Seismic Retrofit of Concrete Buildings Damaged by Corrosion: A Case Study in Southern Italy

Abstract

1. Introduction

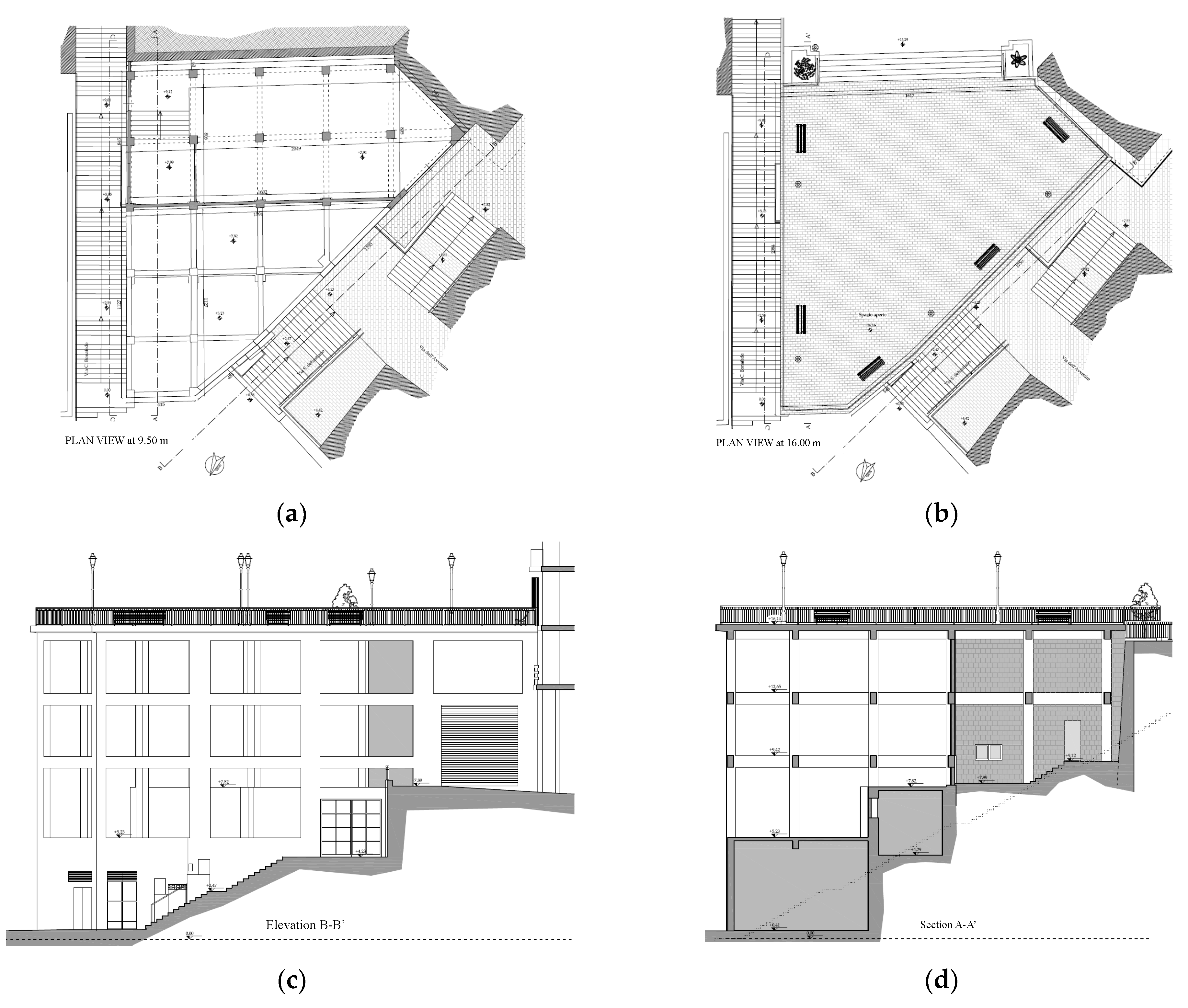

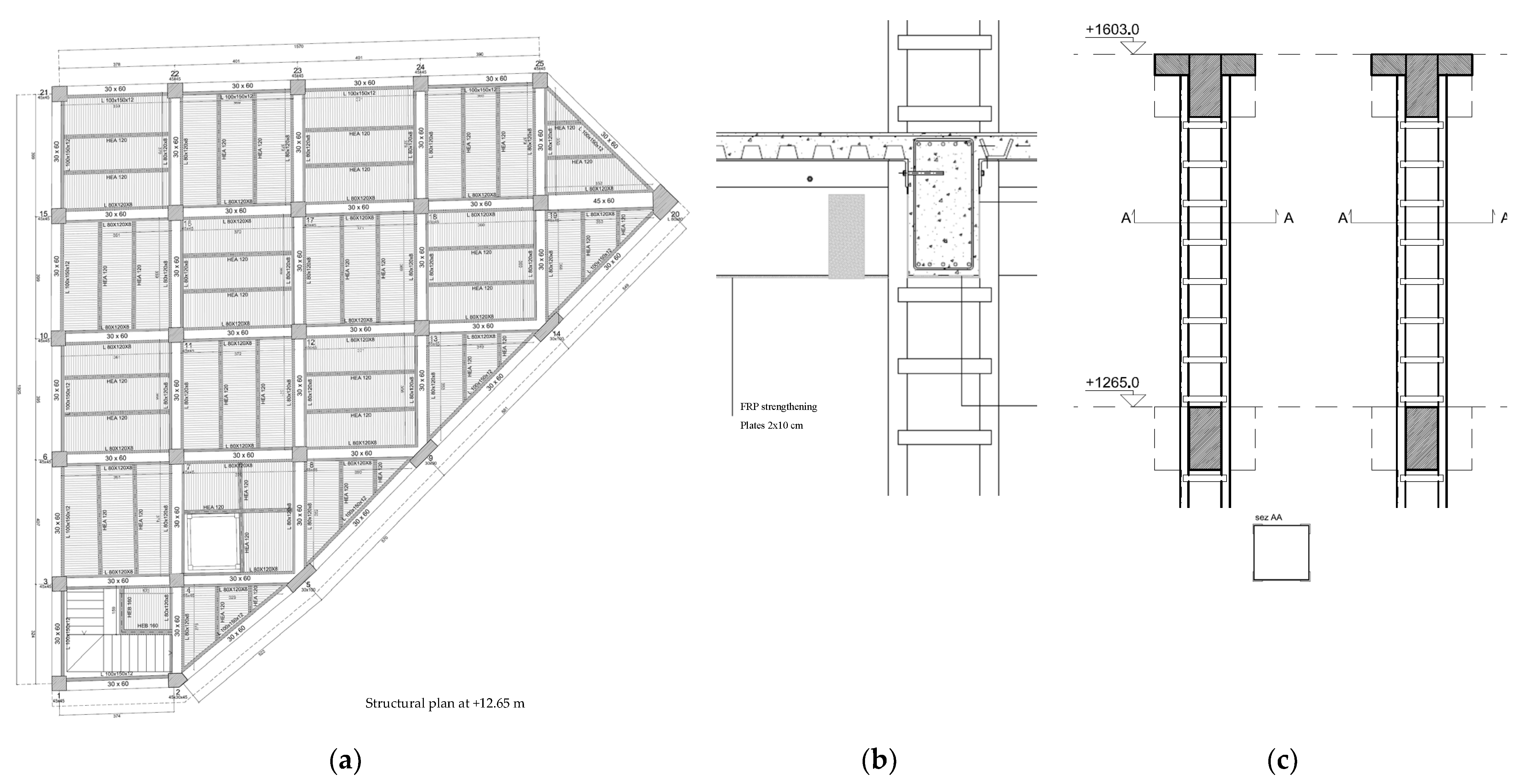

2. Presentation of the Case Study

2.1. Geometry and Preliminary Investigations

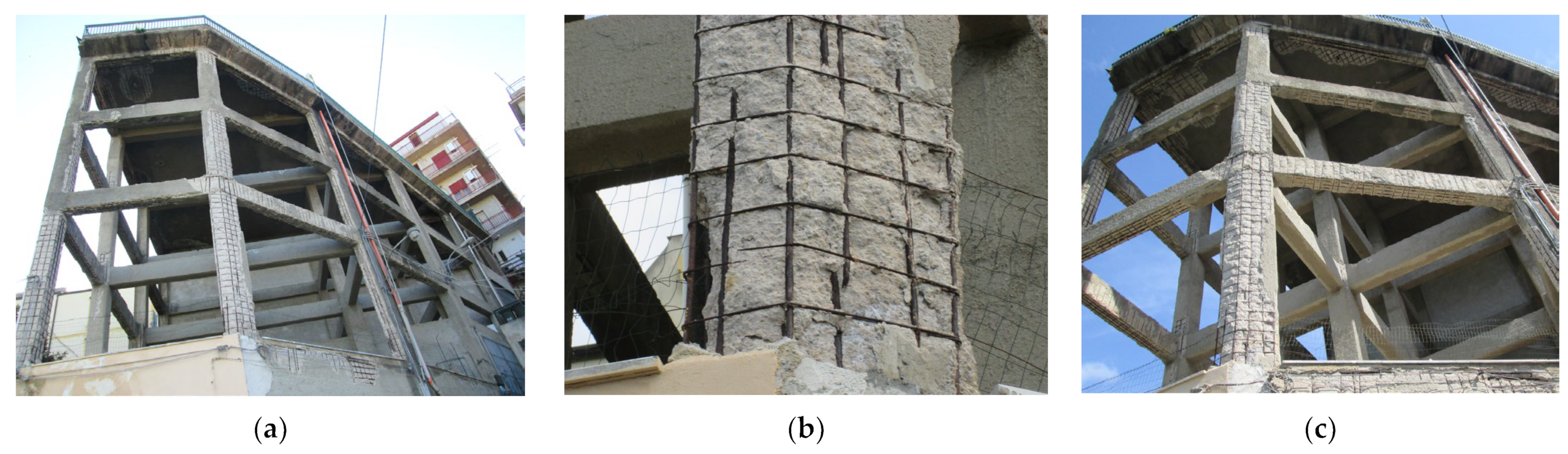

2.2. Degradation Due to Corrosion

2.3. Level of Knowledge of the Existing Structure

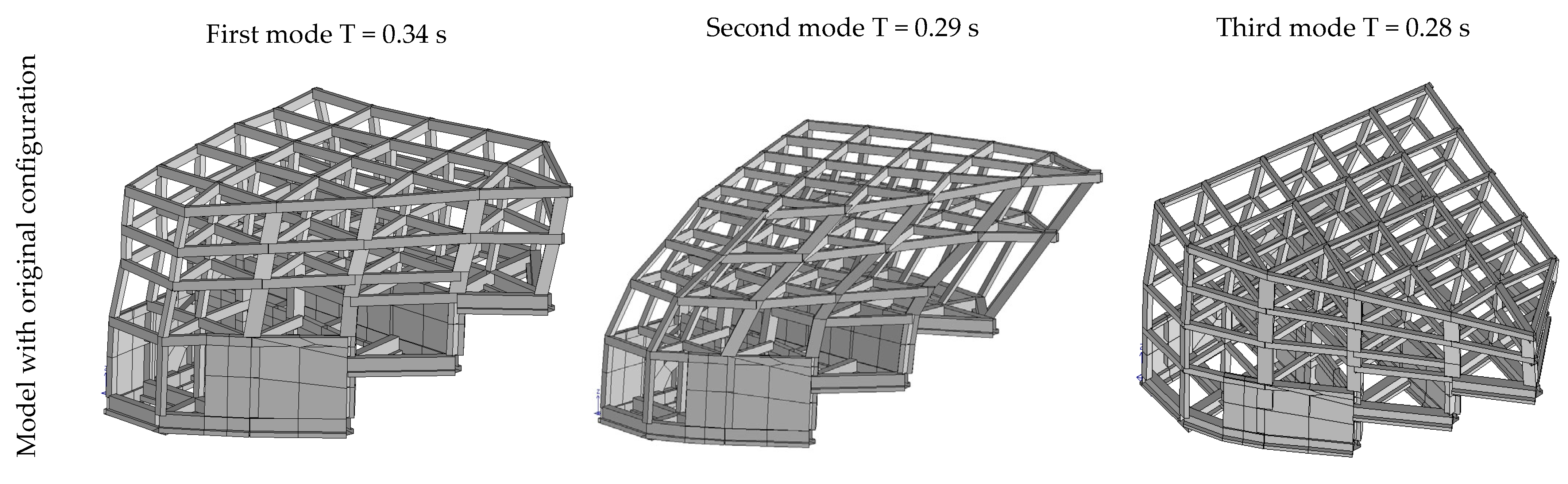

3. Structural Model and Analyses for the Seismic Assessment

3.1. Seismic Load and Linear Dynamic Analysis

- (a)

- The first model, in which the building is analyzed in its original configuration of elements without corrosion (Figure 3a).

- (b)

- The second model, in which the building is analyzed in its original configuration of elements considering corrosion.

- (c)

- The third model, in which the building is analyzed with new intermediate floors and retrofitted structural elements (Figure 3b).

- -

- For ductile structural elements, the seismic load reduced by the behavior factor q (assumed in the range 1.5–3) is applied, checking that the stress or force in every element is less than the corresponding strength value. The authors choose the factor q in accordance with the criteria reported in the chapter 7 of the Italian Standards [2], correlating the overall ductility of the structure to the structural type, taking into account a minimum dissipative condition, that is, low ductility and irregularity in the plan and elevation of the structure. This hypothesis is supported by the following aspects: spatial frames are present in the two directions, strengthening interventions are foreseen for all the load-bearing elements, and the new construction of the missing floors is planned with composite steel–concrete structures in which the top slab thickness makes it possible to consider floors rigid in their plan. Therefore, in accordance with the Italian Standards, a behavior factor q = 2.6 was assumed.

- -

- For brittle structural elements, checks must instead be satisfied with the seismic load reduced by a fixed factor q = 1.5, computing the stress/force and control that it is under the corresponding strength.

