Abstract

Understanding the modification mechanism of C9 petroleum resin (C9PR) on styrene–butadiene–styrene (SBS) polymer modified asphalt properties is of significant importance. In this paper, dynamic shear rheometer (DSR), storage stability, fluorescence morphology (FM), scanning electron microscope (SEM), Fourier transform-infrared (FTIR) spectrometer, and molecular dynamic (MD) simulation were adopted to evaluate the rheological, chemical, and microstructure molecular motion state of C9PR and SBS composite modified asphalt at different aging states. The DSR storage results indicate that the addition of C9PR could improve the high-temperature property, storage stability, and temperature susceptibility. FM and SEM results indicate that the network microstructure was enhanced and the roughness between polymer resins and virgin asphalt was improved at the microscopic scale. The MD results indicate that the heterogeneity between C9PR and SBS modified asphalt was demonstrated, and the bonding energies were enhanced with the addition of C9PR. Moreover, the FTIR results indicate that new function groups were generated in addition to C9PR. In general, the addition of C9PR is a good approach to promote high-quality polymer modified asphalt (PMA) for pavement engineering.

1. Introduction

As a byproduct from petrochemical processes, C9 petroleum resin (C9PR) has garnered extensive attention for its utilization within the realm of material science, attributable to its cost efficiency and superior chemical attributes [1,2,3]. Notably, within the domain of polymer modified asphalt (PMA) research and applications, it has been authenticated that C9PR markedly modulates the compositional distribution and microstructural state of asphalt [4,5]. Such modulation not only augments asphalt’s performance by enhancing its abrasion resistance and anti-aging capabilities, but also exhibits significant potential in cost reduction for production [6,7]. Consequently, the exploration of C9PR not only bears significant implications for the enhancement of current asphalt material performance, but also paves new pathways for the development of novel high-performance materials for road construction endeavors.

C9PR, derived from the polymerization of light aromatic hydrocarbons during petroleum cracking, exhibits excellent chemical stability, thermoplastic adhesion, and compatibility as a thermoplastic resin [8]. These characteristics enable C9PR to play a crucial role in the production of adhesives, inks, coatings, and rubber products in multiple industrial fields [9]. Specifically, the chemical composition of C9PR enables it to play a unique role in modified asphalt systems. Due to its ability to interact with various chemical components in asphalt through the presence of polycyclic aromatic hydrocarbons, C9PR can effectively increase the viscosity and elastic modulus of asphalt, while reducing its temperature sensitivity [10,11,12]. This characteristic makes C9PR an ideal modifier for improving the road performance of styrene–butadiene–styrene (SBS) modified asphalt. SBS is a commonly used high-performance polymer modifier that can significantly improve the elasticity and durability of asphalt [13,14]. However, the cost of SBS modified asphalt is relatively high, and there is still room for improvement in certain performance aspects. The introduction of C9PR provides a new path for optimizing SBS modified asphalt [15]. The research shows that C9PR can improve the anti-aging performance of modified asphalt, reduce the damage of ultraviolet ray and oxidation to asphalt, and enhance its performance stability under extreme weather conditions [16,17]. In addition, the low cost of C9PR also helps to reduce the production cost of overall modified asphalt materials and improve their market competitiveness [18]. In summary, C9PR, with its unique chemical and physical properties, not only has theoretical significance in improving and optimizing the road performance of SBS modified asphalt, but also provides strong support for practical applications, significantly promoting the development of materials science and road engineering.

In recent years, C9PR has been extensively studied as an effective modifier to optimize the performance of polymer modified asphalt (PMA) [19]. The introduction of C9PR has been found to significantly enhance the overall performance of modified asphalt, including improved high-temperature rheological properties, enhanced low-temperature cracking resistance, and increased resistance to water damage [20]. These performance enhancements are primarily attributed to the good compatibility and synergistic effects between C9PR and the asphalt matrix, as well as SBS and other polymer modifiers, thus optimizing the microstructure and macro performance of the modified asphalt [21]. Previous academic research has shown that C9PR can effectively adjust the polymer network structure in SBS modified asphalt, increasing the uniform distribution of the polymer phase [22]. This structural improvement contributes to an increase in the viscoelasticity of SBS modified asphalt, thereby providing better deformation resistance at high temperatures, while maintaining sufficient flexibility at low temperatures to reduce the occurrence of cracks [23,24,25]. Furthermore, the addition of C9PR has been found to improve the aging resistance of SBS asphalt mixtures, due to the specific chemical composition of C9PR that can slow down the oxidation reaction rate in asphalt, thus prolonging its service life [26,27,28]. Overall, C9PR has shown a wide range of application potential in enhancing the performance of SBS modified asphalt.

It is noteworthy that previous scholars have conducted a series of experiments and analyses, such as dynamic shear rheological tests, infrared spectroscopy analysis, and microscopic structure observations, to deeply explore the specific mechanism by which C9PR improves PMA performance [29,30,31]. These studies reveal how C9PR affects the chemical and physical structure of modified asphalt, further proving its potential as an efficient modifier [32]. Therefore, based on the results of these scientific studies, the application of C9PR in improving PMA performance has shown great application prospects and practical value [33,34]. With the rapid development of polymer modified asphalt (PMA) technology, research methods are also constantly advancing [35]. Among these, molecular dynamics (MD) simulation has become an important tool, capable of simulating the interaction between C9PR and the asphalt matrix at the molecular level, providing a new perspective for understanding and predicting material performance. MD simulation, by calculating the forces and movements between molecules, can reveal the dispersion state of the modifier in the asphalt, compatibility, and the mechanism of its impact on asphalt performance, details that are difficult to directly observe with traditional experimental methods [36]. Moreover, by combining experimental data with MD simulation results, researchers can optimize the formula of modified asphalt and predict material performance under different conditions. This approach not only improves research efficiency and reduces experimental costs, but also provides strong theoretical support for the design of high-performance modified asphalt materials.

In this study, five modified bitumen with different contents of C9PR and SBS were prepared. According to the previous studies, the optimal dosage of SBS in composite modified bitumen was 5 wt%, and C9PR at dosage of 3 wt%, 6 wt%, 9 wt%, and 12 wt% was selected. The rheological properties were tested with a dynamic shear rheometer (DSR) in temperature sweep, the storage stability was characterized through difference in softening point, and the functional group changes were represented with a Fourier transform-infrared (FTIR) spectrometer. The microscopic phase structure and interface morphology were observed with a fluorescence microscope (FM) and scanning electron microscope (SEM), respectively. The diffusion and aggregation behaviors of SBS and four components were carried out by MD simulation in terms of mean square displacement (MSD), radial distribution function (RDF), and relative concentration distribution (RCD).

2. Materials and Methods

2.1. Raw Materials

The 70# bitumen utilized in this study was provided by Sinopec Maoming Petrochemical Company (Maoming, China), and its physical properties are listed in Table 1. The SBS modifier for the liner was purchased from Sinopec Paling Petrochemical Co., Ltd. (Yueyang, China), with a butadiene/styrene ratio of 30/70. The C9PR was produced by Zibo Luhua Hongjin New Material Group Co., Ltd. (Zibo, China). The specific model used for production was PRR1-120, and its technical indices are shown in Table 2.

Table 1.

Physical properties of bitumen.

Table 2.

Technical indices of C9PR.

2.2. Preparation of C9PR/SBS Modified Bitumen

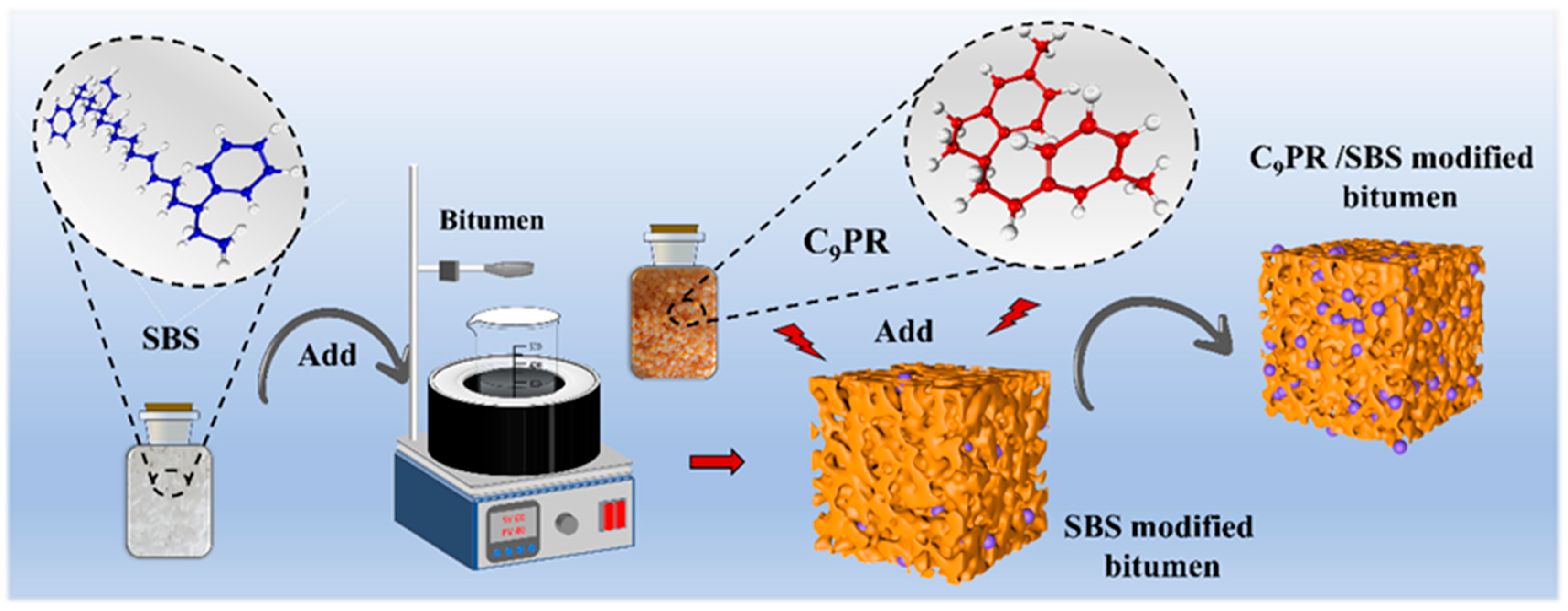

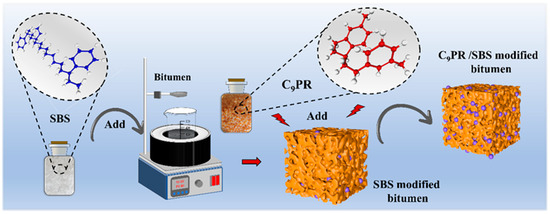

To evaluate the effect of C9PR on the rheological, microstructure, and chemical characteristics of SBS modified bitumen, SBS modified bitumen and C9PR/SBS modified bitumen were prepared in this study. Firstly, virgin bitumen was put into the oven (160 °C, 1.5 h) until it was molten. And the virgin bitumen was poured into the beaker and put in the oil bath. Subsequently, 5 wt% SBS was added into the bitumen and sheared (5000 r/min, 45 min). After that, C9PR (0 wt%, 3 wt%, 6 wt%, 9 wt% and 12 wt%) was mixed into SBS modified bitumen and sheared (5000 r/min, 45 min). Finally, C9PR/SBS modified bitumen was put the oven to swell (160 °C, 2 h). Meanwhile, the preparation procedures were replicated for SBS modified bitumen, as depicted in Figure 1.

Figure 1.

Preparation procedure of C9PR/SBS modified bitumen samples.

2.3. Test Methods

2.3.1. Dynamic Shear Rheometer (DSR)

To assess the rheological properties of the modified bitumen, temperature sweep tests were conducted using the MCR 702 DSR from Anton Paar Inc. (Graz, Austria). The complex modulus (G*) and phase angles (δ) were measured in accordance with ASTM D7175 [37], and the rutting resistance was calculating the rutting factor (G*/sinδ). The range of temperature sweep test was set from 46 °C to 88 °C with an increase of 6 °C, and the test frequency was set to 10 rad/s. The diameter of the rotating shaft plate was set to 25 mm, and the spacing between the rotating shaft plate and the bottom plate was set to 1 mm.

2.3.2. Scanning Electron Microscope (SEM)

The interface morphology of SBS modified asphalt and C9PR/SBS modified asphalt was studied using a scanning electron microscope (JSM 5800LV) produced by Japan Electron Optics Laboratory Co., Ltd. (Akishima, Japan). During the SEM testing, the samples were gold-coated for 100 s in a vacuum using the JFC-1600 precision coating machine (JEOL, Akishima, Japan) to minimize charging effects. The operating temperature of the SEM equipment is typically around 20 °C to ensure the normal operation of the device and to avoid image distortion caused by temperature fluctuations.

2.3.3. Fluorescence Microscope Test

The microstructure and swelling of the polymers and bitumen were determined using FM, MATLAB R2018a, and Image J software. The modified bitumen samples were heated in an oven to a fluid state and then dropped onto slides using a glass rod. Subsequently, a coverslip was pressed onto the slide to form a film of bitumen, ensuring that it can be observed under a fluorescence microscope. Finally, the fluorescence images were binarized using MATLAB software, and the particle sizes of polymer were measured using Image J software to quantitatively analyze the effect of C9PR on SBS modified asphalt.

