Life-Cycle Assessment of Lightweight Partitions in Residential Buildings

Abstract

:1. Introduction

1.1. The Life-Cycle of Buildings and the Concept of Stewart Brand

1.2. Interior Partitions

1.3. LCA without Replacing Interior Partitions during the Entire Life of the Building

1.4. Assumption about the Possible Replacement of Interior Partitions during the Building Lifespan

1.5. Replacement of Interior Partitions during the Building Lifespan

1.6. Importance of Conducting This Study

1.7. Research Gap

2. Materials and Methods

2.1. LCA Method

2.1.1. Functional Unit, System Boundaries, and Data Sources

- (i)

- (ii)

- Production and installation stage: This stage involves acquiring the appropriate raw materials and transporting them to a manufacturing plant, followed by manufacturing the alternatives, transporting them to a construction site, and installing them in a building. The Ecoinvent v3.2 database installed on the SimaPro v9.1 software platform was used to model this stage [30]. Table 1 shows the Ecoinvent v3.2 products and processes used.

- (iii)

- Usage stage: This includes the replacement of an alternative based on its expected service life. Based on [32], Urlainis et al. [23] predicted the service life of the gypsum board, autoclaved aerated concrete blocks, and hollow concrete blocks under four service conditions: light, moderate, standard, and intensive. The authors defined these conditions across a range of negative occupancy-related factors that can lead to damage to the partitions and, therefore, require their replacement.

- (iv)

- End-of-life stage: This stage involves the demolition and transportation of materials/components to a disposal site. The contribution of this stage to the overall LCA of the considered alternatives was reported as being negligible by Ferrández-García et al. [11]. Therefore, the end-of-life stage was excluded from the system boundaries considered here.