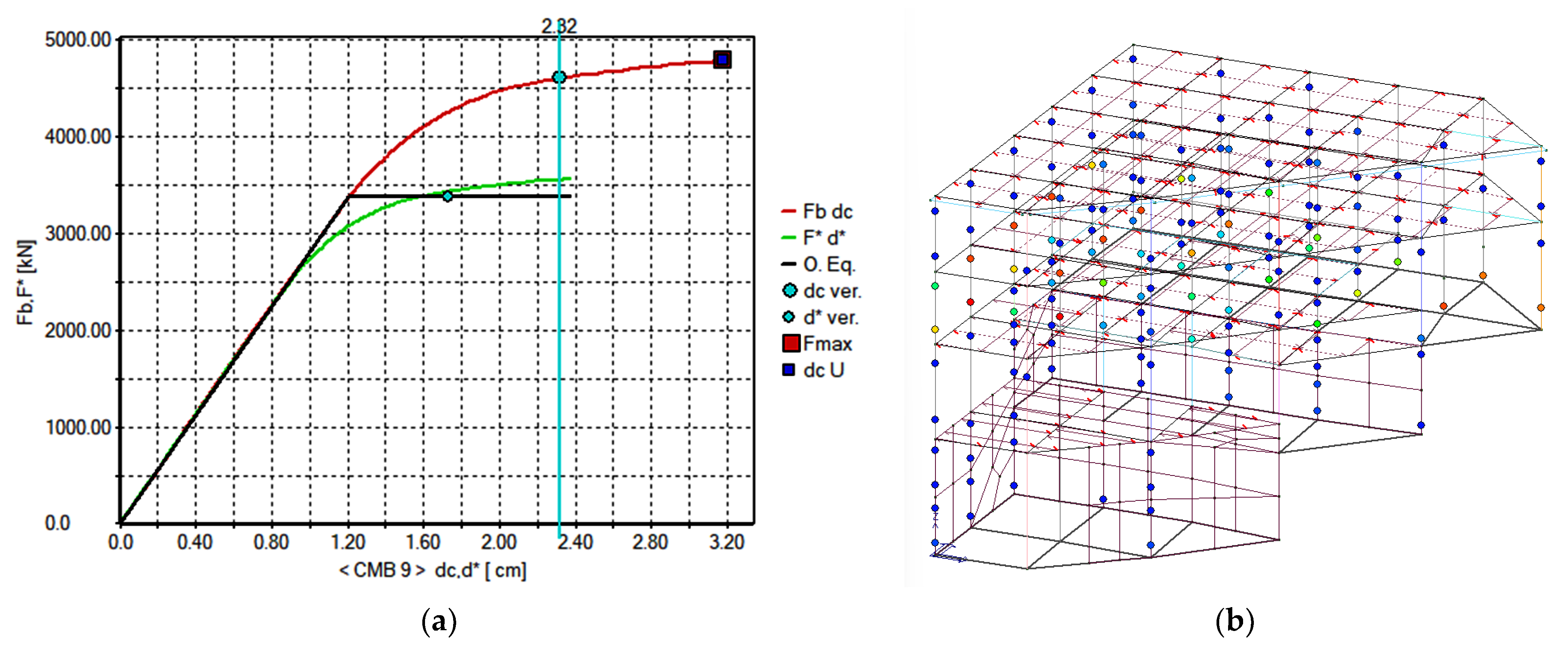

3.2. Nonlinear Static Analysis

4. Seismic Retrofit

4.1. Strategy of Retrofitting Intervention

- (1)

- The new functional configuration of the building corresponds to a new structural organization which is thought of not only for the increased vertical loads, but also for the contemporaneous reorganization of structural elements with the aim of increasing the structural regularity and decreasing the torsional effects of an earthquake on the structure, especially regarding the outermost columns. This can be considered a strategy of the first level for the global improvement through changes in geometry of elements and properties of mass and stiffness.

- (2)

- A strategy of the second level is that of increasing the strength of each structural element (beams and columns) and the overall structural capacity against failure with combined interventions of strength and ductility improvement.

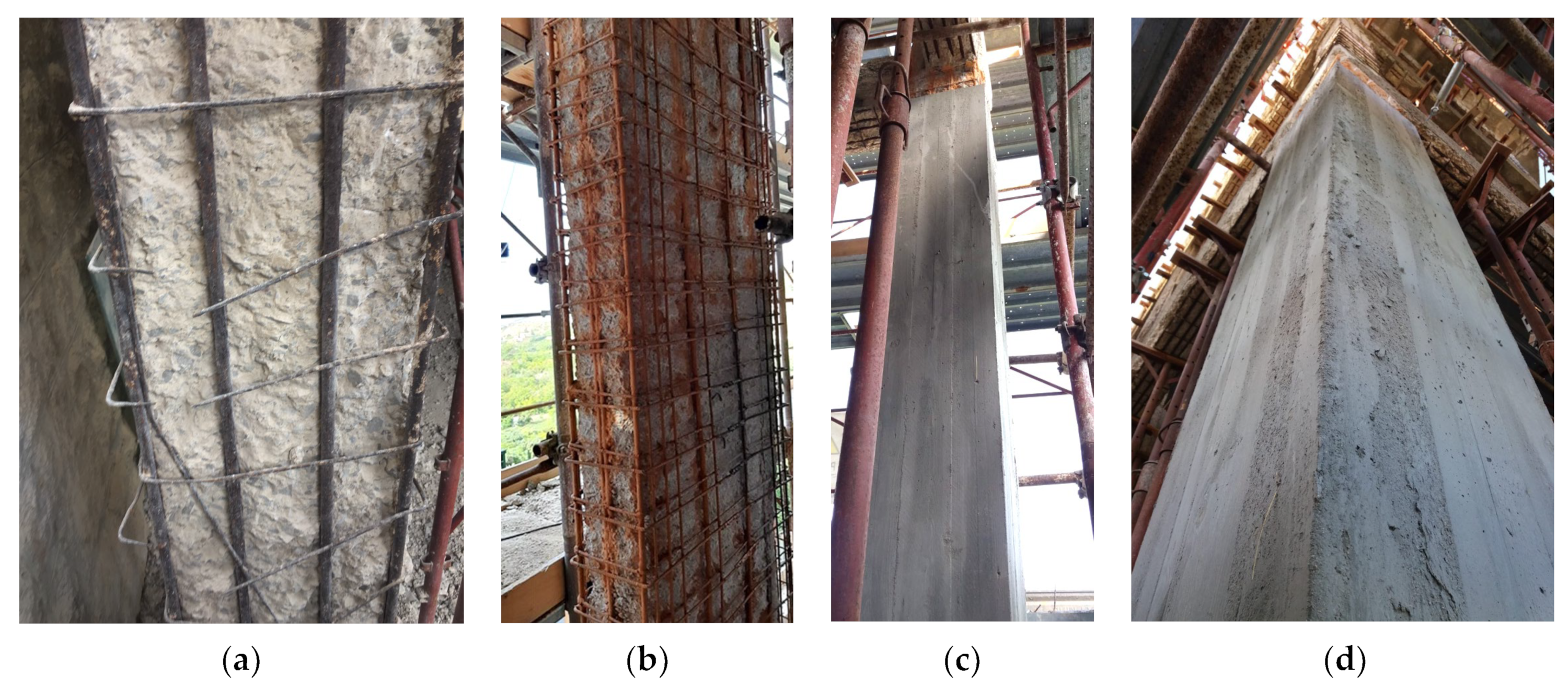

4.2. Aspects Related to Degradation and Corrosion: Concrete Jacketing of Elements

- (1)

- If the level of corrosion is less than 10% and there has been no degradation or cracking of the concrete cover, the reinforcement may be considered still partially effective, with a homogeneous reduction in the steel areas, considering that the hooks guarantee the bar anchoring at the ends, the bars being plain and not ribbed.