2.3.4. Storage Stability

The storage stability is used to assess the stability and quality changes in bitumen during storage process. In this study, the compatibility of SBS modifier and bitumen was determined by the softening point test. After the modified bitumen was heated to a flow state, the glass segregation tubes with a diameter of about 25 mm and a length of about 140 mm were vertically placed on a support in an oven at a temperature of 163 °C for 48 h. Subsequently, the softening points measured at the top and bottom one-third of the sample were used to evaluate the storage stability of the modified bitumen. According to the literature, if the difference in softening points between the two parts is less than 3 °C, the sample is considered to have good high-temperature storage stability [38].

2.3.5. Fourier Transform Infrared Spectroscopy (FTIR)

FTIR was adopted to investigate the change in function group of SBS modified with (0 wt%, 3 wt%, 6 wt%, 9 wt% and 12 wt%) C9PR contents. And the instrument used in this study was the Nicolet iS10 Fourier transform infrared spectrometer. The FTIR spectra were recorded in Attenuated Total Reflection (ATR) mode with the wavelength range from 4000 cm−1~500 cm−1 at a resolution of 4 cm−1 and 64 scans, and the measurements were usually conducted at room temperature.

2.4. Simulation Methods

2.4.1. Model Construction

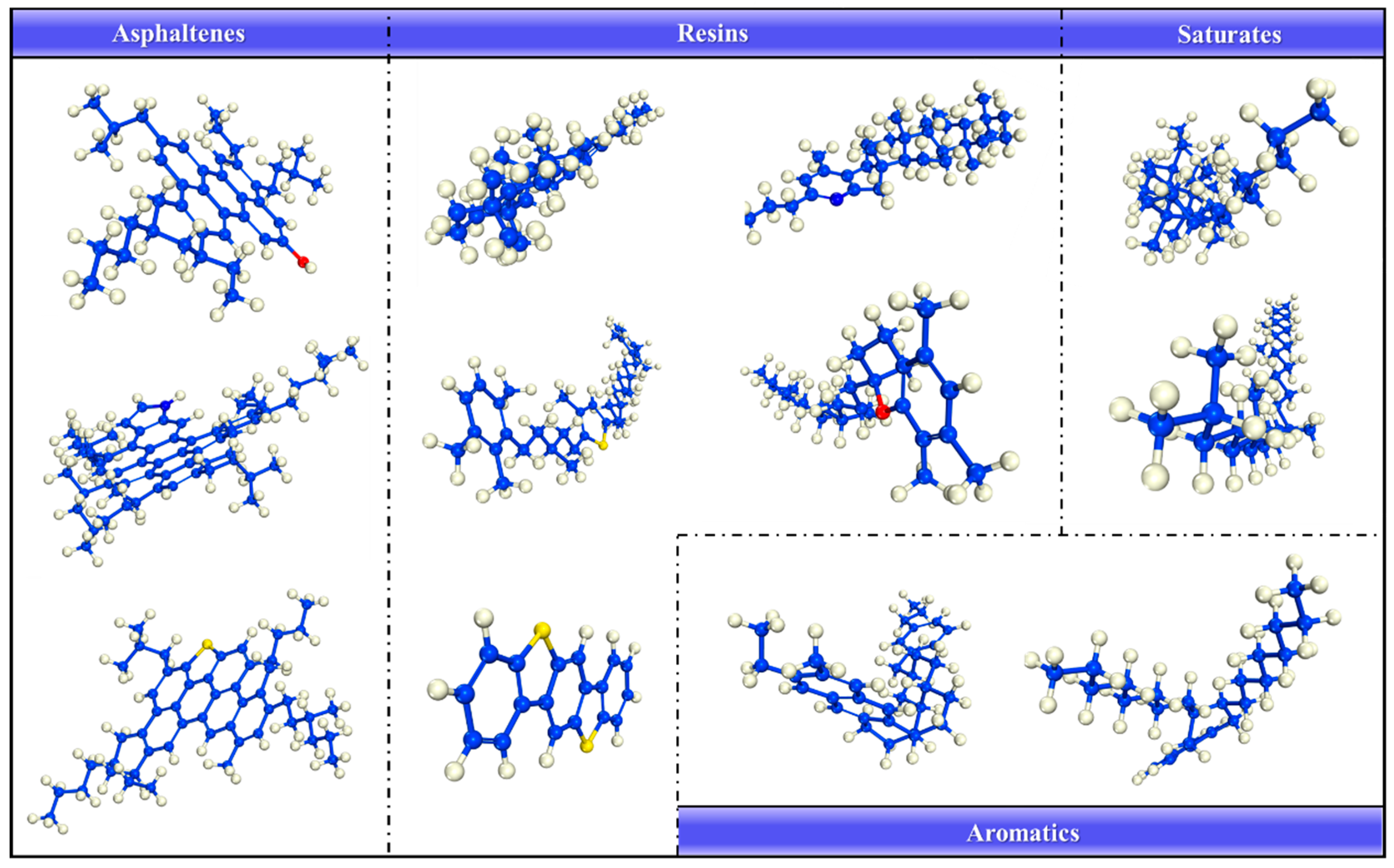

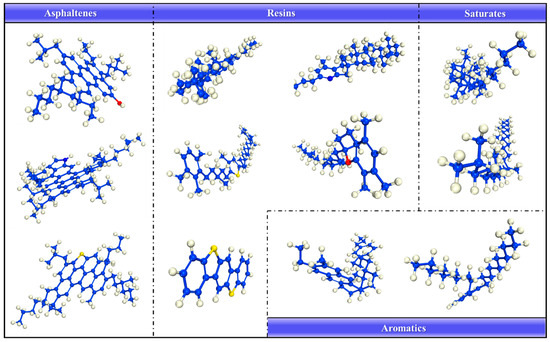

Bitumen is a complex mixture composed of various organic compounds, including hydrocarbons, oxides, and nitrides. In addition, trace metal elements exist in the form of inorganic salts in bitumen, such as vanadium, nickel, iron, sodium, calcium, and copper [39]. Currently, Greenfield proposed the AAA-1 12-component bitumen model, which is closest to real bitumen and widely used for molecular dynamics simulations. It mainly includes asphaltenes (Phenol, Pyrrole, Thiophene), resins (Quinolinohopane, Thioisorenieratane, Benzobisbenzothiophene, Pyridinohopane, Trimethybenzene), saturates (Trimethybenzene, Hopane), and aromatics (PHPN, DOCHN) [40]. The molecular model is shown in Figure 2.

Figure 2.

Twelve-component models of virgin bitumen.

Molecular dynamic (MD) is a computational modeling technique that reveals the macroscopic properties and microscopic mechanisms of materials by simulating the motion trajectories and interaction forces of molecules [41]. It is based on the principles of Newtonian mechanics and primarily calculates various characteristics of molecules from a molecular perspective [42]. As an extension of the COMPASS force field, COMPASS II offers higher precision, better parameter methods, and higher computational efficiency, making it particularly suitable for studying the properties and behaviors of organic compounds, inorganic small molecules, polymers, and metallic materials [43]. Therefore, the dynamics simulation in this study employed the COMPASS II force field.

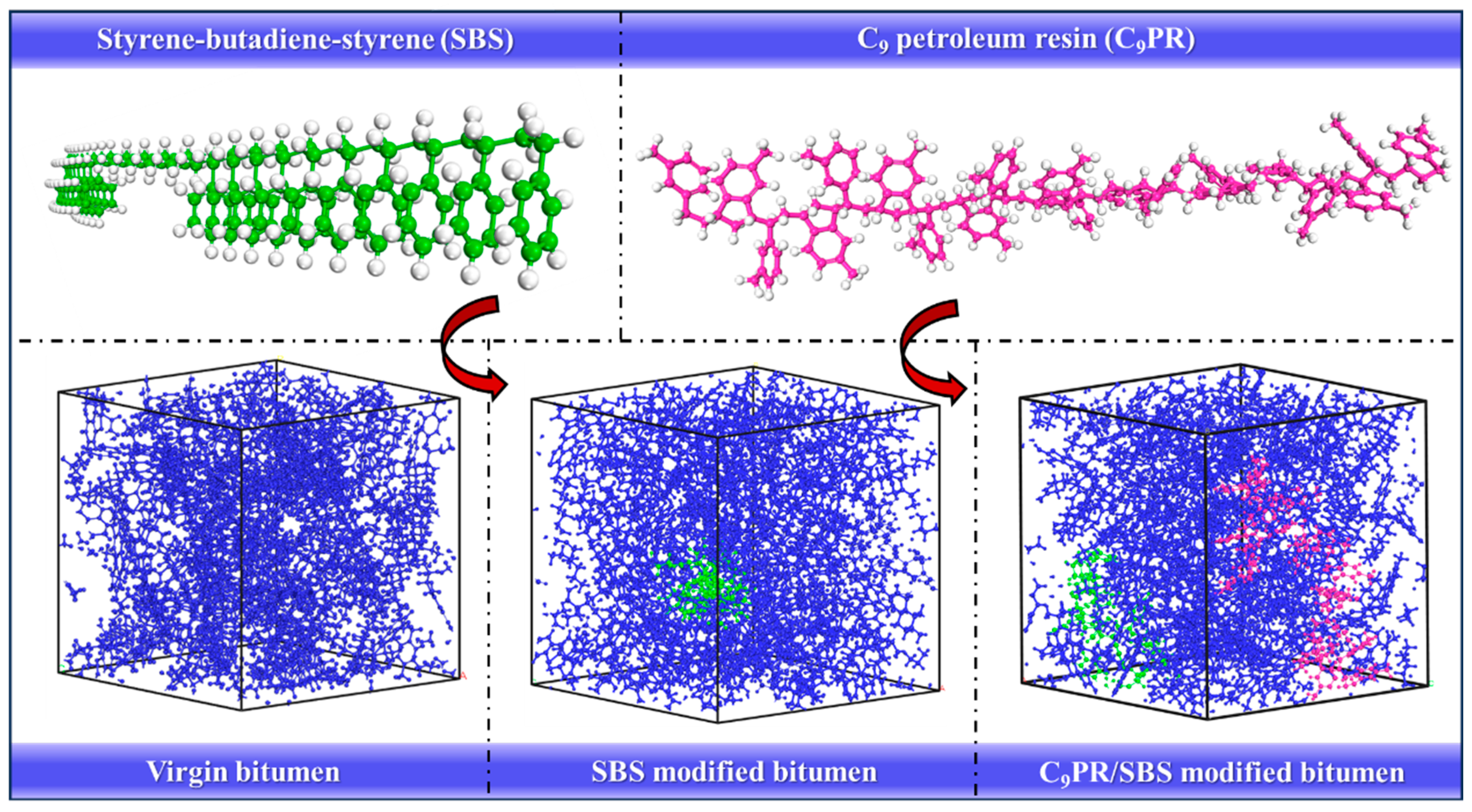

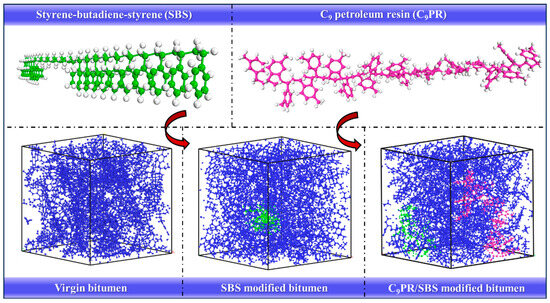

The model of virgin bitumen in this study was constructed using the Amorphous Cell module in Materials Studio 2018 software. The specific simulation process is as follows: (1) Twelve molecules of bitumen were added to the cubic in a certain proportion, and the construction of the initial structure was completed with a density of 0.1 g/cm3. (2) The geometric optimization in the Forcite module was performed to eliminate unfavorable contacts of molecules and achieve energy minimization of the initial structure. The iteration was performed for 100,000 times, and the COMPASS II force field was used. (3) Annealing of the bitumen model was carried out for 5 cycles in the range of 298 K~498 K using the NVE system to eliminate the local high-energy spots in the model. (4) Dynamic simulations were performed at 500 ps under the NPT system, which resulted in full relaxation of the model to reach equilibrium, and the density gradually approached the real value at 1 atm. The models of SBS modified bitumen and C9PR/SBS modified bitumen were duplicated for the construction of virgin bitumen. The parameters are listed in Table 3 and the models are shown in Figure 3.

Table 3.

Molecular parameters of the model.

Figure 3.

Construction of amorphous cell models for bitumen.

