1. Introduction

Building Information Modeling (BIM) serves as the cornerstone of digital transformation within the architecture, engineering, and construction (AEC) industry. With the widespread use of BIM methodology, new difficulties and possibilities have arisen in the sector. One such case involves employing BIM software, Autodesk COBie Extension for Revit 2022, to create a COBie data (Construction Operations Facility Information Exchange) file, which is then used to streamline the handover process to the building’s operators or owners. Additionally, NASA and the White House Office of Science and Technology Policy funded the early development of COBie in the United States in 2005 [

1]. However, COBie was included as a data need in the 2011 BIM Working Party Strategy in the United Kingdom. Furthermore, the COBie format structure became necessary for non-geometric information transmission in the open data format in January 2019 per the UK National Annex in BS EN ISO 19650-2 [

2].

BIM is a digital depiction of a facility’s geometry, materials, systems, and processes, as well as its physical and functional qualities. By utilizing this digital paradigm, facilities management activities may be made more productive and efficient. Facilities managers now have access to comprehensive data on a building’s physical assets and systems, in clouding information on their location, age, maintenance history, and performance metrics. They can utilize these data to create maintenance schedules, rank repair needs, and pinpoint areas for development.

BIM can help facility managers plan for future changes, track occupancy and use, and optimize space. Facility Management (FM) with BIM can integrate data and workflows from design and construction to operations and maintenance. BIM can help the construction and facility management teams share information. BIM helps facility managers collaborate with designers, engineers, and contractors. FM increasingly needs BIM data. Many BIM and FM software (IBM

® TRIRIGA

® version 10.5.0) programs generate data throughout the project [

3,

4]. While BIM has the potential to streamline current procedures, it does necessitate a standardized language for communicating between different parties involved in the construction process. In Malaysia, FM integration in the early stages of BIM projects was studied to understand the advantages and disadvantages of BIM-FM integration [

5].

The Building Information Model and Facility Management industries actively promote the new COBie standard that can be used to precisely track building components to spot operational inefficiencies and react to client requirements fast. COBie is a specification for exchanging data, and it may be seen in basic spreadsheets and complex design, construction, and maintenance programs. COBie is excellent for projects of any size, scope, or complexity because of the flexibility of the standard. In addition, these data collection is presented in a straightforward spreadsheet, which provides consistent and structured data about an asset helpful in post-occupancy facility management and decision-making [

6]. When a project is finished, the crucial information needed moving forward can be included in a unified format using the COBie specification. This method differs significantly from standard practice, in which AEC specialists manually document each stage of the building process [

7,

8].

Using the COBie specification, construction teams can keep their customer or facility operators up to date with accurate, real-time documentation. Because of this, the documentation is simplified for the reader. The management and upkeep of the building can be streamlined if construction teams use the COBie specification for providing accurate, real-time documentation to its clients or facility operators. Building information is organized and exchanged in a structured manner by COBie, which makes it simpler for readers to comprehend and apply the knowledge. For instance, a construction team can utilize COBie to deliver a more condensed set of information that only includes what is pertinent to the facility operator, as opposed to presenting a big, complex set of architectural drawings and specifications. This can ensure that the facility is run and maintained in a safe and effective manner while also reducing confusion and errors.

Collaborative production of information report, which provides an information management methodology for the operational phase of building assets based on open BIM standards IFC and COBie [

9] acknowledges that the provision of structured data for asset information models is necessary [

9]. In addition, Ref. [

10] proposes using open BIM standards IFC and COBie for service life planning and lifecycle costing, respectively, throughout the maintenance phase of buildings. Instances of the IFC’s application include studies by various researchers. For instance, one study proposed a semantic web-based information approach for facility management using IFC objects [

11]. Additionally, another study presented a data model integrating the building condition risk assessment model into BIM [

12]. Furthermore, another study utilized IFC files to integrate probabilistic occupants’ comfort [

13], while yet another study used IFC files to facilitate automated concrete joint positioning solutions [

14].

Regarding research, COBie has only been defined, developed, implemented, and adopted by industries as evidenced by multiple studies [

15,

16]. More studies have yet to be conducted to validate the data produced by the methods used to produce COBie. This study intends to close that knowledge gap by investigating the sources and methods used to generate COBie data in an open-source data setting and by highlighting a baseline for COBie deliverables that conform to client needs.

Before kicking off the project, the clients assign the required BIM uses to be stated in the EIR. However, this often requires the design and construction teams to provide a COBie data handover package to aid in the ongoing management of the built environment. Regarding cost and scope, building owners often need help determining whether their COBie data meet their needs. For this reason, building owners should fight for complete, accurate, valid, and suitable COBie data, which is vital in producing better executed constructed assets and reducing project owners’ stress levels.

From the planning and building stages through maintenance and operations, a building’s owner, manager, or operator should have access to any and all information they need. COBie provides the spreadsheet and the MVD that state the approved specifications of industry knowledge and practices for the data interchange requirements of BIM. Exporting native model information to IFC files or documents that adhere to COBie’s standards is a standard feature of many BIM authoring tools and apps, such as Autodesk Revit COBie Toolkit and FM Systems.

