Experimental Investigation and Prediction for Bending Creep of Glass Fiber-Reinforced Polymer Pultruded Tube

Abstract

:1. Introduction

2. Experimental Methods

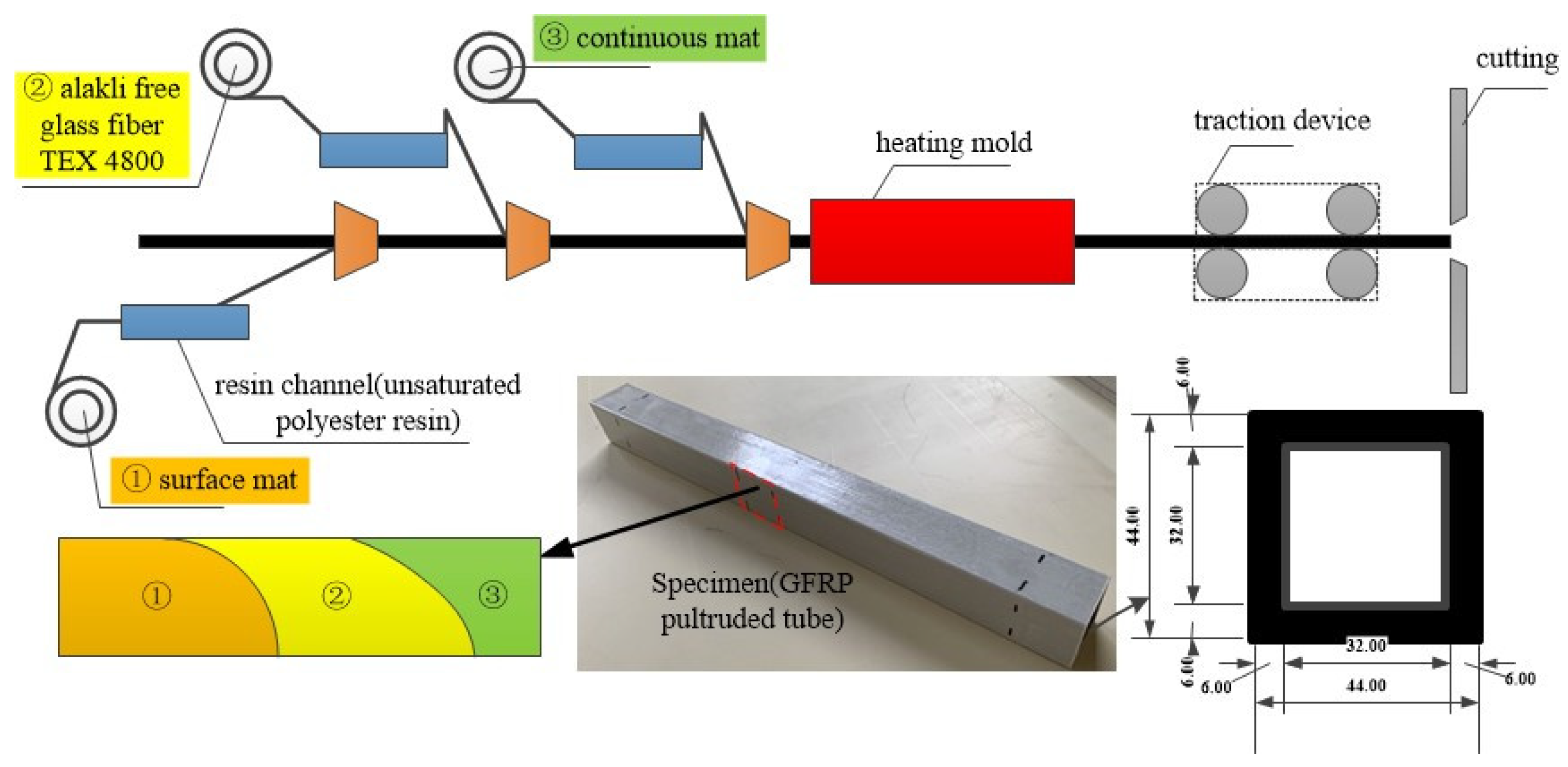

2.1. Description of Specimen

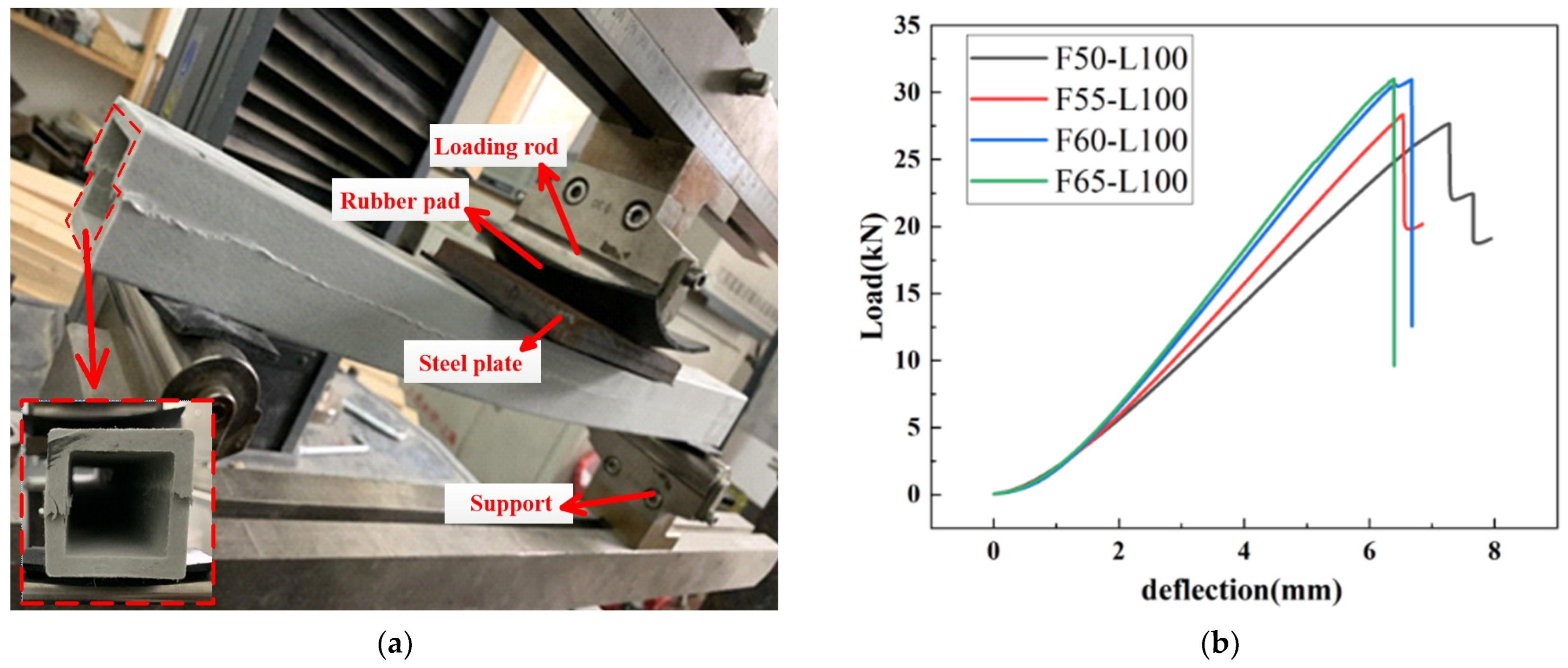

