Advancing Circular Buildings: A Review of Building Strategies for AEC Stakeholders

Abstract

:1. Introduction

- identify key factors essential for the development of circular buildings;

- propose a simplified CB design-thinking approach, to inform AEC stakeholders to effectively embrace circularity.

1.1. Theoretical Background and the Importance of CE in the Building Sector

From Linear to Circular Buildings

2. Methods

- Papers focusing solely on construction and demolition waste (CDW) management were excluded;

- Papers analyzing buildings purely from a green or eco-energy perspective, without a consideration of CE principles, were excluded;

- Papers focused exclusively on urban and infrastructure were selected as being out of the scope;

- Papers focused exclusively on materials science and engineering without viewing materials through the perspective of the CE in buildings were excluded.

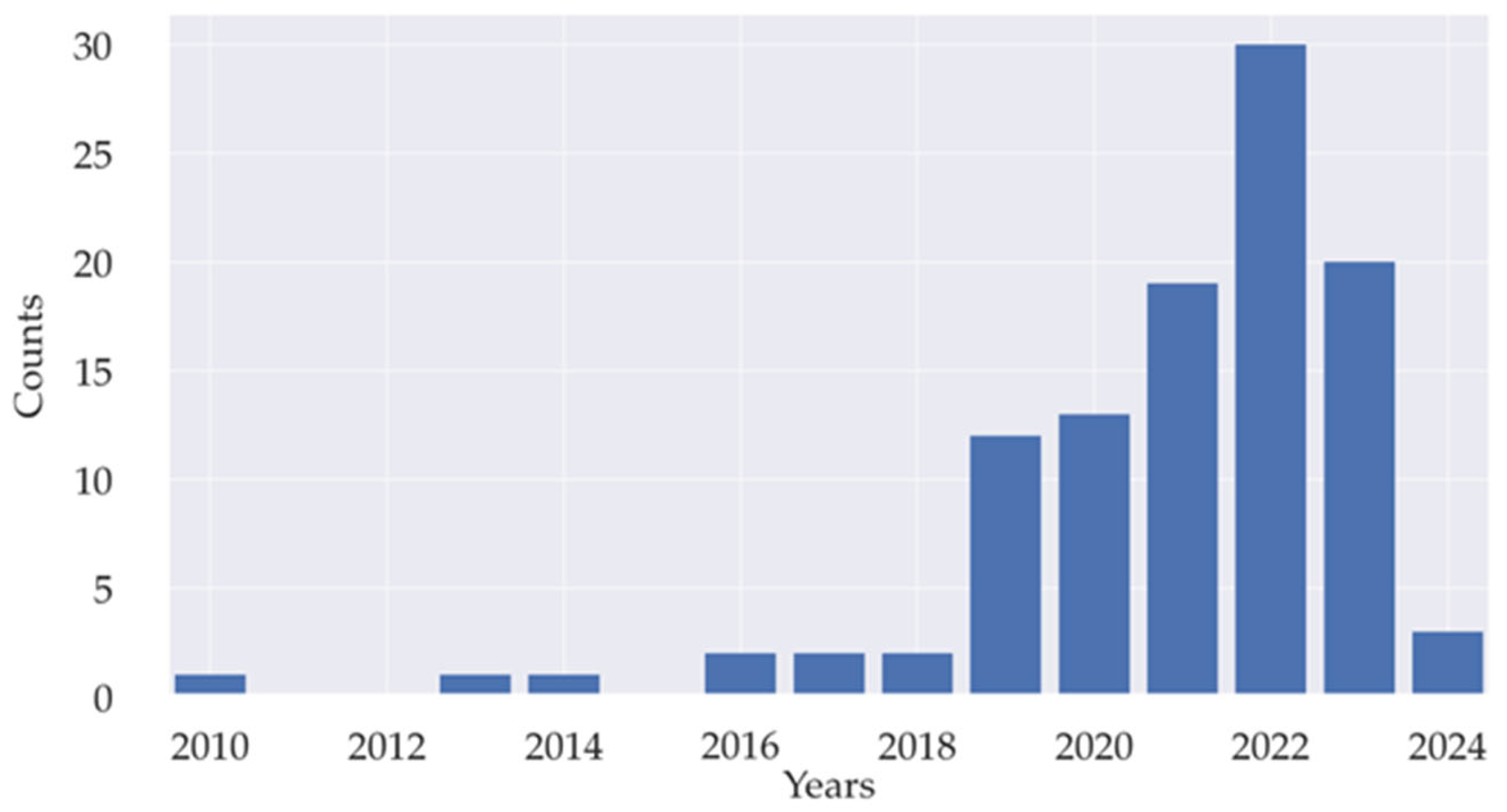

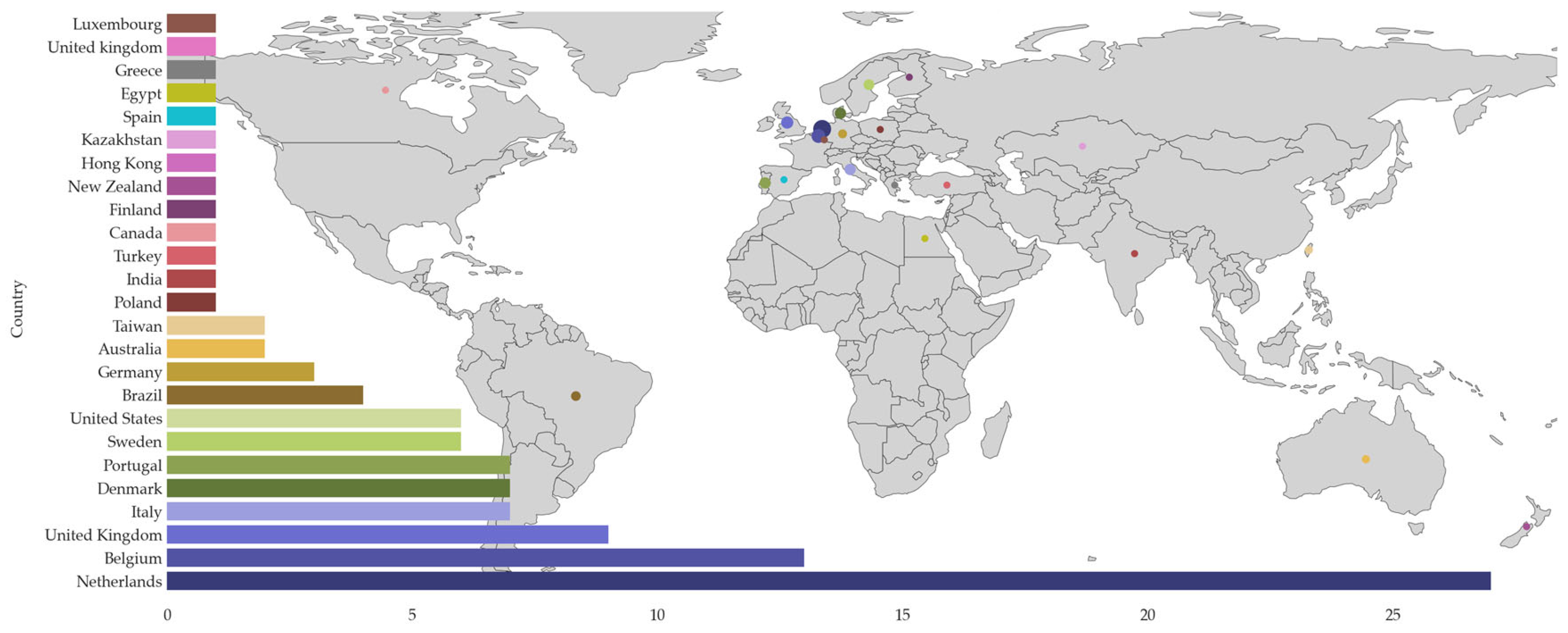

