Abstract

With the sharp increase in global energy demand, industrial and residential buildings are responsible for around 40% of the energy consumed with most of this energy portion being generated by non-renewable sources, which significantly contribute to global warming and environmental hazards. The net-zero energy building (NZEB) concept attempts to solve the global warming issue, whereby a building will produce, on-site, its required energy demand throughout the year from renewable energy sources. This can be achieved by integrating photovoltaic (PV) building materials, called building-integrated photovoltaic (BIPV) modules, throughout the building skin, which simultaneously act as construction materials and energy generators. Currently, architects and builders are inclined to design a building using BIPV modules due to the limited colors available, namely, black or blue, which result in a monotonous building appearance. Therefore, there is an increasing demand/need to develop modern, aesthetically pleasing BIPV green energy products for the use of architects and the construction industry. This review article presents the current stage and future goal of advanced building integrated photovoltaic systems, focusing on the aesthetically appealing BIPV systems, and their applications towards overcoming global challenges and stepping forward to achieve a sustainable green energy building environment. Additionally, we present the summary and outlook for the future development of aesthetically appealing building integrated photovoltaic systems.

1. Introduction

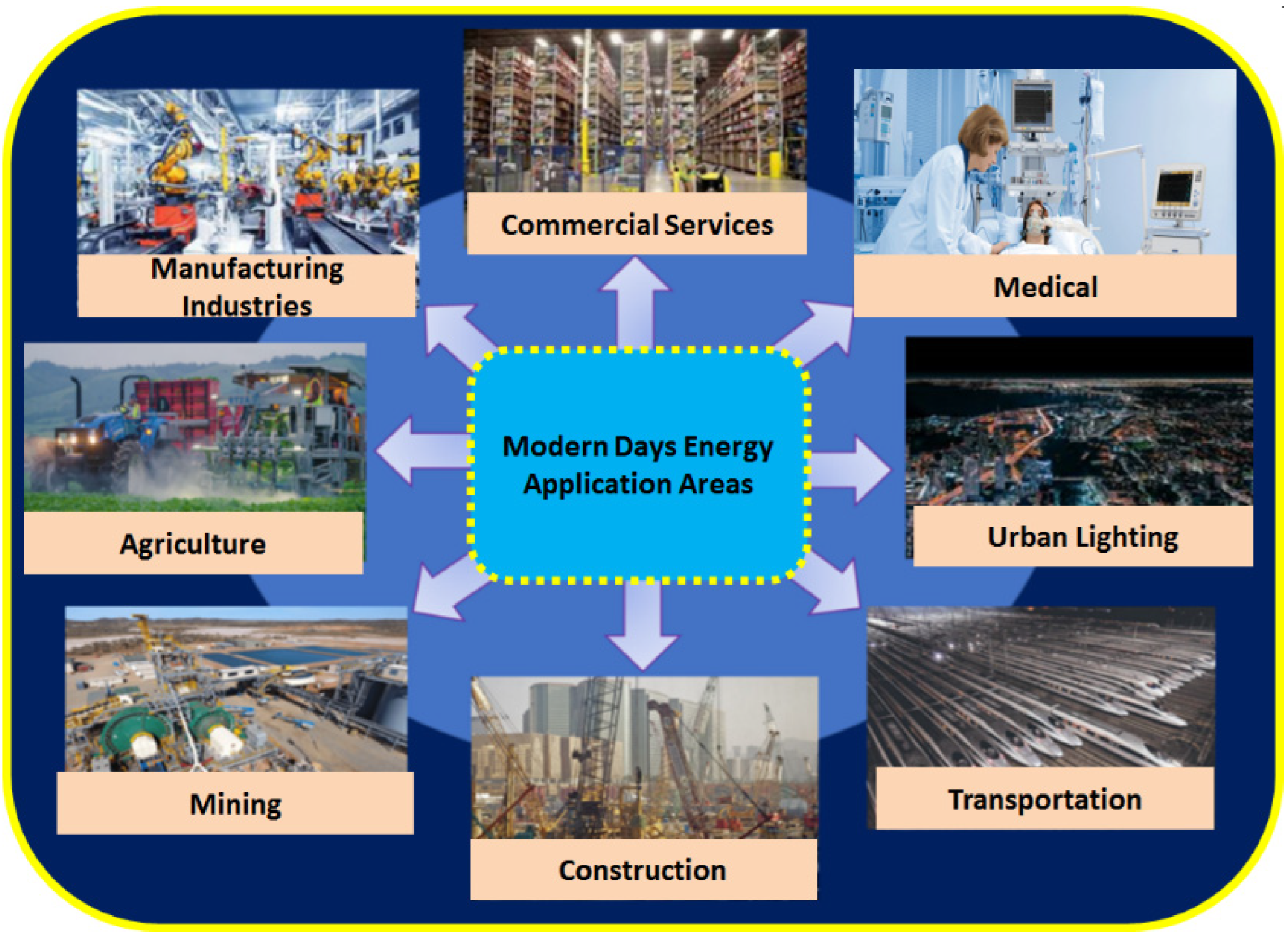

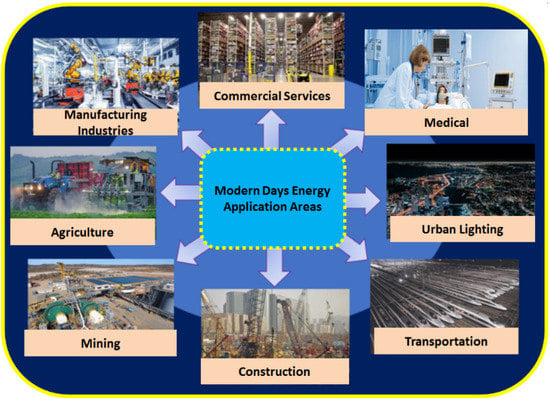

Due to the industrial revolution and the growth in the global population over the past few decades, energy consumption has grown worldwide. By 2050, there will likely be close to 13 billion people on the planet. With such a sizable population and rising industrialization, more energy will be needed to sustain a typical and sustainable way of life. Global energy consumption is anticipated to surpass 0.74 billion Tera Joule (BTJ) by 2040 [1], and around 22.7 billion tons of fossil fuel, primarily anthracite coal, are needed to meet this energy requirement [2]. With increasing industrialization, today’s modern infrastructure, including residential and commercial buildings, use substantially more energy than they did ten years ago. Whilst this increasing industrialization has offered social benefits and financial support to the world population, it has resulted in the migration of more and more people from rural to urban areas, and currently, 30–40% of global energy generated through different means is consumed by buildings and construction infrastructures [3,4,5]. As two-thirds of the world’s population is expected to reside in urban areas by 2050, there will be a huge energy demand to ensure economic and social growth [4]. Environmental risks and global warming brought on by non-renewable fossil fuel-based energy sources are forcing modern architects to consider climate change and on-site clean energy generation in their building designs [2]. In addition to climate change mitigation, employing sustainable renewable energy technology to prevent the use of non-renewable energy sources (oil, coal, and gas), which have been causing other horrendous environmental problems, such as the release of glasshouse gases, pollutants (such as trace metals, particulates, NOx, and SO2) into the atmosphere, tainted water from coal pollution, and unmanageable ash wastes [5]. Among the numerous technologies, photovoltaics (PV) is one of the most promising renewable energy technologies due to its two unique attributes, namely (i) simple and cost-effective, and (ii) low-maintenance operation. PV modules have no moving parts and convert solar energy into electrical energy in a very simplistic way compared to other conversion processes [6]. Figure 1 shows a glimpse of the key modern human civilization application areas where energy is one of the most important elements, besides other basic needs, to fulfill the demand of the world’s large population.

Figure 1.

A glimpse of the key modern human civilization application areas where energy is one of the most important elements.

The application of PV panels in built environments has achieved more popularity due to their capacity to turn a house into a power generator [7]. This is accomplished by integrating PV modules into the building during or after construction. A building-integrated photovoltaic (BIPV) system supplies buildings with electricity, and can be designed to have thermal and sound insulation properties [8,9]. For example, double-glazed semitransparent solar glass panels used as facade elements (instead of plain glass elements) provide protective shielding from smoke, noise, heat, and other weather changes, while generating on-site energy. With the increase in electricity tariffs worldwide and the decrease in the price of PV panels, BIPV systems are becoming cost-effective building materials [10], particularly the semi-transparent BIPV glass panels, which help reduce the power consumption of the building by allowing only a portion (e.g., 40%) of sunlight to enter the building while converting the remaining sunlight to electricity. Commercially available window-glass-based BIPV systems comprise low-emissivity (low-E) thin films in addition to PV panels, which filter and control the spectral components of sunlight, leading to high thermal insulation (less cooling/heating energy consumption), in addition to generating on-site energy [11,12].

BIPV systems have been widely adopted after the net-zero energy buildings (NZEB) concept was announced by the Directive of the European Parliament (2010/31/EU), stating that “all public buildings which are new must consume nearly zero-energy by 2018, and other new buildings by the end of 2020” [13]. The NZEB idea requires that buildings use as much energy as they produce on-site, using only renewable energy sources. The development of smart cities, where energy demand and supply are met by renewable energy sources and storage systems installed in the same city, offers the NZEB its greatest potential [3]. BIPV systems can therefore be used to meet the NZEB, aiming further to reach the goal of total zero-carbon built environment (ZCBE) [3,14,15,16]. According to the concise study found in Ref. [17], significant efforts have been made over the past 20 years to hasten the adoption of solar-electric systems by creating PV products that are completely integrated with building materials. The NZEB requirements have caused the worldwide BIPV industry to exceed yearly installations of 1 GW in the previous few years. The California Public Utilities Commission (CPUC) has established several NZEB targets, including requiring all new residential and commercial construction in the State to be net zero energy buildings by 2020 and 2030, respectively, and demanding retrofitting of 50 percent of existing buildings to meet NZEB targets by that same year [18,19].

Even though BIPV systems can generate power at a low cost when considering both the function of energy generators and the materials used in construction, the predicted BIPV adoption has been overstated. There are also obstacles and constraints, including specifications for design flexibility, aesthetics, durability, cost, performance, grid integration, standard compliance, and operation and maintenance [8,17]. On the other hand, due to the visual and aesthetic limitations of BIPV systems, which display black or dark blue colors depending on the photovoltaic technology employed, modern civilizations still have a negative attitude towards the application of BIPV technology [20,21,22,23,24,25,26,27,28,29,30,31]. To identify significant knowledge gaps in education, target audiences, and teaching objectives, Momir Tabakovic et al. have conducted a comprehensive study on the development of BIPV systems [23], with the issue of “aesthetics” being the topic of most importance, followed by BIPV software/tools, market maturity, and building envelope material attributes, as recommended by renowned BIPV experts and stakeholders. According to statistics, more than 85% of architects and building designers select BIPV products because of their aesthetic qualities rather than their high costs or low conversion efficiencies [32]. To increase public satisfaction and installation rates, BIPV products with apparent transparency, coloring, and adequate conversion efficiency are appealing [8,33,34,35]. However, to reach the NZEB goals and simultaneously protect the environment by lowering the energy demand (fossil fuels based), it is crucial to come across the issues related to the development of visually pleasing and high-performing BIPV products. Many studies have been conducted and reviewed the BIPV system in terms of products properties [36,37], technologies [38], economic analysis [39,40], energy performance evaluation [41], thermal performance [42], design tools [43,44], barriers, and facilitators [45,46]. However, it is quite tough to present state-of-the-art BIPVs in a single review study. According to our knowledge, no studies so far have been conducted to review the performance of aesthetics of the BIPV products, which is the most desired selection criterion for customers.

In this article, we utilize the required knowledge of BIPVs to identify the major issues related to the development of aesthetically attractive BIPV products for the future global PV market and stakeholders. We present the status and challenges of aesthetically pleasing BIPV technologies, products, and their applications, and possible future development techniques to improve simultaneously the physical appearance and electrical performance of BIPV products. We focus on the development of micro-patterned-based-semitransparent thin-film PV panels (multicolored) using a direct printing process of colored (high-definition) images.

2. Current Status and Applications of Aesthetically Attractive BIPV Products

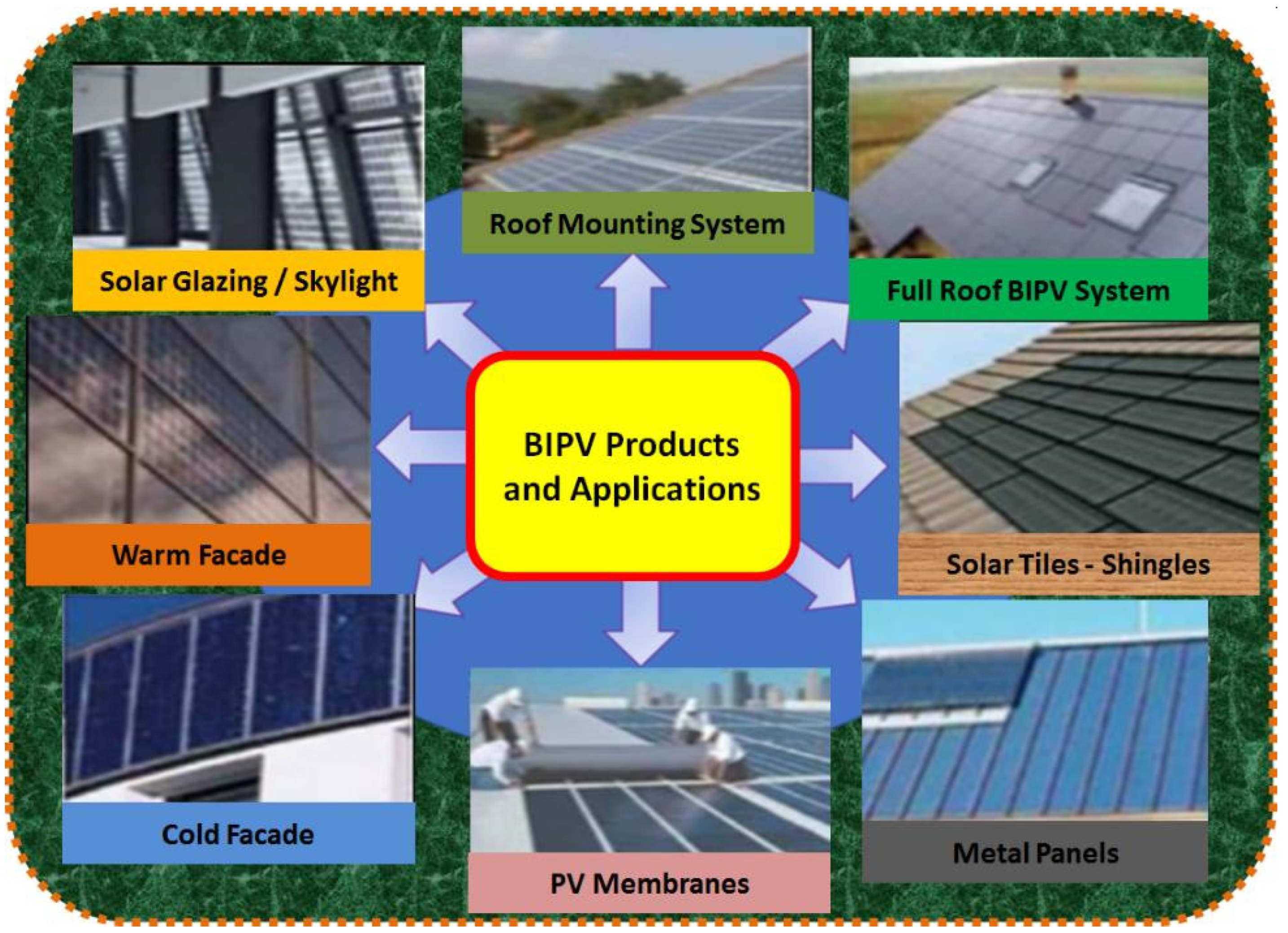

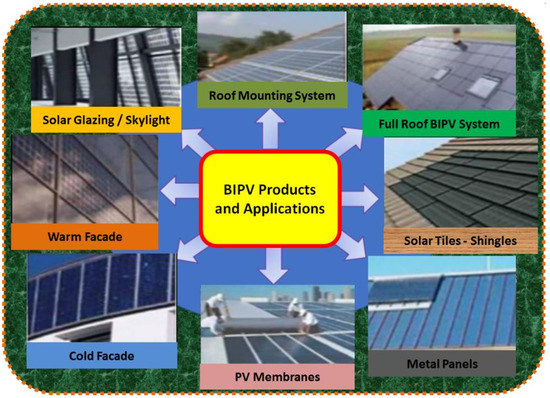

The integration of photovoltaic modules into buildings is possible on flat roofs, sloping roofs, facades, and solar shading systems. BIPV systems, on the other hand, replace the exterior skin of the structure, acting as both a temperature control system and a source of energy production. Therefore, in addition to saving money on electricity, BIPV may also result in material and labor savings [9]. Due to their broad categories, many distinct subcategories may be used to group BIPV products. According to a report on the most common applications of BIPV in Europe [23], two-thirds of BIPV applications are achieved in new construction, with one-third in retrofitted projects. Around 50% of the BIPV components are installed in roof facades, 25% on roofs, with the remaining components being a combined roof/facade product. Residential buildings account for 19% of BIPV installations. In contrast, historic structures, public infrastructure, showroom offices, universities, and schools account for 7%,14%, 13%, and 9%, respectively. Hotels, sports facilities, and agricultural structures are among the other structures that have been using BIPV. Currently, more than 200 BIPV products are commercially available that address the major application areas of pitched roofs, facades, and flat and curved roofs [23,47,48]. Figure 2 presents examples of common BIPV products and their application types.