2.2. Static Bending Test Set-Up

2.3. Bending Creep Test Set-Up

3. Results and Analysis

3.1. Static Bending Results

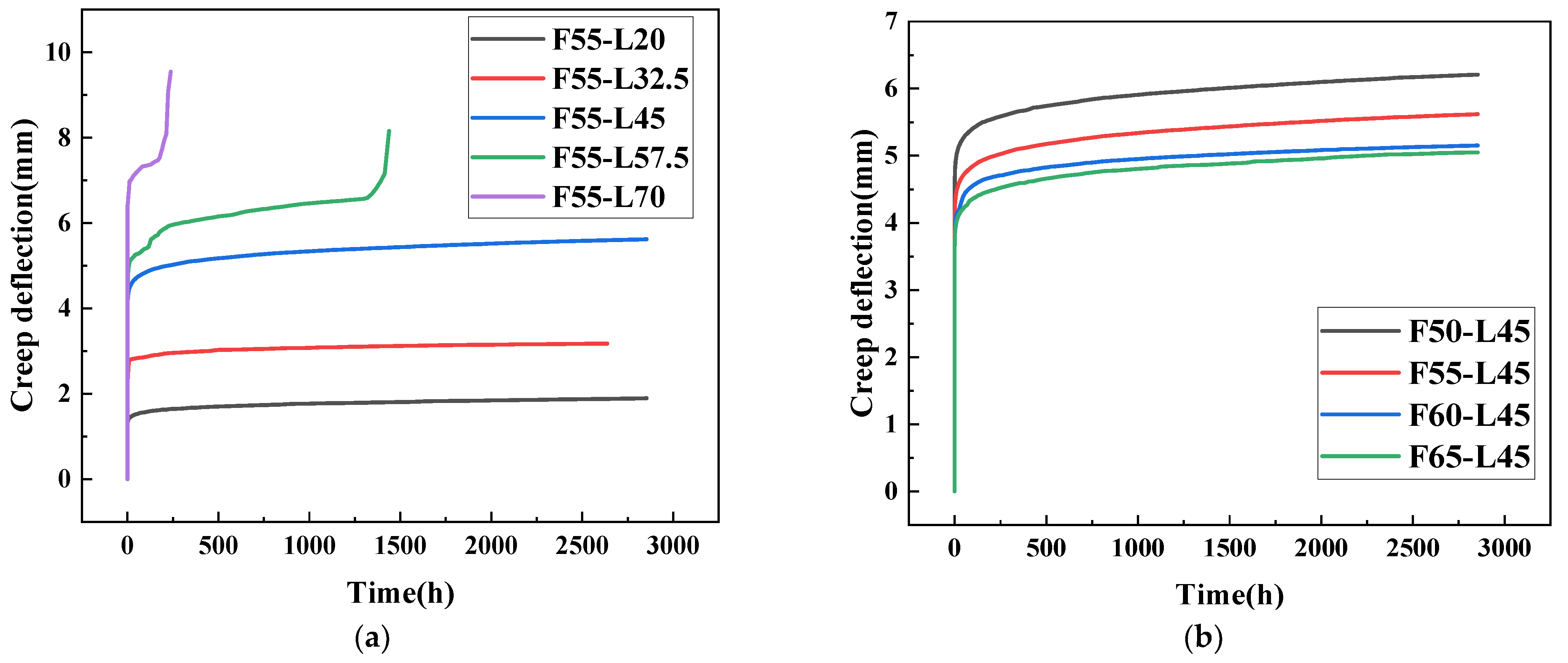

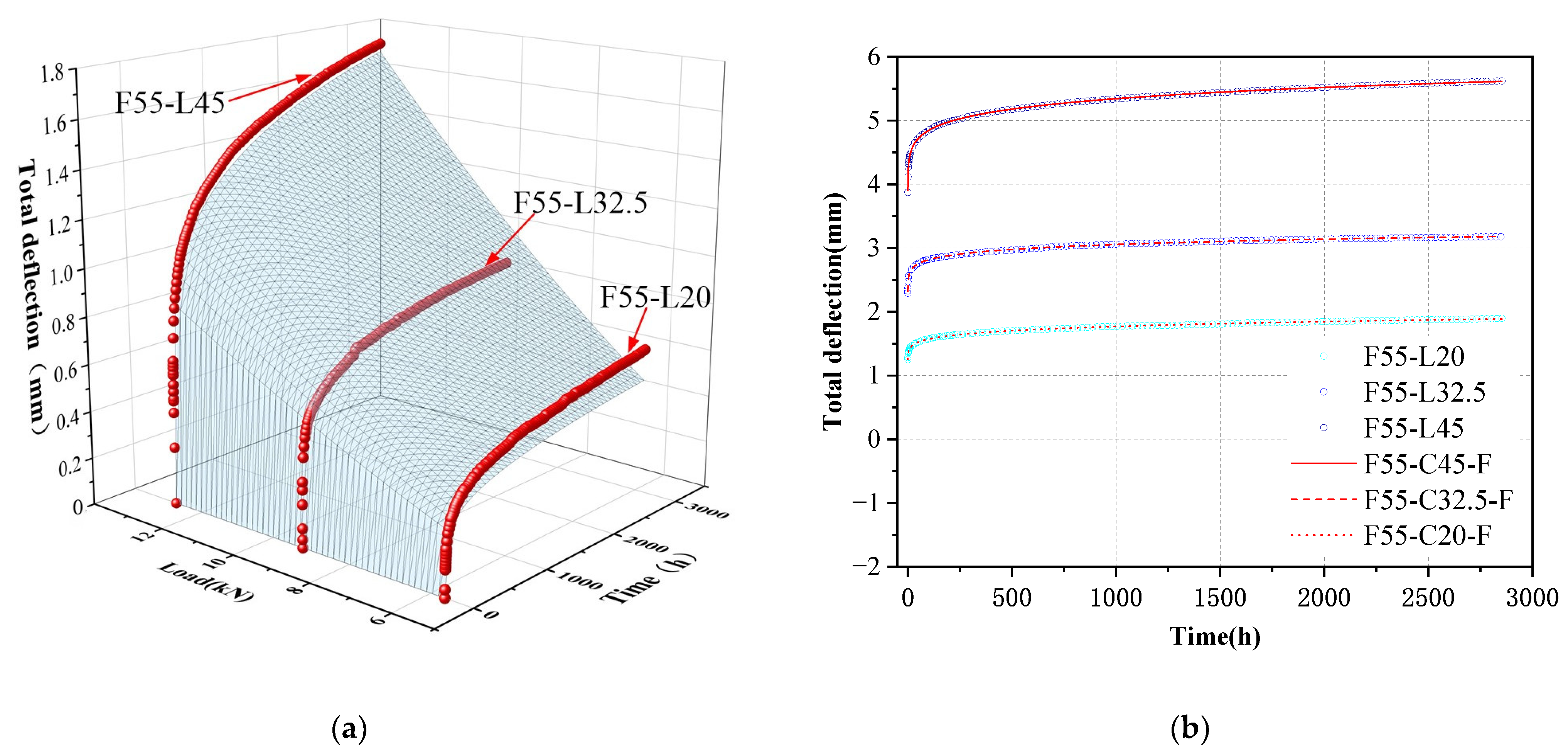

3.2. Bending Creep Results

4. Creep Predictions