2.1.2. Life-Cycle Inventory: Inputs of Materials and Processes

2.1.3. Life-Cycle Impact Assessment

2.2. Statistics

2.3. p-Value Analysis

3. Results and Discussion

3.1. Environmental Impacts

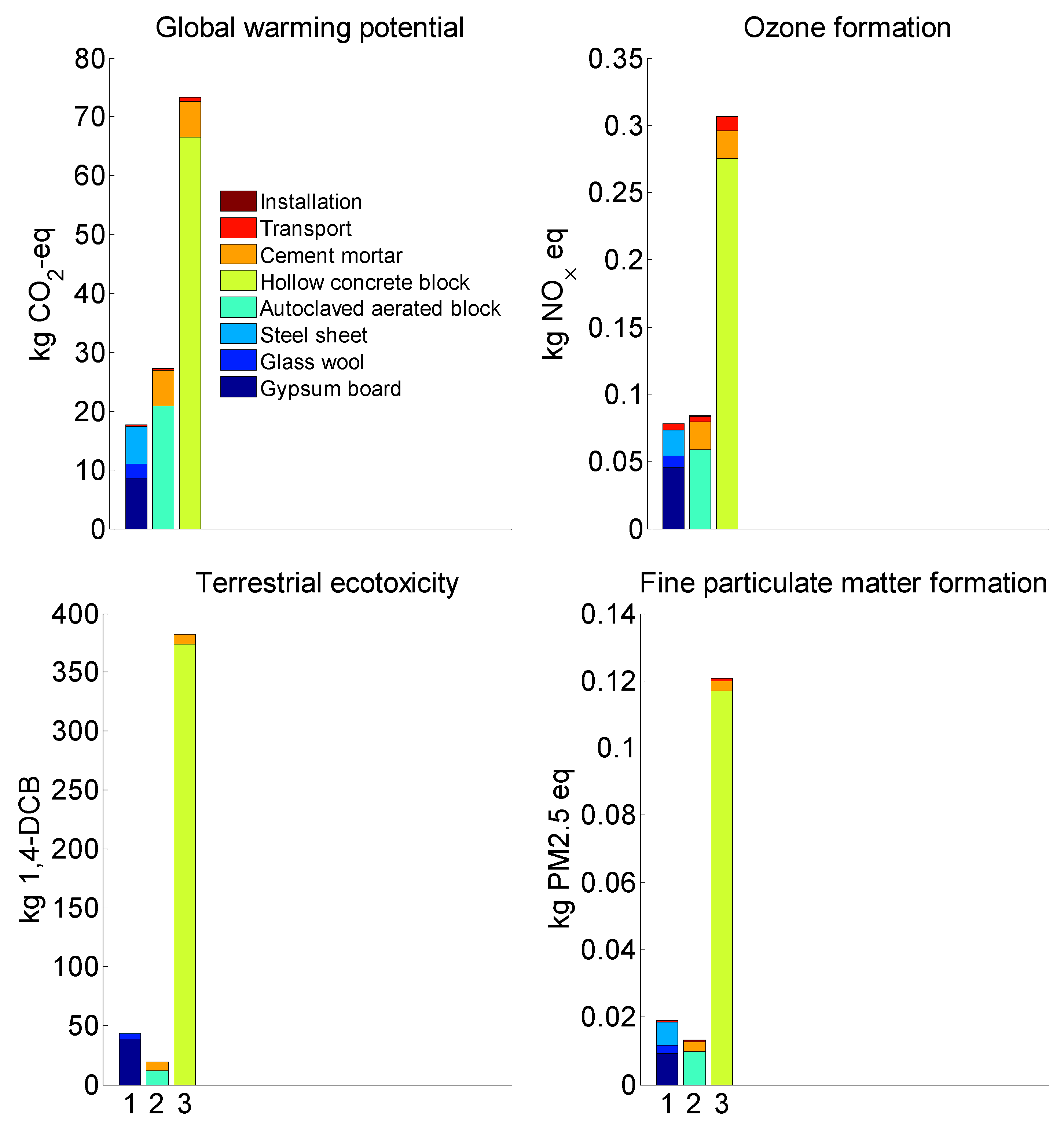

3.1.1. Light or Moderate Service Conditions

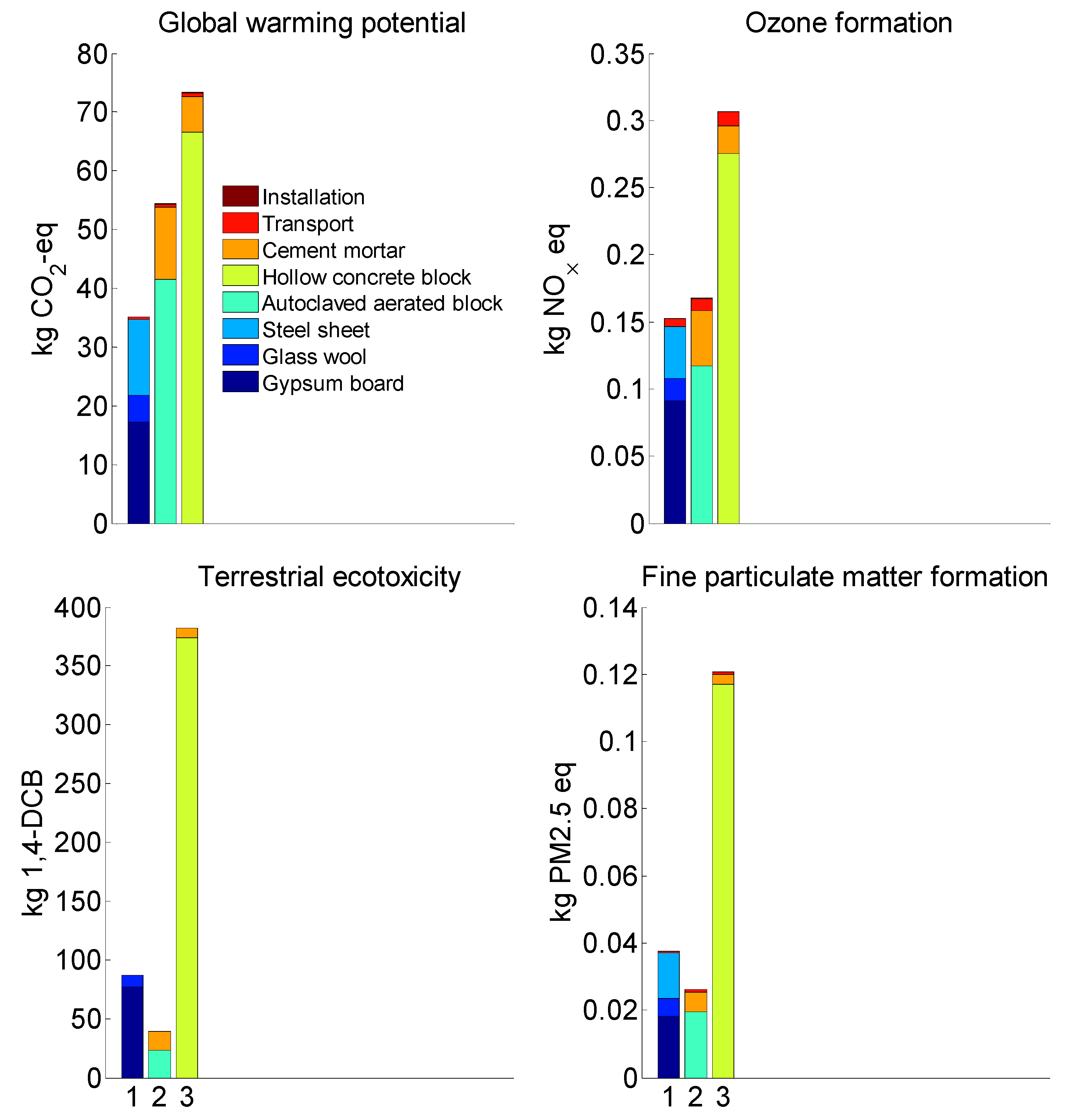

3.1.2. Standard Service Conditions

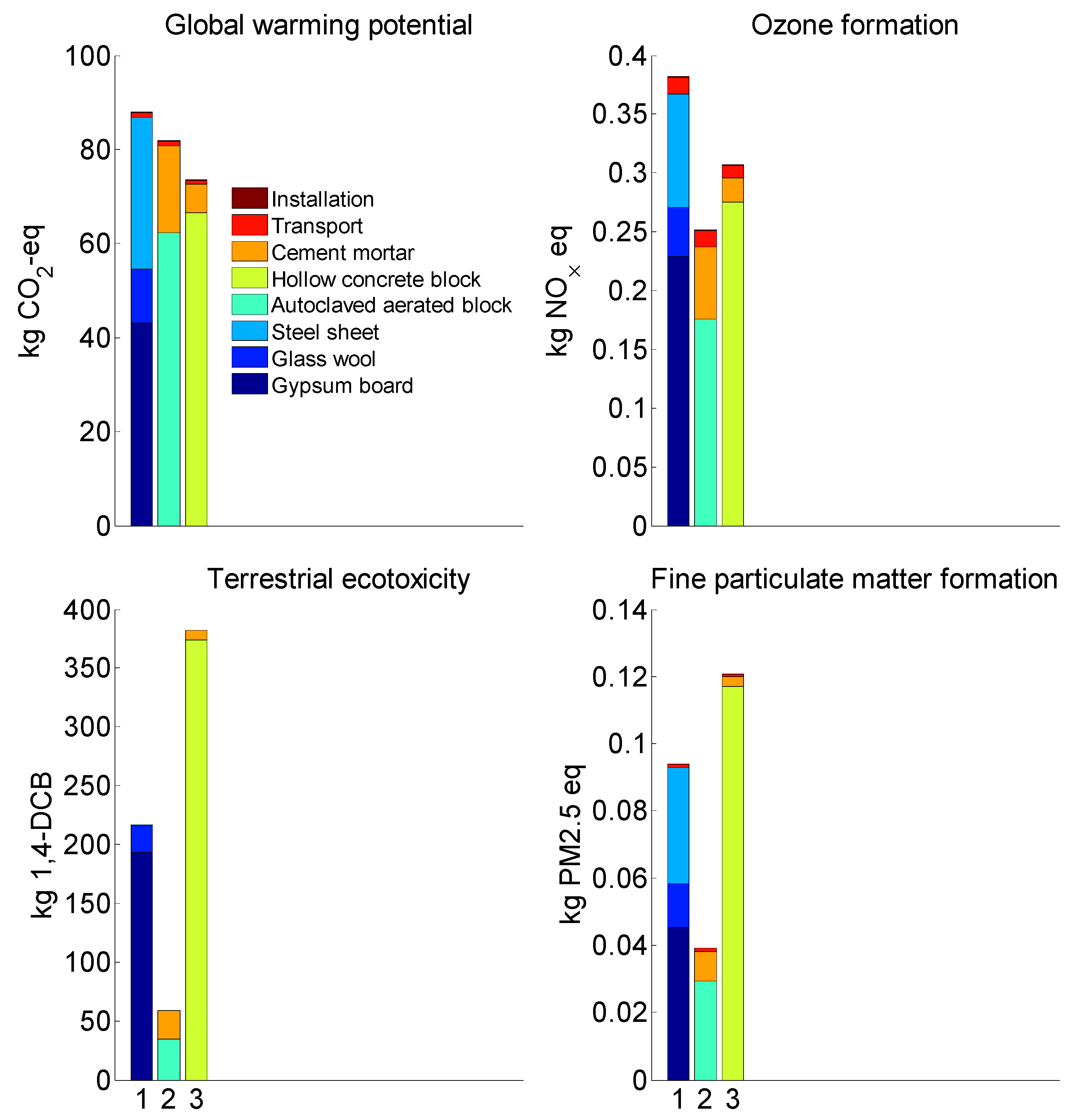

