Abstract

Implementing reverse logistics in the construction industry is considered a crucial method to achieve a circular economy. Despite a wealth of research focusing on improving reverse logistics systems, businesses still encounter challenges during the implementation process. Therefore, this study conducted a systematic literature review utilizing bibliometric methods to analyze 623 articles on reverse logistics in the construction industry published on Web of Science from 1995 to 2023. Additionally, a comprehensive review of 56 high-quality literature on obstacles to implementing reverse logistics in the construction industry and optimizing reverse supply chains was conducted. This review uncovered the current status and challenges of implementing reverse logistics in the construction industry and proposed potential solutions to address these issues. The main findings of this study include: (1) increasing academic interest in construction waste reverse logistics, with Chinese scholars leading the way and publications predominantly in environmental and construction journals, with limited coverage in logistics journals; (2) the primary obstacles to implementing reverse logistics in the construction industry lie in supply chain management, such as lacking deconstruction designs, incomplete recycling markets, difficulties in evaluating the quality of secondary materials, and insufficient supply chain integration; (3) proposing a framework for a construction industry reverse logistics supply chain ecosystem, aiming to establish a platform to facilitate online collection of construction waste, online transactions of secondary materials, end-to-end monitoring, and data analytics for consultation.

1. Introduction

In recent years, with increasing awareness about environmental protection and sustainable development, industries are vying to move toward green, low-carbon, and sustainable development, and the construction industry is no exception. During the whole life cycle of building materials, from extraction to the end of the final structure, the environment is adversely impacted [] because of the generation of a large amount of construction and demolition waste (CDW). CDW refers to the discarded soil generated by construction units, including new constructions, alterations, expansions, and demolitions of various types of buildings, structures, pipeline networks, etc. The waste generated from the process of decoration and renovation of houses by residents is also considered CDW. The construction industry generates approximately 50% of the global solid waste [] some large cities account for 10–30% of the total solid waste and the total generation rate of CDW in construction activities ranges from 38 to 43 kg/m2 []. In many countries and regions, the total CDW is high, for example, in Hong Kong, China, the total amount of CDW is in the range of 53,011 tons/day; in China and European regions, construction solid waste accounts for up to 30–40% of total solid waste and in the UK, more than 50% of the waste constitutes CDW []. Recycling rates for construction and demolition waste vary from region to region, ranging from 7 to 90 percent, with about 35 percent of construction and demolition waste worldwide going to landfills []. However, landfill space is limited, especially in densely populated regions, and the location of these deposits sometimes interferes with urban sprawl []. Thus, it is crucial to reuse waste and residual materials through recycling, reuse, and reprocessing. The network of recycling organizations and their processes and components are essential for ensuring the viability of CDW recycling. This organizational network and its processes and components involve reverse logistics (RL) []. By using RL to close the loop in the construction supply chain (SC), the economic and environmental sustainability of the construction industry can be effectively realized [].

RL is not the same as waste management, waste management focuses on the proper disposal of CDW in order to minimize negative impacts on the environment, whereas RL focuses on the flow of products with recycling value into the reverse supply chain (RSC), where the main output is an economic gain with consideration for the environment [,]. RL in the construction industry as a remedial measure, which is a process of giving “life” back to a building that has lost its value through renovation and reuse []. RL constitutes the core task of implementing a circular economy (CE) in the construction industry, which covers the final (closing) part of the closed SC of CE []. The definition of RL in the construction industry has not yet been harmonized by academics. Chileshe et al. [] defined the RL of a building as the process of transferring goods from their typical final destination by capturing value or ensuring proper disposal. Bao et al. [] defined an RL as a series of activities from the introduction of recyclable materials to the positive SC. Combined with the above discussion, this study defines RL in the construction industry as the entire process of collecting CDW from CDW production divisions for recycling, processing, remanufacturing, and re-selling to recapture the value of the CDW or ensure its proper treatment. This approach can help realize development that is socially, environmentally, and economically sustainable.

RSC is a relative concept to forward SC, which refers to the network chain system consisting of logistics, information flow and financial flow running activities from the upstream of the SC (suppliers) to the downstream (consumers) occurring between relevant interest groups []. RSC is a series of activities to transfer end-of-life, returned and repaired products from the downstream of the SC to the upstream of the SC, which involves the flow of logistics, information flow and financial flow []. Construction RSCs are categorized as open-loop and closed-loop. The open-loop structure mainly refers to the model in which CDW is not returned to the initial producer but is used in other enterprises (third-party producers) [], which is currently the dominant model adopted by enterprises and is also the type discussed in this paper. A closed-loop structure is a model that focuses on the circulation of construction materials from the place of production to the consumer and the transportation of CDW to the place of production, thus creating a closed SC of products [].

1.1. Advocating RL in the Construction Industry

Advocating RL in the construction industry can bring significant benefits to society by helping in achieving economic, environmental, and social sustainability goals.

Economic dimension. RL empowering CE in the construction industry from multiple perspectives []. CE in the construction industry is to maximize economic and social benefits through the circular process of “construction raw materials-construction body—CDW—secondary materials”. The implementation of RL is the basis for the realization of the “CDW—secondary materials” link. Effective RL can reduce the cost of the recurring process [,], promote the circular flow of resources, and promote the realization of the circular economy. The development of the RL industry also contributes to a certain extent to GDP growth []. No RL has hindered the waste of materials and resources during the building life cycle [] and has also triggered a rapid surge in the second-hand building material markets. The high demand potential of this market proves the sustainability of RL practices [].

Environmental dimension. Ortiz et al. [] conducted a comparative analysis of CDW using three treatment options: landfill, recycling, and incineration, the recycling option has been considered the most superior under the indicators taken into account, including environmental performance assessment, followed by incineration and landfill. Implementing RL to recycle and remanufacture CDW prevents as much waste as possible from being sent to landfills. This helps to reduce waste, minimize resource consumption and benefit the environment. The development of recycling technologies, such as the extraction of low porosity sand from CDW [] and the processing of construction wood waste that may be contaminated with magnesium phosphate cement into rapid prototyping cement-bonded particle boards [] helps to reduce the exploitation of natural resources.

Social dimension. CDW contains toxic and hazardous substances [], including mainly construction materials such as construction glues and paints. These materials do not easily undergo biodegradation due to their complex composition. They also contain harmful heavy metal components. Thus, directly disposing of these wastes in landfills without proper treatment can lead to groundwater contamination, potentially harming the health of neighboring residents as well as flora and fauna in the vicinity. In this context, the implementation of RL in the construction industry reflects the attempts to fulfill the environmental expectations of customers and society []. With the introduction of RL, companies have been able to enhance their green image and reputation []. This business philosophy, in turn, has endowed the companies with greater competitiveness and helped them achieve a prominent position in the market. RL-related industries also highlight the potential for local employment [], thus providing a boost to sustainable development in society.

1.2. Research Objectives

Despite the aforementioned and well-recognized advantages of implementing RL in the construction industry, the implementation of RL in many countries and regions is hindered by certain factors. Currently, many scholars have systematically reviewed RL and supply chain management (SCM), and drawn valuable conclusions from different perspectives. For instance, Aryee and Adaku [] fill a gap in systematic scientific research on RL through bibliometric and content analysis, uncovering six critical themes: importance, drivers, implementation resources, practices, empirical studies, and mathematical modeling, via qualitative analysis. Detwal et al. [] research on metaheuristic methods, emphasizing its importance in promoting the realization of circular economy in dealing with SC optimization issues. Moosavi et al. [] research shows that blockchain technology can improve transparency, traceability, efficiency, and information security in SCM, but empirical research in this area still needs more exploration. Moosavi et al. [] study examines the impact of the COVID-19 pandemic on SC performance, emphasizing resilience and sustainability as key themes in SC research. However, these studies have not focused on the construction industry. Given the complexity and uniqueness of RL in construction, a systematic literature review on RL and RSCM in the construction industry is essential.

This study uses a systematic literature review approach to summarize the progress of existing research and explore the future research agenda for the sustainable development of RL in the construction industry from a global perspective. This study aims to answer the following questions: (1) What are the current status and trends of research on RL in the construction industry? (2) What are the barriers to implementing RL in the construction industry? (3) How to realize the sustainable development of RL in the construction industry?

The article is structured as follows: Section 2 describes the methodology of the article, as well as the literature dataset sources and the technology roadmap for this paper. Section 3 presents the analysis of bibliometric findings, including publication volume, sources of publication, countries, author collaboration networks, and keyword co-occurrence, addressing the first question of our paper. Section 4 is divided into three parts. Section 4.1 identifies the obstacles to implementing RL in the construction industry, addressing the second question of the paper. Section 4.2 comprehensively reviews existing research on optimizing the RSC in the construction industry from the perspectives of “material flow, financial flow, and information flow”, identifying gaps in current research and proposing possible future research directions. Building on this analysis, Section 4.3 proposes a potential solution: the concept model of a “Construction Reverse Logistics Supply Chain Ecosystem”. Section 4.2 and Section 4.3 address the third question of our paper.