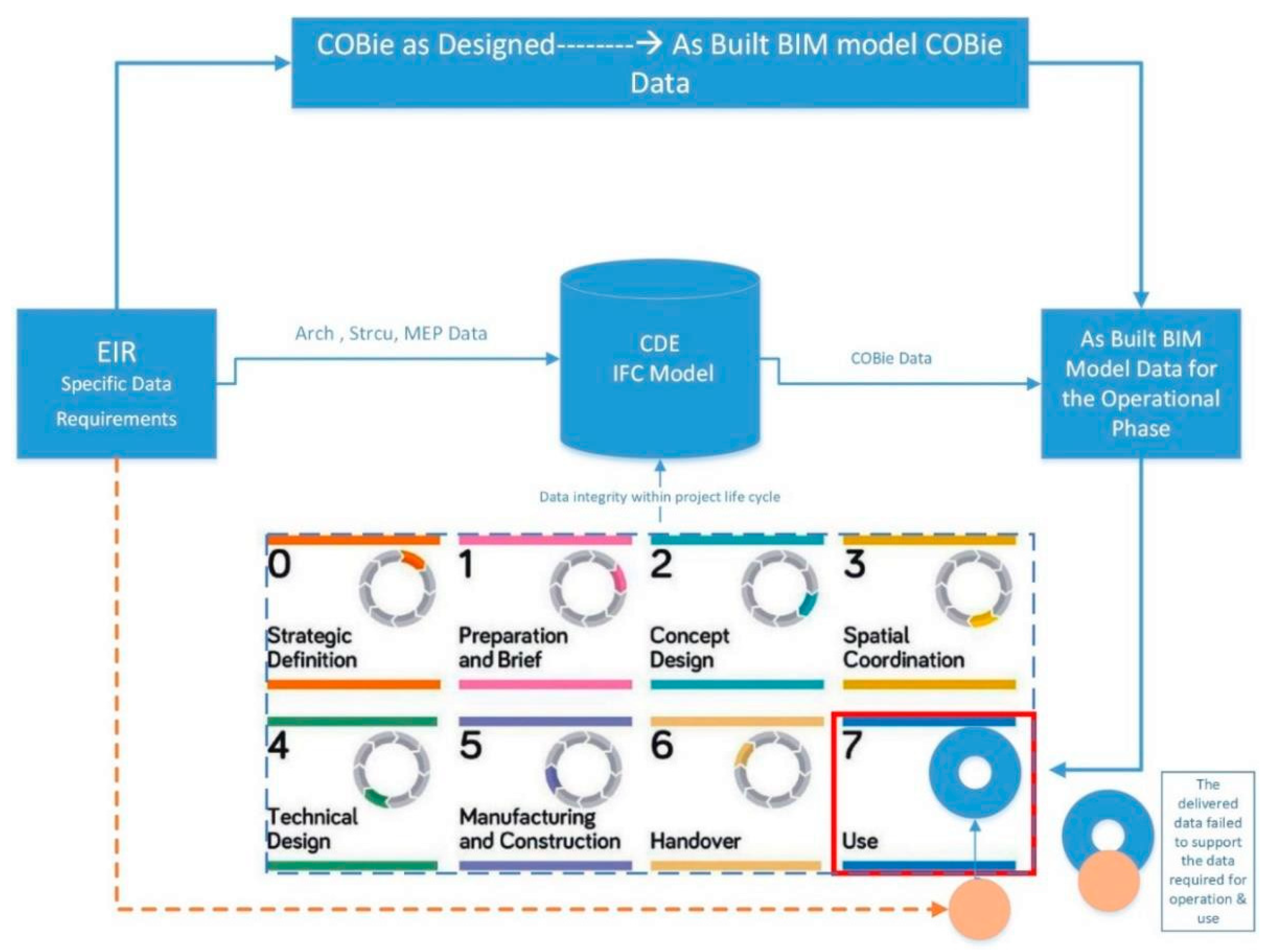

Moreover, all the necessary handover data needed by facility managers or owners are included in a BIM model once the IFC instance files have been translated in accordance with the COBie guidelines. As the project progresses, it is common for as-built BIM models to diverge from Employer Information Requirements (EIRs), which can cause various problems once the buildings are used.

BIM usage choices and COBie data parameters work together to improve efficiency. When BIM data are converted to COBie data, they may be used in CAFM or IWMS systems to store specific information. Facility managers may use gathered data for daily operations, preventative maintenance, and strategic decision-making with this connection. COBie data may be used in facility management applications such as CAFM or IWMS, providing significant resources for facility managers. The detailed warranties, spare parts lists, and maintenance plans simplify facility operations. These data help facility managers optimize maintenance schedules, manage warranties, and plan for lifetime asset management to maximize facility performance.

Integrating COBie data from BIM models within facility management platforms improves predictive maintenance techniques. Facility managers may predict and avoid equipment failures using warranty, maintenance, and equipment data. Data-driven predictive maintenance reduces downtime and improves operational continuity. The owner’s choice of BIM applications and the inclusion of COBie data parameters are crucial for optimal facility operations and management. COBie parameters meticulously capture vital information for a seamless transfer into facility management systems, enabling facility managers to optimize operations, maintenance, and oversight of assets. The synergy between BIM and COBie data enables predictive maintenance solutions to extend building life and performance.

Information on a building’s assets is continuously updated during the design and construction processes, and COBie data are widely acknowledged as the primary source for this information. However, the complexity of COBie can vary greatly depending on the nature of different building projects. This might lead to the accidental omission of crucial data connected to the operation and maintenance phase. Even with the deployment of intelligent or automated systems like the Internet of Things or digital twins, this can restrict the use of such data to optimize the building. In order to facilitate better decision-making throughout the in-use phase of a building, this study seeks to enhance the integration of Employer’s Information Requirements (EIR) needs inside the as-built BIM Model, as depicted in

Figure 1.