3.1.3. Intensive Service Conditions

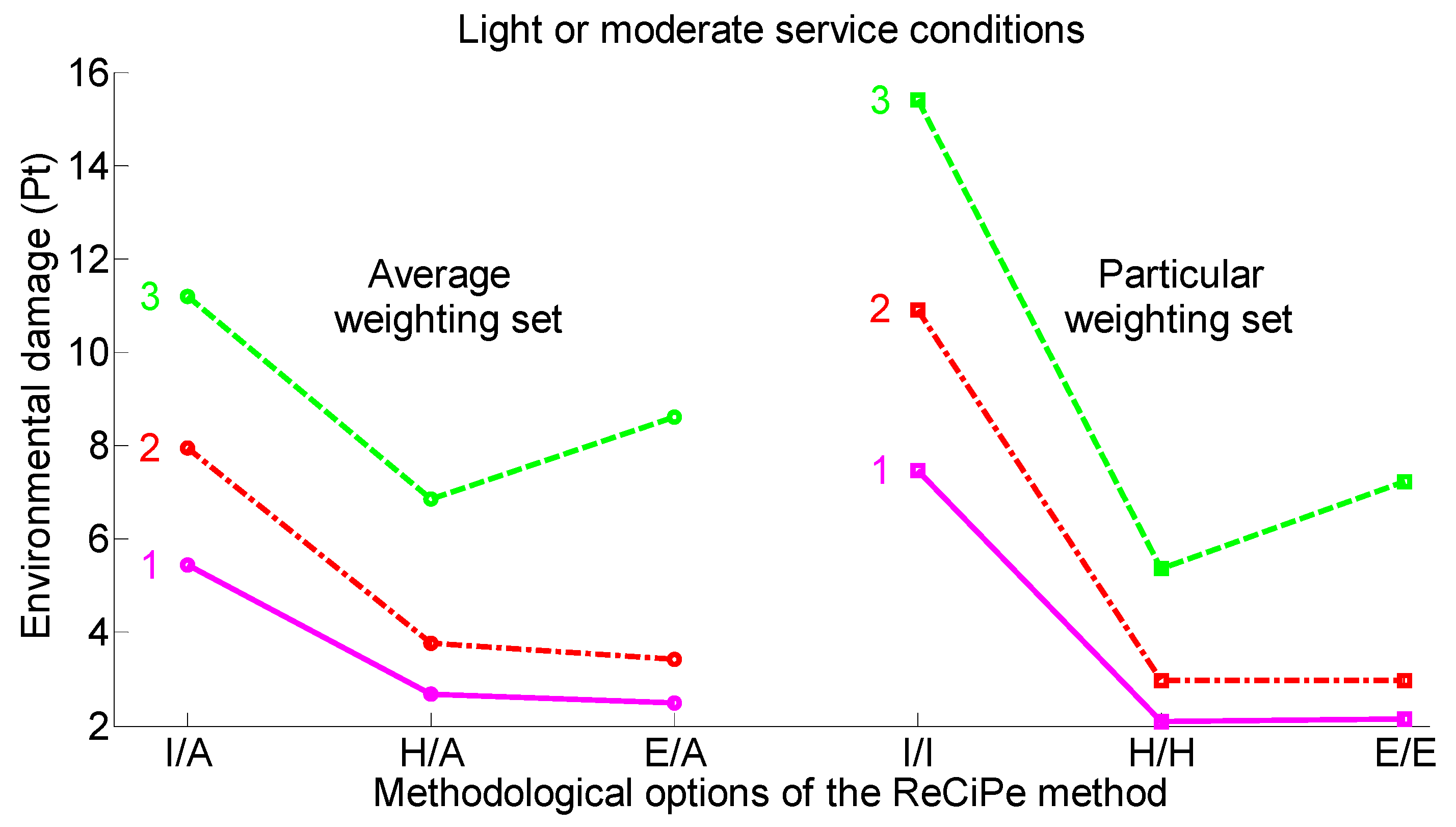

3.2. Environmental Damage: Six Methodological Options

3.2.1. Light or Moderate Service Conditions

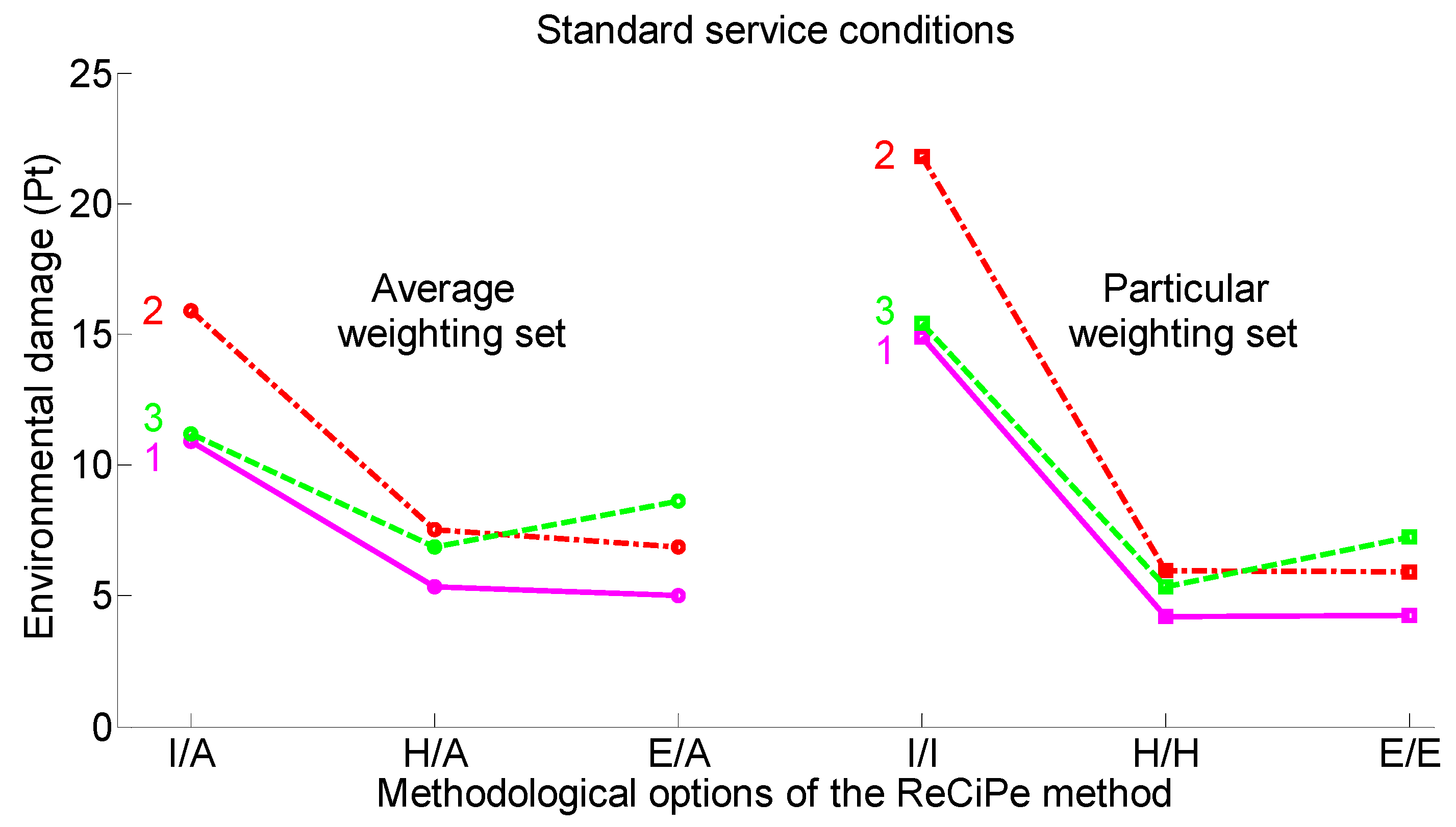

3.2.2. Standard Service Conditions

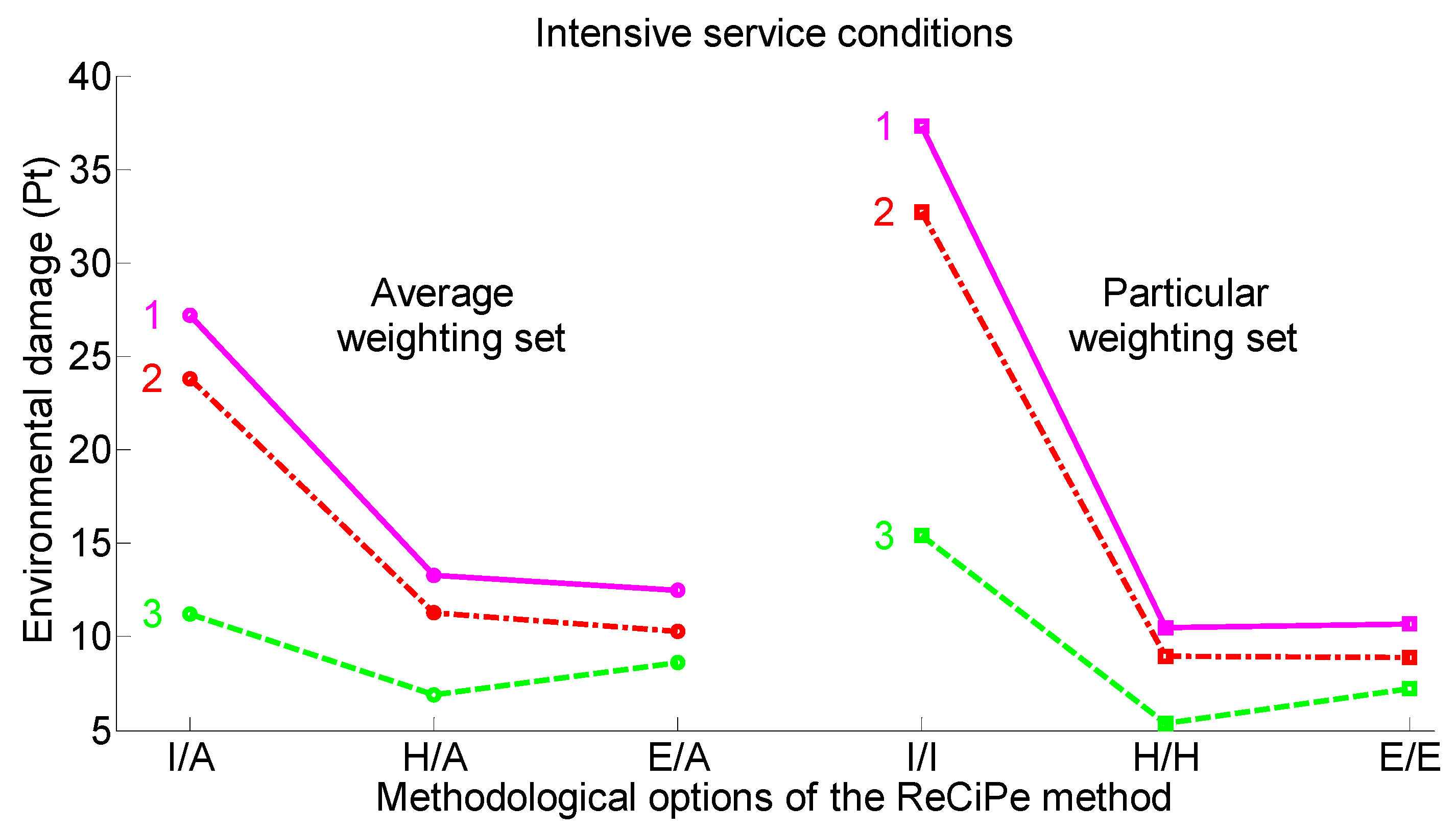

3.2.3. Intensive Service Conditions

4. Conclusions

- Light/moderate and standard service conditions: The ReCiPe midpoint results showed gypsum board to be the best alternative with the least global warming potential and ozone generation impact, while autoclaved aerated blocks were the best alternative with the least terrestrial ecotoxicity and fine particulate matter production. The results for the six methodological options of ReCiPe showed that gypsum board was the most environmentally friendly alternative.

- Intensive service conditions: The ReCiPe midpoint results showed that hollow concrete blocks produced the least global warming potential, while autoclaved aerated concrete blocks caused the least ozone generation, terrestrial ecotoxicity, and fine particulate matter production. The results for the six methodological options of ReCiPe showed that hollow concrete blocks were the most environmentally friendly alternative.