- Overview and descriptive analysis of CB development through the trend of years of publication, countries, themes, and types of documents analyzed;

- Critical analysis of key factors of CB development and the main design strategy factors for AEC adoption.

3. Results and Discussion

3.1. Descriptive Analysis and Trends

3.2. Critical Analysis and CB Design Thinking

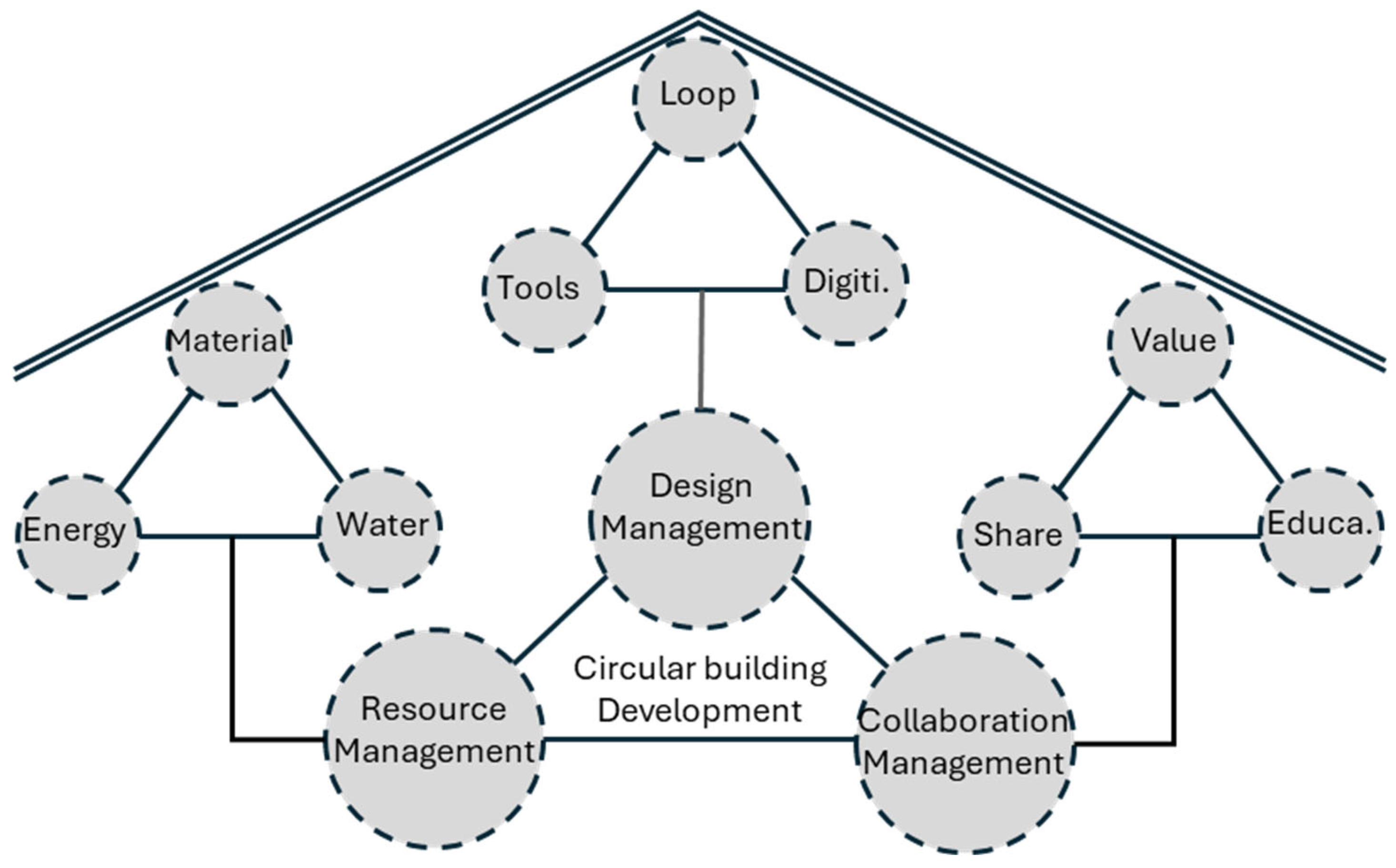

3.3. Key Approaches to CB Development

- Resource management: This encompasses indicators related to building materials, components, products, energy, and water factors and their associated values.

- Design management: This includes a combination of factors related to CE design strategies for constructing buildings, and the necessary tools for evaluation process, supported by advanced technologies for broad digitalization.

- Collaboration management: This covers factors related to stakeholder and supply chain involvement, including AEC interactions, and introduces new collaboration methods and business models in the building and construction industry [61].