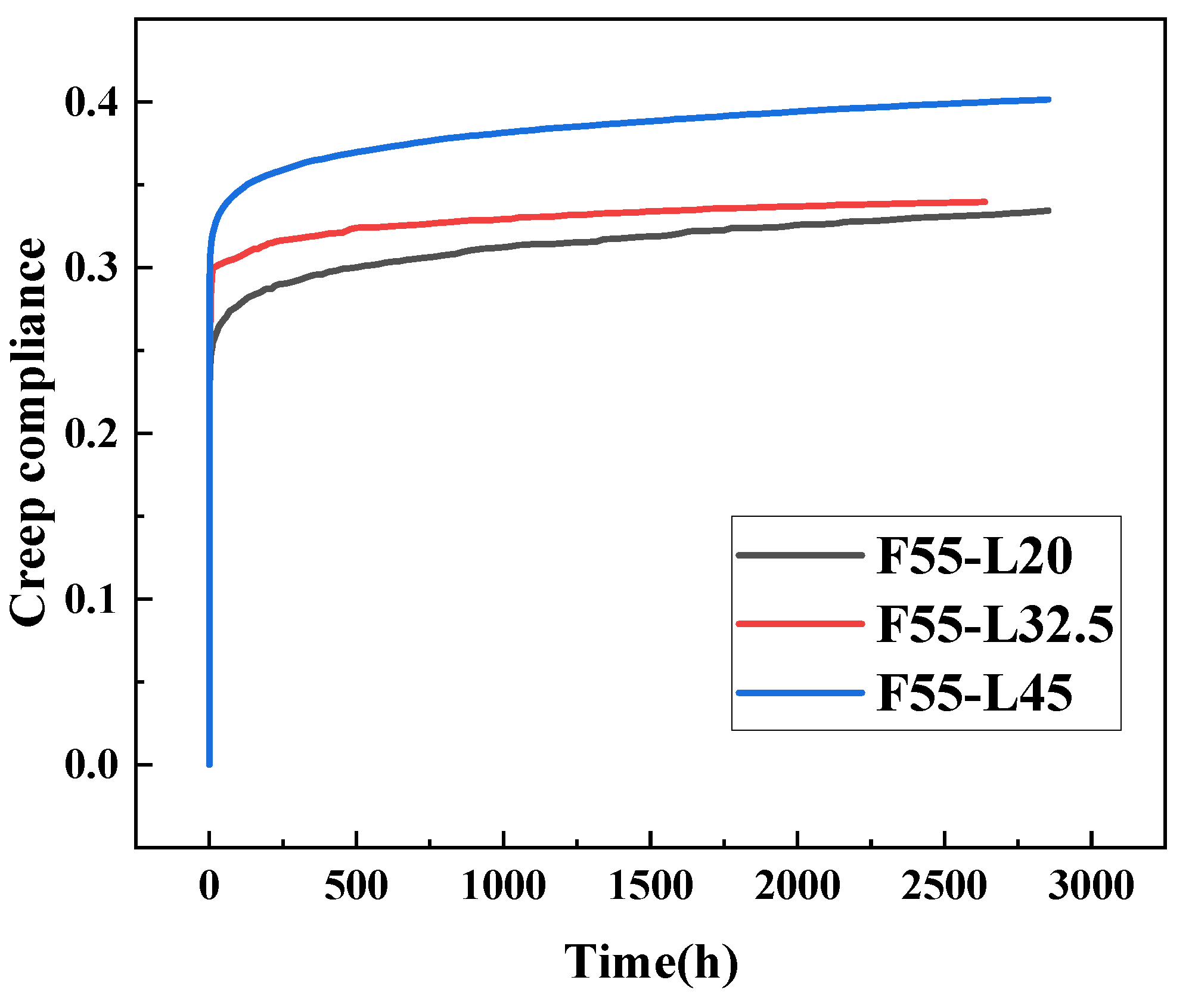

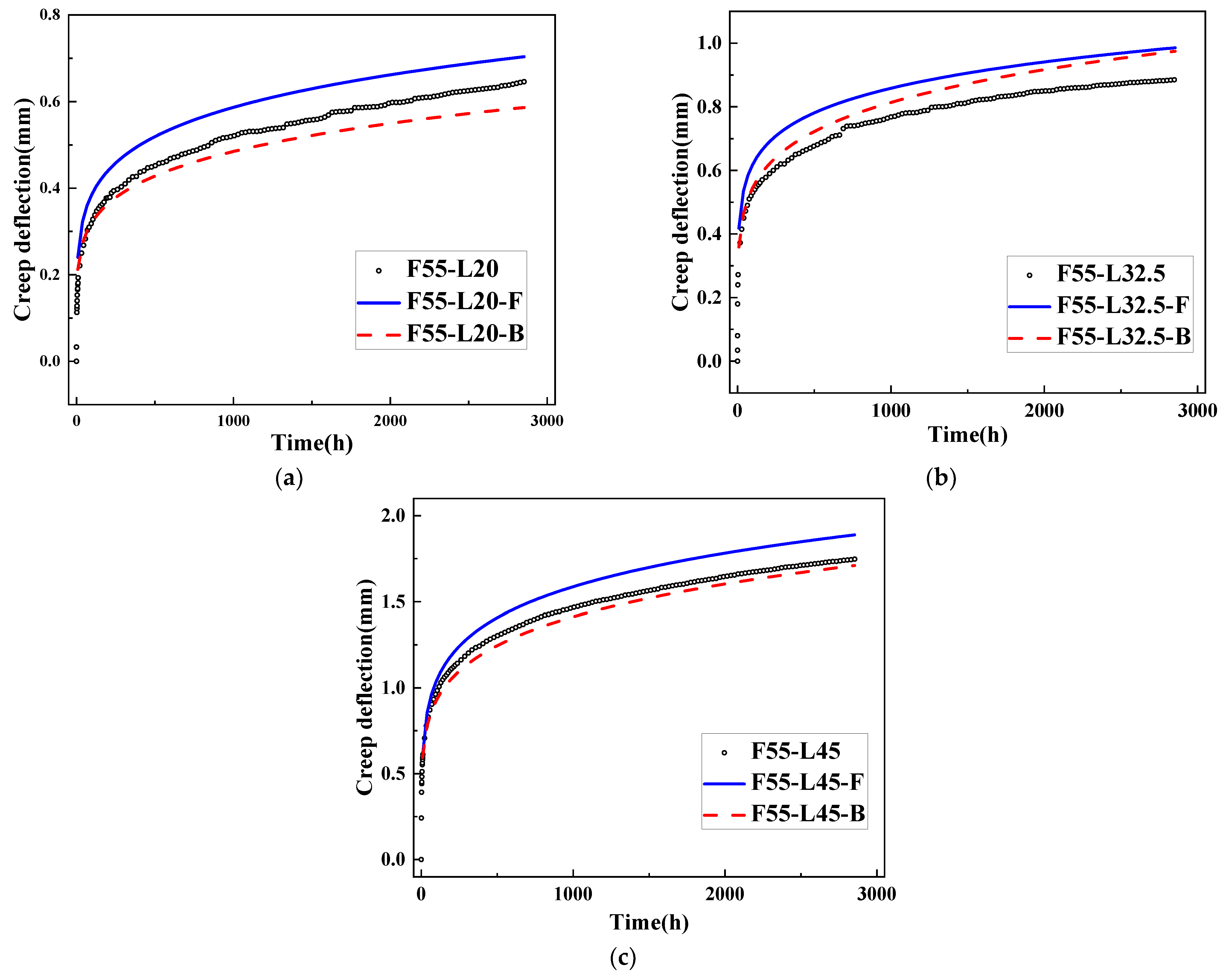

4.1. Prediction of Creep Deflection

4.2. Prediction of Creep Life

5. Relevance of this Research for Practical Implementation

6. Conclusions

- The results reveal that the creep behavior of the GFRP pultrusion tubes exhibits linear viscoelasticity when the load level is below 45%. In terms of creep deflection, the Findley model exhibits superior fitting performance compared to the Bailey–Norton model for the creep curves at 20% and 32.5% load levels. The maximum error between its total deflection curve’s fitted values and the test values is only 0.4%. This is because the Findley model takes into account not only the deflection changes during the creep stage but also the initial static deflection of the specimens.