The main aim of this research is to propose strategies for bridging the information gap between as-built BIM model data (COBie.Type) and the BIM uses assigned by clients in the Employer’s Information Requirement (EIR) for facility management and operation, as illustrated in

Figure 2.

2. Literature Review

Successful BIM implementation requires team members to comprehend the future usage of their generated knowledge. When an architect adds a wall to the architectural model, it may include material quantities, mechanical qualities, structural properties, and other data. Whether and how this information will be utilized, the architect must know. The future usage of these data might affect model development processes or highlight quality control concerns connected to data accuracy for jobs dependent on it. The BIM Plan Procedure starts with the model’s probable end uses to emphasize the information’s lifespan. Before doing so, the project team should evaluate the subsequent stages of a project to determine what information would be useful.

Due to the diverse nature of activities in the construction industry, the parties involved face many difficulties, including the successful completion of projects within the specified cost, time, and high quality, as well as problems of coordination between different disciplines and waste of materials [

3]. These difficulties can be addressed by using collaborative and integrated project delivery methods and bringing together various stakeholders, such as architects, engineers, contractors, and building owners. By doing so, it can be ensured that all project stakeholders are aligned with the project’s objectives and can cooperate to solve problems and reduce waste.

BIM technology is one of the newer tools developed in response to the pressing need to cut project costs, keep implementation times under control, boost efficiency and productivity, and eliminate roadblocks to successful project completion. BIM enables the MEP (mechanical, electrical, and plumbing) design team to collaborate with the client and other project stakeholders [

17]. A digital tool called BIM enables the development and maintenance of a 3D model of a structure, along with all of its parts and systems. The use of BIM can have many advantages that can speed up the building process, including greater stakeholder engagement and communication, improved data accuracy, real-time monitoring of the project timeline, and lower costs due to the early detection of possible problems. In general, BIM offers a shared platform for designing, scheduling, and managing construction projects, enabling more productive and efficient collaboration across various teams and stakeholders. It provides the capability to make changes to the project and see how those changes will affect the budget and schedule for completing the project [

18].

BIM and other FM-related software produce valid data at various project lifecycle stages [

3]. With the provision of accurate and current information on the structure and its systems, the use of BIM and FM software can contribute to improving the efficacy and efficiency of facility management. BIM can be used to produce a digital model of the building and its parts during the design and construction phases. With the help of this model, potential problems can be found early in the design phase, allowing for improvements to be addressed before building starts [

19].

One of the primary concerns in the standardization of BIM in the architecture, engineering, and construction (AEC) and FM sectors was determining the best way to organize the facility’s digital information to facilitate data sharing among different specializations throughout the project’s life cycle. The open data model standard provided by Industry Foundation Classes (IFC) serves as a mechanism for the interchange and standardization of digital facility information [

20]. Building components, systems, and processes can all be represented by a common set of objects defined by the IFC data model. This data model enables more interoperability and data interchange across various systems and platforms, offering a universal language for information communication between different software applications.

COBie, or the Construction Operations Information Exchange, is a standard that developed for CAFM. Selected data may be delivered more easily from the design and construction phases to the operation and maintenance phases thanks to the processes and information described in the specification of FM. To collect and validate building lifecycle data throughout the design, construction, and operation phases, an open, vendor-neutral industry standard known as COBie has been developed [

21]. However, it is currently time-consuming to extract FM-related information from the many papers and electronic paper documents used in the delivery process. While COBie is relatively innovative, there is active advocacy for BIM and FM.

The scope of COBie research has not expanded beyond the initial questions of the idea, development, and adoption by the industry [

16,

22], as evidenced by multiple studies [

16,

17]. The efficiency and effectiveness of these tasks can be increased, according to certain studies that have investigated the use of COBie in facilities management and maintenance. Additional research on COBie’s application to asset management and lifecycle costing has revealed that it can aid firms in making more educated choices regarding the long-term costs and advantages of various building components. Some research has also focused on the integration of COBie with other digital technologies, including BIM and Geographical Information Systems (GIS).

Researchers studied how different technologies can be combined to enhance the creation and administration of structures and infrastructure. While the majority of the studies on COBie have concentrated on its acceptance and development, there is growing interest in investigating how COBie is utilized in actual buildings and comprehending how effective it is at enhancing building operations and maintenance. As a result, the basic concept behind COBie is to capture data as it becomes essential and to save it digitally in a structured manner as soon as it occurs in the project. During the building delivery process, from design and construction to operation and maintenance, COBie is intended to acquire and structure data. The goal is to gather the relevant information as early in the project lifecycle as possible and keep it organized so that stakeholders may readily share it. COBie can help guarantee that stakeholders have the knowledge they need to make informed decisions throughout the project lifecycle by recording data when it becomes necessary.