2. Materials and Methods

Web of Science (WoS) databases are widely used for bibliometric analysis and visualization of scientific literature due to their comprehensive, systematic, and authoritative features []. Compared to other databases, it is able to download complete citation records as “consistently formatted records. Provides researchers with more consistent and standardized records and better graphical displays in citation analysis []. Based on the definition of RL in the construction industry, this study searched the WoS database by using the following keywords: “building projects” OR “construction” OR “edifice” OR “architectural” OR “building materials” OR “construction waste” OR “construction site” OR “construction business” OR “architectural engineering”. These keywords were used to limit the scope of the construction industry. To limit the scope of RL, the following keywords were used: “reverse logistics” OR “reverse supply chain” OR “closed-loop logistics” OR “recycling logistics” OR “waste logistics” OR “waste transportation” OR “waste recycling”. Studies published in SCI-EXPANDED and SSCI-indexed journals between 1 January 1995 and 13 April 2023 were searched; Original articles and Reviews were included, and those published in language other than English were excluded. Based on the aforementioned criteria, a total of 781 documents were retrieved from the WoS database. After excluding irrelevant field articles, 623 documents were retained for this study.

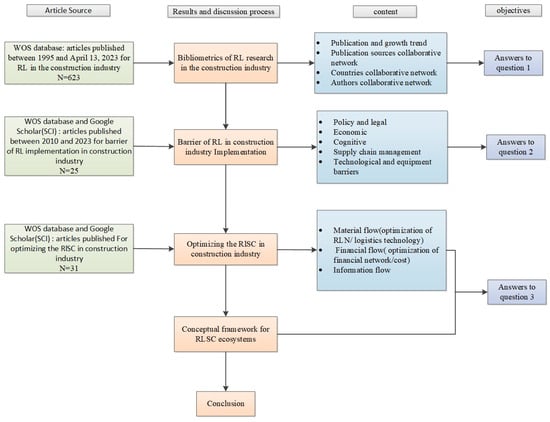

For a comparative analysis with the themes of “green building” and “reverse logistics”, this study searched 2956 and 3058 documents, respectively, based on the same criteria. Bibliometric analysis was carried out using the VOS viewer tool. Given that the quantitative literature provides limited information, this study adopted a “snowballing” approach to screen high-quality literature for a detailed qualitative analysis. The deconstructed arrangement of the results and discussion sections of this paper is shown in Figure 1.

Figure 1.

The research roadmap.

3. Results

3.1. Publication and Growth Trend

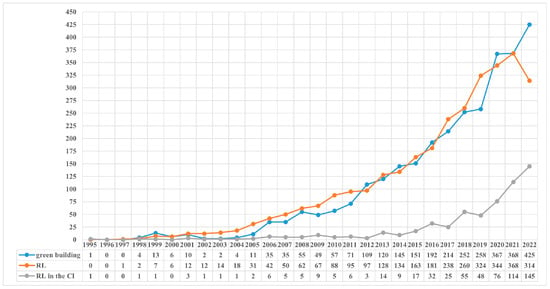

The number of publications reflects considerable research interest in RL in the construction industry at a given time, and it can predict future research trends. As shown in Figure 2, between 1995 and 2012, only a few scholars focused on RL in the construction industry, resulting in the number of publications per year being less than 10. However, from 2013 to date, there has been a gradual and consistent increase in scholarly interest in this domain.

Figure 2.

1995–2022 annual distribution of journal articles.

The research development trends in the fields of RL in the construction industry and “green building” and “RL” are basically consistent, with both exhibiting an upward trend. However, the development speed of RL and green buildings has been higher than that of RL in the construction industry. Specifically, research interest in the RL and green building fields has been increasing since 2005, whereas research on RL in the construction industry field did not show a clear upward trend until 2013. This discrepancy is justified to some extent, mainly because of the relative lag that tends to exist in segmented research. Because of the surge in the number of RL and green building studies, the year 2013 became a turning point for research on RL in the construction industry, marking an increase of approximately 32% in RL-related publications and 10% in green building field research in 2013, compared to that in 2012. Together with the foundation of RL and green building development in the previous period, it has provided suitable opportunities for building RL research. Based on the number of publications related to RL in the construction industry per year as well as the development trend of RL and green building, building RL-related research is anticipated to gain considerable interest in the future.

3.2. Publication Sources, Countries and Authors Collaborative Network

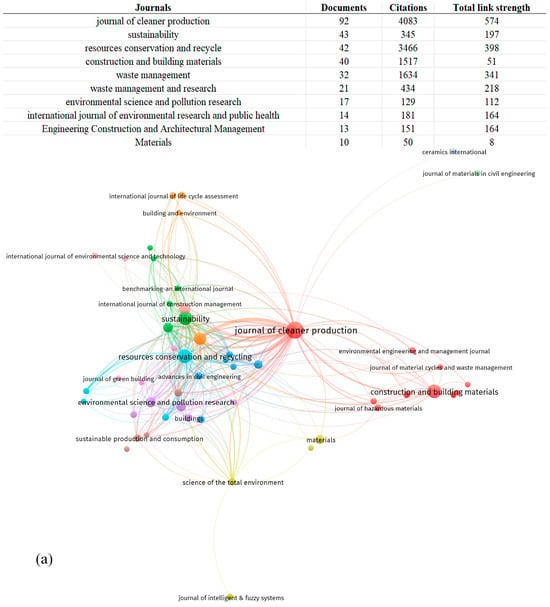

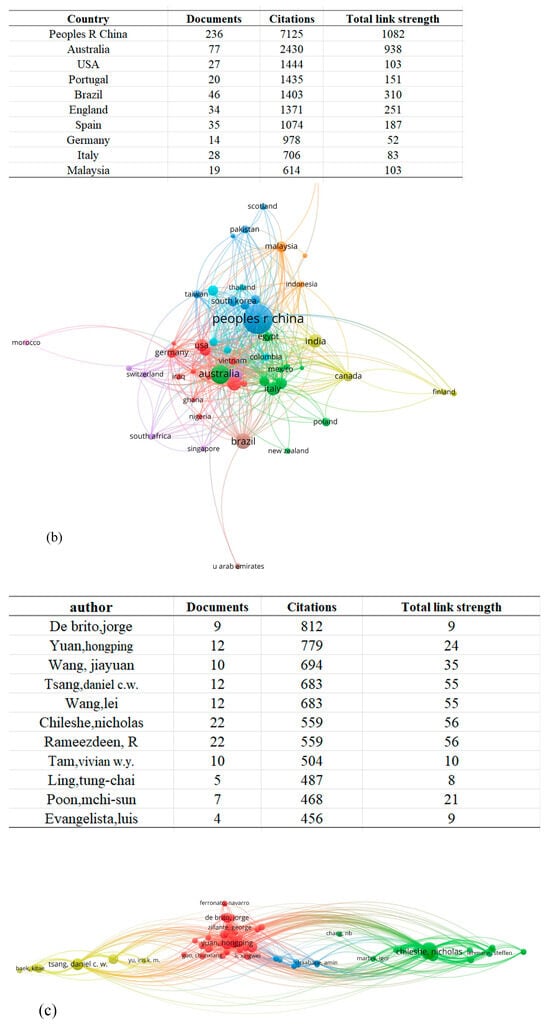

Each node in the VOS visualization graph represents a piece of literature, the larger the node represents the larger number of articles, the distance between the nodes represents the closeness of the relationship between the literature, and the connecting line between the nodes represents the number of co-citations of the two pieces of literature, and the thicker it is, the more co-citations are indicated.

As shown in Figure 3a, The top five journals in terms of publications are these journals: Journal of Cleaner Production (92 articles and 4083 citations), Sustainability (43 articles and 345 citations), Resources Conservation and Recycle (42 articles and 3466 citations), Construction and Building Materials (40 articles and 1517 citations), and Waste Management (32 articles and 1634 citations). The number of articles published in the field of “RL” under the same search criteria was highest in the leading journals related to logistics, such as Operations Research Management Science, Management, Engineering Industrial, and Environmental Sciences. Management Science, Engineering Industrial, and Environmental Sciences are the mainstream journals related to logistics. The journals are mostly in the field of environmental protection and construction, while few journals in the field of logistics deal with RL of CDW.

Figure 3.

(a) Publication sources collaboration network. (b) Countries collaboration network. (c) Authors Collaboration Network.

