Effect of Elevated Temperatures on Compressive Strength, Ultrasonic Pulse Velocity, and Transfer Properties of Metakaolin-Based Geopolymer Mortars

Abstract

1. Introduction

2. Relevant Literature

2.1. Previous Studies on Effect of Temperature on Selected Properties of Geopolymers

2.2. Previous Studies on Permeability of Geopolymers

2.3. Research Gap and Novelty

3. Materials and Methods

3.1. Materials

3.1.1. Binders

3.1.2. Aggregates

3.1.3. Alkaline solution

3.2. Mix Design

3.2.1. OPC Mix Design

3.2.2. Metakaolin-Based Geopolymer Mortar Mix Design

3.3. Mixing, Casting, and Curing

3.4. Specimens, Testing and Heating Procedure

3.5. Permeability Assessment Procedure

4. Results and Discussion

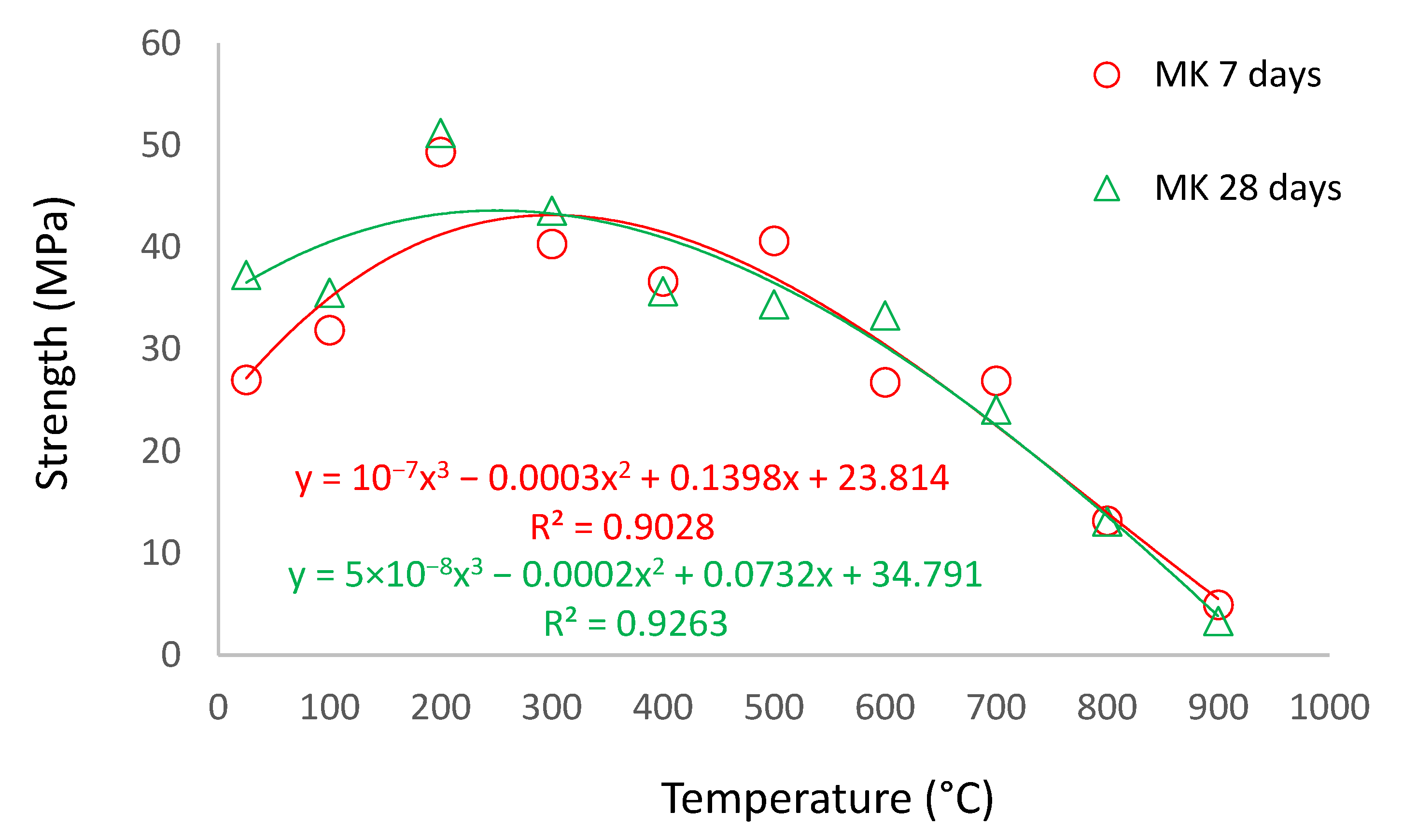

4.1. Compressive Strength

4.2. Mass Loss

4.3. Ultrasonic Pulse Velocity (UPV)

4.4. Discoloration of MK Geopolymer Mortar Specimens

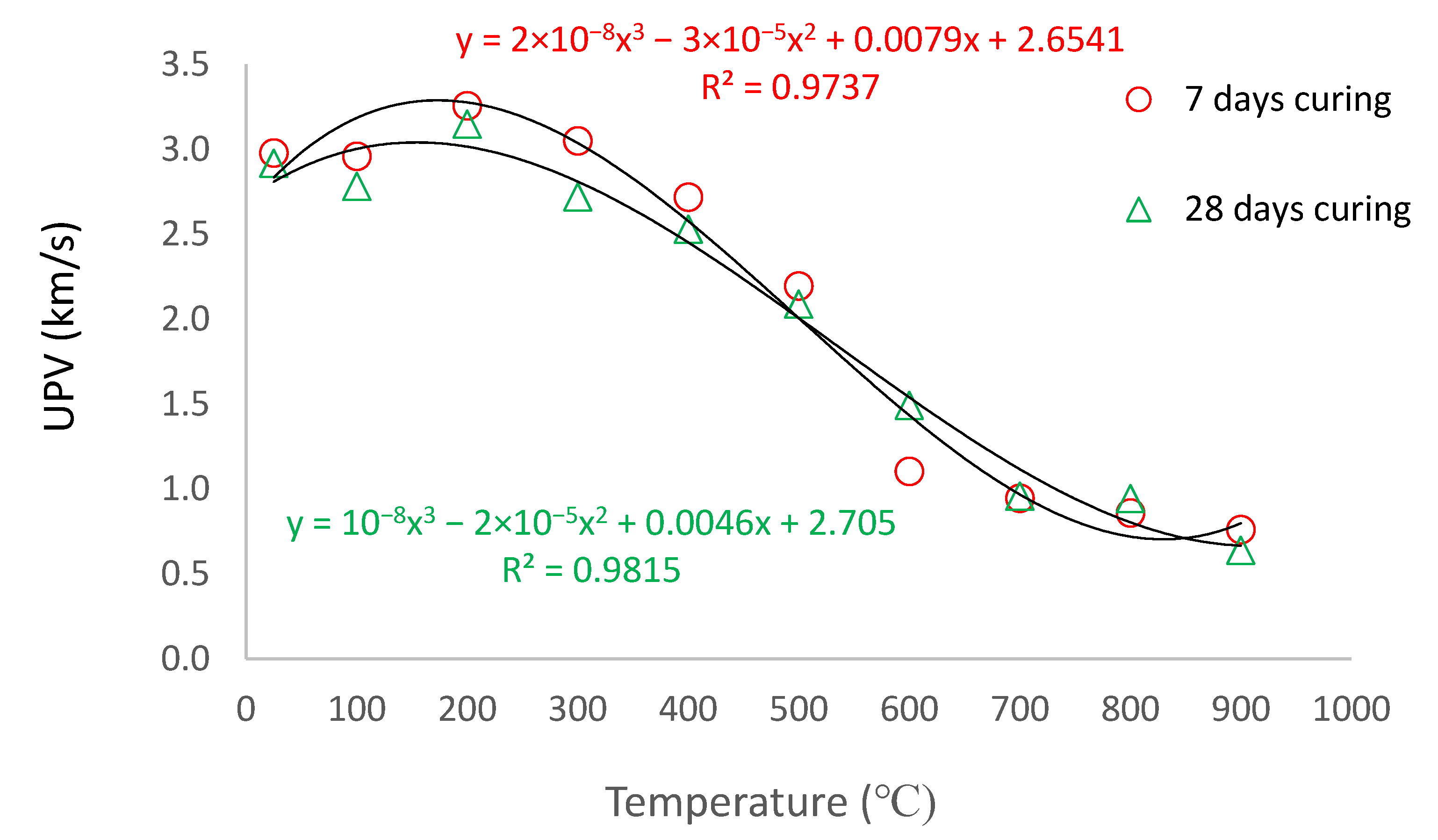

4.5. Transfer Properties (Gas Permeability)

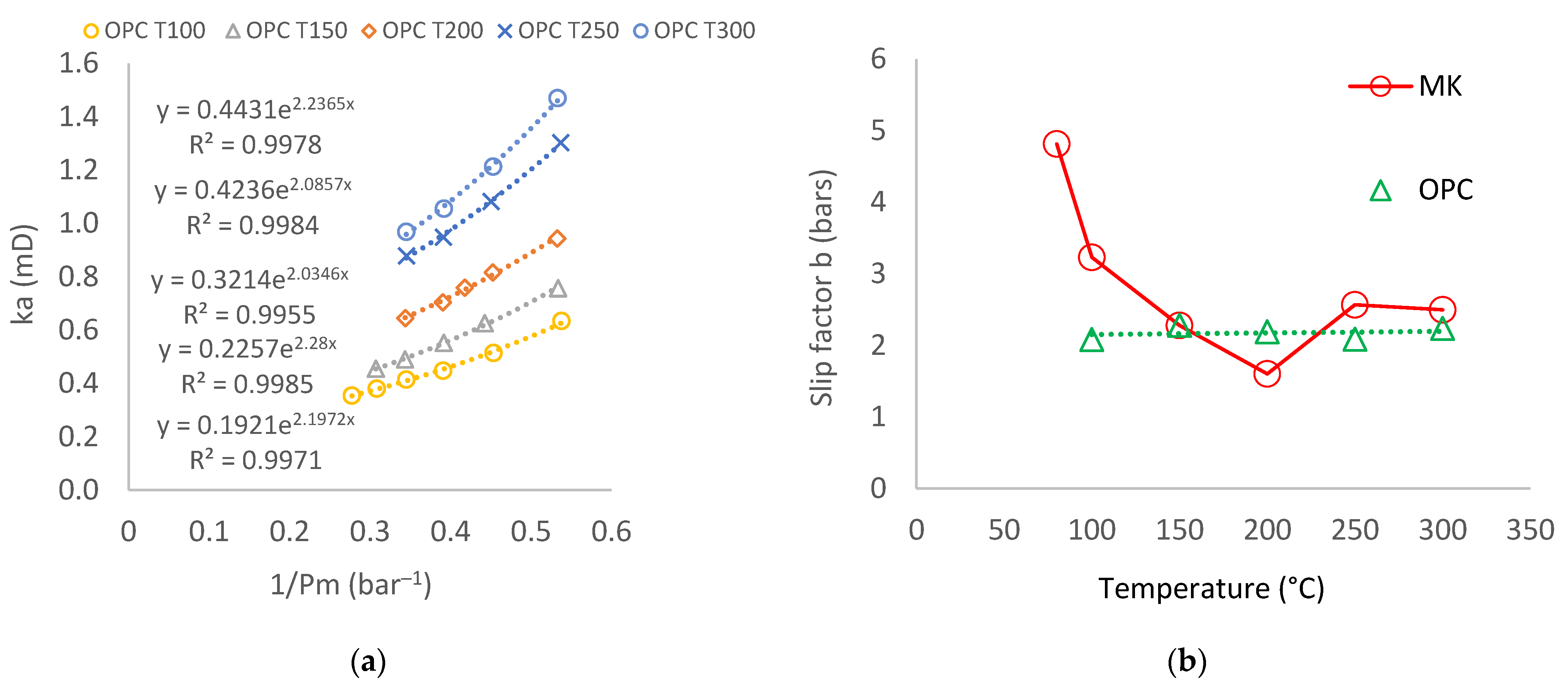

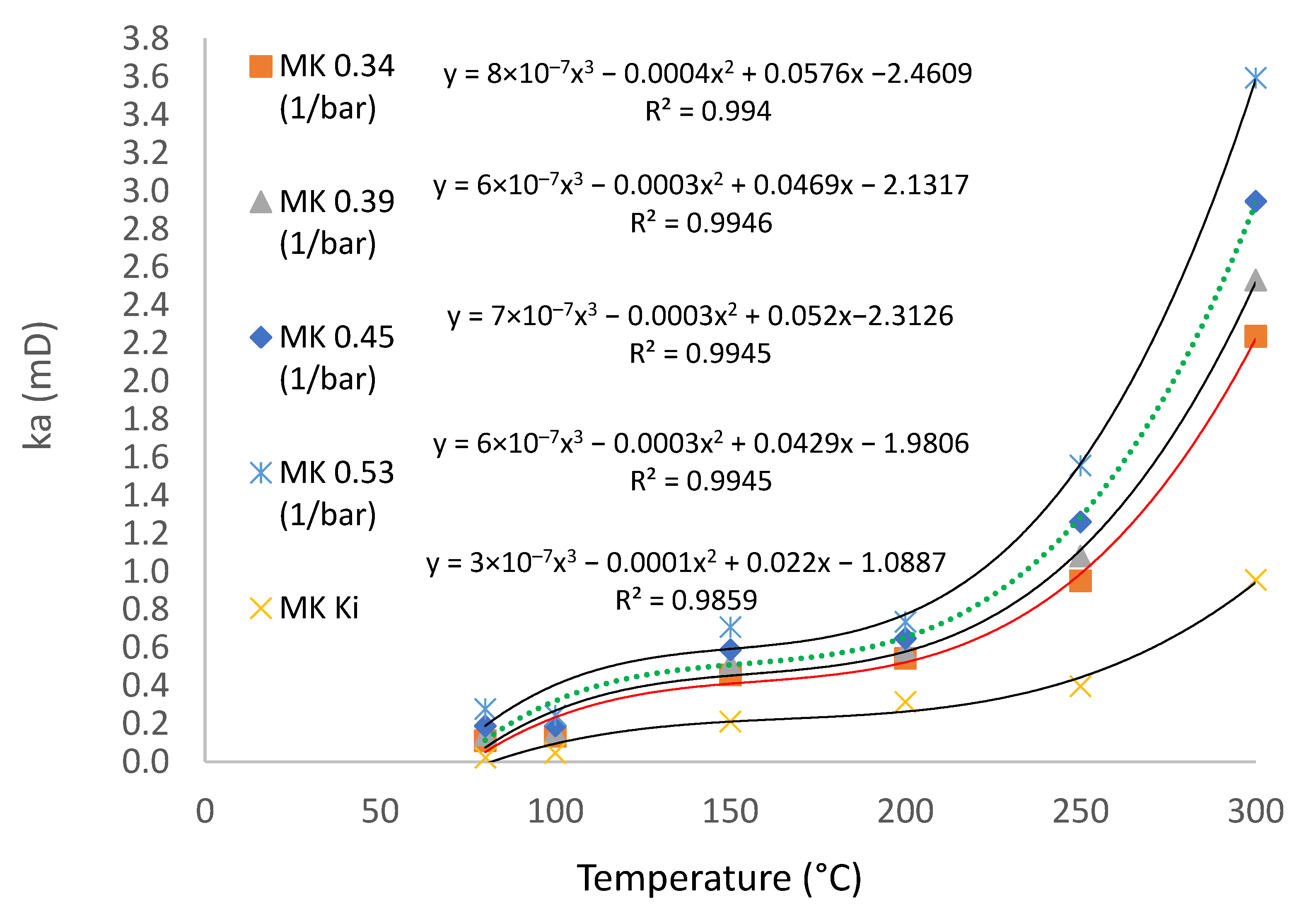