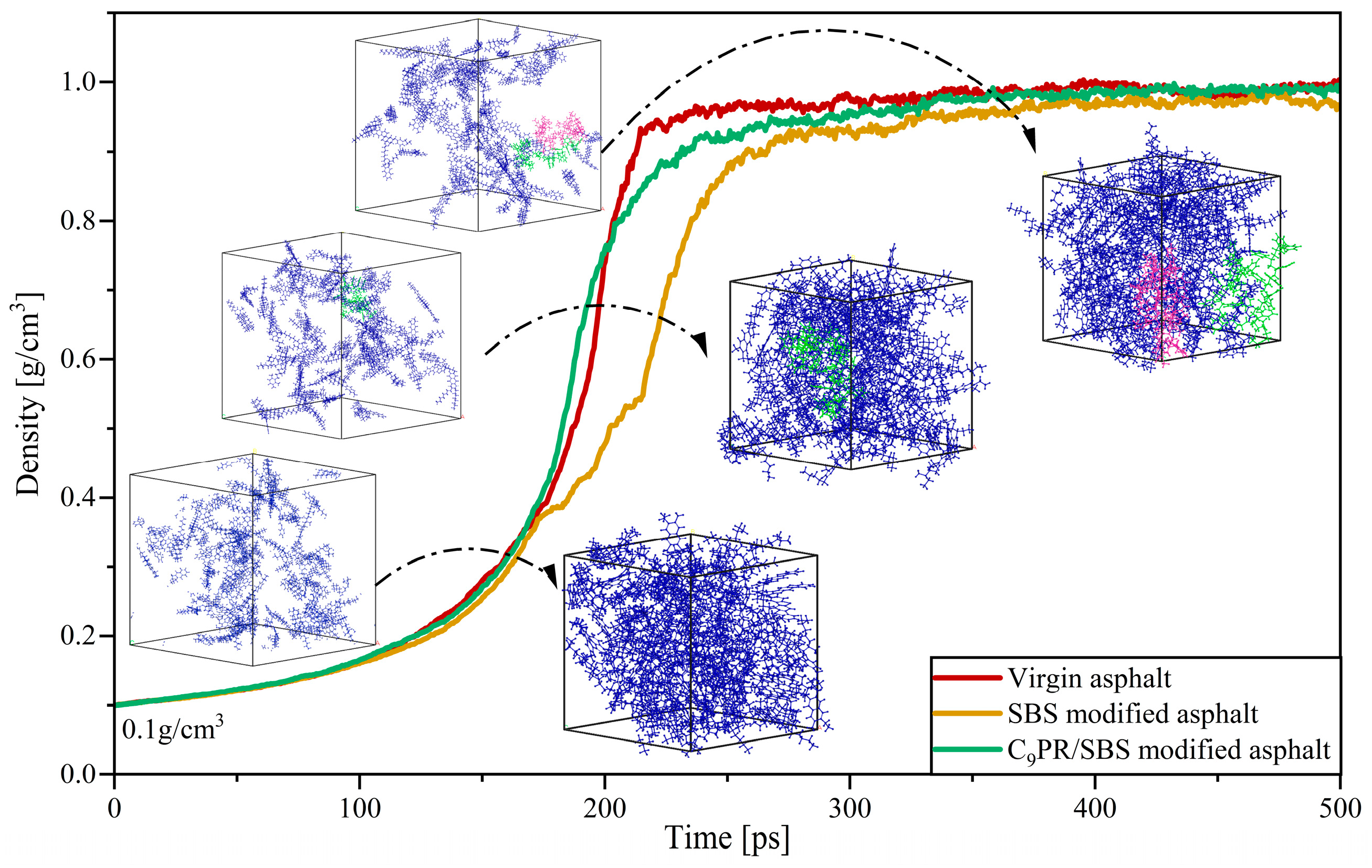

2.4.2. Model Validation

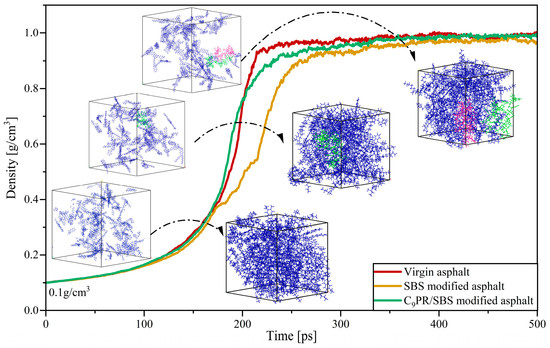

Density. In this study, density was utilized to validate the models for virgin bitumen, SBS modified asphalt, and C9PR/SBS modified asphalt. The simulation results were used to generate density curves under various conditions, as illustrated in Figure 4. The figure indicates that the initial density of virgin bitumen is 0.1 g/cm³, which gradually approaches equilibrium starting from 200 ps, ultimately reaching 0.987 g/cm³. This value is close to the actual density range of virgin bitumen, from 1.01 to 1.04 g/cm³ [44], thus confirming the model’s validity. Simulations for SBS modified asphalt showed that its initial density also starts at 0.1 g/cm³ and stabilizes at 1.005 g/cm³ after approximately 250 ps. For C9PR /SBS modified asphalt, the initial density begins at 0.1 g/cm³ and reaches equilibrium at 1.002 g/cm³ after 300 ps. These results demonstrate the accuracy and practicality of the models in depicting the actual density characteristics of modified asphalts, further supporting the reliability of the simulation methods and models used in this research.

Figure 4.

Density curve of bitumen models.

3. Results and Discussion

3.1. Evaluation of Macroscopic Performance of C9PR in SBS Modified Bitumen

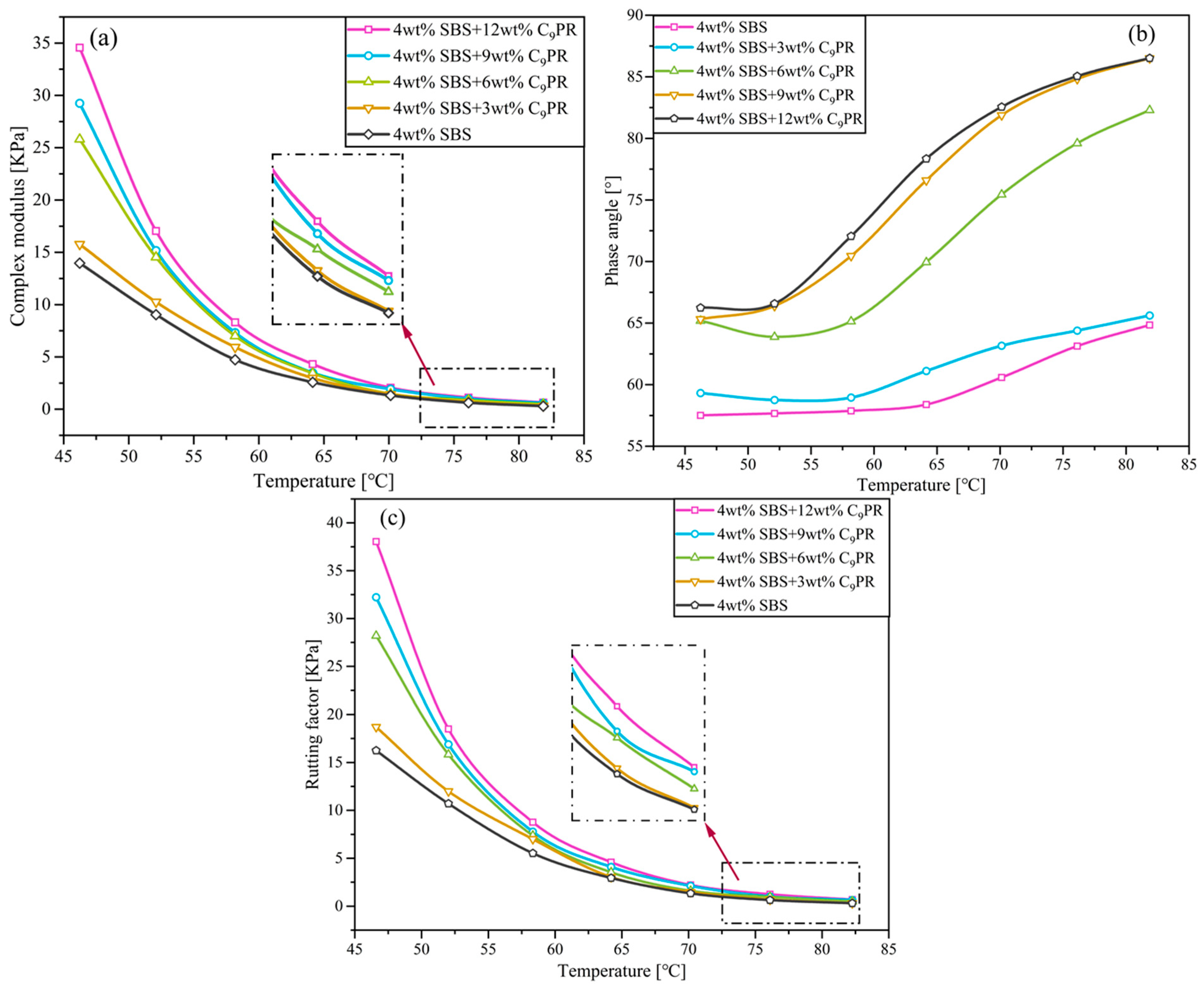

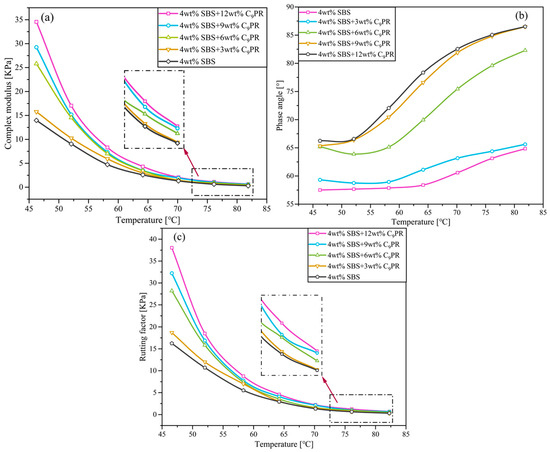

Rheological properties analysis at high temperature. The rheological properties of SBS modified bitumen and C9PR/SBS modified bitumen were evaluated using the temperature scanning method, and the complex shear modulus (G*) and phase angle (δ) were obtained at temperatures ranging from 46 °C to 82 °C. G* is a measure of the total resistance of the material to repeated shearing, with a higher G* indicating increased stiffness and improved resistance to flow deformation of the bitumen. For δ, as an indicator of the viscoelastic proportion of the bitumen, a smaller phase angle indicates a stronger resistance to high-temperature deformation of the bitumen. The rutting factor (G*/sinδ) is employed as an evaluation index for the high-temperature rutting resistance of the bitumen, and a larger G*/sinδ indicates a stronger resistance to rutting at high temperatures [45].

As illustrated in Figure 5a,b, G* and G*/sinδ of SBS modified bitumen exhibit a sharp decrease as the temperature increases. This indicates that higher temperatures result in increased flowability and reduced high-temperature rutting resistance of SBS modified bitumen. However, the addition of C9PR significantly enhances the high-temperature rutting resistance of G* and G*/sinδ of the modified bitumen, as evidenced by the significant increase in G* and G*/sinδ. When the C9PR content reaches 12 wt%, G* and G*/sinδ are increased by 60% and 57.3% at 46 °C, respectively, further enhancing the high-temperature rutting resistance. On the one hand, C9PR promotes the swelling of SBS in the bitumen, reducing the light components in the bitumen and increasing the viscosity of the bitumen as a solvent. On the other hand, C9PR, being a commonly used plasticizer, can increase the elasticity and ductility of the bitumen, which makes the instantaneous elastic recovery of C9PR/SBS modified bitumen increase, and thus shows that the rutting factor becomes greater with the increase in C9PR content. As can be seen from Figure 5c, the δ curve shows a gradual increase with the increase in temperature. The addition of C9PR makes the δ of SBS modified bitumen decrease, which results in a change in the ratio of elastic and viscous components within the bitumen. In summary, C9PR can further improve the rheological properties of SBS modified bitumen and enhance its stability and durability under different temperature conditions.

Figure 5.

Rheological properties of modified bitumen: (a) complex modulus, (b) phase angle and (c) rutting factor.