China is the country with the highest number of publications, the most citations and the most frequent cooperation with other countries, followed by Australia. As shown in Figure 3b, the country with the largest number of publications was China (236 articles with 7125 citations and a total link strength of 1082), followed by Australia (77 articles with 2430 citations) with a total link strength of 938. Brazil was ranked third, with 46 articles, 2430 citations, and a total link strength of 310. As can be seen from the network of national collaborations, research on RL in construction has been conducted on a global scale. The top ten countries in terms of the number of publications are all developed countries, except for China, Brazil and Malaysia, which are developing countries with better economic development.

The study visualized the author collaboration network, revealing that the Portuguese author De Brito, Jorge, stands out as the most cited author with 812 citations, leading in terms of referenced publications. Second in rank is the Chinese author Yuan, Hongping (12 articles and 779 citations), followed by another Chinese author, Wang, Jiayuan (10 articles and 694 citations). In Figure 3c, it is evident that Chileshe, Nicholas, and Rameezdeen, R have the largest node sizes, their prolific publication record with 22 articles.

The formation of research teams in the field of RL in construction is apparent, with De Brito, Jorge, Yuan, Hongping, Wang, Jiayuan, Chileshe, Nicholas, Tam, Vivian W.Y., and Poon, Mchi-sun spearheading these efforts. Their affiliations include Universidade de Lisboa, Guangzhou University, Shenzhen University, University of South Australia, The University of Sydney, The Hong Kong University of Science and Technology, and The Hong Kong Polytechnic University. Additionally, there are scattered scholars like Ferronato, Navarro, and Chaabane, Amin, who delve deeper in-to academic research within the field of construction industry RL, although their research output has not yet reached a substantial scale.

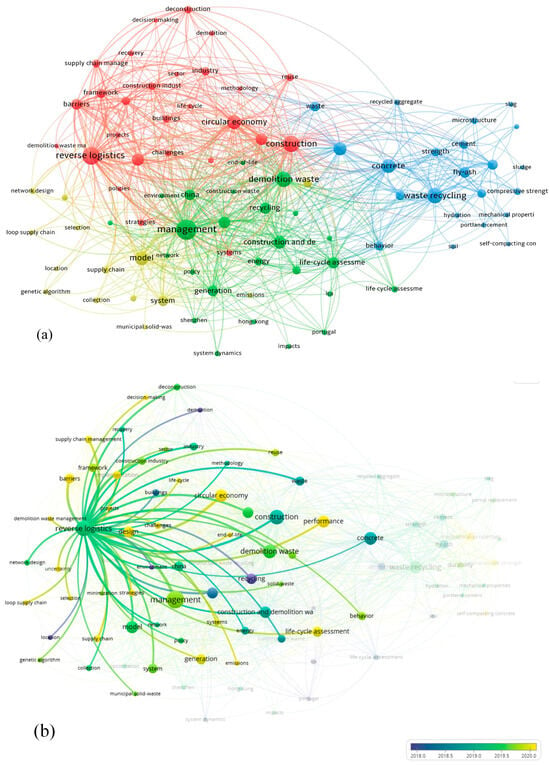

3.3. Keywords Co-Occurrence Analysis

Keywords accurately reflect the hotspot of research on RL in the construction industry. Therefore, we clustered the keywords and analyzed them using all keywords in the keyword covariance; the minimum number of occurrences of a keyword was selected to be 10. The clustering results are shown in Figure 4a. One of the nodes represents a keyword, and the larger the node, the higher the frequency of the keyword. The degree of association between keywords is positively correlated with the distance between nodes, and the closer the distance, the greater the association. There are five main themes in the current RL research: (a) red cluster- circular economy (framework, barriers, life cycle); (b) green cluster—CDW management (life cycle assessment, management, recycling); (c) yellow cluster—models (network design, optimization, systems); (d) blue cluster—construction waste resource utilization (performance, concrete, recycled aggregates).

Figure 4.

(a) A co-occurrence mapping of research hotspots. (b) Co-occurrence keywords overlay visualization.

The lighter the color of the node in the time zone distribution graph, the later the keyword appears. The time zone distribution map in Figure 4b shows that the current phase of research on the topic of RL is directed toward exploring the barriers to development, as well as seeking solutions, emphasizing the dimensions of life cycle assessment, CE, performance, barriers, and SCM.

4. Discussion

4.1. Barriers to RL Implementation

To identify the main barriers to the implementation of RL, we used the keyword “barriers”, which yielded 25 highly cited papers aimed at exploring barriers to the implementation of RL, published after 2010.

The papers selected from the pool of studies were mainly utilized literature reviews, case reports, focus groups, and questionnaire research to identify barriers. Some of the literature applied modeling methods to identify barriers to the implementation of RL. Rameezdeen et al. [] used a cloud-based application for quantitative coding to process qualitative data. Nikmehr et al. [] developed a model to map the association between major factors affecting CDW at the project, industry and national levels for identifying the factors affecting CDW management in Iran []. Pimentel et al. [], applied a combined interpretive structural modeling (ISM) and Matrices d’Impacts cross-multiplication appliqúe a classmate (MICMAC) approach to identify barriers to the implementation of RL in the Portuguese construction industry. The introduction of modeling offers certain advantages because it can help compensate for the subjectivity deficiencies existing in the traditional research methodology and improve the scientific validity and credibility of the study. Future research can use more advanced mathematical models to identify RL barriers.

The ease of RL implementation in construction is closely related to the economy, policy, environmental protection willingness, and other aspects of a country. Most studies on the implementation of RL are from either developed countries or developing countries with high economic development levels. Therefore, studies exploring barriers to the implementation of RL in the construction industry in countries with low economic levels are warranted. This can help assess the intention of the construction industry to implement RL in countries with low economic levels. Specific data are shown in Table 1.

Table 1.

Summary of the methodology and scope of the literature study.

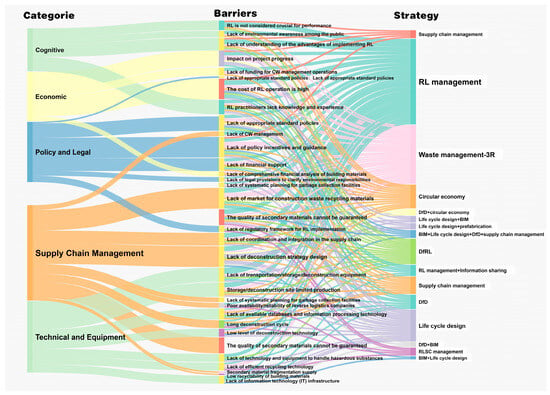

Hosseini et al. [] asserted that barriers to the implementation of RL in the construction industry are either industry-specific or organizational. Chileshe et al. [] classified the barriers as being intra- or extra-organizational and analyzed them. In the present study, based on a literature review, we classify the major barriers into five categories: (1) policy and legal barriers, (2) economic barriers, (3) cognitive barriers, (4) supply chain management barriers, and (5) technological and equipment barriers, totaling 27 barriers; the frequency of these barriers was determined. A Sankey diagrams were drawn (Figure 5).

Figure 5.

Main barriers to the implementation of in the co RL construction industry.

As in Figure 5, Sankey diagram, the leftmost is the different barrier dimensions, the middle one is the specific barriers, and the rightmost is the solution strategies provided in the literature. The width of the connecting lines indicates the flow, and it is clear from Figure 5 that the most significant barriers to the implementation of RL for CDW come from the SCM dimension, where the lack of deconstructive design and the lack of a market for recycled materials from CDW are the most significant issues, and uncertainty about the quality of secondary materials and the lack of coordination and integration in the SC are also of concern. Secondly, from the technology and equipment dimension, where the main barriers are the limited production of storage/deconstruction sites, the lack of transportation/storage/deconstruction equipment, and the lack of available databases and information processing technologies. In addition, the most prominent barriers in the policy and legal, cognitive, and economic dimensions are the lack of policy incentives and guidance, the lack of knowledge and skills to implement RL, and high RL costs.

RL management, SCM, the 3Rs of waste management, circular economy, and total life cycle design are the main solutions offered. Compared to the previous articles, the recent articles mainly advocate the combination of multiple strategies, such as using a combination of the above strategies or combining one strategy with BIM.

4.1.1. Policy and Legal Barriers

The development and operations of RL in the construction industry are constrained by the laws, policies, and other regulations formulated by the government, such as secondary material quality certification, conditions for registration, enterprise certification and licensing, financial subsidies, and tax policies. As shown in Figure 5, the most frequently mentioned factor is a lack of policy incentives and guidance in the policy and rule of law barriers [,,]. Due to the special characteristics of the construction industry, such as long-life cycle and complex SC, highly comprehensive policy support is needed to guide the standardization and effective implementation of RL []. The lack of clear policy incentives and guidance may make the direction unclear for companies and render them unmotivated []. Although financial support is pivotal to the implementation of RL in the construction industry, the level of national or regional financial support has been considered insufficient in many countries such as Brazil, Portugal, and China [,,]. Furthermore, lax monitoring strategies may lead to the occurrence of some illegal handling and dumping of CDW and increase the difficulty of responsible parties not taking responsibility [,].

