Experimental Study on the Mechanical Properties of Rock–Concrete Composite Specimens under Cyclic Loading

Abstract

1. Introduction

2. Materials and Method

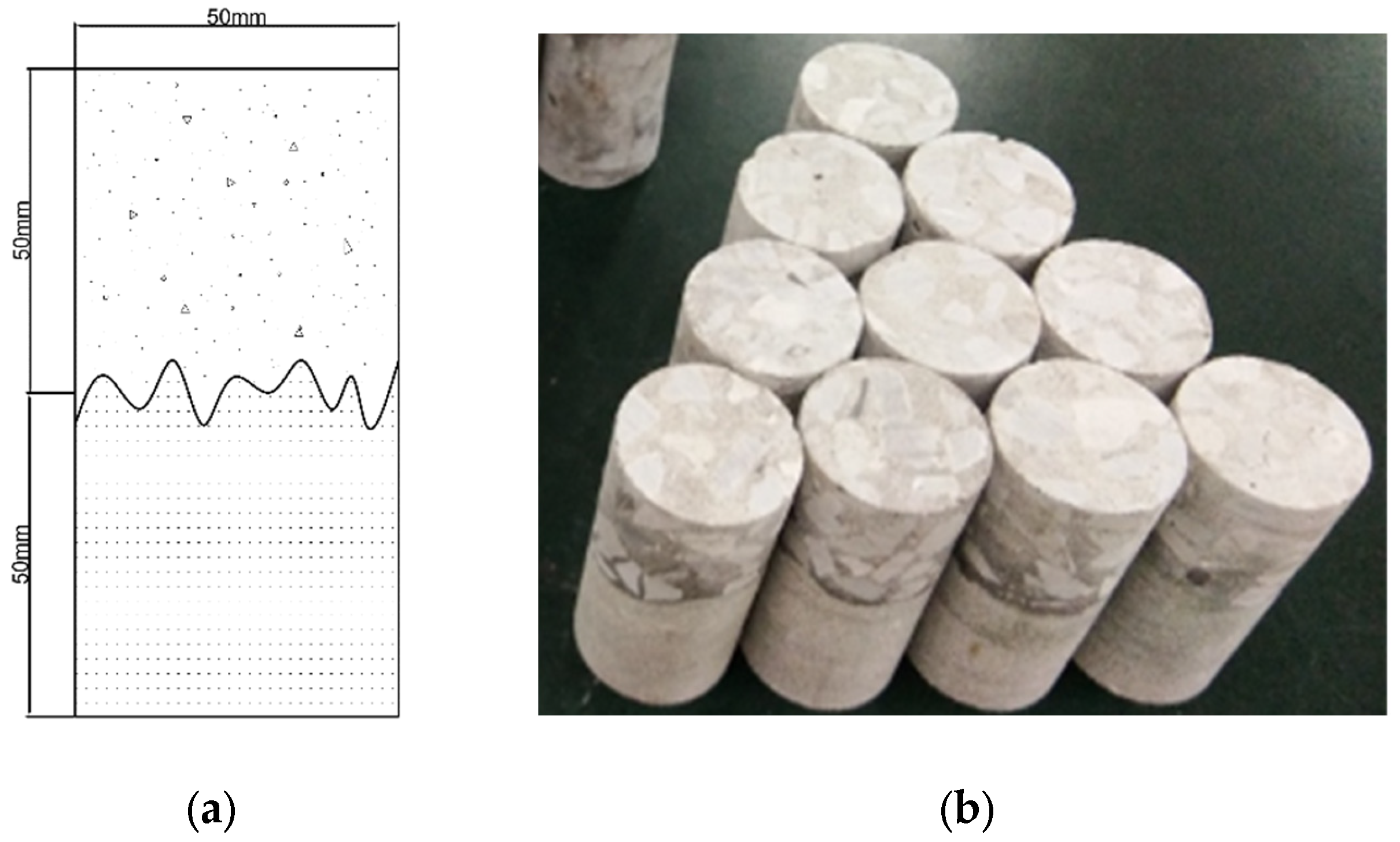

2.1. Specimen Preparation

2.2. Testing Equipment

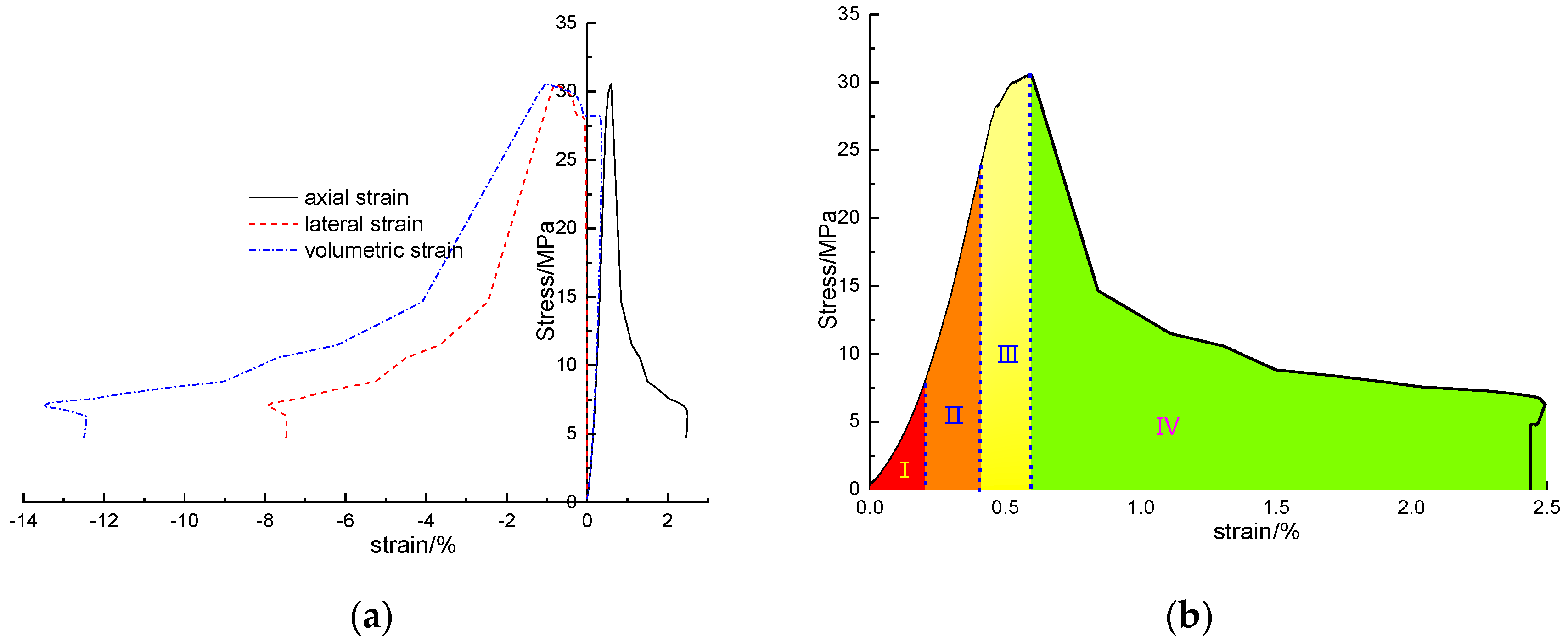

2.3. Preliminary Test

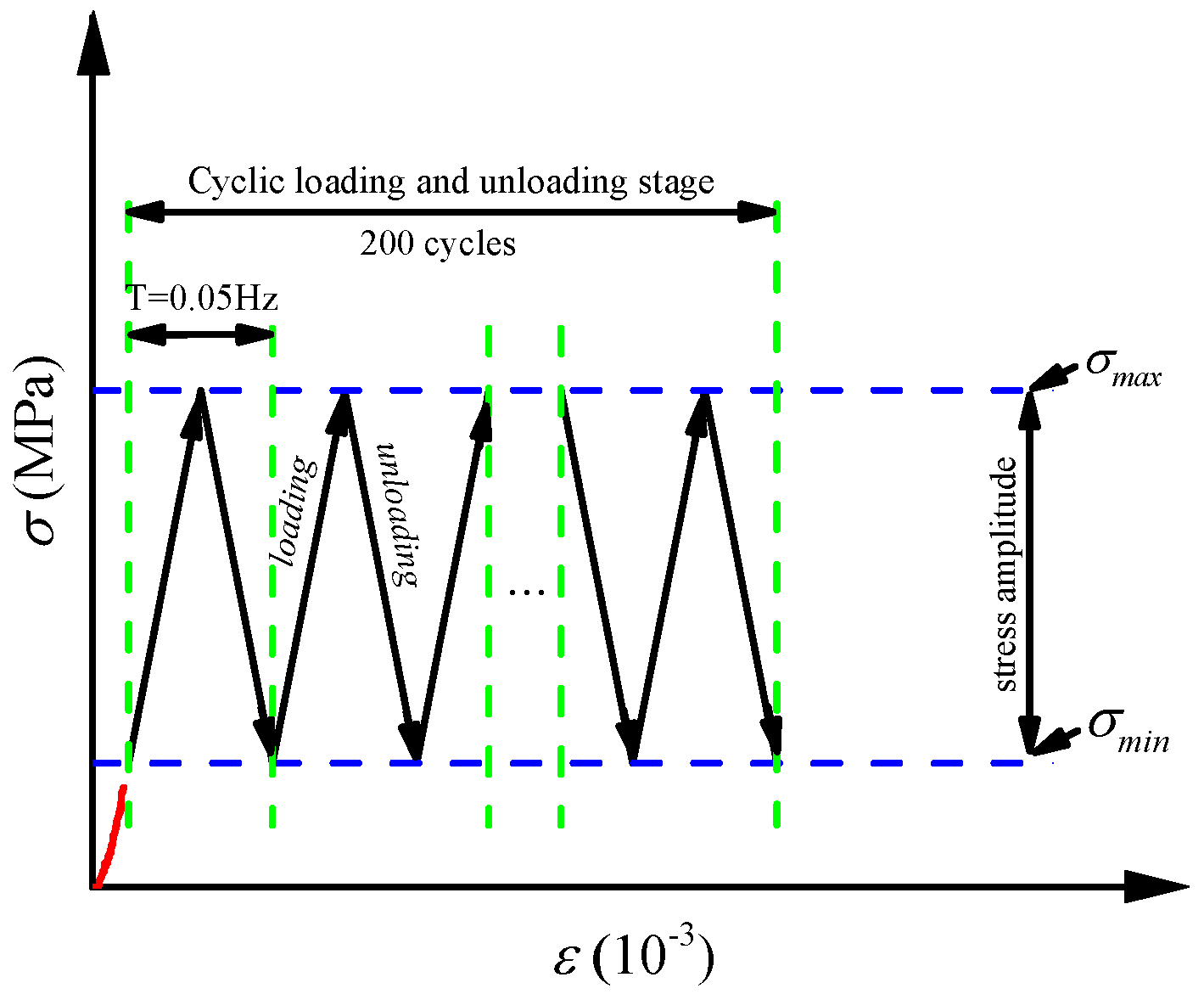

2.4. The Cyclic Loading and Unloading Test Method

3. Results and Discussion

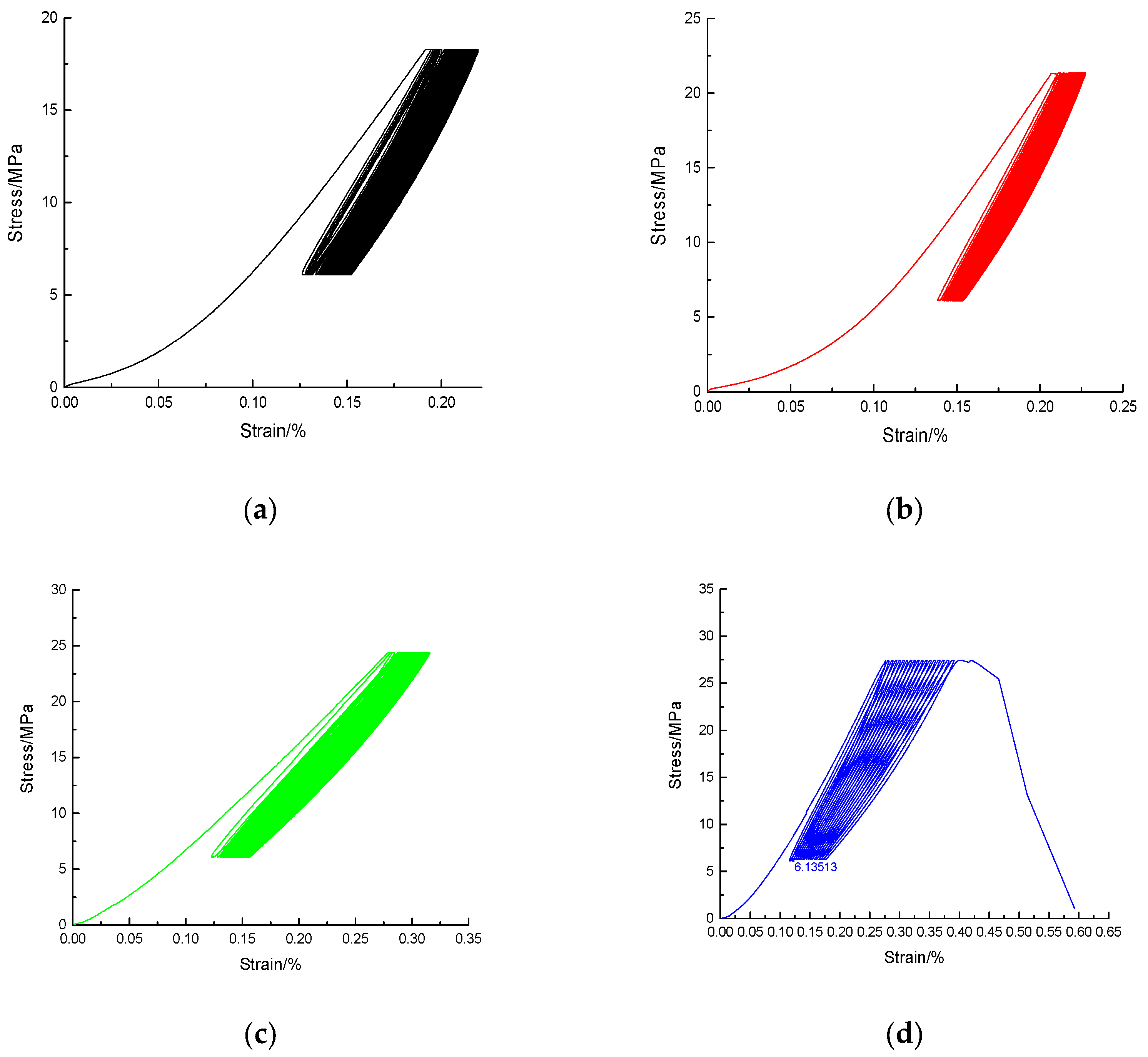

3.1. Mechanical Properties of Composite Specimens under Cyclic Loading and Unloading