5. Limitations of This Study

6. Future Research Directions

Funding

Data Availability Statement

Conflicts of Interest

References

- Munaro, M.R.; Tavares, S.F. A review on barriers, drivers, and stakeholders towards the circular economy: The construction sector perspective. Clean. Responsible Consum. 2023, 8, 100107. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Goulouti, K.; Padey, P.; Galimshina, A.; Habert, G.; Lasvaux, S. Uncertainty of Building Elements’ Service Lives in Building LCA & LCC: What Matters? Build. Environ. 2020, 183, 106904. [Google Scholar]

- Brand, S. How Buildings Learn: What Happens after They’re Built; Viking Press: New York, NY, USA, 1994; 243p, ISBN 978-0-670-83515-7. [Google Scholar]

- Pushkar, S. Application of Life Cycle Assessment to various building lifetime shearing layers: Site, Structure, Skin, Services, Space, and Stuff. J. Green Build. 2015, 10, 198–214. [Google Scholar] [CrossRef]

- Silva, A.; de Brito, J.; Thomsen, A.; Straub, A.; Prieto, A.J.; Lacasse, M.A. Causal Effects between Criteria That Establish the End of Service Life of Buildings and Components. Buildings 2022, 12, 88. [Google Scholar] [CrossRef]

- Addis, W.; Schouton, J. Principles of Design for Deconstruction to Facilitate Reuse and Recycling; CIRIA: London, UK, 2004; ISBN 9780860176077. [Google Scholar]

- Mateus, R.; Neiva, S.; Bragança, L.; Mendonça, P.; Macieira, M. Sustainability assessment of an innovative lightweight building technology for partition walls—Comparison with conventional technologies. Build. Environ. 2013, 67, 147–159. [Google Scholar] [CrossRef]

- Pushkar, S. Design of Sustainable Buildings—Implementation of Multi-Objective Optimization. Ph.D. Thesis, Technion—IIT, Haifa, Israel, 2007. [Google Scholar]

- Samani, P.; Mendes, A.; Leal, V.; Guedes, J.M.; Correia, N. A sustainability assessment of advanced materials for novel housing solutions. Build. Environ. 2015, 92, 182–191. [Google Scholar] [CrossRef]

- Ferrández-García, A.; Ibáñez-Forés, V.; Bovea, M.D. Eco-efficiency analysis of the life cycle of interior partition walls: A comparison of alternative solutions. J. Clean. Prod. 2016, 112 Pt 1, 649–665. [Google Scholar] [CrossRef]

- Atienza, E.M.; Ongpeng, J.M.C. Environmental Impact and Cost Comparison of Different Partition Walls. Chem. Eng. Trans. 2022, 94, 691–696. [Google Scholar]

- Ortiz, O.; Pasqualino, J.C.; Díez, G.; Castells, F. The environmental impact of the construction phase: An application to composite walls from a life cycle perspective. Resour. Conserv. Recycl. 2010, 54, 832–840. [Google Scholar] [CrossRef]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp–lime wall constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Rivas-Aybar, D.; John, M.; Biswas, W. Environmental Life Cycle Assessment of a Novel Hemp-Based Building Material. Materials 2023, 16, 7208. [Google Scholar] [CrossRef] [PubMed]

- Bošković, I.; Radivojević, A. Life cycle greenhouse gas emissions of hemp-lime concrete wall constructions in Serbia: The impact of carbon sequestration, transport, waste production and end of life biogenic carbon emission. J. Build. Eng. 2023, 66, 105908. [Google Scholar] [CrossRef]

- Condeixa, K.; Haddad, A.; Boer, D. Life Cycle Impact Assessment of masonry system as inner walls: A case study in Brazil. Constr. Build. Mater. 2014, 70, 141–147. [Google Scholar] [CrossRef]

- Broun, R.; Menzies, G.F. Life cycle energy and environmental analysis of partition wall systems in the UK. Proc. Eng. 2011, 21, 864–873. [Google Scholar] [CrossRef]

- Condeixa, K.; Qualharini, E.; Boer, D.; Haddad, A. An Inquiry into the Life Cycle of Systems of Inner Walls: Comparison of Masonry and Drywall. Sustainability 2015, 7, 7904–7925. [Google Scholar] [CrossRef]

- Valencia-Barba, Y.E.; Gómez-Soberón, J.M.; Gómez-Soberón, M.C.; Rojas-Valencia, M.N. Life cycle assessment of interior partition walls: Comparison between functionality requirements and best environmental performance. J. Build. Eng. 2021, 44, 102978. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Schneider-Marin, P.; Harter, H.; Tkachuk, K.; Lang, W. Uncertainty Analysis of Embedded Energy and Greenhouse Gas Emissions Using BIM in Early Design Stages. Sustainability 2020, 12, 2633. [Google Scholar] [CrossRef]

- Urlainis, A.; Paciuk, M.; Shohet, I.M. Service Life Prediction and Life Cycle Costs of Light Weight Partitions. Appl. Sci. 2024, 14, 1233. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management Life Cycle Assessment Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 13315-1; Environmental Management for Concrete and Concrete Structures, Part. 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2012.