4.1.2. Cognitive Barriers

Policies are key external factors that guide enterprises to implement RL and can influence their behavior through incentives and constraints. Intrinsically, the perception of enterprises is the major factor for RL implementation. However, many challenges are encountered in the implementation of RL. Lack of public awareness of environmental protection [] may weaken support for RL policies and measures, whereas the lack of corporate awareness about the advantages of RL [] may lead to missed opportunities for resource recycling and reuse. The perception of RL as a secondary business performance [] may lead to its neglect in decision-making about business operations. The lack of RL expertise within firms [] may limit its effective and practical implementation.

4.1.3. Economic Barriers

Businesses generally prioritize making a profit, and therefore, economic factors play a crucial role in RL implementation. Among these, high operating cost is the main challenge that hinders the development of RL; it adversely affects the motivation of enterprises to adopt RL []. The high cost of building RL operations [] is a crucial reason for the scale-up being challenging, especially in small buildings such as small businesses and self-built houses. Many scholars believe that the implementation of RL may affect the project schedule. The lack of funding for CDW operations [] makes it challenging for many firms to sustain the deconstruction business. Moreover, the lack of a comprehensive financial analysis of construction materials [] can decrease the willingness of construction companies to use recyclable building materials, as the cost of recyclable materials tends to increase.

4.1.4. Supply Chain Management Barriers

Challenges can also arise in a SC, particularly in the management aspects. The closed-loop SC for construction materials should be considered from the beginning of building design until the reintroduction of secondary materials into the market to close the loop. Many factors can lead to SC interruptions or delays, as shown in Figure 5. Among these, the quality of secondary materials and consumer distrust in the quality of secondary materials have received more attention from scholars [,,]. More than half of researchers have considered these factors to be the most accountable for the lack of a market for recycled materials from CDW. The other factor is the inconsistent supply of secondary materials []. A large number of construction materials are required in a construction project, and the fragmented supply of secondary materials may result in an insufficient supply of materials, potentially affecting the progress of the project and leading to other problems. Therefore, even if secondary materials have obvious price advantages, construction contractors tend to choose raw material suppliers with a stable supply to mitigate the issues of poor quality and project progress.

Furthermore, lack of deconstructive design, which refers to the lack of consideration of future dismantling and material reuse in building design, can lead to problems such as poor recyclability, high deconstruction costs, and low resourceful reuse of CDW. Thus, planning for recycling processes from the architectural design stage is crucial to implement 3R (reduce, recycle, reuse) waste management; however, appropriate deconstructive design strategies are lacking [,,,,].

Challenges are also encountered in SC coordination and integration, which are related mainly to information sharing and resource integration [,] the lack of an effective information-sharing mechanism leads to a lack of close connection among the various links, affecting the efficient operation of the SC. It is noteworthy that in the raw material procurement stage at the front end of the SC, raw materials play a decisive role in the recycling value of secondary materials. Therefore, implementing green procurement strategies to obtain more sustainable and environmentally friendly raw materials at the source is crucial for the smooth operation of reverse logistics. However, in Iran, among other places, there are many challenges and obstacles to achieving green procurement, including a lack of awareness about lifecycle cost assessment, high costs, and limited supplier capabilities [].

Owing to the insufficient integration of resources, the problem of fragmentation is encountered in the process of the recycling and reuse of CDW, hindering the smooth promotion of RL. The long deconstruction cycle of RL in the construction industry results in unfavorable outcomes such as resource waste, environmental impact, space occupation, obstruction of construction project schedules, and economic loss []. The lack of systematic planning for waste recycling facilities [,] has led to inadequate consideration of later operating costs at the beginning of the recycling facility setup, which increases the complexity of management and operation, thus affecting the efficiency and effectiveness of RL. Presently, CDW transportation in the RL process requires third-party logistics. However, only a few third-party logistics companies are engaged in CDW transportation, which leads to insufficient availability of RL. In addition, some of these companies may have low productivity and thus may resort to illegal dumping, resulting in higher environmental treatment costs []. Moreover, the reliability of some companies is doubtful.

4.1.5. Technical and Equipment Barriers

Technical and equipment barriers refer to the lack of necessary technical and equipment support for implementing RL; these barriers interfere with the successful implementation of RL tasks and are characterized mainly by inferior technology, outdated equipment, and thus low operational efficiency.

Advanced technology and well-equipped facilities are instrumental for companies to reduce costs and increase efficiency. However, the construction industry still lacks transportation, storage, and deconstruction equipment [], efficient recycling technologies [], sufficient information technology infrastructure, and databases and information processing systems for RL []. In addition, fewer analysis and treatment technologies are available [] and deconstruction technologies do not meet the requirements of CDW remanufacturing []. These factors prevent the effective use of modern technologies and facilities, resulting in higher costs for the treatment and reuse of waste. The lack of support from specialized facilities in handling large and complex wastes may lead to safety issues in the workplace []. Specifically, technology and equipment to handle hazardous substances are lacking; improper handling of these hazardous substances may cause the pollution of soil, water, and air, negatively impacting the surrounding inhabitants and ecosystem []. Limited storage and deconstruction sites are also a major problem in many countries or regions, and superior technologies and facilities are needed to improve the efficiency of CDW disposal, shorten the deconstruction cycle, and reduce the space occupied [].

4.1.6. Barrier Resolution Strategies

The deconstruction strategy is considered valuable for CDW management and plays a pivotal role in the RL process. In deconstruction, a building or structure is subjected to selective dismantling and its materials are removed prior to demolishing the structure, avoiding simultaneous dismantling of the whole structure and facilitating dismantling in the reverse order of how it was constructed. The deconstruction strategy focuses on the end-of-life-cycle building demolition phase, and deconstructing a building allows the value of the materials constituting the building to be retained compared with mechanical dismantling, facilitating the re-utilization of materials and effective recycling, leading to higher economic benefits []. The deconstruction design steps include demolition, demolition methods, and material recycling strategies. Deconstruction enables the recirculation of items to be used directly in other construction applications, thereby reducing the amount of waste sent to landfills [].

The 3R CDW management program in the construction industry focuses on reducing the generation of waste at the source, recycling, sorting, and processing CDW to maximize reuse, and reusing the waste to achieve a CE. To reduce production at the source, a common strategy is to maximize the use of recyclable and easily deconstructible materials during the construction phase [] and use prefabricated parts, thereby effectively reducing the generation of waste during demolition [].

According to the life cycle management concept, CDW disposal is considered from the design stage to effectively improve the recyclability and convenience of recycling []. Full life-cycle design combined with building information systems (BIMs) can help identify and categorize building materials, sorting them into those needing recycling and special treatment, thereby making their handling more effective during the demolition phase [].

RL management involves the supervision of the whole process ranging from recycling, reuse, and remanufacturing of CDW until the reintroduction of secondary materials into the secondary materials market []. It covers all activities from the end of a product’s life cycle to the consumer end, aiming to minimize the amount of direct landfill, reduce resource waste, mitigate environmental hazards, and improve resource reuse. For RL management, SC thinking is employed [,], e.g., a coordinated approach to the UK construction SC for creating a database of supplier/reuse component availability to improve reuse rates.

The literature review indicates that the barriers to SCM are more prominent at this stage globally, and to overcome them, the use of RSC management is an important agenda for future research.

4.2. Optimizing the RLSC

4.2.1. Optimization of Material Flow

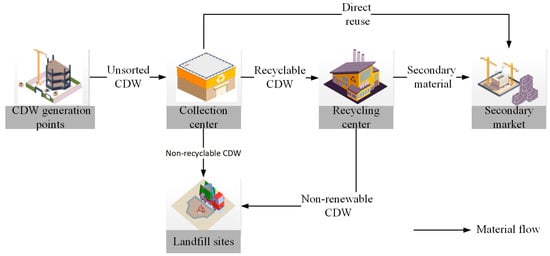

RLSC material flow refers to the entire process from the generation of CDW to re-entry into the secondary material market.

A four-tier RSC material flow network is a typical model, with waste generation stations, transfer stations, waste treatment plants, and consumer markets being the major elements [,].