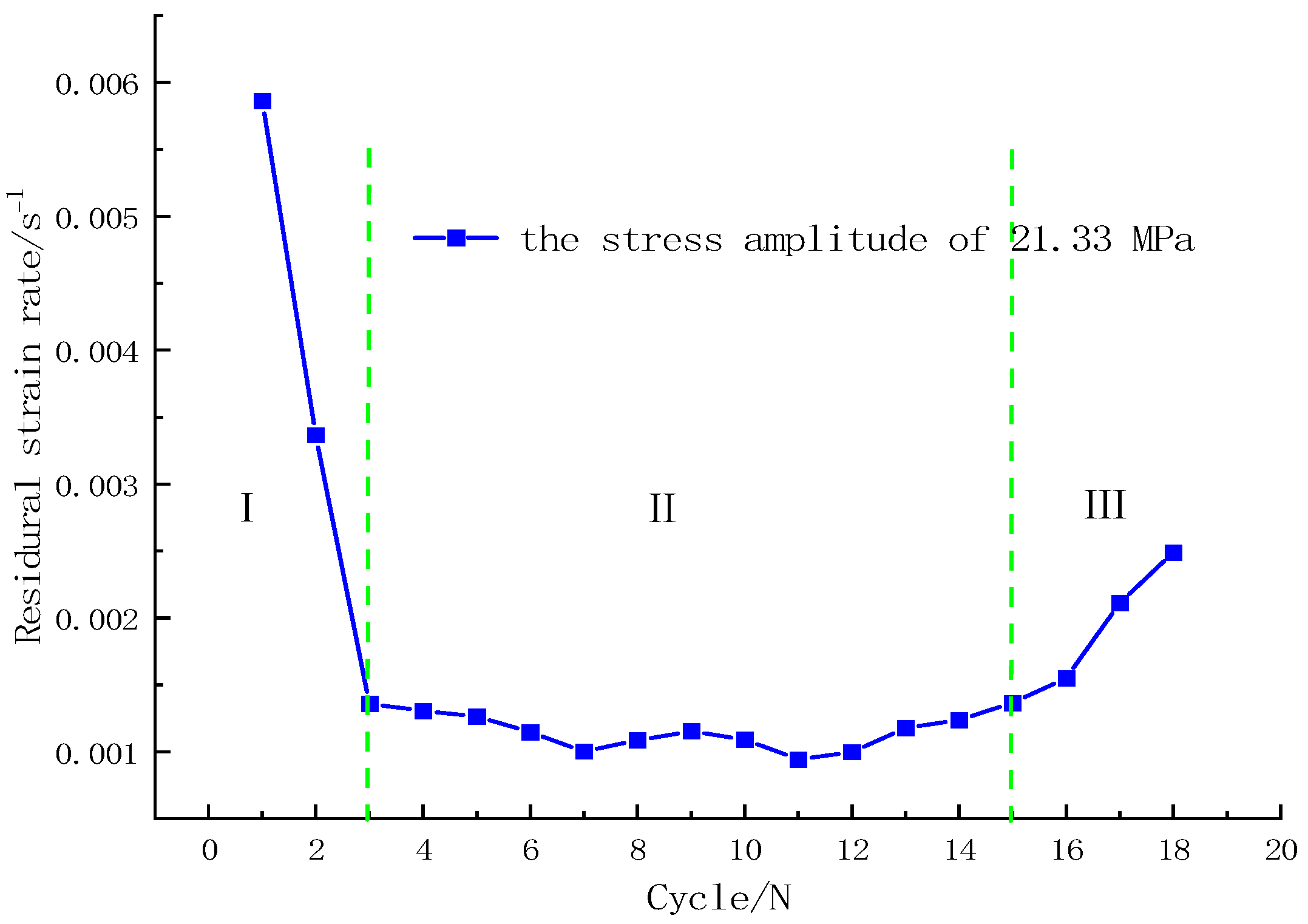

3.1.1. Deformation Characteristics

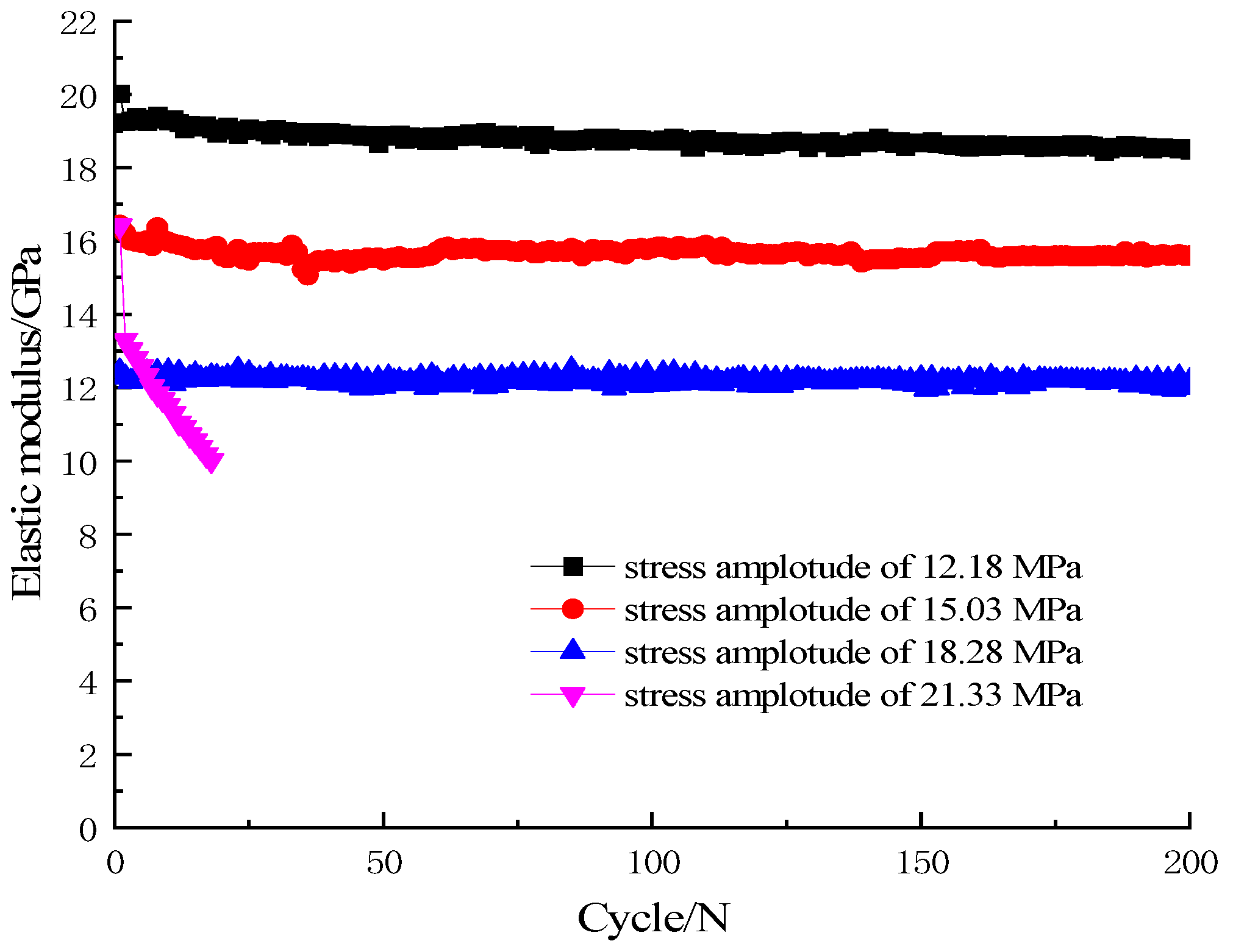

3.1.2. The Elastic Modulus: Changing Characteristics

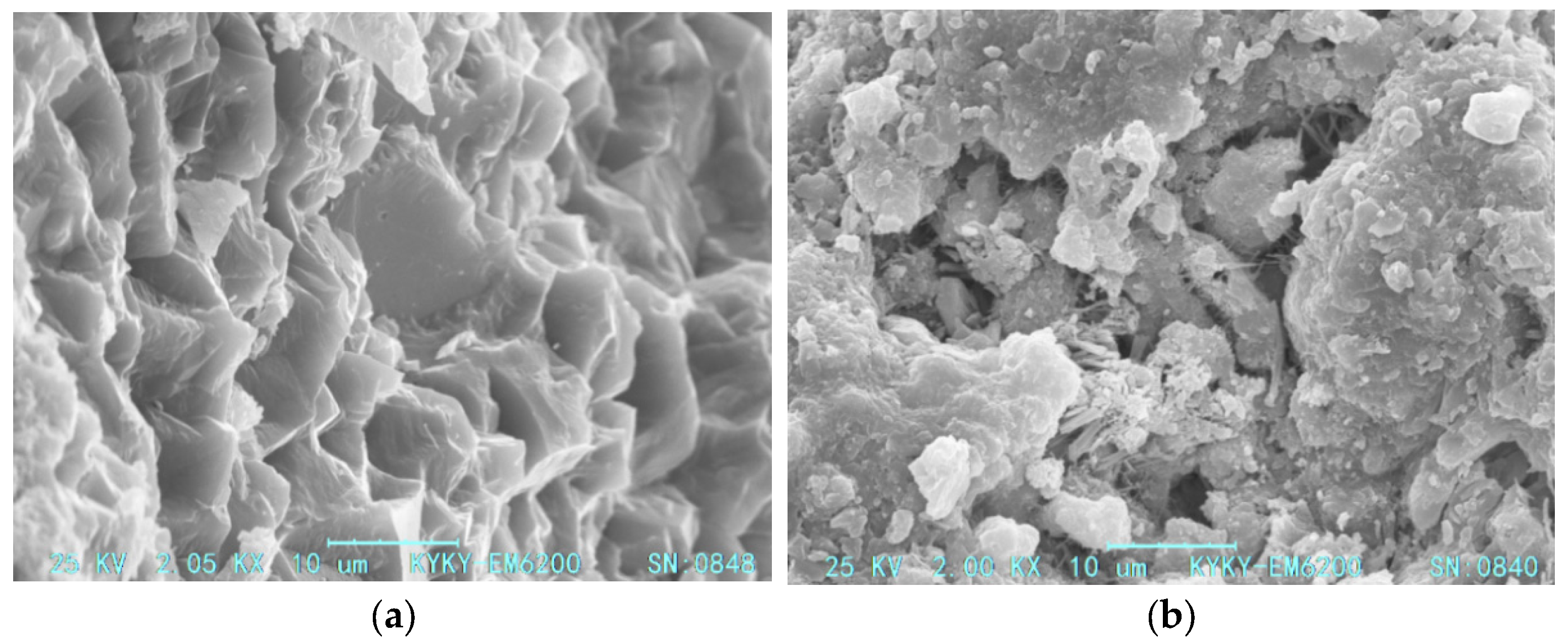

3.2. Failure Mode

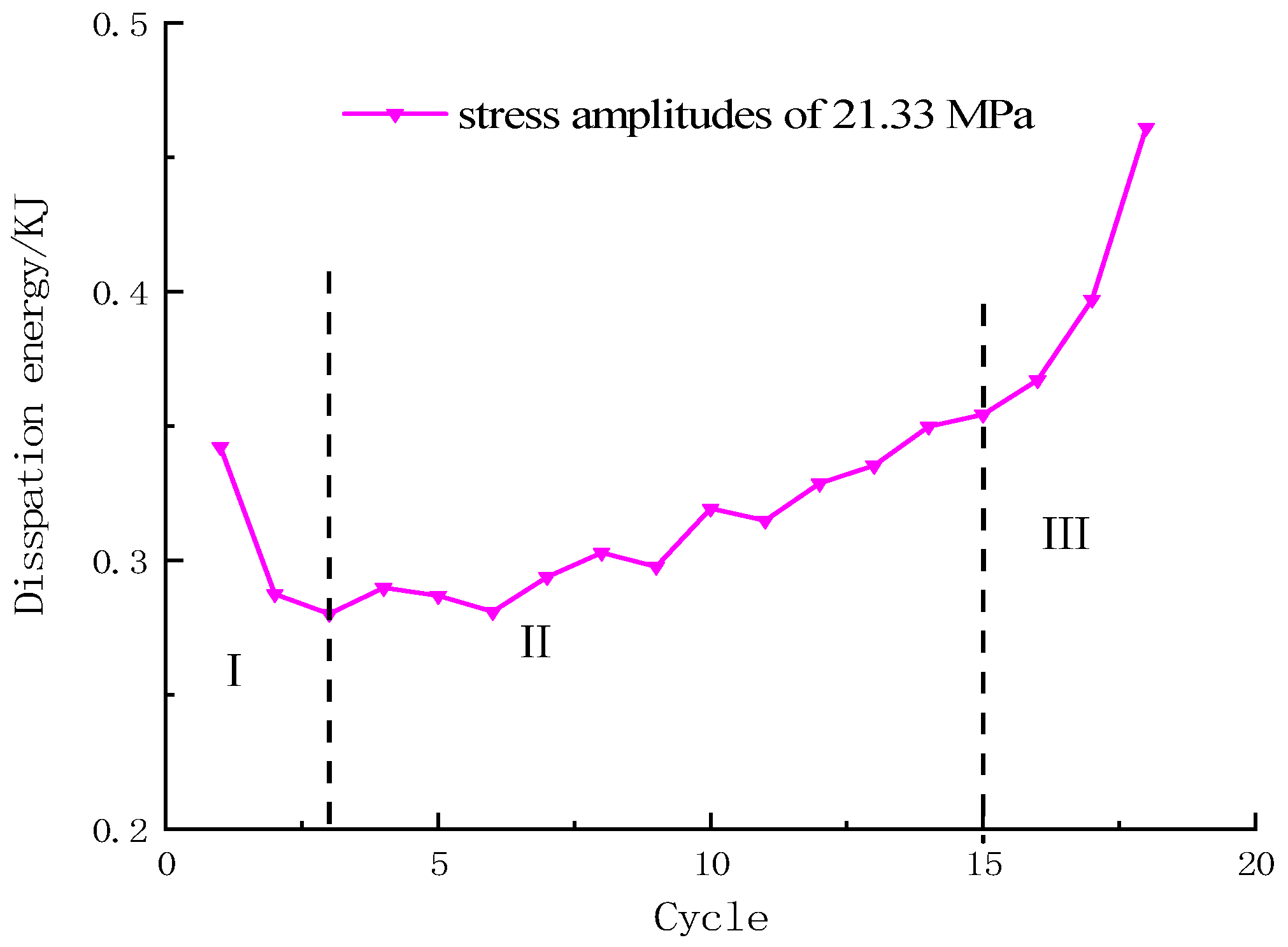

4. The Dissipated Energy Evolution and Analysis of Damage Characteristics

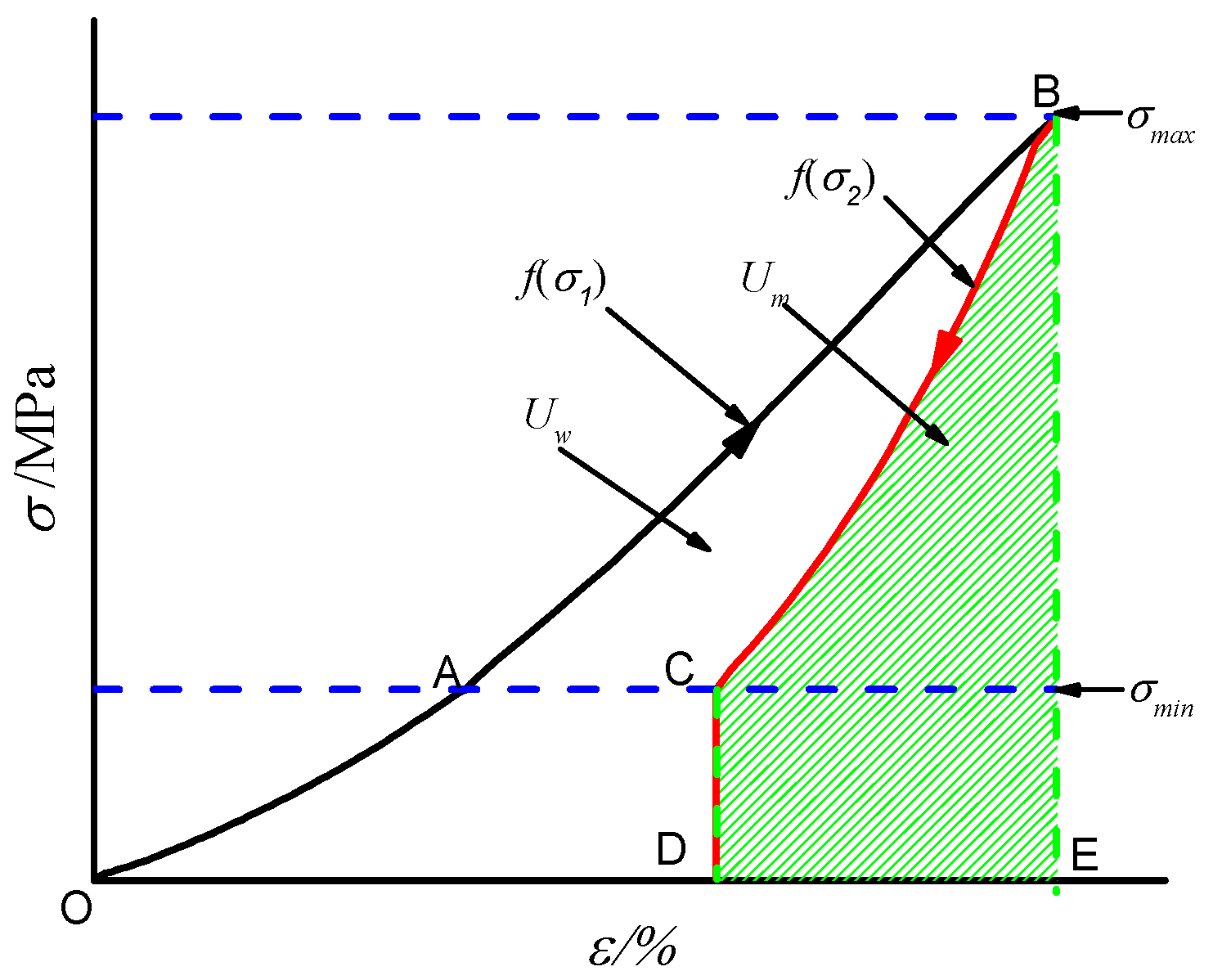

4.1. The Dissipated Energy

4.2. Damage Evolution Law

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xue, F.; Lin, Z.; Wang, T. Experimental