Abstract

The use of phase change materials (PCMs) has become an increasingly common way to reduce a building’s energy usage when added to the building envelope. This developing technology has demonstrated improvements in thermal comfort and energy efficiency, making it a viable building energy solution. The current study intends to provide a comprehensive review of the published studies on the utilization of PCMs in various constructions of energy-efficient roofs, walls, and ceilings. The research question holds massive potential to unlock pioneering solutions for maximizing the usefulness of PCMs in reducing cooling demands, especially in challenging high-temperature environments. Several issues with PCMs have been revealed, the most significant of which is their reduced effectiveness during the day due to high summer temperatures, preventing them from crystallizing at night. However, this review investigates how PCMs can delay the peak temperature time, reducing the number of hours during which the indoor temperature exceeds the thermal comfort range. Additionally, the utilization of PCMs can improve the building’s energy efficiency by mitigating the need for cooling systems during peak hours. Thus, selecting the right PCM for high temperatures is both critical and challenging. Insulation density, specific heat, and thermal conductivity all play a role in heat transfer under extreme conditions. This study introduces several quantification techniques and paves the way for future advancements to accommodate practical and technical solutions related to PCM usage in building materials.

1. Introduction

Incorporating PCMs into the envelope of a building has gained popularity as a means of reducing a building’s energy use in recent years. Increases in both energy efficiency and thermal comfort have been shown with this expanding technology, making it a desirable building energy solution [1,2,3]. Buildings that use PCMs, a rapidly expanding technology, must consider several associated factors that affect the overall energy consumption, including research into new types of PCMs, their effective location inside the envelope, the ideal amount, the manner of integration, and the best passive/active approach to be practically used.

Studying the optimal attributes or thickness of PCM to be included in the building envelope is an important issue, as it affects both the structure’s thermal conductivity and mechanical properties [4]. It has been found that the heat storage capacity of PCMs increases with their quantity, allowing for greater energy savings. However, this concept has its limitations; for instance, Zhang et al. [5] found that adding a 5 mm layer of PCM to the roof only lowered the highest indoor temperature by 2 °C. Additionally, increasing the thickness from 5 mm to 10 mm lowered the highest indoor temperature by only 0.5 °C, and by 0.3 °C when the thickness was further increased to 15 mm. Therefore, the viability of the technology depends not only on the quantity of PCM but also on its substantial impact on the associated costs [6]. While this technology offers superior thermal performance compared to existing insulation, its commercial feasibility may be hindered by its higher cost. To achieve the desired goal, it is important to determine the appropriate amount of PCM needed to maximize thermal performance while minimizing costs [7].

The increasing utilisation of effective cooling systems to counteract warming associated with climate variations and urban growth has placed emphasis on the energy required for cooling, as seen in [8]. Studies have shown an increase in cooling degree days globally [9], prompting a need to minimize summer overheating phenomena using passive cooling solutions. This could play a key role in achieving global energy-usage-reduction objectives [10]. Restoring natural passive cooling is achievable through mitigation and modification methods at both construction and district/city scales [11]. To induce negative radiation forcing, cool materials can be employed as part of a passive cooling strategy, reflecting shortwave radiation into space [12]. Consequently, they enable the mitigation of climate change by reducing urban heat island temperatures [13], decreasing the energy required for cooling structures [14], as well as associated power and fuel consumption, greenhouse gas emissions, and pollution levels.

Energy savings are evident when PCMs are strategically integrated with building envelopes while maintaining interior comfort [15]. Lu et al. [16] conducted an experimental investigation on the roof using PCMs enclosed in polyethylene pipes. Their findings revealed mean decreases of 0.84 °C and 0.58 °C in roof and interior maximum temperatures, respectively, for the studied roof. Pisello et al. [17] studied polychloromethyl methacrylate (a PCM) for its potential use in polyurethane roofing membranes. Their research outcomes led to the development of a prototype waterproof membrane, combining PCMs with cool roofs to enhance the passive cooling ability due to the high latent-heat capacity of PCMs. Li et al. [18] implemented a PCM pitched roof and evaluated its thermal performance inside homes, demonstrating the significant potential of PCM roofs in regulating indoor temperatures. Pasupathy and Velraj [19] tested the impacts of a PCM roof panel with two layers, showing a mitigation of seasonal temperature swings in the building’s interior.

Cui et al. [20] reviewed the application scenarios of PCMs in buildings, covering major applications, geographic areas, types, thermal–physical properties, and effects. This study found that PCM applications are concentrated within four north–south latitude regions, ranging from 25° to 60° and 25° to 40°. Paraffin is the most frequently used PCM (maximum of 87.5%). The most significant impact of PCM application is a decrease in air temperature by up to 4.2 °C.

A brief overview of current PCM technology research and development initiatives in building applications was provided by Akeiber et al. [21]. Their study offered a fundamental explanation of phase changes and their underlying theories, along with information on PCM categorization and applications. Second, they considered the floor, roof, wall, and cooling systems of a building while reviewing and discussing PCM models. Finally, they presented conclusions drawn from the gathered information.

Song et al. [22] reviewed the implications of PCMs in improving building envelopes and equipment from 2004 to 2017. Their study discussed optimization approaches for building envelopes using PCMs for walls, roofs, and floors. This included associated studies that discussed the optimization of building equipment to minimize energy usage through PCM utilization. The study also compared various HVAC systems that utilize thermal energy storage (TES). Additionally, they noted that the phase change melting temperature range of PCMs for equipment varied from −15.4 °C to 77 °C, while for building envelopes, it ranged from 10 °C to 39 °C.

Referring to the preceding discussion, no up-to-date comprehensive investigation has been conducted on the issue of PCM integration in roofs, ceilings, and walls of high-temperature building envelopes in existing structures. In order to provide an in-depth examination of PCM integration in various parts of residential buildings, this research aims to cover the details of the shape and composition of these materials used in residential buildings, highlighting the related difficulties that require further investigation and drawing essential conclusions based on the existing body of published research. This review article discusses several methodological, investigative, and evolutionary approaches associated with phase change materials (PCMs). To focus precisely on recent developments in utilising PCMs to enhance energy savings in residential buildings, specifically in roofs, ceilings, and walls, it should be noted that this review emphasizes research published in the last five years, from 2019 to 2023, while covering more than 70 associated published studies. Accordingly, it is fair to expect that this review will help us to better understand the issues that still need to be addressed concerning PCM integration in the construction materials of roofs, ceilings, and walls in high-temperature building envelopes. The deduced results may also serve as a roadmap for future investigations.

2. PCM Applications in Residential Construction

Constructions with strict temperature requirements might benefit from PCMs’ ability to regulate temperatures, store heat or cold with an elevated storage density, and provide thermal comfort. Thus, when solar energy is properly stored, it can be utilised to mitigate the impact of cold nights. PCMs have the potential to fill the gap in the market for thermal energy, aiding in maintaining a comfortable indoor temperature by storing energy produced throughout the day [23]. The next sections show details about utilising the PCMs’ compounds in different parts of residual buildings, including the roof, ceiling, and wall, with a critical analysis of characteristics affecting building thermal performance. In this regard, the roof is the uppermost covering of a building, which classically contains different layers, such as structural framing, insulation, a waterproofing layer, and roofing materials such as tiles. Thus, the roof would act as a structural support of the ceiling that is exposed to the external environment. The ceiling denotes the overhead interior surface of a room, which is typically made of plaster, drywall, or wood. Lastly, the wall is the vertical structure that customises the interior or exterior boundaries of a building and supports the building.

2.1. Studies Related to PCM in the Roof of Residual Buildings

Latent heat storage materials may benefit from PCMs, since they can absorb or release a large quantity of latent heat at a relatively consistent temperature during melting or freezing. Therefore, with only a slight change in temperature, PCMs coupled with the building’s roof can store more heat. Several factors affect how well a roof with a polymer-modified bitumen (PCM) incorporated into it performs, including the PCM’s material qualities, the roof’s location and thickness, and the weather. The thermal performance of PCM-integrated roofs is often evaluated through experimental approaches. The following studies have been conducted on PCM roof integration.

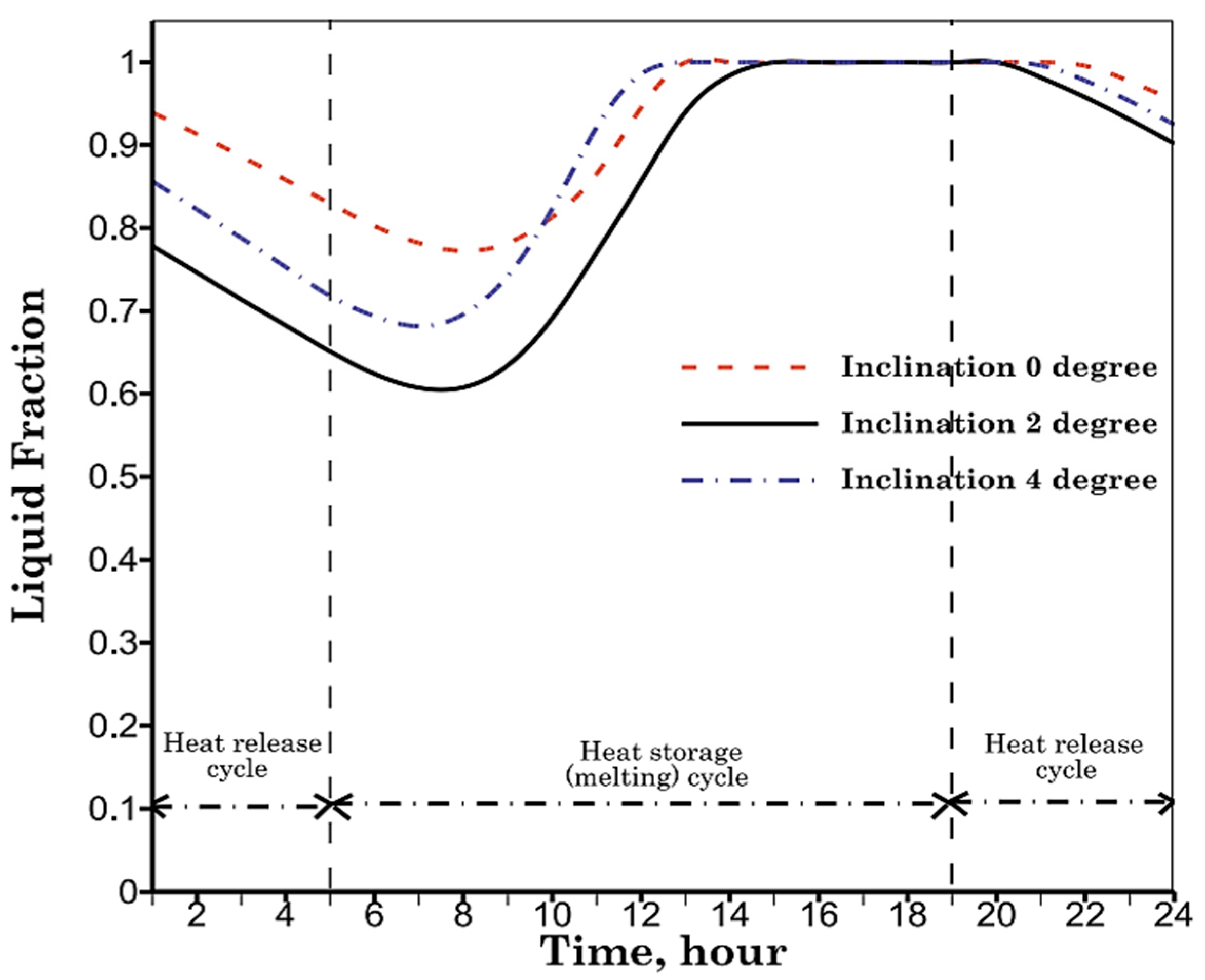

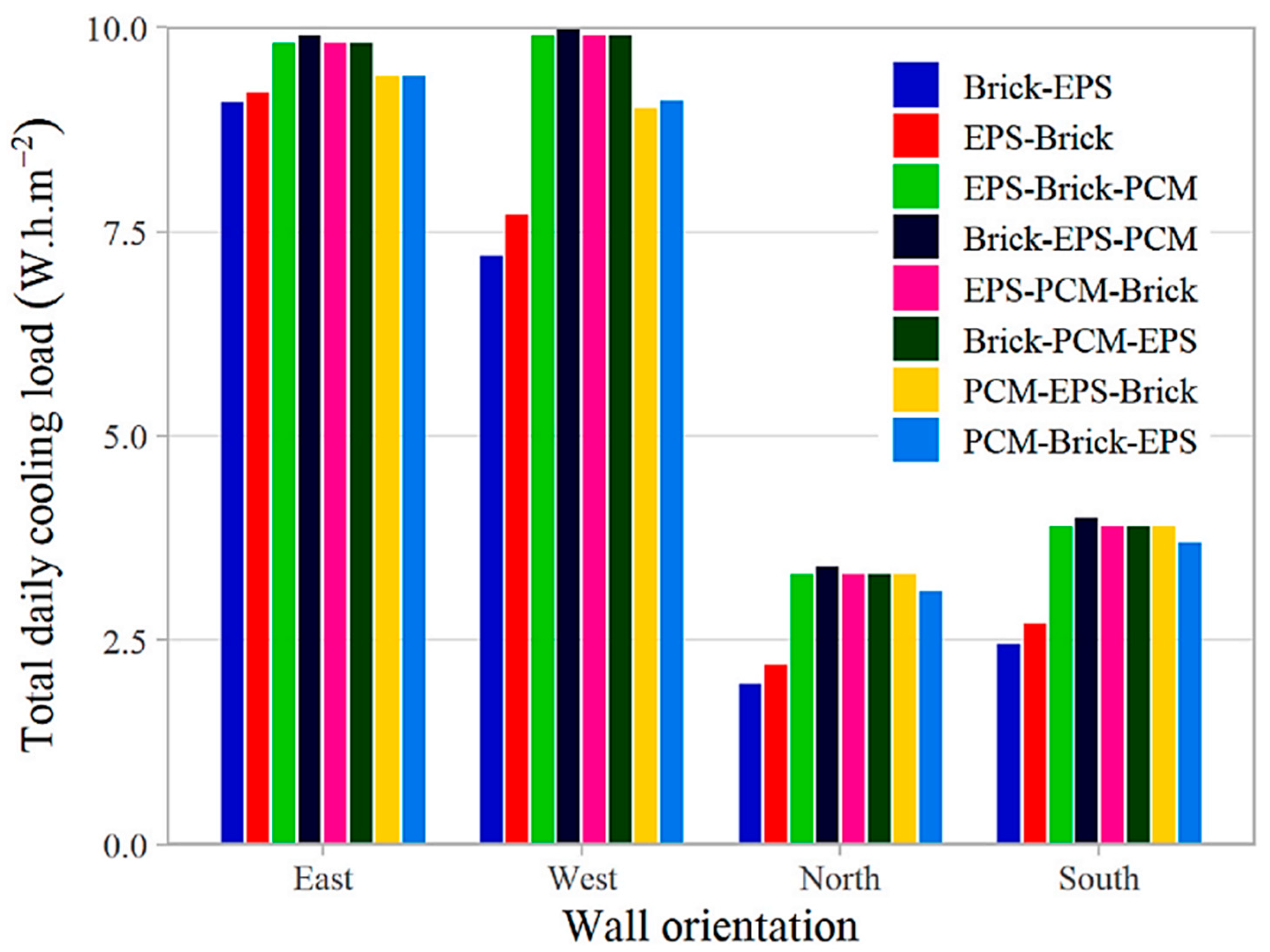

In 2020, Bhamare et al. [24] developed a full-scale three-dimensional numerical model for the flow of a melted PCM. They employed the Pressure Implicit Split Operator (PISO) method to solve model equations in ANSYS Fluent for pressure–velocity coupling, treating it as an incompressible laminar flow. A C++ User-Defined Function (UDF) was used to account for roof radiative and convective bounds. According to numerical models, PCM-integrated roofs reduce peak heat loads and maintain ceiling temperatures within an optimal range for Chennai’s climate. Various inclined PCM layers were evaluated for their thermal performance, with performance assessed using PCM layer inclination angles of 0°, 2°, and 4°. It has been ascertained that an inclination angle of 2° for a PCM layer would provide excellent performance in terms of ceiling temperature control and heat gain reduction. Figure 1 indicates that no PCM slab design had fully melted and solidified, with a liquid percentage of 1 and a solidification percentage of 0, ideally completing the melting cycle.

Figure 1.

Different inclination-angle liquid fractions. Reprinted with permission from Ref. [24].

Bhamare et al. (2020) [25] proposed a new metric, called the Measure of Key Response (MKR) index, to aid in selecting PCMs and assessing the impact of PCM thermophysical factors on the integrated roof thermal performance across different Indian climatic regions (Delhi, Ahmadabad, and Kolkata). Parameters such as ceiling temperature, time lag, decrement factor, and heat gain from PCM-integrated roofs influence such metrics. Using experimental methods and numerical simulations, PCM-integrated roofs were tested in three Indian climatic regions. Response Surface Methodology was employed to conduct tests and determine the optimal PCM. The study illustrated how PCM characteristics affect building thermal performance, noting that each climate zone has different thermophysical characteristics and an optimal PCM. Specifically, the optimum selection of a PCM can be proposed while considering the greatest MKR index. In this regard, it was concluded that thermal conductivity and melting temperature are the primary thermal performance indicators affecting the MKR index compared to density, latent heat, and specific heat. This is specifically associated with the consideration of the composite climatic zone, represented by the city of Delhi, which signified thermal conductivity as the first influential thermophysical characteristic. However, the analysis for the city of Ahmedabad (a hot zone) and a dry and humid zone (Kolkata) indicated that the melting temperature, followed by the thermal conductivity, has the highest effect on the MKR. Indeed, the optimum MKR index was ascertained with the maximum thermal conductivity and minimum melting temperature. Up to this point, enhancing the thermal performance of a PCM-integrated roof in a building has been quite viable. The results also showed that all PCMs with a melting temperature of 28 °C and 0.39 W/mK are chosen as the optimum PCM.