Figure 2.

Example of BIPV products and their applications towards facing the green global challenges and achieving a sustainable green globe.

Visually appealing BIPV products have significant consumer demand despite having limited photo-conversion efficiency. Aesthetic attractiveness can be enhanced by transparent and colored BIPV products. The percentage of transparency and flexibility of color options defines the aesthetic of BIPV products. Therefore, a comprehensive review of the current trend and future developments of semitransparent and colored BIPV products can be helpful for the scientific community and the BIPV industry.

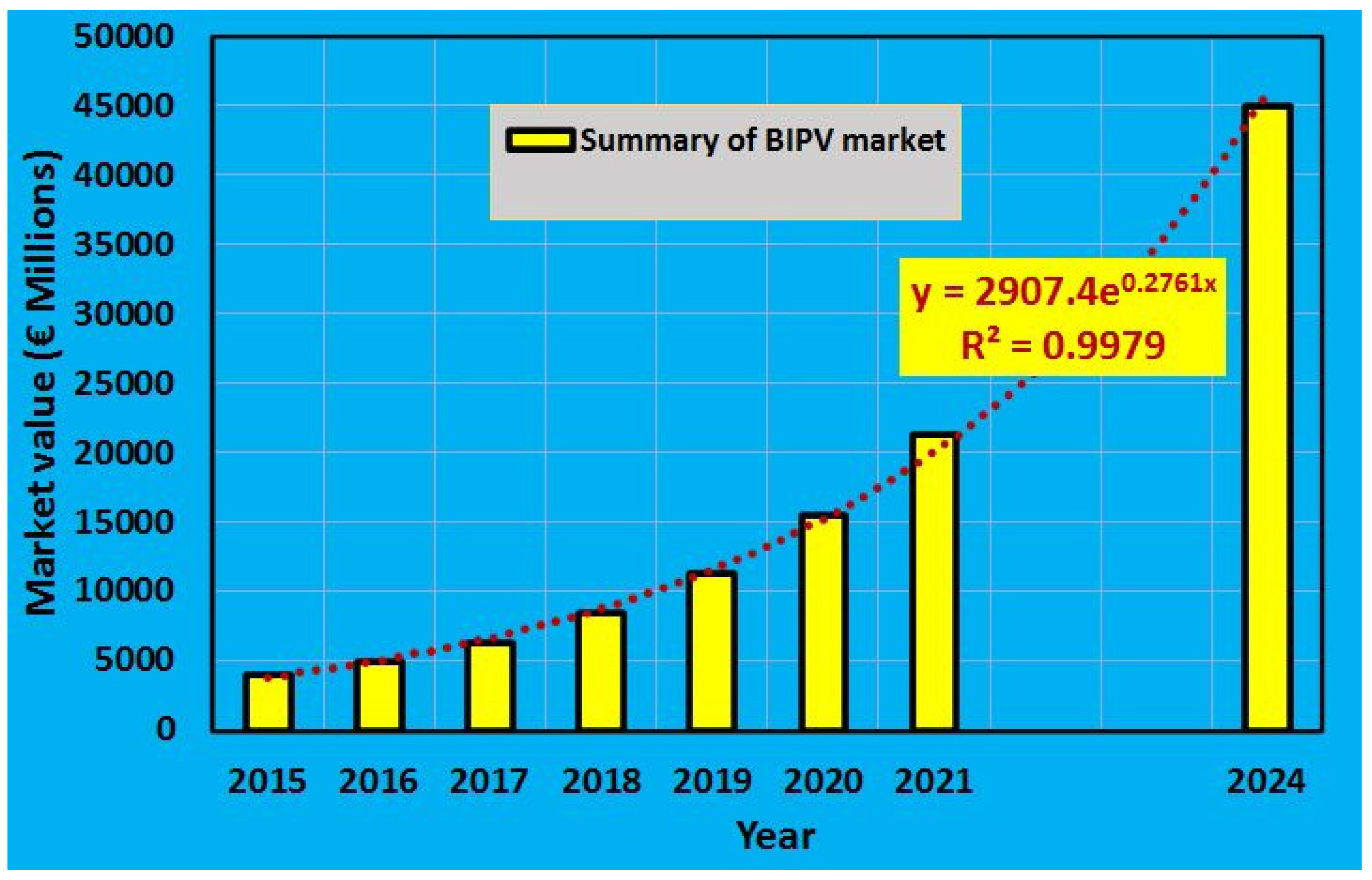

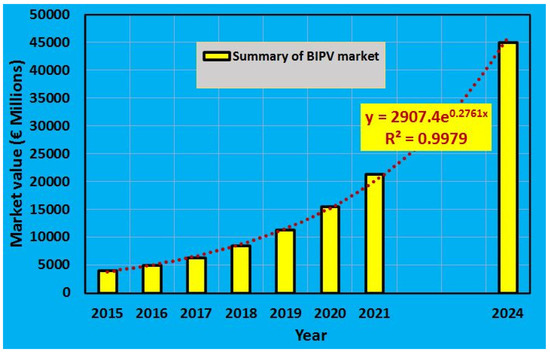

Many research groups have adopted different technologies for the development of transparent BIPV products, namely, windows, skylights, and curtain walls, driven by their high market demand. The overall market size of BIPV is presented in Figure 3. According to the report in Ref. [49], the price of BIPV products is now cost-effective compared to conventional building products and it will be even more cost-effective in the future. In addition to the need for efficiency and lifetime improvement, the BIPV products should have merit in their unique aesthetics and design considerations, such as color, transparency, flexibility, different form-factors, and even being indistinguishable from conventional construction materials, such as architectural glass.

Figure 3.

Summary of predicted BIPV technologies’ market shares. This figure is reproduced by using the data up to 2021 that is presented in Ref. [50]. The data are digitally extracted and may have some variations from the original presentation. The BIPV technologies market share can be expected to reach above 45,000 (€ Millions) if the energy market grows without global disruption.

Very few thin film-based BIPV module types exhibit a semitransparent appearance due to the use of transparent conductive oxides as electrodes in place of grey-colored metals. Though it is quite tough to create a BIPV module that is completely transparent since the PV active layer must absorb part of the incident light to turn it into energy, but it is possible to create an acceptable BIPV product with the help of modern technologies and advanced knowledge. Another option is to change the distance between the PV-active zones, which would increase the BIPV module’s transparency while simultaneously decreasing its area-specific efficiency. Typically, the BIPV system efficiency should be as high as possible, especially when the space on the roof and facade regions is limited [51].

2.1. Dye-Sensitized Solar Cells (DSSC) for BIPV Applications

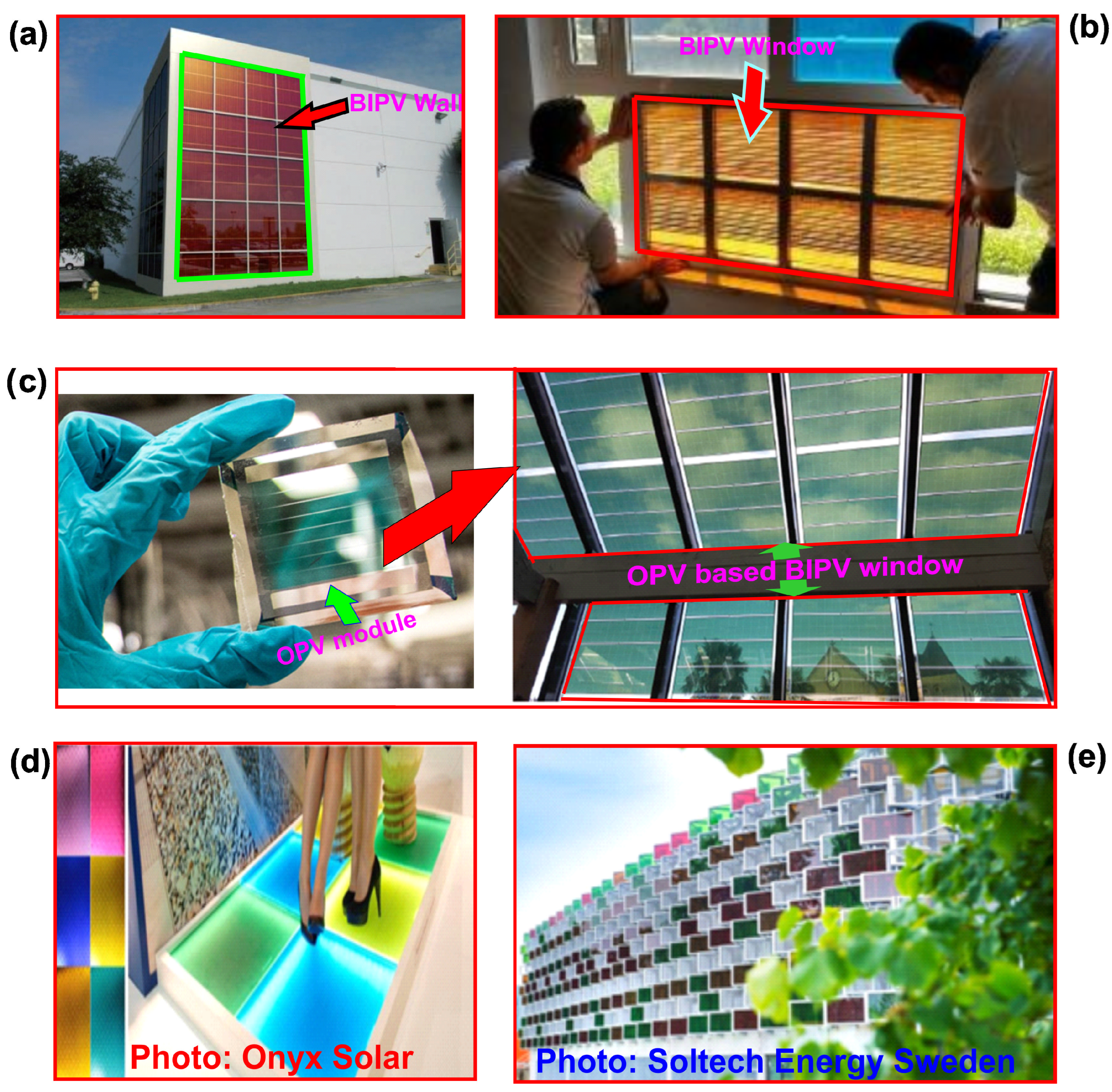

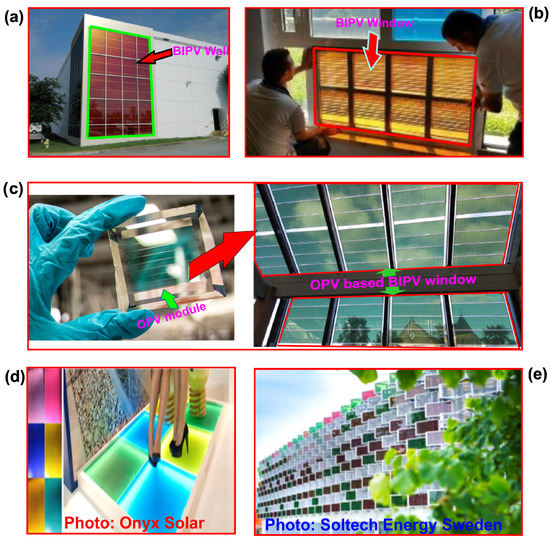

In 2007, Seigo et al. [52] developed a highly transparent dye-sensitized solar cell (DSSC) through a screen printing process, where a Titanium dioxide (TiO2) nanoparticles layer of 17 µm was printed on fluorine-doped tin oxide (FTO) coated glass. This screen-printed DSSC-PV device possessed around 60% transparency with 9.2% conversion efficiency. DSSC-based semi-transparent BIPV (orange-brown color) modules are installed as windows in the CSIRO Energy Institute, Australia [53,54]. Despite the simple fabrication process of screen-printed DSSC, the instability of liquid electrolytes at different temperatures makes it unfavorable for architects and building planners. Zhang et al., in 2015, fabricated TiO2 nanotube-based DSSCs using the electrophoretic deposition (EPD) method [55]. Transparency of this type of solar cell was achieved by properly controlling the length, thickness, and inner diameter of the nanotubes. This type of DSSCs exhibited an average transparency of 55% along with 7.10% photon conversion efficiency (PCE); however, the complicated fabrication procedure for these DSSCs makes them suitable for laboratory scales only [56]. Zhang et al. developed two transparent solar cell models based on quantum dots (QDs). In the first model, lead sulfide colloidal quantum dots (PbS CQDs) were used, which enable tuning the bandgap that matches the infrared spectral components of light. This PbS-based semi-transparent colloidal-quantum-dots-based solar cells (SCQDSCs), which were developed on transparent fluorine-doped tin oxide (FTO) glass, combining a Molybdenum trioxide (MoO3) film as a hole transporting layer (HTL) and TiO2 film as an electron transporting layer (ETL) that showed the AVT of around 22% and PCE of 3.88% only [50]. In the second solar cell model, Zhang et al. reduced the optical losses of the transparent Ag and Au electrodes by replacing them with a transparent nanolayered MoO3/Au/MoO3 (MAM) film structure that significantly increased the PCE to 5.4% and AVT to 24.1% [57]. These types of solar cells are still facing the problems of quantum dots loading and device stability, thus making them impractical commercially [58]. Figure 4 presents several examples of semitransparent and colored BIPV modules and their applications. A colored and semitransparent wall was developed by Konarka Technology, as indicated by the green line in Figure 4a, and a yellow-orange colored window based on DSSC technology developed by Daunia Solar Cell (Figure 4b) [54].

Figure 4.

Semitransparent and colored BIPV modules and their applications. (a) DSSC-based red-orange colored wall installation [54], which is marked by the Green rectangular line; System provider. Konarka Technology (this company is out of market [59]), (b) DSSC-based yellow-orange colored window installation marked by the red line; system provider: Daunia solar cell (reproduced and modified from Ref. [53]), (c) OPV module; (image courtesy: Robert Coelius/Michigan Engineering) (reproduced and modified from Refs. [60,61], and OPV based BIPV windows (photo courtesy. Dr. Renaud Demadrille (CEA Grenoble) and OPV modules are made by OPVIUS GmbH, Kitzingen, Germany. www.opvius.com, accessed on 20 November 2022 (reproduced and modified with permission from Ref. [62] (d) PVB polymer-based flooring products (reproduced and modified with permission from https://www.onyxsolar.com) [8], and (e) PVB polymer-based facade elements using thin-film technology (reproduced and modified with permission from www.soltechenergy.com) [8].

Dye-sensitized solar cells (DSSCs) exhibit great promise as a technology for generating electricity from sunlight due to their high efficiency and low cost. The efficiency of DSSCs can be optimized by increasing the fill factor, which is a metric that quantifies the cell’s ability to convert generated current into usable power. The short-circuit current density and open-circuit voltage are crucial factors that affect the electrical output of the cell. Stability is a key factor that influences the long-term viability of DSSCs and can be enhanced by employing stable dyes and electrolytes. Additionally, the incident photon-to-current efficiency and spectral response of DSSCs are significant performance parameters that determine the cell’s capability to convert various wavelengths of light into electrical energy. Through careful optimization of these performance parameters, DSSCs have the potential to emerge as a substantial source of renewable energy.

