Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

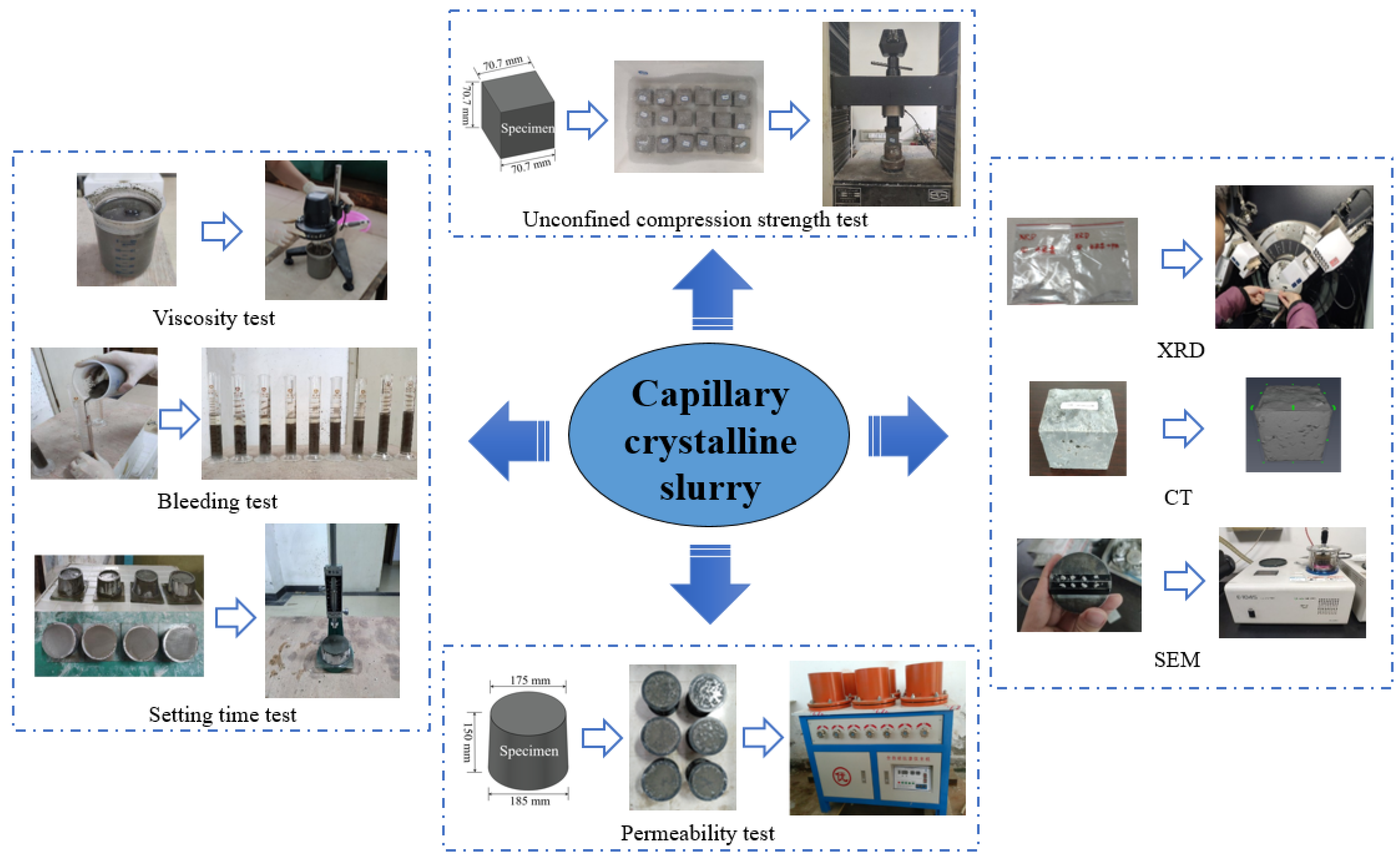

2.3. Test Methods

2.3.1. Viscosity Test

2.3.2. Bleeding Rate Test

2.3.3. Setting Time Test

2.3.4. Permeability Test