- (2)

- If the corrosion level exceeds 10% and surface concrete detachment or cracking occurs, then the reduction in the effectiveness of the bars must be greater because it is possible that the bond is no longer guaranteed by the hooked ends, so bending and shear strength is compromised and a strong reduction in the effectiveness of the rebar must be taken into account (in the present case it was considered 50% of area reduction for stirrups and longitudinal bars);

- (3)

- In the elements where the bars are uncovered, the concrete is deteriorated, stirrups are broken and longitudinal bars strongly corroded, the contribution of the original reinforcement has been neglected and new reinforcements have been integrated into the repaired element before the successive strengthening in order to restore the original section of the structural member.

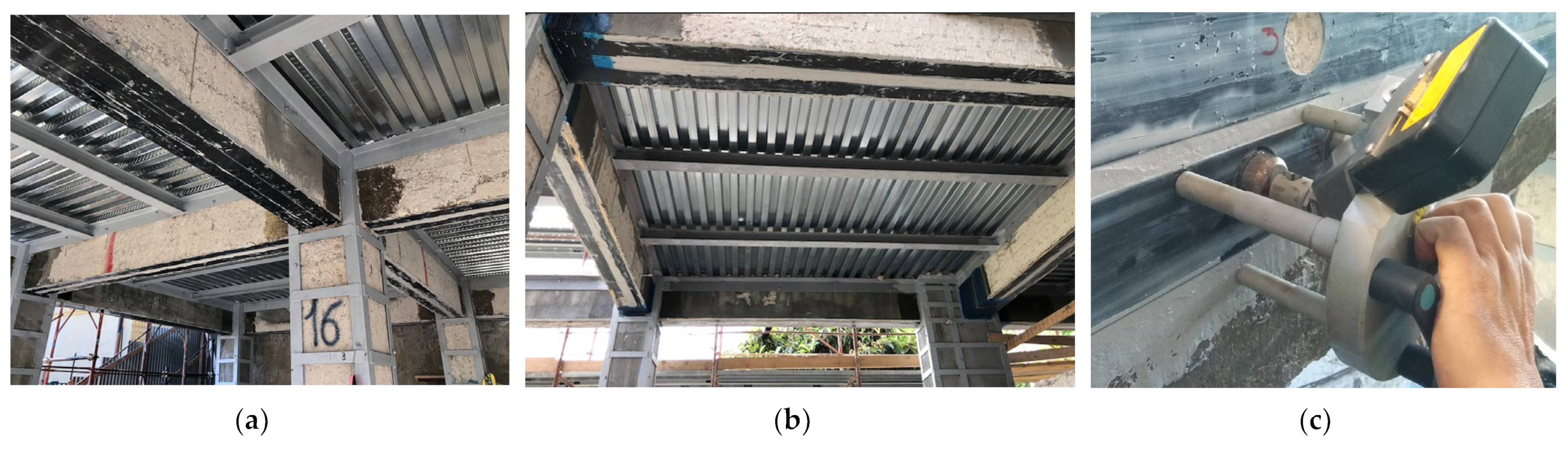

4.3. Strengthening Interventions: Steel Exoskeleton

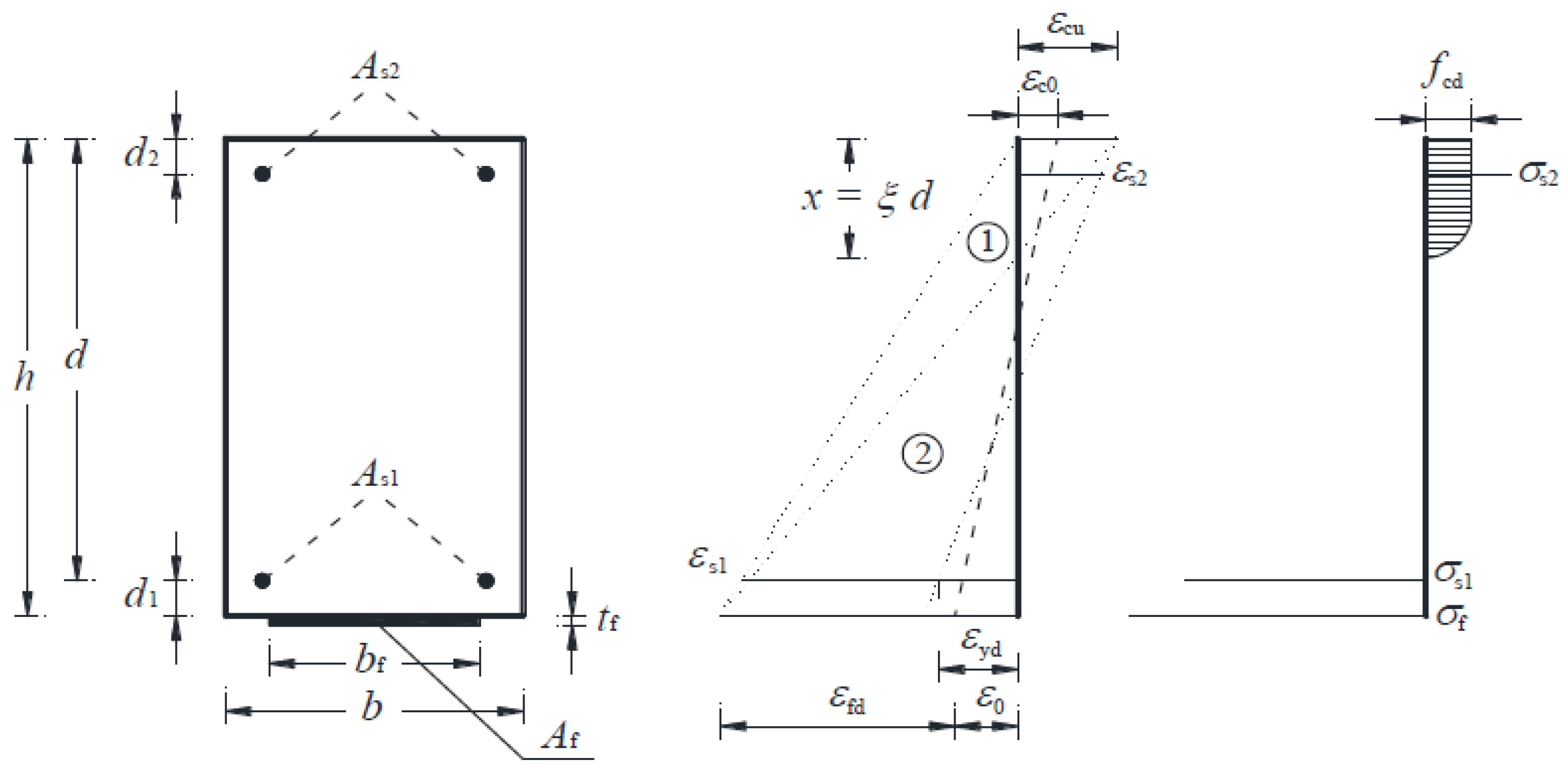

4.4. Strengthening Interventions through CFRP

4.5. Alternative Strategies and Motivations of Choices for Retrofitting

- (1)

- An alternative strategy could be to use CFRP wrapping extensively on columns and beams as well as for joint confinement. This solution was excluded because the quantities and layers of fabric needed for such an intervention were unrealistic and it would also have been necessary to provide a concrete jacketing of all the columns and beams because the CFRP tissues do not easily adhere to an irregular surface such the one presented by some concrete elements.