4.5.1. Analysis of Apparent Permeability

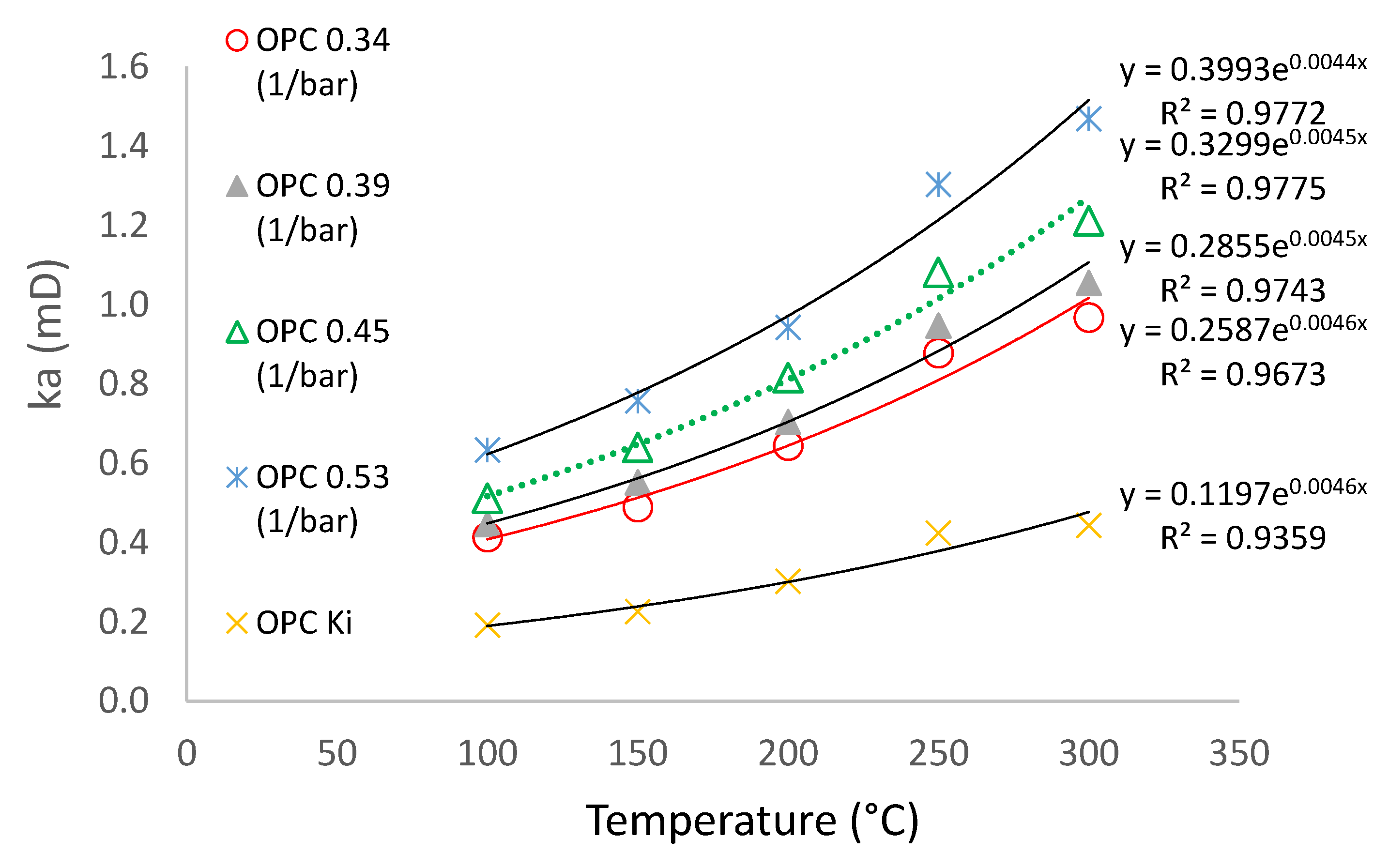

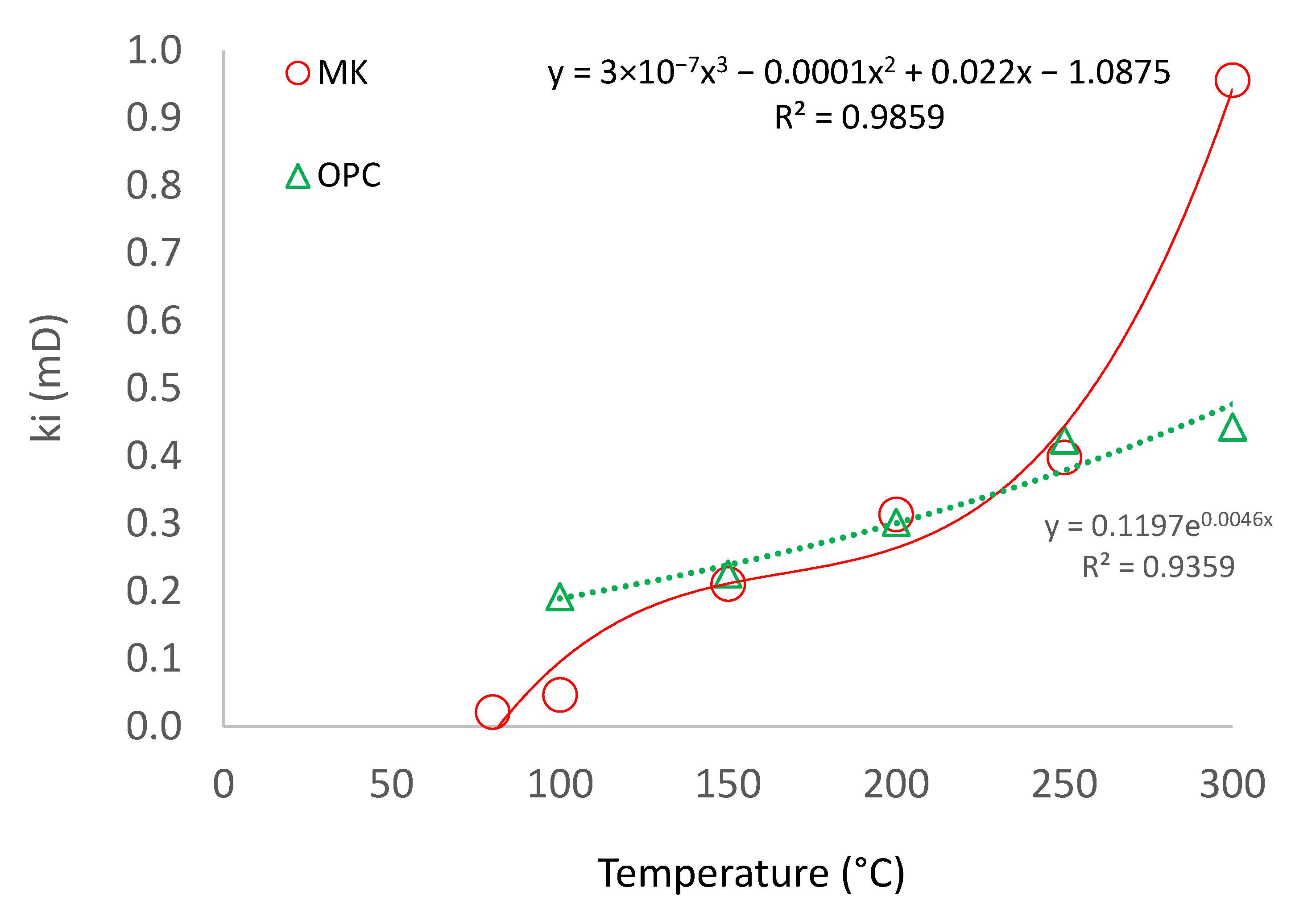

4.5.2. Apparent and Intrinsic Permeability Versus Temperature

5. Practical Applications and Use of the Data

- Masonry chimneys and flues in which the mortar needs to withstand high temperatures from burning fuel.