- SI 5 Part 1; Concrete Blocks: Blocks for Walls. The Standards Institution of Israel: Tel Aviv, Israel, 2003. (In Hebrew)

- SI 268; Autoclaved Aerated Concrete Masonry Units. The Standards Institution of Israel: Tel Aviv, Israel, 2017. (In Hebrew)

- SI 1490 Part 1; Gypsum Partitions and Linings: Boards. The Standards Institution of Israel: Tel Aviv, Israel, 1997. (In Hebrew)

- SI 1920 Part 2; Plaster: The Plastering System at the Site. The Standards Institution of Israel: Tel Aviv, Israel, 2002. (In Hebrew)

- PRé Consultants. SimaPro, version 9.1. 0.35; PRé Consultants: Amersfoort, The Netherlands, 2019.

- Israeli Electricity Sector—Annual Report 2021. Available online: www.gov.il/BlobFolder/generalpage/dochmeshek/he/Files_Netunei_hashmal_THE%20ELECTRICITY%20AUTHORITY%20_ANNUAL%20REPORT_2021.pdf (accessed on 18 April 2024).

- ISO 15686-2:2012; Buildings and Constructed Assets—Service Life Planning Part 2: Service Life Prediction Procedures. International Organization for Standardization: Geneva, Switzerland, 2012.

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Goedkoop, M.; Spriensma, R. The Eco-Indicator 99—A Damage Oriented Method for Life Cycle Impact Assessment; PRé Consultants: Amersfoort, The Netherlands, 2001. [Google Scholar]

- Silva, F.B.; Reis, D.C.; Mack-Vergara, Y.L.; Pessoto, L.; Feng, H.; Pacca, S.A.; Lasvaux, S.; Habert, G.; John, V.M. Primary Data Priorities for the Life Cycle Inventory of Construction Products: Focus on Foreground Processes. Int. J. Life Cycle Assess. 2020, 25, 980–997. [Google Scholar] [CrossRef]

- Thompson, M.; Ellis, R.; Wildavsky, A. Political cultures. In Cultural Theory; Westview Press: Boulder, CO, USA, 1990. [Google Scholar]

- Tang, M.; Miri, T.; Soltani, F.; Onyeaka, H.; Al-Sharify, Z.T. Life Cycle Assessment of Plant-Based vs. Beef Burgers: A Case Study in the UK. Sustainability 2024, 16, 4417. [Google Scholar] [CrossRef]

- Picquelle, S.J.; Mier, K.L. A practical guide to statistical methods for comparing means from two-stage sampling. Fish. Res. 2011, 107, 1–13. [Google Scholar] [CrossRef]

- Pushkar, S.; Yezioro, A. Life Cycle Assessment Meeting Energy Standard Performance: An Office Building Case Study. Buildings 2022, 12, 157. [Google Scholar] [CrossRef]

- Hurlbert, S.H.; Lombardi, C.M. Final collapse of the Neyman-Pearson decision theoretic framework and rise of the neoFisherian. Ann. Zool. Fenn. 2009, 46, 311–349. [Google Scholar] [CrossRef]

- Hurlbert, S.H.; Lombardi, C.M. Lopsided reasoning on lopsided tests and multiple comparisons. Aust. N. Z. J. Stat. 2012, 54, 23–42. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Italy 2023 Energy Policy Review. Available online: https://iea.blob.core.windows.net/assets/71b328b3-3e5b-4c04-8a22-3ead575b3a9a/Italy_2023_EnergyPolicyReview.pdf (accessed on 24 May 2024).

- Soroka, I. Building Materials—Properties and Uses Part I; Copyright © 1988 by I. Soroka; The Cement Foundation, Ministry of Industry and Commerce and the Technion Research and Development Foundation Ltd.: Haifa, Israel, 1989. (In Hebrew) [Google Scholar]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Conejo, A.N.; Birat, J.-P.; Dutta, A. A review of the current environmental challenges of the steel industry and its value chain. J. Environ. Manag. 2020, 259, 109782. [Google Scholar] [CrossRef] [PubMed]

- Liang, T.; Wang, S.; Lu, C.; Jiang, N.; Long, W.; Zhang, M.; Zhang, R. Environmental impact evaluation of an iron and steel plant in China: Normalized data and direct/indirect contribution. J. Clean. Prod. 2020, 264, 121697. [Google Scholar] [CrossRef]

- Pushkar, S. Life Cycle Assessment of Flat Roof Technologies for Office Buildings in Israel. Sustainability 2016, 8, 54. [Google Scholar] [CrossRef]

- Cordella, M.; Tugnoli, A.; Spadoni, G.; Santarelli, F.; Zangrando, T. LCA of an Italian lager beer. Int. J. Life Cycle Assess. 2008, 13, 133–139. [Google Scholar] [CrossRef]

- Laleman, R.; Albrecht, J.; Dewulf, J. Life cycle analysis to estimate the environmental impact of residential photovoltaic systems in regions with a low solar irradiation. Renew. Sustain. Energy Rev. 2011, 15, 267–281. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life Cycle Assessment in the Construction Sector: A Review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Masood, R.; Fang, Z.; Lim, J.B.P. A Comparative Study on the Life Cycle Assessment of New Zealand Residential Buildings. Buildings 2022, 12, 50. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Porras-Amores, C.; Villoria-Sáez, P.; Morales-Conde, M.J.; Flores-Colen, I. Characterization and performance of building composites made from gypsum and woody-biomass ash waste: A product development and application study. Constr. Build. Mater. 2024, 419, 135435. [Google Scholar] [CrossRef]

- Figueiredo, A.; Silva, T.; Gonçalves, M.; Samagaio, A. Application of Novel Phase Change Material Constructive Solution for Thermal Regulation of Passive Solar Buildings. Buildings 2024, 14, 493. [Google Scholar] [CrossRef]