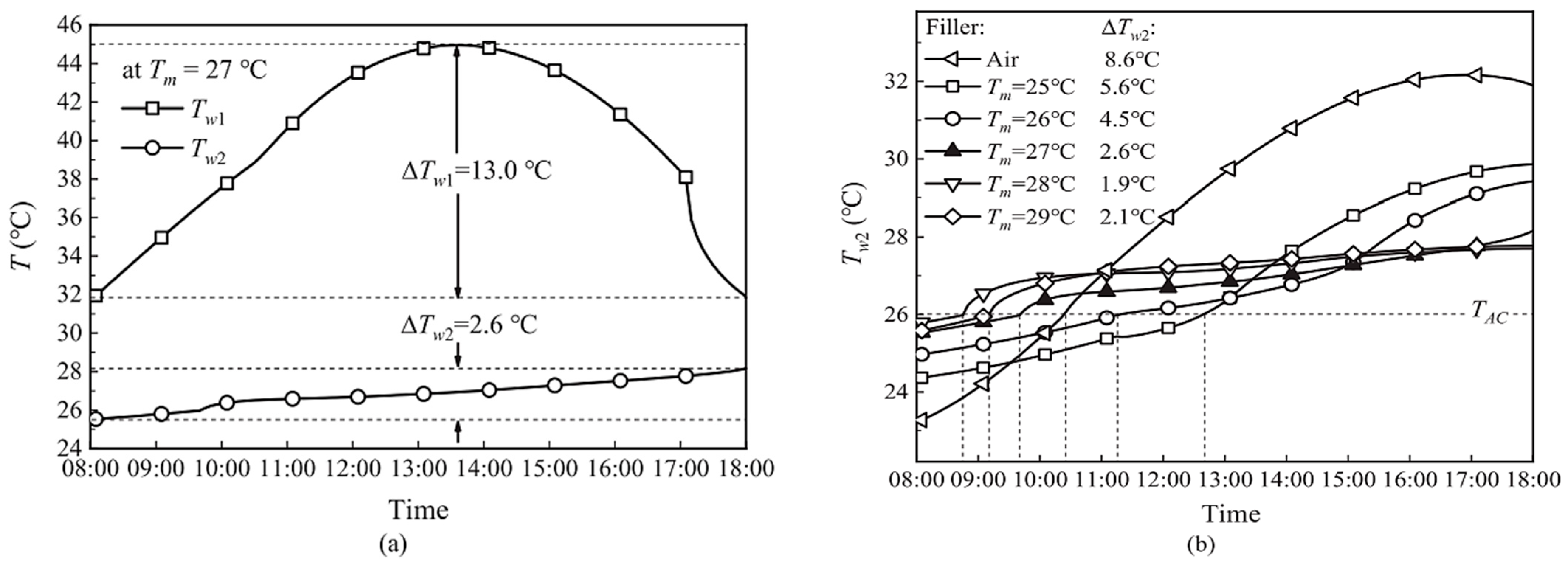

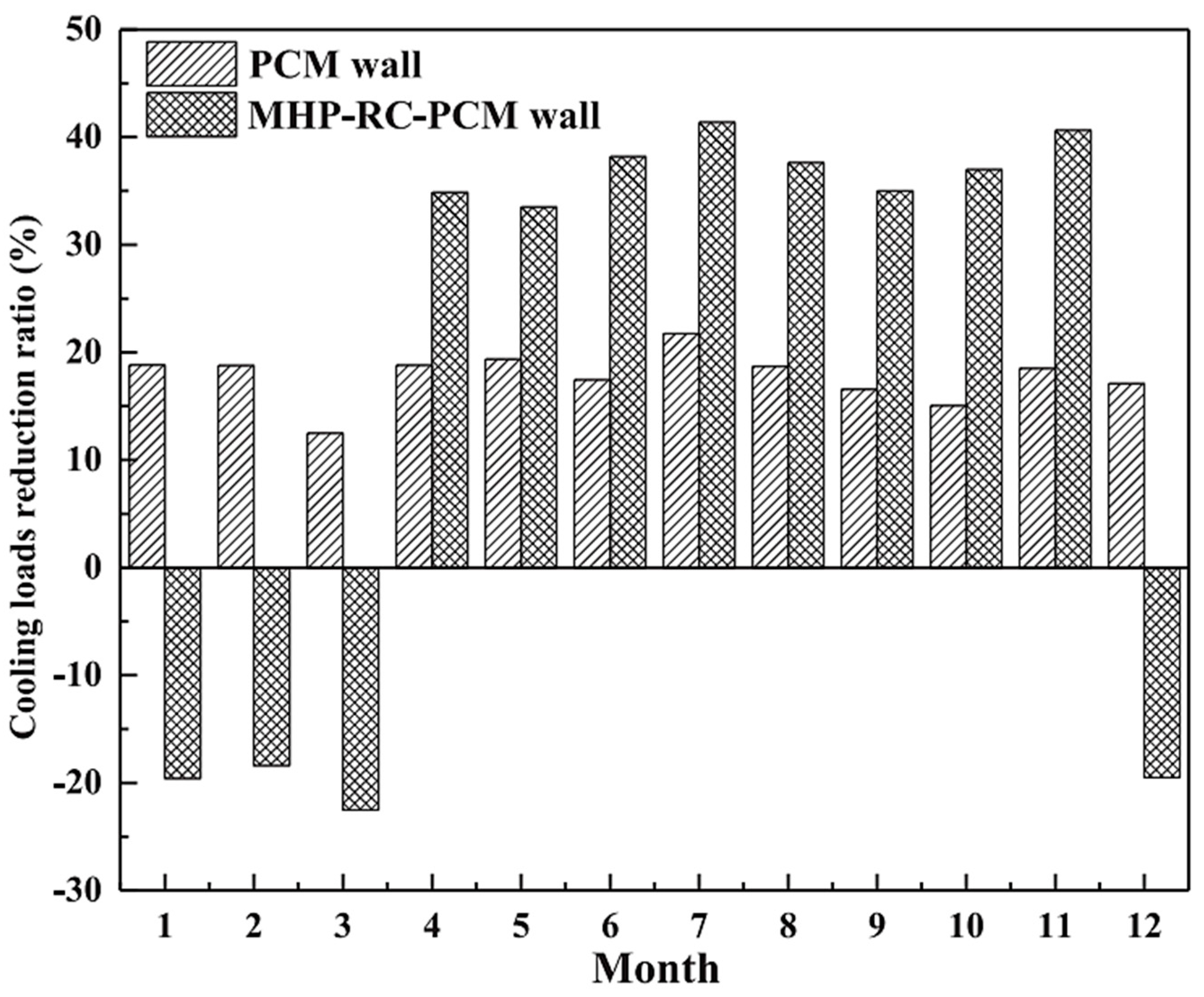

In their study, Luo et al. (2020) [26] utilised data from a typical June in 2019 in Shanghai to investigate the heat transmission characteristics of a porous brick roof filled with PCMs. The PCM used was paraffin wax, known for its multiple phase transition temperatures (Tm). The researchers employed an MRT-LBM method, which was GPU-accelerated, due to its flexibility and parallel computing capabilities. At temperatures of 25 °C and 26 °C, the PCMs melted completely throughout the day, and a lower Tm resulted in a higher liquid content. There was a significant difference in midday temperatures between the PCM-filled and air-filled porous roofs, indicating the PCMs’ considerable thermal buffering capability. Compared to an air-filled porous-brick roof, a PCM-filled roof at a temperature of 27 °C reduced the heat flow from 73.4% to 67.8 kJ/m2. Additionally, the classic porous-brick roof filled with air exhibited the largest temperature variation, reaching 8.6 °C. Thus, the porous-brick roof filled with PCMs displayed a noteworthy improvement in the thermal inertia of the roof, and the energy consumption by the air-conditioning system could be mitigated for that reason. As demonstrated in Figure 2, the PCM-filled porous-brick roof exhibited modest temperature fluctuations.

Figure 2.

The roof’s top and bottom temperatures (a), Tw2 at Tm = 27 °C; (b) porous brick that filled with the air, and PCMs with varying temperatures of phase transition. TW1 and TW2 are the temperatures on the top surface of the roof and on the bottom surface of the roof. Reprinted with permission from Ref. [26].

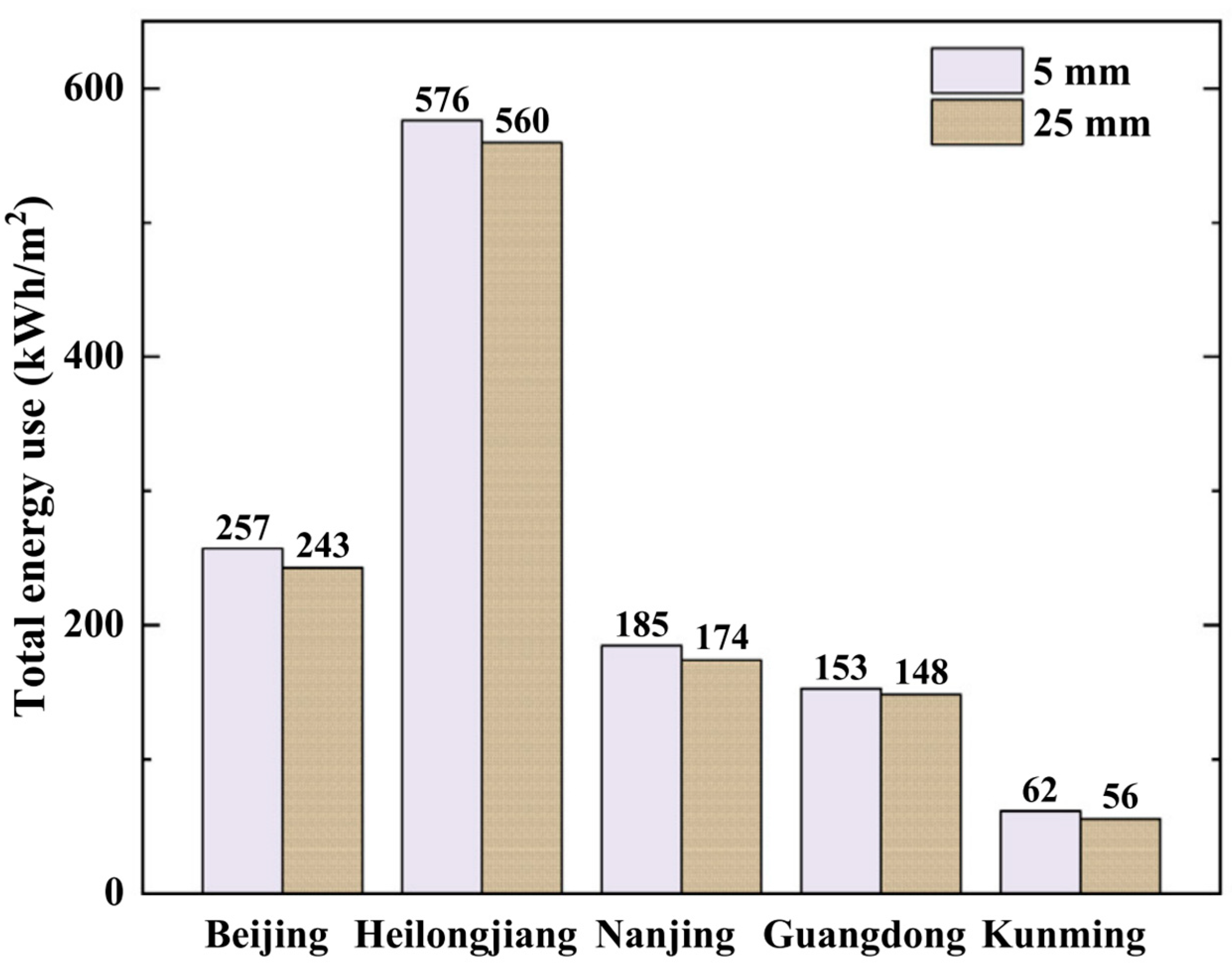

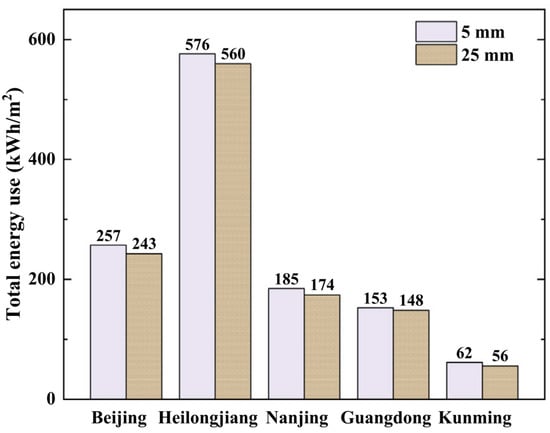

Hu et al. (2020) [27] suggested adaptable building roofs that respond to changing weather to improve energy efficiency. The roofs of the adapted buildings were outfitted with thermo-chromic (TC) coatings and/or layers of PCM to control the intelligent absorption/reflection and thermal energy transfer of solar radiation. The results of simulations demonstrated that TC, PCM, and TC/PCM roofs can save 13%, 15%, and 17% more energy than asphalt roofs, respectively. TC/PCM roofs also manage building energy use seasonally. Increasing the TC coating thickness from 10 mm to 50 mm has reduced the cooling load by 7% (5.1 kWh/m2), 8% (3.0 kWh/m2), 5% (5.2 kWh/m2), 5% (7.0 kWh/m2), and 10% (5.1 kWh/m2) for Beijing, Heilongjiang, Nanjing, Guangdong, and Kunming, respectively, as indicated in Figure 3.

Figure 3.

The thickness of TC coating affects the overall usage of energy in five cities. Reprinted with permission from Ref. [27].

Triano-Juárez et al. (2020) [28] statistically examined concrete roof heat transmission using a PCM intermediate layer. Three placements and thicknesses of PCM layers, as well as two values for roof solar absorptance (grey and white), were examined. Additionally, a characteristic summer week in a Mexican city with warm, moist weather was analysed. At a constant temperature, the internal border was in contact with the indoor air. A 2 cm layer of PCM on the internal surface of the grey roof reduced the temperature by 6.4 °C on the internal surface, and the heat gain by 22.2%. Negligible variances were observed in the maximum temperatures of the interior surface and the heat gains across various thicknesses and positions of the PCM layer for the white roof. As the PCM layer became closer to the roof’s interior and thicker, its melting cycles were altered. The use of a white reflective coating lowered the maximum interior temperature of the surface by 14.7–15.4 °C and reduced the cooling load by 58.1–62.7%. Accordingly, it can be said that the integration of PCMs and reflective coatings would offer a favourable solution for mitigating energy consumption in buildings located in warm humid zones.

Fabiani et al. (2020) [29] added 15%, 25%, or 35% wt.% of non-encapsulated PCMs to a liquid waterproof-polyurethane-based cool membrane mix to create a shape-stabilized composite with enhanced heat-storage capability. The behaviour of this composite material under humidity, accelerated temperature increase, and UV radiation cycles was examined using standardized long-term weathering experiments (QUV tests). Controlled air flow and a continuous monitoring of the surface temperature were used to study the membrane degradation caused by weathering stress. The optimised surface finishing of the prototype was achieved by adding 25% PCM by weight, resulting in improved thermal–optical behaviour and reduced thermal-induced degradation and leakage. Specifically, 25 wt.% PCM can provide an excellent balance between enhanced durability and reduced solar reflectance.