COBie is delivered through data drops: standardized collections of information that stakeholders can share at specific project lifecycle stages. Each data drop contains building parts, tools, and maintenance specifications. A structured format like COBie is used to organize data drops to make them easy to understand and use. By structuring data this way, COBie makes it easier for stakeholders to access and use the data they need to manage and maintain the building across its lifecycle [

23]. Consequently, the theoretical foundation and literature studies in this chapter will center on validating COBie data against customer needs. The COBie plugin is an asset management tool that encompasses the organization and documentation of information about spaces and equipment. The concept is intricately linked to BIM methods to design, construct, and manage constructed assets [

24,

25]. COBie was developed as part of HBIM to analyze the cost implications of routine maintenance versus full restoration of historical structures. This was exemplified through a case study of the “Aidkeen Al-Bendqdari Dome” within the Prince Taz Palace, situated in the historic region of Cairo, Egypt [

26].

In 2011, COBie was approved as a mandatory component of the National BIM Standard in the United States (NBIMS-US). Additionally, a British Standard adopted it in 2014. In recent years, the building SMART Alliance has established a set of tools and recommendations for deploying COBie and undertaken a series of tests to verify the COBie exchange functions incorporated into several BIM software products [

27].

As an additional indicator, COBie incorporates the most typical forms of building data needed in FM. However, the transmission of building information from building to FM requires specialized settings that must be developed to accommodate the demands and requirements of actual projects and financial management institutions. A further issue with COBie deployment is the wide variety of building categorization systems used nationally. These variations are represented in the various regulatory needs of other nations. Information retrieval from the project’s BIM delivery papers was one area where COBie deployment on a building project using Sweden’s BSAB national categorization system fell short [

28].

The primary objectives of this study are to investigate the significant gaps and discrepancies that exist between the as-built BIM model and COBie deliverables within the domain of facility management. Additionally, the study seeks to assess the effects of the divergence of as-built BIM models from Employer Information Requirements (EIRs) on the operational and maintenance phases of a building project. Furthermore, the research aims to enhance the translation process of BIM models into IFC instance files following COBie guidelines, with a specific focus on ensuring the inclusion of all essential handover data. Another crucial aspect is the evaluation of the current role of COBie in the exchange of facility management and project handover data, coupled with suggestions for potential improvements. Moreover, the study aims to develop a comprehensive framework for manually checking the COBie dataset against client requirements using the Solibri Model Checker (SMC). Finally, the research aims to devise an automated checking framework using the Java programming language, aligning owners’ requirements during the design phase with COBie deliverables in facility management.

3. Methodology

BIM has transformed the construction business by digitizing physical and functional building attributes. The COBie format captures and manages critical facility data in BIM. Efficiency in facility management and operations depends on the owner’s BIM usage and COBie data characteristics. These factors are interrelated, and this research examines their effects on the administration of assets, operations, and predictive maintenance. The decision made by owners or facility administrators regarding BIM usage directly affects the COBie data parameters in the model. When an owner prioritizes asset management in BIM, various COBie data parameters are needed to capture relevant information. These characteristics, such as Warranty Guarantor Parts, Warranty Duration Parts, Warranty Guarantor Labor, Warranty Duration Labor, and Warranty Duration Unit, help record equipment listings, warranties, spare parts, and maintenance schedules.

Several interviews with specialists in the field, research into implementation situations, and literature evaluation revealed 25 BIM uses per project phase (

Figure 3). The descriptions were written to provide the project team members unfamiliar with BIM use with a quick introduction and offer extra information that may be useful throughout the selection process. Each description provides a BIM use overview, possible advantages, team capabilities, and links for further information.

Figure 3 shows a BIM use description.

In operational asset management, BIM is used for primary and secondary purposes to improve efficiency. While there is no common list of 25 major and secondary BIM applications, several important ones for operational asset management have been identified in this study.

As we can see from

Figure 4, these three uses for BIM have shared goals that must be met throughout the operating phase. Meanwhile, every BIM use that has been stated has unique parameters that must be examined and verified in the BIM use’s deliverable. Additionally, the owner wants to have a comprehensive data model that the FM and operator may utilize. Moreover, the asset management and its associated properties are shared by various BIM purposes. Such data are sent in the form of COBie data. However, COBie contains a variety of features, not all of which are connected to the chosen BIM purposes. Consequently, each possible value from these allocated BIM uses was analyzed and matched with a COBie.type dataset, as

Figure 5 illustrates.

This study has been conducted by utilizing the case study research approach to investigate the relationship between the COBie dataset from the as-built BIM model and owners’/FM BIM use selection by proposing a framework to evaluate the COBie dataset, as shown in

Figure 6.

Derived from the identified problem statements and research objectives, this study has formulated a set of objectives and work procedures to address critical issues at the intersection of Building Information Modeling (BIM) and the Construction Operations Building Information Exchange (COBie) standard. To investigate the major gaps and discrepancies prevailing between the as-built BIM model and COBie deliverables during facility management, construction documents of as-built conditions and use case requirements for facility management were thoroughly reviewed and analyzed. A comparative analysis was performed between various as-built BIM models and corresponding COBie deliverables to identify the major gaps and discrepancies. Quantitative data analysis techniques and expert insights were employed to understand the reasons behind these discrepancies, as illustrated in

Figure 7.

To evaluate the impact of the divergence of as-built BIM models from Employer Information Requirements (EIRs) on the operation and maintenance phase of a building project, a case study analysis of different building projects where the as-built BIM models diverged from the EIRs was conducted. The predefined BIM uses and goals were analyzed, stakeholders were interviewed, and a survey was administered to understand the extent and impact of such divergence on the operation and maintenance phase, as elaborated in

Figure 8.