study on effects of cyclic loading paths on cracking behavior and fracture characteristics of granite. Eng. Fract. Mech. 2024, 295, 109761. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F. A review of experimental and theoretical research on the deformation and failure behavior of rocks subjected to cyclic loading. J. Rock Mech. Geotech. Eng. 2021, 13, 1203–1230. [Google Scholar] [CrossRef]

- Arora, K.; Chakraborty, T.; Rao, K.S. Experimental study on stiffness degradation of rock under uniaxial cyclic sinusoidal compression loading. Rock Mech. Rock Eng. 2019, 52, 4785–4797. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, J.; Pu, H.; Yu, L.; Wu, J.; Wang, C. Mechanical properties of limestone after high-temperature treatment under triaxial cyclic loading and unloading conditions. Rock Mech. Rock Eng. 2021, 54, 6413–6437. [Google Scholar] [CrossRef]

- Xiao, F.; Jiang, D.; Wu, F.; Zou, Q.; Chen, J.; Chen, B.; Sun, Z. Effects of prior cyclic loading damage on failure characteristics of sandstone under true-triaxial unloading conditions. Int. J. Rock Mech. Min. Sci. 2020, 132, 104379. [Google Scholar] [CrossRef]

- Tang, L.X.; Fan, J.Y.; Li, Z.Z.; Chen, J.; Liu, W. A new constitutive model for salt rock under cyclic loadings based on state variables. Geoenergy Sci. Eng. 2024, 233, 212433. [Google Scholar] [CrossRef]

- Guo, J.C.; Li, X.Y.; Lu, C. Modified Model and Simulation Verification of Rock-Fatigue Damage Considering Repeated Discharge Impact. Processes 2023, 11, 2366. [Google Scholar] [CrossRef]

- Ren, C.H.; Yu, J.; Liu, X.Y. Cyclic constitutive equations of rock with coupled damage induced by compaction and cracking. Int. J. Min. Sci. Technol. 