2.3.5. Unconfined Compression Strength Test (UCS)

2.3.6. XRD

2.3.7. CT

2.3.8. SEM

3. Results and Discussion

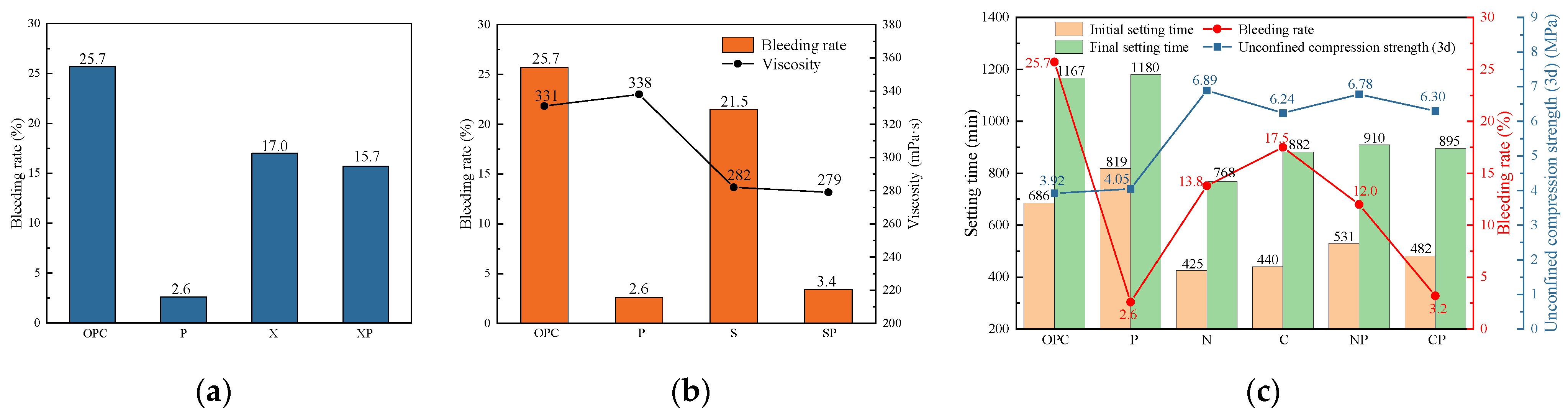

3.1. Pre-Experiment

3.2. Orthogonal Experiment

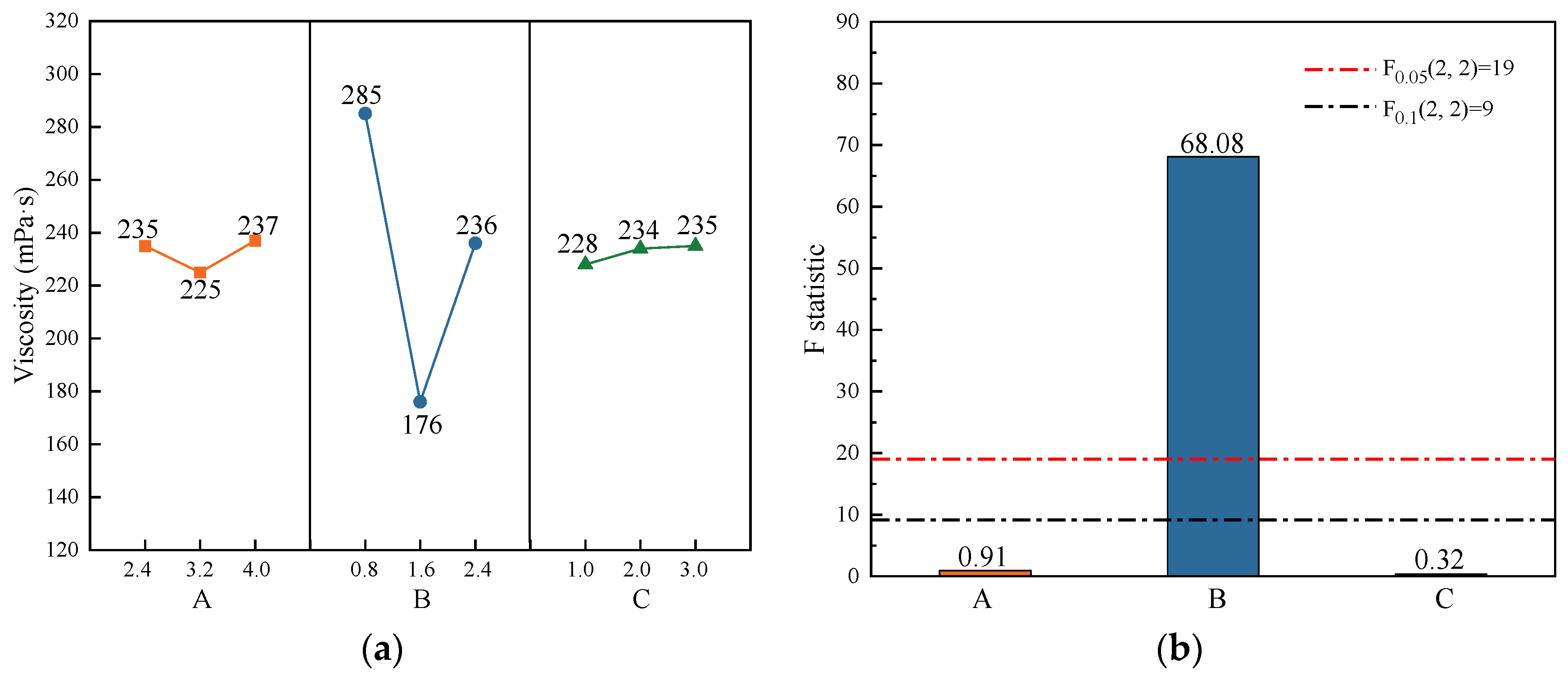

3.2.1. Viscosity