- (2)

- Another solution would be to use non-dissipative or dissipative bracings for the exoskeletons outside the building. This solution was also disregarded because it implies the use of very invasive steel elements that interfered with new functions and architectural aspects, as well as reducing the already rather limited outdoor spaces.

- (3)

- The use of shear walls was not considered suitable in this case because other walls were present on the three levels of the foundation and because it would not significantly change the solutions to repair the corroded elements and for the construction of the new elements.

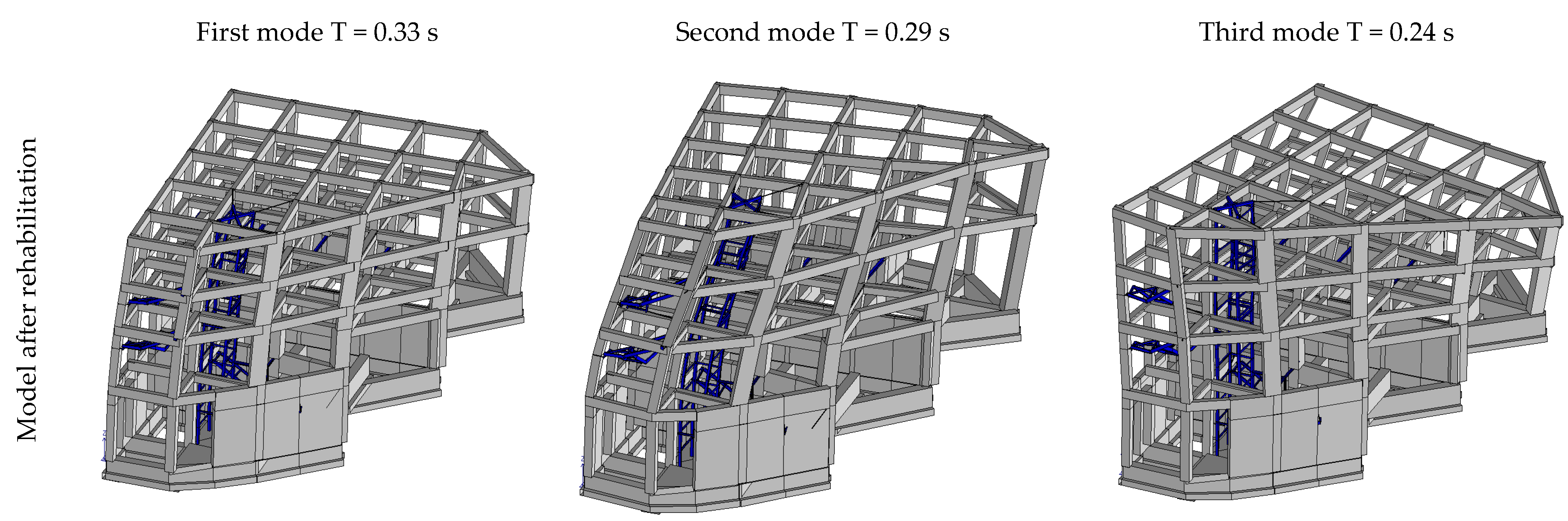

4.6. Results of the FE Model Analysis after Rehabilitation

5. Conclusions

- (1)

- A structural steel exoskeleton with an extensive use of steel jacketing supplies complete bending and shear strengthening and a confinement of the vertical elements and nodes, especially when the steel jacket is connected to the steel strengthening profiles of the beams.

- (2)

- The extensive use of FRP for strengthening and for the confinement of joints is not always applicable, and has higher costs with less effectiveness.

- (3)

- The analysis of an existing structure degraded by corrosion can be carried out on Finite Element models in an intact and damaged condition for the evaluation of corrosion-related deficits, which can be recovered through concrete jacketing. This methodology helps to separate structural seismic deficits from those due to damage.