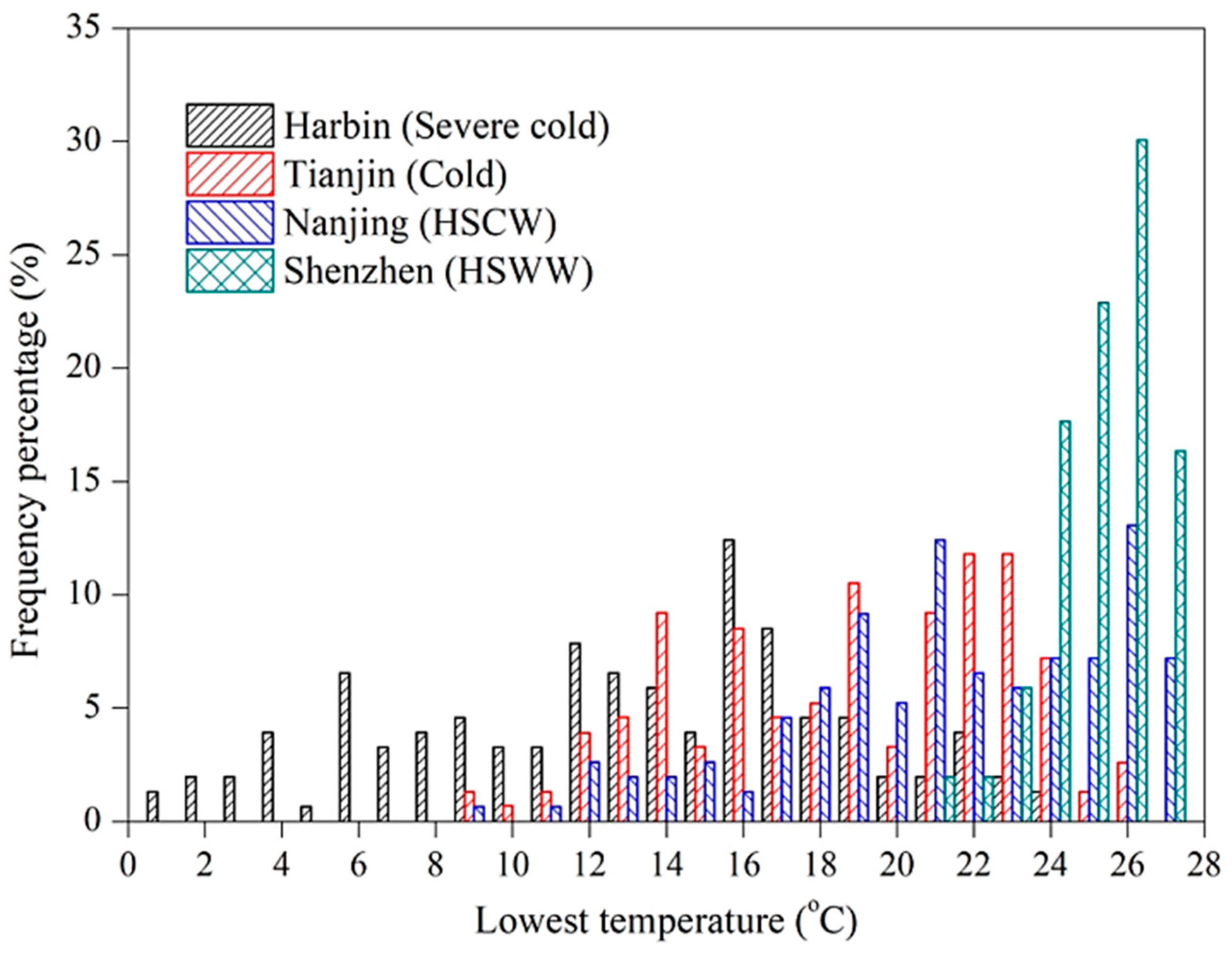

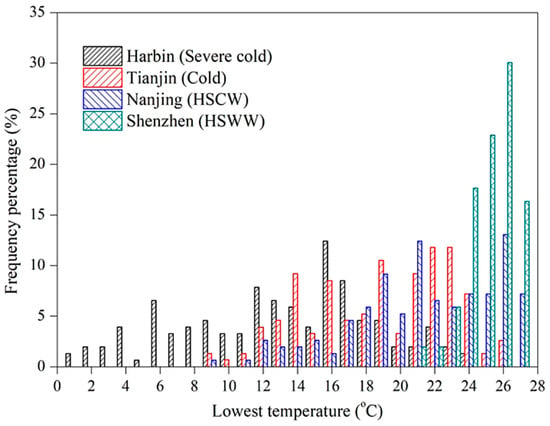

Li et al. (2020) [30] experimentally and numerically investigated the thermal performance of a ventilated roof composed of multiple phase-change materials (VR-MPCM). A comparative test was conducted in two full-scale chambers. Compared to conventional ventilated roofs (CVRs), the VR-MPCM reduced the peak internal temperature by 16.9–18.8% and delayed the peak temperature occurrence by 30–50 min. Additionally, a cumulative heat flux over 4320 min indicated that the VR-MPCM achieved energy savings of up to 97.1% compared to CVRs. Simulations demonstrated that intermittent vent opening resulted in the greatest reduction in heat gain. Local comparisons suggested that the VR-MPCM may also achieve energy savings in extreme cold and cold-temperature regions. Accordingly, this study establishes the viability and potential of VR-MPCMs for refining the thermal performance of buildings and dropping energy consumption. Figure 4 illustrates the frequency distribution of daily minimum temperatures during the cooling season. The data indicate significant differences in daily minimum temperatures across the four building climatic zones.

Figure 4.

Daily low temperature frequency in research cities. Reprinted with permission from Ref. [30].

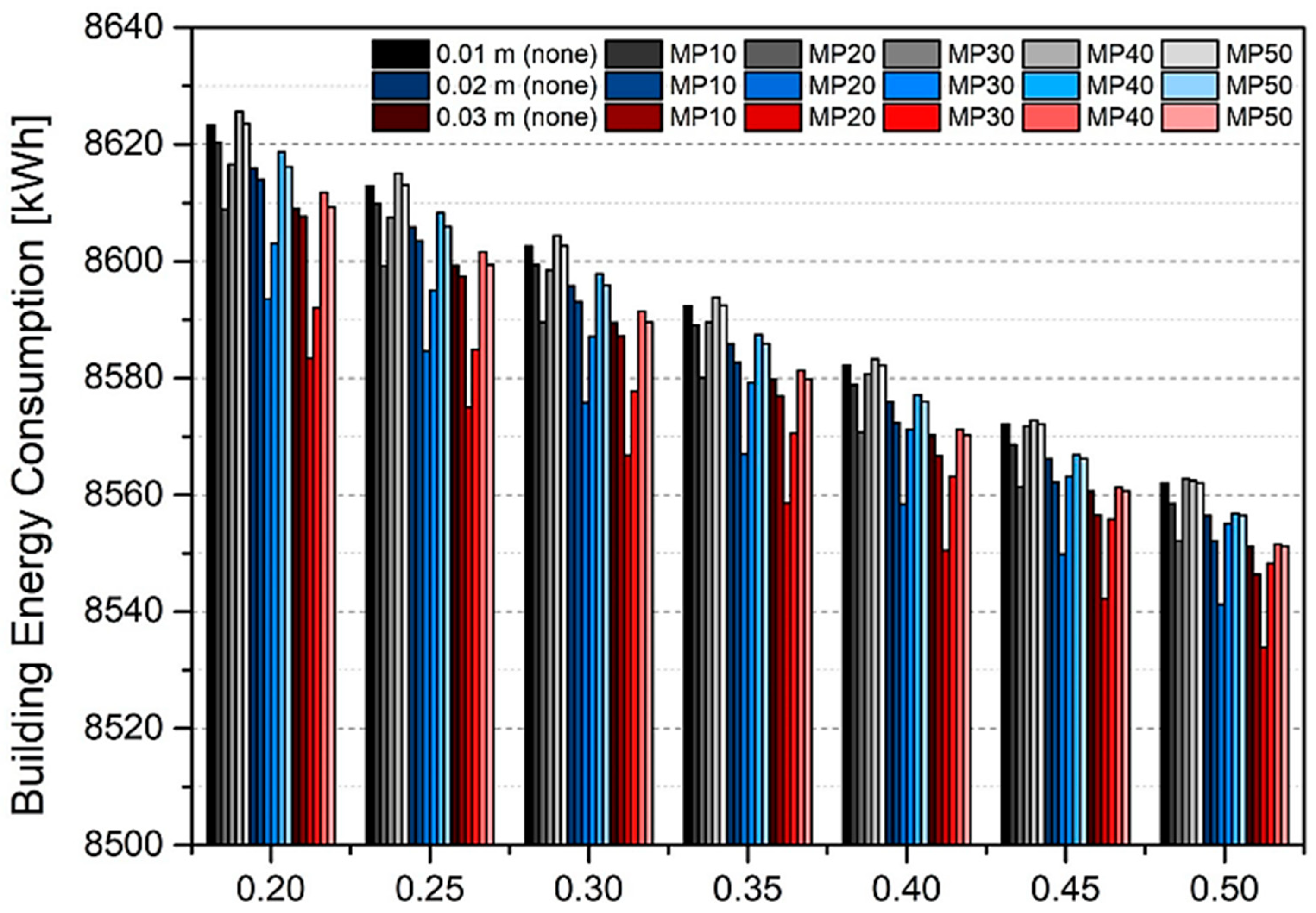

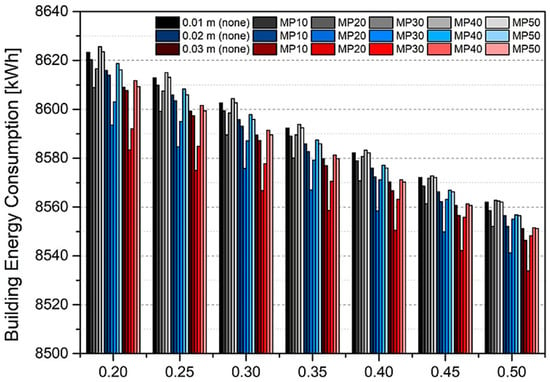

Lowering the surface temperature of the roof, improving interior thermal comfort, and increasing energy efficiency were all goals of the phase change material/wood–plastic (PCM/WPC) composite roof module system proposed by Chang et al. [31]. Increased reflectivity significantly reduces roof surface temperature, as indicated by thermal performance evaluations. However, due to a lower surface temperature, a higher reflectivity can increase the demand for heating and pose difficulties with freezing in winter. The surface temperatures were reduced by 7.37 °C thanks to the PCM/WPC roof module system. The decrease in surface temperature was observed to increase with PCM thickness. PCMs at 30 °C provided the best reduction in surface temperature, while PCMs at 20 °C improved thermal comfort and construction energy efficiency. Since the PCM was implemented externally in the building, economic efficiency, intended use, and reflectance should guide the choice of PCM type and thickness. Accordingly, a valuable reference for developing energy-efficient and comfortable buildings with enhanced thermal performance was approved in this study. Figure 5 illustrates that the house without the PCM/WPC roof module system used 8631.2 kWh for heating and cooling.

Figure 5.

Building energy consumption with PCM/WPC roof modules. Reprinted with permission from Ref. [31].

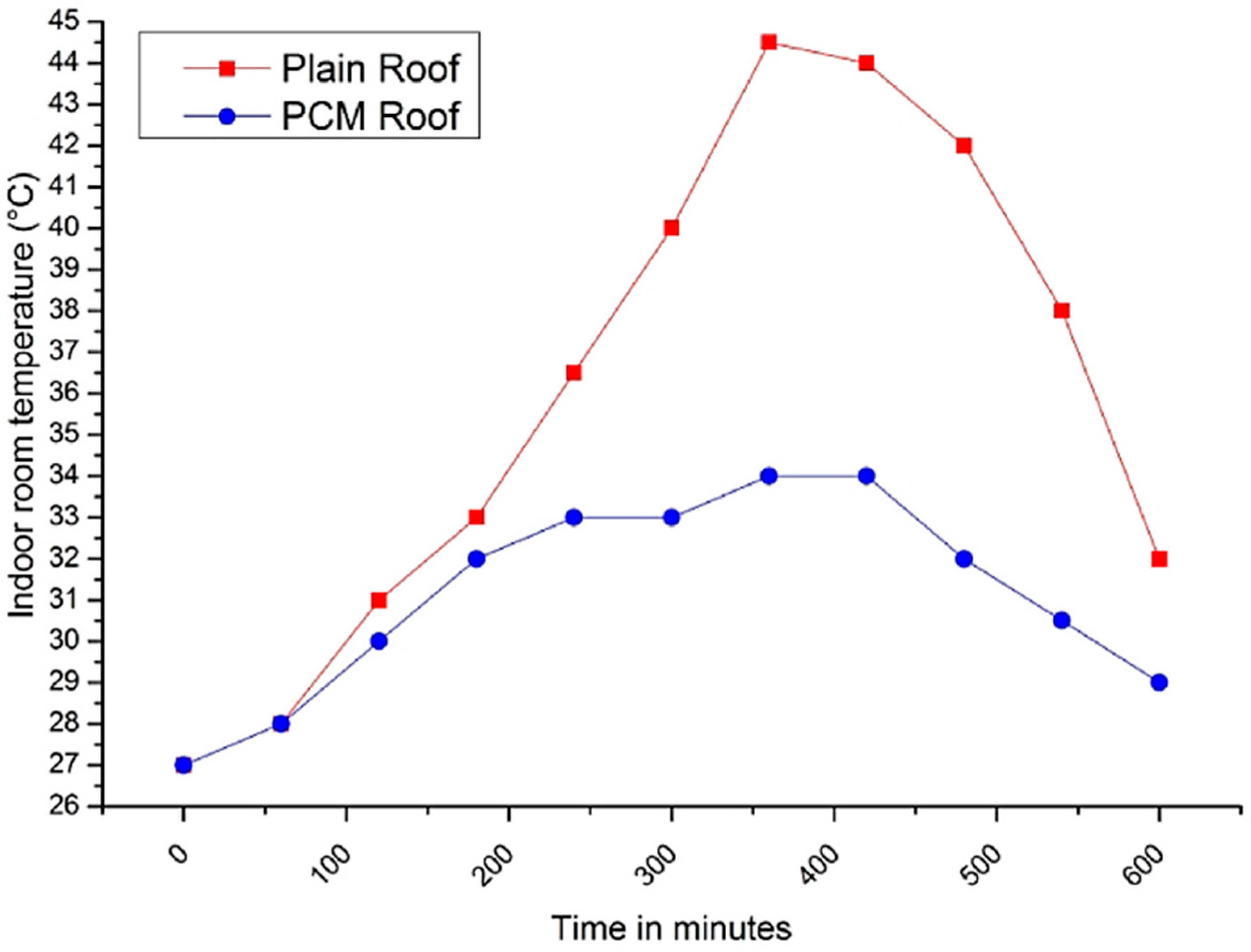

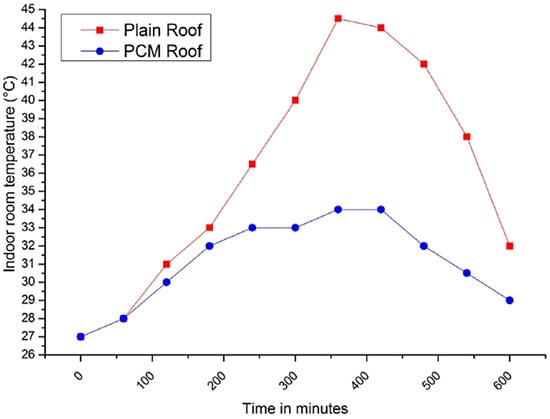

An experiment was carried out by Boobalakrishnan et al. [32] to reduce the interior temperature of a one-story industrial structure with a metal roof using a PCM based on paraffin. This approach aimed to reduce the building’s cooling load and minimize traditional electricity usage. An investigation was conducted using a scale model of the suggested skyscraper. The experiment involved comparing a roof with encapsulated paraffin as the PCM to an uncoated roof. The tests revealed that encapsulating the PCM in the single-story structure’s metal roof significantly lowered the outside, inner, and inside temperatures. In this regard, encapsulating the PCM within the roof meaningfully mitigated the outer roof temperature by 7.5 °C throughout peak solar hours, and by 1.5 °C on average. The PCM also aided in reducing the inner ceiling temperature by 12.5 °C throughout peak solar hours, and by 5.5 °C on average. In contrast, without the PCM, interior temperatures rose rapidly. However, the paraffin-integrated roof exhibited lower daytime temperature changes. Figure 6 illustrates that the uncoated roof reached 44.5 °C after midday, whereas the PCM roof could not surpass 34 °C.

Figure 6.

Trial-day indoor room temperature. Reprinted with permission from Ref. [32].

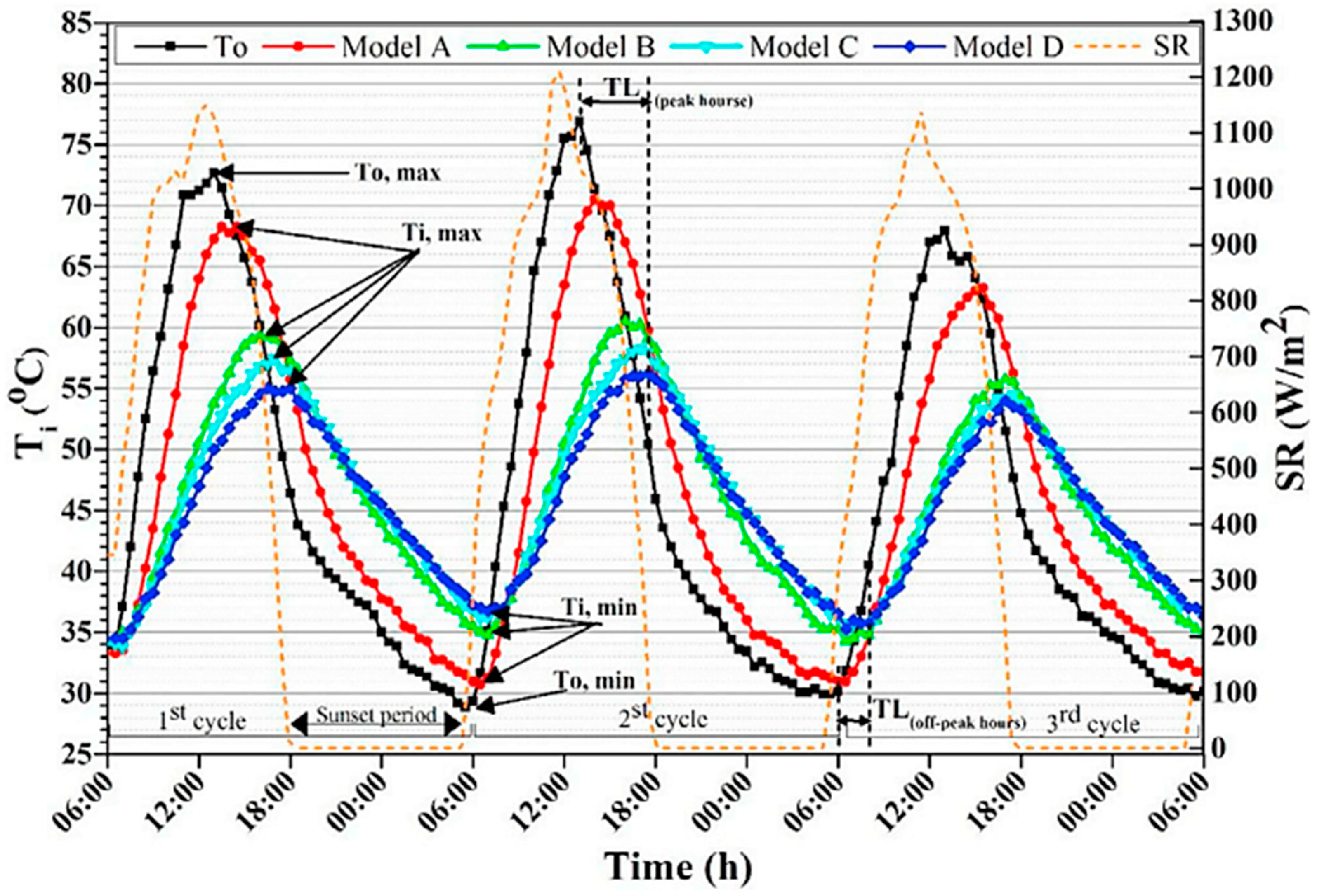

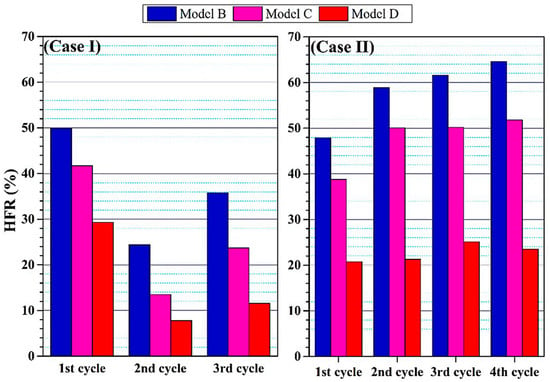

Al-Yasiri et al. [33] investigated the optimal PCM layer thickness for a composite roof under very hot environmental conditions. Roofs with PCM thicknesses of 10, 15, and 20 mm were compared to a control roof without PCMs in a typical Iraqi home. The least thermally efficient roof in the study was the composite roof, which comprised four layers: a 4 mm Isogam layer, a 50 mm concrete layer, an 8 mm gypsum board, and a cladding layer. The trial data indicated that compared to the reference roof, the room temperature could be reduced by as much as 9 °C. Additionally, the thermal performance of the 20 mm thick composite roof was the best, outperforming the reference example by 13.9% in room maximum temperature reduction (RMTR), 10.74 °C in average temperature fluctuation reduction (ATFR), 44.7% in DF, and 190 min in TL. Thus, the influence of a PCM heat-discharging medium and the economic side of its use should be considered when installing large PCM thicknesses/quantities into real-scale buildings. Figure 7 demonstrates that daytime interior surface temperatures decreased more than night-time temperatures as solar radiation decreased.