2022, 32, 1153–1165. [Google Scholar] [CrossRef]

- Li, Y.Q.; Huang, D. Mechanical Responses and Damage Model of Anchored Jointed Rock Mass under Fatigue Shear Load. Int. J. Geomech. 2022, 23, 3. [Google Scholar] [CrossRef]

- Li, P.; Cai, M. Energy evolution mechanism and failure criteria of jointed surrounding rock under uniaxial compression. J. Cent. S. Univ. 2021, 28, 1857–1874. [Google Scholar] [CrossRef]

- Peng, R.D.; Ju, Y.; Wang, J.G.; Xie, H.P.; Gao, F.; Mao, L.T. Energy Dissipation and Release During Coal Failure Under Conventional Triaxial Compression. Rock Mech. Rock Eng. 2015, 48, 509–526. [Google Scholar] [CrossRef]

- Sun, Y.D.; Yang, Y. Energy and Fatigue Damage Evolution of Sandstone under Different Cyclic Loading Frequencies. Shock. Vib. 2021, 2021, 5585983. [Google Scholar] [CrossRef]

- Meng, Q.B.; Liu, J.F.; Pu, H.; Huang, B.X.; Zhang, Z.Z.; Wu, J.Y. Effects of cyclic loading and unloading rates on the energy evolution of rocks with different lithology. Geomech. Energy Environ. 2023, 34, 100455. [Google Scholar] [CrossRef]