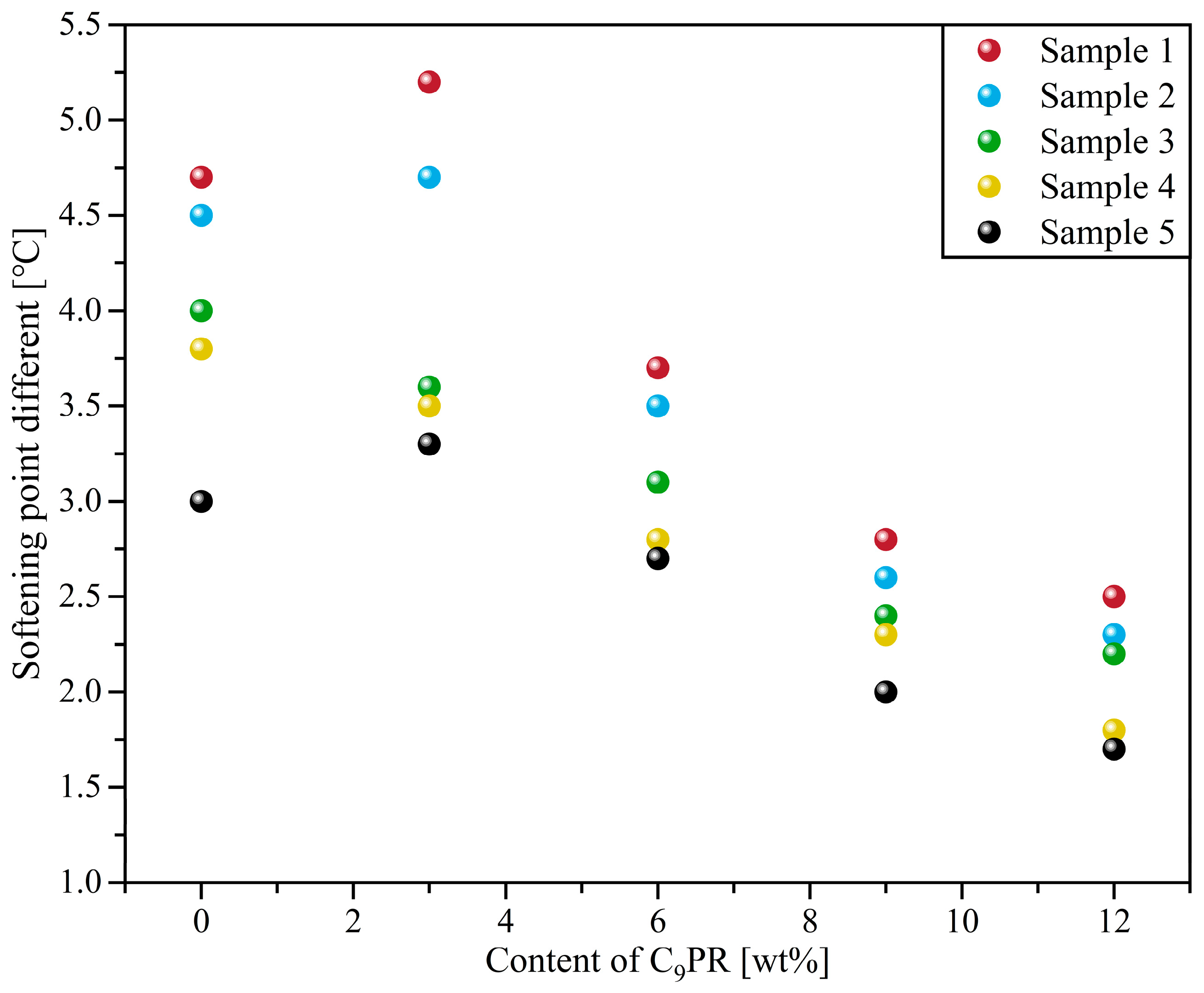

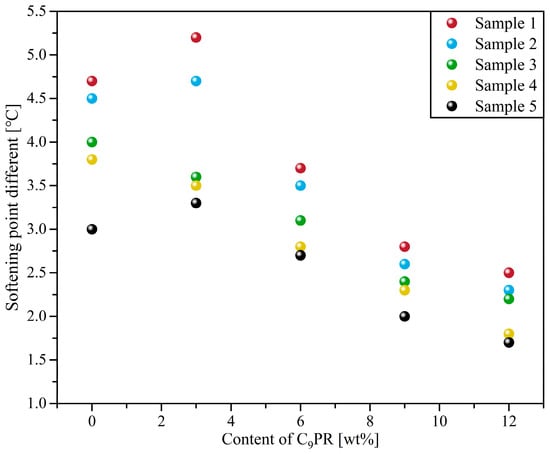

Storage Stability Analysis. To investigate the effect of C9PR content on the storage stability of C9PR/SBS modified bitumen, five groups of samples were selected for high-temperature storage tests, as shown in Figure 6. Observing the SBS modified bitumen and C9PR/SBS modified bitumen (C9PR with 3 wt% content) in Figure 6, the softening point difference showed unstable fluctuations, which may be attributed to the fact that the C9PR/SBS modified bitumen was not sufficiently sheared and miscible during the preparation process, and failed to achieve the role of promoting compatibility. With the increase in C9PR content from 3 wt% to 12 wt%, the difference in softening point appeared to be significantly reduced, which also indicates that the addition of C9PR gradually improved the compatibility of SBS and bitumen. This is due to the fact that C9PR, as a product of petroleum distillation, has excellent compatibility with bitumen, which is beneficial for the preparation of modified bitumen with good storage stability. In addition, petroleum resin as a thermoplastic resin has good solubility and plasticity, while SBS as an elastomer has good elasticity and flexibility. Since their chemical structures are similar, C9PR can interact with SBS, showing excellent compatibility.

Figure 6.

Storage stability results of modified bitumen samples.

Based on the results of the five samples in Figure 6, the average value of the difference in softening point of C9PR/SBS modified bitumen with different contents was calculated, as shown in Table 4. The data in Table 4 show that the difference in softening point is less than 3 only when the content of C9PR is 9 wt% and 12 wt%, which meets the requirement of storage stability for modified bitumen. This indicates that, although C9PR has the potential to improve the compatibility between SBS and bitumen, the storage stability of C9PR/SBS modified bitumen is sufficiently good when the C9PR content reaches 9 wt% and 12 wt%, especially at 12 wt%.

Table 4.

Average of softening point differences in modified bitumen samples.

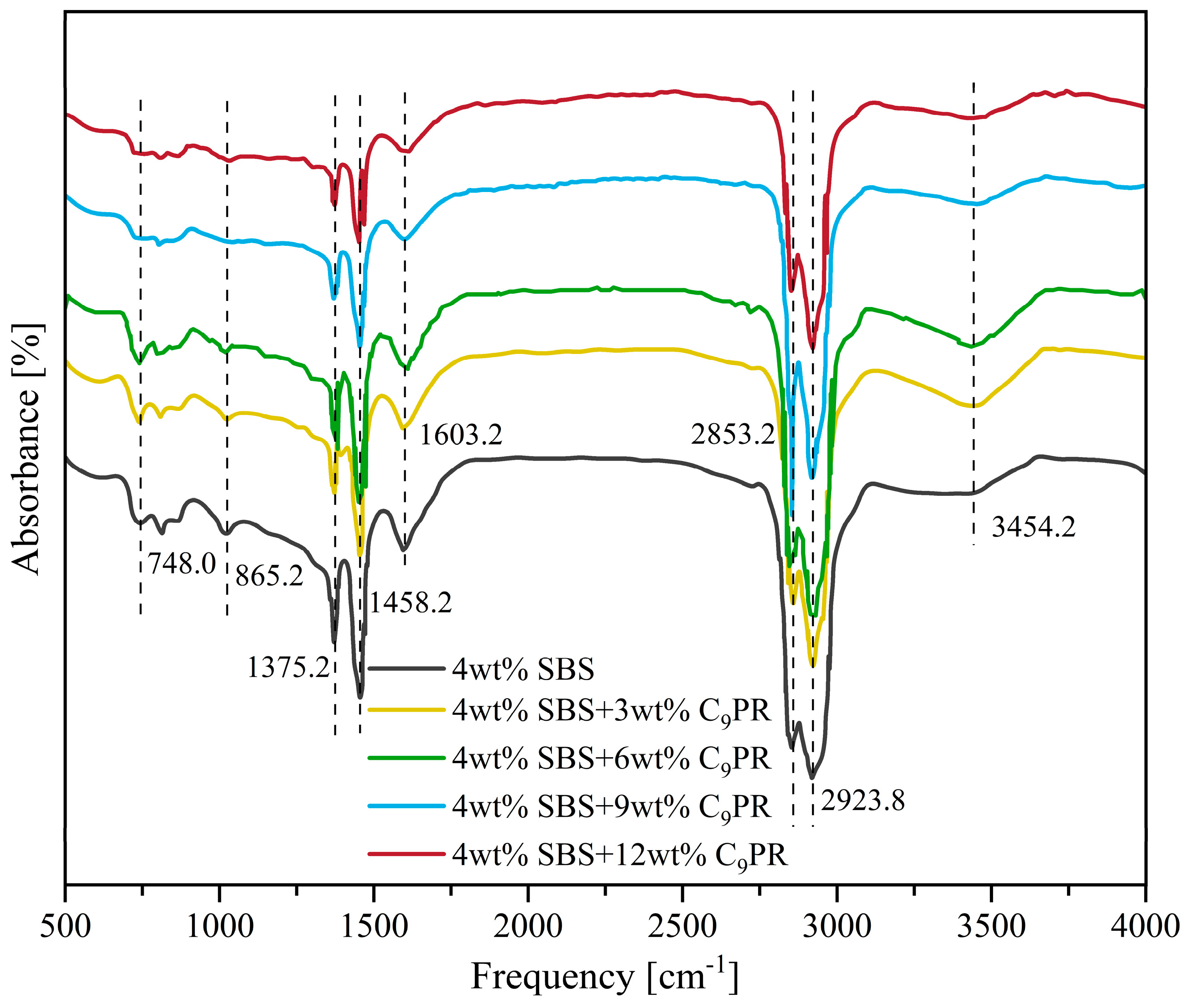

3.2. Evaluation of Microscopic Morphologies of C9PR on SBS Modified Bitumen

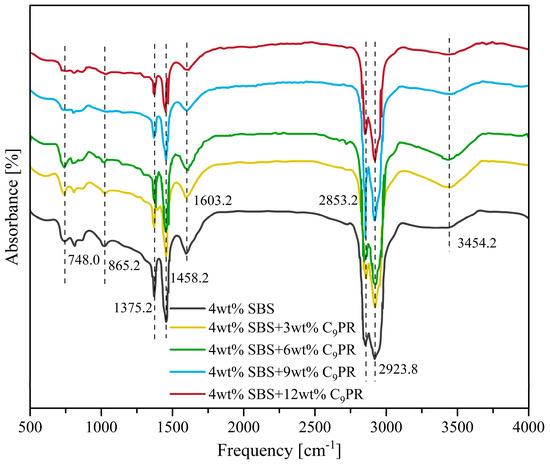

Functional groups characterization. FTIR spectroscopy was used to analyze the changes in bitumen functional groups after the addition of SBS and different contents of C9PR (0 wt%, 3 wt%, 6 wt%, 9 wt%, 12 wt%). From the spectra, it can be observed that the SBS modified bitumen spectrum exhibits a strong absorption peak at 2924 cm−1, which is attributed to the anti-symmetric stretching vibration of the methyl ethyl C=H bond. A peak at 2863 cm−1 corresponds to the symmetric stretching vibration of methylene groups, while a peak at 1603 cm−1 represents the stretching vibration of aromatic rings. Peaks at 1458 cm−1 and 1375 cm−1 correspond to the in-plane and out-of-plane bending vibrations of saturated C=H bonds (Figure 7).

Figure 7.

FTIR spectroscopy of modified bitumen.

Comparing the infrared spectra of SBS modified bitumen and C9PR/SBS modified bitumen, it is found that the positions of the absorption peaks remain relatively unchanged. However, a relatively weak absorption peak appears at 1157 cm−1, which is attributed to the stretching vibration of the C–O bond. The peak at 1458 cm−1 increases with the increase in C9PR content, confirming that C9PR can effectively improve the compatibility of bitumen. Additionally, the introduction of different contents of C9PR (0 wt%, 3 wt%, 6 wt%, 9 wt%, 12 wt%) alters the intensity of multiple absorption peaks at 1375 cm−1, 1458 cm−1, and 2923 cm−1, indicating the superposition or weakening effect of C9PR on SBS. Therefore, it can be inferred that the modification of SBS modified bitumen with C9PR is a physical modification.

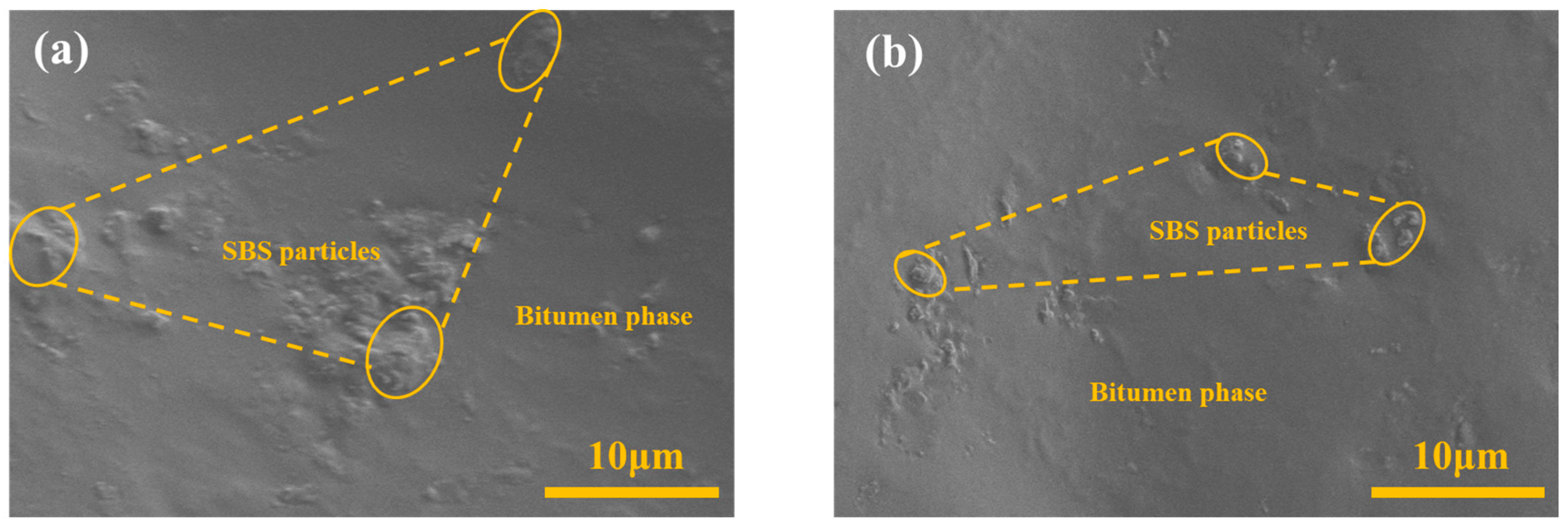

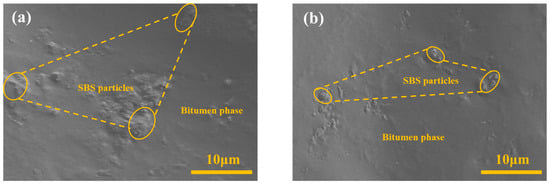

Interfacial morphologies characterization. The interfacial morphologies of SBS and bitumen before and after C9PR modification were observed using SEM, and the comparison images are shown in Figure 8. From Figure 8a, it can be seen that there are large agglomerates of SBS polymer particles, and bitumen in SBS modified bitumen, and the number of agglomerates is high. The surface between SBS and bitumen is also clearly observed, indicating that SBS is not uniformly dispersed in the bitumen, with poor compatibility, and prone to phase separation. When the interface is subjected to force and water damage, the adhesion and mechanical properties will sharply decrease. On the contrary, the incorporation of C9PR changed the morphology of the interface between SBS and bitumen, as shown in Figure 8b. Comparing with Figure 8a, under the dispersing effect of C9PR, SBS particles are more uniformly dispersed with minimal agglomeration. This is manifested by a smoother and flatter bitumen surface, indicating an improvement in the compatibility between SBS and bitumen and an enhancement of the adhesion between the interfaces. In summary, a stable and uniform interface relationship can improve the adhesion and compatibility between SBS and bitumen.