3.3.1. Approaches to CB Resource Management

3.3.2. Approaches to CB Collaboration Management

3.3.3. Approaches to CB Design Management

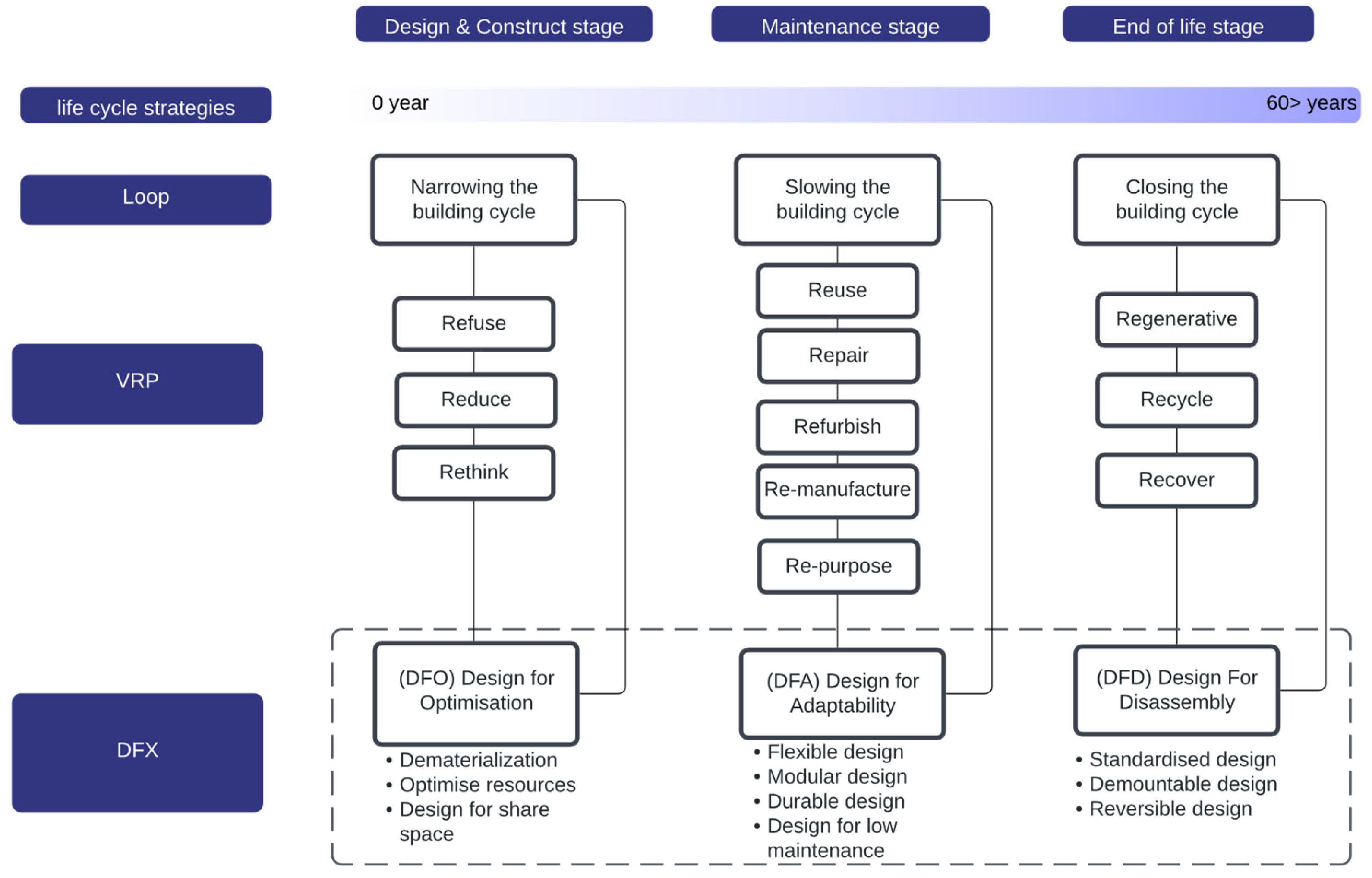

3.3.4. CB Loop-Based Process

3.3.5. Assessment Tools

3.3.6. Digitalization

3.4. Simplified Design Strategies Approach towards CB Developmnet

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nußholz, J.; Çetin, S.; Eberhardt, L.; De Wolf, C.; Bocken, N. From circular strategies to actions: 65 European circular building cases and their decarbonisation potential. Resour. Conserv. Recycl. Adv. 2023, 17, 200130. [Google Scholar] [CrossRef]

- Kayaçetin, N.C.; Verdoodt, S.; Lefevre, L.; Versele, A. Integrated decision support for embodied impact assessment of circular and bio-based building components. J. Build. Eng. 2023, 63, 105427. [Google Scholar] [CrossRef]

- UNEP. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UNEP: Brussels, Belgium, 2022. [Google Scholar]

- Fernandes, J.; Ferrão, P. A New Framework for Circular Refurbishment of Buildings to Operationalize Circular Economy Policies. Environments 2023, 10, 51. [Google Scholar] [CrossRef]

- Malabi Eberhardt, L.C.; van Stijn, A.; Nygaard Rasmussen, F.; Birkved, M.; Birgisdottir, H. Development of a life cycle assessment allocation approach for circular economy in the built environment. Sustainability 2020, 12, 9579. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe. 2020. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 12 January 2023).

- Zhang, N.; Han, Q.; de Vries, B. Building Circularity Assessment in the Architecture, Engineering, and Construction Industry: A New Framework. Sustainability 2021, 13, 12466. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- Mahpour, A. Prioritizing barriers to adopt circular economy in construction and demolition waste management. Resour. Conserv. Recycl. 2018, 134, 216–227. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- AlJaber, A.; Martinez-Vazquez, P.; Baniotopoulos, C. Barriers and enablers to the adoption of circular economy concept in the building sector: A systematic literature review. Buildings 2023, 13, 2778. [Google Scholar] [CrossRef]

- Cruz Rios, F.; Grau, D.; Bilec, M. Barriers and enablers to circular building design in the US: An empirical study. J. Constr. Eng. Manag. 2021, 147, 04021117. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. The ecodesign methodologies to achieve buildings’ deconstruction: A review and framework. Sustain. Prod. Consum. 2022, 30, 566–583. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Qi, J.; Zhao, J.; Li, W.; Peng, X.; Wu, B.; Wang, H. Origin and Background of Circular Economy Development. In Development of Circular Economy in China; Research Series on the Chinese Dream and China’s Development Path; Springer: Singapore, 2016; pp. 1–19. [Google Scholar]

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A review of the circularity gap in the construction industry through scientometric analysis. J. Clean. Prod. 2021, 298, 126870. [Google Scholar] [CrossRef]

- Hild, P. The Circular Economy and Circular Building Practices in Luxembourg. Circ. Econ. Sustain. 2023, 3, 1963–1988. [Google Scholar] [CrossRef]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482. [Google Scholar] [CrossRef]

- AlJaber, A.; Alasmari, E.; Martinez-Vazquez, P.; Baniotopoulos, C. Life Cycle Cost in Circular Economy of Buildings by Applying Building Information Modeling (BIM): A State of the Art. Buildings 2023, 13, 1858. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Esquivias, P.M.; Muntean, R. Eco-Efficient analysis of a refurbishment proposal for a social housing. Sustainability 2020, 12, 6725. [Google Scholar] [CrossRef]

- Parece, S.; Rato, V.; Resende, R.; Pinto, P.; Stellacci, S. A Methodology to Qualitatively Select Upcycled Building Materials from Urban and Industrial Waste. Sustainability 2022, 14, 3430. [Google Scholar] [CrossRef]