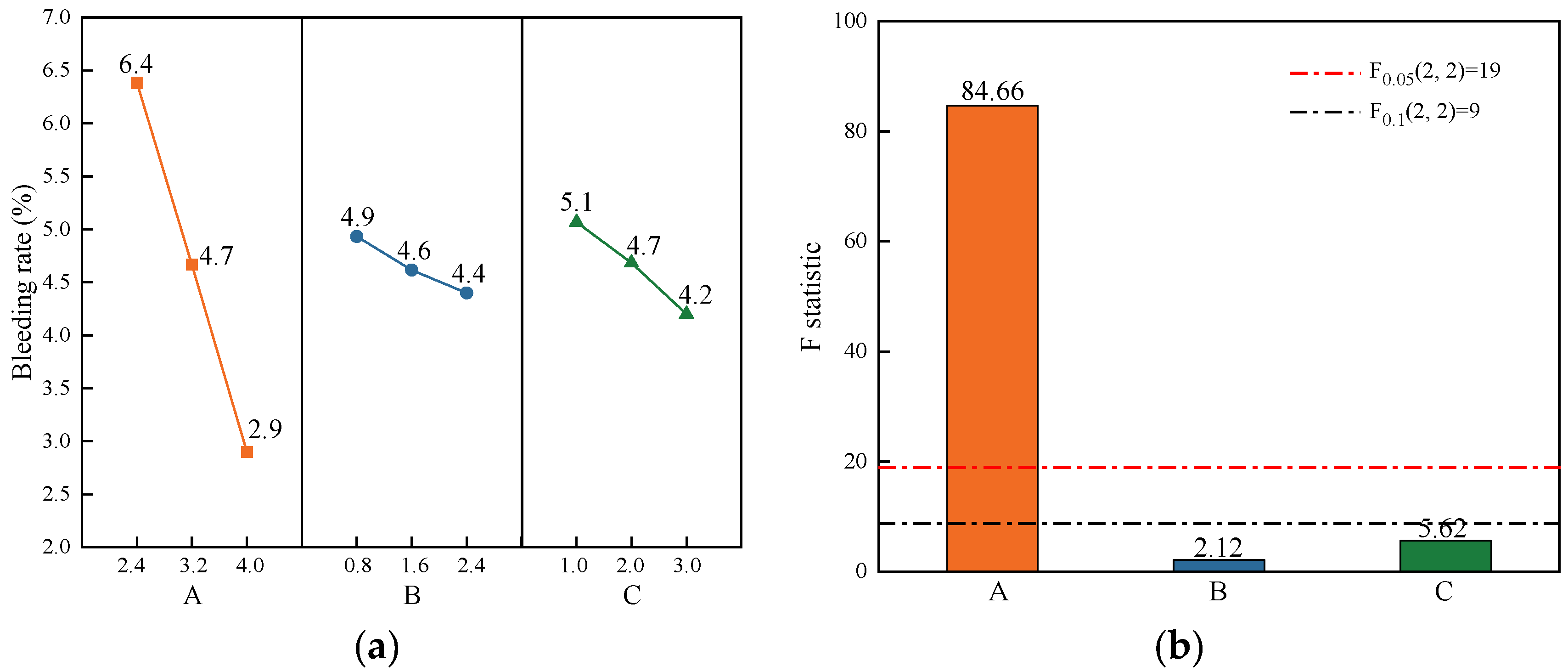

3.2.2. Bleeding Rate

3.2.3. Setting Time

3.2.4. Permeability Coefficient

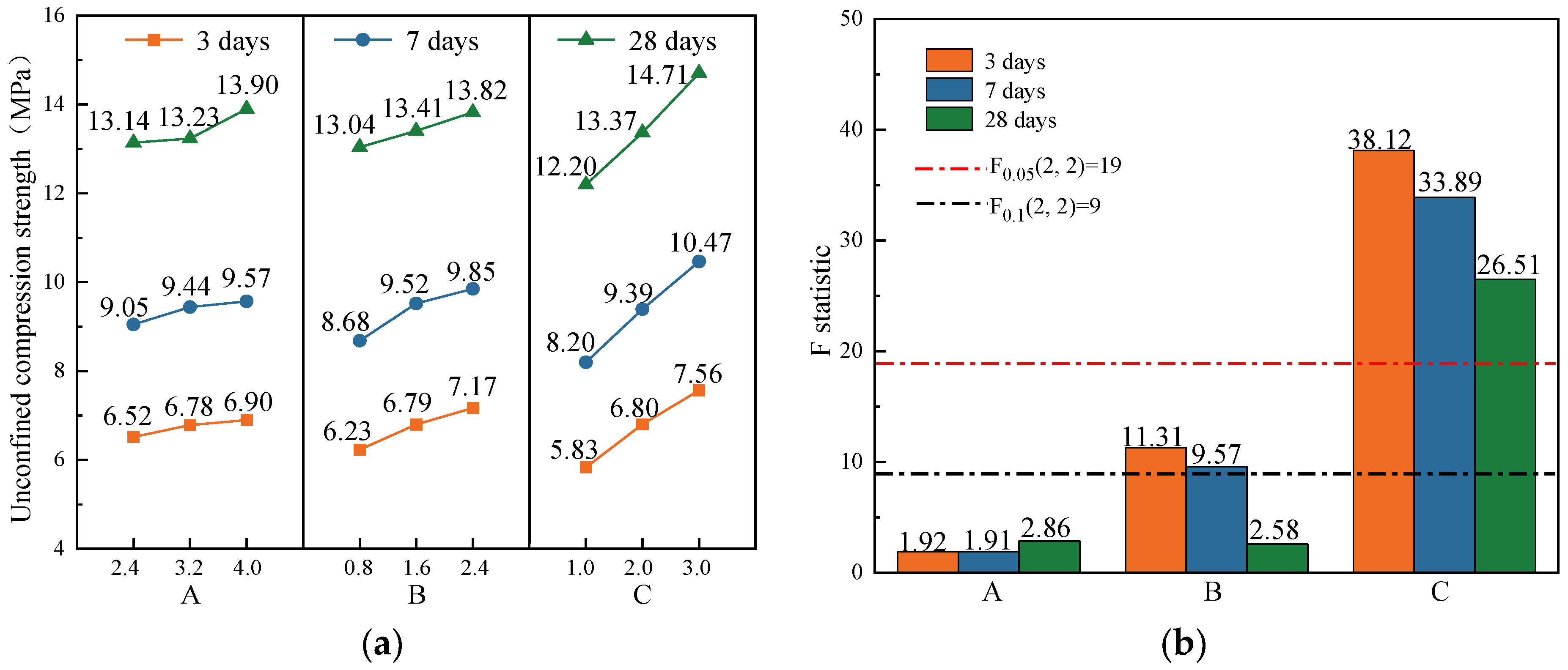

3.2.5. Unconfined Compression Strength

3.3. Phase Composition and Microstructure Analysis