To improve the translation process of BIM models into IFC instance files according to COBie guidelines, ensuring the inclusion of all essential handover data, the Solibri Model Checker software v9.9.5.113 was utilized to critically review and check the COBie datasets. The review focused on the completeness of data and compliance with COBie guidelines. Based on the findings, enhancements to the translation process were proposed, including both technical and procedural improvements.

To assess the current role of COBie in the exchange of facility management and project handover data, and suggest potential improvements, an extensive literature review was carried out to understand the theoretical role of COBie in data exchange. Real-world practices were obtained through case studies, surveys, and interviews with industry professionals. The findings led to the identification of gaps and the proposal of improvements, which included recommendations for revised procedures, technology enhancements, and policy changes.

A methodology was devised to evaluate the compliance of the Construction Operations Building Information Exchange (COBie) dataset with client specifications delineated in the Employer’s Information Requirements (EIR) through the utilisation of Solibri Model Checker (SMC). This entailed the delineation of pivotal evaluation criteria rooted in the client’s requirements. Subsequently, a systematic, stepwise protocol was delineated for the application of SMC to conduct evaluations vis-à-vis these criteria. The efficacy of this methodology was validated through its application in real-world project scenarios, followed by an iterative refinement process based on accrued results and stakeholder feedback. This iterative refinement ensured that the methodology remained pragmatic, precise, and comprehensive in fulfilling client expectations.

To design an automated checking framework using the Java programming language that aligns owners’ requirements as defined in the BIM compliance sheet (during the design phase) with COBie deliverables in facility management, requirements and specifications for the automated checking framework were defined based on industry standards and expert opinions. A prototype of the system was designed and developed using the Java programming language. This system allows owners/FM to better understand BIM uses and goals and facilitate the process of defining project needs. Moreover, this system was tested and validated against real-world scenarios to ensure its effectiveness, involving several iterative cycles of development, testing, and refinement based on feedback and results.

5. Case Study

In the case study of a clinic structure, the usefulness of the COBie dataset is analyzed.

Figure 14 depicts the clinic’s building layout. The medical center has three stories and is partitioned into five sections: A, B, C, D, and E. The clinic’s unorthodox Block A floor design is depicted in

Figure 15. The clinic’s structure was examined to learn more about the construction paperwork. The COBie file contained information about the building’s construction that was extracted by the authorities. Combining data from the clinic’s installation and warranty stages, the final COBie file makes many assumptions about what is and is not included in the finished building. This medical facility has implemented a COBie dataset to interpret building data better. Following is a description of the most typical file formats in our case study clinic’s administrative database. Space and component-type data have subsequently been evaluated in this work.

The COBie data columns contain information about various elements of the components in a clinic building project. The “Name” column specifies the identifier or name of each component. The “CreatedBy” and “CreatedOn” columns indicate the user or entity responsible for creating the component and the date it was created, respectively. The “Category” column classifies the components into specific categories. The “Description” column provides a brief summary of each component. The “AssetType” column denotes the type of asset or equipment. The “Manufacturer” and “ModelNumber” columns specify the manufacturer and model number of the components. The “WarrantyGuarantorParts”, “WarrantyDurationParts”, “WarrantyGuarantorLabor”, and “WarrantyDurationLabor” columns contain information about the warranty coverage for parts and labor. The “WarrantyDurationUnit” column represents the unit of measurement for the warranty duration. The “ExtSystem”, “ExtObject,” and “ExtIdentifier” columns relate to external systems or objects associated with the components. The “ReplacementCost” column indicates the cost of replacing each component. The “ExpectedLife” and “DurationUnit” columns specify the expected lifespan of the components and the unit of measurement for the duration. The “WarrantyDescription” column provides a detailed description of the warranty coverage. Additionally, other columns contain specific details about the components, such as dimensions, references, shape, size, color, finish, grade, material, constituents, features, and performance in terms of accessibility, building codes, and sustainability standards.

Figure 16 represents the dataset of COBie type of the clinic building. In COBie (Construction Operations Building Information Exchange), when certain data columns in an Excel sheet appear as purple and display “N/A,” it typically indicates that there is no applicable or relevant data available for those specific fields. The color purple is often used as a visual indicator to highlight cells where data is not applicable or unavailable. “N/A” stands for “Not Applicable” or “Not Available,” indicating that the information for that particular field is not relevant or cannot be provided at the moment. This color and notation help users quickly identify areas where data may be missing or where certain information is not applicable to the context of the project or dataset being analyzed. It’s essential for maintaining data integrity and transparency within the COBie datasheet.

The initial investigation makes it clear that the volume of data is too great to manage effectively. Handling such a large dataset in an Excel-based datasheet takes a lot of time and effort. The process becomes laborious when new information must be gathered to make edits. Here is a description of the most challenging aspects of working with COBie data. Professionals face these challenges when handling the COBie component and type datasets.

The COBie datasheet collects a large amount of interconnected and scattered information across multiple workbooks. Additionally, as the project develops, so does the information contained inside the COBie datasheet. Because updating one piece of information affects other information, these alterations are spread across several worksheets. Users need to put in a lot of time and effort to track down these updates in the COBie spreadsheet. Spotting a change will require much work from the user, including zooming in and out, scrolling down, filtering, and sorting.