2.2. Organic Photovoltaic (OPV) Cells

Richard Lunt and his research group demonstrated a transparent organic photovoltaic (OPV) solar cell which absorbs near-infrared (NIR) wavelengths of light and transmits visible light only. This kind of OPV glass showed around 65% transparency with a small conversion efficiency of 1.3 (± 0.1) % only [63]. An organic solar cell having 10% efficiency together with 40% transparency has been developed for window applications by a research group at the University of Michigan, as can be seen in Figure 4c [61,62]. In addition, OPV manufacturing requires a very complex process of mixing multiple organic components, which typically have a limited lifetime, i.e., of a couple of years, which is much less than the 25-year lifetime of conventional inorganic solar panels. Neither OPV nor DSC has been able to increase their market share over a few years as was predicted. The product stability is poor and does not meet the standards of building materials (more than 20 years of functioning). However, vigorous DSC research efforts might create more potential BIPV devices over the next 10 years [54]. Chen et al., from the University of California, fabricated a transparent polymer solar cell (PSC) using solution processing technology, where a silver nanowire (AgNWs) coated organic conductor was used on the top of the front side electrode [64]. This PSC demonstrated an efficiency of around 4% and transparency of around 66% at 550 nm wavelength. The low efficiency and stability of such PSCs make them impractical for commercial applications. Onyx Solar, a solar panel manufacturer, has introduced PV-colored glasses that show different transparency levels with significant electrical, mechanical, optical, and thermal properties [8]. These colored products can be used in facades, skylights, flooring, canopies, and walkways as shown in Figure 4d. The Onyx technology involves laminating different polyvinyl butyral (PVB)-polymer colors with amorphous silicon solar cells. The colored polyvinyl butyral (PVB) encapsulants have also been developed SolTech Energy for building facades using CdTe-based thin-film solar panels (Figure 3e) [8]. However, in hot climates, the PVB interlayer typically softens when the PV module becomes warmer, at above 65 ℃, which significantly affects the panels’ performance [64].

2.3. Perovskite Solar Cells

A semi-transparent perovskite material-based solar cell was fabricated by the University of Antioquia, Spain [65] using an evaporation deposition technique. This single-junction perovskite solar cell contained a transparent methylammonium lead halide perovskite layer, which had lower bandgap energy than a photon leading to high near-infrared (NIR) absorption and visible light transmission, simultaneously. This semi-transparent perovskite solar cell exhibited transparency of 30% and a power conversion efficiency (PCE) of 6.4%. Additionally, a research team from Stanford University developed a tandem solar cell configuration using opaque electrode perovskite (1.1 eV bandgap) on the bottom cell and semi-transparent perovskite (1.7–1.8 eV bandgap) on the top [66]. This tandem perovskite solar cell structure exhibited around 12.7% efficiency and a 77% peak transparency at about 800 nm. Yu et al. reported a semi-transparent perovskite solar cell development that exhibited 10% transparency and 16.75% PCE, which was the highest efficiency of its kind [67]. However, perovskite-based solar cells have limited stability and higher volatility [62]. Whilst Patel et al. developed the first-ever ultraviolet (UV) sensitive semi-transparent heterojunction solar cell utilizing the configuration of Ag/CuOx/TiO2/FTO, where the p-CuOx/n-TiO2 layer was made extremely narrow (150 nm) [68]. On the other hand, Kang et al. have demonstrated a color-neutral, flexible, and high-efficiency transparent solar cell utilizing the freestanding structure of n-type crystalline silicon microwires (SiMWs) [69]. For TSCs, a p-type polymer layer was developed on top of an n-type flat-tip SiMWs to form a heterojunction. This type of TSC utilized the visible wavelengths of light, exhibiting 8% PCE with average transparency (AVT) of around 10% and structural flexibility. Furthermore, Lee et al. have fabricated a transparent monocrystalline silicon solar cell by creating periodic microholes, which are invisible to the human eye, on the bare silicon wafer [70]. These micro holes act as transmission windows that allow the transfer of incident light resulting in the transparent substrate. The remaining opaque areas were dedicated to harnessing the incident light and converting it to electricity. This type of solar cell showed a PCE of around 12.2% with an AVT of 20%.

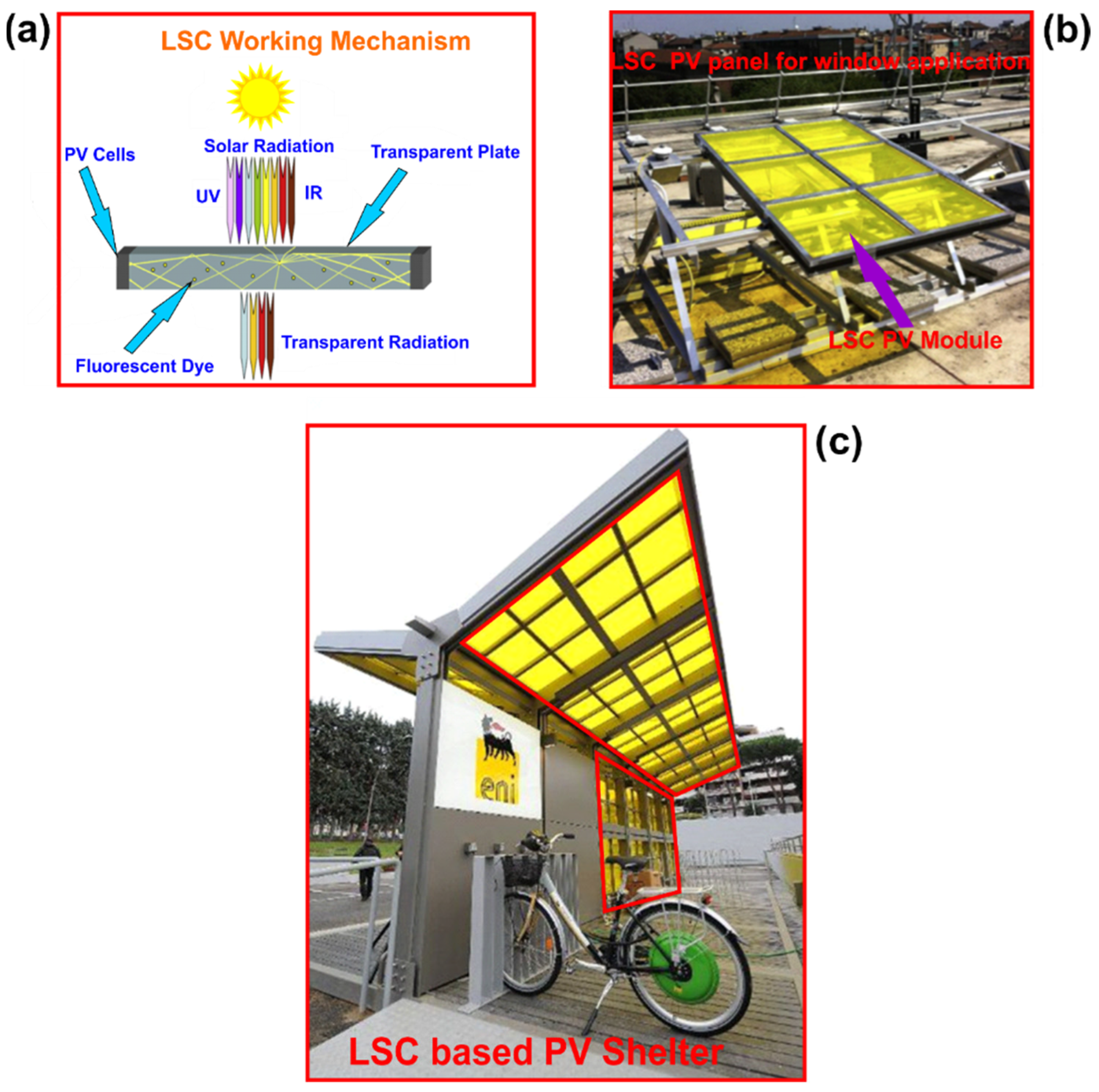

2.4. Luminescent Solar Concentrator (LSC) Based Transparent PV/BIPV Systems

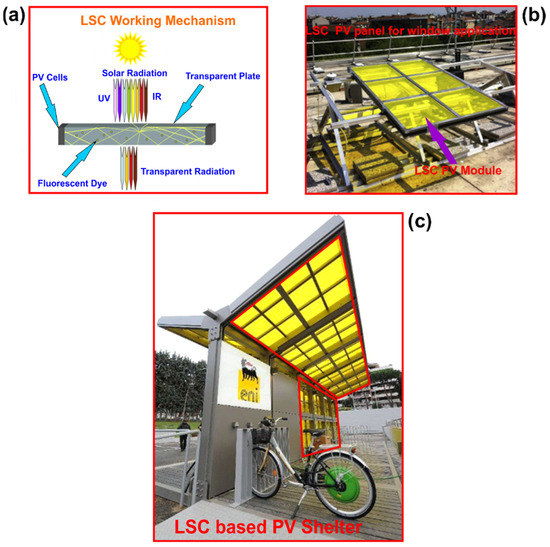

A research team from Michigan State University has developed highly transparent, about 86% AVT, solar cells using a transparent luminescent solar concentrator (TLSC) based on organic salts [71]. In this TLSC, transparent NIR fluorescent dyes were utilized to harness NIR and UV light and transform them into visible light, then guide them to reach the edges of the glass where the opaque solar cells are mounted to convert the routed light to electricity. Figure 5a–c presents the working mechanism of LSC base PV modules, including custom build LSC-PV-based window panels, and practically installed as BIPV products. This TLSC demonstrated a PCE of about 0.4% only. Increased efficiency of around 2.35% for a concentrated type of transparent PV structure was later developed using phosphor pigments based on inorganic luminescent materials, coating-based transparent heat mirror (near-IR) reflector at the rear side, transparent diffractive materials, and thin-film based CuInSe2 (CIS) PV modules at the edges [72]. The LSC-based semitransparent yellowish PV is shown in Figure 5b. In 2012, the Eni Research Center for Renewable Energy and the Environment in Novara successfully built an LSC-based BIPV shelter in Rome, Italy (shown in Figure 5c) to recharge electric bicycles and cars [73].

Figure 5.

(a) The working mechanism of an LSC PV module (source: ENI Donegani Institute) (reproduced and modified with permission from Refs. [74,75], (b) LSC-based window for BIPV (reproduced and modified with permission from Refs. [74,75], and (c) LSC-based BIPV shelter in Rome, Italy (reproduced and modified from [61,73]).

2.5. Thin Film Based Semitransparent/Highly Transparent PV Systems

2.5.1. Silicon-Based Thin-Film BIPV Systems

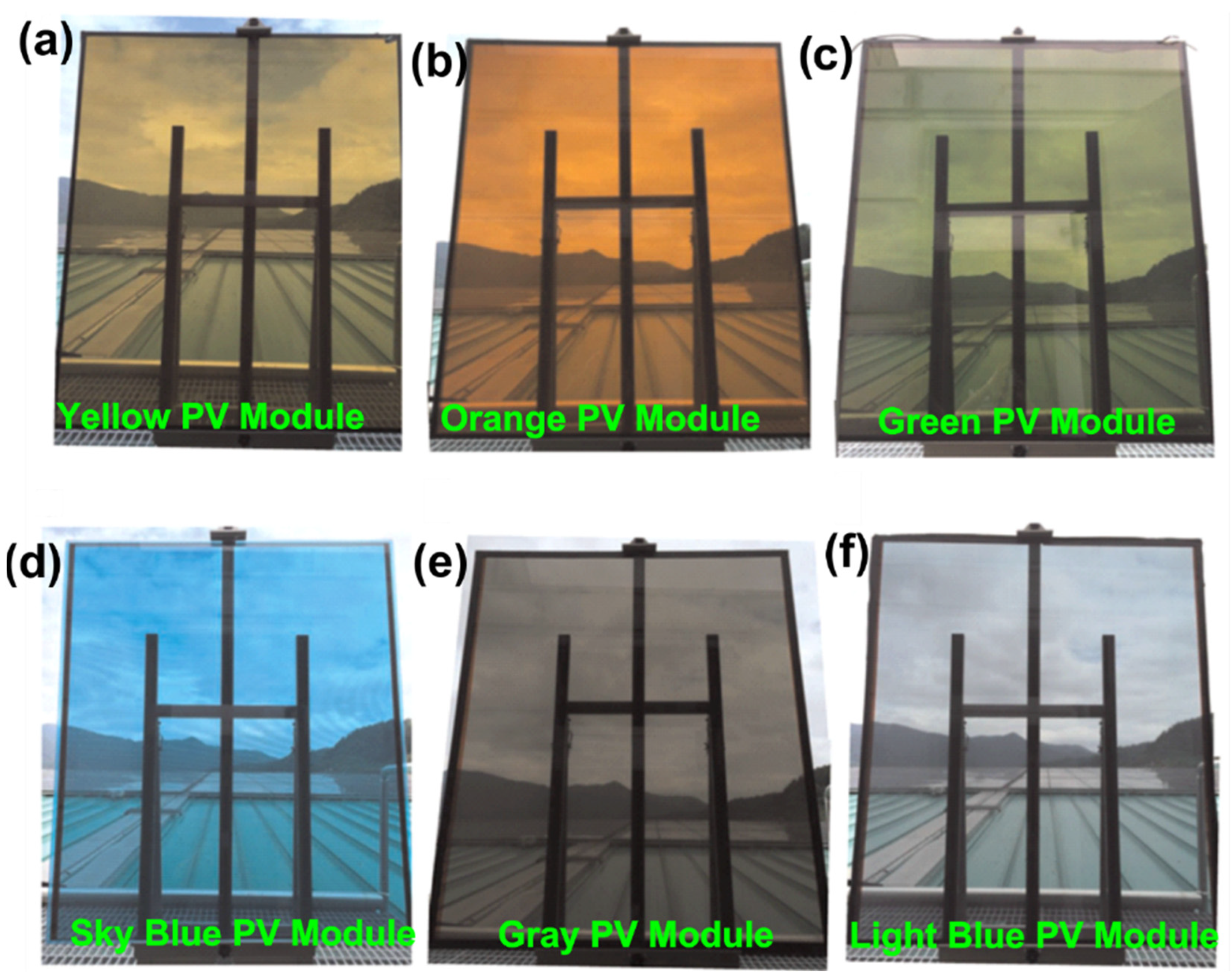

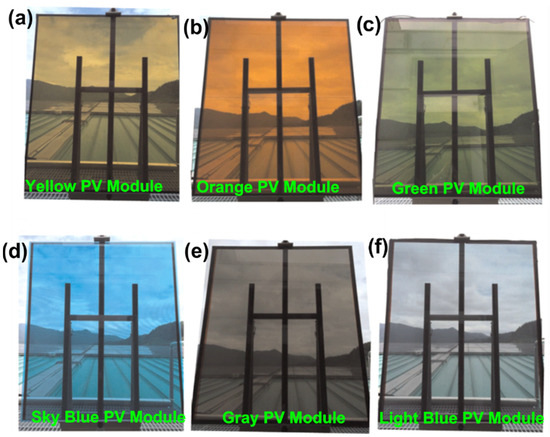

Lim et al. fabricated a thin-film-based full-penetration (FP) semitransparent hydrogenated amorphous silicon (a-Si. H) solar cell, where they used 115 nm thickness of absorber layer with triple high band (HB) layers that significantly increase the carrier collection and decrease the shunt loss. This type of cell offers a PCE of 6.92% and average transmittance (AVT) of 23.6% [76]. Several colorful semi-transparent glass-to-glass (GTG) photovoltaic (PV) modules for BIPV applications were designed and fabricated (shown in Figure 6) by S. Y. Myong et al. in 2015, and are based on large-area hydrogenated amorphous silicon (a-Si.H). The combination of back contact transparency and laser patterning processes enabled several color choices. Although these colorful PV modules are aesthetically pleasing, they are not suited for commercial use due to their reduced transparency and photo conversion efficiency [77].

Figure 6.

Front views of the fabricated a-Si:H semi-transparent glass-to-glass (GTG) PV module. (a) yellow PV module, (b) orange PV module, (c) green PV module, (d) sky blue PV module, (e) gray PV module, and (f) light blue PV module (reproduced and modified with permission from Ref. [77]).