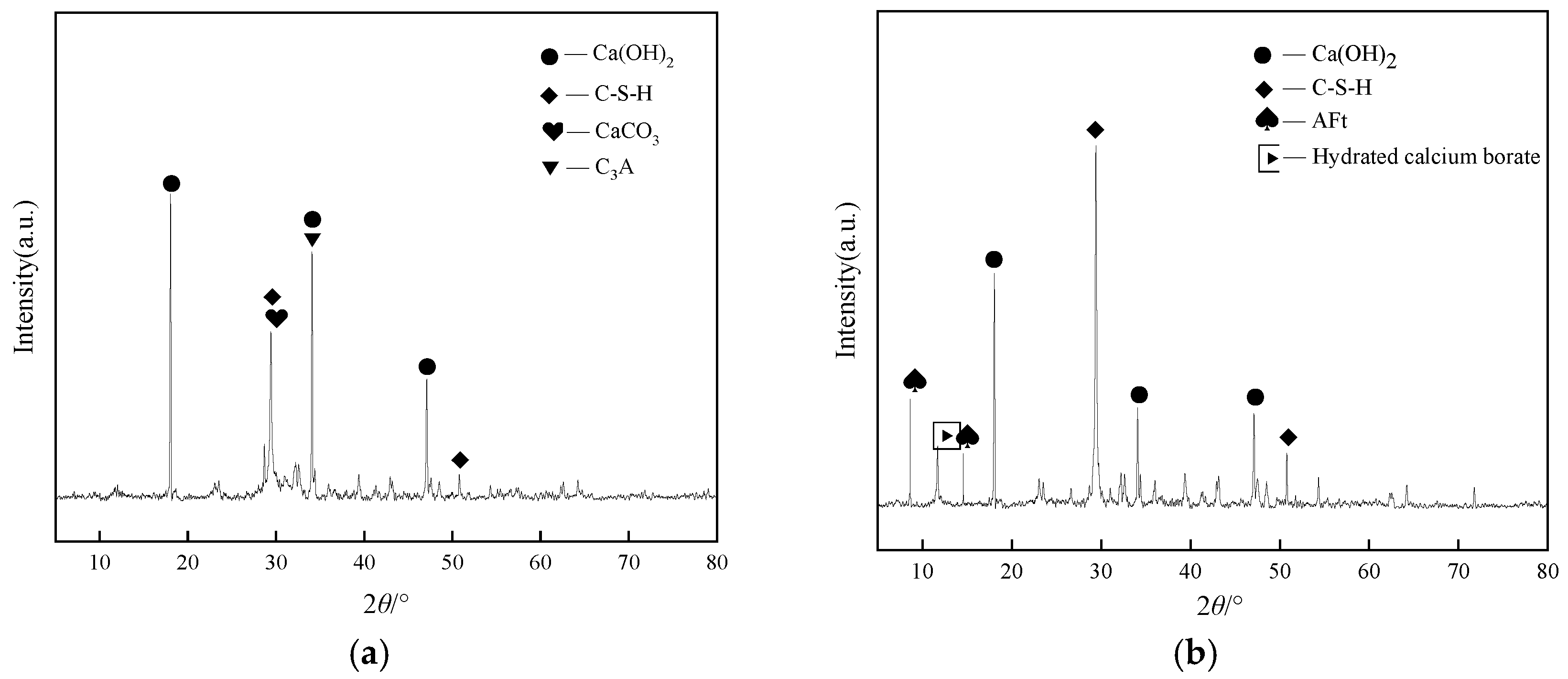

3.3.1. XRD

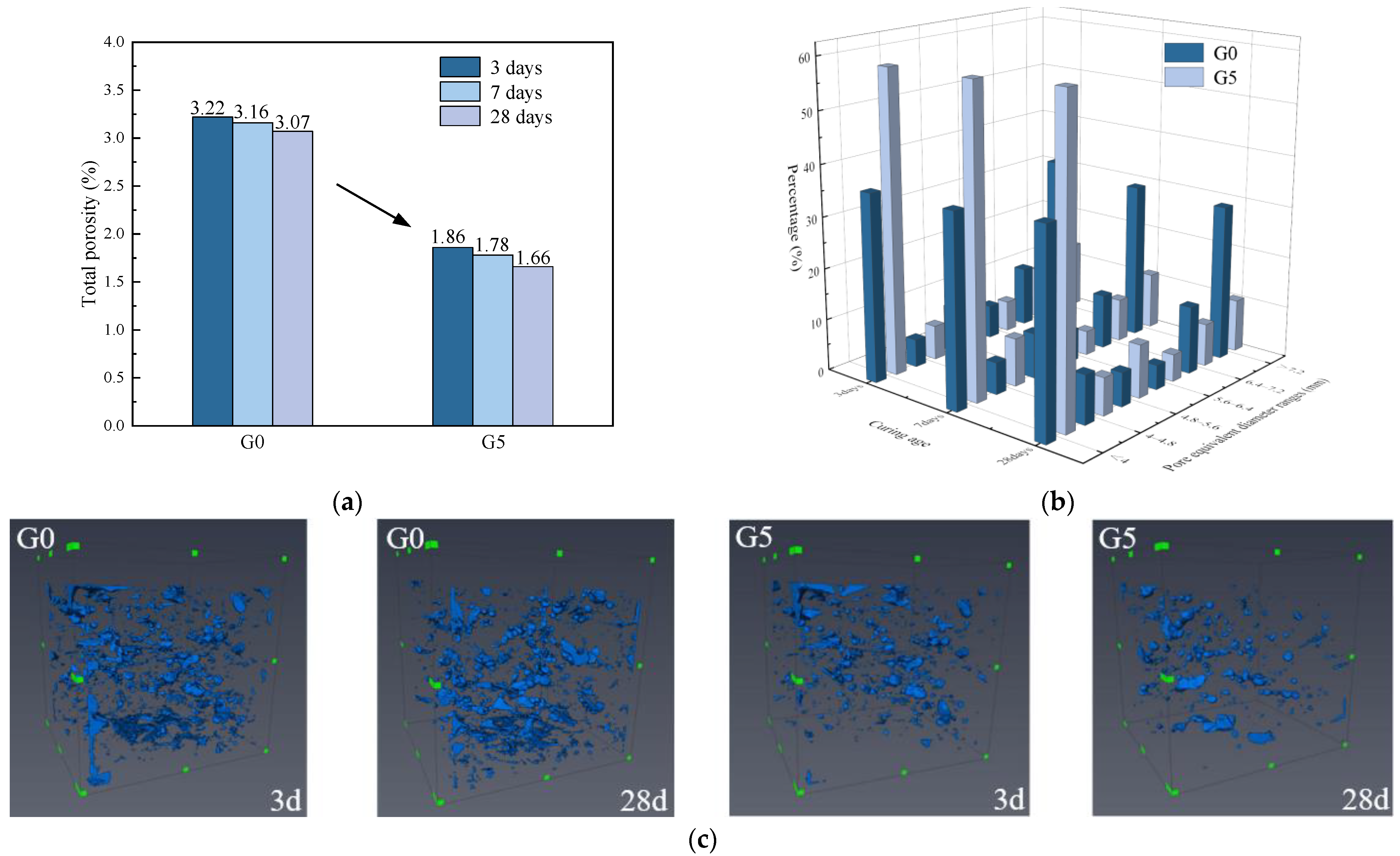

3.3.2. CT Results

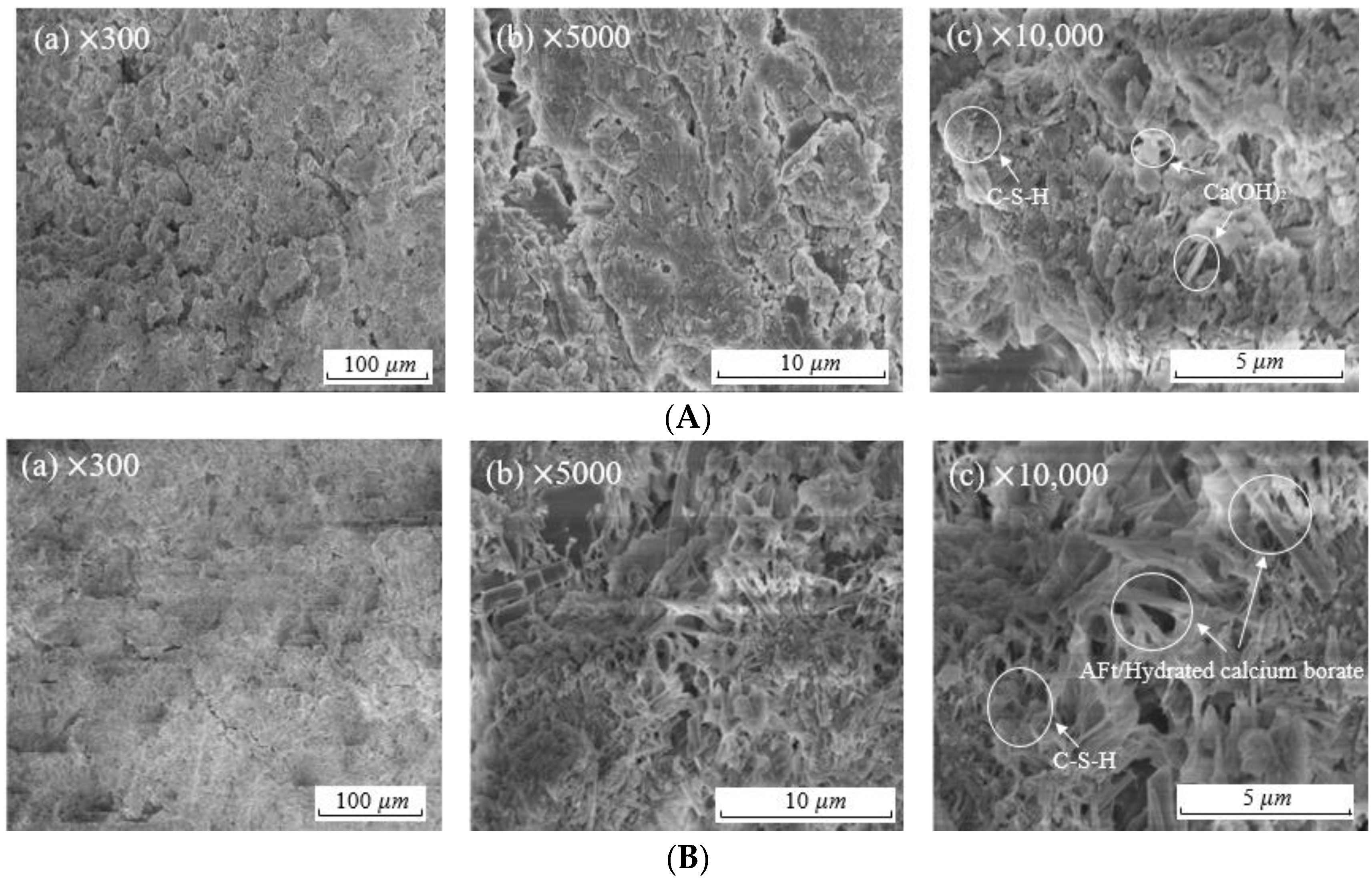

3.3.3. SEM Results

4. Conclusions

- (1)

- When the capillary crystalline material PNC803 is added to the cement-based slurry with bentonite, sodium chloride, and TEA, their respective effects on the slurry are weakened. However, PNC803 exhibits good synergistic effects with sulfate, calcium chloride, and TIPA.