Figure 7.

Experimental model Ti profile. Reprinted with permission from Ref. [33].

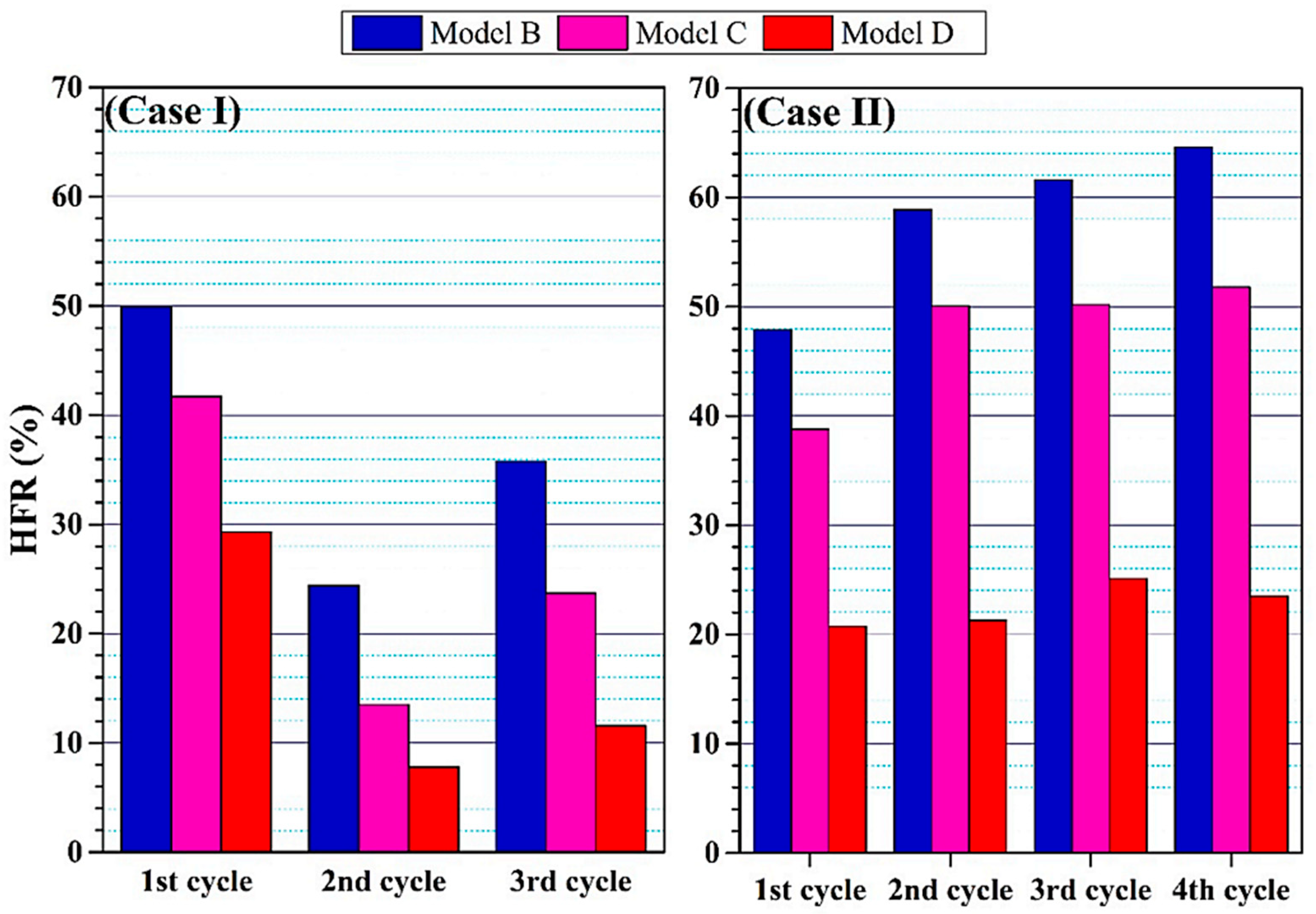

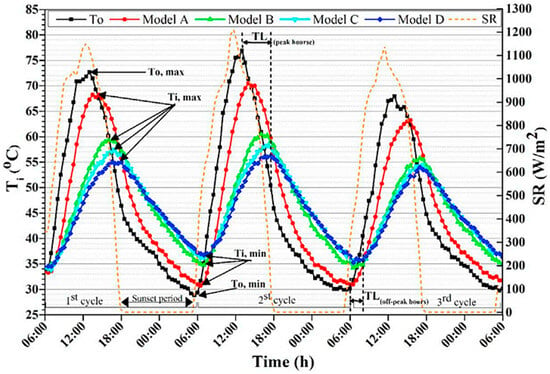

Al-Yasiri et al. [34] conducted tests to determine the optimal location for a PCM-incorporated composite roof in Iraq. Common roofing materials in Iraq include gypsum board (8 mm), Isogam (4 mm), and concrete (50 mm). Four models were developed and evaluated, with Model A serving as the reference roof, while the other three included PCMs. In Model C, a PCM was placed between the Isogam and concrete; in Model D, between the concrete and gypsum board; and in Model B, within the concrete layer. Indicators such as heat flow reduction, decrement factor, time lag, average temperature variation, and maximum room temperature were examined. Model B demonstrated a greater reduction in conductive heat flow compared to Model A, followed by Model C and Model D. The results demonstrated that the optimal position for a PCM in a composite roof under hot climate conditions is between the finishing and the main roof layers. The model with a PCM in this position attained an optimum reduction in room temperature of 12.9% and an average temperature fluctuation reduction of 8.4%. Figure 8 illustrates that Model B’s maximum heat flow reduction in Case I was 49.9% in the initial cycle and 64.6% in the fourth cycle in Case II.

Figure 8.

Case I/II HFR for Model B, C and D. Reprinted with permission from Ref. [34].

Elawady et al. [35] examined the thermal behaviour of PCM-coated roofs, comparing different PCMs. Enthalpy–porosity and simplified thermal models are needed to simulate the melting of the PCM layer, with the simpler model being preferable for long-term modelling. Roofs with three different PCMs and various thicknesses were tested. In the hot summer climate of Aswan, Egypt, simulations were conducted on roofs with and without PCMs over an extended period. The use of PCMs in roof construction reduced internal heat flux and brought the temperatures of interior walls to the desired level. Increased PCM thickness improved performance. A four-month simulation projected an average inside-wall temperature of 32.5 °C for the roof without PCMs and 29.4 °C for the roof with PCMs. Over the course of four summer months, a roof structure incorporating 40 mm of RT31-PCM reduced the energy gain by 40%. This study demonstrated that the using of long-term simulations is vital to capture the melting and solidification behaviour of PCMs over a longer period.

Rangel et al. [36] conducted tests on PCMs and natural ventilation to enhance the thermal efficiency of roofs in semi-arid climates. Thermal comfort was also evaluated using an adaptive model. The effectiveness of both the base roof and the PCM was influenced by factors such as surface temperature, heat flow, lag time to reach peak temperature, and internal air temperature. Four scenarios were tested, including continuous roof components (Case A) and air gaps (Case B) with and without natural ventilation. The results showed that PCM systems had a peak lag time ranging from −10 to 70 min and led to a maximum decrease in internal air temperature ranging from 3.94% to 7.02%. Natural ventilation increased the PCM solidification time by 19–41%. The maximum cooling load reduction was 6.85%, thermal comfort improved by 50 min, and the best performance was achieved by a PCM with a 30 cm air gap in the absence of natural ventilation, resulting in a maximum reduction of 2.5 °C in internal air temperature.

Wang et al. [37] introduced an adaptable building roof utilizing a shape-stabilized PCM with an adjustable transparency. To prevent unexpected heat gain or loss, the envelope can regulate solar absorptivity based on ambient temperature. The experiments validated a mathematical model. For Beijing, it was advised to use (24 °C) and (8 mm) for the PCM, while for Changsha and Guangzhou, (24 °C) and (4 mm) were recommended. In Urumqi, (21 °C) and (5 mm) were suggested. Additionally, for both transparent and opaque states, the optimal extinction coefficients for PCMs were 10 and 250 m−1, respectively. Reflective film with a reflectivity of 0.95 was utilized in all four cities. The annual cumulative loads for Beijing, Changsha, Guangzhou, and Urumqi were (55, 42, 22, and 85 kWh/m2), respectively. Furthermore, the energy savings rates were USD 14.06, 17.65, 31.25, and 9.57 per year.

Meng et al. [38] physically manufactured a PCM foamed cement with variable foaming rates. Researchers measured the thermal conductivity of the PCM foamed cement over a range of temperatures. Finally, real building roofs were covered with the PCM foamed cement to create the roof. In Case 1, a high-reflectivity film was applied to the outside of the roof, while in Case 2, it was not. The thermal performance of the PCM foamed cement roof (FCR) was tested in two different scenarios: one with a traditional roof and the other with an FCR. The results showed that when using PCM FCRs and FCRs, the temperature of the interior surface of the roof may be lowered by 2 °C and 1.1 °C in Case 1, and by 2.9 °C and 2.5 °C in Case 2, respectively. Typically, PCM FCRs and FCRs reduce heat gain by 48.5% and 19.4%, respectively, as seen in Scenario 1. Scenario 2 yielded average reductions of 59.0% and 51.2%. Among the three roofs, the PCM FCR had the greatest impact on reducing interior surface temperature and heat gain.

Rahi et al. [39] quantitatively examined the effectiveness of macro-encapsulated PCMs in RCC roof slabs. Researchers investigated how the form, heat transmission area, and thermal shading with a similar PCM reduced the inner roof temperature. A reference case and another 12 cases were evaluated. Additionally, the structural performance of the RCC traditional slab, as well as the slab with PCM capsules, was outlined. The research indicated that a thinner cuboid was optimal. An increased heat transfer area improved the thermal performance and provided the best scenario, reducing peak and average temperatures by 3.2 °C and 1.2 °C, respectively. Thermal shading improved the outcomes during the winter solstice. The deflection of all slab examples was within limits. However, it should be noted that the utilisation of a PCM in a single layer in the roof slab can cause a considerable issue if the PCM gets damaged and leaks, and this would completely affect the layer. Interestingly, this issue can be resolved by using PCM capsules at systematic intervals in the entire slab.

Sedaghat et al. [40] used experimental and computational methodologies to investigate bioPCMs and cool roof coverings as energy-saving strategies in three hot climates. Two similar portable cabins were carefully built and tested under two cooling settings. Since their thermal similarity has been empirically established, these rooms are ideal for evaluating energy-saving methods. TRNSYS created a six-zone model to analyse bioPCM-integrated walls. In Kuwait, Australia, and India, bioPCMs in three wall and roof locations saved 22%, 23%, and 53% of energy, respectively. Simulations showed that sandwich panels may reduce energy use by 35.7% and 43.8% in Kuwait and Australia compared to autoclaved aerated concrete blocks. However, sandwich panels also increased energy consumption by 126.2% in tropical Kodaikanal, India.

One way to reduce the amount of heat transmitted indoors during the summer is by using a PCM cool roof, as suggested by Jiang et al. [41]. The environmental and thermal aspects of three full-size rooms (PCM, PCMC, and Ordinary) were studied from July to September 2022. Experimental and numerical studies examined roof heat transmission and energy savings. With the PCMC roof, the real-time temperatures of the outside and inside of the roof decreased by 30.0 and 6.4 °C, respectively, and the flow of heat from the roof’s inside was reduced by 33.3% to 66.7%. Compared to other roof studies, the cooling advantages and energy savings were much higher. To evaluate the energy savings of PCMC roofs, a correlation study was conducted between seven parameters, following the mathematical model of roof heat transfer.

Nguyen et al. [42] examined the passive effect of using six roof constructions with PCM capsules in variable locations and orientations to regulate heat loss and boost thermal resistance. The thermal behaviour and energy loss of an externally slanted magnetic field were also examined. Roof temperatures were replicated, and the finite element approach solved the governing equations for solid components and PCM capsules. Streamlines, isotherms, thermal resistance graphs, and melted volume percentages were presented. The results revealed that the magnetic field has little influence on thermal conductivity, owing to the capsule size. A horizontal capsule orientation reduced heat conduction, melting, and roof structure thermal resistance. Moving horizontal capsules near the hot interface slowed PCM melting. In this regard, the optimal position of the PCM is indicated to be inside the insulation layer. Furthermore, the cylindrical forms of PCM perform the best.

Yu et al. [43] examined the thermal performance of a shape-stabilized PCM ventilation roof. For analysing heat transfer on the roof, a combination of the number of transfer units (NTUs) heat exchange model and the resistance–capacity dynamic heat network model were utilized. Factors such as indoor air temperature, roof surface temperature, and summer cooling load were all modelled and examined for in Wuhan. Based on the statistics, PCMs and night ventilation were found to be energy efficient. With a 30 mm PCM, there was a 19.2% reduction in cumulative cooling demand, a 2.9 °C reduction in peak interior air temperature, and a 5.5 °C reduction in the highest temperature of the internal surface. When comparing the PCM roof with the reference roof, night ventilation (v = 3 m/s) increased the rate of the mean latent heat utilization of the PCM layer and decreased the collective cooling load by 22.9% and 37.5%, respectively.

Nguyen et al. [44] examined how different PCM layouts in roof structures affect thermal resistance and energy losses. The layouts of phase change materials and bricks were tested in the following ways: tiny blocks of PCM were spread throughout the building, several lengthy blocks of PCM were dispersed vertically or horizontally, a single block of PCM was placed in either the left half or the right, and a single block of PCM was placed in either the bottom or top half. Different configurations and two Rayleigh numbers (Ra) were used to evaluate the hydrothermal behaviour of a melting PCM. The findings showed that a single block of PCM at the cavity top and bricked from the hot source had the maximum thermal resistance for low Ra. Multiple vertical blocks of PCM provided the highest resistance for high Ra. Ra did not affect PCM melting when the phase change material was positioned in several tiny or horizontal blocks. Generally, PCM melting occurred quickest when the block was near the heat source and in one or more vertical blocks.

An external magnetic field was applied to a roof structure using Ferro-PCM augmented with nanoparticles by Nguyen et al. [45]. The roof structure held a round-corner semi-hexagonal block of Ferro-PCM horizontally or vertically. The equations were discretized and solved by employing the method of control volume finite element. Vertical Ferro-PCM blocks had a 30% lower thermal resistance than the horizontal ones in the absence of a magnetic field. Increasing the Hartmann number from 0 to 200 increased vertical thermal resistance by 80% and horizontal thermal resistance by 45%. The PCM melted 30% quicker and had a 45% lower thermal resistance if the magnetic field was vertically implemented instead of horizontally.

Under large daily temperature changes, Luo et al. [46] used the approach of a multiple-relaxation time lattice Boltzmann for quantitatively exploring heat transfer and the energy-saving potential of porous bricks packed with paraffin waxes. In their study, the authors selected a typical July day in Shanghai, Urumqi, Hohhot, Harbin, and Xining, utilising Meteonorm software to derive their meteorological parameters as dynamic boundary conditions. The software computed the total heat flux from the roof, the temperature fluctuation of the roof’s interior surface, and the frequency of thermal discomfort (FTD). Comparing Shanghai and Urumqi elucidated the impact mechanisms of diurnal temperature fluctuations on PCM performance. At the phase transition temperature of 28 °C, Urumqi exhibited a significantly lower FTD of 7.4% compared to Shanghai’s 37.2%. The adaptability of phase transition temperature to climatic parameters is crucial for PCM application in building roofs. Porous brick roofs in Shanghai, Urumqi, Hohhot, Harbin, and Xining demonstrated excellent performance with paraffin waxes at phase transition temperatures of 28 °C, 28 °C, 26 °C, 28 °C, and 24 °C, respectively. Corresponding FTDs were 37.2%, 7.4%, 0%, 0%, and 0%, while the total heat fluxes from the roof were 163.3, 95.2, 23.0, 61.6, and 0 kJ·m−2. This research offers insights into optimizing PCM–night ventilation combinations for buildings in regions with substantial diurnal temperature fluctuations.

Table 1 depicts a critical analysis of the associated studies on using PCMs in building roofs.

Table 1.

Outline of studies on using PCMs in building roofs.

2.2. Studies Related to PCMs in the Ceilings of Residual Buildings

Around 30% of global energy use goes to building heating and cooling [47]. Technologies that effectively store heat and cold are needed to enhance the percentage of sustainable sources of energy and improve thermal system efficacy. PCM features may inspire new compact thermal energy storage solutions. This technique stores energy more densely and with fewer losses than sensible energy storage. Adding PCMs to the structure of the building improves heat storage with minimal design adjustments. A PCM can hold a high amount of energy (heat) in a tiny volume, making it appealing to builders. Below is research on PCMs in construction ceilings.