- Firewalls and compartmentation walls that separate different areas of a building to contain fires. The mortar needs to maintain its integrity and bond the bricks or blocks together.

- Industrial furnaces and kilns in which mortars must handle extreme heat without degrading or failing.

- Exterior brick and stonework to prevent water infiltration, protecting the masonry from damage caused by moisture, freezing, and salt erosion.

- Basements and foundations, to prevent water seepage and dampness in below-ground structures.

- Swimming pools and water features in which mortars are required to be resistant to water penetration and chemical erosion from pool chemicals.

6. Conclusions

- MK-based geopolymer mortars possess better compressive strength and thermal stability than OPC-based mortars after exposure to elevated temperatures.

- MK-based geopolymer mortars retained their initial strength after exposure to temperatures in the range of 600–700 °C, whereas OPC-based mortars completely lost their strength after exposure to temperatures in the range of 500–600 °C.

- The compressive strength peak for MK-based geopolymer mortars is achieved after exposure to 200 °C. This can be attributed to increased geopolymerization occurring after 28 days of curing, followed by heat treatment, ideally at 200 °C.

- The mass loss evolution with temperature exposure for both OPC and MK-based geopolymer mortars is found to be similar. Most of the mass loss occurs in the temperature range of 100–200 °C, primarily due to the evaporation of free and bound water.

- UPV is found to be correlated with the compressive strength of MK-based geopolymer mortar.

- The initial intrinsic permeability of MK-based geopolymer mortars is found to be significantly lower, at 3.84 units, compared to that of OPC-based mortars after exposure to a temperature of 100 °C.

- In OPC-based mortar, the permeability shows an exponential increase with temperature. In contrast, MK-based mortars exhibit a continuous increase in permeability, albeit at a slower rate between 100 and 200 °C. Beyond 200 °C, the permeability of MK-based mortars begins to increase exponentially. This indicates that MK-based mortars are significantly more thermally sensitive in terms of permeability compared to OPC mortar.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akarken, G.; Cengiz, U. Fabrication and characterization of metakaolin-based fiber reinforced fire resistant geopolymer. Appl. Clay Sci. 2023, 232, 106786. [Google Scholar] [CrossRef]

- Albidah, A.; Alqarni, A.S.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of Metakaolin-Based geopolymer concrete at ambient and elevated temperatures. Constr. Build. Mater. 2022, 317, 125910. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Qiu, G.H.; Kodur, V.; Yuan, Z. Spalling behavior of metakaolin-fly ash based geopolymer concrete under elevated temperature exposure. Cem. Concr. Compos. 2020, 106, 103483. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Wu, B.; Cao, L.; Wang, F. Thermal behavior and mechanical properties of geopolymer mortar after exposure to elevated temperatures. Constr. Build. Mater. 2016, 109, 17–24. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Razak, S.N.A.; Shafiq, N.; Guillaumat, L.; Farhan, S.A.; Kumar, V. Fire-Exposed Fly-Ash-Based Geopolymer concrete: Effects of burning temperature on mechanical and microstructural properties. Materials 2022, 15, 1884. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Gong, X. Effect of elevated temperature on mechanical properties of High-Volume Fly Ash-Based geopolymer concrete, mortar and paste cured at room temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, L.B.; De Azevedo, A.R.G.; Marvila, M.T.; Pereira, E.C.; Fediuk, R.; Vieira, C.M.F. Durability of geopolymers with industrial waste. Case Stud. Constr. Mater. 2022, 16, e00839. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.; Debbarma, S.; Rashid, R.S.M. Fire resistance of geopolymer concrete: A critical review. Constr. Build. Mater. 2022, 324, 126722. [Google Scholar] [CrossRef]

- Yang, Z.; Mocadlo, R.; Zhao, M.; Sisson, R.D.; Tao, M.; Liang, J. Preparation of a geopolymer from red mud slurry and class F fly ash and its behavior at elevated temperatures. Constr. Build. Mater. 2019, 221, 308–317. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W.; Luo, W.; Shen, C. An investigation of the microstructure and durability of a fluidized bed fly ash–metakaolin geopolymer after heat and acid exposure. Mater. Eng. 2015, 74, 125–137. [Google Scholar] [CrossRef]

- Razak, S.N.A.; Shafiq, N.; Nikbakht, E.; Mohammed, B.S.; Guillaumat, L.; Farhan, S.A. Fire performance of fly-ash-based geopolymer concrete: Effect of burning temperature on mechanical and microstructural properties. Mater. Today Proc. 2022, 66, 2665–2669. [Google Scholar] [CrossRef]

- Razak, S.N.A.; Shafiq, N.; Guillaumat, L.; Wahab, M.M.A.; Farhan, S.A.; Husna, N.; Ismail, F.I. Fire performance of Fly Ash-Based Geopolymer concrete: Effect of burning temperature. IOP Conf. Ser. Earth Environ. Sci. 2021, 945, 012062. [Google Scholar] [CrossRef]