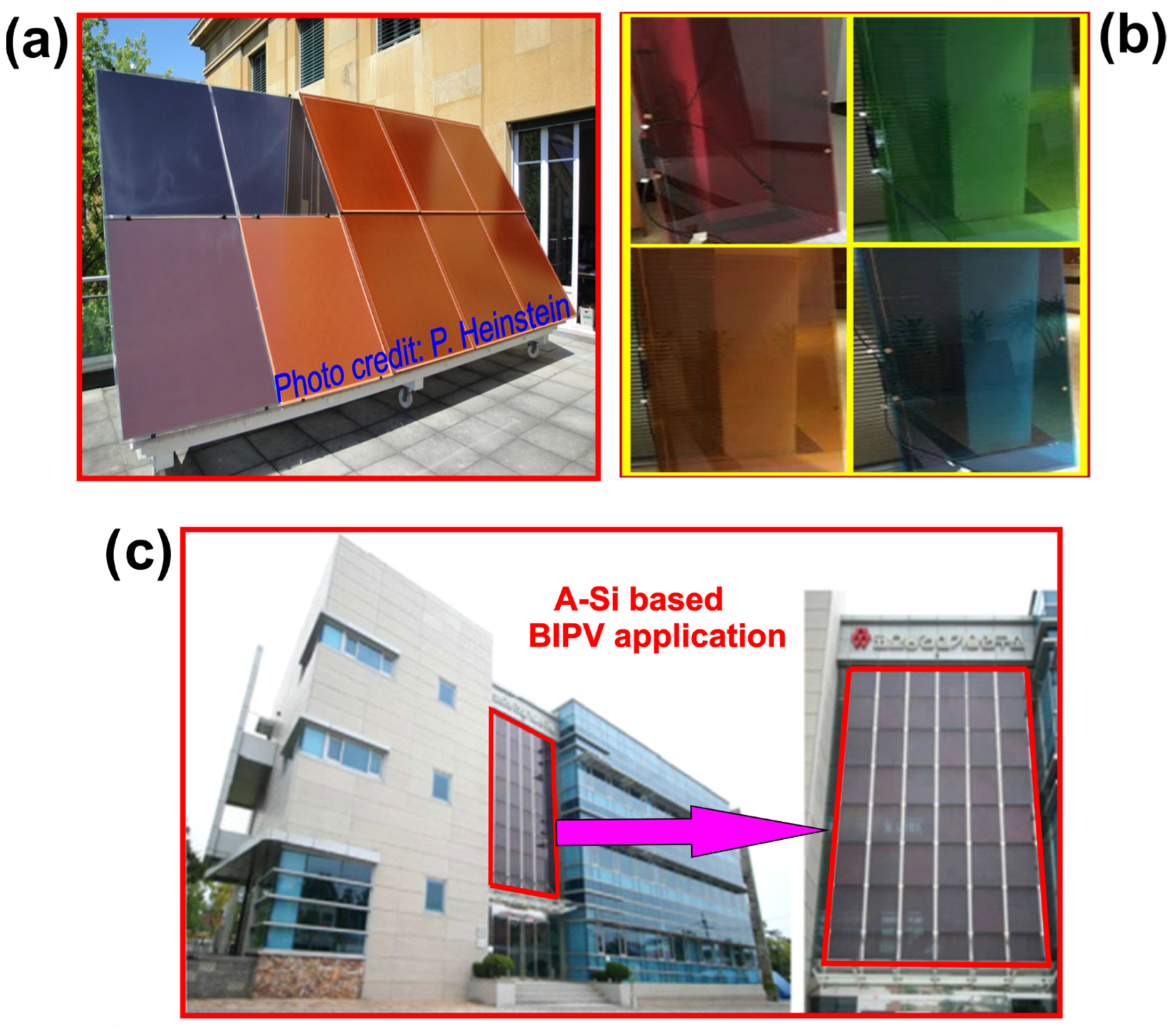

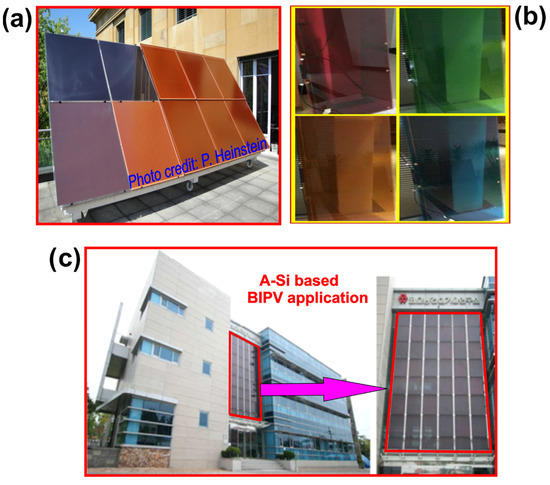

Figure 7 presents a glimpse of a-Si-thin-film-based colored BIPV modules and their possible applications. IMT Neuchatel (Switzerland) designed and developed the first ever fully homogenous terracotta-like a-Si thin-film PV module (Archinsolar), shown in Figure 7a, using a textured anti-reflective front glass [54]. Recently, Xiamen Solar First Energy Technology Co., Ltd. has commercialized four different colored semitransparent PV modules, which are very attractive, as shown in Figure 7b [78]. Jong-Ho Yoon et al. investigated transparent thin-film amorphous silicon-based BIPV modules installed at the front glass part of the newly constructed R&D Institute building of Kolon Engineering and Construction, Co., Ltd., which is in Yongin city, Gyeonggi, in the central region of Korea. A front view of the structure is shown in Figure 7c, along with the BIPV module that has been set up in the lobby. Similar amorphous thin-film-based BIPV modules, made by KANEKA, Japan, have been deployed in Japan [79].

Figure 7.

A-Si-based colored BIPV modules and their application. (a) First ever fully homogeneous colored BIPV products (reproduced and modified from [54]); (b) Four different colors commercialized PV modules (reproduced and modified from [78]); and (c) A-Si-based front surface building (reproduced and modified with permission from Ref. [79]).

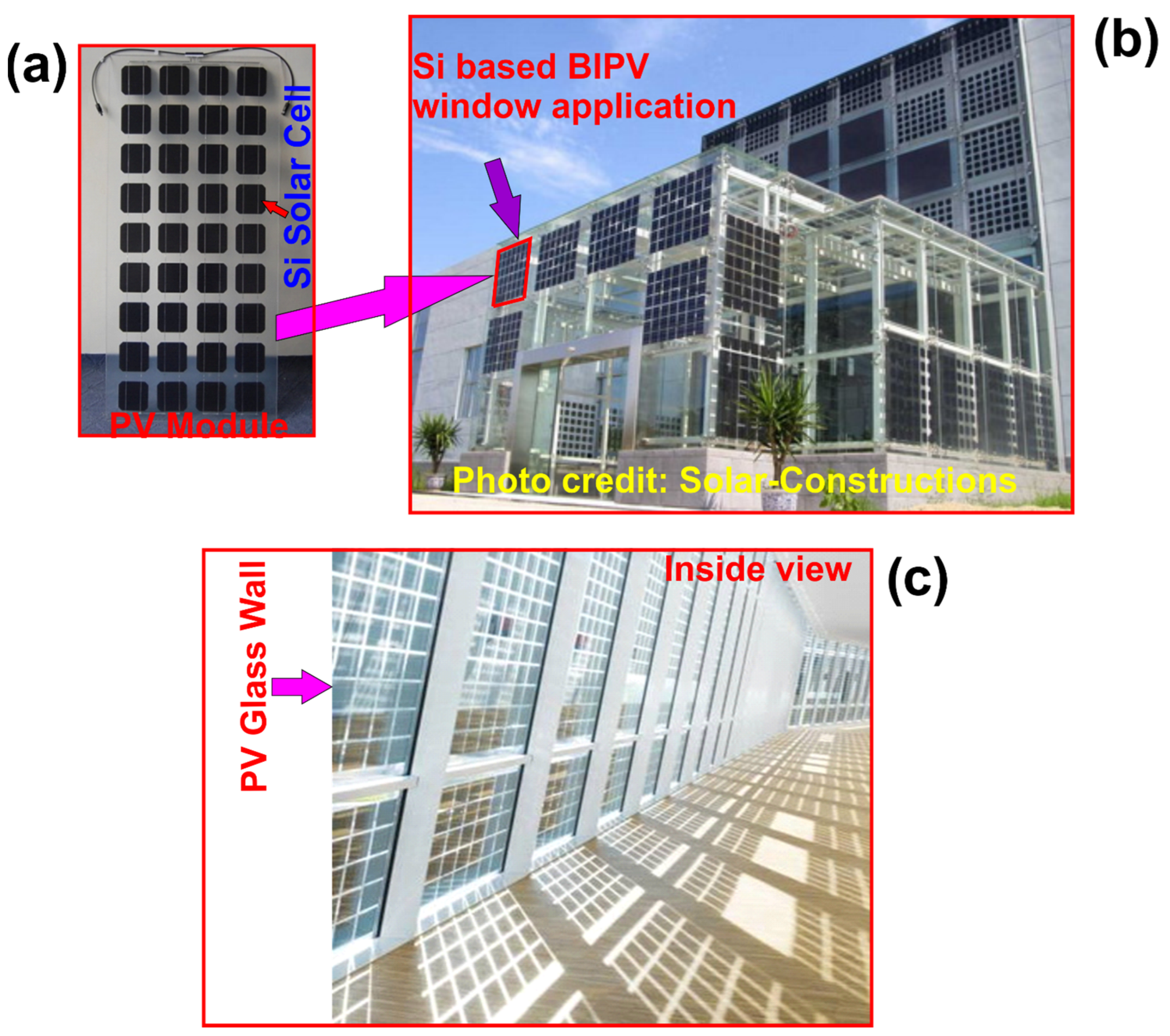

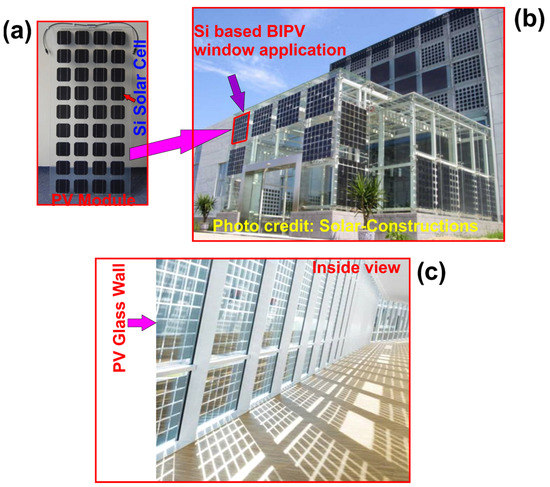

Solar Constructions [80] has designed and developed a silicon solar cell-based semi-transparent PV module by placing PV Cells on a panel of glass. The light transmission and, subsequently, the amount of shadowing supplied within the structure may be controlled by varying the spacing between Solar PV Cells. The transparency of such solar PV panels increases with the spacing between the cells; however, their PCE increases with the decrease of the space. Although these PV modules are mechanically stable and comparatively highly transparent and efficient, the inside views attained with a crystalline-Si semitransparent glass curtain wall look less appealing and very occluded by light and external view, hence causing visual fatigue, as shown in Figure 8 [80,81].

Figure 8.

Crystalline silicon-based BIPV (a) Si module (reproduced and modified with permission from Ref. [80]); (b) application in building (reproduced and modified with permission from [80]) [80]; (c) inside views attained with glass curtain wall (reproduced and modified from [81]).

2.5.2. Cadmium Telluride (CdTe) Based Thin-Film BIPV Systems

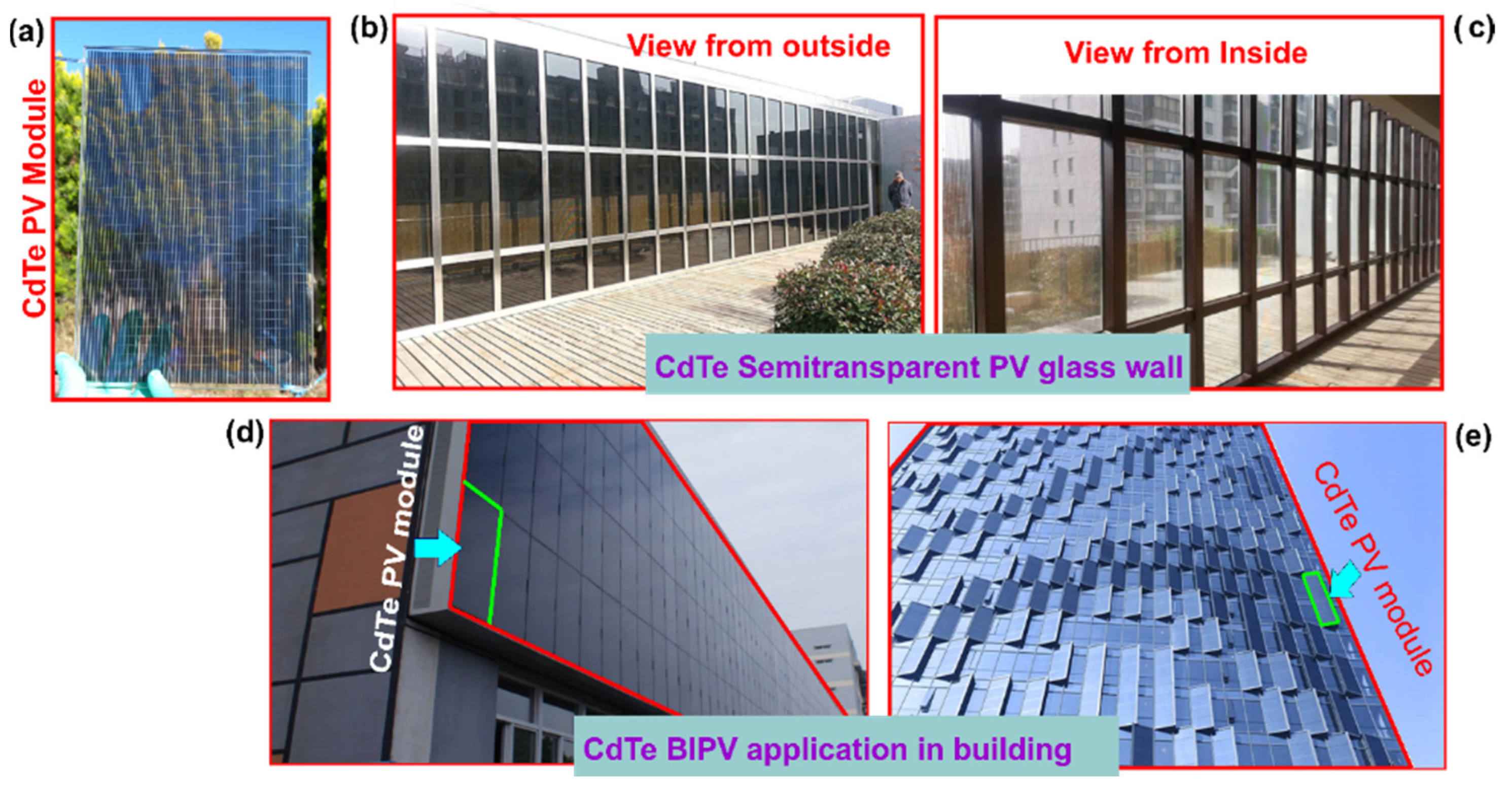

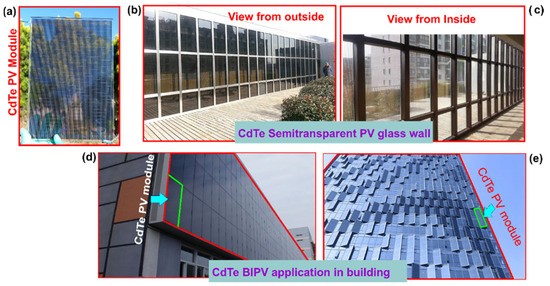

The most efficient semitransparent BIPV glass is that made by Advanced Solar Power (ASP)-China [82], which is based on thin-film cadmium telluride (CdTe) PV materials that are partially removed using laser micromachining to simultaneously achieve transparency and sunlight-to-electricity conversion. The ASP CdTe semitransparent PV glass shown in Figure 9a is currently the best BIPV option due to several reasons, namely: (i) relatively high efficiency (13% compared to 10% for the amorphous silicon counterpart and 3% for clear PV glass), (ii) most cost-effective (i.e., lowest $/peak-watt), (iii) easy to manufacture (compared to crystalline silicon semitransparent glass), (vi) arbitrary transparency (10–90%, depending on how much of the PV material is removed by laser micromachining), and (v) less shadowing effect, as illustrated in Figure 9b,c, which offers beautiful appearance, uniform lighting, and light transmission, hence, a clear exterior view. The BIPV application of CaTd-based PV panels as façade and curtain wall is shown in Figure 9d,e, respectively. Note that the amount of CdTe material in the overall thin-film PV material is ∼0.1% by weight, which is a minimal amount. In addition, because of (i) the small quantity, (ii) low solubility of CdTe, and (iii) module encapsulation, CdTe modules have been considered, at their end-of-life time, as non-hazardous waste according to the Toxicity Characteristic Leaching Procedure [83].