- After establishing a clear definition of the creep stages, a distinct transition point from the primary creep stage to the second creep stage at 300 h can be prominently observed for the load levels of 20%, 32.5%, and 45%. Creep failure is observed in specimens subjected to load levels of 57.5% and 70%, with corresponding failure times of 107.88 h and 9.84 h. As the load level increases, the specimen’s time to failure significantly decreases, indicating that the load level has a crucial impact on the creep behavior of GFRP pultrusion tubes. Furthermore, with increasing load levels, the failure mode gradually shifts from shear failure of the web to overall bending failure. By comparing the time required for Mu to decrease to M and the time required for shear creep of the web leading to shear failure, a reasonable explanation can be provided for distinct failure modes exhibited at different load levels. When the time required for Mu to decrease to match M is longer than the time needed for web shear failure to occur, shear failure takes place. Conversely, when the time for Mu to decrease to match M begins to approach or becomes less than the time needed for web deformation to induce shear failure, overall bending failure occurs.

- Based on experimental results and the Findley model, a method has been proposed for predicting the creep life of GFRP composite pultrusion tubes. This method allows for the derivation of predictive formulas for creep life, and computed results show a good agreement with experimental findings. However, since this method solely considers the influence of load levels, further research is needed in the future to investigate the impact of other parameters (e.g., temperature and humidity) on creep life.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- National Natural Science Foundation of China, Chinese Academy of Sciences. Development Strategy of Disciplines in China: Civil Engineering and Engineering Mechanics; Science Press: Beijing, China, 2016.

- Shen, G.L. Mechanics of Composite Materials; Tsinghua University Press: Beijing, China, 1996. [Google Scholar]

- Hu, Q.; Duan, Y.; Liu, Z.; Zheng, X.; Xu, Z. Current status of carbon fiber reinforced polymer composites recycling and re-manufacturing. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar]

- Chen, R.; Cheng, L.; Gu, J.; Yuan, H.; Chen, Y. Research progress in chemical recovery technology of fiber-reinforced polymer composites. CIESC J. 2023, 74, 981–994. [Google Scholar]

- Wu, J.; Zhu, Y.; Li, C. Experimental Investigation of Fatigue Capacity of Bending-Anchored CFRP Cables. Polymers 2023, 15, 2483. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Oh, H. Comparison between Multiple Regression Analysis, Polynomial Regression Analysis, and an Artificial Neural Network for Tensile Strength Prediction of BFRP and GFRP. Materials 2021, 14, 4861. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Shi, J.; Huang, Z. Application of composite materials in marine vessels. Glass Fiber Reinf. Plast./Compos. 2012, 2, 269–273. [Google Scholar]

- Yue, Q.; Yang, Y. Review of durability research on fiber-reinforced composite strengthened structures. J. Build. Struct. 2009, 30, 8–15. [Google Scholar]

- Teng, J. New material composite structures. J. Civ. Eng. 2018, 51, 1–11. [Google Scholar]

- Ye, L.; Feng, P. Application and development of FRP in engineering structures. J. Civ. Eng. 2006, 3, 24–36. [Google Scholar]

- Mario, F.S.; Augusto, M.G.; João, R.C.; Nuno, S. Flexural creep response of pultruded GFRP deck panels: Proposal for obtaining full-section viscoelastic moduli and creep coefficients. Compos. Part B Eng. 2016, 98, 213–224. [Google Scholar]

- Bottoni, M.; Mazzotti, C.; Savoia, M. Creep tests on GFRP pultruded specimens subjected to traction or shear. Compos. Struct. 2014, 108, 514–523. [Google Scholar] [CrossRef]

- Zou, X.X.; Lin, H.W.; Feng, P.; Bao, Y.; Wang, J.Q. A review on FRP-concrete hybrid sections for bridge applications. Compos. Struct. 2021, 262, 113336. [Google Scholar] [CrossRef]

- Scott, D.W.; Zureick, A.H. Compression creep of a pultruded e-glass/vinylester composite. Compos. Sci. Technol. 1998, 58, 1361–1369. [Google Scholar] [CrossRef]