Furthermore, not all data can be relied upon to be mechanically retrieved from the BIM model and inserted into the COBie document. A considerable amount of information needs to be gathered manually. Manual data collection increases the risk of human error because the user must verify the accuracy of all dependencies and links between data cells across all workbooks. Checking data correctness and consistency in data and method, finding these changes, and ensuring all relevant data are correctly captured are challenging tasks requiring high levels of cognitive knowledge.

The COBie responsibility matrix and the COBie guidebook are two documents used to guide a COBie data dump. A few things could be improved with COBie data dumps, even though the method has some admirable goals. However, knowing the COBie data drop process is crucial for thoroughly exploring these challenges. Multiple authors and organizations have offered their definitions of the data drop phases. For instance, categorized data drops into six stages: as-planned, as-designed, as-constructed, as-occupied, as-built, and as-maintained. Every time a COBie data dump is made, it must be thoroughly verified to ensure that the COBie datasheet remains consistent. An investigational study was conducted using NIBS’s BIM Model for COBie-related research. Exploratory studies were conducted to learn more about the COBie datasheet’s layout, connections, and data origin.

There are logical relationships between several pieces of information inside the COBie datasheet (for instance, the “Jobs” worksheet has a column for mentioning the activities that came before them). However, existing COBie verifiers like the ONUMA COBie validator [

29] or the COBie QC tool cannot spot any errors in these data (because they only verify the data format and essential connections). These quality assurance measures often just examine values and relationships. The COBie datasheet is part of a larger, living document and should not be viewed in isolation. The development of the project’s assets can be better understood if the team can track the history of the information included in the COBie datasheet.

The lack of visualization and query functionality in COBie datasheets is a crucial hindrance to their use. To address the issue of visually representing the COBie datasheet and COBie datasheet with a node-link diagram, OWL language was developed as a query instrument for COBie. The main issue with previous attempts is that they need to view the COBie datasheet as a separate entity, deal with the dynamic nature of the data contained inside COBie, and provide a suitable visual representation. The COBie data must be visualized over time to detect trends and anomalies. Patterns and changes can be seen by charting the data on a timeline. Trends in energy use or repair requests, for instance, may appear over time and might influence facility management and planning decisions. This visualization might help clarify the extent to which a project’s changes affect the data in COBie. Patterns and shifts in a COBie sheet could be highlighted using such visualization tools (for instance, data without any link signify that supporting data are absent, which is a mistake in COBie output).

Since COBie requires merging data from all trades (architecture, MEP (Mechanical, Electrical, and Plumbing), landscape, infrastructure) into one single file and manual entry is possible in the COBie datasheet; duplication of data is possible. Due to the fact that all trade data are combined into one file, it is possible for the same information to be entered more than once, which might cause confusion and mistakes. To prevent any duplication or conflicts, it is crucial to make sure the data recorded in COBie are precise, full, and consistent. The risk of duplication may be reduced, and the accuracy of the data can be guaranteed with the use of BIM software and tools that can automate the process of data entry and validation.

After determining the verification scope, it was decided that the verification system should notify users of a wide range of missing COBie datasheet data in addition to detecting errors. This improves data collection. The owner’s preferences determine a COBie capturing procedure. The COBie guidebook lists mandatory hardware and minimum settings. COBie uses several database clusters to build. This research developed a new verification system for COBie datasets. The database lists project parameters, owner specifications, and COBie guide parameters. This database helps consumers make better decisions and improves verification.

This study created a prototype model to better understand the difficulties of measuring the COBie dataset. The initial concept model shown in

Figure 17 was built in Autodesk Revit. Managing the COBie dataset presents several difficulties. In order to avoid the problems mentioned above, this research has built a framework for validating and delivering construction information to the client. The first step in using this framework is to gather the design and client requirements for the building project referenced in the EIR. The user will import an IFC model into SMC and assign all BIM uses based on the EIR specifications. Because Autodesk supports COBie data formats, building projects can save COBie data. SMC will then validate the client’s specifications built on the BIM uses using the IFC file. The user will be prompted to select the requisite BIM uses specified in the EIR. After determining the allocated BIM uses, a Python script will be executed automatically. This script thereafter examines the corresponding characteristics for each chosen BIM application. Afterward, these characteristics are correlated with the COBie dataset. Categorizing these characteristics aids in pinpointing the precise COBie dataset that needs verification. In addition, the algorithm detects shared characteristics to avoid data duplication throughout the verification process. Consequently, a customized ruleset is implemented for every shared characteristic group, denoted in this situation as a COBie.type. However, if the COBie information in the IFC file does not meet design and client requirements, the process will restart to enter the data correctly. The primary client will receive the validated design and client requirements after the iteration phase. The customized framework can check the validity of COBie.type attributes. Data validation and correctness can only be achieved by precise examination of the information present in the BIM model throughout the design and post-construction phase. It necessitates a comprehensive assessment of the data entry, verification, and updates that are included in the BIM model. It is crucial to have a system in place for spotting mistakes and inconsistencies and swiftly fixing them.

The SMC helps parties discuss data relevance and detail. This feature helps designers set a baseline for data collection and prioritize data at each stage. The case study examined the Clinic and Residence Hall’s COBie dataset for physical security, quality, quantity, and model integrity. The building model was “X-rayed”, revealing design flaws and conflicting components. For easier resolution, generated problems are grouped.