Figure 9.

CdTe-based semitransparent BIPV (a) ASP CdTe semitransparent PV module, (b) Outside view (reproduced and modified from [84]), (c) inside view (reproduced and modified from [84,85], (d) Application of CdTe Thin-Film based semi-transparent PV Glass as BIPV façade (reproduced and modified from [85] and (e) Application of CdTe Thin-Film based semi-transparent PV Glass as BIPV curtain wall (reproduced and modified from [85]).

Note that the development of semitransparent PV glass faces several challenges, namely: (i) selection of PV materials [86], (ii) fabrication processes that enable arbitrary transparency and minimum vision distortion, (iii) high insulation properties and (iv) cost-effectiveness [56]. Different semitransparent PV glass technologies are currently being developed worldwide; however, around 80% of these technologies are still in the initial commercialization stages (under development and trials). The remaining 20% of semitransparent PV glass types available in the market or are close to commercialization suffer from various issues [87], including instability, volatility, low transparency, low PCE, high cost, and complexity [56]. To create a clear PV glass, the thickness of the PV strips required to be made small enough that the naked eye cannot visualize them; however, these typically act as diffraction gratings, thus leading to visual distortion. Nevertheless, the use of nonuniform spacing between the PV strips, i.e., quasi-crystal (aperiodic) structure, can resolve this problem to develop low-distortion commercially acceptable BIPV modules. Researchers summarizes the overall key performance of different types of BIPV products and their techno-economic aspects [88,89,90,91].

3. Colored BIPV Systems, Status, and Challenges

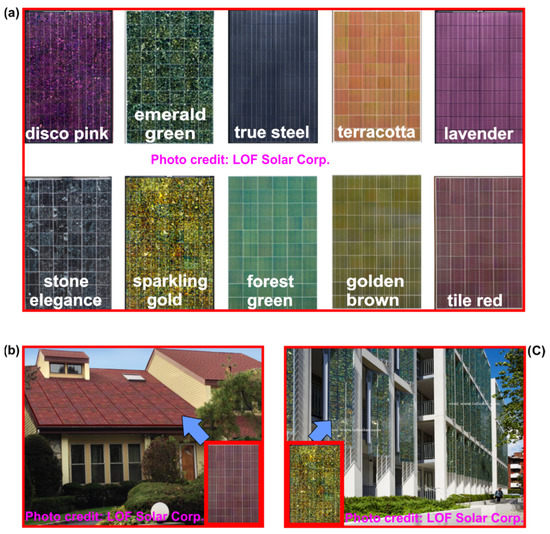

On the other hand, the colorization of the BIPV products has significantly enhanced the aesthetics of the building because the color is the primary element that draws attention to how a panel appears [35]. Colored BIPV is a novel approach to integrating colored PV panels into current and historic building types. The main goal is to conceal the PV cells and make them invisible [75]. Researchers and manufacturers have followed different approaches to develop colored opaque PV panels, namely: (i) solar cells with anti-reflection coating; (ii) colored polymeric encapsulant films; (iii) layers or interlayers containing solar filters, colored or patterned coatings; (iv) semi-transparent and/or colored PV-active layers; and (v) printed, coated, or finished front glass [87]. Several studies reported that modification of antireflection (AR) coatings and dielectric materials made of silicon nitride (SiNx) can generate a variety of colors in crystalline silicon solar cells [35,92,93,94]. Additionally, by manipulating the thickness of AR film, different colors, namely, yellow, blue, green, pink, and orange, can be generated on top of the silicon solar cells [8]. Lof Solar was the first and world-leading inventor in the development of high-efficiency-colored solar cells since 2008 [95]. It has commercialized different colored polycrystalline Si solar cells produced by changing the thickness of the AR coating, as shown in Figure 10a [95]. Figure 10b shows the red-colored PV panels applied on the rooftop of the building [96]. The facade of the Kingsgate House, West London (Figure 10c) has been designed by Harden Cherry Lee Architects (HCL) [97] using a LOF Sparkling Gold PV module [98]. This aesthetically appealing building façade has installed 8000 LOF BIPV modules that can generate 29 kW of electricity [98]. LOF Solar technology created several attractive colored solar cells by modification of the AR-layer thickness that lowers the cell efficiency [99].

CSEM [100], a private, non-profit Swiss research and technology organization, has developed a patterned/colored interlayer that can be laminated inside the PV module as an extra encapsulant and act as an optical filter that diffuses and reflects the incoming visible solar spectrum, thus producing white appearance, as shown in Figure 11, and transmitting the infrared spectrum through, which is converted to electricity. This technique typically reduces the PCE to around 40%, compared to conventional uncolored solar modules [8].

Figure 11.

White appearance BIPV products based on using solar filtering. (a) white appearance nano film, working mechanism, and PV module of CSEM technology, (b) White BIPV product integrated into a building (reproduced and modified with permission from Refs. [103,104]), (c) Mitrex solar façade layers (reproduced and modified from [105]), and (d) Application of Mitrex solar façade in building (reproduced and modified with permission from Ref. [106]).

Figure 10.

Crystalline Si-based opaque colored PV modules and their BIPV applications. (a) Various colored PV modules (reproduced and modified with permission from Ref. [95]), (b) red-colored BIPV rooftop application (reproduced and modified with permission from Ref. [101]), and (c) Sparkling gold BIPV façade application (reproduced and modified with permission from Ref. [102]).

Figure 10.

Crystalline Si-based opaque colored PV modules and their BIPV applications. (a) Various colored PV modules (reproduced and modified with permission from Ref. [95]), (b) red-colored BIPV rooftop application (reproduced and modified with permission from Ref. [101]), and (c) Sparkling gold BIPV façade application (reproduced and modified with permission from Ref. [102]).

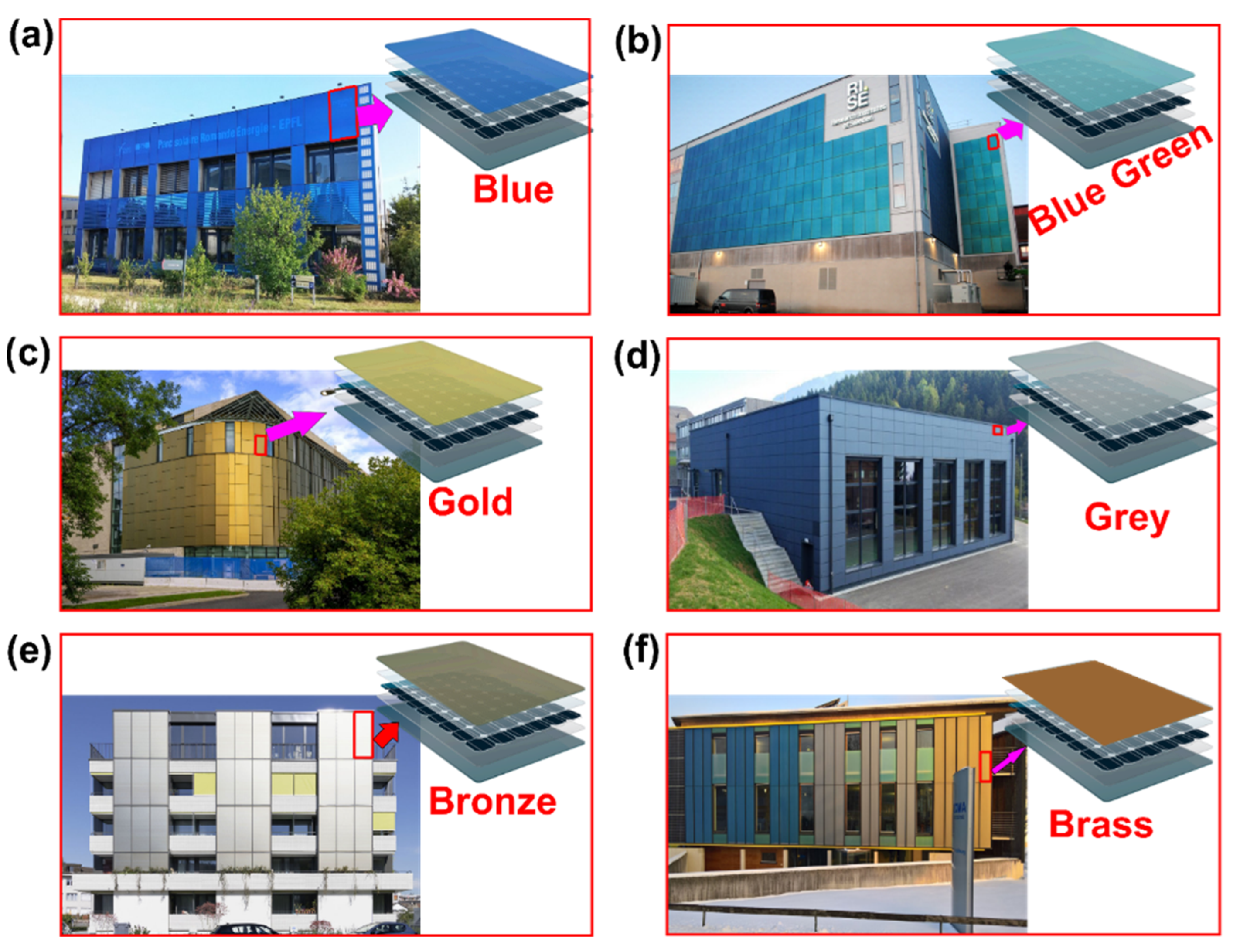

Many research groups and manufacturers have studied how to make PV panels more aesthetic and appealing by modifying the front glass cover of the solar panel. KromatixTM technology by SwissINSO has developed a reflective coating having multiple nanolayers of TiO2 and SiO2. To achieve high transmittance and colors that change depending on the viewing angle, this coating was put to the front glass of the PV module [107] The use of highly effective and ecologically friendly nanotechnology surface treatments designed for solar energy is what KromatixTM technology does to deliver color-treated glass for photovoltaic (PV) and thermal insulation properties (photovoltaic and thermal). This KromatixTM technology has no paint, tint, screen printing, or digital printing; instead, they use atomic deposition methods to give the solar glass color. SwissINSO offers a variety of sizes and thicknesses of KromatixTM glass and full-colored solar (PV or Thermal) panels. The BIPV application of KromatixTM, which is now offered in ten colors, including grey, dark grey, blue, green, blue-green, orange, bronze, and brass is depicted in Figure 12 [108]. The Swiss Federal Institute of Technology of Lausanne (EPFL) Campus, Lausanne, Switzerland retrofitted a building equipped with Kromatix™ blue PV modules, shown in Figure 12a, that covers a surface area of 1130 sq/ft where the installed capacity is 12 KWp [109]. Building integrated photovoltaics along with KromatixTM blue-green to create a magnificent solar wall were the sustainable retrofitting choices made by the Swedish Research Institute (RISE) in Bors, Sweden, shown in Figure 12b. SolarLAB has installed solar walls of 6000 square meters with a 720 kWp capacity [109]. SolarLAB has installed another aesthetical BIPV facade at the Red River College Innovation Center, shown in Figure 12c, which is located in Winnipeg, Canada, using a KromatixTM gold module. This façade uses varying sizes and shapes of custom panels that are up to 1400 by 2450 mm [110]. In a joint effort between Somiral [111,112] and Antec [113] a KromatixTM grey solar wall with a capacity of about 55 kW is built for the school gymnasium (Figure 12d) in Leysin, Switzerland [114]. Swiss Architect bureau Kampfen Architects [101], in collaboration with Doma Solar [115], retrofitted the fifty-apartment residential building in Zurich, Switzerland, where Kromatix™ bronze colored PV modules were installed on the façade of a 180 sqm area [102]. Only renewable energy sources are used to meet the heating and hot water needs of the office and the production hall of Doma Solartechnik Headquarters located in Satteins, Austria. On the facades of 83 sqm, KromatixTM blue, blue-green, grey, and brass are employed, shown in Figure 12f, which provides a stylish building-integrated thermal collector solution [116]. However, this technology is costly, time-consuming for color creation, and yields layers with poor transmittance [117,118] which is hard to be accepted by consumers.

Figure 12.

KromatixTM technology-based PV modules and their applications. (a) Retrofitted building of Swiss Federal Institute of Technology of Lausanne (EPFL) with blue modules (reproduced and modified with permission from Ref. [109]), (b) blue-green BIPV wall made by the Swedish Research Institute (RISE) in Bors, Sweden (reproduced and modified with permission from Ref. [109]), (c) BIPV façade by gold PV panels of the Red River College Innovation Center, at Winnipeg, Canada (use with the permission; copyright. SolarLab.dk and Garry Kopelow) [110], (d) grey BIPV of the school gymnasium in Leysin, Switzerland (reproduced and modified with permission from Ref, [114]), (e) bronze colored BIPV façade in a residential building in Zurich, Switzerland (reproduced and modified with permission from Ref. [102]), and (f) Doma Solartechnik Headquarters in Satteins, Austria (reproduced and modified with permission from Ref. [116]).

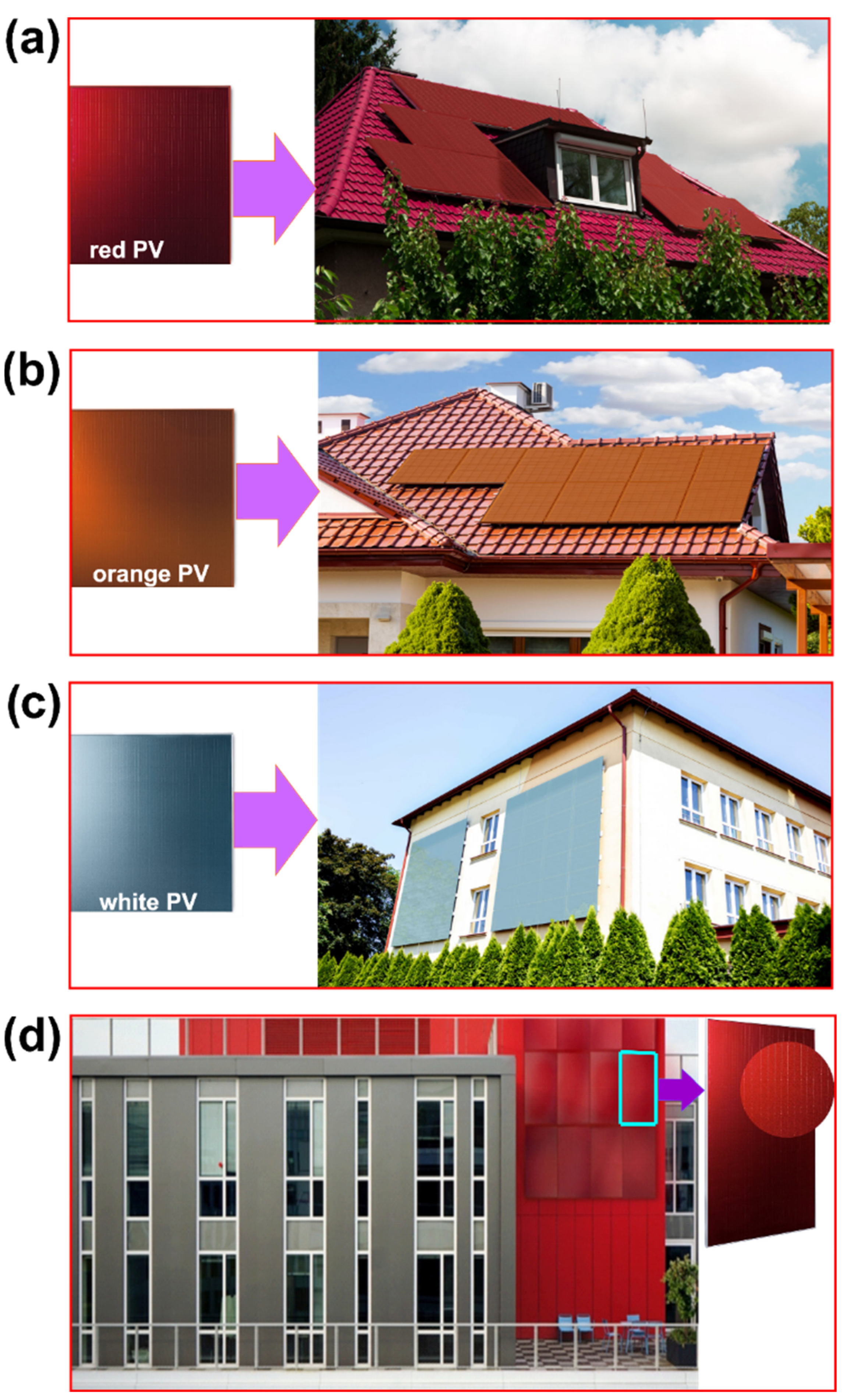

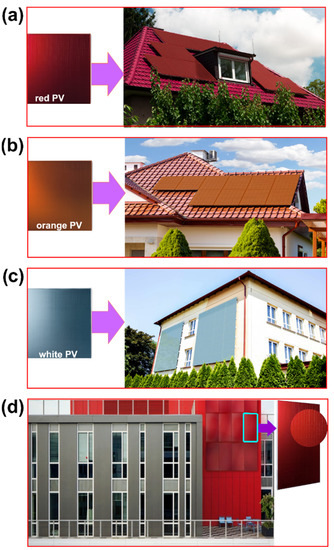

For demanding architectural solutions, Italian solar producer FuturaSun has created a red, building-integrated (BIPV) solar module of wattages around 230–245 W with an efficiency of 13.45% max. The 120 monocrystalline, multi-busbar, half-cut cells that make up the Silk Pro Red module may be created with a bespoke frame color. A brand-new line of colorful items comprises orange and silver modules. Wattages for the silver product vary from 280 W to 295 W, while those for the orange module range from 240 W to 255 W. The firm noted that these colored panels are ideal for conservative structures, repairs requiring installation on traditional roofs with tiles and brick tiles, or for usage surrounding historical architectures in town centers, where it is vital to guarantee overall harmony. These colored panels are perfect for use on pitched roofs and in creative facade compositions that take use of light and color [119,120,121]. Figure 13a–c shows the application of red-, orange-, and silver-colored PV modules in a building adaptive photovoltaic (BAPV). These colored PV modules can also be installed in a BIPV system, as shown in Figure 13d.