- Liu, X. Research on Long-Term Performance and Prediction Methods of FRP Pultruded Profiles in Marine Environment. Ph.D. Thesis, Tsinghua University, Beijing, China, 2021. [Google Scholar]

- Lu, Z.; Zhang, Q.; Cao, Y.; Luo, F.; Liu, M. Calculation method for flexural behavior of concrete beams strengthened with FRP profiles. J. Wuhan Univ. Technol. 2021, 43, 54–58. [Google Scholar]

- Lu, Z.; Luo, F.; Zhang, Q.; Cao, Y.; Liu, M. Experimental study on flexural capacity of concrete beams strengthened with GFRP profiles. J. Wuhan Univ. Technol. (Transp. Sci. Eng. Ed.) 2023, 274, 1–8. [Google Scholar]

- Liu, D.Q. Mechanical Performance Study of CFPR Angle Steel Tube Concrete Pure Bending Members with Embedded I-Shaped CFRP Profiles. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2019. [Google Scholar]

- Fei, H.Y.; Zhao, J.Y.; Cui, B.J.; Chen, X.B.; Yan, C.R. Performance study of continuous glass fiber mat/polyester insulation profiles. Insul. Mater. 2020, 53, 6–9. [Google Scholar]

- Feng, X.; Li, G.C.; Yang, Z.J.; Cao, W.Z. Study on bidirectional eccentric compression performance of long columns with square steel tube and embedded I-shaped CFRP profiles. Adv. Struct. Steel Res. 2021, 23, 32–42+52. [Google Scholar]

- Li, A. Experimental Study and Theoretical Analysis of Flexural Performance of GFRP Profile-Concrete Composite Beams. Master’s Thesis, Hunan University of Science and Technology, Xiangtan, China, 2018. [Google Scholar]

- Zhang, Z.W. Study on Flexural Performance of FRP Profile-Concrete Composite Beams. Master’s Thesis, Yangzhou University, Yangzhou, China, 2022. [Google Scholar]

- Li, X.; Liu, W.; Fang, H.; Huo, R.; Wu, P. Flexural creep behavior and life prediction of GFRP-balsa sandwich beams. Compos. Struct. 2019, 224, 111009. [Google Scholar] [CrossRef]

- Li, X.; Liu, W.; Fang, H.; Huo, R.; Wu, P. Flexural creep behavior of web reinforced GFRP-balsa sandwich beams: Experimental investigation and modeling. Compos. Part B 2020, 196, 108150. [Google Scholar] [CrossRef]

- Dutta, P.K.; Hui, D. Creep rupture of a GFRP composite at elevated temperatures. Compos. Struct. 2000, 76, 153–161. [Google Scholar] [CrossRef]

- Zhang, X.G.; Zhang, Y.B. Study on the bending creep behavior of glass fiber reinforced vinyl resin composite. Aviat. Manuf. Technol. 2013, 45, 71–72+79. [Google Scholar]

- Xu, B.; van den Hurk, B.; Lugger, S.J.D.; Liu, T.; Blok, R.; Teuffel, P. Effect of environmental humidity on the creep behavior of flax fiber-reinforced polymer composites. Polym. Compos. 2023, 44, 6108–6121. [Google Scholar] [CrossRef]

- Pavlović, A.; Donchev, T.; Petkova, D. Analytical Estimation of the Creep Behaviour of Basalt FRP Bars Below the Creep Rupture Limit. Build. Future Durable Sustain. Resilient 2023, 349, 739–746. [Google Scholar]

- Alhayek, A.; Syamsir, A.; Supian, A.B.M.; Usman, F.; Najeeb, M.I.; Asyraf, M.R.M. A Mathematical Model of Flexural-Creep Behaviour for Future Service Expectancy of a GFRP Composite Cross-Arm with the Influence of Outdoor Temperature. Fibers Polym. 2023, 24, 2425–2437. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Syamsir, A.; Alhayek, A.; Asyraf, M.R.M.; Itam, Z. The Reduction Factor of Pultrude Glass Fibre-Reinforced Polyester Composite Cross-Arm: A Comparative Study on Mathematical Modelling for Life-Span Prediction. Material 2023, 16, 5328. [Google Scholar]

- Shi, H.; Liu, W.; Fang, H. Damage characteristics analysis of GFRP-Balsa sandwich beams under four-point fatigue bending. Compos. Part A Appl. Sci. Manuf. 2018, 109, 564–577. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, W.; Ling, Z.; Fang, H.; Jin, D. Mechanical performance of GFRP-profiled steel sheeting composite sandwich beams in four-point bending. Compos. Struct. 2018, 206, 921–932. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, N.; Deng, J.; Smith, G. Flexural creep behavior of sandwich panels containing Kraft paper honeycomb core and wood composite skins. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2011, 528, 5621–5626. [Google Scholar] [CrossRef]