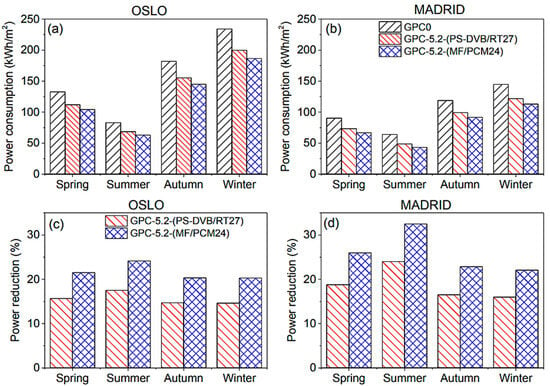

Basher et al. [48] tested a PCM as thermal insulation in building walls and ceilings. The researchers used ESP-r version 12.0 for numerical simulation. Energy and weather database software used climatic data for Kut city (32.5° N) and (45.8° E) in their simulation. ESP-r software had two identical 1.5 m × 1.5 m × 1 m rooms: a standard room for comparison and a test room for experimentation. The thickness and orientation (ceiling, west wall, east wall, south wall, and north wall) of the PCM were investigated in several cases. With PCM insulation, zone interior temperature, cooling load, and energy consumption were decreased. The outcomes represented the prosperity of PCM thickness to regulate the temperature. Thicker layers offer excellent insulation at reduced indoor temperatures. Also, PCM orientation can impact the performance. Using PCMs on the south wall exhibited the most-weighty temperature reduction due to direct solar exposure. Lastly, PCMs successfully mitigated cooling loads, leading to potential energy savings.

Yasin et al. [49] created a TRNSYS room model for a novel cooled ceiling using PCMs. Laboratory and real-scale building monitoring data verified the room model. The chilled –PCM-ceiling model employed TRNSYS type 399, designed to simulate large thermo-active building components using PCMs. The authors indicated that type 399 can be utilised for the chilled PCM ceiling, provided that model geometry limitations are considered. Root mean square errors (RMSEs) of ±0.3 °C and ±0.6 °C were found for the simulated and observed temperature deviations for the operational and PCM temperatures, respectively. The ceiling cooling-power simulation of PCMs exhibited a greater variance, with an RMSE of ±0.19 kW. Accordingly, the model was able to precisely predict the temperature of the PCM and the cooling power of the ceiling. The model developed can be utilised to optimise the design and operation of these systems, which can improve thermal comfort and energy savings.

Abden et al. [50] developed a composite FSPCM from gypsum board by directly impregnating it with methyl stearate and diatomite. Several methods were utilized to assess the thermal behaviour of the methyl stearate/diatomite composite and its properties to assess its suitability for use in building materials, especially gypsum board. The FSPCM proved to be dependable and robust for long-term temperature management in thermogravimetric data and thermal cycle tests. An energy-efficient test ceiling was created by combining an FSPCM with gypsum board. The authors modelled a small test room with a ceiling made of gypsum board integrated with an FSPCM. The thermal/energy performance and economic analysis were compared to ordinary gypsum boards without FSPCMs under actual environmental circumstances. The FSPCM in gypsum board ceilings saved 16.2% of cooling demand, making it economically viable.

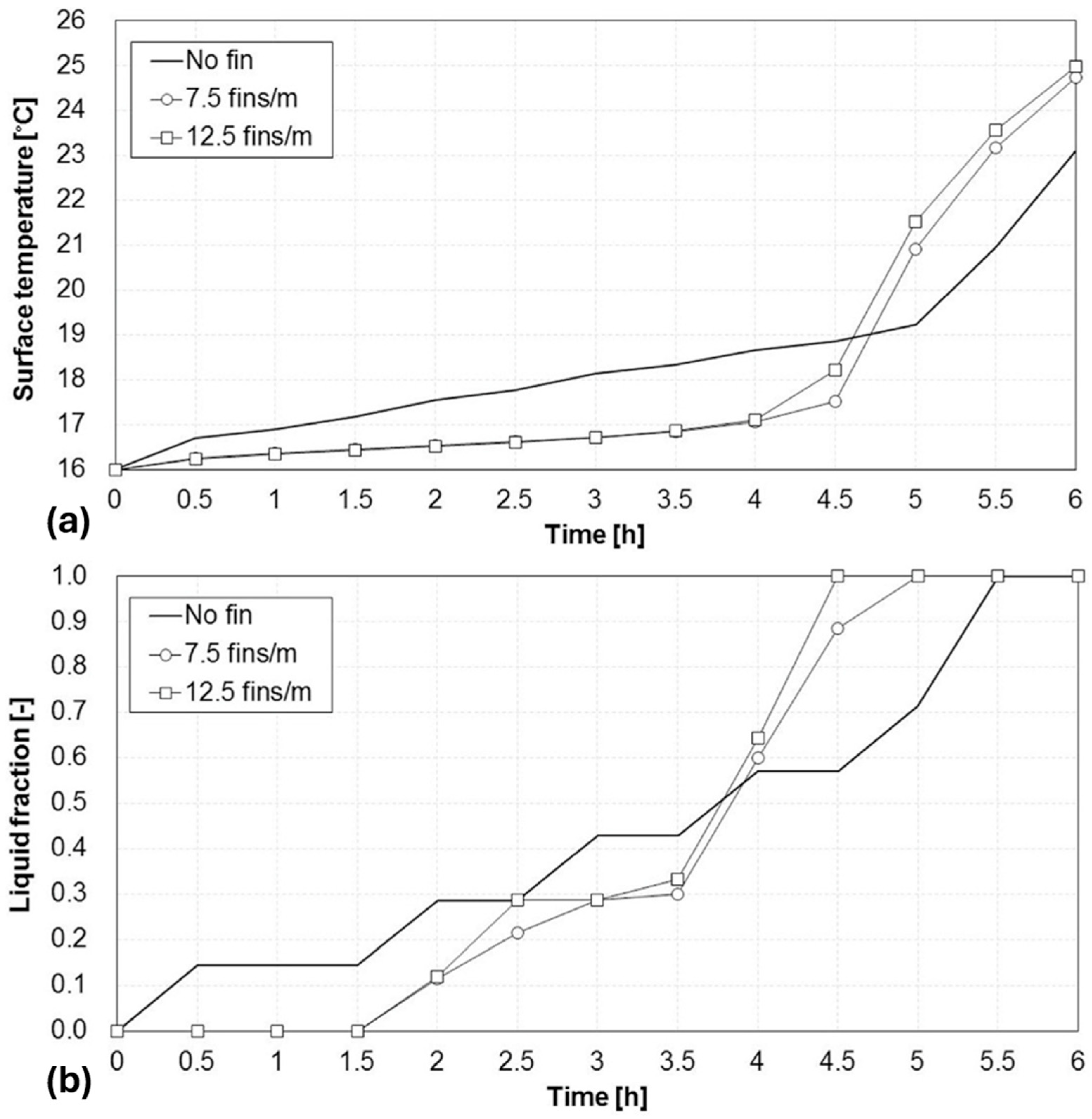

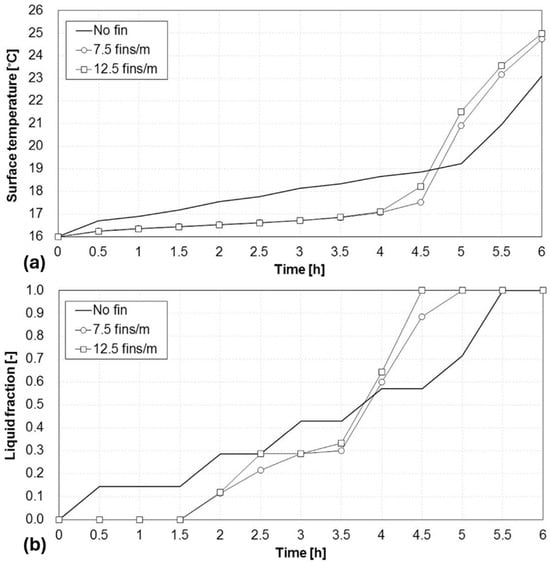

By simulating the suggested cooling panel numerically, Lim et al. [51] were able to determine the optimal design of the PCM layers to maintain the panel’s surface temperature set-point constant while it was operating, all without using TEMs. The critical design factors for the cooling effectiveness of the PCM-TERCP (thermoelectric radiant cooling panel) were identified using parametric analysis. The layer thickness and the number of heat fins inside the PCM had a significant influence on the panel’s surface temperature. For conditioned space applications, the most practical PCM-TERCP solution was a thick layer (10 mm) of PCM with over five panel heat fins per unit length (Figure 9). Additionally, the PCM liquid’s percentage should be around 0.6–0.65 to optimally utilize its latent heat by improving heat transmission.

Figure 9.

PCM-TERCP melting performance. (a) is the maximum surface temperature and (b) is the liquid fraction of the PCM layer. Reprinted with permission from Ref. [51].

The convective heat transfer of the Al2O3 (Alumina)-water nanofluid in a 3D mini-channel heat sink was estimated numerically by Yan et al. [52]. The finite volume approach (FOV) discretized the governing equations, and the algorithms LINE SOR and TDMA solved them. FORTRAN was created for numerical calculations. The micro-encapsulated phase change material covered the mini-channel ceiling. The phase transition material is N-eicosane, which melts at 34.7 °C and contains 24,300 J/kg latent heat. All simulations used three solid volume fractions of nanoparticles, 0%, 2%, and 10%, a Reynolds number of 500–2000, and two outside-ceiling surface temperatures: 28 °C and 30 °C. Micro-encapsulated PCMs reduced ceiling heat flow in the heating section. Additionally, MEPCM melted quicker at lower Reynolds numbers.

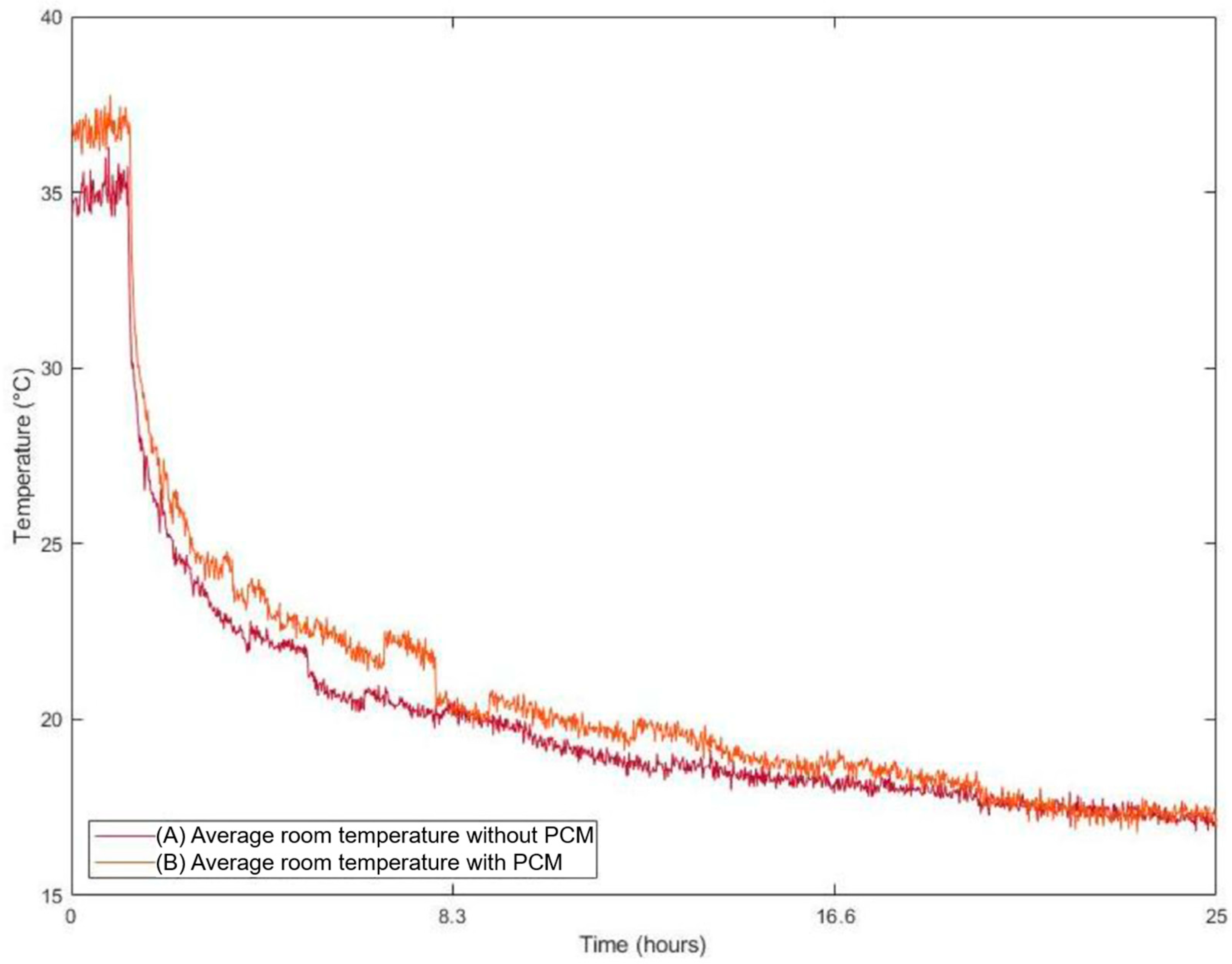

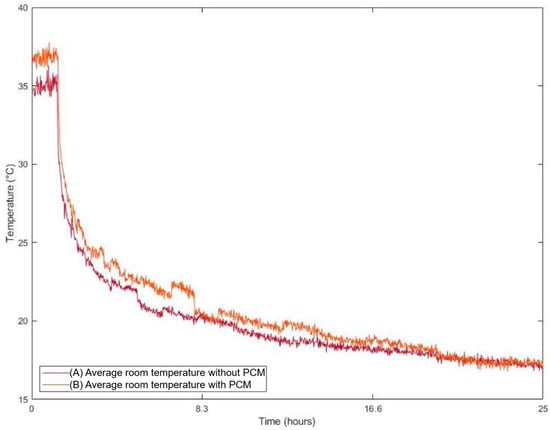

Velasco-Carrasco et al. [53] examined how S23 ceiling panels improve building performance. A test room was artificially heated to determine the melting point of the PCM panels. S23 panels absorbed and raised the ambient temperature by 5 °C. PCM ceiling tiles assist in maintaining sustained room temperatures up to (+1.5 °C) during cooling. After 6 h of cooling, the S23 panel temperature dropped below its melting point, completing the thermal cycle. Additionally, the S23 panel can safely encapsulated the PCM and enhanced the exchange of heat with the thermal atmosphere, making it ideal for building inclusion. The results also demonstrated that the thermal conductivity of the S23 panels varies between 0.19 and 0.24 W/(m K), which is a competitive option if compared to other commercially available PCMs. The room temperature of the PCM declined to 14.6 °C during the initial 6 h, reaching 22.1 °C, below the melting point of PCM, as illustrated in Figure 10.

Figure 10.

Comparing room cooling temperatures. Reprinted with permission from Ref. [53].

Bogatu et al. [54] evaluated a new macro-encapsulated PCM panel (MEP) with integrated pipes compared to commercial radiant cooling technologies as an effective ceiling cooling component. The cooling demand can be shifted to off-peak hours when the PCM is fully depleted, thanks to the built-in heat-storage capacity. At (20 °C) and (140 kg/h), the specific cooling power of the MEP on the active ceiling surface averaged 11.3 W/m2, with a range of 5.3–27.7 W/m2. The results also demonstrated that the total heat capacity of the PCM contained in one MEP between 16 °C and 31 °C was about 361 Wh/m2 and 242 Wh/m2 within the melting range. For 83% of the occupied time, the performance of the MEP was comparable to that of radiant ceiling panels, offering a thermal atmosphere classified as Category (II) according to EN16798. Compared to effectively cooled gypsum panels with MEP pipes touching but not embedded, it represents a significant improvement.

Gallardo and Berardi [55] defined the design, size, and control of the radiant ceiling panel (RCP)-PCM system. Parametric dynamic simulations simplify RCP-PCM system sizing and design for cooling applications. Optimal energy storage capacity and thermal comfort were achieved with a 0.015 m PCM panel thickness and a supply of 15 °C water. The simplified method in a case study demonstrated that the RCP-PCM system could maintain room temperatures within the thermal comfort range (−0.5 < PMV < 0.5) in over 90% of occupied times in cooling-dominated climates. The suggested strategy for building an RCP-PCM system effectively maintained PMV values below −0.6, with no annual values above 0.8. Additionally, in a particularly humid and hot zone, an RCP-PCM system can save 22% more energy than an all-air system.

Sinacka and Szczechowiak [56] studied the dynamic behaviour of a room with hanging thermally triggered ceiling panels packed with 60% paraffin. The densities of convective and radiant heat fluxes, as well as the coefficients of heat transfer at the ceiling surface, were computed. Analyses reveal that switching the system activation to lower night-time temperatures preserves thermal comfort. The results demonstrated that integrating the thermally actuated ceiling with the PCM complicates the design, energy audit, and the creation of a control strategy, requiring unsteady-state assessments. Also, the total supplied energy to the PCM through regeneration increased due to an increase in the mass flow rate of the water. The heat transfer coefficients upsurge with increasing the temperature difference between the ceiling surface and the air. However, experimental investigations are needed for each new system, since the PCM, location, and ceiling panel structure affect thermal characteristics.

Skovajsa et al. [57] investigated whether PCMs in cooling ceiling systems can reduce cooling energy use and air temperature fluctuations. The authors designed and prototyped the PCM-based cooling ceiling. An experimental validation of TRNSYS transient simulations was conducted. Based on the results, extensive simulations were run for Czechia’s climate. A comprehensive method, from the prototype design to trials, partial simulations, and complicated simulations founded upon factors as well as the economic assessment were utilised. Based on the change rate of air, the suggested cooling ceiling system can minimize temperature peaks by 3.2 °C and save 27% in energy usage. Furthermore, it was ascertained that the PCM panels can passively mitigate daytime peak temperatures by up to 3 K. In addition, the active discharging of PCMs is more active than passive discharging.