- Lovrenčić Butković, L.; Mihić, M.; Sigmund, Z. Assessment methods for evaluating circular economy projects in construction: A review of available tools. Int. J. Constr. Manag. 2023, 23, 877–886. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- European Commission. Clean energy for all Europeans. Euroheat Power 2019, 14, 3–4. [Google Scholar]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and barriers towards circular economy in the building sector: Stakeholder interviews and analysis of five European countries policies and practices. J. Clean. Prod. 2022, 336, 130395. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Többen, J.; Opdenakker, R. Developing a framework to integrate circularity into construction projects. Sustainability 2022, 14, 5136. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Dokter, G.; Thuvander, L.; Rahe, U. How circular is current design practice? Investigating perspectives across industrial design and architecture in the transition towards a circular economy. Sustain. Prod. Consum. 2021, 26, 692–708. [Google Scholar] [CrossRef]

- International Labor Organization. A Circular Economy Can Promote Decent Work. Available online: https://www.ilo.org/global/about-the-ilo/multimedia/video/institutional-videos/WCMS_771256/lang--en/index.htm (accessed on 6 August 2024).

- Malabi Eberhardt, L.C.; van Stijn, A.; Kristensen Stranddorf, L.; Birkved, M.; Birgisdottir, H. Environmental design guidelines for circular building components: The case of the circular building structure. Sustainability 2021, 13, 5621. [Google Scholar] [CrossRef]

- Kibert, C.J. Deconstruction: The start of a sustainable materials strategy for the built environment. Ind. Environ. 2003, 26, 84–88. [Google Scholar]

- van Stijn, A.; Eberhardt, L.M.; Jansen, B.W.; Meijer, A. A circular economy life cycle assessment (CE-LCA) model for building components. Resour. Conserv. Recycl. 2021, 174, 105683. [Google Scholar] [CrossRef]

- Antonini, E.; Boeri, A.; Lauria, M.; Giglio, F. Reversibility and Durability as Potential Indicators for Circular Building Technologies. Sustainability 2020, 12, 7659. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- EMF. Circularity in the Built Environment. 2016. Available online: https://emf.thirdlight.com/link/bpso50t2ia56-9bw2n5/@/preview/1?o (accessed on 2 March 2024).

- Askar, R.; Bragança, L.; Gervásio, H. Design for adaptability (DfA)—Frameworks and assessment models for enhanced circularity in buildings. Appl. Syst. Innov. 2022, 5, 24. [Google Scholar] [CrossRef]

- Brand, S. How Buildings Learn: What Happens after They’re Built; Penguin: London, UK, 1995. [Google Scholar]

- Iyer-Raniga, U. Using the ReSOLVE framework for circularity in the building and construction industry in emerging markets. IOP Conf. Ser. Earth Environ. Sci. 2019, 294, 012002. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdottir, H.; Birkved, M. Potential of Circular Economy in Sustainable Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 092051. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection criteria for building materials and components in line with the circular economy principles in the built environment—A review of current trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Oke, A.; Omotayo, T.; Obi, L.I. A systematic review of circular economy research in the construction industry. Smart Sustain. Built Environ. 2020, 11, 39–64. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 1–9. [Google Scholar] [CrossRef]

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular material passports for buildings—Providing a robust methodology for promoting circular buildings. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012049. [Google Scholar] [CrossRef]

- Núñez-Cacho, P.; Górecki, J.; Molina, V.; Corpas-Iglesias, F.A. New Measures of Circular Economy Thinking in Construction Companies. J. EU Res. Bus. 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- Caldas, L.R.; Silva, M.V.; Silva, V.P.; Carvalho, M.T.M.; Toledo Filho, R.D. How Different Tools Contribute to Climate Change Mitigation in a Circular Building Environment?—A Systematic Literature Review. Sustainability 2022, 14, 3759. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. 2019. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 12 July 2023).

- Zhu, H.; Liou, S.-R.; Chen, P.-C.; He, X.-Y.; Sui, M.-L. Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability 2024, 16, 1729. [Google Scholar] [CrossRef]

- van Eck, J. Innovation in a Large Scale Agile Organisation: A Case Study of ABN AMRO. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Sanderson, K. Greener buildings. Nature 2022, 611, S18–S19. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. Capital project planning for a circular economy. Constr. Manag. Econ. 2018, 36, 303–312. [Google Scholar] [CrossRef]

- Al-Obaidy, M.; Courard, L.; Attia, S. A parametric approach to optimizing building construction systems and carbon footprint: A case study inspired by circularity principles. Sustainability 2022, 14, 3370. [Google Scholar] [CrossRef]

- Cottafava, D.; Ritzen, M. Circularity indicator for residential buildings: Addressing the gap between embodied impacts and design aspects. Resour. Conserv. Recycl. 2021, 164, 105120. [Google Scholar] [CrossRef]

- de Feijter, F.J. Trust in circular design: Active stakeholder participation in Chinese and Dutch housing retrofit projects. Build. Res. Inf. 2023, 51, 105–118. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Ajayi, S.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Bello, S.A.; Jaiyeoba, B.E.; Kadiri, K.O. Design for Deconstruction (DfD): Critical success factors for diverting end-of-life waste from landfills. Waste Manag. 2017, 60, 3–13. [Google Scholar] [CrossRef] [PubMed]

- Van Stijn, A.; Jansen, B.W.; Gruis, V.; van Bortel, G. Towards implementation of circular building components: A longitudinal study on the stakeholder choices in the development of 8 circular building components. J. Clean. Prod. 2023, 420, 138287. [Google Scholar] [CrossRef]

- Van Oorschot, J.; Sprecher, B.; Rijken, B.; Witteveen, P.; Blok, M.; Schouten, N.; van der Voet, E. Toward a low-carbon and circular building sector: Building strategies and urbanization pathways for the Netherlands. J. Ind. Ecol. 2023, 27, 535–547. [Google Scholar] [CrossRef]

- Zhuang, G.-L.; Shih, S.-G.; Wagiri, F. Circular economy and sustainable development goals: Exploring the potentials of reusable modular components in circular economy business model. J. Clean. Prod. 2023, 414, 137503. [Google Scholar] [CrossRef]

- Çimen, Ö. Development of a circular building lifecycle framework: Inception to circulation. Results Eng. 2023, 17, 100861. [Google Scholar] [CrossRef]

- Hamida, M.B.; Remøy, H.; Gruis, V.; Jylhä, T. Circular building adaptability in adaptive reuse: Multiple case studies in the Netherlands. J. Eng. Des. Technol. 2023. [Google Scholar] [CrossRef]