SMC loads the BIM before checking a COBie dataset. This step is crucial because it allows the software to analyze model information and validate it against COBie check rules. SMC accepts IFC and Revit files for BIM model import. Importing a BIM model into SMC takes just a few clicks. We can also use the software to review the model information, such as the objects, properties, and relationships, and ensure that they are complete and accurate, as shown in

Figure 18. It is important to note that the quality of the COBie dataset is dependent on the quality of the BIM model that is loaded into SMC. Therefore, it is essential to ensure that the BIM model is accurate, complete, and up to date before importing it into the software. This will ensure that the COBie dataset that is generated from the model is of the highest quality and meets the required standards. In summary, the first step in checking a COBie dataset using SMC is to import the BIM model into the software. This step provides the platform for the software to analyze the model information and validate it against the COBie check rules. It is important to ensure that the BIM model is accurate, complete, and up to date to guarantee that the COBie dataset that is generated from the model meets the required standards.

Selecting the BIM uses in SMC is the most crucial event; however, a JAVA tool has been developed to allow users to assign the desired BIM uses, as indicated by the dashed rectangular line in

Figure 19. The assignment will occur in Solibri Model Checker associated with the EIR, which requires a methodical and deliberate approach:

Comprehend EIR Requirements: examine the EIR comprehensively to understand the employer’s requirements, goals, and precise details related to BIM implementation. The EIR delineates the specific data and delivery preferences that the employer necessitates for the project.

Synchronize BIM uses with Employer’s Information Requirements (EIR): align the uses of BIM with the precise criteria specified in the EIR. Identify the BIM uses, procedures, or outputs that will successfully meet these needs.

Specify and define the criteria and structures: verify that the uses of BIM are in accordance with the prescribed criteria, formats, and procedures outlined in the EIR. These considerations may include factors such as file formats, data interchange protocols, level of detail (LOD) requirements, or any particular program preferences.

Incorporate EIR requirements into the workflow: integrate the EIR requirements smoothly into the project procedure. This entails integrating the uses of Building Information Modeling (BIM) with the project schedule, significant events, and other project-specific procedures. Ensuring that BIM uses are in line with the EIR is essential for satisfying the employer’s expectations and guaranteeing the effective delivery of project information in the correct format and quality.

The third step in checking a COBie dataset using SMC is to set up the COBie check rules. This step is critical as it determines the level of detail and accuracy required for the COBie dataset, ensuring that the model information is compliant with industry standards and best practices. SMC comes with a built-in library of COBie check rules that can be used to validate the completeness and accuracy of the model information. These rules are organized into categories such as basic information, assets, spaces, and systems, and can be customized to meet the specific requirements of a building project.

To set up the COBie check rules in SMC, you need to select the appropriate check category from the library and apply it to the model. The process of applying the COBie check rules is straightforward and can be completed in just a few clicks. You can select one or more categories and apply the rules to the entire model or to specific parts of the model, depending on your requirements, as shown in

Figure 20.

Once the COBie check rules have been set up, SMC will use them to analyze the model information and identify any issues or inconsistencies found. The software will provide a clear and concise report of the results, highlighting any errors or omissions in the model information. This report can be used by building professionals to quickly identify and resolve any issues with the model information.

It is important to note that the COBie check rules are customizable and can be tailored to meet the specific requirements of a building project. This gives the data validation procedure flexibility and ensures that the COBie output complies with the project’s standards and criteria. Java programming can be used to customize the COBie check rules. For example, you can create custom check rules to verify that specific information, such as asset names or space numbers, is correctly formatted and entered into the model.

In conclusion, establishing the COBie check rules is the second stage of checking a COBie dataset with SMC. This is a crucial stage because it establishes the requirements for the COBie dataset and verifies that the model data adhere to best practices and standards. The COBie check rules included in SMC can be modified to better suit the needs of a given construction project. Professionals in the construction industry receive a clear and concise report of the results after the model information is analyzed using the COBie check rules, which identify any problems or inconsistencies discovered. These rules can be modified to meet the specific requirements of a building project. After running the BIM model through the COBie check rules, any issues or discrepancies found are documented and relayed to the construction experts. By verifying the accuracy and completeness of the model data, this reduces the likelihood of mistakes and omissions occurring during the design and construction phases.

A ruleset contains information about the order of the rules and possible sub-rulesets, as well as parameter values used for the rules. Rules are parametric, which means their behavior can be controlled by setting the parametric values. In this research, the following rulesets were selected to check the validity of the data. In this phase, the building elements that are not classified should be classified. As shown in

Figure 21, several architectural components modeled in ArchiCAD required classification in SMC. However, in the unclassified components, several exterior walls needed classification in SMC.

The fourth step in checking a COBie dataset using Solibri Model Checker (SMC) is to review and resolve any issues or inconsistencies identified in the model information.

Figure 22 represents the illustration of the checking interface in Solibri Model Checker (SMC). This step is crucial as it ensures that the COBie dataset meets the required standards and best practices and is complete and accurate. SMC provides a clear and concise report of any issues or inconsistencies found in the model information during the COBie check process. The report is organized by category, such as basic information, assets, spaces, and systems, and highlights any errors or omissions in the model information.

To review and resolve the issues, you need to go through the report and identify the specific items that need to be addressed. You can use the report to navigate directly to the relevant parts of the model, making it easy to identify and resolve the issues. Once you have identified the issues, you need to make the necessary corrections to the model information. This could involve adding missing information, modifying incorrect information, or correcting any formatting errors. The corrections can be made directly in SMC or in the original BIM model, depending on your preference.