- (2)

- A reasonable quality ratio for this high-efficiency cement-based capillary crystalline grouting material is water/cement/PNC803/sodium sulfate/calcium chloride/TIPA = 1:1:0.032:0.016:0.03:0.00075. Its viscosity is 164 mPa∙s, its bleeding rate is 4.4%, and the initial setting time and final setting time are 402 and 804 min, respectively. The permeability coefficients of the grouted materials at 7 and 28 d are 7.06 × 10−6 and 3.08 × 10−6 cm/s, respectively. The compression strengths of the hardened grout at 3, 7, and 28 d are 7.62, 10.63, and 14.78 MPa, respectively.

- (3)

- The enhancement in the impermeability of the grouted material is related to the improvement in the internal pore structure. The crystalline products in the slurry effectively fill the larger pores within the structure, further refining the pores in the slurry and blocking water passage inside the structure, thereby improving the impermeability.

- (4)

- The capillary crystalline material PNC803 and cement admixtures promote cement hydration in different ways, producing numerous C-S-H gels, AFt crystals, and hydrated calcium borate crystals. These substances can serve as crystallization centers, reducing the solidification energy barrier of the slurry and accelerating the setting and hardening of the cement. In addition, they can play reinforcing, skeletal, and filling roles in pores, thereby improving the strength and density of cured structures.

- (5)

- This article only studied the slurry’s performance parameters as an anti-seepage grouting material and did not determine the grouting parameters of the slurry during the construction process. Therefore, subsequent research will analyze the effects of factors such as the grouting pressure, grouting time, and rock friction coefficient on the grouting effect using model experiments and numerical simulations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gong, X.N.; Guo, P.P. Prevention and mitigation methods for water leakage in tunnels and underground structures. China J. Highw. Transp. 2021, 34, 1–30. (In Chinese) [Google Scholar] [CrossRef]

- Chang, Z.; Mei, H.P.; Yan, C.G.; Shi, Y.L.; Zhu, X.M.; Lu, Z.F.; Jia, Z.L. Health status evaluation of highway tunnel inverted arch based on variable weight and extension cloud model. Eng. Fail. Anal. 2024, 157, 107939. [Google Scholar] [CrossRef]

- Chakrabarti, S.; Banerjee, S.; Chaudhuri, B.; Bhattacharijee, S.; Dutta, B.K. Application of biodegradable natural polymers for flocculated sedimentation of clay slurry. Bioresour. Technol. 2008, 99, 3313–3317. [Google Scholar] [CrossRef] [PubMed]

- Nosrati, A.; Addaimensah, J.; Skinner, W. Rheological behavior of muscovite clay slurries: Effect of water quality and solution speciation. Int. J. Miner. Process. 2012, 102, 89–98. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J.; Ou, X.; Fu, J.; Xie, Y.; Liang, X. Clay dosage and water/cement ratio of clay-cement grout for optimal engineering performance. Appl. Clay Sci. 2018, 163, 312–318. [Google Scholar] [CrossRef]

- Yang, X.H.; Yu, Y.H. Application of cement-silicate double solution grouting in loess tunnel construction. China J. Highw. Transp. 2004, 2, 69–73. (In Chinese) [Google Scholar] [CrossRef]

- Ye, F.; Sun, C.H.; Mao, J.H.; Han, X.; Chen, Z. Analysis on grouting mechanism for shied tunnel segment by cement and sodium silicate mixed grout mixed grout in consideration of time-dependency and space effect of viscosity. China J. Highw. Transp. 2017, 30, 49–56. (In Chinese) [Google Scholar] [CrossRef]

- Li, S.C.; Sha, F.; Liu, R.T.; Zhang, Q.S.; Li, Z.F. Investigation on fundamental properties of microfine cement and cement-slag grouts. Constr. Build. Mater. 2017, 153, 965–974. [Google Scholar] [CrossRef]

- Mozumder, R.A.; Laskar, A.I.; Hussain, M. Penetrability prediction of microfine cement grout in granular soil using Artificial Intelligence techniques. Tunn. Undergr. Space Technol. 2018, 72, 131–144. [Google Scholar] [CrossRef]

- Shin, E.C.; Park, J.J.; Yu, J.; Patra, C.R. Prediction of Grouting Efficiency by Injection of Cement Milk into Sandy Soil Using an Artificial Neural Network. Soil Mech. Found. Eng. 2018, 55, 305–311. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.C.; Liu, R.T.; Zhang, Q.S.; Li, Z.F.; Liu, H.J. Performance and engineering application of effective microfine cement-based grout for water-rich sand strata. Chin. J. Rock Mech. Eng. 2019, 38, 1420–1433. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.Y.; Zhou, A.X.; Wu, Y.F.; Deng, L.; Zhu, K.C.; Lu, F. Research and Development of Self-Waterproofing Concrete for Tunnel Lining Structure and Its Impermeability and Crack Resistance Characteristics. Materials 2023, 16, 5557. [Google Scholar] [CrossRef]

- Yan, D.; Lai, L.P.; Xiao, X.D.; Zhang, L.; Zhao, Z.L.; Zhao, J. Water Consolidation Performance of Acrylic-Polymer-Modified Materials and Their Concrete Impermeability Repair Characteristics. Gels 2023, 9, 764. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.Z.; Zhao, W.Q.; Zhang, J.J.; Zhou, J.H. Epoxy-based grouting materials with super-low viscosities and improved toughness. Constr. Build. Mater. 2020, 267, 121104. [Google Scholar] [CrossRef]

- Wang, Y.X.; Liu, Q.S. Investigation on fundamental properties and chemical characterization of water-soluble epoxy resin modified cement grout. Constr. Build. Mater. 2021, 299, 123877. [Google Scholar] [CrossRef]