- Tweedie, C.A.; Van Vliet, K.J. Contact creep compliance of viscoelastic materials via nanoindentation. J. Mater. Res. 2006, 21, 1576–1589. [Google Scholar] [CrossRef]

- Du, Y.; Yan, N.; Kortschot, M.T. An experimental study of creep behavior of lightweight natural fiber-reinforced polymer composite/honeycomb core sandwich panels. Compos. Struct. 2013, 106, 160–166. [Google Scholar] [CrossRef]

| Specimen ID | Number of Specimens | Fiber Content (%) | Load Level (%) | Load (kN) |

|---|---|---|---|---|

| F50-L100 | 5 | 50 | 100 | 27.68 |

| F55-L100 | 5 | 55 | 100 | 28.34 |

| F60-L100 | 5 | 60 | 100 | 30.97 |

| F65-L100 | 5 | 65 | 100 | 31.01 |

| Specimen ID | Number of Specimens | Fiber Content (%) | Load Level (%) | Load (kN) |

|---|---|---|---|---|

| F55-L20 | 5 | 55 | 20 | 5.67 |

| F55-L32.5 | 5 | 55 | 32.5 | 9.21 |

| F55-L45 | 5 | 55 | 45 | 12.75 |

| F55-L57.5 | 5 | 55 | 57.5 | 16.30 |

| F55-L70 | 5 | 55 | 70 | 19.84 |

| F50-L45 | 5 | 50 | 45 | 12.46 |

| F60-L45 | 5 | 60 | 45 | 13.94 |

| F65-L45 | 5 | 65 | 45 | 13.95 |

| (a) Creep test results of square tube with different glass fiber contents under 45% load level | ||||

| Specimen ID | Static Deflection(mm) | Total Deflection (mm) | Creep Deflection (mm) | Creep Coefficient |

| F50-L45 | 4.377 | 6.208 | 1.831 | 0.42 |

| F55-L45 | 3.873 | 5.620 | 1.747 | 0.45 |

| F60-L45 | 3.585 | 5.155 | 1.570 | 0.44 |

| F65-L45 | 3.498 | 5.050 | 1.550 | 0.44 |

| (b) Creep test results of square tube with 55% glass fiber content | ||||

| Specimen ID | Static Deflection (mm) | Total Deflection (mm) | Creep Deflection (mm) | Creep Coefficient |

| F55-L20 | 1.250 | 1.896 | 0.646 | 0.51 |

| F55-L32.5 | 2.291 | 3.176 | 0.885 | 0.39 |

| F55-L45 | 3.873 | 5.620 | 1.747 | 0.45 |

| F55-L57.5 | 4.457 | 6.588 | 2.131 | 0.48 |

| F55-L70 | 6.335 | 7.465 | 1.130 | 0.19 |

| Specimen ID | di | a | N | De | DF | Error (%) |

|---|---|---|---|---|---|---|

| F55-L20 | 1.104 | 0.230 | 0.154 | 1.896 | 1.8877 | 0.43 |

| F55-L32.5 | 1.857 | 0.616 | 0.096 | 3.176 | 3.1825 | 0.20 |

| F55-L45 | 3.154 | 1.011 | 0.112 | 5.620 | 5.6141 | 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, K.; Wang, Y.; Fang, H.; Qian, C.; Wu, P. Experimental Investigation and Prediction for Bending Creep of Glass Fiber-Reinforced Polymer Pultruded Tube. Buildings 2023, 13, 2714. https://doi.org/10.3390/buildings13112714

Cheng K, Wang Y, Fang H, Qian C, Wu P. Experimental Investigation and Prediction for Bending Creep of Glass Fiber-Reinforced Polymer Pultruded Tube. Buildings. 2023; 13(11):2714. https://doi.org/10.3390/buildings13112714

Chicago/Turabian StyleCheng, Kaige, Yaohui Wang, Hai Fang, Changgen Qian, and Peng Wu. 2023. "Experimental Investigation and Prediction for Bending Creep of Glass Fiber-Reinforced Polymer Pultruded Tube" Buildings 13, no. 11: 2714. https://doi.org/10.3390/buildings13112714

APA StyleCheng, K., Wang, Y., Fang, H., Qian, C., & Wu, P. (2023). Experimental Investigation and Prediction for Bending Creep of Glass Fiber-Reinforced Polymer Pultruded Tube. Buildings, 13(11), 2714. https://doi.org/10.3390/buildings13112714