Figure 13.

Colored PV modules of FuturaSun and their application (Photos by FuturaSun). (a) Red-colored BAPV (reproduced and modified with permission from Ref. [119]), (b) orange-colored BAPV (reproduced and modified with permission from [119]), (c) silver-colored BAPV (reproduced and modified with permission from Ref. [119]), and (d) red-colored BIPV (reproduced and modified from [120,121] with proper permission).

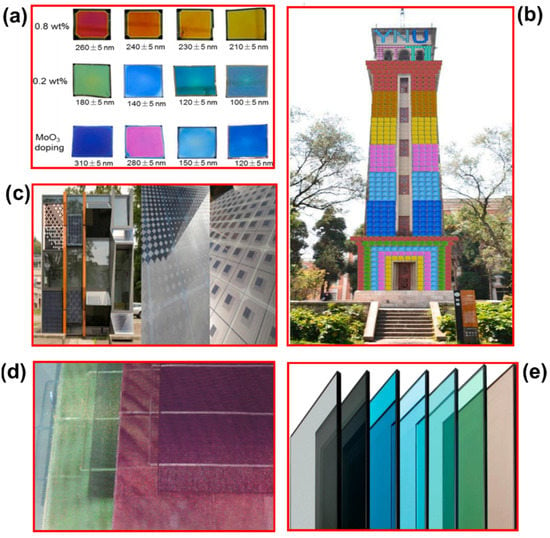

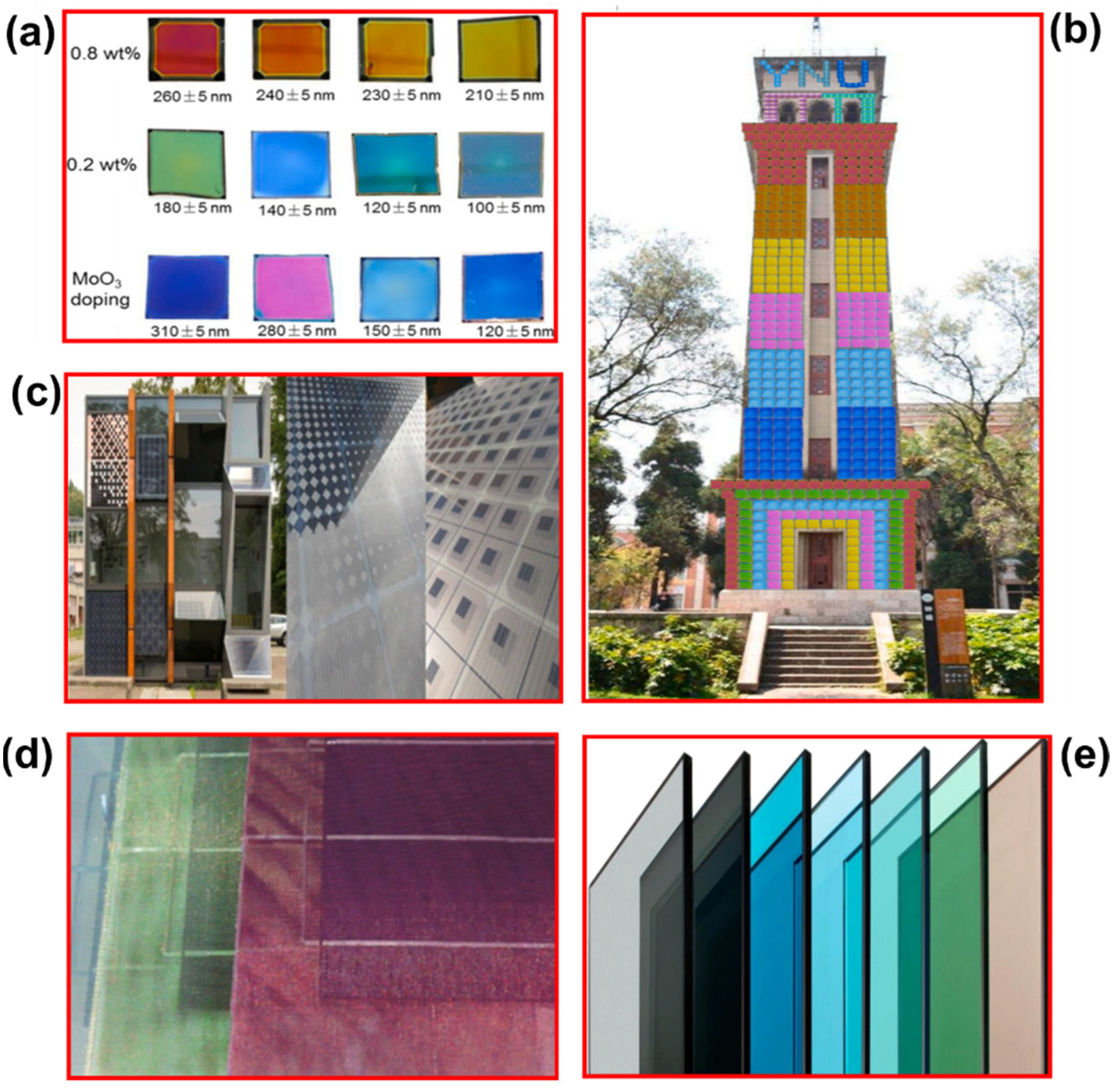

Lei-Ming Yu et al. have used a simple and efficient technique for developing polymer/Si heterojunction PVs with efficient color without the use of extra functional layers, all by adjusting the polymer layer’s optical path [118], as shown in Figure 14. Constructive interference and reflectance were created by adjusting the optical refractive index and the thickness of the polymer layer at a certain wavelength. High color saturation and a wide color spectrum are seen in the resultant polymer/Si planar heterojunction PVs (e.g., pink, orange, yellow, green, blue, purple, etc.) in Figure 14a. Figure 14b shows the Bell tower of Yunnan University, China, which is decorated with vivid-colored polymer/Si-based Hybrid solar cells [122], These multicolored heterojunction polymer/Si PVs exhibits good PCEs, with a peak value of 13.2% [122]. Another technique for developing aesthetic PV panels was reported, based on sandblasting, where sands are sprayed with higher velocities on the front surface of PV glass to create a milky white image [8]. ConstructPV [123] has designed and developed some BIPV glass sheets, as shown in Figure 14c, where attention was paid to the balance among power output, costs, and aesthetical appearance. However, the mechanical and optical properties of the PV glass are severely affected by this technique, making their lifetime short [124,125]. Hoffman [126] has proposed another technique for aesthetic coloration of a skylight facade system using ceramic digital printing. In this technology, an image is first printed on float PV glass by spraying ceramic ink pigments using multi-nozzle printer heads. With this technique, the most common printing pattern is typically seen as dots and commercially applied in a facade system. The limitation of the single-colored image of this method has been overcome by a research group at Lucerne University of Applied Sciences. They developed a printing method that produces multicolored images on the BIPV glass as illustrated in Figure 14d [112]. However, this printing approach severely attenuates solar irradiation by shading the PV cells, reducing the PV module’s maximum output power [124].

The coloration processes of the front glass of the PV modules based on incorporating various types of impurities in glass is still ongoing research worldwide [127]. The most common impurity is iron oxide, which is responsible for the greenish color of the glass. This greenish color is a mixture of blue and yellow. The densities of coloring agents, such as iron oxide, could be tuned for different functions. For example, a low concentration of iron oxide is needed for glass panels employed as the front surface of the solar panel so that maximum light can be transmitted through to the solar cells to enhance the efficiency of the solar module [128]. Similarly, other metal oxide impurities can be used as coloring agents for the creation of a variety of color glass, as illustrated in Figure 14e [129,130]. Another route for the surface coloration of flat glass is based on the ion exchange process, whereby flat glasses are immersed into salt baths containing metallic ions, such as copper or silver, for red-brown or yellow-brown coloration, respectively [131,132]. Note that organic and inorganic color paints have been used to colorate PV panels. However, as discussed earlier, organic paints are not ideal due to their chemical instability. Inorganic paint colors are widely applied using screen printing, or using brushing or spraying [133,134]. All the colored PV glass panels suffered from the solar shading effect, leading to significantly reduced PCE [92]. Additionally, the conventional PV coloration technologies that maintain practical PEC levels have limited aesthetical colors.

Figure 14.

Realizing colored PVs using various technology. (a) Photographic images of different colorful polymer/Si-based Hybrid solar cells where polymer layers were doped with different MoO3 doping concentrations (reproduced and modified with permission from Ref. [122]), (b) Bell tower of Yunnan University, China decorated with different colored polymer/Si-based Hybrid solar cells (reproduced and modified with permission from Ref. [122]), (c) BIPV glass modules realized using sandblast technique (reproduced and modified from Ref. [8], Source: SUPSI), (d) Ceramic digital printed PV cells (reproduced and modified from Ref. [135], Source. SmartFlex Solarfacades), and (e) AGC Glass Europe manufactured different colors of glasses used for the front cover of the PV module (reproduced and modified from AGC Glass Europe [136,137]).

Figure 14.

Realizing colored PVs using various technology. (a) Photographic images of different colorful polymer/Si-based Hybrid solar cells where polymer layers were doped with different MoO3 doping concentrations (reproduced and modified with permission from Ref. [122]), (b) Bell tower of Yunnan University, China decorated with different colored polymer/Si-based Hybrid solar cells (reproduced and modified with permission from Ref. [122]), (c) BIPV glass modules realized using sandblast technique (reproduced and modified from Ref. [8], Source: SUPSI), (d) Ceramic digital printed PV cells (reproduced and modified from Ref. [135], Source. SmartFlex Solarfacades), and (e) AGC Glass Europe manufactured different colors of glasses used for the front cover of the PV module (reproduced and modified from AGC Glass Europe [136,137]).

The major issues of using existing BIPV products in buildings are: (i) limited colors and customers having no choice of any custom colors, or multiple colors in the same PV module; and (ii) low power conversion efficiency of commercially available colored BIPV modules. Although many industries have been commercializing several colored BIPV products, using, for example, intermediate encapsulant foil, multi-crystalline solar cell, EVA (ethyl vinyl acetate) encapsulated foil, multilayer interference optical filter, and digitally printed ceramic inks, these products are still suffered from: (i) dull appearance and no color flexibility, (ii) low conversion efficiency, or (iii) high production cost. Therefore, an innovative and cost-effective method is needed to ensure color flexibility (almost all colors) with high contrast and resolution and commercially viable PCE. As a result, the development of new superior, cost-effective high-definition colored Photovoltaic (PV) glass technology and effective studies are very much needed to scale up the BIPV products and market as well.