Mousavi et al. [58] investigated a recently constructed PCM-RCC (PCM-entrenched radiant chilled ceiling) in a cabin positioned in Melbourne. For evaluating the thermal and energy system performance, the authors examined the transient thermal conduction of the PCM panels through the charging–discharging cycles, as well as electrical peak consumption, interior comfort, and other factors. The suggested PCM-RCC can offer sufficient comfort and load shifting with a sophisticated working plan. The design considers numerous variables to maximize PCM recharge overnight efficiency. If the battery does not overheat before midnight, 6–8 h should be sufficient. The existing panel design has problems with the poor heat transfer rate of water capillary tubes and particularly the absence of thermal contact between PCM and tubes. The PCM-RCC maintained an ISO 7730 [59] Class C operational temperature for 58–70% of occupancy. Thus, this study assured that the application of optimal operating and control strategies is essential to fully realise the potential of PCM-RCC technology.

A new, adaptable cooling system for commercial buildings was introduced by Gallardo and Berardi [60] to substitute traditional all-air systems. The gadget stored thermal energy using macro-encapsulated PCMs that were covertly placed under the standard radiant ceiling panels’ serpentine Cu coil. The system of RCP-PCM was tested in a walk-in double climate chamber for shifting the cooling loads to off-peak hours. Additionally, the rate of heat removal capacity and the interior thermal atmosphere enhancements were evaluated. The passive cooling power ranged from 11 W/m2 to 31.4 W/m2, with an average value of 17.3 W/m2. The results showed that the system of RCP-PCM can transfer cooling loads to off-peak hours while preserving thermal comfort during working hours (8:00 a.m.–18:00 p.m.). During testing, the system passively absorbed heat gains (180–230 Wh/m2) throughout the day and operated effectively at night during unoccupied hours.

Mustafa et al. [61] improved the RCC with PCMs and detailed its thermal study in Saudi Arabia’s Tabuk environment. A PCM was incorporated into RCC roofs by creating air gaps. The exchange of heat from the ceiling decreased by 57.6% annually and by 22.6% from April to October with an air gap and adequate PCM installation. Daytime phase alterations allowed for increased PCM performance. To work throughout the day, the PCM must freeze overnight. Additionally, the chilly ambient wind cooled the water, and a nanofluid-filled ground heat exchanger accelerated PCM freezing. Moreover, the initial approach accelerated PCM solidification by 78.6%, whereas the second and third approaches did so by 16.5%. When cold airflow enters the internal ventilation, it may reduce electricity usage by 26.1% in April and 25.3% in October, but not in July and August.

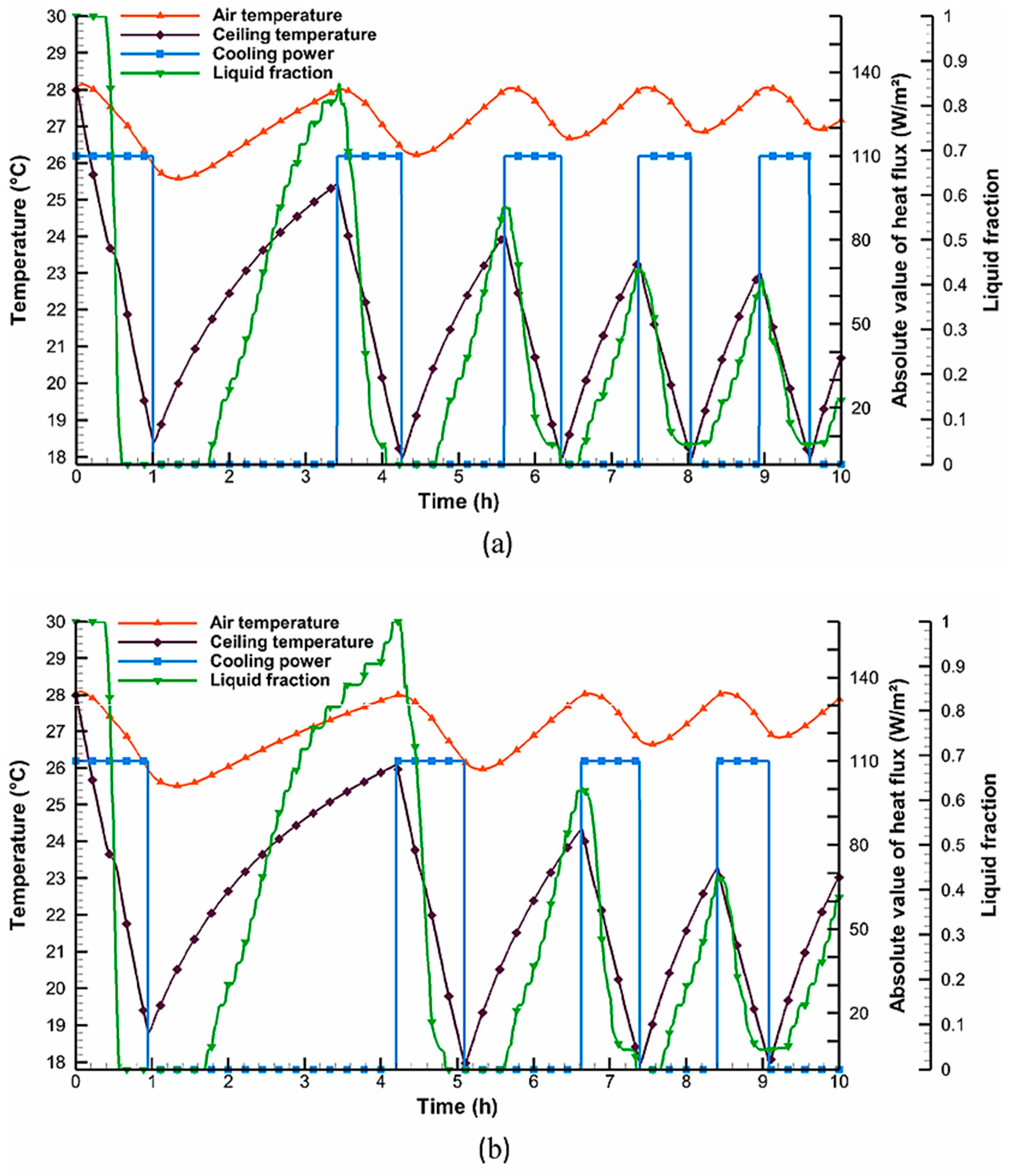

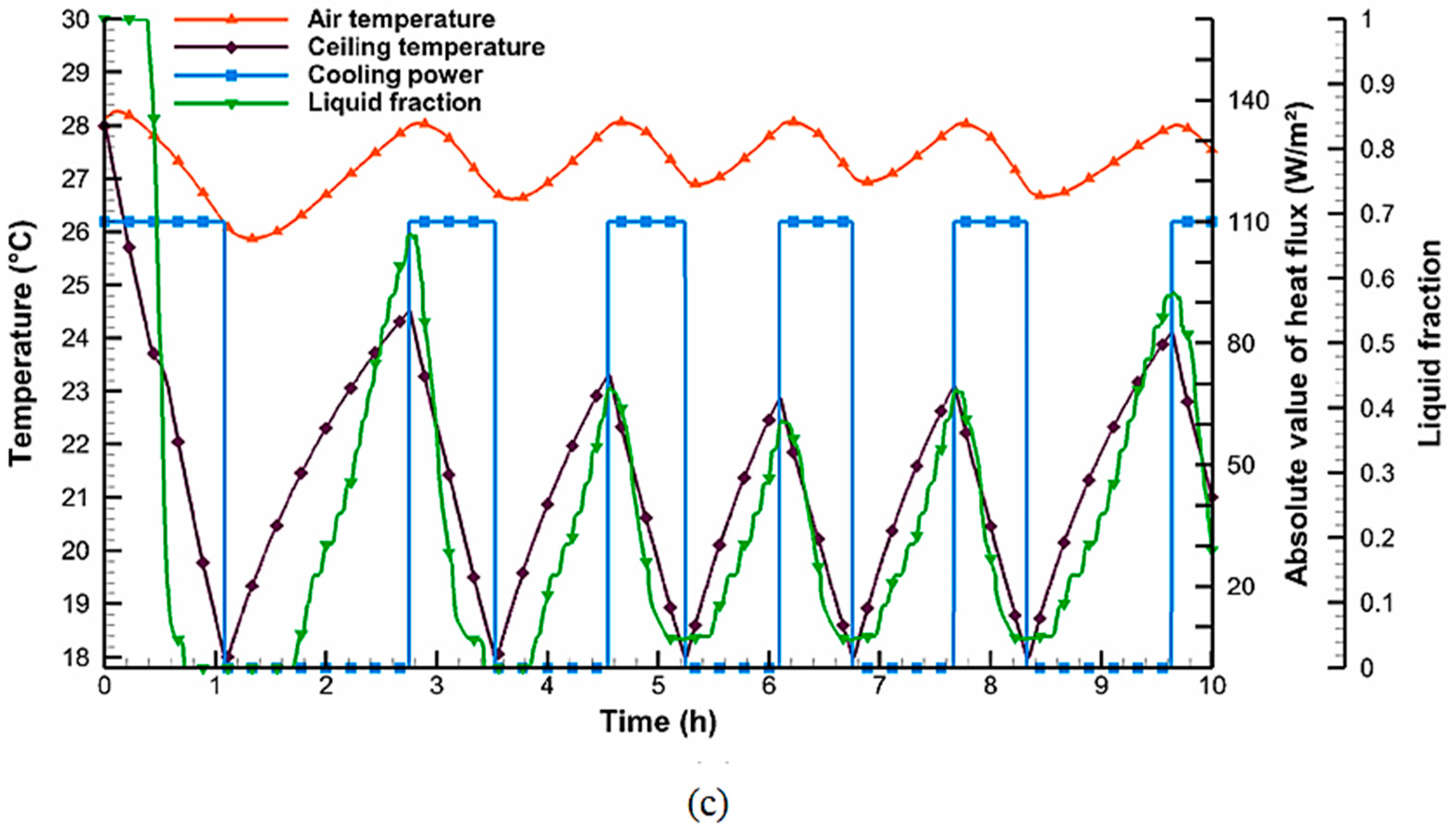

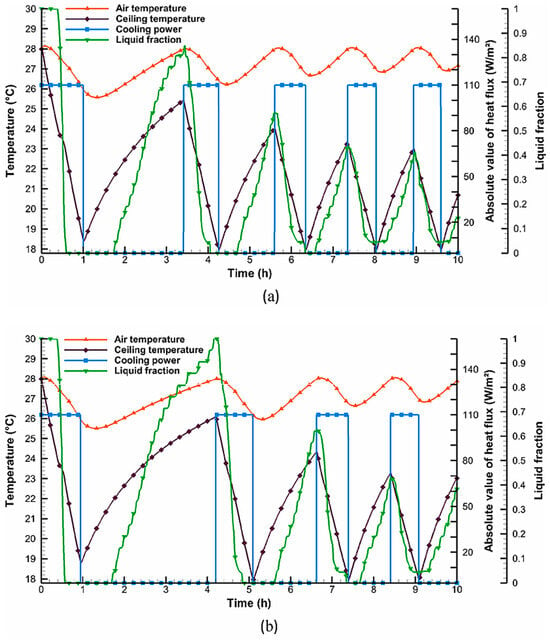

Inside a ventilated room with three Moroccan climates reflecting three Köppen–Geiger climate types, Khattari et al. [62] examined the energy and thermal benefits of employing PCMs in a governed cooling ceiling system. A controlled cooling power maintained the temperature of the interior air within a small thermal comfort range with no waste of energy. By merging the genuine ambient temperatures of Marrakech (BSh climate), Fez (Csa climate), and Ifrane (Csb climate), a thorough 2D transient simulation was used to solve physical equations numerically using computational fluid dynamics (CFD). The authors examined how paraffin C13 PCM may improve the system of cooling the ceiling in an effectively ventilated room. The paraffin C13 PCM was shown to reduce indoor air temperature fluctuation in the three climate types, and in the Csa and Csb climates, it saved 17.07% and 16.30% of cooling power, respectively. Referring to Figure 11, the four graphs vary greatly across cities, because the three Moroccan cities have diverse Köppen–Geiger climates. Up to this point, this study introduced the potential of PCMs to improve the performance of cooling ceiling systems in terms of both thermal comfort and energy efficacy.

Figure 11.

Thermal properties of (a) Fez, (b) Ifrane, and (c) Marrakech rooms with cooling ceilings and PCMs. Reprinted with permission from Ref. [62].

Yang et al. [63] examined conjugate heat transport via oleic acids, capric, a lauric PCM, the shell of the panel, and air, which was chosen as a PCM enclosed into acrylonitrile butadiene styrene plastic thin-shell enclosures for attractive ceiling panels. Depending on the full-scale investigational data, a CFD model was used to analyse PCM ceiling panel discharge and design. Pyramid array panels outperform tetrahedral panels in thermal performance, with an average melting rate 20.8% greater at 250 mL. Also, the active area of heat transfer and the panel’s natural convection conditions will affect its thermal effectiveness if its geometric aspects are changed. Finally, suspending the panel from the ceiling improved heat transmission more than simply attaching it. Accordingly, it can be said that this study has the potential of PCM-based ceiling panels for passive cooling in buildings and delivered appreciated insights for optimising their design and performance.

Model-based predictive control was used by Hlanze et al. (2023) [64] to improve PCM ceiling panels and heat pumps with a multi-stage air-source. Using the low and the medium compression stages for cooling and heating rooms and elevated compression stages to charge the PCM energy storage devices, the lab built and tested a three-stage prototype heat pump system. The technique of mixed-integer linear programming was developed for the optimum governing of the integrated heat pump system by linearizing the heat pump model and reformulating the PCM dynamic governing equations. In order to optimize the charging schedules for PCMs and the temperature zones inside a building at a similar period, taking advantage of the passive materials of building construction and the effective capabilities of PCM storage, a predictive governing plan was developed and applied in a receding horizon scheme founded upon the control formulation. The results of the tests demonstrated that a time-of-use rate tariff may result in a savings of 20.4% in power costs with a fine-tuned rule-based governing approach and a 27.1% savings with the PCM-integrated heat pump.

Two building test models were compared in an experimental investigation by Arivazhagan et al. [65] to determine the effect of PCM put into the ceilings on heat management. Encased in high-density polyethylene (HDPE) was a saleable organic phase change material (OM-30) with a highest melting temperature of 31.1 °C. The research included PCM melting temperatures above, within, near, and far from the PCM. PCM installation successfully reduced the interior air temperature by 1.69 °C, 5.79 °C, 2.26 °C, and −2.87 °C, resulting in a differential of the phase change material melting temperature of 8.77 °C, 1.55 °C, 1 °C, and 0.44 °C under free-floating ambient conditions. Furthermore, in comparison to the room in which PCMs were absent, the room including PCMs used 3.2%, 31.4%, 6.9%, and 12.27% of the entire latent heat energy for attaining temperature differences of 1.69, 5.79, 2.26, and −2.87 °C.

Mousavi et al. [66] tested a system of PCM-RCCs in a full-scale examination cabin using panels of PCM for thermal efficiency and energy performance. The cooling energy provided through the cycles of charging–discharging and the PCM ceiling panel transient thermal behaviour were explored. The PCM panels were completely recharged after 4–5 h of cold-water movement overnight. And over 80% of the time of occupancy was categorized as “Class B” thermal comfort under the ISO 7730 standard. The majority of the power of system use occurs in the off-peak hours, almost 70% of the overall utilisation. Also, the governing timetable reacted to the conduction of the transient heat of the indoor space as well as the ceiling panels of PCM, but a further dynamic, predictive timetable is needed for improving the efficacy of the system and the indoor thermal comfort in reaction to the changing ecological circumstances.

A crucial assessment of the performed studies using PCMs in the ceilings of the buildings is depicted in Table 2.

Table 2.

Outline of the studies using the phase change material (PCM) in building ceilings.

2.3. Studies Related to the PCM in the Wall of Residual Buildings

Residential space cooling energy consumption is anticipated to expand rapidly, owing to rising family incomes in emerging nations. PCMs in building walls can minimize cooling energy usage and peak cooling loads to meet rising cooling demands. PCM factors, like phase change temperature and wall placement, must be chosen carefully to achieve the stated advantages of PCM integration. The following section discusses the most relevant studies that integrated PCMs into building walls.