- Diana, L.; Passarelli, C.; Polverino, F.; Pugliese, F. A Decision Framework for the Regeneration Awareness of Large-Sized Public Housing Using a Building Transformability Assessment: A Test Case in Italy (Latina). Buildings 2024, 14, 148. [Google Scholar] [CrossRef]

| Material/Process | Ecoinvent v3.2 Data |

|---|---|

| Gypsum board | Gypsum board, at plant/CH |

| Glass wool | Glass wool mat/CH |

| Steel sheet | Galvanized steel sheet, at plant/RNA |

| Autoclaved aerated block | Autoclaved aerated block, at plant/CH |

| Cement mortar | Cement mortar, at plant/CH |

| Hollow concrete block | Lightweight concrete block, at plant/CH |

| Transportation | Lorry transport; Euro 0, 1, 2, 3, 4 mix; 22 t total weight |

| Installation energy (coal) | Hard coal/ES |

| Installation energy (natural gas) | Natural gas/ES |

| Installation energy (PV) | PV/CH |

| Material/Component | Energy Consumption (kWh/m2) 1 | ||

|---|---|---|---|

| Gypsum Board | Autoclaved Aerated Block | Hollow Concrete Block | |

| Gypsum board | 0.0234 | - | - |

| Glass wool | 0.0338 | - | - |

| Steel sheet | 0.0037 | - | - |

| Autoclaved aerated block | - | 0.0160 | - |

| Cement mortar | - | 0.0103 | 0.0103 |

| Hollow concrete block | - | - | 0.1490 |

| Alternative | Service Conditions | |||||

|---|---|---|---|---|---|---|

| Light or Moderate | Standard | Intensive | ||||

| Service Life (Years) 1 | Replacement Rate | Service Life (Years) 1 | Replacement Rate | Service Life (Years) 1 | Replacement Rate | |

| Gypsum board | 47 | 0 | 27 | 1 | 11 | 4 |

| Autoclaved aerated block | >50 | 0 | 32 | 1 | 18 | 2 |

| Hollow concrete block | >50 | 0 | >50 | 0 | 38 | 0 |

| Material/Process | Service Conditions | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Light or Moderate | Standard | Intensive | |||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| Gypsum board (kg) | 24 | - | - | 48 | - | - | 120 | - | - |

| Glass wool (kg) | 1.5 | - | - | 3 | - | - | 7.5 | - | - |

| Steel sheet (kg) | 2.4 | - | - | 4.8 | - | - | 12 | - | - |

| Autoclaved aerated block (kg) | - | 50 | - | - | 100 | - | - | 150 | - |

| Cement mortar (kg) | - | 32 | 32 | - | 64 | 32 | - | 96 | 32 |

| Hollow concrete block (kg) | - | - | 165 | - | - | 165 | - | - | 165 |

| Transportation (t/km) | 2.7 | 4.1 | 9.9 | 5.4 | 8.2 | 9.9 | 13.6 | 12.3 | 9.9 |

| Installation energy (coal) (kWh) | 0.02 | 0.02 | 0.05 | 0.03 | 0.04 | 0.05 | 0.07 | 0.08 | 0.05 |

| Installation energy (natural gas) (kWh) | 0.04 | 0.07 | 0.16 | 0.08 | 0.13 | 0.16 | 0.21 | 0.24 | 0.16 |

| Installation energy (PV) (kWh) | 0.01 | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 | 0.02 | 0.03 | 0.02 |

| Alternative | GWP | OF | TE | FPMF |

|---|---|---|---|---|

| Gypsum board | 3rd | 3rd | 2nd | 2nd |

| Autoclaved aerated blocks | 2nd | 1st | 1st | 1st |

| Hollow concrete blocks | 1st | 2nd | 3rd | 3rd |

| Alternative | Gypsum Board | Autoclaved Aerated Blocks | Hollow Concrete Blocks |

|---|---|---|---|

| Gypsum board | X | 0.0025 | 0.0005 |

| Autoclaved aerated blocks | X | 0.0011 | |

| Hollow concrete blocks | X |

| Alternative | Gypsum Board | Autoclaved Aerated Blocks | Hollow Concrete Blocks |

|---|---|---|---|

| Gypsum board | X | 0.0027 | 0.0065 |

| Autoclaved aerated blocks | X | 0.0622 | |

| Hollow concrete blocks | X |

| Alternative | Gypsum Board | Autoclaved Aerated Blocks | Hollow Concrete Blocks |

|---|---|---|---|

| Gypsum board | X | 0.0105 | 0.0011 |

| Autoclaved aerated blocks | X | 0.0017 | |

| Hollow concrete blocks | X |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushkar, S. Life-Cycle Assessment of Lightweight Partitions in Residential Buildings. Buildings 2024, 14, 1704. https://doi.org/10.3390/buildings14061704

Pushkar S. Life-Cycle Assessment of Lightweight Partitions in Residential Buildings. Buildings. 2024; 14(6):1704. https://doi.org/10.3390/buildings14061704

Chicago/Turabian StylePushkar, Svetlana. 2024. "Life-Cycle Assessment of Lightweight Partitions in Residential Buildings" Buildings 14, no. 6: 1704. https://doi.org/10.3390/buildings14061704