- (4)

- A reliable analysis of the structure after rehabilitation with extensive retrofitting should be carried out not only in terms of element strengthening but also in terms of global modification of masses and stiffnesses in the new configuration.

- (5)

- Dynamic linear analysis is, in many cases, not sufficient for the determination of deficits for structural assessment and subsequent retrofitting, while nonlinear static analysis facilitates the evaluation of the collapse mechanisms to know the most critical elements, in addition to an overall assessment in terms of displacement and base shear. Therefore, it is advisable to carry out pushover analyses both in the original condition and after the intervention to compare the two structural behaviors.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Italian Ministry of Infrastructures. Norme Tecniche per le Costruzioni DM 14.01.2008; Consiglio Superiore LL. PP, Ed.; Italian Ministry of Infrastructures: Roma, Italy, 2008. (In Italian) [Google Scholar]

- Italian Ministry of Infrastructures. Norme Tecniche per le Costruzioni DM 17.01.2018; Consiglio Superiore LL. PP, Ed.; Italian Ministry of Infrastructures: Roma, Italy, 2018. (In Italian) [Google Scholar]

- Bru, D.; Gonzàlez, F.; Baeza, J.; Ivorra, S. Seismic behaviour of 1960’s RC buildings exposed to marine environment. Eng. Fail. Anal. 2018, 90, 324–340. [Google Scholar] [CrossRef]

- Saetta, A.; Simioni, P.; Berto, L.; Vitaliani, R. Seismic response of corroded r.c. structures. In Tailor Made Concrete Structures; Walraven, Stoelhorst, Eds.; Taylor & Francis: Abingdon, UK, 2008; pp. 1031–1035. [Google Scholar]

- Berto, L.; Vitaliani, R.; Saetta, A.; Simioni, P. Seismic assessment of existing RC structures affected by degradation phenomena. Struct. Saf. 2009, 31, 284–297. [Google Scholar] [CrossRef]

- Coccia, S.; Imperatore, S.; Rinaldi, Z. Influence of corrosion on the bond strength of the steel rebars in concrete. Mater. Struct. 2016, 49, 537–551. [Google Scholar] [CrossRef]

- Bossio, A.; Lignola, G.P.; Prota, A. An overview of assessment and retrofit of corroded reinforced concrete structures. Procedia Struct. Integr. 2018, 11, 394–401. [Google Scholar] [CrossRef]

- Minafò, G.; Di Trapani, F.; Amato, G. Strength and ductility of RC jacketed columns: A simplified analytical method. Eng. Struct. 2016, 122, 184–195. [Google Scholar] [CrossRef]

- Karayannis Chris, G.; Chalioris Constantin, E.; Sirkelis George, M. Local retrofit of exterior RC beam-column joints using thin RC jackets-An experimental study. Earthq. Engng Struct. Dyn. 2008, 37, 727–746. [Google Scholar] [CrossRef]

- Campione, G.; Cavaleri, L.; Di Trapani, F.; Ferrotto, M.F. Frictional Effects in Structural Behavior of No-End-Connected Steel-Jacketed RC Columns: Experimental Results and New Approaches to Model Numerical and Analytical Response. J. Struct. Eng. ASCE 2017, 143, 04017070. [Google Scholar] [CrossRef]

- Ferrotto, M.F.; Cavaleri, L.; Papia, M. Compressive response of substandard steel-jacketed RC columns strengthened under sustained service loads: From the local to the global behavior. Constr. Build. Mater. 2018, 179, 500–511. [Google Scholar] [CrossRef]

- Taleb, O.Y.; Susanne, H.; Ola, D.; Ghazi, A.-F.; Yahia, A.-J. Retrofitting of reinforced concrete beams using composite laminates. Constr. Build. Mater. 2011, 25, 591–597. [Google Scholar]

- Italian Ministry of Infrastructures. Linee Guida per la Progettazione, l’Esecuzione ed il Collaudo di Interventi di Rinforzo di Strutture di c.a., c.a.p. e Murarie Mediante FRP; Consiglio Superiore LL. PP, Ed.; Italian Ministry of Infrastructures: Roma, Italy, 2009. (In Italian) [Google Scholar]

- Ruggieri, S.; Vukobratović, V. The influence of torsion on acceleration demands in low-rise RC buildings. Bull. Earthq. Eng. 2024, 22, 2433–2468. [Google Scholar] [CrossRef]

- Kaatsız, K.; Sucuoğlu, H. Identification of torsionally stiff and flexible asymmetric systems, and their comparative seismic response evaluation for low-rise frames. J. Earthq. Eng. 2023, 28, 998–1014. [Google Scholar] [CrossRef]

- Landge, M.V.; Ingle, R.K. Comparative study of floor response spectra for regular and irregular buildings subjected to earthquake. Asian J. Civ. Eng. 2021, 22, 49–58. [Google Scholar] [CrossRef]

- Ruggieri, S.; Uva, G. Accounting for the spatial variability of seismic motion in the pushover analysis of regular and irregular RC buildings in the new Italian building code. Buildings 2020, 10, 177. [Google Scholar] [CrossRef]

- Rinaldi, Z.; Valente, C.; Pardi, L. A simplified methodology for the evaluation of the residual life of corroded elements. Struct. Infrastruct. Eng. 2008, 4, 139–152. [Google Scholar] [CrossRef]

- Al-Sulaimani, G.J.; Kaleemullah, M.; Basunbul, I.A.; Rasheeduzzafar. Influence of corrosion and cracking on bond behavior and strength of reinforced concrete members. ACI Struct. J. 1990, 87, 220–231. [Google Scholar]