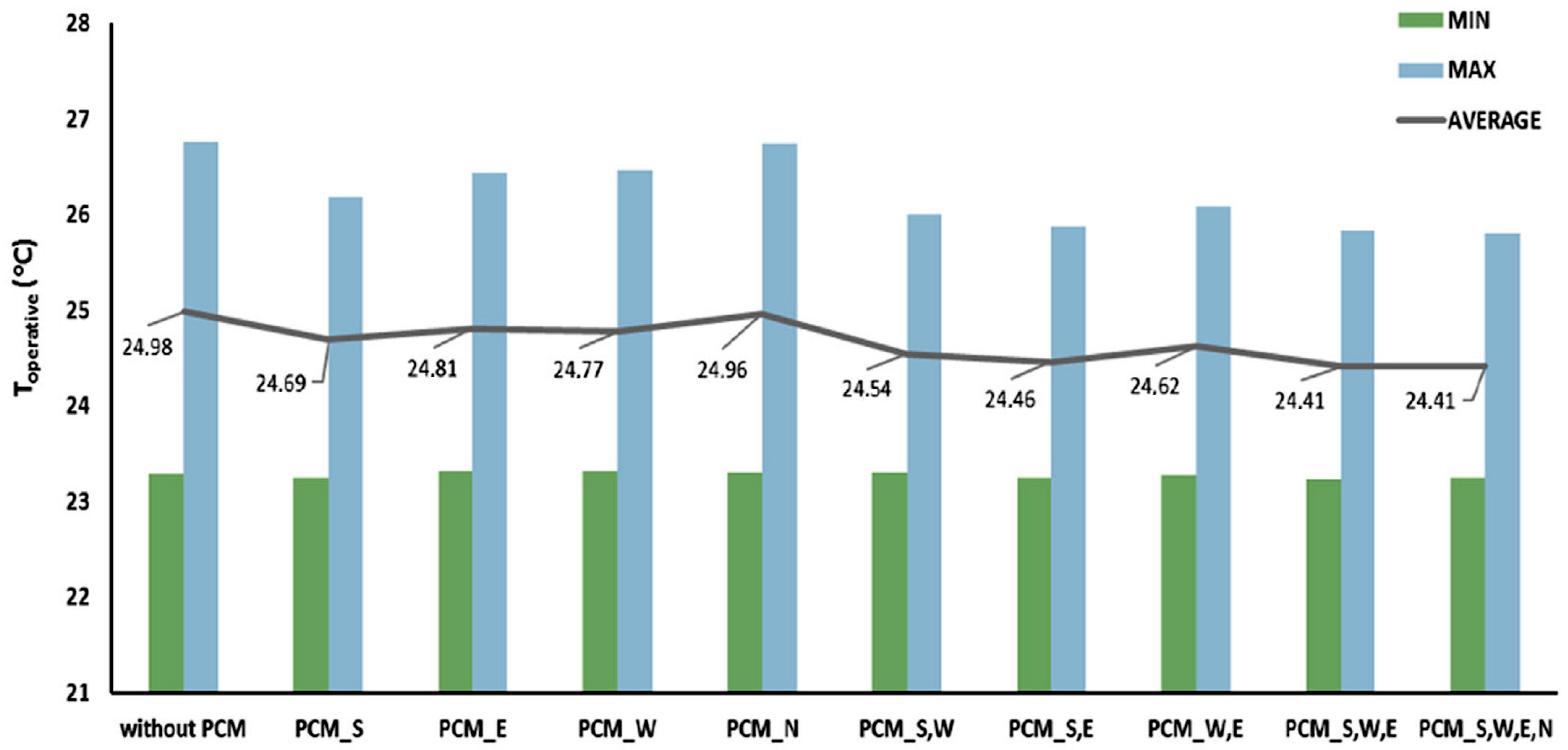

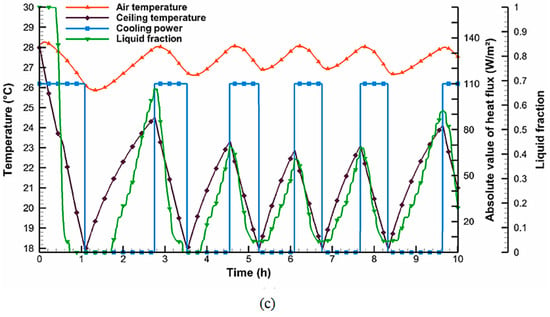

Plytaria et al. [67] incorporated PCMs into the radiant walls of a building’s solar cooling system while examining the energy as well as the cost of a radiant wall solar cooling system. The building has a 100 m2 floor space and is situated in Athens, Greece. The evacuated tube collectors and a single-influence absorption chiller provide cold water for the radiant walls of the building. The PCM was tested on the entire outside walls of the building and under various circumstances, as well as using PCMs in just selected walls. Different collection areas and storage tank levels were studied to find the best design for each circumstance. The key considerations of this study assured that PCMs can afford additional thermal storage capacity, besides mitigating the need for the absorption chiller to operate as frequently. This can improve the overall efficacy by reducing the auxiliary energy consumption. The findings also demonstrated that the optimal PCM layer position is the south wall, reducing the supplementary energy by 30%, increasing the solar coverage by 3.8%, and reducing the system cost by 3%. Figure 12 shows that all scenarios have provided thermal comfort in indoor temperatures. Despite the cost reduction of 3%, the modified integration of PCMs into the radiant walls can have a positive influence on the overall cost.

Figure 12.

Minimum, maximum, and average summer interior temperatures in Athens for all instances. Reprinted with permission from Ref. [67].

Li et al. [68] investigated the thermal effectiveness of the traditional walls of buildings in Isfahan, Iran, using thirteen PCMs. Cement (3 cm), plaster (2 cm), and clay brick (15 cm) foundation walls were used in this investigation. In two instances, PCM location within the wall affected heat transfer: this occurred near the interior and close to the outside. The finite volume technique solved the nonlinear governing equations. The findings revealed that the PCM’s thermal conductivity, melting point, and phase change enthalpy had an important impact on the wall’s performance. The PCM with a greater latent heat of phase change, lower thermal conductivity, and a phase change temperature closer to room temperature can limit the transfer of heat to the internal area more effectively. Thermal conductivity trumps other PCM thermophysical parameters. The inside receives less heat because of the reduced PCM thermal conductivity. Increasing PCM thickness by two times has reduced heat transmission by less than twofold.

Sun et al. [69] devised three PCM wall specimens with variable assemblies to evaluate summer and winter thermal performance. Experimental data were used to validate a mathematical model. The suggested walls’ thermal performance was compared with that of a reference wall by testing, simulating, and analysing their interior surface temperatures, daily heat fluxes, and thermal inertia. During summer, the highest amplitude of internal surface temperature dropped by 21.4%, and during winter, it dropped by 23.9%. Thermal inertia, which measures the wall’s temperature resistance, has been increased by 60.3% from 1.24 to 2.0. PCM spheres in the first, second, and third layers saved 17.7%, 20.2%, and 23.1% of energy annually. PCM spheres were best in the third layer for summer, fourth for winter, and third for yearly use.

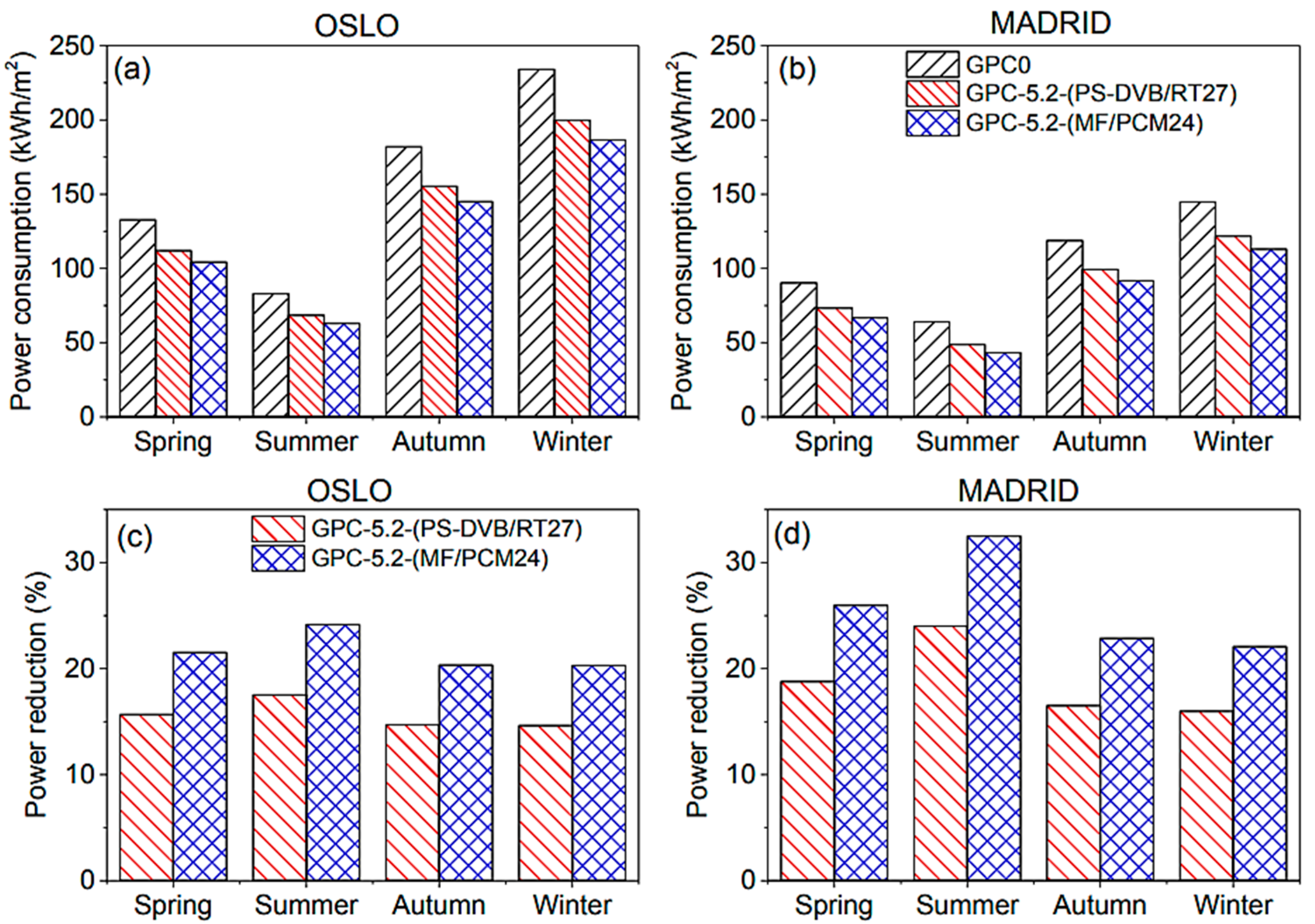

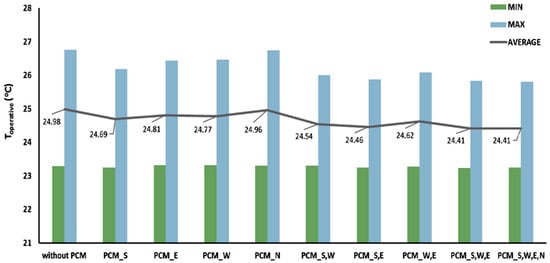

Cao et al. [70] studied the performance of geopolymer concrete (GPC) walls with a micro-encapsulated phase change material (MPCM) in a range of architectural environments. Increasing the amount of MPCM as well as the thickness of the concrete walls improved the building’s energy efficiency. Building energy efficiency has been enhanced by employing a PCM with a melting point that is comparable to typical indoor and outdoor temperatures. A numerical calculation was made to determine the effectiveness of GPC using two MPCMs, namely PS-DVB/RT27, with paraffin Rubitherm® RT27. Additionally, electricity use and savings are greatly impacted by the wall direction and the time of year. The results in Madrid are better for MPCM-containing GPC than those in Oslo (Figure 13). The model is capable of quantifying the MPCM–concrete wall design in various climates.

Figure 13.

(a,b) The average consumption of power and (c,d) the average decrease in power. Reprinted with permission from Ref. [70].

Cao et al. [71] utilized a finite differences numerical model to study the impact of wall design, human comfort temperature, and seasonal changes on the thermal effectiveness of a single-family home with multi-layer walls incorporating phase change materials in Oslo, Norway. Additional insulation and adjustments to the estimated temperature for human comfort were given particular consideration, as they had received little attention previously. Integrating MPCMs into the geopolymer concrete and adding neat PCMs to multi-layer walls improved thermal performance. Placing PCMs near the outdoors also enhanced its effectiveness. Increasing the thickness of the insulating layer and reducing thermal conductivity decreased the energy usage of heating and cooling systems, but reduced MPCM/PCM heat storage capacity.

Kant et al. [72] simulated a typical building wall and reported the PCM melting percentage and heat flow at the internal surface. To minimize heat transmission to the interior environment, the PCM layer needs to be inserted among layers of fiberglass insulation, its melting temperature needs to be close to the indoor air temperature, and its thickness needs to be increased. Real meteorological conditions were incorporated for three days in the numerical simulation using four PCMs (RT-25, RT-26, RT-28, and n-octadecane), which reduced heat transmission to the interior environment by 33.18%, 33.94%, 34.40%, and 37.13%, respectively, for the three days. Up to this point, this study showed the prosperity of utilising PCMs to meaningfully mitigate cooling loads in buildings, which in turn would lead to energy savings and enhance indoor comfort.

Byon and Jeong [73] designed and evaluated an energy-harvesting block, a passive power producer. Energy from waste heat in building exteriors was harvested by the thermoelectric generator-based passive energy-harvesting block, which uses PCMs. PCMs acted as a heat sink for converting sensible heat into latent heat to cool the thermoelectric generator’s cold side. Monthly typical wall-temperature profiles were used for experiments. Phase shift and power production were measured using voltage and temperature data. From these tests, this analysis anticipated the energy-harvesting block’s yearly power output. The findings revealed a 2.1 kWh/m2 annual power generation. The average generated power was 0.03 W, and the voltage was 0.3 V. This showed that three–four energy-harvesting blocks could power contemporary digital circuits like sensors and controllers.

In their 2020 study, Vukadinović et al. [74] examined separate residential structures with a sunspace and a 20 cm thick concrete thermal storage wall, either with or without a PCM. The construction models being examined were P0, P1, P2, and P3. Other models (PCM 3-M182/Q29, 2-M182/Q25, 1-M182/Q21) included a PCM in their 0.2 m thermal storage walls; however, Model P0 did not. P3 had lower energy requirements than P0: 1.90% for Niš, 1.79% for Belgrade, 1.77% for Novi Sad, 0.91% for Kopaonik, and 1.27% for Zlatibor. The study of the PCM placements in model P3’s wall at three different locations—just under the outer wall component, in the central wall, and exactly under the internal wall portion—was conducted since this model had the lowest cooling and heating energy usage. And, at each site, the middle-wall PCM location was highly effective. The energy need for P3 with a middle-wall PCM location was lower than P0 in Niš, Belgrade, Novi Sad, Kopaonik, and Zlatibor (2.37%, 2.41%, 2.14%, and 1.06%, respectively).

Khan et al. [75] examined how a PCM affects building-wall heat transmission and interior thermal comfort. Two building-wall-fragment models were created for experimentation. One model tested several placements of the layer of PCM in the wall of the building to find the best one. To determine how a PCM affects building-wall-fragment heat transmission, a model tested the PCM, air gap, and other standard materials of the building (sand and brickbat) one at a time. According to the results, the rise in temperature within the bath of cold water is reduced compared to the heat sink when the layer of PCM is located nearer to the heat source. With the help of the PCM, the internal bath of cold water of the building wall fragment lowered its temperature rise to its lowest point and even caused it to slope. Thus, it can be said that PCMs can efficiently mitigate the heat transfer rate in a building’s wall and advance indoor thermal comfort. In this regard, the optimum position of the PCM layer is closer to the heat source.

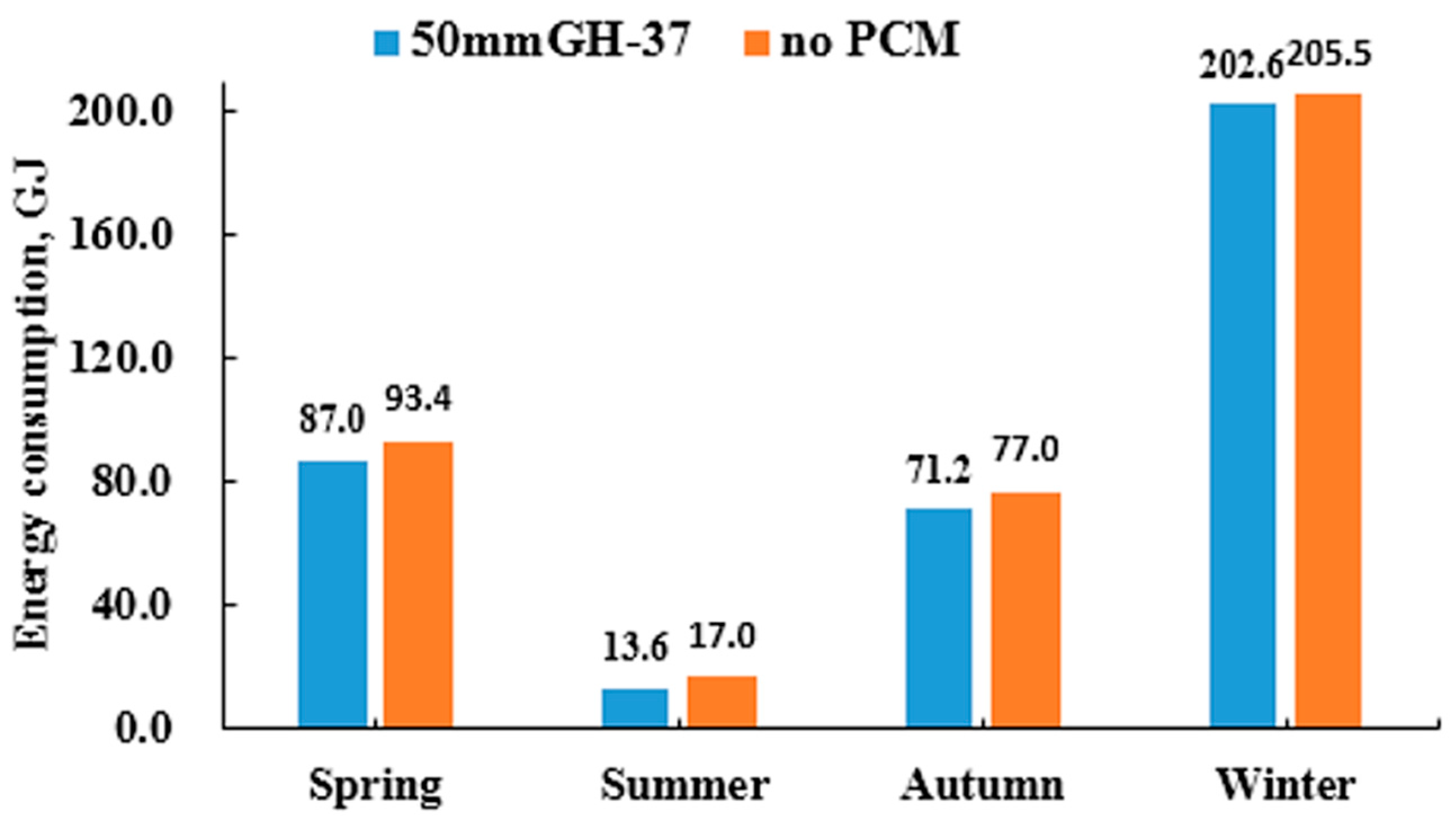

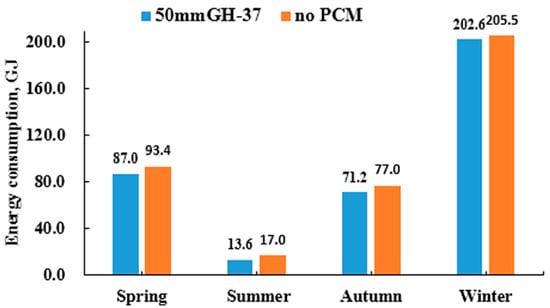

Yu et al. [76] reported choosing PCMs for the inner surface of solar passive curing buildings’ principal sun-facing walls. Experimental data from the Hebei Province curing building were used to calibrate EnergyPlus simulations. The simulations showed that a 50 mm GH-37 PCM panel is adequate for such a structure. The GH-37 PCM phase transition occurs between 37.4 °C and 43.5 °C with a 227.5 kJ/kg latent heat. The PCM raised the nightly and monthly mean temperature of the internal surface of the chief sun-facing wall by 1.3 °C and 2.7 °C, respectively. Spring, autumn, summer, and winter decreased heating demands by 6.4, 5.8, 3.4, and 2.9 GJ, respectively. Steam usage dropped by 4.7% per year. Additionally, the PCM wall usage reduced the heating load. It can also be noted that the heating load of the solar steam-keeping room with a phase change material was 202.6, 71.2, 13.6, and 87 GJ in winter, autumn, summer, and spring times, respectively, as depicted in Figure 14.