- Liu, W.T.; Sun, Y.D.; Meng, X.X.; Qin, Y.Y. Experimental analysis of Nano-SiO2 modified waterborne epoxy resin on the properties and microstructure of cement-based grouting materials. Energy 2023, 268, 126669. [Google Scholar] [CrossRef]

- Naudts, A. Irreversible changes in the grouting industry caused by polyurethane grouting: An overview of 30 years of polyurethane grouting. In Proceedings of the 3rd International Conference on Grouting and Ground Treatment, Reston, VA, USA, 10–12 February 2003; pp. 1266–1280. [Google Scholar]

- Saleh, S.; Yunus, N.Z.M.; Ahmad, K.; Ali, N. Improving the strength of weak soil using polyurethane grouts: A review. Constr. Build. Mater. 2019, 202, 738–752. [Google Scholar] [CrossRef]

- Hao, M.M.; Li, X.L.; Zhong, Y.H.; Zhang, B.; Wang, F.M. Experimental Study of Polyurethane Grout Diffusion in a Water-Bearing Fracture. J. Mater. Civil. Eng. 2021, 33, 04020485. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, Y.; Zhang, D.L. Research on application of waterborne capillary crystalline waterproof material in tunnel engineering. J. China Railw. Soc. 2018, 40, 137–145. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, K.L.; Yang, X.H.; Chen, R.; Xu, L.X. Application of a capillary crystalline material to enhance cement grout for sealing tunnel leakage. Constr. Build. Mater. 2019, 214, 497–505. [Google Scholar] [CrossRef]

- Li, Z.C.; Huang, F.; Yang, Y.Y.; Xiong, Y.F.; Su, F.; Wang, Y.J.; Tian, X. Improving the Anti-washout Property of Acrylate Grouting Material by Bentonite: Its Characterization, Improving Mechanism, and Practical Application. Polymers 2023, 15, 3865. [Google Scholar] [CrossRef] [PubMed]

- Ebigbo, A.; Phillips, A.; Gerlach, R.; Helmig, R.; Cunningham, A.B.; Class, H.; Spangler, L.H. Darcy-scale modeling of microbially induced carbonate mineral precipitation in sand columns. Water Resour. Res. 2012, 48, W07519. [Google Scholar] [CrossRef]

- Van Wjngaarden, W.K.; Van Paassen, L.A.; Vermolen, F.J.; Van Meurs, G.A.M.; Vuik, C.A. Reactive Transport Model for Biogrout Compared to Experimental Data. Transp. Porous Media 2016, 111, 627–648. [Google Scholar] [CrossRef]

- Dong, B.Q.; Fang, G.H.; Wang, Y.S.; Liu, Y.Q.; Hong, S.X.; Zhang, J.C.; Lin, S.M.; Xing, F. Performance recovery concerning the permeability of concrete by means of a microcapsule based self-healing system. Cem. Concr. Compos. 2017, 78, 84–96. [Google Scholar] [CrossRef]

- Zheng, G.; Huang, J.Y.; Diao, Y.; Ma, A.Y.; Su, Y.M.; Chen, H. Formulation and performance of slow-setting cement-based grouting paste (SCGP) for capsule grouting technology using orthogonal test. Constr. Build. Mater. 2021, 302, 124204. [Google Scholar] [CrossRef]

- Zhang, L.Q.; Yu, J.L.; Wang, Y.Y.; Han, B.G.; Chen, M.C.; Xu, K.C. Study on cementitious composites with permeable crystalline agent: A review. Mater. Rep. 2024, 38, 22100014. (In Chinese) [Google Scholar]

- Yang, X.H.; Zheng, K.L.; Xu, L.X. Experiment on effect of capillary crystalline material additives on cement slurry performance. China J. Highw. Transp. 2019, 32, 129–135. (In Chinese) [Google Scholar] [CrossRef]

- Liu, P.; Liu, M.L.; Sha, F.; Chen, Y.; Zhi, W.T.; He, S.S.; Yu, Z.W. Preparation and performance investigation of a high efficiency cement permeation type waterproofing materials. Constr. Build. Mater. 2022, 365, 130140. [Google Scholar] [CrossRef]

- Qi, M.; Pu, Y.D.; Yang, S.; Sheng, K.; Yuan, X.Y. Effect of graphene oxide on the impermeability of cementitious capillary crystalline waterproofing. Acta Mater. Compos. Sin. 2023, 40, 1598–1610. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.W. Research on the Composition and Properties of Cementitious Capillary Crystalline Waterproofing Coating Mixture. Master’s Thesis, Chongqing University, Chongqing, China, 2006. (In Chinese). [Google Scholar] [CrossRef]

- Tang, C.J. Research on Cementitious Capillary Crystalline Waterproofing Coating Mixture. Master’s Thesis, South China University of Technology, Guangzhou, China, 2009. (In Chinese). [Google Scholar] [CrossRef]

- JJG 1002-2005; Verification Regulation of Rotational Viscometers. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standards Press of China: Beijing, China, 2005.

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Ministry of Transport of the People’s Republic of China; Standards Press of China: Beijing, China, 2020.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standards Press of China: Beijing, China, 2011.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the People’s Republic of China; State Administration for Market Regulation. China Architecture and Building Press: Beijing, China, 2019.