4. Future Possible Research and Development in Aesthetics of the BIPV System

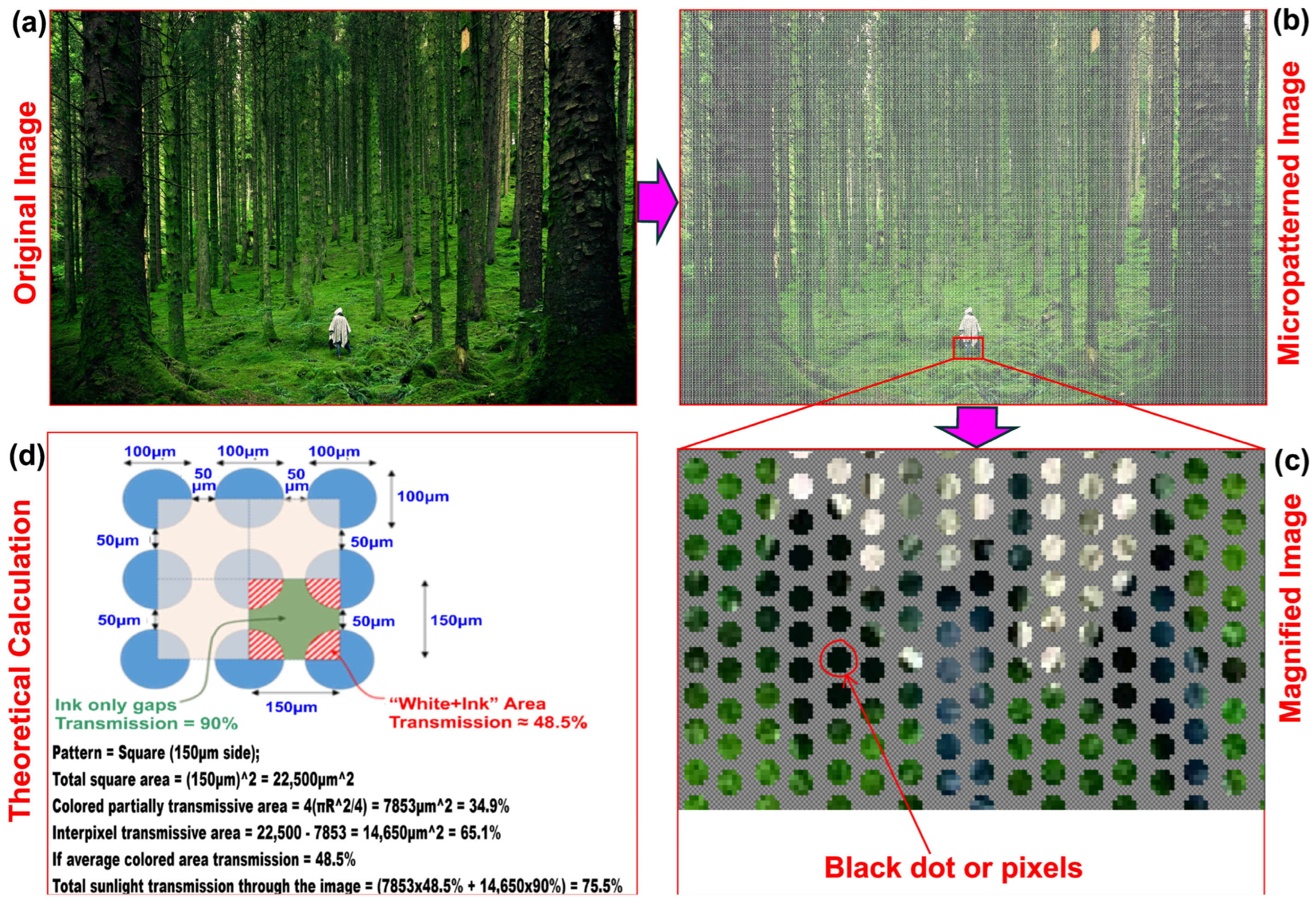

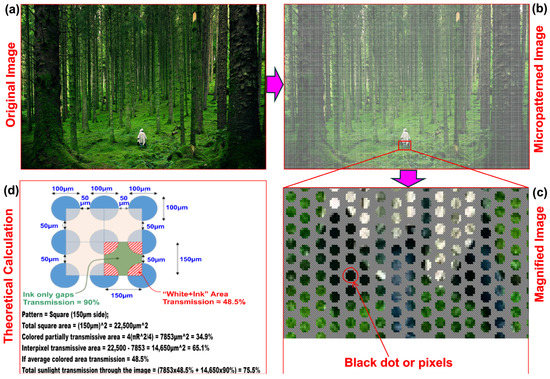

Currently, there is an urgent need for a high-definition colored PV technology that addresses the future zero-net-energy buildings goal through the development of viable and versatile BIPV solutions. Such a colored-imaging-based PV technology would enable the development of high-definition arbitrarily colored solar panels, which can be realized using a new micro-scale printing approach based on direct printing of high-resolution images onto the surfaces of flat or flexible PV panels. Several attempts have been made to print colored images onto PV panels in the printing laboratories at Edith Cowan University, Australia; however, printing thin layers of inks of different colors directly onto a dark solar panel typically yields dark images of very low contrast, making direct printing impractical. Additionally, placing a high-definition image in front of a PV panel typically blocks most of the incident light, thus significantly reducing the panel’s efficiency. To overcome this issue an optimal invisible micro-gap structure between the ink dots that maximize light penetration is one of the modern techniques to enhance output power while confirming an adequate image contrast, as reported by Basher et al. [138]. To the best of our knowledge, the current research on the development of colored PV modules is limited to only a few colors, and no studies have demonstrated micropatterned-based colored PV panels. Using the colored image-based PV technology, any image or painting can appear on the PV panels; however, an improved PCE is needed to be commercially acceptable. To enhance the efficiency, a high-resolution image (shown in Figure 15) can be converted to a micropatterned-based image by using Python, a high-level programming language, GIMP, image manipulation, and graphic design software. Figure 15 a–c presents the outcome of micropatterning of the randomly selected high-resolution multi-color image with a magnified view (Figure 15c) of the micropatterned image consisting of microdots and micro gaps. The micropattern acts as a mask for the image and only the microdots can print. A UV-flatbed printer can be used to print micropatterned images on off-the-shelf thin-film solar panels. Basher et al. theoretically calculated (Figure 15d) that about 75.5% of sunlight can be transmitted to the PV module through the micropatterned image. It is known that the more sunlight reaches the PV module, the higher efficiency will be achieved. The efficiency of the module can be further increased by carefully managing the black dots (Figure 15d) present in the micropatterned images. This is because the PV module underneath the micropatterned images is completely black. For example, if an image contains around 10% black microdots, 10% more light, which means a possibility of 85% sunlight incidence to the PV module, thus confirming the enhancement of photo-conversion efficiency.

Figure 15.

Formation of micropatterned image and light transmission calculation through it. (a) A randomly selected high-resolution nature image (reproduced and modified from [139]), (b) micropatterned image, (c) a magnified view of the micropatterned image, and (d) theoretical calculation of light transmission through a micropatterned image (reproduced and modified from [138]).

In addition, the image quality mostly depends on the number of dots per inch (DPI). It is clear from Figure 15b,c that increasing the DPI value increases the quality of the image. Additionally, the thickness of white ink and color ink dots significantly enhance image quality and conversion efficiency. However, the parameters, namely, the diameter of the dots, the gap between the dots, and the thickness of white ink and color ink, significantly limit the PCE of the PV panel. In addition, a selective micropatterning approach (where some dark color microdots mean to be omitted) can be a potential research objective to enhance the PCE without compromising the visual aesthetic of the BIPV products. In the future, comprehensive research investigations can lead to achieving the goal of developing cost-effective, highly efficient, and aesthetically appealing BIPV modules with arbitrary color options. In addition to many advanced applications, such as building materials and energy generation, the prospective PV modules will provide an aesthetically appealing appearance, so that these can be suitable for various parts of buildings, namely, facades, curtain walls, roof tiles, etc. Therefore, architects will be able to design aesthetic green buildings featuring high energy generation capacities using the skin of buildings. Additionally, homeowners will have more options to choose aesthetically colorful multi-functional modern BIPV products that can be retrofitted and easily replaceable, thus contributing towards achieving the global net-zero energy buildings (NZEB) goal.

5. Conclusions

In this article, we have reviewed the existing literature on the realization, the current stage, market size, aesthetics, and challenges of BIPV products and materials required for future BIPV applications. In particular, we have reviewed the aesthetically attractive BIPV products and their applications and limitations. We have also discussed future approaches for solving the current issues of realizing aesthetic BIPV modules that open the way towards achieving net-zero energy buildings (NZEB). The advanced technical approach based on the development of high-definition colored PV modules with adequate image contrast and a power conversion efficiency (PCE) exceeding 85% of that of a bare PV panel will boost the use of BIPV products and expand their market values in near future. The performance of currently available BIPV products has so far obtained great improvement; however, some issues still should be considered in order to make a strong position in the energy niche market, such as the mechanism of improving the aesthetic of solar cells in conjunction with the carrier transport layer and interfaces. Furthermore, the application of image processing using nontoxic inks on PVs with high performance and stability should be explored. This is an ongoing research project; our group is actively working to establish an easy and cost-effective process to improve the efficiency of thin-film-based BIPV modules simultaneously with a highly acceptable visual appearance.

Author Contributions

Conceptualization, M.K.B. and K.A.; methodology, M.K.B., M.N.-E.-A. and K.A.; software, M.K.B.; validation, M.K.B., M.N.-E.-A. and K.A.; formal analysis, M.K.B., M.N.-E.-A., M.M.R., S.H. and K.A.; investigation, M.K.B., M.N.-E.-A., M.M.R., S.H. and K.A.; resources, S.H. and K.A.; data curation, M.K.B., S.H. and K.A.; writing—original draft preparation, M.K.B. and K.A.; writing—review and editing, M.K.B., M.N.-E.-A., M.M.R., S.H. and K.A.; visualization, M.K.B., M.N.-E.-A. and K.A.; supervision, K.A. and S.H.; project administration, M.K.B., K.A. and S.H.; funding acquisition, M.K.B., K.A. and S.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The research was supported by the School of Science, Edith Cowan University, Australia.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| NZEB | Net-zero energy building |

| PV | Photovoltaic |

| BIPV | Building-integrated photovoltaic |

| BTJ | Billion Tera Joule |

| NOx | nitrogen oxides |

| SO2 | Sulfur dioxide |

| low-E | Low-emissivity |

| DEP | Directive of the European Parliament |

| ZCBE | Zero-carbon built environment |

| GW | gigawatt |

| CPUC | California Public Utilities Commission |

| DSSC | Dye-sensitized solar cell |

| TiO2 | Titanium dioxide |

| µm | micrometer |

| FTO | Fluorine-doped tin oxide |

| CSIRO | Commonwealth Scientific and Industrial Research Organization |

| EPD | Electrophoretic deposition |

| PCE | Photon conversion efficiency |

| PbS CQDs | Lead sulfide colloidal quantum dots |

| SCQDSCs | Semi-transparent colloidal-quantum-dots-based solar cells |

| MoO3 | Molybdenum trioxide |

| HTL | Hole transporting layer |

| ETL | Electron transporting layer |

| AVT | Average Visual Transmittance |

| OPV | Organic photovoltaic |

| NIR | Near-infrared |

| AgNWs | Silver nanowire |

| SiNx | Silicon nitride |

| CuOx | Copper oxide |

| SiMWs | Silicon microwires |

| LSC | Luminescent solar concentrator |

| TLSC | Transparent luminescent solar concentrator |

| UV | Ultraviolet |

| IR | Infrared |

| CIS | CuInSe2 |

| ENI | A research center in Novara, Italy |

| a-Si:H | Hydrogenated amorphous silicon |

| CdTe | Cadmium telluride |

| kW | Kilowatt |

| kWp | Kilowatt peak |

| EVA | Ethyl vinyl acetate |

| GIMP | Image Manipulation Program |

| DPI | Dots per inch |

References

- Tripathy, M.; Sadhu, P.K.; Panda, S.K. A Critical Review on Building Integrated Photovoltaic Products and Their Applications. Renew. Sustain. Energy Rev. 2016, 61, 451–465. [Google Scholar] [CrossRef]

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Recent Developments in Solar Energy-Harvesting Technologies for Building Integration and Distributed Energy Generation. Energies 2019, 12, 1080. [Google Scholar] [CrossRef]

- Attia, S. Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and Implementation; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128124628. [Google Scholar]

- Owusu, P.A.; Asumadu-Sarkodie, S. A Review of Renewable Energy Sources, Sustainability Issues and Climate Change Mitigation. Cogent Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- Asumadu-Sarkodie, S.; Owusu, P.A. Feasibility of Biomass Heating System in Middle East Technical University, Northern Cyprus Campus. Cogent Eng. 2016, 3, 1134304. [Google Scholar] [CrossRef]

- Kumar, N.M.; Sudhakar, K.; Samykano, M. Performance Comparison of BAPV and BIPV Systems with C-Si, CIS and CdTe Photovoltaic Technologies under Tropical Weather Conditions. Case Stud. Therm. Eng. 2019, 13, 100374. [Google Scholar] [CrossRef]

- Snow, M.; Prasad, D. A Source Book for Building Integrated Photovoltaics(BiPV); Routledge: London, UK, 2005; pp. 1–128. [Google Scholar]

- Eder, G.; Peharz, G.; Trattnig, R.; Bonomo, P.; Saretta, E.; Frontini, F.; Polo López, C.S.; Rose Wilson, H.; Eisenlohr, J.; Martin Chivelet, N.; et al. Coloured BIPV Market, Research and Development IEA PVPS Task 15, Subtask E Report T 15-07: 2019; Report IEA-PVPS T15-07: 2019; International Energy Agency: Paris, French, 2019; p. 60. [Google Scholar]

- Jelle, B. Building Integrated Photovoltaics: A Concise Description of the Current State of the Art and Possible Research Pathways. Energies 2015, 9, 21. [Google Scholar] [CrossRef]

- Gholami, H.; Røstvik, H.N. Economic Analysis of BIPV Systems as a Building Envelope Material for Building Skins in Europe. Energy 2020, 204, 117931. [Google Scholar] [CrossRef]

- Ng, P.K.; Mithraratne, N.; Kua, H.W. Energy Analysis of Semi-Transparent BIPV in Singapore Buildings. Energy Build. 2013, 66, 274–281. [Google Scholar] [CrossRef]

- Leite Didoné, E.; Wagner, A. Semi-Transparent PV Windows: A Study for Office Buildings in Brazil. Energy Build. 2013, 67, 136–142. [Google Scholar] [CrossRef]

- EUR-Lex-02010L0031-20181224-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2010/31/2018-12-24 (accessed on 13 April 2020).

- Wong, P.W.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Semi-Transparent PV: Thermal Performance, Power Generation, Daylight Modelling and Energy Saving Potential in a Residential Application. Renew. Energy 2008, 33, 1024–1036. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical Investigation of the Energy Saving Potential of a Semi-Transparent Photovoltaic Double-Skin Facade in a Cool-Summer Mediterranean Climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Bayoumi, M. Impacts of Window Opening Grade on Improving the Energy Efficiency of a Façade in Hot Climates. Build. Environ. 2017, 119, 31–43. [Google Scholar] [CrossRef]

- Ballif, C.; Perret-Aebi, L.E.; Lufkin, S.; Rey, E. Integrated Thinking for Photovoltaics in Buildings. Nat. Energy 2018, 3, 438–442. [Google Scholar] [CrossRef]

- California [USA]-NZEB. Available online: https://nzebnew.pivotaldesign.biz/definitions-policies/international-roadmaps/california-usa/ (accessed on 15 November 2022).

- Zero Net Energy. Available online: https://www.cpuc.ca.gov/industries-and-topics/electrical-energy/demand-side-management/energy-efficiency/zero-net-energy (accessed on 15 November 2022).

- Cohen, J.J.; Reichl, J.; Schmidthaler, M. Re-Focussing Research Efforts on the Public Acceptance of Energy Infrastructure: A Critical Review. Energy 2014, 76, 4–9. [Google Scholar] [CrossRef]

- Mittag, M.; Kutter, C.; Ebert, M.; Wilson, H. Power Loss Through Decorative Elements in the Front Glazing of BIPV Modules, In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 26 September 2017.

- Munari Probst, M.C.; Roecker, C. Criteria for Architectural Integration of Active Solar Systems IEA Task 41, Subtask A. Energy Procedia 2012, 30, 1195–1204. [Google Scholar] [CrossRef]

- Tabakovic, M.; Fechner, H.; Van Sark, W.; Louwen, A.; Georghiou, G.; Makrides, G.; Loucaidou, E.; Ioannidou, M.; Weiss, I.; Arancon, S.; et al. Status and Outlook for Building Integrated Photovoltaics (BIPV) in Relation to Educational Needs in the BIPV Sector. Energy Procedia 2017, 111, 993–999. [Google Scholar] [CrossRef]

- Goh, K.C.; Goh, H.H.; Yap, A.B.K.; Masrom, M.A.N.; Mohamed, S. Barriers and Drivers of Malaysian BIPV Application: Perspective of Developers. Energy Procedia 2017, 180, 1585–1595. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X.W. Building Integrated Photovoltaics (BIPV): Costs, Benefits, Risks, Barriers and Improvement Strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Karakaya, E.; Sriwannawit, P. Barriers to the Adoption of Photovoltaic Systems: The State of the Art. Renew. Sustain. Energy Rev. 2015, 49, 60–66. [Google Scholar] [CrossRef]

- Yang, R.J. Overcoming Technical Barriers and Risks in the Application of Building Integrated Photovoltaics (BIPV): Hardware and Software Strategies. Autom. Constr. 2015, 51, 92–102. [Google Scholar] [CrossRef]

- Azadian, F.; Radzi, M.A.M. A General Approach toward Building Integrated Photovoltaic Systems and Its Implementation Barriers: A Review. Renew. Sustain. Energy Rev. 2013, 22, 527–538. [Google Scholar] [CrossRef]

- Taleb, H.M.; Pitts, A.C. The Potential to Exploit Use of Building-Integrated Photovoltaics in Countries of the Gulf Cooperation Council. Renew. Energy 2009, 34, 1092–1099. [Google Scholar] [CrossRef]

- Prieto, A.; Knaack, U.; Auer, T.; Klein, T. Solar Façades—Main Barriers for Widespread Façade Integration of Solar Technologies. J. Facade Des. Eng. 2017, 5, 51–62. [Google Scholar] [CrossRef]

- Scognamiglio, A.; Privato, C. Starting Points for a New Cultural Vision of Bipv. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 1–5 September 2008. [Google Scholar]

- Lee, K.T.; Lee, J.Y.; Seo, S.; Guo, L.J. Colored Ultrathin Hybrid Photovoltaics with High Quantum Efficiency. Light. Sci. Appl. 2014, 3, e215. [Google Scholar] [CrossRef]

- Lien, S.-Y. Artist Photovoltaic Modules. Energies 2016, 9, 551. [Google Scholar] [CrossRef]

- Attoye, D.E.; Aoul, K.A.T.; Hassan, A. A Review on Building Integrated Photovoltaic Façade Customization Potentials. Sustainability 2017, 9, 2287. [Google Scholar] [CrossRef]

- Peharz, G.; Berger, K.; Kubicek, B.; Aichinger, M.; Grobbauer, M.; Gratzer, J.; Nemitz, W.; Großschädl, B.; Auer, C.; Prietl, C.; et al. Application of Plasmonic Coloring for Making Building Integrated PV Modules Comprising of Green Solar Cells. Renew. Energy 2017, 109, 542–550. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent Advancement in BIPV Product Technologies: A Review. Energy Build. 2017, 140, 188–195. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C.; Drolsum Røkenes, H. Building Integrated Photovoltaic Products: A State-of-the-Art Review and Future Research Opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Able Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Gholami, H.; Røstvik, H.N.; Müller-Eie, D. Holistic Economic Analysis of Building Integrated Photovoltaics (BIPV) System: Case Studies Evaluation. Energy Build. 2019, 203, 109461. [Google Scholar] [CrossRef]

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A Review of Solar Photovoltaic Levelized Cost of Electricity. Renew. Able Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Martellotta, F.; Cannavale, A.; Ayr, U. Comparing Energy Performance of Different Semi-Transparent, Building-Integrated Photovoltaic Cells Applied to “Reference” Buildings. Energy Procedia 2017, 126, 219–226. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Wang, X.; Xie, L.; Liu, Z.; Wu, J.; Zhang, Y.; He, X. A Comparative Study on Thermal Performance Evaluation of a New Double Skin Façade System Integrated with Photovoltaic Blinds. Appl. Energy 2017, 199, 281–293. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. A Comprehensive Review on Design of Building Integrated Photovoltaic System. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

- Jakica, N. State-of-the-Art Review of Solar Design Tools and Methods for Assessing Daylighting and Solar Potential for Building-Integrated Photovoltaics. Renew. Able Sustain. Energy Rev. 2018, 81, 1296–1328. [Google Scholar] [CrossRef]

- Curtius, H.C. The Adoption of Building-Integrated Photovoltaics: Barriers and Facilitators. Renew. Energy 2018, 126, 783–790. [Google Scholar] [CrossRef]

- Carlander, J.; Thollander, P. Barriers to Implementation of Energy-Efficient Technologies in Building Construction Projects-Results from a Swedish Case Study. Resour. Environ. Sustain. 2022, 11, 100097. [Google Scholar] [CrossRef]

- Frontini, F.; Bonomo, P.; Chatzipanagi, A.; Verberne, G.; van den Donker, M.N.; Folkerts, W. BIPV Product Overview for Solar Facades and Roofs 2015. Available online: https://repository.tno.nl//islandora/object/uuid:001d6c37-b26c-40e5-af19-8f39cc9989a5 (accessed on 22 November 2022).