As shown in Figure 6, the waste generation station is the starting point of material flow, where contractors can choose between two modes of sorting and recycling: on-site and off-site. Contractors generally tend to prefer off-site or process-site CDW sorting over on-site sorting and recycling []. Therefore, constructing transfer stations (collection centers), conducting primary sorting and processing at collection centers, sending non-recyclable waste to landfills for landfilling and recyclable waste to recycling centers (waste treatment plants) for reproduction, storing secondary materials from the raw plants, and finally, distributing the recycled products to the consumer market according to the market demand is essential.

Figure 6.

Construction RLSC material flow.

Optimization of RL Network

Reverse logistics network (RLN) optimization is a valuable tool for optimizing material flow. Table 2 shows a summary of recent studies in this field. Given that RLN involves more relevant interest groups and is associated with many uncertainties, its planning is a long-term and complex strategic decision-making issue. Most scholars prefer multi-period dynamic models for network design, considering uncertainty factors such as waste supply and transportation costs [], and waste recycling rates []. However, other uncertainty factors such as the quality of secondary materials and the location of CDW generation sites have been less studied [].

Table 2.

Common Approaches and Objectives for RLN optimization.

In designing an RLN for the construction industry, cost (profit) indicators are considered essentially by researchers when designing objectives; environmental indicators are also considered by most scholars, but social impact indicators have been rarely studied. Cost minimization (profit maximization) objectives are mainly achieved through the total cost of RL operations [], maximum revenue per ton of waste [], selling recycled materials to the secondary market for maximum profit [], and so on. Environmental impact factors can be controlled mainly by minimizing total carbon emissions [] and landfill flow [], among others.

To achieve logistics network optimization, this study summarizes the following research prospects: (1) Focus should be placed on uncertainty factors in network design, especially the uncertainty of secondary material quality and CDW generation locations. (2) More flexible two-stage stochastic models should be developed for network design to provide more robust and adaptive decision-making options. (3) Game theory and other methods should be used to study the interaction between multiple decision-makers and identify the best solution that meets the needs of multiple stakeholders. (4) Social impact indicators, such as the social equity dimension, should be considered to observe whether the distribution of logistics facilities can provide convenience to different social groups. To observe whether the installation of CDW recycling nodes can create more job opportunities for local residents, the social responsibility dimension should be considered. (5) Ali et al. showed that methods such as Lagrangian relaxation and Benders decomposition show potential in solving complex optimization problems with uncertainty in closed-loop SC networks []. Therefore, future research can further explore effective strategies for combining the theory of these methods with heuristic or meta-heuristic algorithms to be applied to the optimization of RLN in the construction industry, so as to find the optimal or near-optimal solution within a reasonable time frame.

Optimization of Logistics Technology

Technological support is an indispensable requirement for the efficient operation of logistics networks. Shi et al. [] proposed that the development of RL in the construction industry is in line with the three stages of the technology paradigm. This implies that the technological development of a certain field exhibits an “S” type development trend and undergoes the competition phase, diffusion phase, and shift phase []. Currently, RL technologies in the construction industry have completed the first two phases and are in the shift phase. Therefore, technological innovation is needed to overcome the developmental barriers and achieve sustainable development. In this regard, intelligent information technology and smart logistics technology are important breakthroughs. Intelligent logistics is a new type of logistics approach that has been widely recognized by the academic community, with modern logistics technology as the core. It uses information technology, artificial intelligence, and other advanced technological means to achieve intelligent application and management of logistics operations, thereby providing robust digital RSC [].

Based on logistics functional elements, smart logistics technologies can be classified into two types: transportation and warehousing. Regarding smart transportation technologies, Zhang and Atkins [] developed a smart plasterboard waste management system using RFID technology to monitor the fleet and waste status. Cheng and Ma [] developed a CDW recycling assessment system by using BIM that calculates CDW disposal charges as well as vehicle demand levels. Using information and communication technologies, Dhawan et al. [] optimized current RL transport operations. Regarding smart warehousing technologies, Huang et al. [] integrated BIM, Warehouse Management System, and the application programming interface plug-in and designed a WRFSS for the selection of CDW recycling facilities, as well as for the development of optimal transportation plans. Gao et al. [] utilized GIS to provide a reference for the locating of CDW treatment and resource facilities in Beijing. Dong et al. [] created a boundary-aware transformer to recognize the granularity of mixed CDW, providing a basis for CDW sorting sessions. Chen et al. [] proposed a deep learning-based CDW sorting robot implementation technique.

Literature review result revealed that the widely used smart logistics technologies include automated storage and retrieval system (AS/RS) stereoscopic warehouses and robots for internal logistics; however, the applications of these technologies in CI are lacking. These technologies, if used correctly, can contribute to sustainable and high-quality development of construction RL.

In an AS/RS stereoscopic warehouse, automated systems are used to manage and operate the storage and retrieval of goods, and space in the vertical direction is fully utilized []. It is often used for sorting and storing recycling waste products, collecting relevant data, such as inventory and goods in and out of the warehouse, and realizing process plasticity []. Recycling all types of waste materials is challenging because of site constraints and the limited number of recycling facilities []. Insufficient hazardous waste disposal sites [] and the problem of sorting CDW inevitably hinder RL activities, and these problems can be circumvented by the use of AS/RS three-dimensional warehouses capable of storing and compacting the waste, which increases the density of waste storage. In addition to increasing the storage rate of warehouses, three-dimensional warehouses can reduce the footprint and provide a favorable environment for waste disposal []. Due to the complex composition of CDW, the sorting accuracy should be high []. The latest research indicates that sorting clutter is feasible, and detailed research in this direction can enhance the possibility of applying AS/RS stereoscopic warehouse technologies in RL for the construction industry.

Robotics for internal logistics refers to automated robots that are specifically designed and serviced to support operations and material transportation within a company []. The progress of a project is a key indicator, which can be greatly improved by using logistics robots in engineering projects; it can quickly transfer CDW from the construction site or other places to the waste disposal center. Moreover, compared with manual handling of CDW, the use of logistics robots can greatly reduce labor costs, effectively control costs, and improve the accuracy of handling []. Importantly, CDW may comprise some dangerous and hazardous substances [], and the deconstruction process also produces a large amount of dusty waste; therefore, the implementation of deconstruction inevitably poses a safety risk to CDW recycling staff []. Replacing human operators with logistics robots can effectively reduce staff safety risks, thereby improving work safety. Integrating intralogistic robots with artificial intelligence is well-suited for automation. Because of its ability to allow rapid information exchange and analysis to achieve new dimensions of robot flexibility, devise new planning strategies, and control production systems [], it is suitable for use in CDW disposal.

Research prospects for logistics technology optimization can be summarized as follows: (1) The applicability of technologies such as AS/RS and robotic systems for internal logistics in the construction industry should be examined, and special intelligent logistics technologies should be developed. (2) Cost-benefit analysis of technological inputs is recommended to determine the optimal timing, quantity, and location of the introduction of technology to balance the relationship between technological inputs and outputs, as well as to increase the willingness of enterprises to apply new technologies.

4.2.2. Optimization of Financial Flow

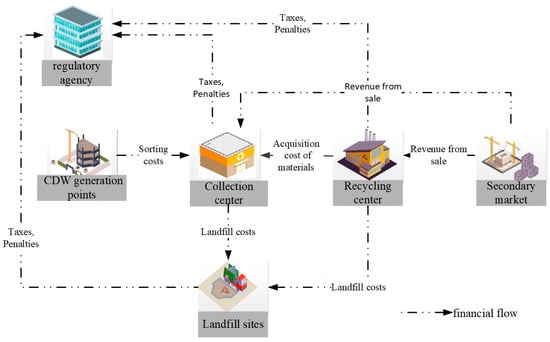

In the construction industry, RL is a commercial activity. The essence of commercial activities is to obtain profits; therefore, financial flow is the driver of SC activities that can ensure their smooth and sustainable execution. Financial flow is usually unidirectional; the cost of the last enterprise is the next enterprise’s revenue. By the demand side, flow into the core business, by the core business and then to the upstream suppliers of the flow.

In the construction RLSC financial flow, as shown in Figure 7, the value is usually low for untreated CDW, whereas direct landfills bear the costs of transportation and landfill treatment. Therefore, construction companies usually choose to entrust the responsibility of waste removal to collection centers to lower their expenses. The main expenses of collection centers include CDW removal, transportation, sorting, and disposal of non-recyclable materials, whereas they gain revenues mainly from commissioning fees from construction companies and proceeds from the sale of secondary materials and recyclable CDW. The main expenditures of recycling centers include the production of secondary materials and the disposal of non-recyclable waste, whereas they derive income mainly from the sales proceeds of secondary materials.

Figure 7.

Construction RLSC financial flow.