- Temizel-Sekeryan, S.; Rios, F.C.; Geremicca, F.; Bilec, M.M. Circular Design and Embodied Carbon in Living Buildings: The Missing Potential. J. Archit. Eng. 2023, 29, 04023013. [Google Scholar] [CrossRef]

- Whiting, P.; Cullen, V.; Adkins, H.; Chatteur, F. A new retail interior design education paradigm for a circular economy. Sustainability 2023, 15, 1487. [Google Scholar] [CrossRef]

- Balogun, H.; Alaka, H.; Egwim, C.N.; Ajayi, S. Systematic review of drivers influencing building deconstructability: Towards a construct-based conceptual framework. Waste Manag. Res. 2023, 41, 512–530. [Google Scholar] [CrossRef] [PubMed]

- Munaro, M.R.; Tavares, S.F. Design for adaptability and disassembly: Guidelines for building deconstruction. Constr. Innov. 2023, 23. [Google Scholar] [CrossRef]

- Lespagnard, M.; Galle, W.; De Temmerman, N. The equitable housing workshop. Mapping and improving stakeholders’ decision-making process for circular equitable housing projects. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012024. [Google Scholar] [CrossRef]

- Nemeth, I.; Schneider-Marin, P.; Figl, H.; Fellner, M.; Asam, C. Circularity evaluation as guidance for building design. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012082. [Google Scholar] [CrossRef]

- Hamida, M.B.; Jylhä, T.; Remøy, H.; Gruis, V. Circular building adaptability and its determinants—A literature review. Int. J. Build. Pathol. Adapt. 2023, 41, 47–69. [Google Scholar] [CrossRef]

- Vardopoulos, I. Industrial building adaptive reuse for museum. Factors affecting visitors’ perceptions of the sustainable urban development potential. Build. Environ. 2022, 222, 109391. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M. Design for Circularity: The case of the building construction industry. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 062026. [Google Scholar] [CrossRef]

- Wouterszoon Jansen, B.; van Stijn, A.; Gruis, V.; van Bortel, G. Cooking Up a Circular Kitchen: A Longitudinal Study of Stakeholder Choices in the Development of a Circular Building Component. Sustainability 2022, 14, 15761. [Google Scholar] [CrossRef]

- Dabaieh, M.; Maguid, D.; El-Mahdy, D. Circularity in the new gravity—Re-thinking vernacular architecture and circularity. Sustainability 2021, 14, 328. [Google Scholar] [CrossRef]

- Andersen, R.; Jensen, L.; Ryberg, M.W. Adaptation of circular design strategies based on historical trends and demolition patterns. IOP Conf. Ser. Earth Environ. Sci. 2022, 1085, 012062. [Google Scholar] [CrossRef]

- Dokter, G.; Jansen, B.; Thuvander, L.; Rahe, U.; Duijghuisen, J. Cards for Circularity (CFC): Reflections on the use of a card-based circular design tool in design education. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012057. [Google Scholar] [CrossRef]

- Lucanto, D. Advanced Circular Design, a Life Cycle Approach: Methods and Tools for an Eco-Innovative Life Cycle Approach for Buildings Energy and Resource Optimization. In Proceedings of the International Symposium: New Metropolitan Perspectives, Reggio Calabria, Italy, 24–26 May 2022; pp. 1870–1878. [Google Scholar]

- Talla, A.; McIlwaine, S. Industry 4.0 and the circular economy: Using design-stage digital technology to reduce construction waste. Smart Sustain. Built Environ. 2024, 13, 179–198. [Google Scholar] [CrossRef]

- Tleuken, A.; Torgautov, B.; Zhanabayev, A.; Turkyilmaz, A.; Mustafa, M.; Karaca, F. Design for deconstruction and disassembly: Barriers, opportunities, and practices in developing economies of Central Asia. Procedia CIRP 2022, 106, 15–20. [Google Scholar] [CrossRef]

- Rajagopalan, N.; Brancart, S.; De Regel, S.; Paduart, A.; Temmerman, N.D.; Debacker, W. Multi-criteria decision analysis using life cycle assessment and life cycle costing in circular building design: A case study for wall partitioning systems in the circular retrofit lab. Sustainability 2021, 13, 5124. [Google Scholar] [CrossRef]

- Buser, M.; Gottlieb, S.C.; de Gier, A.J.; Andersson, R. From Concept to Practice: Implementation of Circular Building as a Process of Translation. In Proceedings of the 37th Annual ARCOM Conference, Association of Researchers in Construction Management Conference, Glasgow, UK, 6–7 September 2021; pp. 584–593. [Google Scholar]

- Rahla, K.M.; Mateus, R.; Bragança, L. Implementing circular economy strategies in buildings—From theory to practice. Appl. Syst. Innov. 2021, 4, 26. [Google Scholar] [CrossRef]

- Van Gulck, L.; Leenknecht, E.; Debusseré, E.; Van Steenkiste, J.; Steeman, M.; Van Den Bossche, N. Development of a circularity assessment method for facade systems. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012008. [Google Scholar] [CrossRef]

- Bakos, N.; Schiano-Phan, R. Bioclimatic and regenerative design guidelines for a circular university campus in India. Sustainability 2021, 13, 8238. [Google Scholar] [CrossRef]

- Al-Obaidy, M.; Santos, M.; Baskar, M.; Attia, S. Assessment of the circularity and carbon neutrality of an office building: The case of’t Centrum in Westerlo, Belgium. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012025. [Google Scholar] [CrossRef]

- Oorschot, L.; Asselbergs, T. New housing concepts: Modular, circular, biobased, reproducible, and affordable. Sustainability 2021, 13, 13772. [Google Scholar] [CrossRef]

- Mhatre, P.; Gedam, V.; Unnikrishnan, S.; Verma, S. Circular economy in built environment—Literature review and theory development. J. Build. Eng. 2021, 35, 101995. [Google Scholar] [CrossRef]

- Attia, S.; Santos, M.; Al-Obaidy, M.; Baskar, M. Leadership of EU member States in building carbon footprint regulations and their role in promoting circular building design. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012023. [Google Scholar] [CrossRef]

- Çetin, S.; De Wolf, C.; Bocken, N. Circular digital built environment: An emerging framework. Sustainability 2021, 13, 6348. [Google Scholar] [CrossRef]

- Hartwell, R.; Macmillan, S.; Overend, M. Circular economy of façades: Real-world challenges and opportunities. Resour. Conserv. Recycl. 2021, 175, 105827. [Google Scholar] [CrossRef]

- Gerhardsson, H.; Lindholm, C.; Andersson, J.; Kronberg, A.; Wennesjö, M.; Shadram, F. Transitioning the Swedish building sector toward reuse and circularity. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042036. [Google Scholar] [CrossRef]