- Zhang, H.; Sarker, P.K.; Wang, H.; He, B.; Kuri, J.C.; Jiang, Z. Comparison of compressive, flexural, and temperature-induced ductility behaviours of steel-PVA hybrid fibre reinforced OPC and geopolymer concretes after high temperatures exposure. Constr. Build. Mater. 2023, 399, 132560. [Google Scholar] [CrossRef]

- Picandet, V.; Khelidj, A.; Bellegou, H. Crack effects on gas and water permeability of concretes. Cem. Concr. Res. 2009, 39, 537–547. [Google Scholar] [CrossRef]

- Ezzedine El Dandachy, M.; Briffaut, M.; Pont, S.D.; Dufour, F. Induced Anisotropic Gas Permeability of Concrete due to Coupled Effect of Drying and Temperature. Key Eng. Mater. 2016, 711, 871–878. [Google Scholar] [CrossRef]

- Choińska, M.; Khelidj, A.; Chatzigeorgiou, G.; Pijaudier-Cabot, G. Effects and interactions of temperature and stress-level related damage on permeability of concrete. Cem. Concr. Res. 2007, 37, 79–88. [Google Scholar] [CrossRef]

- Hager, I.; Tracz, T.; Choińska, M.; Mróz, K. Effect of cement type on the mechanical behavior and permeability of concrete subjected to high temperatures. Materials 2019, 12, 3021. [Google Scholar] [CrossRef]

- Hachem, Y.; Dandachy ME, E.; Khatib, J. Physical, Mechanical and transfer Properties at the Steel-Concrete Interface: A review. Buildings 2023, 13, 886. [Google Scholar] [CrossRef]

- Bouhjiti, D.E.-M.; Ezzedine El Dandachy, M.; Dufour, F.; Dal Pont, S.; Briffaut, M.; Baroth, J.; Masson, B. New Continuous Strain-Based Description of Concrete’s Damage-Permeability Coupling. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 1671–1697. [Google Scholar] [CrossRef]

- Klinkenberg, L.J. The Permeability of Porous Media to Liquids and Gases. In Drilling and Production Practice; API-41-200; American Petroleum Institute: New York, NY, USA, 1 January 1941. [Google Scholar]

- Fathi, E.; Tinni, A.; Akkutlu, I.Y. Correction to Klinkenberg slip theory for gas flow in nano-capillaries. Int. J. Coal Geol. 2012, 103, 51–59. [Google Scholar] [CrossRef]

- Hu, Z.; Duan, X.; He, Y.; Wu, J.; Chang, J.; Liu, L.; Wu, K.; Ma, Z. Influence of reservoir primary water on shale gas occurrence and flow capacity. Nat. Gas Ind. B 2019, 6, 71–78. [Google Scholar] [CrossRef]

- Li, Z.; Wang, A.; Li, L.; Li, J.; Zhang, N.; Jin, K.; Chang, J. Influence mechanism of gas pressure on multiscale dynamic Apparent Diffusion-Permeability of coalbed methane. ACS Omega 2023, 8, 35964–35974. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yu, L.; Yuan, Q. Experimental study on permeability in tight porous media considering gas adsorption and slippage effect. Fuel 2019, 253, 561–570. [Google Scholar] [CrossRef]

- Nasvi, M.; Ranjith, P.; Sanjayan, J.; Bui, H.H. Effect of temperature on permeability of geopolymer: A primary well sealant for carbon capture and storage wells. Fuel 2014, 117, 354–363. [Google Scholar] [CrossRef]

- Liang, X.; Ji, Y. Mechanical properties and permeability of red mud-blast furnace slag-based geopolymer concrete. SN Appl. Sci. 2021, 3, 23. [Google Scholar] [CrossRef]

- Van Den Heede, P.; Gruyaert, E.; De Belie, N. Transport properties of high-volume fly ash concrete: Capillary water sorption, water sorption under vacuum and gas permeability. Cem. Concr. Compos. 2010, 32, 749–756. [Google Scholar] [CrossRef]

- Sitarz, M.; Choińska, M.; Hager, I.; Khelidj, A. Mechanical behaviour and permeability of geopolymer mortars. MATEC Web Conf. 2020, 322, 01043. [Google Scholar] [CrossRef]

- Sagoe–Crentsil, K.; Brown, T.; Yan, S.Q. Medium to long term engineering properties and performance of High-Strength geopolymers for structural applications. Adv. Sci. Technol. 2010, 69, 135–142. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Pang, E. Strength and Microstructure of Geopolymer Based on Fly Ash and Metakolin. Materials 2022, 15, 3732. [Google Scholar] [CrossRef]

- ASTM C150/C150M-20; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003. [CrossRef]

- BS EN 196-1:2016; Methods of Testing Cement Determination of Strength. British Standards Institution: Cambridge, UK, 2016.

- ASTM C597-22-22; Standard Test Method for Ultrasonic Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Darcy, H. Les Fontaines Publiques de la Ville de Dijon; Dalmont: Paris, France, 1856; 647p. [Google Scholar]

- Lion, M.; Skoczylas, F.; Lafhaj, Z.; Sersar, M. Experimental study on a mortar. Temperature effects on porosity and permeability. Residual properties or direct measurements under temperature. Cem. Concr. Res. 2005, 35, 1937–1942. [Google Scholar] [CrossRef]

- Gambo, S.; Ibrahim, K.; Aliyu, A.M.; Ibrahim, A.; Abdulsalam, H. Performance of metakaolin based geopolymer concrete at elevated temperature. Niger. J. Technol. 2020, 39, 732–737. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, B.; Yuan, Q.; Huang, D.; Peng, H. Characterization, factors, and fractal dimension of pore structure of fly ash-based geopolymers. J. Mater. Res. Technol. 2023, 26, 3395–3407. [Google Scholar] [CrossRef]

- Pont, S.D.; Schrefler, B.A.; Ehrlacher, A. Intrinsic Permeability evolution in High Temperature Concrete: An Experimental and Numerical analysis. Transp. Porous Media 2005, 60, 43–74. [Google Scholar] [CrossRef]