- Robuschi, S.; Sumearll, J.; Fernandez, I.; Lundgren, K. Bond of naturally corroded, plain reinforcing bars in concrete. Struct. Infrastruct. Eng. 2021, 17, 792–808. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, S. Anchorage of Plain, Naturally Corroded Reinforcement Bars with End-Hooks. Master’s Thesis, Department of Architecture and Civil Engineering, Chalmers University of Technology, Gothenburg, Sweden, 2021. [Google Scholar]

- Habib, A.; Yildirim, U.; Eren, O. Column repair and strengthening using RC jacketing: A brief state-of-the-art review. Innov. Infrastruct. Solut. 2020, 5, 75. [Google Scholar] [CrossRef]

- Campione, G.; Fossetti, M.; Giacchino, C.; Minafò, G. RC columns externally strengthened with RC jackets. Mater. Struct. 2014, 47, 1715–1728. [Google Scholar] [CrossRef]

- Dolce, M.; Manfredi, G. Linee Guida per Riparazione e Rafforzamento di Elementi Strutturali, Tamponature e Partizioni; Doppiavoce: Naples, Italy, 2011; ISBN 978-88-89972-29-8. (In Italian) [Google Scholar]

- Campione, G. RC Columns Strengthened with Steel Angles and Battens: Experimental Results and Design Procedure. Pract. Period. Struct. Des. Constr. ASCE 2013, 18, 1–11. [Google Scholar] [CrossRef]

- Eurocode 8, CEN; Design of Structures for Earthquake Resistance. Part 3: Strengthening and Repair of Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2003.

- Eurocode 4, CEN; Design of Composite Steel and Concrete Structures. Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 1994.

- Adam, J.M.; Ivorra, S.; Pallares, F.J.; Giménez, E.; Calderón, P.A. Axially loaded RC columns strengthened by steel cages. Proc. Inst. Civ. Eng. ICE Struct. Build. 2009, 162, 199–208. [Google Scholar] [CrossRef]

- Adam, J.M.; Giménez, E.; Calderón, P.A.; Pallares, F.J.; Ivorra, S. Experimental study of beam-column joints in axially loaded RC columns strengthened by steel angles and strips. Steel Compos. Struct. 2008, 8, 329–342. [Google Scholar] [CrossRef]

- Nagaprasad, P.; Sahoo, D.R.; Rai, D.C. Seismic strengthening of RC columns using external steel cage. Earthq. Engng Struct. Dyn. 2009, 38, 1563–1586. [Google Scholar] [CrossRef]

- Garzón-Roca, J.; Ruiz-Pinilla, J.; Adam, J.M.; Calderón, P.A. An experimental study on steel-caged RC columns subjected to axial force and bending momento. Eng. Struct. 2011, 33, 580–590. [Google Scholar] [CrossRef]

- Li, J.; Gong, J.; Wang, L. Seismic behavior of corrosion-damaged reinforced concrete columns strengthened using combined carbon fiber-reinforced polymer and steel jacket. Constr. Build. Mater. 2009, 23, 2653–2663. [Google Scholar] [CrossRef]

- Colajanni, P.; Recupero, A.; Spinella, N. Increasing the flexural capacity of RC beams using steel angles and pre-tensioned stainless steel ribbons. Struct. Concr. 2016, 17, 848–857. [Google Scholar] [CrossRef]

- Cirtek, L. RC columns strengthened with bandage—Experimental programme and design recommendations. Constr. Build. Mater. 2001, 15, 341–349. [Google Scholar] [CrossRef]

- Granata, M.F.; Recupero, A. Serviceability and Ultimate Safety Checks of Segmental Concrete Bridges through N-M and M-V Interaction Domains. J. Bridge Eng. ASCE 2015, 20, B4014003. [Google Scholar] [CrossRef]

| Class | Life Vn [Years] | Functional Coefficient | Period Vr [Years] | Type of Ground | Slope |

|---|---|---|---|---|---|

| IV | 100 | 2.0 | 200.0 | B | T2 |

| Limit State | Prob. of Exceeding [%] | Tr [Years] | ag [g] | Fo [-] | T*c [s] | S [-] | TB [s] | TC [s] | TD [s] |

|---|---|---|---|---|---|---|---|---|---|

| SLO | 81.0 | 120 | 0.101 | 2.320 | 0.280 | 1.440 | 0.132 | 0.397 | 2.005 |

| SLD | 63.0 | 201 | 0.128 | 2.320 | 0.290 | 1.440 | 0.136 | 0.409 | 2.110 |

| SLV | 10.0 | 1898 | 0.287 | 2.480 | 0.320 | 1.338 | 0.147 | 0.442 | 2.748 |

| SLC | 5.0 | 2475 | 0.313 | 2.510 | 0.320 | 1.303 | 0.147 | 0.442 | 2.851 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Granata, M.F. Seismic Retrofit of Concrete Buildings Damaged by Corrosion: A Case Study in Southern Italy. Buildings 2024, 14, 1064. https://doi.org/10.3390/buildings14041064

Granata MF. Seismic Retrofit of Concrete Buildings Damaged by Corrosion: A Case Study in Southern Italy. Buildings. 2024; 14(4):1064. https://doi.org/10.3390/buildings14041064

Chicago/Turabian StyleGranata, Michele Fabio. 2024. "Seismic Retrofit of Concrete Buildings Damaged by Corrosion: A Case Study in Southern Italy" Buildings 14, no. 4: 1064. https://doi.org/10.3390/buildings14041064

APA StyleGranata, M. F. (2024). Seismic Retrofit of Concrete Buildings Damaged by Corrosion: A Case Study in Southern Italy. Buildings, 14(4), 1064. https://doi.org/10.3390/buildings14041064