- van Stijn, A.; Gruis, V. Towards a circular built environment: An integral design tool for circular building components. Smart Sustain. Built Environ. 2020, 9, 635–653. [Google Scholar] [CrossRef]

- Geldermans, B.; Tavakolly, N.; Udding, H. Circular building design for the infill domain: Materialisation, and value network study of the niaga ECOR panel innovation. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042035. [Google Scholar] [CrossRef]

- Van Stijn, A.; Eberhardt, L.; Jansen, B.W.; Meijer, A. Design guidelines for circular building components based on LCA and MFA: The case of the Circular Kitchen. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042045. [Google Scholar] [CrossRef]

- Finch, G.; Marriage, G.; Gjerde, M.; Pelosi, A.; Patel, Y. Understanding the challenges of circular economy construction through full-scale prototyping. In Proceedings of the International Conference of Architectural Science Association, Auckland, New Zealand, 26–27 November 2020. [Google Scholar] [CrossRef]

- Kozminska, U. Circular Economy in Nordic Architecture. Thoughts on the process, practices, and case studies. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042042. [Google Scholar] [CrossRef]

- Futas, N.; Rajput, K.; Schiano-Phan, R. Cradle to Cradle and Whole-Life Carbon assessment—Barriers and opportunities towards a circular economic building sector. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012036. [Google Scholar] [CrossRef]

- Huovila, P.; Iyer-Raniga, U.; Maity, S. Circular economy in the built environment: Supporting emerging concepts. IOP Conf. Ser. Earth Environ. Sci. 2019, 297, 012003. [Google Scholar]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and flexible infill concepts: Integration of the residential user perspective. Sustainability 2019, 11, 261. [Google Scholar] [CrossRef]

- Rasmussen, F.N.; Birkved, M.; Birgisdóttir, H. Upcycling and Design for Disassembly—LCA of buildings employing circular design strategies. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012040. [Google Scholar] [CrossRef]

- Kozminska, U. Circular design: Reused materials and the future reuse of building elements in architecture. Process, challenges and case studies. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012033. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Omoteso, K.; Bilal, M.; Akinade, O.O.; Ajayi, A.O.; Delgado, J.M.D.; Owolabi, H.A. Disassembly and deconstruction analytics system (D-DAS) for construction in a circular economy. J. Clean. Prod. 2019, 223, 386–396. [Google Scholar] [CrossRef]

- Zabek, M.; Hildebrand, L.; Brell-Cokcan, S.; Wirth, M. Used building materials as secondary resources—Identification of valuable building material and automized deconstruction. J. Facade Des. Eng. 2017, 5, 25–33. [Google Scholar]

- Geldermans, R. Design for change and circularity—Accommodating circular material & product flows in construction. Energy Procedia 2016, 96, 301–311. [Google Scholar]

- Bocken, N.M.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Hamidi, B.; Bulbul, T. A comparative analysis of sustainable approaches to building end-of-lifecycle: Underlying deconstruction principles in theory and practice. In ICSDEC 2012: Developing the Frontier of Sustainable Design, Engineering, and Construction—Proceedings of the 2012 International Conference on Sustainable Design and Construction, Fort Worth, TX, USA, 7–9 November 2012; ASCE: Reston, VA, USA, 2013; pp. 155–162. [Google Scholar]

- Antonini, E.; Giurdanella, V.; Zanelli, A. Reversible design: Strategies to allow building deconstruction and a second life for salvaged materials. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies Main Proceedings, Ancona, Italy, 28–30 June 2010; pp. 1207–1217. [Google Scholar]

- Van Gulck, L.; Steeman, M. The environmental impact of circular building design: A simplified approach to evaluate remountable building elements in life cycle assessment. Build. Environ. 2024, 254, 111418. [Google Scholar] [CrossRef]

- Kapica, B.; Targowski, W.; Kulowski, A. Is the Concept of Zero Waste Possible to Implement in Construction? Buildings 2024, 14, 428. [Google Scholar] [CrossRef]

- Talpur, B.D.; Liuzzi, S.; Rubino, C.; Cannavale, A.; Martellotta, F. Life Cycle Assessment and Circular Building Design in South Asian Countries: A Review of the Current State of the Art and Research Potentials. Buildings 2023, 13, 3045. [Google Scholar] [CrossRef]

- Jansen, B.W.; van Stijn, A.; Eberhardt, L.C.M.; van Bortel, G.; Gruis, V. The technical or biological loop? Economic and environmental performance of circular building components. Sustain. Prod. Consum. 2022, 34, 476–489. [Google Scholar] [CrossRef]

- Cascione, V.; Roberts, M.; Allen, S.; Dams, B.; Maskell, D.; Shea, A.; Walker, P.; Emmitt, S. Integration of life cycle assessments (LCA) in circular bio-based wall panel design. J. Clean. Prod. 2022, 344, 130938. [Google Scholar] [CrossRef]

- Van Gulck, L.; Wastiels, L.; Steeman, M. How to evaluate circularity through an LCA study based on the standards EN 15804 and EN 15978. Int. J. Life Cycle Assess. 2022, 27, 1249–1266. [Google Scholar] [CrossRef]

- Gomes, V.; Valdivia, S.; Pulgrossi, L.; da Silva, M.G. Measuring circularity from buildings to neighbourhoods. Acta Polytech. CTU Proc. 2022, 38, 656–671. [Google Scholar] [CrossRef]

- Van Stijn, A.; Eberhardt, L.; Jansen, B.W.; Meijer, A. Environmental design guidelines for circular building components based on LCA and MFA: Lessons from the circular kitchen and renovation façade. J. Clean. Prod. 2022, 357, 131375. [Google Scholar] [CrossRef]

- Bourgeois, I.; Queirós, A.; Oliveira, J.; Rodrigues, H.; Vicente, R.; Ferreira, V.M. Development of an Eco-Design Tool for a Circular Approach to Building Renovation Projects. Sustainability 2022, 14, 8969. [Google Scholar] [CrossRef]

- Jansen, B.W.; van Stijn, A.; Gruis, V.; van Bortel, G. A circular economy life cycle costing model (CE-LCC) for building components. Resour. Conserv. Recycl. 2020, 161, 104857. [Google Scholar] [CrossRef]

- Andersen, C.M.E.; Kanafani, K.; Zimmermann, R.K.; Rasmussen, F.N.; Birgisdóttir, H. Comparison of GHG emissions from circular and conventional building components. Build. Cities 2020, 1, 379–392. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Hamidi, B.; Bulbul, T. An Evaluation of Life Cycle Analysis (LCA) Tools for Environmental Impact Analysis of Building End-of-Life Cycle Operations. In Computing in Civil and Building Engineering; ASCE: Reston, VA, USA, 2014; pp. 1943–1950. [Google Scholar]