During the construction period, RLSC companies must be regulated by regulatory agencies. Typically, they are imposed fines in case of violation of the regulations issued by the regulatory agency. In most countries and regions, companies are required to pay income tax, excise tax, and other taxes to the regulatory agency for production and sales activities.

Optimization of Financial Network

The concept of financial network optimization encompasses not only financial flows within the enterprise but also financial interactions among different organizations and entities. Finance funds flow between governments, suppliers, customers, financial institutions, and other stakeholders. Financial subsidies and taxation facilitate the flow of funds between the government and enterprises. In a recent study in this domain, Liu and Wang [] explored the impact of tax incentives on the economic efficiency of enterprises utilizing CDW resources, concluding that the tax incentives reaching 70% yield the greatest benefits, with the preferential education surcharge policy and urban construction tax having the least impact on economic efficiency. Sun’s study results imply that government agencies can improve overall economic efficiency by adopting an active monitoring approach in the RL operation of the construction industry and introducing policies to encourage cooperation by remanufacturers and recyclers [].

In addition to maintaining the stability of enterprises in the RLSC in the construction industry, fair and reasonable distribution mechanisms help realize the effective resource allocation of each node enterprise and improve the efficiency of resource utilization. Wang et al. [] proposed a risk assessment model for CDW resourcing PPP projects, and based on the model, combined with capital input, contribution, and project participation, they modified the Shapley value benefit distribution model to obtain a more fair and reasonable benefit distribution system.

Economic benefit analysis is one of the key means of capital network optimization, providing a theoretical basis for stakeholder decision-making. Research in this area is relatively mature. Hao et al. [] examined the factors affecting the economic performance of CDW emission reduction and the interrelationships between those factors, eventually developing a system dynamics model to examine the economic performance of CDW. Positive factors for the economic performance of CDW reduction identified in the study were enhanced waste separation, reduced illegal dumping behavior, increased government financial subsidies for waste recycling, and increased landfill fees. Neto et al. [] conducted an economic analysis of three distinct treatments in a CDW recycling platform. Ruiz et al. [] showed that better economic benefits can be obtained by using coarse aggregates than by using conventional concrete, influenced by landfills and transportation distances.

Regarding financial network optimization, this study suggests the following: (1) Models of benefit distribution between stakeholder firms should be explored. (2) The role of financial institutions in the construction industry should be investigated in terms of sustainable finance and social responsibility. (3) The mechanism by which financial institutions can promote the use of CDW as resources should be examined.

Optimization of Cost

Cost optimization is crucial in RL in the construction industry, encompassing the economic benefits and competitiveness of enterprises, along with the effective use of resources, environmental protection, and the realization of sustainable development. Therefore, cost optimization is a crucial aspect that deserves consideration in the research and practice of financial optimization in RL in the construction industry. To reduce the total cost of CDW logistics management, Ahmed and Zhang [] designed a network of multi-stage models, considering the Hong Kong region as an example, and verified the reliability of the model, achieving a total cost reduction of approximately 24%. Subsequently, a multi-layer value stream assessment (time, cost, environmental quality, and process efficiency) methodology was developed based on lean thinking to assess the overall RLN of inert CDW management. Elshaboury and Marzouk [] used deep learning algorithms to evaluate various fleet combinations in conjunction with four dimensions, namely time, cost, energy, and emissions of waste transportation, to find optimal solutions for optimizing the cost of the transportation chain. Using an improved ant colony algorithm, Fan [] attempted to solve the transportation vehicle path optimization problem for cost control. Shi et al. [] established a mixed integer nonlinear programming model (MINLP) to determine the total cost reduction under two carbon policies for optimizing the circular SC of the construction industry and thereby achieving cost reduction and efficiency.

For cost optimization, the following suggestions are proposed: (1) Focus should be placed on cost optimization in recycling, sorting and reuse of construction materials. (2) Solutions to cost optimization in different regions and specific contexts must be explored. (3) The balance and trade-off between cost optimization and environmental and social benefits must be examined.

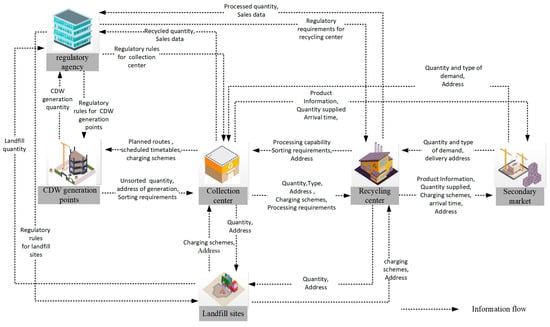

4.2.3. Optimization of Information Flow

The full life cycle management of CDW, starting from building design to the new inflow of secondary materials into the market is a long process requiring efficient information flow to support optimal system operation []. As shown in Figure 8, information flow is usually bi-directional and occurs between various nodes; information exchange between enterprises and between enterprises–regulators form a tight information network. Enterprises are required to provide relevant information to the government for monitoring purposes. CDW generators need to submit information about their waste disposal needs to collection centers, which in turn, will provide feedback on collection costs, treatment schedules, and other relevant information. Recycling centers should provide the collection centers with information on the procurement of treatment materials, and the collection centers should provide timely feedback on material prices and transaction schedules. In addition, recycling centers and collection centers should provide landfills with information on landfill quantities, while landfills need to provide landfill quotes and specific addresses. As for consumers of secondary materials, they need to provide information related to the procurement of secondary materials, while collection centers and recycling centers will provide transaction information such as prices.

Figure 8.

Construction RLSC information flow.

Optimizing information flow is essential to enhance information sharing, achieve immediate information transfer, enhance the transparency of the SC, and provide managers with real-time and accurate data and information to improve the operational efficiency of the SC. In addition, it can enhance the ability of SC node enterprises to collect, process, and analyze information, thus helping them make more informed decisions. Information flow can be optimized by integrating and applying intelligent information technology in the construction industry.

Intelligent information technologies such as blockchain, big data analysis, and the Internet of Things (IoT) constitute the backbone of intelligent technology for RLs, providing the necessary information support for their efficient operation.

Blockchain technology helps support RL traceability by enabling secure, decentralized, and transparent tracking and verification for the monitoring of the entire process of logistics and information flows []. Therefore, incorporating blockchain into the RSC can effectively increase the resilience of the SC and reduce the risk of its disruptions [].

IoT enables the identification of faulty components in the RL process for refurbishment by considering the number of faulty components returned, repair rates, reused repaired parts, and costs and benefits. Accordingly, it facilitates timely maintenance, repair, or replacement, thereby streamlining the process and avoiding the accumulation of spurious components []. Hence, designing a solid waste collection kanban system using IoT technology can shorten the time and amplify the quantity of garbage collection. It can also help determine the geographic proximity of bulk collection points to the recycling-in-manufacturing point [].

Big data processing technology enables the rapid acquisition of valuable information on different types of data involved in RL, including the collection, preprocessing, storage and management, analysis, and mining, thereby providing data processing technology support for RL management decision-making, logistics network design, and RL inventory management [,,].

Some preliminary studies on the construction industry have been conducted. Currently, the most widely researched and applied technology in this field is big data analytics. Lu et al. [] used this technology to obtain CDW bulk density. Lu [] used it to identify illegally dumped CDW. Lu et al. [] used it for performance management with big data drives. Studies on other technology references are still in the early stages. Huang et al. [] proposed a CDW management system based on the inherent characteristics of blockchain, including untamperability and reliability. The designed system can be used to assess waste recyclability and the proposed system framework can help technicians develop software. However, due to the high cost of blockchain technology and the difficulty of algorithm design, its application remains limited. By integrating BIM technologies with IoT, Tong et al. [] proposed an excavated soil recovery system based on BIM-GIS-IoT. Yuvaraj et al. [] developed a vehicle networking technology that facilitated data transfer between IoT and electric vehicles; they used blockchain technology for data protection.

The synergistic development of multiple technologies can generate synergies to establish a highly transparent and shared information platform. Hrouga et al. [] combined blockchain technology with IoT to manage asbestos waste in a highly digitized manner. Tong et al. [] integrated the BIMs with IoT to establish a soil recovery system for effectively managing excavated soil.

To achieve information system optimization, this study recommends the following: (1) The application of smart information technologies in the field of building recycling as well as the cross-fertilization application of multiple smart technologies should be comprehensively examined. (2) Intelligent tracking and identification technologies should be developed to realize the full life-cycle supervision of CDW. (3) Big data, blockchain, IoT and other technologies should be used, information technology infrastructure should be upgraded, and a large digital platform for RL in the construction industry should be established to facilitate the digital transformation of the construction recycling industry.