- Gawin, D.; Alonso, C.; Andrade, C.; Majorana, C.; Pesavento, F. Effect of damage on permeability and hygro-thermal behaviour of HPCs at elevated temperatures: Part 1. Experimental results. Comput. Concr. Int. J. 2005, 2, 189–202. [Google Scholar] [CrossRef]

- Ezzedine El Dandachy, M.; Briffaut, M.; Dufour, F.; Pont, S.D. An original semi-discrete approach to assess gas conductivity of concrete structures. Int. J. Numer. Anal. Methods Geomech. 2016, 41, 940–956. [Google Scholar] [CrossRef]

- Pasupathy, K.; Berndt, M.; Sanjayan, J.; Rajeev, P.; Cheema, D.S. Durability of low-calcium fly ash based geopolymer concrete culvert in a saline environment. Cem. Concr. Res. 2017, 100, 297–310. [Google Scholar] [CrossRef]

- He, R.; Dai, N.; Wang, Z. Thermal and mechanical properties of geopolymers exposed to high temperature: A literature review. Adv. Civ. Eng. 2020, 2020, 7532703. [Google Scholar] [CrossRef]

- Hager, I.; Sitarz, M.; Mróz, K. Fly-ash based geopolymer mortar for high-temperature application—Effect of slag addition. J. Clean. Prod. 2021, 316, 128168. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

| Temperature Range | Material | Properties | Key Findings | Research Gaps | Reference |

|---|---|---|---|---|---|

| 200, 400 and 800 °C | Fiber reinforced Metakaolin-based geopolymer block | Strength and Microstructure | Reduction in strength, more pronounced for fiber-free blocks. Micro-cracks are visible in SEM even after 200 °C. Fibers prevented the cracks’ propagation. | Only three temperatures were investigated. Aggregates were not included in the study. | [1] |

| Ambient, 200, 400, and 600 °C | Metakaolin-Based geopolymer concrete | Compressive Strength, Modulus of Elasticity, Water Absorption, and Weight Loss | Compressive Strength and Modulus of Elasticity decreased with the increase in temperature. Water absorption increased after 200 °C. SEMs after heating at 400 °C show a porous structure, which explains the loss of strength. | Only three temperatures were investigated. The study focused on geopolymer concrete but did not investigate mortars. | [2] |

| Ambient, 100, 300, 400, 500, 600 and 700 °C | Metakaolin-fly ash-based geopolymer concrete | Compressive and Splitting tensile strengths, sorptivity test, and chemical composition (X-ray) | The compressive strength of geopolymer concrete decreases with temperatures below 500 °C; the decrease is at a slower rate in the 500–700 °C range. The water absorption and sorptivity coefficient of geopolymer concretes with different strengths increased greatly with the increase in temperature. Concrete permeability of higher strength tends to increase at a higher pace. The permeability of geopolymer concrete was found to be higher than that of OPC-based concrete at any temperature. | Water permeability by the sorptivity test is performed. No information was given regarding gas permeability. The study focused on concrete; mortar mixes were not investigated. | [3] |

| Compressive, tensile and Flexural Strengths | Strength increases at 100 °C, then decreases due to micro-cracks mainly caused by differential thermal expansion behavior between binder and aggregates at 300–600 °C and a significant decrease due to thermal decomposition at 700 °C. | Effects of temperatures of 200, 400, 600 °C, and beyond 700 °C were not investigated. The study focused on mechanical properties; permeability was not studied. | [4] | ||

| Ambient, 100, 300, 500, 700 °C | Geopolymer mortar with 1:1 fly-ash to MK blend | Mass loss | Greater mass loss is attributed to the rapid evaporation of free water and part of chemically bound water in the 25–800 °C range, leading to micro-cracking | ||

| Thermal expansion | High thermal incompatibility between the paste and fine aggregates potentially leads to micro-cracking and strength loss beyond 100 °C. | ||||

| 20, 500 and 1200 °C | Fly ash-based geopolymer concrete | Compressive Strength, Mass loss, and Microstructure by SEM | Geopolymer concrete exhibited minor cracks compared to OPC-based concrete. Better strength retention was obtained for geopolymer concrete. Some geopolymer mixes with lower grades (20 and 40 Mpa) exhibited strength gain after exposure to 500 °C. Mass loss was lower for geopolymer concrete. | Only two temperatures were investigated. The study focused on geopolymer concrete but did not investigate mortars. Permeability was not studied. | [6] |

| Ambient and 100–800 °C with 100 °C increment | Fly Ash and slag blend-based geopolymer concrete, mortar, and paste | Compressive, tensile, and Flexural Strengths, XRD and SEM | Increase in geopolymer mortar strength with the increase in temperature up to 200 °C, followed by a decrease. However, the initial strength is retained even after exposure temperature of 500 °C. | Metakaolin-based mixes were not investigated. The study focused on mechanical properties and microstructural changes. Permeability was not studied. | [7] |

| 20 °C and 100–1000 °C with 100 °C increment | Geopolymeric materials with industrial residues | Durability properties | Geopolymer paste is superior to Portland cement paste, as indicated by the relatively lower mass and strength losses. | The study was limited to a geopolymer paste that is based on a blend of fly ash and metakaolin. | [8] |

| Ambient, 160, 400, 600, 800, and 1000 °C | Red mud slurry and fly ash-based geopolymer pastes | Mechanical behavior, volume change, weight loss, and microstructural change | Geopolymer retains its strength up to 600 °C. Weight loss was attributed to the loss of free and structural water as well as the dehydroxylation reaction. The breakdown of the geopolymer matrix as well as recrystallization, as clearly shown in the X-ray, took place at 600 °C and above. | Aggregates were not included in the mixes. Permeability was not investigated. | [10] |