- Graf, O.; Brenner, E. Experiments for investigating the resistance of concrete under often repeated compression loads. Bull. Dtsch. Aussch. Fur Stahlbeton Berl. 1934, 35, 17–25. [Google Scholar]

- Cook, D.J.; Chindaprasirt, P. Influence of loading history upon the compressive properties of concrete. Mag. Concr. Res. 1980, 32, 89–100. [Google Scholar] [CrossRef]

- Long, X.; Mao, M.H.; Su, T.X.; Su, Y.T.; Tian, M.K. Machine learning method to predict dynamic compressive response of concrete-like material at high strain rates. Def. Technol. 2023, 23, 100–111. [Google Scholar] [CrossRef]

- Yang, S.C. Special Issue on Fatigue, Performance, and Damage Assessments of Concrete. Appl. Sci. 2024, 14, 1845. [Google Scholar] [CrossRef]

- Bian, H.B.; Liu, Y.Z.; Guo, Y.D.; Liu, Y.; Shi, W.J. Investigating stress–strain relationship and damage constitutive model of basalt fiber reinforced concrete under uniaxial compression. J. Build. Eng. 2023, 73, 106789. [Google Scholar] [CrossRef]

- Lei, X.; Sun, X.J.; Yu, Z.P.; Guan, Z.X.; Long, A.X.; Lian, H.H.; Lian, Y.J. Experimental study and theoretical analysis on dynamic mechanical properties of basalt fiber reinforced concrete. J. Build. Eng. 2022, 62, 105334. [Google Scholar]

- Li, X.N.; An, H.W.; Chen, Y.L.; Qin, Y.; Li, Y.C.; Zhou, Y.J. Mechanical properties of recycled aggregate concrete under cyclic loading and unloading in alpine areas. J. Build. Eng. 2024, 85, 108759. [Google Scholar] [CrossRef]

- Feng, S.W.; Zhou, Y.; Wang, Y.; Lei, M.D. Experimental research on the dynamic mechanical properties and damage characteristics of lightweight foamed concrete under impact loading. Int. J. Impact Eng. 2020, 140, 103558. [Google Scholar] [CrossRef]

- He, H.Q.; Liang, X.; Shang, J.K.; Long, Y.S. Experimental study on residual mechanical properties after cyclic loading of steel-concrete composite-laminated beams. Case Stud. Constr. Mater. 2023, 19, 202257. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, Y.H.; Zheng, H.Z.; Xu, F.; Zhang, Q.B.; Wang, S.Z. Seismic behaviour and modelling of rectangular FRP-concrete-steel tubular columns under axial compression and cyclic lateral loading. Structures 2023, 48, 1505–1518. [Google Scholar] [CrossRef]

- DZ/T 0276.19-2015 19; Regulation for Testing the Physical and Mechanical Properties of Rock-Part 19: Test for Determing the Deformability of Rock in Uniaxiail Compression. Standards Press of China: Beijing, China, 2015. (In Chinese)

- Li, T.T.; Pei, X.J.; Guo, J.; Meng, M.H.; Huang, R.Q. An Energy-Based Fatigue Damage Model for Sandstone Subjected to Cyclic Loading. Rock Mech. Rock Eng. 2020, 53, 5069–5079. [Google Scholar] [CrossRef]

- LI, S.C.; Xu, J.; Tao, Y.Q.; Tang, X.-J.; Yang, H.-W. Low cycle fatigue damage model and damage cariable expression of rock. Rock Soil Mech. 2009, 30, 1611–1614+1619. (In Chinese) [Google Scholar]

- Liu, Y.; Dai, F.; Dong, L.; Xu, N.; Feng, P. Experimental investigation on the fatigue mechanical properties of intermittently jointed rock models under cyclic uniaxial compression with different loading parameters. Rock Mech. Rock Eng. 2018, 51, 47–68. [Google Scholar] [CrossRef]

| Specimen/No | Upper Stress/MPa | Lower Stress/MPa | Stress Amplitude/MPa | Cycles/N | Loading Speed/(kN/s) |

|---|---|---|---|---|---|

| RC-1 | 18.29 | 6.11 | 12.18 | 200 | 0.2 |

| RC-2 | 21.34 | 6.11 | 15.03 | 200 | 0.2 |

| RC-3 | 24.39 | 6.11 | 18.28 | 200 | 0.2 |

| RC-4 | 27.44 | 6.11 | 21.33 | 200 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhao, B.; Hou, Z.; Min, H. Experimental Study on the Mechanical Properties of Rock–Concrete Composite Specimens under Cyclic Loading. Buildings 2024, 14, 854. https://doi.org/10.3390/buildings14030854

Li H, Zhao B, Hou Z, Min H. Experimental Study on the Mechanical Properties of Rock–Concrete Composite Specimens under Cyclic Loading. Buildings. 2024; 14(3):854. https://doi.org/10.3390/buildings14030854

Chicago/Turabian StyleLi, Hongjun, Baoyun Zhao, Zhengjun Hou, and Hongyao Min. 2024. "Experimental Study on the Mechanical Properties of Rock–Concrete Composite Specimens under Cyclic Loading" Buildings 14, no. 3: 854. https://doi.org/10.3390/buildings14030854

APA StyleLi, H., Zhao, B., Hou, Z., & Min, H. (2024). Experimental Study on the Mechanical Properties of Rock–Concrete Composite Specimens under Cyclic Loading. Buildings, 14(3), 854. https://doi.org/10.3390/buildings14030854