Figure 8.

Interfacial morphologies of SBS and bitumen: (a) SBS modified asphalt and (b) C9PR/SBS modified asphalt.

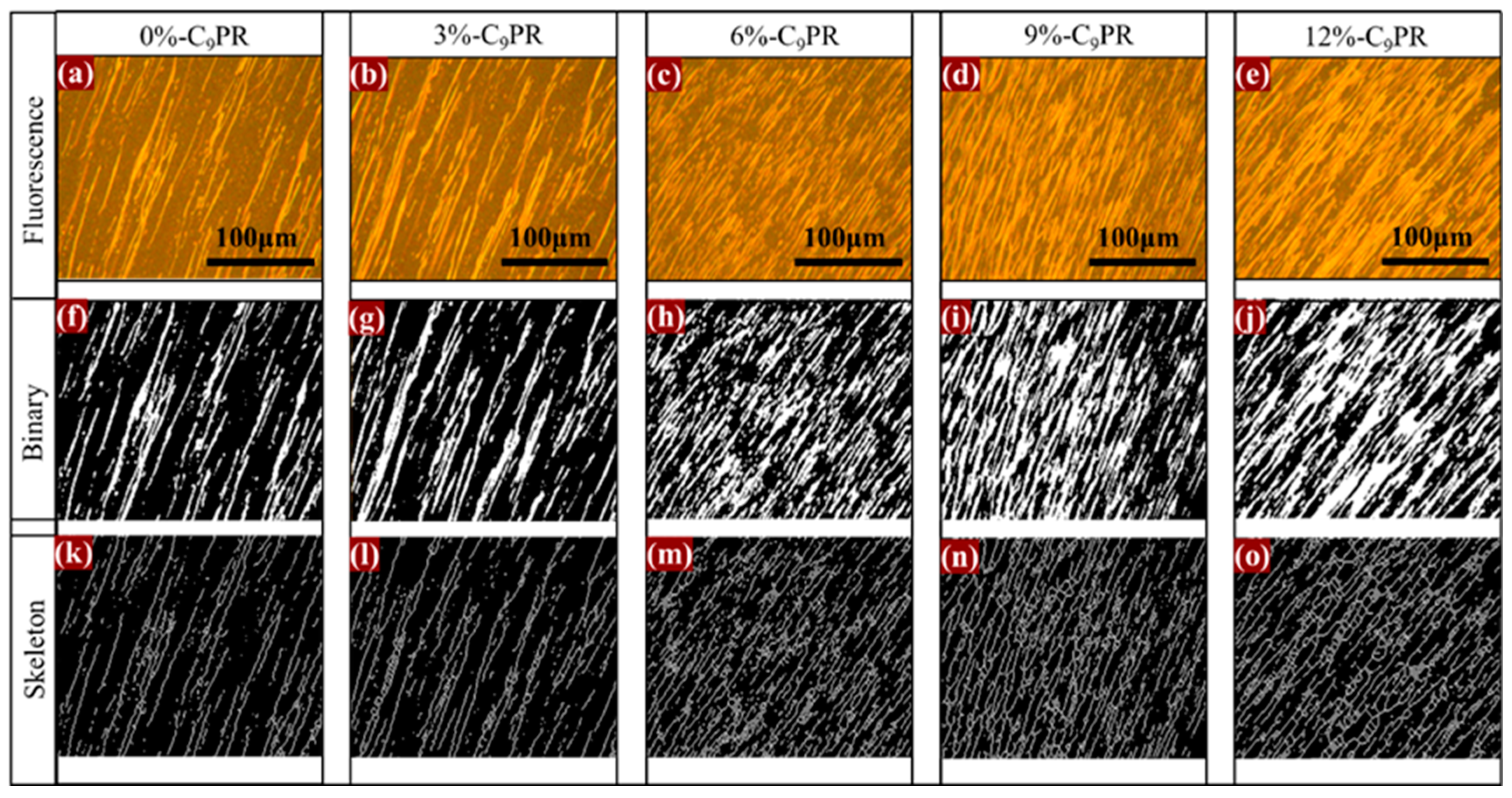

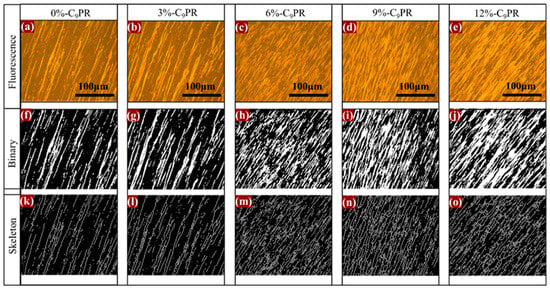

Dispersed phase structure characterization. Fluorescence microscopy was used to observe the phase distribution of SBS with bitumen at different contents of C9PR (0 wt%, 3 wt%, 6 wt%, 9 wt%, 12 wt%), as shown in Figure 9. Figure 9a–e shows that SBS is distributed in the bitumen phase in a micro-filamentary form. When the C9PR content is 0 wt%, the distribution of SBS in the bitumen phase is minimal and the interface is obvious. With the addition of C9PR, the distribution of SBS gradually increases, and the interface between SBS and bitumen gradually tends to be blurred. This phenomenon promotes the dispersion of SBS in bitumen more uniformly, and gradually forms a three-dimensional network structure.

Figure 9.

Microscopic morphologies of SBS and modified bitumen: (a–e) fluorescence, (f–j) binary and (k–o) skeleton.

To quantitatively analyze the effect of C9PR on SBS modified bitumen, the fluorescence microscope images were binarized using MATLAB software and their skeleton images were obtained. Then, the Image J software was used for measurements and calculations, and the results of image processing and measurement are shown in Figure 9 and Table 5. When C9PR content was 0 wt%, SBS dissolved in bitumen showed short and discontinuous molecular chains, which was the reason for the uplift and segregation of SBS during storage and the poor modification effect. When the C9PR content was 3 wt%, SBS continued to swell and form partially continuous molecular chains; however, there was no obvious entanglement between the molecular chains. When the content reached 6 wt%, the entanglement phenomenon between SBS molecular chains was extremely obvious. As the content of C9PR continued to increase, SBS molecular chains appeared in numerous short-branched chains, and the degree of swelling increased significantly. This is attributed to the high polarity and active groups of C9PR, which can undergo cross-linking reactions with the active groups in SBS to form a network structure and improve the compatibility.

Table 5.

Area and skeleton length of SBS.

For the same SBS content, the difference in the state after swelling is very large due to the different particle sizes after shearing. As far as the SBS area is concerned, the maximum value (C9PR content of 12 wt%) increased by 23.65% compared to the minimum value (C9PR content of 0 wt%). Meanwhile, the maximum SBS skeleton length (C9PR content of 12 wt%) is 2.43 times that of the minimum value (C9PR content of 0 wt%). The results show that, the larger the C9PR content, the longer the SBS skeleton length, and the easier it is to cross-link and form a network structure. When the C9PR content is less than 9 wt%, the increase in SBS area and skeleton length is larger. On the contrary, when the C9PR content is higher than 9 wt%, the increase tends to level off. Therefore, it can be considered that C9PR doping at 9 wt% is optimal.