| Compressive Strength | Continued to increase with the temperature exposure, even up to 400 °C. | The study was limited to paste; aggregates were not included in the study. Permeability was not studied. | [11] | ||

| Thermal shrinkage | Ordinary cement paste shows a higher rate of shrinkage compared to geopolymer paste after the thermal exposures. | ||||

| 20, 100–1000 °C with 100 °C increment. | Geopolymer paste combining fly ash and MK | Mass loss | The majority of mass loss takes place in the range of 100–400 °C for geopolymer paste. Beyond 400 °C, mass loss becomes almost stable for geopolymers but continues to increase for ordinary cement. | ||

| Sorptivity | The test shows lower water absorption in geopolymer compared to ordinary cement paste. | ||||

| Pore size distribution | The geopolymer paste microstructure becomes more dense with the increase in temperature in the range of 100–400 °C, possibly due to further geopolymerization. The total pore volume is higher for ordinary cement paste compared to geopolymer paste. | ||||

| 25, 500 and 1200 °C. | Fly ash-based geopolymer concrete | Compressive Strength | An increase was attained at a temperature of 500 °C attributed to further geopolymerization reaction | Only two elevated temperatures were examined. Permeability was not investigated. | [12] |

| Microstructural | The matrix of geopolymer concrete is denser compared to ordinary concrete. It becomes more dense after exposure to 500 °C due to further geopolymerization of unreacted binder particles. |

| Temperature Range | Material | Properties | Key Findings | Research Gaps | Reference |

|---|---|---|---|---|---|

| Ambient and 200–1000 °C with 200 °C increment | High strength ordinary concrete with various cement types, CEM I and CEM III | Compressive and tensile strength, static modulus of elasticity, and gas permeability | Concrete with CEM III exhibited lower permeability. The permeability of concrete increases exponentially with total damage for both types of cement. | Geopolymer mixes were not investigated in the study. | [18] |

| 23–70 °C | Fly ash-based geopolymer pastes | Permeability at down-hole stress conditions | The permeability of fly ash-based geopolymer paste is found to be lower than OPC-based paste. | The study was limited to geopolymer paste. Temperature in the range of 23–70 °C was only investigated. | [26] |

| Ambient | Red mud-blast furnace slag-based geopolymer concrete | Mechanical, Permeability, and Microscopic properties | The permeability of geopolymer concrete and average pore size were found to be three times lower than ordinary concrete due to lower total porosity and better pore structure. The development of silicon-aluminum octahedron improved the strength of the geopolymer significantly. | The effect of temperature on the properties was not investigated. | [27] |

| Ambient | High volume Fly ash-based ordinary concrete | Gas permeability, capillary water sorption, total porosity | Apparent permeability was found to be linearly proportional to total porosity. The fly ash-based concrete apparent gas permeability was found to be 78% lower compared to ordinary concrete. | The effect of temperature on the properties was not investigated. | [28] |

| Ambient | Fly ash and slag-based geopolymer mortar | Modulus of elasticity, tensile and compressive strength, gas permeability | Apparent gas permeability decreased with the increase in fly ash replacement by slag. | The effect of temperature on the properties was not investigated. | [29] |

| Ambient and 65 °C | Fly ash-based geopolymer concrete | High-pressure water and gas permeability | The water permeability of geopolymer concrete was found to be 10 times higher than that of ordinary concrete. Gas permeability was found alike. | The effect of elevated temperatures on the permeability was not investigated. | [30] |

| Chemical Properties | |||||||

|---|---|---|---|---|---|---|---|

| % by Weight | 38.5 | 58.7 | 0.85 | 0.72 | 0.5 | 0.38 | 0.2 |

| Mix Component | Cement | Sand | Water |

|---|---|---|---|

| Ratio to binder by mass | 1 | 3 | 0.7 |

| Mass | 427 | 1280 | 299 |

| Mix Component | Metakaolin | Sand | Solution | Solution |

|---|---|---|---|---|

| Ratio to binder by mass | 1 | 3 | 0.857 | 0.343 |

| Mass | 401.6 | 1204.8 | 344.2 | 137.7 |

| Temperature °C | MK-Based Geopolymer at 7 Days | MK-Based Geopolymer at 28 Days |

|---|---|---|

| 25 |  |  |

| 100 |  |  |

| 200 |  |  |

| 300 |  |  |

| 400 |  |  |

| 500 |  |  |

| 600 |  |  |

| 700 |  |  |

| 800 |  |  |

| 900 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ezzedine El Dandachy, M.; Hassoun, L.; El-Mir, A.; Khatib, J.M. Effect of Elevated Temperatures on Compressive Strength, Ultrasonic Pulse Velocity, and Transfer Properties of Metakaolin-Based Geopolymer Mortars. Buildings 2024, 14, 2126. https://doi.org/10.3390/buildings14072126

Ezzedine El Dandachy M, Hassoun L, El-Mir A, Khatib JM. Effect of Elevated Temperatures on Compressive Strength, Ultrasonic Pulse Velocity, and Transfer Properties of Metakaolin-Based Geopolymer Mortars. Buildings. 2024; 14(7):2126. https://doi.org/10.3390/buildings14072126

Chicago/Turabian StyleEzzedine El Dandachy, Mohamad, Lovey Hassoun, Abdulkader El-Mir, and Jamal M. Khatib. 2024. "Effect of Elevated Temperatures on Compressive Strength, Ultrasonic Pulse Velocity, and Transfer Properties of Metakaolin-Based Geopolymer Mortars" Buildings 14, no. 7: 2126. https://doi.org/10.3390/buildings14072126

APA StyleEzzedine El Dandachy, M., Hassoun, L., El-Mir, A., & Khatib, J. M. (2024). Effect of Elevated Temperatures on Compressive Strength, Ultrasonic Pulse Velocity, and Transfer Properties of Metakaolin-Based Geopolymer Mortars. Buildings, 14(7), 2126. https://doi.org/10.3390/buildings14072126