- Wang, C.H.; Xiao, J.; Zhang, Q.H.; Shi, J.Y.; Zhang, Z.D.; Long, C.Y. Influences of the joint action of sulfate erosion and cementitious capillary crystalline waterproofing materials on the hydration products and properties of cement-based materials: A review. J. Build. Eng. 2023, 68, 106061. [Google Scholar] [CrossRef]

- Cui, D.X.; Qin, H.G.; Guo, W.; Pan, W.Y.; Yang, Y.W. The influence of Na2SO4 content in water reducing agents on the performance of concrete. Chin. Concr. Cem. Prod. 2009, 4, 18–20. (In Chinese) [Google Scholar] [CrossRef]

- Yang, X.D. Technical Manual of Anchorage and Grouting; China Electric Power Press: Beijing, China, 2009; pp. 319–320. [Google Scholar]

- Huang, H.; Li, X.R.; Shen, X.D. Hydration of ternary cement in the presence of triisopropanolamine. Constr. Build. Mater. 2016, 111, 513–521. [Google Scholar] [CrossRef]

- Gartner, E.; Myers, D. Influence of Tertiary Alkanolamines on Portland Cement Hydration. J. Am. Ceram. Soc. 1993, 76, 1521–1530. [Google Scholar] [CrossRef]

- Li, G.Y.; Huang, X.F.; Lin, J.S.; Jiang, X.; Zhang, X.Y. Activated chemicals of cementitious capillary crystalline waterproofing materials and their self-healing behavior. Constr. Build. Mater. 2019, 200, 36–45. [Google Scholar] [CrossRef]

- Wang, G.; Shen, J.N.; Chu, X.Y.; Cao, C.J.; Jiang, C.H.; Zhou, X.H. Characterization and analysis of pores and fissures of high-rank coal based on CT three-dimensional reconstruction. J. China Coal Soc. 2017, 42, 2074–2080. (In Chinese) [Google Scholar] [CrossRef]

- Huang, D.; Gao, Y.K.; Huang, W.B. Research on pore structural change of gravel soil under seepage erosion based on CT scanning. Hydrogeol. Eng. Geol. 2024, 51, 123–131. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Z.X.; Dong, S.N.; Nan, S.H.; Zhang, D.Y.; Liu, D. Micro-CT analysis of void characteristics at the top of middle ordovician limestone in Hanxing mining area. J. Min. Saf. Eng. 2021, 38, 343–352. (In Chinese) [Google Scholar] [CrossRef]

- Kuang, Y.C.; Ou, J.P. Experiment and research on permeable crystallization self-repairing performance of concrete. J. Railw. Sci. Eng. 2008, 1, 6–10. (In Chinese) [Google Scholar] [CrossRef]

| No. | PNC803 (%) | Bentonite (%) | Na2SO4 (%) | NaCl (%) | TEA (%) | CaCl2 (%) | TIPA (%) | Response |

|---|---|---|---|---|---|---|---|---|

| OPC | — | — | — | — | — | — | — | Viscosity, bleeding rate, setting time, unconfined compression strength |

| P | 4 | |||||||

| X | 10 | Bleeding rate | ||||||

| XP | 4 | 10 | ||||||

| S | 0.8 | Viscosity, bleeding rate | ||||||

| SP | 4 | 0.8 | ||||||

| N | 1.0 | 0.05 | Bleeding rate, setting time, unconfined compression strength | |||||

| NP | 4 | 1.0 | 0.05 | |||||

| C | 2.0 | 0.05 | ||||||

| CP | 4 | 2.0 | 0.05 |

| No. | Factors | Results | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A (%) | B (%) | C (%) | Viscosity (mPa·s) | Bleeding Rate (%) | Setting Time (min) | Permeability Coefficient (×10−6 cm/s) | UCS (MPa) | |||||

| Initial | Final | 7 d | 28 d | 3 d | 7 d | 28 d | ||||||

| G0 | — | — | — | 331 | 25.7 | 686 | 1167 | 315 | 94.20 | 3.92 | 5.78 | 11.49 |

| G1 | 2.4 | 0.8 | 1.0 | 276 | 7.3 | 665 | 1087 | 15.23 | 8.21 | 5.05 | 7.13 | 11.81 |

| G2 | 2.4 | 1.6 | 2.0 | 185 | 6.3 | 529 | 945 | 14.74 | 7.78 | 6.81 | 9.48 | 12.90 |

| G3 | 2.4 | 2.4 | 3.0 | 245 | 5.6 | 387 | 792 | 13.82 | 6.76 | 7.69 | 10.54 | 14.71 |

| G4 | 3.2 | 0.8 | 2.0 | 282 | 4.9 | 553 | 973 | 10.32 | 5.16 | 6.25 | 8.68 | 12.68 |

| G5 | 3.2 | 1.6 | 3.0 | 164 | 4.4 | 402 | 804 | 7.06 | 3.08 | 7.62 | 10.63 | 14.78 |

| G6 | 3.2 | 2.4 | 1.0 | 230 | 4.7 | 645 | 1068 | 9.67 | 4.92 | 6.48 | 9.01 | 12.24 |

| G7 | 4.0 | 0.8 | 3.0 | 297 | 2.6 | 448 | 839 | 2.59 | 0.83 | 7.39 | 10.24 | 14.63 |

| G8 | 4.0 | 1.6 | 1.0 | 179 | 3.2 | 676 | 1102 | 3.21 | 1.47 | 5.96 | 8.46 | 12.54 |

| G9 | 4.0 | 2.4 | 2.0 | 235 | 2.9 | 484 | 886 | 1.57 | 0.41 | 7.34 | 10.01 | 14.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Yang, X.; Zheng, K.; Chen, R. Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material. Buildings 2024, 14, 1439. https://doi.org/10.3390/buildings14051439

Wang M, Yang X, Zheng K, Chen R. Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material. Buildings. 2024; 14(5):1439. https://doi.org/10.3390/buildings14051439

Chicago/Turabian StyleWang, Mengjie, Xiaohua Yang, Kunlong Zheng, and Rui Chen. 2024. "Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material" Buildings 14, no. 5: 1439. https://doi.org/10.3390/buildings14051439

APA StyleWang, M., Yang, X., Zheng, K., & Chen, R. (2024). Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material. Buildings, 14(5), 1439. https://doi.org/10.3390/buildings14051439