- Delponte, E.; Marchi, F.; Frontini, F.; López, C.S.P.; Fath, K.; Batey, M. BIPV in EU28, from Niche to Mass Market: An Assessment of Current Projects and the Potential for Growth through Product Innovation. In Proceedings of the 31st European Photovoltaic Solar. Energy Conference and. Exhibition (EU PVSEC 2015), Hamburg, Germany, 14–18 September 2015; pp. 3046–3050. [Google Scholar] [CrossRef]

- Project Reports. Available online: https://www.pvsites.eu/downloads/category/project-results?page=3 (accessed on 22 November 2022).

- Zhang, X.; Eperon, G.E.; Liu, J.; Johansson, E.M.J. Semitransparent Quantum Dot Solar Cell. Nano Energy 2016, 22, 70–78. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J.; Song, A. Comparison of the Overall Energy Performance of Semi-Transparent Photovoltaic Windows and Common Energy-Efficient Windows in Hong Kong. Energy Build. 2016, 128, 511–518. [Google Scholar] [CrossRef]

- Ito, S.; Chen, P.; Comte, P.; Nazeeruddin, M.K.; Liska, P.; Péchy, P.; Grätzel, M. Fabrication of Screen-Printing Pastes from TiO2 Powders for Dye-Sensitised Solar Cells. Prog. Photovolt. Res. Appl. 2007, 15, 603–612. [Google Scholar] [CrossRef]

- Acciari, G.; Adamo, G.; Ala, G.; Busacca, A.; Caruso, M.; Giglia, G.; Imburgia, A.; Livreri, P.; Miceli, R.; Parisi, A.; et al. Experimental Investigation on the Performances of Innovative PV Vertical Structures. Photonics 2019, 6, 86. [Google Scholar] [CrossRef]

- Heinstein, P.; Ballif, C.; Perret-Aebi, L.-E. Building Integrated Photovoltaics (BIPV): Review, Potentials, Barriers and Myths. Green 2013, 3, 125–156. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.; Yang, P.; Que, W.; Liu, W. Deposition of Transparent TiO2 Nanotubes-Films via Electrophoretic Technique for Photovoltaic Applications. Sci. China Mater. 2015, 58, 785–790. [Google Scholar] [CrossRef]

- Husain, A.A.F.; Hasan, W.Z.W.; Shafie, S.; Hamidon, M.N.; Pandey, S.S. A Review of Transparent Solar Photovoltaic Technologies. Renew. Able Sustain. Energy Rev. 2018, 94, 779–791. [Google Scholar] [CrossRef]

- Zhang, X.; Hägglund, C.; Johansson, M.B.; Sveinbjörnsson, K.; Johansson, E.M.J. Fine Tuned Nanolayered Metal/Metal Oxide Electrode for Semitransparent Colloidal Quantum Dot Solar Cells. Adv. Funct. Mater. 2016, 26, 1921–1929. [Google Scholar] [CrossRef]

- Mora-Seró, I. Current Challenges in the Development of Quantum Dot Sensitized Solar Cells. Adv. Energy Mater. 2020, 10, 2001774. [Google Scholar] [CrossRef]

- Konarka Technologies—Wikipedia. Available online: https://en.wikipedia.org/wiki/Konarka_Technologies (accessed on 9 January 2023).

- Solar Cells with 30-Year Lifetimes for Power-Generating Windows. Available online: https://ece.engin.umich.edu/stories/solar-cells-with-30-year-lifetimes-for-power-generating-windows (accessed on 10 January 2023).

- Semi-Transparent Organic Solar Cell for Window Applications—Pv Magazine International. Available online: https://www.pv-magazine.com/2021/09/16/semi-transparent-organic-solar-cell-for-window-applications/ (accessed on 18 July 2022).

- Brus, V.V.; Lee, J.; Luginbuhl, B.R.; Ko, S.J.; Bazan, G.C.; Nguyen, T.Q. Solution-Processed Semitransparent Organic Photovoltaics: From Molecular Design to Device Performance. Adv. Mater. 2019, 31, 1900904. [Google Scholar] [CrossRef]

- Lunt, R.R.; Bulovic, V. Transparent, near-Infrared Organic Photovoltaic Solar Cells for Window and Energy-Scavenging Applications. Appl. Phys. Lett. 2011, 98, 113305. [Google Scholar] [CrossRef]

- Chen, C.-C.; Dou, L.; Zhu, R.; Chung, C.-H.; Song, T.-B.; Zheng, Y.B.; Hawks, S.; Li, G.; Weiss, P.S.; Yang, Y. Visibly Transparent Polymer Solar Cells Produced by Solution Processing. ACS Nano 2012, 6, 7185–7190. [Google Scholar] [CrossRef]

- Roldán-Carmona, C.; Malinkiewicz, O.; Betancur, R.; Longo, G.; Momblona, C.; Jaramillo, F.; Camacho, L.; Bolink, H.J. High Efficiency Single-Junction Semitransparent Perovskite Solar Cells. Energy Environ. Sci. 2014, 7, 2968–2973. [Google Scholar] [CrossRef]

- Bailie, C.D.; Christoforo, M.G.; Mailoa, J.P.; Bowring, A.R.; Unger, E.L.; Nguyen, W.H.; Burschka, J.; Pellet, N.; Lee, J.Z.; Grätzel, M.; et al. Semi-Transparent Perovskite Solar Cells for Tandems with Silicon and CIGS. Energy Environ. Sci. 2015, 8, 956–963. [Google Scholar] [CrossRef]

- Yu, J.C.; Sun, J.; Chandrasekaran, N.; Dunn, C.J.; Chesman, A.S.R.; Jasieniak, J.J. Semi-Transparent Perovskite Solar Cells with a Cross-Linked Hole Transport Layer. Nano Energy 2020, 71, 104635. [Google Scholar] [CrossRef]

- Patel, D.B.; Chauhan, K.R. 50% Transparent Solar Cells of CuO /TiO2: Device Aspects. J. Alloys Compd. 2020, 842, 155594. [Google Scholar] [CrossRef]

- Kang, S.B.; Kim, J.-H.; Jeong, M.H.; Sanger, A.; Kim, C.U.; Kim, C.-M.; Choi, K.J. Stretchable and Colorless Freestanding Microwire Arrays for Transparent Solar Cells with Flexibility. Light. Sci. Appl. 2019, 8, 121. [Google Scholar] [CrossRef]

- Lee, K.; Kim, N.; Kim, K.; Um, H.-D.; Jin, W.; Choi, D.; Park, J.; Park, K.J.; Lee, S.; Seo, K. Neutral-Colored Transparent Crystalline Silicon Photovoltaics. Joule 2020, 4, 235–246. [Google Scholar] [CrossRef]

- Zhao, Y.; Meek, G.A.; Levine, B.G.; Lunt, R.R. Near-Infrared Harvesting Transparent Luminescent Solar Concentrators. Adv. Opt. Mater. 2014, 2, 606–611. [Google Scholar] [CrossRef]

- Vasiliev, M.; Alameh, K.; Badshah, M.; Kim, S.-M.; Nur-E-Alam, M. Semi-Transparent Energy-Harvesting Solar Concentrator Windows Employing Infrared Transmission-Enhanced Glass and Large-Area Microstructured Diffractive Elements. Photonics 2018, 5, 25. [Google Scholar] [CrossRef]

- In Rome, Transparent Photovoltaic Shelters That Recharge Electric Bikes and Cars—GreenMe. Available online: https://www.greenme.it/mobilita/trasporti/pensiline-fotovoltaico-trasparente-eni/ (accessed on 26 July 2022).

- Aste, N.; Tagliabue, L.C.; Del Pero, C.; Testa, D.; Fusco, R. Performance Analysis of a Large-Area Luminescent Solar Concentrator Module. Renew. Energy 2015, 76, 330–337. [Google Scholar] [CrossRef]

- Ghosh, A. Potential of Building Integrated and Attached/Applied Photovoltaic (BIPV/BAPV) for Adaptive Less Energy-Hungry Building’s Skin: A Comprehensive Review. J. Clean. Prod. 2020, 276, 123343. [Google Scholar] [CrossRef]

- Wook Lim, J.; Shin, M.; Lee, D.J.; Hyun Lee, S.; Jin Yun, S. Highly Transparent Amorphous Silicon Solar Cells Fabricated Using Thin Absorber and High-Bandgap-Energy n/i-Interface Layers. Sol. Energy Mater. Sol. Cells 2014, 128, 301–306. [Google Scholar] [CrossRef]

- Yeop Myong, S.; Won Jeon, S. Design of Esthetic Color for Thin-Film Silicon Semi-Transparent Photovoltaic Modules. Sol. Energy Mater. Sol. Cells 2015, 143, 442–449. [Google Scholar] [CrossRef]

- China Hot Sale High Efficiency 40W Transparent Thin Film Solar Panel—China Solar Panel, Transparent Solar Panel. Available online: https://esolarfirst.en.made-in-china.com/product/eyxnjoXvrWVR/China-Hot-Sale-High-Efficiency-40W-Transparent-Thin-Film-Solar-Panel.html (accessed on 10 August 2022).

- Yoon, J.-H.; Song, J.; Lee, S.-J. Practical Application of Building Integrated Photovoltaic (BIPV) System Using Transparent Amorphous Silicon Thin-Film PV Module. Sol. Energy 2011, 85, 723–733. [Google Scholar] [CrossRef]

- Transparent Solar Panels Semi Transparent Solar Panels. Available online: http://www.solar-constructions.com/wordpress/transparent-solar-panels/ (accessed on 9 November 2022).

- Solar BIPV/BIPV/Transparent Solar Panel—Energor Technology Co., Ltd.-Ecplaza.Net. Available online: https://www.ecplaza.net/products/solar-bipv-bipv-transparent-solar-panel_627393 (accessed on 1 August 2022).

- Advanced Solar Power|ASP-LAM3 (164-218W)|Solar Panel Datasheet|ENF Panel Directory. Available online: https://www.enfsolar.com/pv/panel-datasheet/Thin-film/1024?utm_source=ENF&utm_medium=panel_profile&utm_campaign=enquiry_company_directory&utm_content=20020 (accessed on 9 November 2022).

- Sinha, P.; Wade, A. Assessment of Leaching Tests for Evaluating Potential Environmental Impacts of PV Module Field Breakage. IEEE J. Photovolt. 2015, 5, 1710–1714. [Google Scholar] [CrossRef]

- Photovoltaic Modules. Available online: http://www.aldi.ru/page/view/16 (accessed on 1 August 2022).

- Solstice Solar—BIPV Solution Provider. Available online: https://solstice.id/products/cadmium-telluride-pv-glass/ (accessed on 1 August 2022).

- Liao, W.; Xu, S. Energy Performance Comparison among See-through Amorphous-Silicon PV (Photovoltaic) Glazings and Traditional Glazings under Different Architectural Conditions in China. Energy 2015, 83, 267–275. [Google Scholar] [CrossRef]

- Pelle, M.; Lucchi, E.; Maturi, L.; Astigarraga, A.; Causone, F. Coloured BIPV Technologies: Methodological and Experimental Assessment for Architecturally Sensitive Areas. Energies 2020, 13, 4506. [Google Scholar] [CrossRef]

- Reddy, P.; Surendra Gupta, M.V.N.; Nundy, S.; Karthick, A.; Ghosh, A. Status of BIPV and BAPV System for Less Energy-Hungry Building in India—A Review. Appl. Sci. 2020, 10, 2337. [Google Scholar] [CrossRef]

- Green, M.A.; Hishikawa, Y.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Yoshita, M.; Ho-Baillie, A.W.Y. Solar Cell Efficiency Tables (Version 53). Prog.Photovolt. Res. Appl. 2019, 27, 3–12. [Google Scholar] [CrossRef]

- Solar Power 101: Complete Guide to Solar Energy|EnergySage. Available online: https://www.energysage.com/solar/ (accessed on 10 March 2023).

- Best Research-Cell Efficiency Chart|Photovoltaic Research|NREL. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 10 March 2023).

- Sehati, P.; Malmros, I.; Karlsson, S.; Kovacs, P. Aesthetically Pleasing PV Modules for the Built Environment; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2019; ISBN 9789188907301. [Google Scholar]

- Peharz, G.; Grosschädl, B.; Prietl, C.; Waldhauser, W.; Wenzl, F.P. Tuning the Colors of C-Si Solar Cells by Exploiting Plasmonic Effects. In Next Generation Technologies for Solar Energy Conversion VII; Sulima, O.V., Conibeer, G., Eds.; SPIE: Bellingham, WA, USA, 2016; Volume 9937, p. 99370P. [Google Scholar]

- McIntosh, K.R.; Amara, M.; Mandorlo, F.; Abbott, M.D.; Sudbury, B.A. Advanced Simulation of a PV Module’s Color. AIP Conf. Proc. 2018, 1999, 020017. [Google Scholar]

- Solar Module Standard-PV-Module—Lof Solar—Color Solar Cell. Available online: http://www.lofsolar.com/Standard-PV-Module#6 (accessed on 13 September 2022).

- Red Solar Panel on the Roof-Lof Solar-Color Solar Cell. Available online: http://www.lofsolar.com/LofsolarPerformance/redsolarpanelontheroof-172.html (accessed on 13 September 2022).

- Hcl Architects—Kingsgate House. Available online: http://www.hcla.co.uk/projects/type/kingsgate-house (accessed on 15 November 2022).

- London Kingsgate House-Sustainable Homes Level 4-Lof Solar—Color Solar Cell. Available online: http://www.lofsolar.com/LofsolarPerformance/londonkingsgatehouse-sustainablehomeslevel4-69.html (accessed on 13 September 2022).

- Aesthetically Pleasing PV Modules for the Built Environment. Available online: https://www.researchgate.net/publication/331036665_Aesthetically_pleasing_PV_modules_for_the_Built_Environment (accessed on 15 November 2022).

- Perret-Aebi, L.-E.; Escarré, J.; Li, H.-Y.; Sansonnens, L.; Galliano, F.; Cattaneo, G.; Heinstein, P.; Nicolay, S.; Bailat, J.; Eberhard, S.; et al. When PV Modules Are Becoming Real Building Elements: White Solar Module, a Revolution for BIPV (Presentation Recording); Dhere, N.G., Wohlgemuth, J.H., Jones-Albertus, R., Eds.; SPIE: San Diego, CA, USA, 2015; p. 95630Q. [Google Scholar]

- Home—Fight Zince + Partner Ag. Available online: https://kaempfen.com/ (accessed on 15 November 2022).

- SwissINSO—Stettbachstrasse. Available online: https://www.swissinso.com/stettbachstrasse (accessed on 25 October 2022).

- Topic of the Week: BIPV (Part 3): A Solar Module as White as a Wall-Pv Europe—Solar Technology and Applications. Available online: https://www.pveurope.eu/Products/Solar-Generator/Solar-modules/Topic-of-the-Week-BIPV-Part-3-A-solar-module-as-white-as-a-wall (accessed on 27 April 2020).

- BIPV Technology—Mitrex. Available online: https://www.mitrex.com/technology/ (accessed on 24 September 2022).