Model information determines COBie dataset quality. Before generating the COBie dataset, all issues must be resolved, and model information must be complete and accurate. This ensures that the COBie dataset meets standards and best practices and provides building professionals with the information they need to manage and maintain the building. The third step in SMC-checking a COBie dataset is to review and fix model information issues. This step ensures that the COBie dataset is complete and accurate. SMC provides a clear and concise report of model information issues and inconsistencies, making them easy to identify and resolve.

When using Solibri Model Checker (SMC) to validate a COBie.type dataset, step five involves examining the generated data. In this step, the COBie attributes are validated according to the assigned BIM uses, while common shared attributes for the selected BIM uses are referred to in their COBie dataset.

During the fifth step, you check the generated COBie dataset for accuracy and ensure it contains all the necessary data. This stage entails checking the related attributes to ensure that all COBie.type fields are complete and accurate. It is a crucial stage because it allows for the review of the COBie.type dataset’s accuracy and completeness before it is sent to the building owner or facility manager. Building professionals can have confidence in the data they use to manage and maintain the building by reviewing and verifying the generated COBie dataset.

After developing the customized ruleset framework, this study conducted a demo architectural model to validate its data using the suggested framework. The demo model investigates the data validity of COBie datasets such as IFC Schema type, components, and elements.

Figure 23 represents the demo model in the Solibri Model Checker (SMC) platform, illustrating the typical interface of the SMC software v9.9.5.113.

Solibri Model Checker (SMC) is a user-friendly Building Information Modeling (BIM) verification and validation software. Its interface is designed to be intuitive and easy to use, providing building professionals with the tools they need to effectively check their models for accuracy and completeness.

The main interface of SMC consists of a ribbon bar at the top of the screen, a navigation tree on the left-hand side, a model view in the center, and a report view on the right-hand side. The ribbon bar provides access to the main functions and tools in SMC, including model loading, checking, and reporting. The navigation tree offers a hierarchical view of the elements in the model, enabling quick location and selection of specific parts of the model for inspection. The model view is used to visualize the 3D representation of the model, while the report view provides a clear and concise summary of any issues or inconsistencies found in the model information.

SMC also provides a range of tools and functions to help you check and validate your models, including automatic checking, manual checking, and issue resolution. The automatic checking function uses a set of predefined rules and best practices to check the model information for accuracy and completeness. The manual checking function allows you to create custom checks for inspecting specific parts of the model for issues or inconsistencies. The issue resolution function provides a clear and concise report of any issues or inconsistencies found in the model information, making it easy to identify and resolve them. Additionally, SMC offers customization options to tailor the software to your specific needs and requirements.

In summary, the interface of Solibri Model Checker is designed to be user-friendly and intuitive, providing building professionals with the tools they need to effectively check their models for accuracy and completeness. The main interface consists of a ribbon bar, a navigation tree, a model view, and a report view, and provides a range of tools and functions to help you check and validate your models.

Figure 24 checks and validates the IFC version of the typical architectural model of a building. It also measures and validates the space and component type elements. Along with the SMC ruleset framework, this study has also developed a JAVA code to check COBie.type dataset against BIM uses assignment data automatically.

The suggested customized ruleset framework was implemented on the clinic building as a case study. Initially, the research team considered the IFC files of the architectural model for analysis. Subsequently, this implementation was applied to check the COBie type dataset. The basic steps are described below.

Step 1—Load the Model: load the Building Information Model (BIM) into SMC, either by importing an IFC file or by connecting to a BIM authoring tool.

Figure 25 represents the imported IFC model for the clinic building, mainly the architectural BIM model.

Step 2—Assign the BIM uses: as shown in

Figure 25, select the relevant BIM use as described in the EIR and best practices that should be applied to the model. The BIM uses tab provides a range of pre-defined uses. However, some of the BIM uses are grayed out, as they are needed in the planning, design, and construction phases. Meanwhile, this study focuses on the operational phase, and the three selected BIM uses are common for building assets management in this phase.

Figure 26 illustrates the assignment of BIM uses to fulfill the EIR requirements. Accordingly, an automated ruleset will be run, which in our case is the COBie.type Checker.

Step 3—Develop a customized ruleset for COBie.type: SMC provides a range of predefined rules, or you can create custom rules to meet your specific needs. In this study, a customized ruleset to verify COBie.type attributes has been developed. Additionally, the validation will scan COBie.type attributes and list the invalid values in the report. The rules were incorporated into the models using the ruleset manager and set to run directly once the BIM uses were assigned.

Step 4—Run the Checks: start the checking process by clicking on ‘Next’, then the ‘Check Model’ button. SMC will then automatically apply the selected rules to the model, identifying any issues or inconsistencies in the information, as illustrated in

Figure 26.

Step 5—Review the Results:

Figure 27 shows the results of the check, which will be displayed in the report view. The report will provide a clear and concise summary of any issues or inconsistencies found in the model, including their location and severity.

Step 6—Repeat the Process: repeat the checking process until all the issues have been resolved, and the model information is complete and accurate.

Step 7—Export the Results: export the results of the check in a range of formats, including COBie, HTML, and PDF. This makes it easy to share the results with other stakeholders, such as building owners or facility managers. In summary, checking a model using SMC involves loading the model, defining the rules, running the checks, reviewing the results, resolving the issues, repeating the process, and exporting the results. These basic activities provide a systematic and thorough approach to verifying and validating BIM models.