3.3. Analysis of Interaction Behavior between C9PR and SBS Modified Bitumen

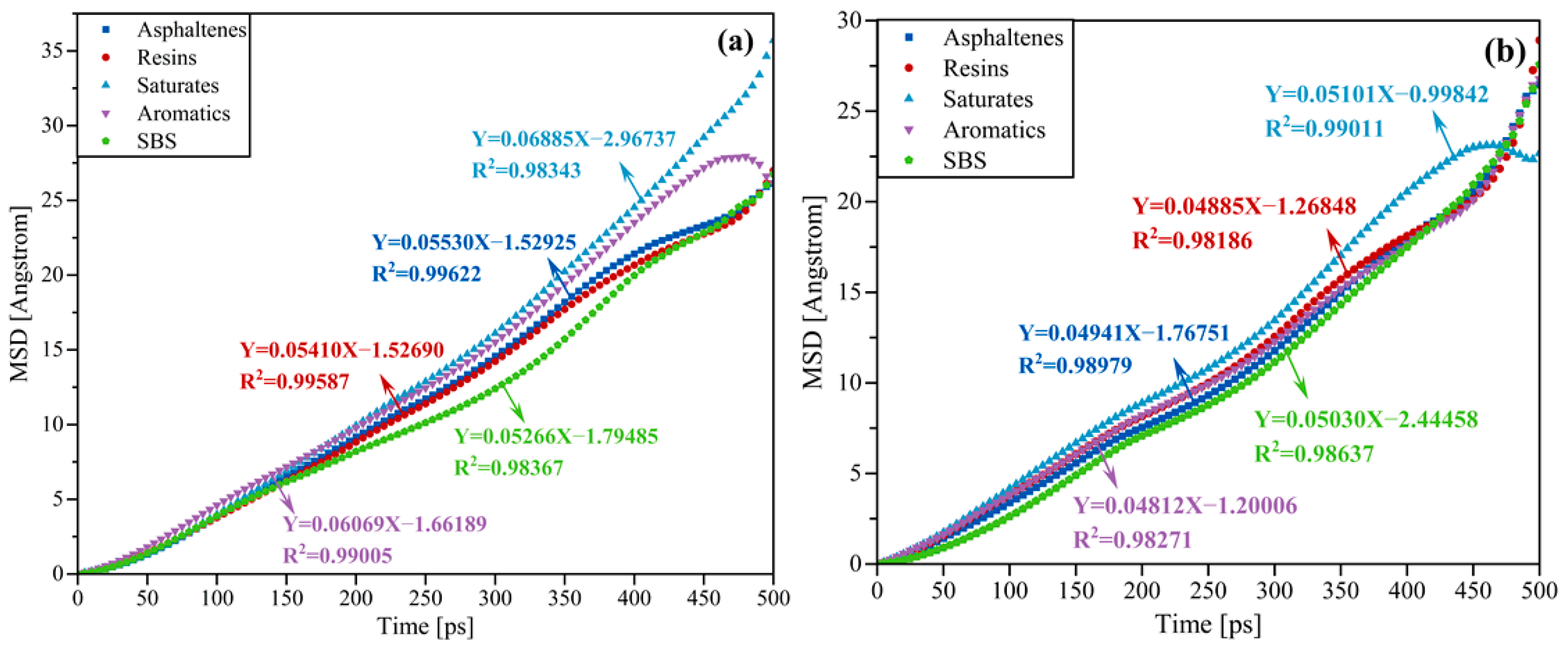

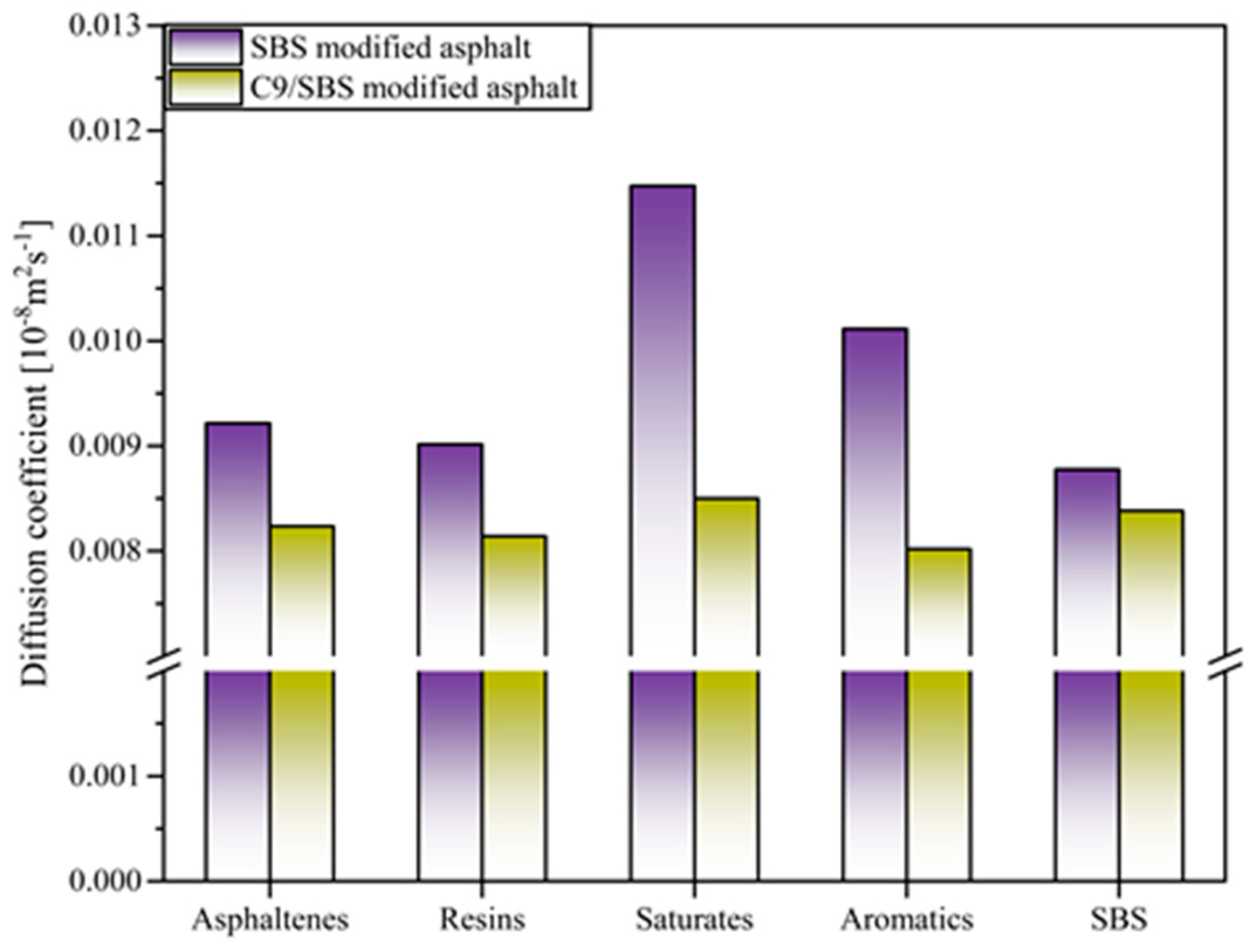

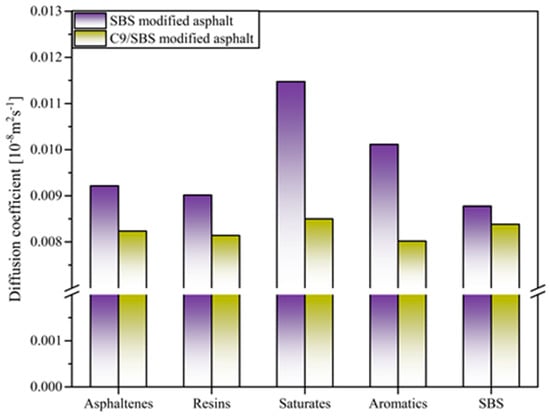

Diffusion behavior analysis. Mean square displacement is an average and unique indicator that describes the movement of molecules within a certain period, reflecting the changes in the motion properties and kinetic behavior of molecules in bitumen [46]. The MSD curve of bitumen’s four components and SBS molecules is obtained by calculating the average of the unique squares within different time intervals using Equation (1), as shown in Figure 10 [47]. The slope of the MSD curve can reflect the diffusion of molecules, with a larger slope indicating faster molecular diffusion, as shown in Figure 11.

Figure 10.

MSD and linear fitting curves of SBS and four components: (a) SBS modified asphalt and (b) C9PR/SBS modified asphalt.

Figure 11.

Diffusion coefficient of SBS and four components.

In Equation (1), ⟨⟩ denotes the average value, ri(t) denotes the position vector of particle the at time t, N and D denote the number of particles in the system and the molecular diffusion coefficient, respectively, while d/dt denotes the differentiation of the equation, MSD(t) represents the mean square displacement curve, and D is the diffusion coefficient.

The figures show the MSD values of bitumen, colloid, aromatic fraction, and saturated fraction in SBS modified bitumen and C9PR/SBS modified bitumen systems, respectively. The curves exhibit a rapid increase in the initial stage of simulation, and the MSD values in the C9PR/SBS modified bitumen are greater than those in the SBS modified bitumen. In the second stage of simulation, the diffusion rate gradually stabilizes, and the MSD values in the SBS modified bitumen are greater than those in the C9PR/SBS modified bitumen. Initially, the four components of bitumen and SBS molecules rapidly come into contact, filling the pores. Subsequently, under the influence of van der Waals forces and electric field forces, the molecules continue to diffuse, reaching a state of equilibrium in molecular interactions. The changes in the MSD curves indicate that the addition of C9PR makes the SBS modified bitumen system more stable.

According to the fitting results of the MSD curves in Figure 10, the correlation coefficients (R2) of the four components in the SBS modified bitumen and C9PR/SBS modified bitumen systems are all greater than 0.99, indicating a high linear correlation of the MSD curves and that the slope can satisfy the accuracy of diffusion coefficients. Comparing the diffusion results of the four components in the SBS modified bitumen and C9PR/SBS modified bitumen, it is found that the addition of C9PR reduces the diffusion coefficients of the four components, indicating faster diffusion of the four component molecules in the SBS modified bitumen. However, SBS molecules exhibit the opposite diffusion trend, with a diffusion coefficient of 2.194 × 10−8 m2·s−1 in SBS modified bitumen and 0.237 × 10−8 m2·s−1 in C9PR/SBS modified bitumen, reaching the maximum diffusion coefficient in the C9PR/SBS modified bitumen. The four components and SBS molecules interact with each other during the diffusion process, and the addition of C9PR enhances the interaction strength between SBS and the four components of bitumen, thereby restraining the diffusion motion of the four components. Meanwhile, SBS molecules move closer to each component of bitumen during the diffusion process. This also verified the results according to which the elastic components of bitumen decreased and the viscous components gradually became dominant in the macroscopic experiment.

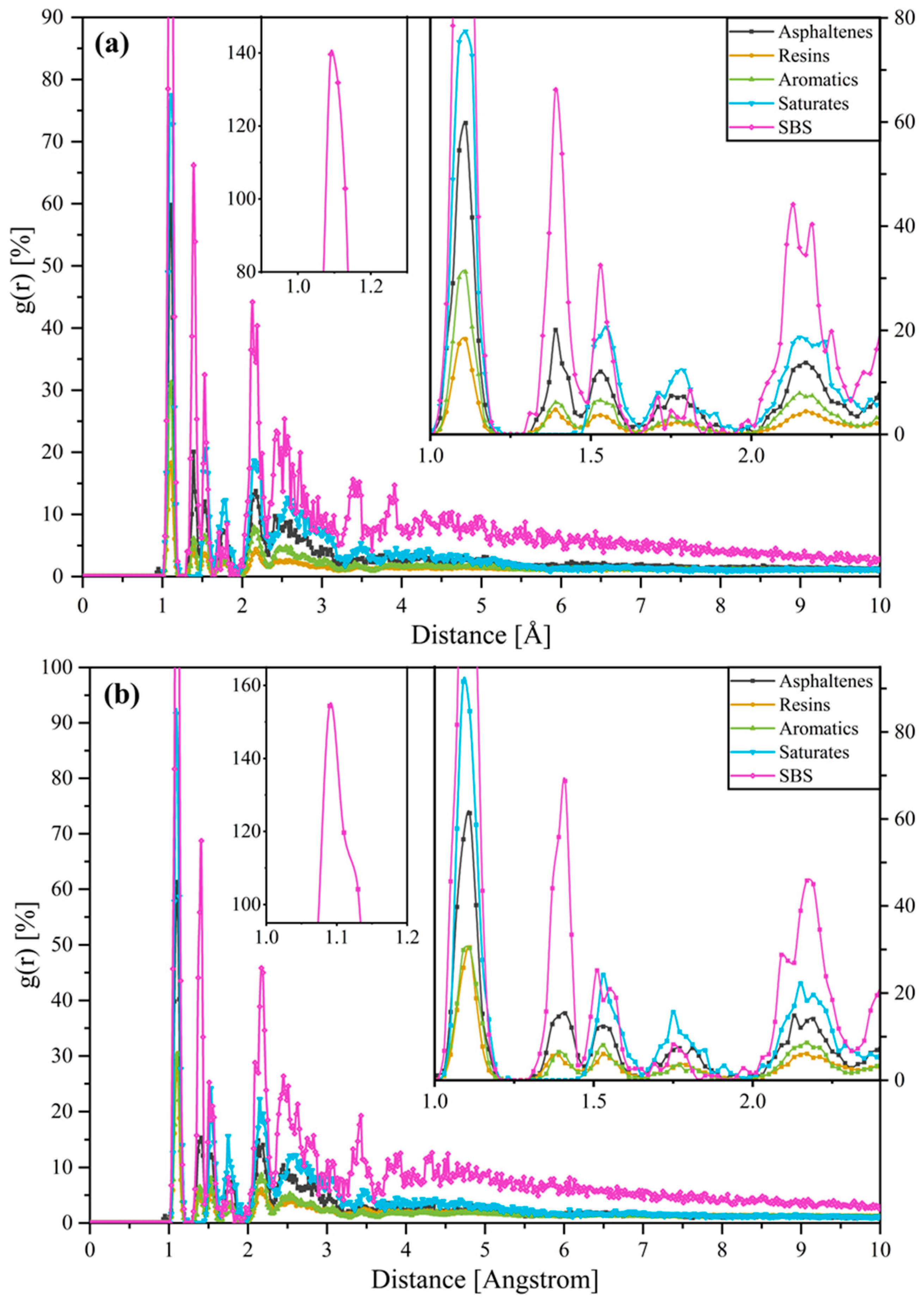

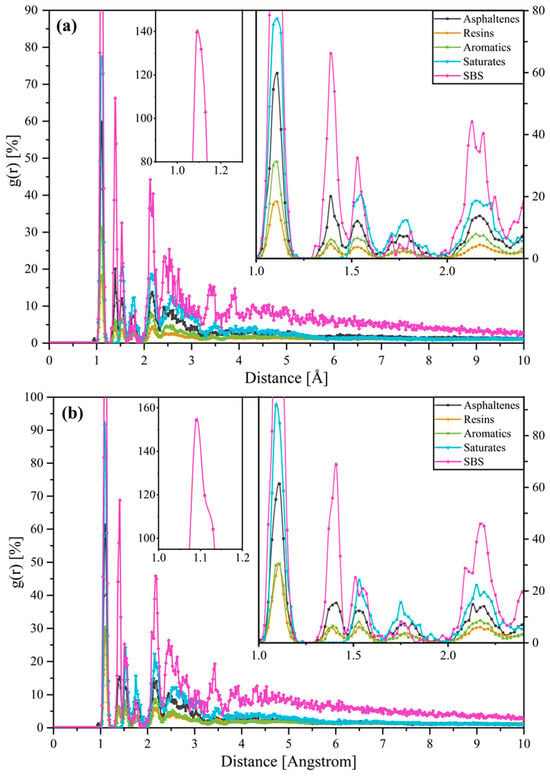

Aggregation behavior analysis. According to the RDF curve of SBS modified bitumen in Figure 12, both SBS and bitumen components exhibit peaks between 1.03 Å and 1.19 Å. The peak for SBS is at (1.09 Å, 139.65%), the peak for asphaltene is at (1.11 Å, 59.58%), the peak for resin is at (1.11 Å, 18.31%), the peak for aromatic fraction is at (1.11 Å, 30.18%), and the peak for saturates is at (1.09 Å, 77.44%). Figure 12 shows the RDF curve of SBS and bitumen components after the addition of C9PR, and the peaks remain within the range from 1.03 Å to 1.19 Å. The peak for SBS is at (1.09 Å, 154.40%), the peak for asphaltene is at (1.11 Å, 61.32%), the peak for resin is at (1.11 Å, 30.49%), the peak for aromatic fraction is at (1.09 Å, 30.34%), and the peak for saturates is at (1.09 Å, 91.62%). Compared to SBS modified bitumen, the peaks of SBS and bitumen components are enlarged, indicating an enhancement in molecular order. This result is attributed to the cross-linking structure formed by C9PR and SBS, which maintains stability even at high temperatures and alleviates disorderly movement. From a macroscopic perspective, the increased order of SBS and bitumen components significantly improves the temperature sensitivity of bitumen, allowing it to remain stable at high temperatures while maintaining flexibility at low temperatures. Additionally, the peaks of SBS and bitumen components do not shift, indicating that C9PR does not affect the aggregation of SBS modified bitumen. Comparing the changes in peak values, the aromatic fraction increases by 0.16% and the saturates increase by 14.18%, which also suggests that the addition of C9PR effectively supplements the light components in bitumen, increasing their proportion and enhancing system stability.

Figure 12.

RDF of SBS and four components: (a) SBS modified bitumen and (b) C9PR/SBS modified bitumen.