- Aguiar, A.; Vonk, R.; Kamp, F. BIM and circular design. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012068. [Google Scholar] [CrossRef]

- Cambier, C.; Galle, W.; De Temmerman, N. Research and development directions for design support tools for circular building. Buildings 2020, 10, 142. [Google Scholar] [CrossRef]

- Setaki, F.; van Timmeren, A. Disruptive technologies for a circular building industry. Build. Environ. 2022, 223, 109394. [Google Scholar] [CrossRef]

- Giglio, F.; Lauria, M.; Sansotta, S. Circular design strategies through Additive manufacturing: MoDom, a “circular building” Housing Model. Acta Polytech. CTU Proc. 2022, 38, 678–686. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular strategies enabled by the internet of things—A framework and analysis of current practice. Sustainability 2019, 11, 5689. [Google Scholar] [CrossRef]

- Pelicaen, E.; Janssens, B.; Knapen, E. Circular building with raw earth: A qualitative assessment of two cases in Belgium. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012002. [Google Scholar] [CrossRef]

- Nußholz, J.L.; Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Wouterszoon Jansen, B.; Duijghuisen, J.-A.; van Bortel, G.; Gruis, V. Comparing Circular Kitchens: A Study of the Dutch Housing Sector. Buildings 2023, 13, 1698. [Google Scholar] [CrossRef]

- Huovila, P.; Iyer-Raniga, U.; Cheong, C.; Malhotra, R.; Choudhary, Y.; Penagos, G. Circular design in the Global South. Acta Polytech. CTU Proc. 2022, 38, 642–648. [Google Scholar] [CrossRef]

- Cambier, C.; Poppe, J.; Galle, W.; Elsen, S.; De Temmerman, N. The Circular Retrofit Lab: A multi-disciplinary development of a building envelope according to circular design qualities. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012013. [Google Scholar] [CrossRef]

- Roberts, M.; Allen, S.; Clarke, J.; Searle, J.; Coley, D. Understanding the global warming potential of circular design strategies: Life cycle assessment of a design-for-disassembly building. Sustain. Prod. Consum. 2023, 37, 331–343. [Google Scholar] [CrossRef]

- Ghasemi, E.; Azari, R.; Zahed, M. Carbon Neutrality in the Building Sector of the Global South—A Review of Barriers and Transformations. Buildings 2024, 14, 321. [Google Scholar] [CrossRef]

- Kanters, J. Circular building design: An analysis of barriers and drivers for a circular building sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Gerding, D.; Wamelink, H.; Leclercq, E. Implementation of circularity in the building process: A case study research into organizing the actor network and decision-making process. Management 2020, 556, 565. [Google Scholar]

- Senaratne, S.; Abhishek, K.; Perera, S.; Almeida, L. Promoting stakeholder collaboration in adopting circular economy principles for sustainable construction. In Proceedings of the 9th World Construction Symposium, Online, 9–10 July 2021; pp. 471–482. [Google Scholar] [CrossRef]

- Andrade, J.; Araújo, C.; Castro, M.d.F.; Bragança, L. New methods for sustainable circular buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012037. [Google Scholar] [CrossRef]

- van der Zwaag, M.; Wang, T.; Bakker, H.; van Nederveen, S.; Schuurman, A.; Bosma, D. Evaluating building circularity in the early design phase. Autom. Constr. 2023, 152, 104941. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Cascione, V.; Walker, P. Upscaling bio-based construction: Challenges and opportunities. Build. Res. Inf. 2023, 51, 764–782. [Google Scholar] [CrossRef]

- Cramer, J. How circular economy and digital technologies can support the building sector to cope with its worldwide environmental challenge? npj Urban Sustain. 2023, 3, 28. [Google Scholar] [CrossRef]

- Serrano-Bedia, A.-M.; Perez-Perez, M. Transition towards a circular economy: A review of the role of higher education as a key supporting stakeholder in Web of Science. Sustain. Prod. Consum. 2022, 31, 82–96. [Google Scholar] [CrossRef]

- Ababio, B.K.; Lu, W.; Ghansah, F.A. Transitioning from green to circular procurement in developing countries: A conceptual framework for Ghana’s construction sector. Build. Res. Inf. 2023, 51, 798–815. [Google Scholar] [CrossRef]

- Wielopolski, M.; Bulthuis, W. The Better Building Initiative—A Collaborative Ecosystem Involving All Stakeholders as Catalyst to Accelerate the Adoption of Circular Economy Innovations in the Construction Sector. Circ. Econ. Sustain. 2023, 3, 719–733. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Joensuu, T.; Leino, R.; Heinonen, J.; Saari, A. Developing Buildings’ Life Cycle Assessment in Circular Economy-Comparing methods for assessing carbon footprint of reusable components. Sustain. Cities Soc. 2022, 77, 103499. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.; Oti-Sarpong, K.; Wuni, I.Y.; Tetteh, M.O. Systematic review on the integration of building information modelling and prefabrication construction for low-carbon building delivery. Build. Res. Inf. 2023, 51, 279–300. [Google Scholar] [CrossRef]

- Banaitė, D. Towards Circular Economy: Analysis of Indicators in the Context of Sustainable Development. Soc. Transform. Contemp. Soc. 2016, 4, 142–150. [Google Scholar]

- de Lima, P.R.B.; de Souza Rodrigues, C.; Post, J.M. Integration of BIM and design for deconstruction to improve circular economy of buildings. J. Build. Eng. 2023, 80, 108015. [Google Scholar] [CrossRef]

- Bilal, M.; Musarat, M.A.; Afzal, M.; Irfan, M. BIM Role for Circular Economy in the Built Environment Context: A Review and Way Forward. Preprints 2023, 2023100027. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life cycle assessment of a Danish office building designed for disassembly. Build. Res. Inf. 2019, 47, 666–680. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Regional circular economy of building materials: Environmental and economic assessment combining material flow analysis, input-output analyses, and life cycle assessment. J. Ind. Ecol. 2022, 26, 562–576. [Google Scholar] [CrossRef]

- Kang, H.; Lee, Y.; Kim, S. Sustainable building assessment tool for project decision makers and its development process. Environ. Impact Assess. Rev. 2016, 58, 34–47. [Google Scholar] [CrossRef]

- Gan, V.J.; Lo, I.M.; Ma, J.; Tse, K.T.; Cheng, J.C.; Chan, C.M. Simulation optimisation towards energy efficient green buildings: Current status and future trends. J. Clean. Prod. 2020, 254, 120012. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep learning model for Demolition Waste Prediction in a circular economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. Opportunities and challenges in IoT-enabled circular business model implementation—A case study. Resour. Conserv. Recycl. 2020, 162, 105047. [Google Scholar] [CrossRef]