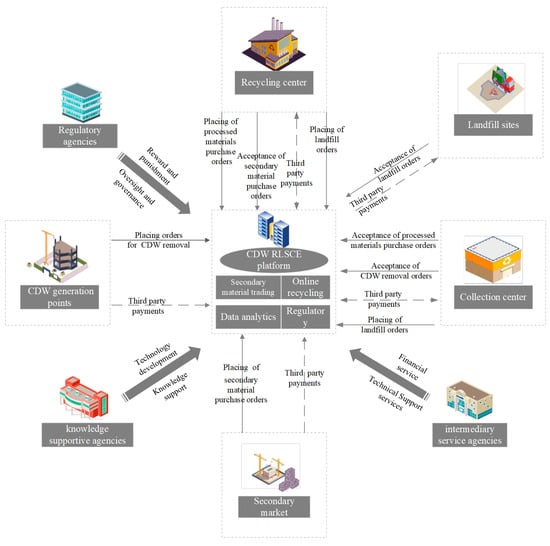

4.3. Conceptual Framework for RLSC Ecosystems

RL in the construction industry has broad market prospects; however, its implementation is hindered by specific barriers. In the era of big data, the traditional business model must also adapt to the needs of the times and explore new development paths to overcome these barriers []. With the rapid emergence of digital platforms such as community-based, innovative, and transactional, RL in the construction industry provides new ideas. In this regard, the example of a mature digital platform ecosystem development model can be cited, “Cainiao”, which is China’s first logistics cloud platform. It integrates logistics, warehousing, data analysis, and other resources, thereby providing an intelligent, efficient, and open logistics platform, whose main business includes order access, intelligent warehousing, distribution, data analysis and prediction, SC finance, and logistics traceability. Overall, it provides full-chain logistics services to merchants and consumers.

Moore [] introduced the ecosystem theory from nature to the business world, defining a business ecosystem as an “economic association based on organizational interactions”. Later, Moore [] extended the concept and proposed a new definition: “a business ecosystem is a dynamic structural system composed of organizations or groups with certain interests, such as customers, suppliers, major producers, investors, trading partners, standard-setting bodies, trade unions, governments, social and public services, and other stakeholders”.

The continuous development and improvement of the business ecosystem theory has resulted in its high citation in the field of SC. Though SC is characterized by bilateral contracts that manage prices and quantities, ecosystems are characterized by non-contractual forms of governance []. Research on logistics ecosystems has also been initiated. Hong et al. [] investigated the factors affecting organizational synergy and a conceptual framework of smart logistics ecosystems. Huang et al. [] explored the trend of ecological cooperation between logistics platforms and suppliers from the perspective of business ecosystems.

Notably, there remains a gap in research on reverse logistics supply chain ecosystems (RLSCE) in the construction industry. Compared with the traditional industry, companies within the RLSCE provide a series of advantages, including lower transaction costs, easier resource utilization, and lower information asymmetry []. These advantages may help address the multiple barriers existing in RL for CDW and promote its development. Therefore, to ensure full utilization of these advantages and promote sustainable industrial growth, an in-depth study of the RL ecosystem in the construction industry is warranted.

In summary, based on the advanced SC concept and enterprise ecosystem theory of the traditional manufacturing industry, combined with the CDW RL industry development, this study recommends construction companies establish their own industry-wide RLSCE platforms.

Construction industry RLSCE comprises elements such as individuals, enterprises, organizations, and government agencies responsible for the accomplishment of RL activities. The internal factors and the external environment constitute the construction industry RLSCE, encompassing regulatory agencies (environmental protection departments, transportation departments, local governments, regulatory agencies, and tax departments), supply and demand agencies (CDW generation points, collection center, recycling centers, secondary market, and landfills), knowledge support agencies (industry associations and organizations, universities, research institutes, consulting agencies, and training and education institutions), and intermediary service institutions (banks, insurance companies, digital platforms and applications, certification, and standards bodies). External factors of the system cover six dimensions, namely political, economic, social, cognitive and cultural, natural environment, and technological. The overall framework is depicted in Figure 9.

Figure 9.

A conceptual framework for RLSCE in the construction industry.

As shown in Figure 9, the main business of the platform includes online trading of secondary materials, online recycling, data analysis, whole process monitoring and quality management. In the online recycling business module, the CDW generation point puts forward an order for waste treatment demand to the collection center through the platform, and the collection center receives the order. Waste recycling centers and collection centers that need to be landfilled can also contact landfills for removal on the platform. The platform tracks the transportation time and route of the removal vehicles through a big data monitoring system and regulates the collection centers to complete their tasks on time and in compliance by setting penalties for non-compliance. In the online trading business module for secondary materials, recycling centers publish information on secondary materials for sale on the platform, and consumers of secondary materials place orders for purchase on the platform according to their needs. The platform must monitor the quality of the products sold online, and if quality problems occur, support consumers to quickly return the products and penalize the recycling centers. The data analytics business module takes on the responsibility of processing all transaction data, using GPS, big data and other advanced technologies to provide companies with the best strategies, including recommendations for the nearest collection centers and landfill sites, price recommendations, and the best quality secondary materials. Full monitoring and quality management is carried out throughout the service to ensure that companies participate in the SC in a compliant manner, while also facilitating supervision by regulatory authorities. In addition, the platform utilizes third-party payment methods to ensure the safety and reliability of order delivery.

This framework can help realize a close association among various links in the SC, ensure synergistic operation and promote sustainable development. In addition, it can increase SC transparency, resource sharing, and risk sharing, increasing the competitiveness of the entire construction industry.

5. Conclusions

The implementation of RL in the construction industry has the potential to bring sustainable benefits to society. However, its development is still in its early stages, and businesses face numerous challenges in the process. Therefore, this paper conducts a comprehensive literature review with the aim of revealing the current status and issues related to implementing RL in the construction industry, as well as identifying potential opportunities for development. The main conclusions of this study are as follows:

- (1)

- Literature studies have shown that there is increasing attention from academics on RL related to CDW. In terms of author origins, most scholars originate from China, while many other scholars hail from developed countries such as the United States and Australia. In terms of journal sources, the top ten journals with the highest number of published articles are primarily focused on environmental protection and construction, although few logistics-related journals cover RL in CDW. Regarding research content, the circular economy, barriers to implementing RL, and SCM are recent research focal points.

- (2)

- According to literature research, the main obstacles to the implementation of RL in the construction industry come from SCM, of which the lack of deconstructive design, the inadequacy of the recycling market, the difficulty of evaluating the quality of secondary materials, and the lack of integration in the SC are the most important obstacles. Therefore, SCM optimization is the main direction for the development of RL in the construction industry. This study takes the articles related to SC optimization and analyzes them from the perspectives of material flow, capital flow, and cash flow, and summarizes the research gaps, as well as the direction of future research for each module. An example is the optimization module of RLN, where past studies have primarily focused on uncertain factors like recycling rates and quantities. However, there has been a lesser emphasis on uncertainties surrounding the quality of secondary materials and the origins of CDW generation. Future research can shift its focus toward these underexplored uncertainties. In comparison to optimizing for economic and environmental benefits, studies of social benefits are relatively scarce. Future research should give more consideration to factors of employment opportunities and convenience for the people. Detailed summaries of other modules are elaborated upon in each respective subsection.

- (3)

- This paper proposes a conceptual framework of an RLSCE for the construction industry, and builds an Eco-Platform within the RSC: ① Build an online recycling platform for CDW, and realize accurate matching of supply and demand of CDW through big data analysis. ② Track the whole process of the logistics of CDW recycling through big data monitoring technology, forming a whole chain monitoring from the construction site to the secondary material consumption market. ③ Creating a trading platform for secondary materials, improving the quality supervision of secondary materials, and solving the problems of difficulty in determining the quality of secondary materials and insufficient convenience in trading. ④ Provide consulting advice on waste disposal and secondary material procurement for enterprises through big data analysis.

However, this study also has some limitations. First, it used only the WoS database for the bibliometric analysis, and thus, the retrieved literature is not sufficiently comprehensive. Future research can consider including other databases such as SCOPUS and EI to ensure a more detailed analysis and robust findings. The second limitation is that the barriers were not differentiated geographically while sorting in this study. Because the current status of implementation differs across regions, a comparative study for a certain region or multiple regions is highly warranted in the future.

Author Contributions

Conceptualization, D.Q. and X.C.; formal analysis, X.C.; investigation, X.C.; data curation, X.C. and Y.C.; writing—original draft preparation, D.Q. and X.C.; writing—review and editing, D.Q., X.C. and Y.C.; supervision, D.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fujian Provincial Science and Technology Major Special Project “Research on Key Technology and Industrialization Demonstration and Application of Green Construction of Assembled Mixed-Earth Buildings” (Project No. 2019HZ07011-3).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Correction Statement

This article has been republished with a minor correction to resolve spelling and grammatical errors. This change does not affect the scientific content of the article.