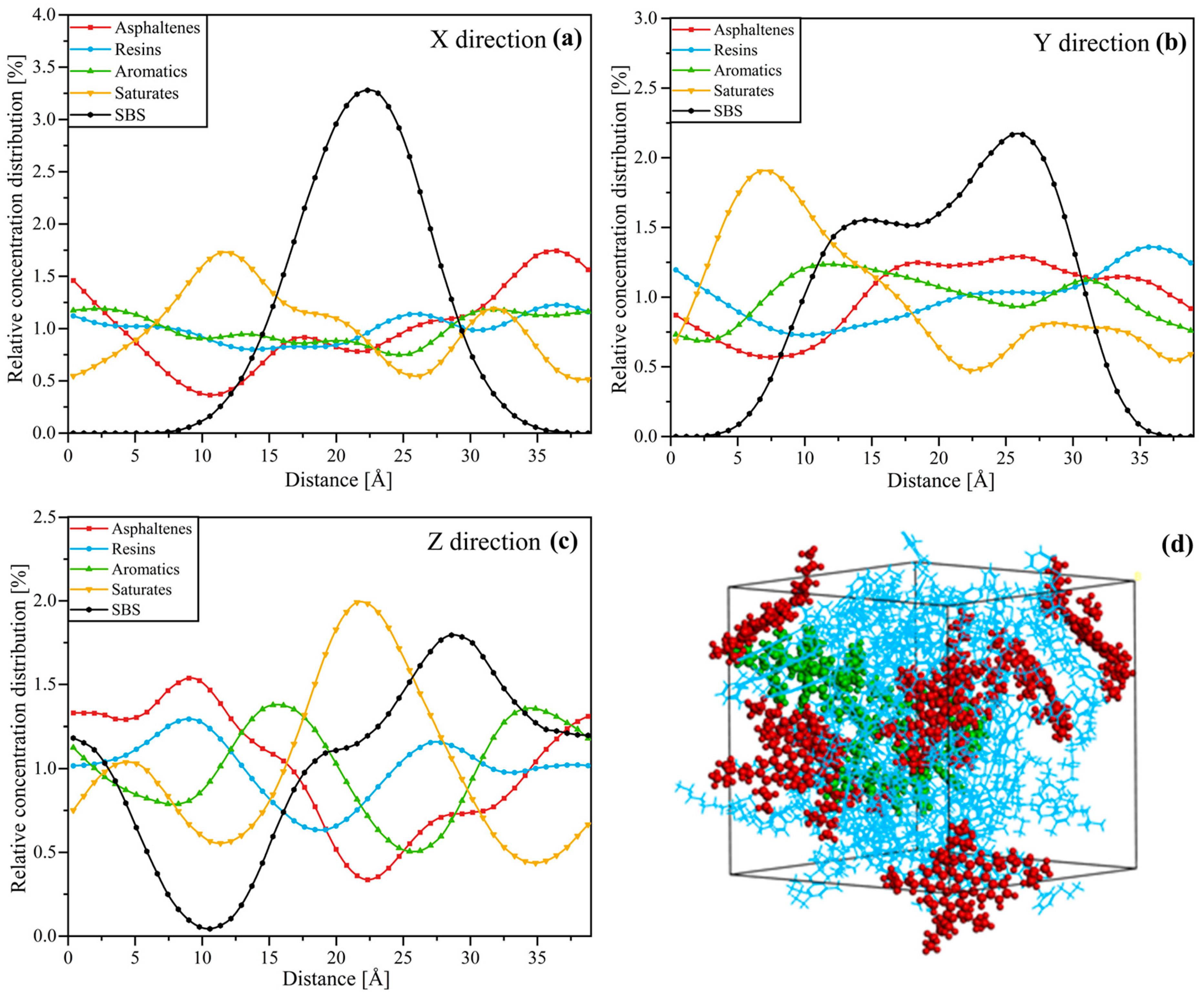

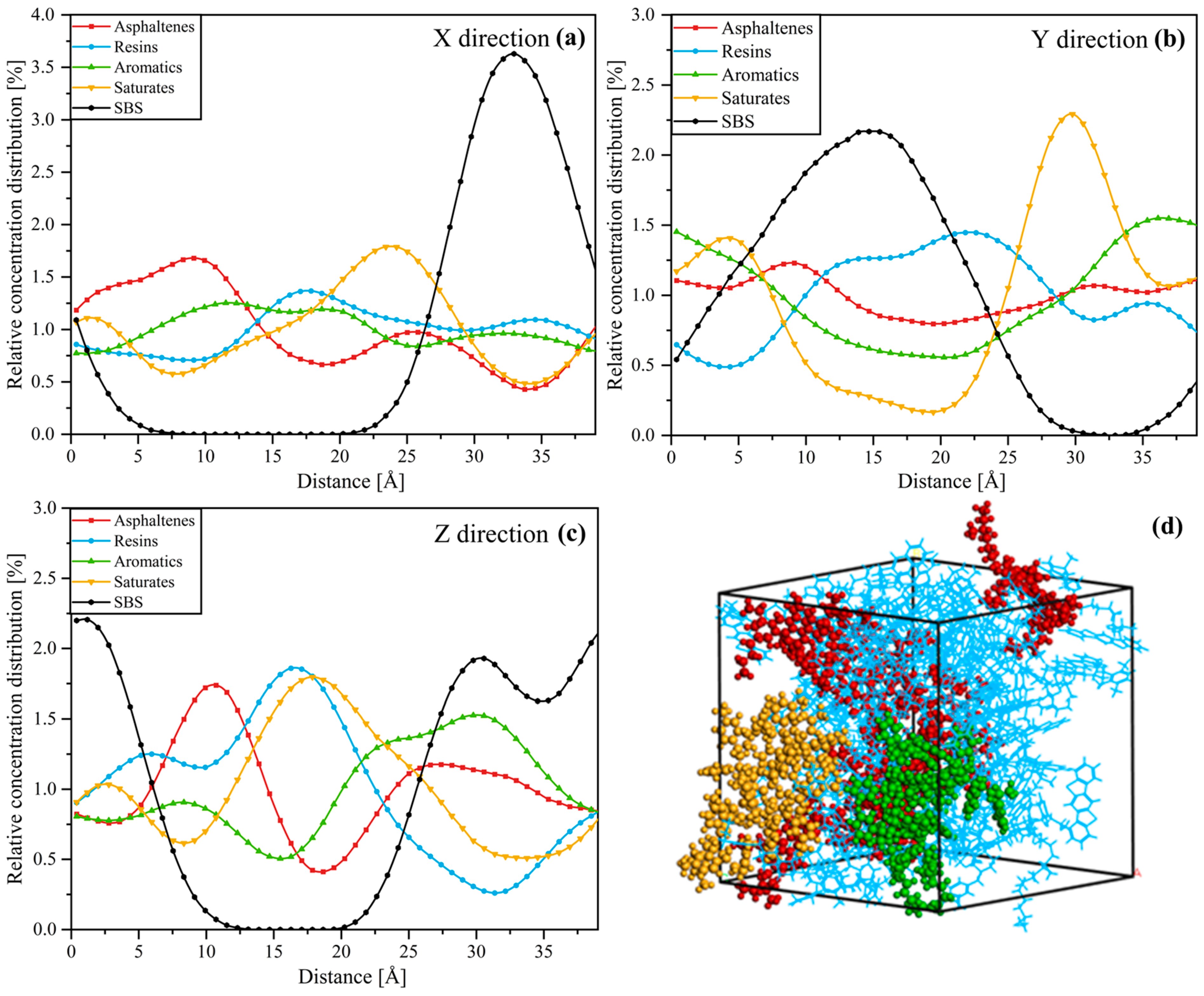

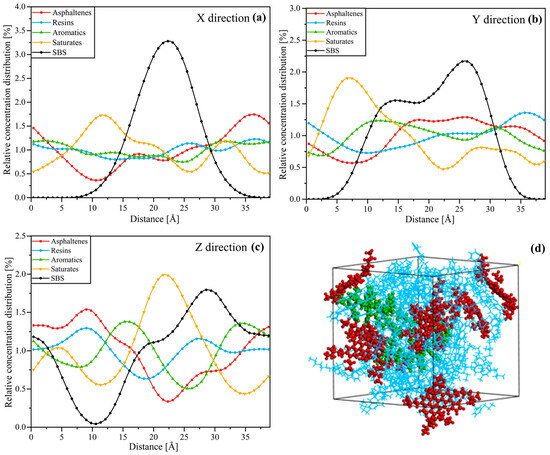

Concentration distribution analysis. The relative concentration distribution can deeply analyze the spatial distribution of molecules in the system. Figure 13 shows the distribution of four components of SBS modified bitumen and C9PR/SBS modified bitumen system, as well as the distribution of SBS molecules. In the SBS modified bitumen system, asphaltene, colloid, and aromatic components exhibit relatively uniform distribution, while saturated components and SBS show varying degrees of aggregation in different directions (X, Y, Z). Among them, saturated components and SBS molecules always maintain adjacent aggregation states. The aggregation peak of saturated components appears near the coordinates (11, 6, 23), and SBS shows strong aggregation near (23 ± 7, 14 ± 5, 28 ± 5), which is the adsorption effect of SBS on saturated components. Similarly, when saturated components and aromatic components show strong aggregation behavior, the aggregation behavior of asphaltene weakens. When asphaltene shows a strong aggregation peak, the aggregation peaks of saturated components and aromatic components are smaller, which also demonstrates the competition between SBS and asphaltene for light components.

Figure 13.

Relative concentration distribution: (a) X direction, (b) Y direction, (c) X direction and molecular morphology (d) of SBS modified bitumen.

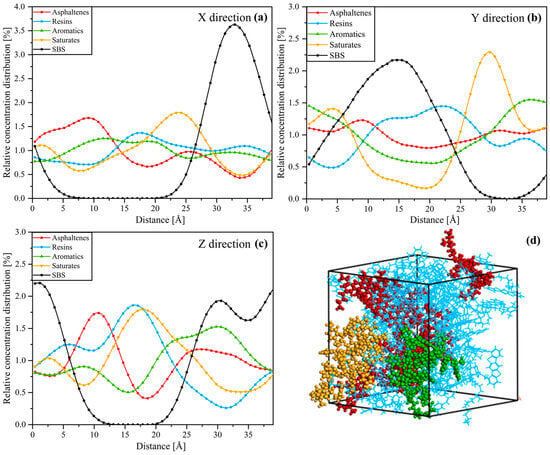

By comparing the concentration distribution of the four components and SBS in the C9PR/SBS modified bitumen system with Figure 14, significant changes can be observed, especially the significant fluctuations in the colloid curve, indicating strong aggregation behavior. SBS and saturated components still maintain strong adjacent aggregation behavior, and the peak values of asphaltene are enhanced in the X and Z directions. Comparing the average upper and lower limits of the relative concentrations of the four components in the C9PR/SBS modified bitumen system in the three directions, the average values of asphaltene, colloid, aromatic components, and saturated components are 1.05%, 1.02%, 1.03%, and 1.17%, respectively. However, for SBS modified bitumen, these values are 0.97%, 0.95%, 0.96%, and 1.17%, respectively. The addition of C9PR increases the peak values of the four components of bitumen, especially the peak of heavy components. At the same time, compared with SBS modified bitumen, the average peak value decreases by 0.12%, which is due to the further promotion of SBS by C9PR in competing for light components and enhancing adsorption capacity. This result is consistent with the conclusion of RDF analysis.

Figure 14.

Relative concentration distribution: (a) X direction, (b) Y direction, (c) X direction and molecular morphology (d) of C9PR/SBS modified bitumen.

4. Conclusions

This study has substantially enhanced our understanding of the influence of C9PR on SBS modified asphalt, elucidating its effects on rheological, microstructural, and chemical properties through a detailed examination using DSR, storage stability tests, fluorescence microscopy, SEM, FTIR, and molecular dynamic simulations. The results highlight C9PR’s significant improvements in the performance of SBS modified asphalt, crucial for developing advanced pavement materials.

- (1)

- A key finding from this research is C9PR’s role in optimizing the balance between the elastic and viscous components of the asphalt. This optimization enhances the material’s stability and resistance to deformation under varying temperatures, crucial for the durability of pavement surfaces. Notably, a C9PR content of 12 wt% was found to be optimal for maximizing storage stability. This concentration enhances the compatibility of SBS and bitumen without causing significant chemical reactions, as confirmed by FTIR analysis.

- (2)

- Microscopic evaluations revealed that C9PR positively affects the distribution and adhesion of SBS within the bitumen matrix. Adding C9PR leads to a more uniform dispersion of SBS, smoothing the interface between SBS and bitumen and enhancing material cohesion and adhesion. This improvement marks significant progress in developing asphalt composites with superior mechanical properties and longevity.

- (3)

- MD*-simulations offered deeper insights into the molecular interactions facilitating these enhancements. The inclusion of C9PR limits the diffusion of bitumen molecules, suggesting a stronger intermolecular force. This mechanism indicates that C9PR improves stability by promoting a competitive absorption process, aiding the integration of SBS into the bitumen and enhancing the overall performance of the composite.

- (4)

- This research conclusively shows that integrating C9PR into SBS modified asphalt is an effective strategy to improve the material’s performance across various metrics, including low-temperature properties, storage stability, and temperature susceptibility. The combination of empirical testing and molecular simulation has validated the benefits of C9PR and laid a strong foundation for its future use in pavement engineering. The outcomes of this study are expected to guide the development of more advanced asphalt materials, contributing to the creation of more durable, sustainable, and high-performing road infrastructures.