- Ding, S.; Tukker, A.; Ward, H. Opportunities and risks of internet of things (IoT) technologies for circular business models: A literature review. J. Environ. Manag. 2023, 336, 117662. [Google Scholar] [CrossRef] [PubMed]

- Khadim, N.; Agliata, R.; Marino, A.; Thaheem, M.J.; Mollo, L. Critical review of nano and micro-level building circularity indicators and frameworks. J. Clean. Prod. 2022, 357, 131859. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18, 93–113. [Google Scholar] [CrossRef]

- Kamara, J.M.; Heidrich, O.; Tafaro, V.E.; Maltese, S.; Dejaco, M.C.; Re Cecconi, F. Change Factors and the Adaptability of Buildings. Sustainability 2020, 12, 6585. [Google Scholar] [CrossRef]

- Salama, W. Design of concrete buildings for disassembly: An explorative review. Int. J. Sustain. Built Environ. 2017, 6, 617–635. [Google Scholar] [CrossRef]

- Fuster, A.; Gibb, A.; Austin, S.; Beadle, K.; Madden, P. Adaptable Buildings: Three Non-Residential Case Studies; Wamelink, H., Prins, M., Geraedts, R., Eds.; TU Delft: Delft, The Netherlands, 2009; pp. 5–9. [Google Scholar]

- Giglio, F.; Sansotta, S.; Grillo, E. Reversible building technologies and unconventional materials for the circular and creative reuse of small centers. In Proceedings of the International Symposium: New Metropolitan Perspectives, Reggio Calabria, Italy, 24–26 May 2022; pp. 2778–2789. [Google Scholar]

- Klinge, A.; Roswag-Klinge, E.; Paganoni, S.; Radeljic, L.; Lehmann, M. Design concept for prefabricated elements from CDW timber for a circurlar building. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012022. [Google Scholar] [CrossRef]

- Roithner, C.; Cencic, O.; Honic, M.; Rechberger, H. Recyclability assessment at the building design stage based on statistical entropy: A case study on timber and concrete building. Resour. Conserv. Recycl. 2022, 184, 106407. [Google Scholar] [CrossRef]

- Manewa, A.; Siriwardena, M.; Ross, A.; Madanayake, U. Adaptable buildings for sustainable built environment. Built Environ. Proj. Asset Manag. 2016, 6, 139–158. [Google Scholar] [CrossRef]

| Design Management | Description | Sources | No. of Papers |

|---|---|---|---|

| CE Loop * | Factors of 10Rs and design strategies. | [1,2,4,5,13,14,20,29,31,33,35,38,42,57,58,60,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110] | 65 |

| Tools | Assessment factors of LCA, BIM, LCC, MP, MFA, Circ-Flex, etc. | [1,2,5,35,37,57,58,67,83,88,100,103,111,112,113,114,115,116,117,118,119,120,121,122,123], [22,50,52,81,86,92,95,96,105,122,124,125] | 37 |

| Digitalization | Factors of AI, digital twins, Block chain, IOT, etc. | [81,93,126,127,128] | 5 |

| Resource Management | |||

| Materials | Indicators of bio-based, renewable, innovative, secondary, and low impact materials, components product, etc. | [2,5,20,29,35,37,46,50,52,58,63,67,81,83,86,88,89,90,93,94,97,99,101,104,114,115,116,118,119,120,122,124,127,128,129,130,131,132,133] | 39 |

| Energy | Indicators of carbon (CO2), GHG, etc. | [1,67,88,91,93,96,100,103,112,117,119,121,122,130,133,134,135] | 17 |

| Water | Indicators of recycled and grey water. | [46,80,136] | 3 |

| Collaboration Management | |||

| Value | Factors of take back scheme, business model, tax incentives, reverse supply chain model. | [4,29,40,75,76,89,90,93,96,130,137,138,139] | 13 |

| Share | Factors of sharing system, innovative ownership model, etc. | [33,40,60] | 3 |

| Education | Factors of knowledge exchange, actor learning, traceability, etc. | [29,33,40,60,68,93,108,112,135,137,139,140] | 12 |

| Loops | Strategies | Sources | No. of Papers | |

|---|---|---|---|---|

| CB Narrow Loop | VRP | Refuse | [65,68] | 2 |

| Reduce | [65,68] | 2 | ||

| Rethink | [65,68] | 2 | ||

| DFX | Design for optimization | [57] | 1 | |

| Dematerialization | [57] | 1 | ||

| Design for share spaces | [52] | 1 | ||

| CB Slow Loop | VRP | Reuse | [2,5,64,65,68,72,78,81,82,83,88,94,97,99,103,104,109,112,116,118,133] | 21 |

| Repair | [65,68] | 2 | ||

| Refurbishment/Renovation/Retrofit | [4,60,65,68,101,116,133] | 8 | ||

| Re-manufacture | [65,68] | 2 | ||

| Repurpose/Adaptive reuse | [57,65,66,68,74,78,111] | 7 | ||

| DFX | Design for adaptability | [14,35,42,66,70,73,83,107,133] | 9 | |

| Design for flexibility | [66,88,102] | 3 | ||

| Modular & Prefab design | [64,70,89,97,98,118,133,165] | 8 | ||

| Design for low maintenance | [99] | 1 | ||

| Design for durability | [35,38] | 2 | ||

| CB close Loop | VRP | Regenerative | [77,80,87,92,100] | 8 |

| Recycle | [2,5,65,67,78,81,103,106,109,112,116] | 11 | ||

| Recover | [65,68,81,88,97] | 5 | ||

| DFX | Design for disassembly | [4,13,14,42,57,70,72,82,88,94,99,103,105,106,109,134,165] | 17 | |

| Design for deconstruction | [69] | 1 | ||

| Demountable design | [94,111,165] | 3 | ||

| Reversible design | [29,38,42,98,99] | 5 | ||

| Standardization | [70] | 1 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motiei, M.; Iyer-Raniga, U.; Andamon, M.M.; Khodabakhshian, A. Advancing Circular Buildings: A Review of Building Strategies for AEC Stakeholders. Buildings 2024, 14, 2594. https://doi.org/10.3390/buildings14092594

Motiei M, Iyer-Raniga U, Andamon MM, Khodabakhshian A. Advancing Circular Buildings: A Review of Building Strategies for AEC Stakeholders. Buildings. 2024; 14(9):2594. https://doi.org/10.3390/buildings14092594

Chicago/Turabian StyleMotiei, Mohana, Usha Iyer-Raniga, Mary Myla Andamon, and Ania Khodabakhshian. 2024. "Advancing Circular Buildings: A Review of Building Strategies for AEC Stakeholders" Buildings 14, no. 9: 2594. https://doi.org/10.3390/buildings14092594