References

- Pushpamali, N.; Agdas, D.; Rose, T.M. A Review of Reverse Logistics: An Upstream Construction Supply Chain Perspective. Sustainability 2019, 11, 4143. [Google Scholar] [CrossRef]

- Sagan, J.; Sobotka, A. Analysis of Factors Affecting the Circularity of Building Materials. Materials 2021, 14, 7296. [Google Scholar] [CrossRef] [PubMed]

- Bakshan, A.; Srour, I.; Chehab, G.; El-Fadel, M. A field based methodology for estimating waste generation rates at various stages of construction projects. Resour. Conserv. Recycl. 2015, 100, 70–80. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The circular economy in the construction and demolition waste management: A comparative analysis in emerging and developed countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Krook, J.; Svensson, N.; Eklund, M. Landfill mining: A critical review of two decades of research. Waste Manag. 2012, 32, 513–520. [Google Scholar] [CrossRef]

- Nunes, K.R.A.; Mahler, C.; Valle, R.A. Reverse logistics in the Brazilian construction industry. J. Environ. Manag. 2009, 90, 3717–3720. [Google Scholar] [CrossRef]

- Schultmann, F.; Sunke, N. Energy-oriented deconstruction and recovery planning. Build. Res. Inf. 2007, 35, 602–615. [Google Scholar] [CrossRef]

- Mishra, A.; Dutta, P.; Jayasankar, S.; Jain, P.; Mathiyazhagan, K. A review of reverse logistics and closed-loop supply chains in the perspective of circular economy. Benchmarking Int. J. 2023, 30, 975–1020. [Google Scholar] [CrossRef]

- Chileshe, N.; Rameezdeen, R.; Hosseini, M.R.; Martek, I.; Li, H.X.; Panjehbashi-Aghdam, P. Factors driving the implementation of reverse logistics: A quantified model for the construction industry. Waste Manag. 2018, 79, 48–57. [Google Scholar] [CrossRef]

- Chileshe, N.; Rameezdeen, R.; Hosseini, M.R. Drivers for adopting reverse logistics in the construction industry: A qualitative study. Eng. Constr. Arch. Manag. 2016, 23, 134–157. [Google Scholar] [CrossRef]

- Bao, Z.; Lee, W.M.W.; Lu, W. Implementing on-site construction waste recycling in Hong Kong: Barriers and facilitators. Sci. Total Environ. 2020, 747, 141091. [Google Scholar] [CrossRef] [PubMed]

- Brandao, M.S.; Godinho Filho, M. Changing terms, evolving strategies: The tailoring of supply chain management terms and its implications. Supply Chain Manag. Int. J. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Prahinski, C.; Kocabasoglu, C. Empirical research opportunities in reverse supply chains. Omega 2006, 34, 519–532. [Google Scholar] [CrossRef]

- Kalverkamp, M. Hidden potentials in open-loop supply chains for remanufacturing. Int. J. Logist. Manag. 2018, 29, 1125–1146. [Google Scholar] [CrossRef]

- Difrancesco, R.M.; Huchzermeier, A. Closed-loop supply chains: A guide to theory and practice. Int. J. Logist. Res. Appl. 2016, 19, 443–464. [Google Scholar] [CrossRef]

- Julianelli, V.; Caiado, R.G.G.; Scavarda, L.F.; de Mesquita Ferreira Cruz, S.P. Interplay between reverse logistics and circular economy: Critical success factors-based taxonomy and framework. Resour. Conserv. Recycl. 2020, 158, 104784. [Google Scholar] [CrossRef]

- Rahimi, M.; Ghezavati, V. Sustainable multi-period reverse logistics network design and planning under uncertainty utilizing conditional value at risk (CVaR) for recycling construction and demolition waste. J. Clean. Prod. 2018, 172, 1567–1581. [Google Scholar] [CrossRef]

- Hiete, M.; Stengel, J.; Ludwig, J.; Schultmann, F. Matching construction and demolition waste supply to recycling demand: A regional management chain model. Build. Res. Inf. 2011, 39, 333–351. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Jiang, Y.; Wang, X. Explore potential barriers of applying circular economy in construction and demolition waste recycling. J. Clean. Prod. 2021, 326, 129400. [Google Scholar] [CrossRef]

- Ding, L.; Wang, T.; Chan, P.W. Forward and reverse logistics for circular economy in construction: A systematic literature review. J. Clean. Prod. 2023, 388, 135981. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Financial and economic evaluation of construction and demolition waste recycling in Hanoi, Vietnam. Waste Manag. 2021, 131, 294–304. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, O.; Pasqualino, J.C.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef] [PubMed]

- Ulsen, C.; Kahn, H.; Hawlitschek, G.; Masini, E.A.; Angulo, S.; John, V.M. Production of recycled sand from construction and demolition waste. Constr. Build. Mater. 2013, 40, 1168–1173. [Google Scholar] [CrossRef]

- Wang, L.; Yu, I.K.; Tsang, D.C.; Yu, K.; Li, S.; Poon, C.S.; Dai, J.-G. Upcycling wood waste into fibre-reinforced magnesium phosphate cement particleboards. Constr. Build. Mater. 2018, 159, 54–63. [Google Scholar] [CrossRef]

- Koc, K.; Okudan, O. Assessment of Life Cycle Risks of Deconstruction in Urban Regeneration Projects. J. Constr. Eng. Manag. 2021, 147, 04021137. [Google Scholar] [CrossRef]

- Shaik, M.N.; Abdul-Kader, W. Comprehensive performance measurement and causal-effect decision making model for reverse logistics enterprise. Comput. Ind. Eng. 2014, 68, 87–103. [Google Scholar] [CrossRef]

- Aryee, R.; Adaku, E. A review of current trends and future directions in reverse logistics research. Flex. Serv. Manuf. J. 2024, 36, 379–408. [Google Scholar] [CrossRef]

- Detwal, P.K.; Agrawal, R.; Samadhiya, A.; Kumar, A. Metaheuristics in circular supply chain intelligent systems: A review of applications journey and forging a path to the future. Eng. Appl. Artif. Intell. 2023, 126, 107102. [Google Scholar] [CrossRef]

- Moosavi, J.; Naeni, L.M.; Fathollahi-Fard, A.M.; Fiore, U. Blockchain in supply chain management: A review, bibliometric, and network analysis. Environ. Sci. Pollut. Res. 2021, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Moosavi, J.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Supply chain disruption during the COVID-19 pandemic: Recognizing potential disruption management strategies. Int. J. Disaster Risk Reduct. 2022, 75, 102983. [Google Scholar] [CrossRef] [PubMed]

- Ranjbari, M.; Saidani, M.; Esfandabadi, Z.S.; Peng, W.; Lam, S.S.; Aghbashlo, M.; Quatraro, F.; Tabatabaei, M. Two decades of research on waste management in the circular economy: Insights from bibliometric, text mining, and content analyses. J. Clean. Prod. 2021, 314, 128009. [Google Scholar] [CrossRef]

- Li, N.; Han, R.; Lu, X. Bibliometric analysis of research trends on solid waste reuse and recycling during 1992–2016. Resour. Conserv. Recycl. 2018, 130, 109–117. [Google Scholar] [CrossRef]

- Rameezdeen, R.; Chileshe, N.; Hosseini, M.R.; Lehmann, S. A qualitative examination of major barriers in implementation of reverse logistics within the South Australian construction sector. Int. J. Constr. Manag. 2016, 16, 185–196. [Google Scholar] [CrossRef]

- Nikmehr, B.; Hosseini, M.R.; Rameezdeen, R.; Chileshe, N.; Ghoddousi, P.; Arashpour, M. An integrated model for factors affecting construction and demolition waste management in Iran. Eng. Constr. Archit. Manag. 2017, 24, 1246–1268. [Google Scholar] [CrossRef]

- Pimentel, M.; Arantes, A.; Cruz, C.O. Barriers to the Adoption of Reverse Logistics in the Construction Industry: A Combined ISM and MICMAC Approach. Sustainability 2022, 14, 15786. [Google Scholar] [CrossRef]

- Couto, J.; Couto, A. Analysis of Barriers and the Potential for Exploration of Deconstruction Techniques in Portuguese Construction Sites. Sustainability 2010, 2, 428–442. [Google Scholar] [CrossRef]

- del Río Merino, M.; Gracia, P.I.; Azevedo, I.S.W. Sustainable construction: Construction and demolition waste reconsidered. Waste Manag. Res. J. Sustain. Circ. Econ. 2010, 28, 118–129. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Developing an LCA methodology to account for the environmental benefits of design for deconstruction. Build Environ. 2012, 57, 387–395. [Google Scholar] [CrossRef]