Figure 14.

Comparison of heating load. Reprinted with permission from Ref. [76].

Arunkumar et al. [77] examined the heat transmission of PCM-filled and unfilled hollow blocks (walls) in Chennai’s natural climate. Based on the average temperature in the specified region, organic material OM29 PCM was chosen as a thermal barrier for reducing the heat entering the room. The result revealed a 5.7% temperature decrease and a 33% reduction in heat gain over the hollow block dimensions on the interior surface, with identical temperatures at different spots. Furthermore, the temperature at different points on the surface of the PCM-filled wall was more identical compared to the wall without PCMs. The selected PCM reduced the transmission of heat from the exterior face to the interior face in hot climates, but in moderate climates, solar intensity varies daily, affecting the transmission loads of cooling and the employability of PCMs. The PCM was effective from April to July, after numerical calculations and experimental validation.

The ideal parameters for reducing cooling season gains and heating season losses were determined by a large-scale computational analysis on PCM integration into building walls, which was conducted by Kishore et al. [78]. The authors used five cities in the U.S. in various climatic zones in accordance with the International Energy Conservation Code to determine the optimum temperature of transition, the location of the PCM in the wall, and the energy-saving potential of PCM-integrated building walls. The results revealed that PCM in building walls does not always enhance energy usage; improper applications might increase energy use. Optimized PCMs in the walls of U.S. buildings can reduce yearly heat gains by 3.5–47.2% and heat losses by 2.8–8.3%, depending on the climate.

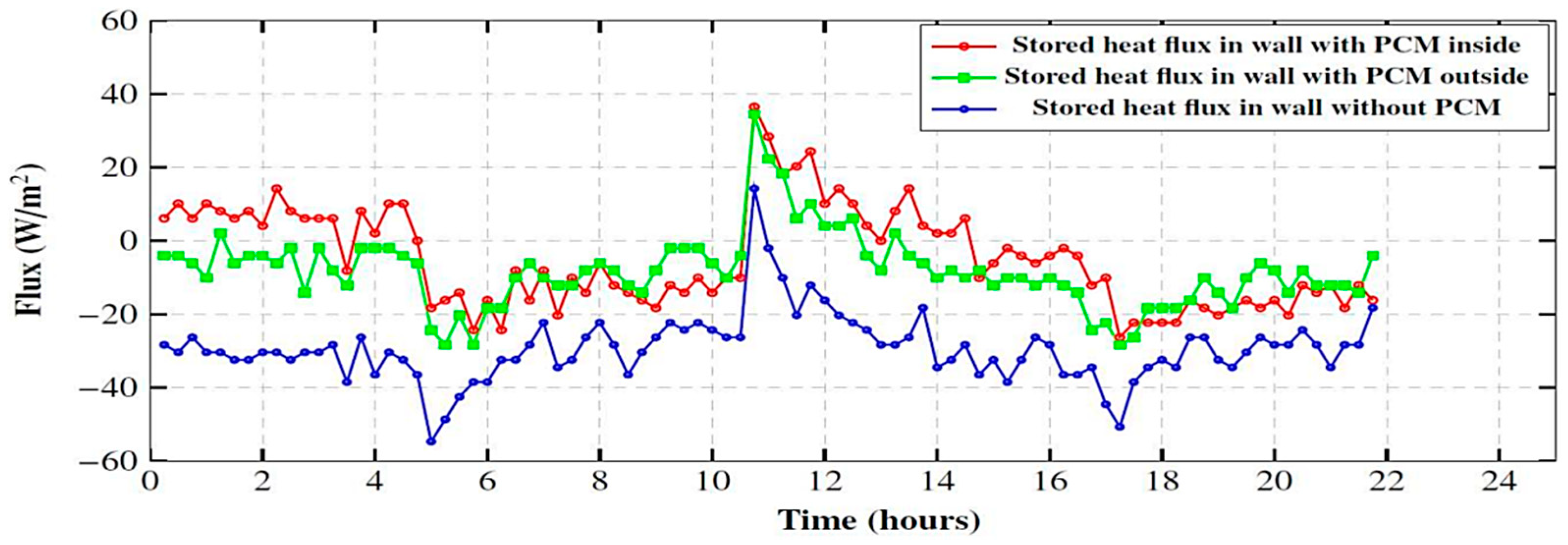

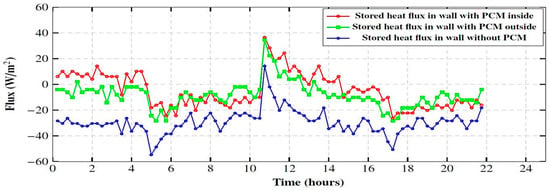

A PCM was applied to a clay–straw wall in Morocco’s Drâa-Tafilalet zone by Zaid et al. [79] to reduce the energy usage of the building. The decrease in the surface temperature of the wall as well as the flow of surface heat was also examined using PCM placement. Heat movement and storage were computed by measuring the temperatures of the internal and external layers of the wall. The findings indicated that adding PCMs to the clay–straw walls could lower surface temperatures by up to 3 °C. Placing PCMs near the heat source reduced the surface temperature by 1 °C, compared to placing it on the outer wall layer. Additionally, the PCM-integrated wall possessed a 31.95% lower maximum heat flow than a clay–straw wall with no PCM. Furthermore, the clay–straw wall with PCMs on the external layer had a 26.5% lower maximum heat flow, and the PCM-integrated wall had conserved an average of 14.17 W/m2 of intake heat flux. Figure 15 shows that the wall stores positive heat flux and releases negative heat flux.

Figure 15.

Wall heat storage. Reprinted with permission from Ref. [79].

Pirasaci [80] studied the incorporation of PCM layers in built-up buildings while highlighting their thermal effectiveness in winter and their energy savings potential. The research verified a numerical model of building attributes, resident behaviour, and outside variables using experimental data from the literature. Different wall structures under shifting weather conditions were simulated numerically. Although PCM layer integration reduced winter heating energy needs, it is not acceptable, as PCM usage is unrealistic without a phase shift.

Ouhsaine et al. [81] suggested a state-space model for a solar-effective wall-based phase change material. Its simplicity in providing internal node and input/output settings maintains its benefit. Cheap computation is an advantage over a hefty numerical procedure. The suggested numerical model was used for a multi-layer wall with phase change material wallboards (PCMW) between the interior and the outside surroundings. The state-space model can predict the system’s thermal behaviour and PCM embedding in the wall’s interior face. It greatly stabilizes interior temperatures and ensures thermal comfort.

By using PCMs, micro-channel heat pipes (MHPs), and radiative cooling, Shen et al. [82] created a unique wall. Primary experiments focused on the radiative plate emissivity as well as the MHP homogenous temperature. Next, the RC-PCM wall mathematical model was created. The external speed of wind, the thickness of the PCM, and the radiative plate emissivity were then numerically calculated. The RC-PCM’s inner surface temperature was inversely connected with wind speed and favourably correlated with emissivity. Also, the cooling loads of the RC-PCM wall were 25% less than the similar brick-wall thickness, and 42% in the optimal conditions, indicating excellent PCM use.

A model of heat transfer employing LBW-PCM was created and confirmed by Liu et al. [83]. The PCM parameter’s effect on the thermal performance of LBM was investigated and evaluated by numerical simulations. These characteristics include specific heat, density, thermal conductivity, latent heat, thickness, and the position temperature of transition. First, PCMs can greatly enhance LBW thermal performance. Second, there is an optimal value for each PCM parameter. Third, at an appropriate phase-transition temperature, the PCM fixed in the wall centre is better than the PCM installed on the inside or outside. Fourth, when compared with the reference wall (without a PCM), there is a 6.86 h delay, a 90.45% drop in attenuation rate, and a 45% drop in peak and average heat flux.

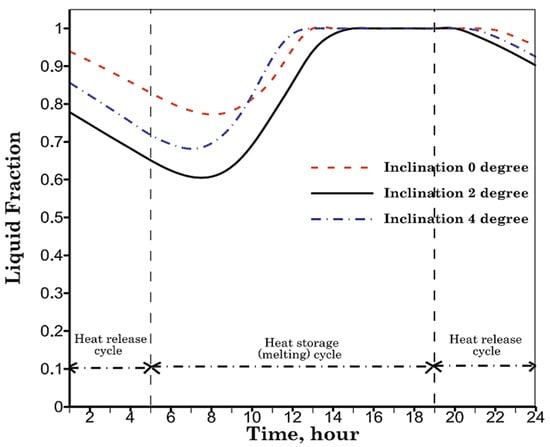

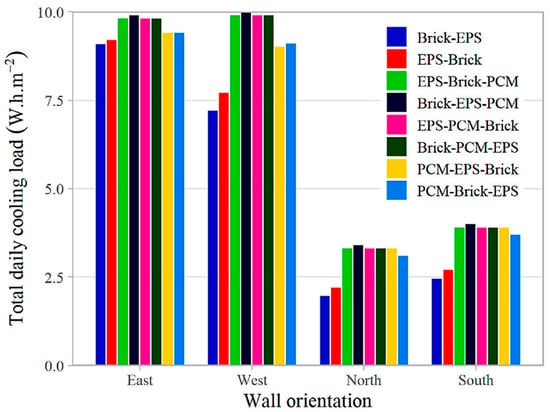

In order to identify its features and provide straightforward design advice, Rai [84] investigated the energy efficacy of brick masonry walls combined with PCMs for controlling the cooling load in residential constructions beneath periodic steady-state circumstances. The study indicated that the wall layouts with equivalent thermal resistances under identical boundary circumstances had equal daily gains of heat as well as cooling loads independent of the latent heat storage of the PCM. Even with night-time ventilation, the cooling load of a well-insulated wall has not been reduced by adding a PCM layer to it. Additionally, the PCM, which possesses a melting point near the interior set-point and is insulated to a sufficient degree to shield it from outside conditions, should be mounted upon the wall inside. EPS–brick walls showed somewhat greater cooling loads (0.1–0.5 Wh·m−2) than brick–EPS walls in all orientations. Figure 16 shows that PCM-enhanced walls have cooling loads 2–53% greater than EPS–brick walls, depending upon the design of the wall and the location.

Figure 16.

A comparison between the requirements of cooling loads for the walls with insulation alone and those with insulation plus PCMs for various locations with night-time ventilation. Reprinted with permission from Ref. [84].

An innovative design of a wall, featuring a layer of PCM sandwiched between two layers of DIMS (dynamic insulation material and system), was presented by Kishore et al. [85]. The authors found that the PCM-DIMS-integrated wall retains more energy than the DIMS-only or the PCM-only integrated wall in various climates and wall locations. Depending on the conditions, the PCM-DIMS integrated wall might reduce the yearly heat input by (15–72%) and heat loss by (7–38%). The research concluded that buildings should utilize thermal energy storage systems and scalable dynamic insulations.

Using ANSYS version 14.0, Govindasamy and Govindasamy & Panwar [86] examined how the thickness of bio-phase change materials (b-PCM) affects building wall thermal performance and comfort. Two models were simulated: a reference room without b-PCM and one with varying thickness. The lower thermal conductivity, as well as the greater latent heat of phase transition, help b-PCMs reduce the heat transmission to the room’s internal side. Thermal conductivity also surpasses other PCM thermophysical parameters. The PCM’s reduced thermal conductivity decreases the room’s heat gain.

Researchers Hattan et al. [87] investigated how well a shape-stabilized PCM (SSPCM) performed mechanically and thermally as part of Iran’s conventional wall system for thermal engineering structural repairs (TESs). PEG 600 was vacuum-impregnated into the porous silica fume to stabilize its shape. Cement mortars for plastering masonry brick walls were prepared using the SSPCM. The mechanical testing of the SSPCM-incorporated mortars showed positive outcomes for masonry wall-finishing plaster. Additionally, a unique experimental setup was utilised to examine SSPCM-incorporated mortar-plastered wall specimens in ambient temperatures of two cities. It has been ascertained that the inclusion of SSPCM to cement mortar can decrease the compressive strength, but the mortars still met the compulsory strength for plastering applications. The SSPCM-plastered walls presented noteworthy decreases in peak temperature and indoor temperature fluctuations compared to the control walls.

Zaid et al. [88] utilized a PCM in a clay–straw wall to minimize building energy consumption in the Saharan region. The aim was to maximize the storage capacity of clay–straw walls. The authors employed computational methods to investigate the thermal efficiency of clay–straw walls with PCM integration in Errachidia, Morocco. Winter thermal performance analysis revealed that clay–straw walls incorporating PCM24 offer an excellent solution for this location. In clay–straw walls, PCM24 increased the density of internal heat flux by 33.33%, while decreasing the density of heat flux in cement walls by 36.36%. Furthermore, compared to cement construction, the clay–straw building with PCM24 reduced the density of internal heat flux by 72.72%. PCM32 reduced the peak heat flow in Errachidia city during the summer. Additionally, PCM32 decreased the density of interior heat flux in clay–straw walls by 13.04% and in cement walls by 23.68%.

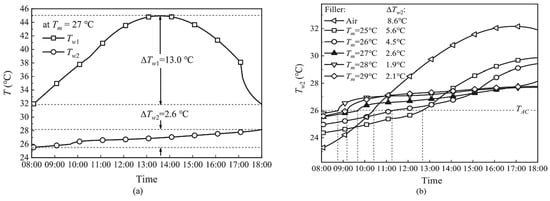

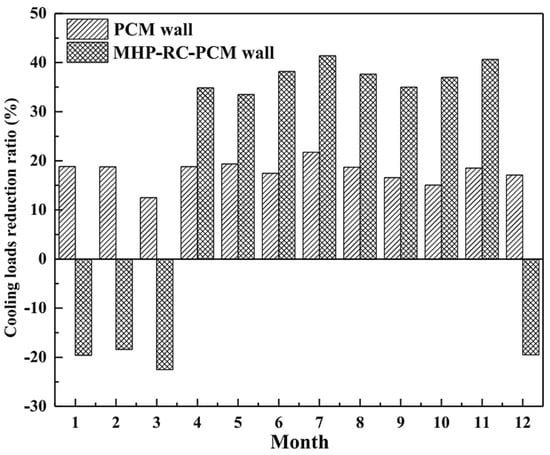

Tian et al. [89] employed a novel experimental setup to compare PCM-integrated walls with conventional walls in a two-sided virtual environment simultaneously. PCM layers were placed externally, in the middle (sandwiched), and within the brick walls. Meanwhile, the other side of the wall was maintained at a constant temperature to replicate indoor air-conditioned conditions, while the opposite side fluctuated to simulate outdoor summer temperatures. Walls with PCM layers on the exterior exhibited the best insulation properties. Furthermore, their internal surface was 0.2 °C cooler, had a 19.6% lower surface heat flow density, showed a 19.94% less effective average heat transfer, and exhibited a 1.33 h longer temperature delay time compared to standard walls. The decreasing ratio of the yearly load of cooling/heating was 18.2% and 0.4% greater than the PCM. Figure 17 shows that July’s high ambient air temperature improved the radiative plate exterior radiative cooling influence.

Figure 17.

The yearly reduction ratio of the load of the cooling/heating of the MHP-RC-PCM wall. Reprinted with permission from Ref. [90].

Yu et al. [90] conducted preliminary tests to investigate radiative plate emissivity and PCM (paraffin, RT28HC) characteristics. Subsequently, thermal behaviour was simulated using numerical models of MHP-RC-PCM walls. While the latent heat of the PCM had a minor effect on the cooling load reduction ratio, the liquid percentage and the internal surface temperature of the MHP-RC-PCM wall were significantly influenced by the phase conversion temperature of the PCM. At 31 °C, the reduction ratio of the cooling load was 4% higher than at 26 °C. Moreover, the MHP-RC-PCM wall saved 18.2% more energy throughout the year compared to a brick wall of similar thickness and 0.4% more than the PCM wall in Guangzhou city, China. The reduction ratio of the yearly cooling/heating load is 18.2% greater than that of the PCM. Figure 17 illustrates how the high ambient air temperature in July enhanced the radiative cooling influence of the exterior radiative plate.

Liu et al. [91] investigated the thermal environment of a small lightweight building in various orientations. A characteristic 2D model of heat transfer was used to explore the principles of influence and the appropriateness of PCM factors on LBW thermal effectiveness in different directions. The findings revealed that walls facing different orientations had varying impacts on PCM application and suitable values. The east- and south-facing walls should have the PCM position (phase conversion temperature set to 20–30 °C) in the centre, whereas the west- and north-facing walls should have it set outside (24–34 °C) or inside (18–28 °C). With maximum and mean heat flow decreased by 62.8–66.4% and 28.2–29.5%, respectively, and the delay time increased by 5–5.34 h compared to the reference wall, the east- and west-facing walls achieved the highest thermal performance gain at optimum PCM settings.