Author Contributions

Conceptualization: C.Y. and T.Z.; methodology, C.Y.; software, T.Z.; validation, S.T.A.G.; formal analysis, S.T.A.G.; investigation, K.H. and T.Z.; data curation, S.T.A.G.; writing—original draft preparation, C.Y. and T.Z.; writing—review and editing, K.H.; visualization, W.Z.; supervision, W.Z.; project administration, K.H.; funding acquisition, K.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundamental Research Fund of Natural Science Foundation of China [52208434], the Fundamental Research Funds for the Central Universities, CHD [300102213507], Yangling Vocational & Technical College 2023 Science and Technology Innovation Key Projects [ZKZ23-04], Natural Science Foundation of Henan Province [222300420142], Postdoctoral Re-search Grant in Henan Province [202103107], Science and Technology Project of Henan Province [192102310229], China Postdoctoral Science Foundation [2022M711079], Young backbone teachers plan of Henan University of Technology [21420156], Open Fund of National Engineering Research Center of Highway Maintenance Technology (Changsha University of Science and Technology) [kfj230206], Tianshan leading talents in scientific and technological innovation [2022TSYCLJ0045].

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Joohari, I.B.; Giustozzi, F. Chemical and high-temperature rheological properties of recycled plastics-polymer modified hybrid bitumen. J. Clean. Prod. 2020, 276, 123064. [Google Scholar] [CrossRef]

- Xu, J.; Fan, Z.; Lin, J.; Liu, P.; Wang, D.; Oeser, M. Study on the effects of reversible aging on the low temperature performance of asphalt binders. Constr. Build. Mater. 2021, 295, 123604. [Google Scholar] [CrossRef]

- Yao, H.; Liu, J.; Xu, M.; Ji, J.; Dai, Q.; You, Z. Discussion on molecular dynamics (MD) simulations of the materials. Adv. Colloid Interface Sci. 2022, 299, 102565. [Google Scholar] [CrossRef] [PubMed]

- Hassanpour-Kasanagh, S.; Ahmedzade, P.; Fainleib, A.M.; Behnood, A. Rheological properties of asphalt binders modified with recycled materials: A comparison with Styrene-Butadiene-Styrene (SBS). Constr. Build. Mater. 2020, 230, 117047. [Google Scholar] [CrossRef]

- Yin, W.; Ye, F.; Lu, H. Establishment and experimental verification of stability evaluation model for SBS modified asphalt: Based on quantitative analysis of microstructure. Constr. Build. Mater. 2021, 131, 291–302. [Google Scholar] [CrossRef]

- Xu, X.; Sreeram, A.; Leng, Z.; Yu, J.; Li, R.; Peng, C. Challenges and opportunities in the high-quality rejuvenation of unmodified and SBS modified asphalt mixtures: State of the art. J. Clean. Prod. 2022, 378, 134634. [Google Scholar] [CrossRef]

- Azizi, H.; Faghihi, J. Effect of nanoclay on mechanical and thermal properties of triblock SBS (styrene–butadiene–styrene) and its binary blend nanocomposites: Comparison between polyethylene and polystyrene. Plast. Rubber Compos. 2018, 47, 429–437. [Google Scholar] [CrossRef]

- Jiang, Z.; Easa, S.M.; Hu, C.; Zheng, X. Evaluation of new aspect of styrene-butadiene-styrene modified bitumens: Damping property and mechanism. Constr. Build. Mater. 2020, 242, 118185. [Google Scholar] [CrossRef]

- Xu, X.; Chen, G.; Wu, Q.; Leng, Z.; Chen, X.; Zhai, Y.; Tu, Y.; Peng, C. Chemical upcycling of waste PET into sustainable asphalt pavement containing recycled concrete aggregates: Insight into moisture-induced damage. Constr. Build. Mater. 2022, 360, 129632. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Dong, X.; Cui, B.; Hu, D. Mechanism and performance of graphene modified asphalt: An experimental approach combined with molecular dynamic simulations. Case. Studi. Constr. Mater. 2023, 18, e01749. [Google Scholar] [CrossRef]

- Huang, T.; Cao, Z.; Lv, S.; Yu, H.; Peng, X.; Jiang, H.; Wu, L. Road behavior and micro characteristics of high-performance asphalt based on compound modification approach. Constr. Build. Mater. 2023, 371, 130622. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, C.; Muhammad, Y.; Chen, L.; Zhou, D.; Wang, S.; Li, J.; Chen, Q. Fabrication and performance evaluation of aminopropyl triethoxysilane-dopamine-MoS2 incorporated SBS modified asphalt. Constr. Build. Mater. 2020, 265, 120346. [Google Scholar] [CrossRef]

- Zhang, W.; Qiu, L.; Liu, J.; Hu, K.; Zou, L.; Chen, Y.; Yang, C.; Wang, F.; Zang, J. Modification mechanism of C9 petroleum resin and its influence on SBS modified asphalt. Constr. Build. Mater. 2021, 306, 124740. [Google Scholar] [CrossRef]

- Nie, X.; Hou, T.; Yao, H.; Li, Z.; Zhou, X.; Li, C. Effect of C9 petroleum resins on improvement in compatibility and properties of SBS-modified asphalt. Petrol. Sci. Technol. 2019, 306, 124740. [Google Scholar] [CrossRef]

- Yaphary, Y.L.; Leng, Z.; Wang, H.; Ren, S.; Lu, G. Characterization of nanoscale cracking at the interface between virgin and aged asphalt binders based on molecular dynamics simulations. Constr. Build. Mater. 2022, 335, 127475. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- Ma, F.; Li, C.; Fu, Z.; Huang, Y.; Dai, J.; Feng, Q. Evaluation of high temperature rheological performance of polyphosphoric acid-SBS and polyphosphoric acid-crumb rubber modified asphalt. Constr. Build. Mater. 2021, 306, 124926. [Google Scholar] [CrossRef]

- Xu, G.; Yao, Y.; Ma, T.; Hao, S.; Ni, B. Experimental study and molecular simulation on regeneration feasibility of high-content waste tire crumb rubber modified asphalt. Constr. Build. Mater. 2023, 369, 130570. [Google Scholar] [CrossRef]

- Tang, Y.; Fu, Z.; Ma, F.; Liu, J.; Sun, Q.; Li, C. Carbon nanotubes for improving rheological and chemical properties of styrene–butadiene–styrene modified asphalt binder. Int. J. Pavement Eng. 2023, 24, 2211212. [Google Scholar] [CrossRef]

- Wang, P.; Zhai, F.; Dong, Z.-J.; Wang, L.-Z.; Liao, J.-P.; Li, G.-R. Micromorphology of asphalt modified by polymer and carbon nanotubes through molecular dynamics simulation and experiments: Role of Strengthened Interfacial Interactions, Energy. Fuels 2018, 32, 1179–1187. [Google Scholar] [CrossRef]

- Zhao, P.; Song, X.; Dong, M.; Sun, H.; Wu, W.; Zhang, R.; Sun, M.; Zhao, X. Preparation and characterization of CQDs/SBS composites and its application performance as asphalt modifier. Constr. Build. Mater. 2022, 320, 126312. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, S.B.; Peng, A.; Xuan, W.; Li, W. Analysis of the performance and mechanism of desulfurized rubber and low-density polyethylene compound-modified asphalt. J. Appl. Polym. Sci. 2019, 136, 48194. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, L.; Wang, Y.; Liu, J.; Yang, C.; Di, J.; Hu, H.; Yang, Z. Influence of high viscosity petroleum resin (HV-PR) on the intermediate and high temperature performances of Styrene–Butadiene–Styrene block copolymer (SBS) modified bitumen. Arab. J. Sci. Eng. 2022, 47, 12521–12533. [Google Scholar] [CrossRef]

- Zhang, F.; Kaloush, K.; Underwood, S.; Hu, C. Preparation and performances of SBS compound modified asphalt mixture by acidification and vulcanization. Constr. Build. Mater. 2023, 296, 123693. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Zhang, Y.; Yan, C.; Lv, Q.; Guan, W. Evaluation of the terminal blend crumb rubber/SBS composite modified asphalt. Constr. Build. Mater. 2021, 278, 122377. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, C. Deterioration effects of oxidative aging on graphene-asphalt nanocomposite interfaces: Multiscale Modeling. Langmuir 2023, 39, 8339–8353. [Google Scholar] [CrossRef] [PubMed]

- Roja, K.L.; Rehman, A.; Ouederni, M.; Krishnamoorthy, S.K.; Abdala, A.; Masad, E. Influence of polymer structure and amount on microstructure and properties of polyethylene-modified asphalt binders. Mater. Struct. 2021, 54, 2. [Google Scholar] [CrossRef]

- Xu, J.; Sun, L.; Pei, J.; Xue, B.; Liu, T.; Li, R. Microstructural, chemical and rheological evaluation on oxidative aging effect of SBS polymer modified asphalt. Road Constr. Build. Mater. 2021, 267, 121028. [Google Scholar] [CrossRef]

- Li, J.; Jiang, H.; Han, F.; Lin, Z.; Zhao, Z.; Jin, X.; Liu, Y. Investigation of the effects of chemical modification and oxidative aging on the properties and compatibility of rubber asphalt based on thermodynamic principles. J. Clean. Prod. 2023, 428, 139070. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, Z.-C.; Huang, J.-L.; Ma, T.; Huang, X.-M.; Miao, C.-W. A molecular dynamics study of calcium silicate hydrates-aggregate interfacial interactions and influence of moisture. Appl. Surf. Sci. 2021, 28, 16–28. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H. Molecular modeling of asphalt-aggregate debonding potential under moisture environment and interface defect. Appl. Surf. Sci. 2022, 606, 154858. [Google Scholar] [CrossRef]

- Fan, J.; Zhu, Y.; Ma, T.; Xu, G.; Ding, X. Multiscale study on aging process and mechanism of high viscosity Asphalt: Macro-micro experiments and quantum chemical molecular simulation. Constr. Build. Mater. 2023, 402, 133059. [Google Scholar] [CrossRef]

- Yu, C.; Yang, Q. Investigation of the interfacial interaction of carbon nanomaterials with asphalt matrix: Insights from molecular simulations. Mol. Simulat. 2022, 49, 208–222. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, D.; Xiang, M.; Cui, M.; Liu, N. Experimental study on aging performance of polyethylene gas pipelines. IOP Conf. Ser. Earth Environ. Sci. 2021, 631, 012066. [Google Scholar] [CrossRef]

- Li, M.; Min, Z.; Wang, Q.; Huang, W.; Shi, Z. Effect of epoxy resin content and conversion rate on the compatibility and component distribution of epoxy asphalt: A MD simulation study. Constr. Build. Mater. 2021, 319, 126050. [Google Scholar] [CrossRef]

- Shi, K.; Fu, Z.; Liu, J.; Song, R.; Ma, F.; Dai, J.; Li, C.; Wen, Y. Multiscale investigation of waste soybean oil rejuvenated asphalt binder utilising experimental methodologies and molecular dynamics simulations. Int. J. Pavement Eng. 2023, 24, 2181961. [Google Scholar] [CrossRef]

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM: West Conshohocken, PA, USA, 2005.

- Qian, C.; Fan, W.; Yang, G.; Han, L.; Xing, B.; Lv, X. Influence of crumb rubber particle size and SBS structure on properties of CR/SBS composite modified asphalt. Constr. Build. Mater. 2020, 235, 117517. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, X.; Zhang, Y. Diffusive dynamics and structural organization of moisture in asphaltic materials based on molecular dynamics simulation. J. Mater. Civil. Eng. 2021, 33, 04020403. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Jiao, B.; Pan, B.; Che, T. Evaluating impacts of desulfurization and depolymerization on thermodynamics properties of crumb rubber modified asphalt through molecular dynamics simulation. Constr. Build. Mater. 2022, 323, 126360. [Google Scholar] [CrossRef]

- Cui, W.; Huang, W.; Hassan, H.M.Z.; Cai, X.; Wu, K. Study on the interfacial contact behavior of carbon nanotubes and asphalt binders and adhesion energy of modified asphalt on aggregate surface by using molecular dynamics simulation. Constr. Build. Mater. 2022, 316, 125849. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H. Molecular interaction of Asphalt-Aggregate interface modified by silane coupling agents at dry and wet conditions. Appl. Surf. Sci. 2022, 572, 151365. [Google Scholar] [CrossRef]

- Long, Z.; You, L.; Tang, X.; Ma, W.; Ding, Y.; Xu, F. Analysis of interfacial adhesion properties of nano-silica modified asphalt mixtures using molecular dynamics simulation. Constr. Build. Mater. 2020, 255, 119354. [Google Scholar] [CrossRef]

- Yu, C.; Hu, K.; Yang, Q.; Chen, Y. Multi–scale observation of oxidative aging on the enhancement of high–temperature property of SBS–modified asphalt. Constr. Build. Mater. 2021, 313, 125478. [Google Scholar] [CrossRef]

- Yu, J.; Zheng, H.; Hou, D.; Zhang, J.; Xu, W. Silane coupling agent modification treatment to improve the properties of rubber–cement composites. ACS Sustain. Chem. Eng. 2021, 9, 12899–12911. [Google Scholar] [CrossRef]

- Luo, L.; Chu, L.; Fwa, T.F. Molecular dynamics analysis of oxidative aging effects on thermodynamic and interfacial bonding properties of asphalt mixtures. Constr. Build. Mater. 2021, 269, 121299. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).