± 0.009 | 0.092 ± 0.008 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piska, M.; Urbancova, K. Advanced Machining of Joint Implant UHMWPE Inserts. Machines 2022, 10, 1008. https://doi.org/10.3390/machines10111008

Piska M, Urbancova K. Advanced Machining of Joint Implant UHMWPE Inserts. Machines. 2022; 10(11):1008. https://doi.org/10.3390/machines10111008

Chicago/Turabian StylePiska, Miroslav, and Katerina Urbancova. 2022. "Advanced Machining of Joint Implant UHMWPE Inserts" Machines 10, no. 11: 1008. https://doi.org/10.3390/machines10111008

APA StylePiska, M., & Urbancova, K. (2022). Advanced Machining of Joint Implant UHMWPE Inserts. Machines, 10(11), 1008. https://doi.org/10.3390/machines10111008