Harnessing Natural Pozzolan for Sustainable Heating and Cooling: Thermal Performance and Building Efficiency in Moroccan Climates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

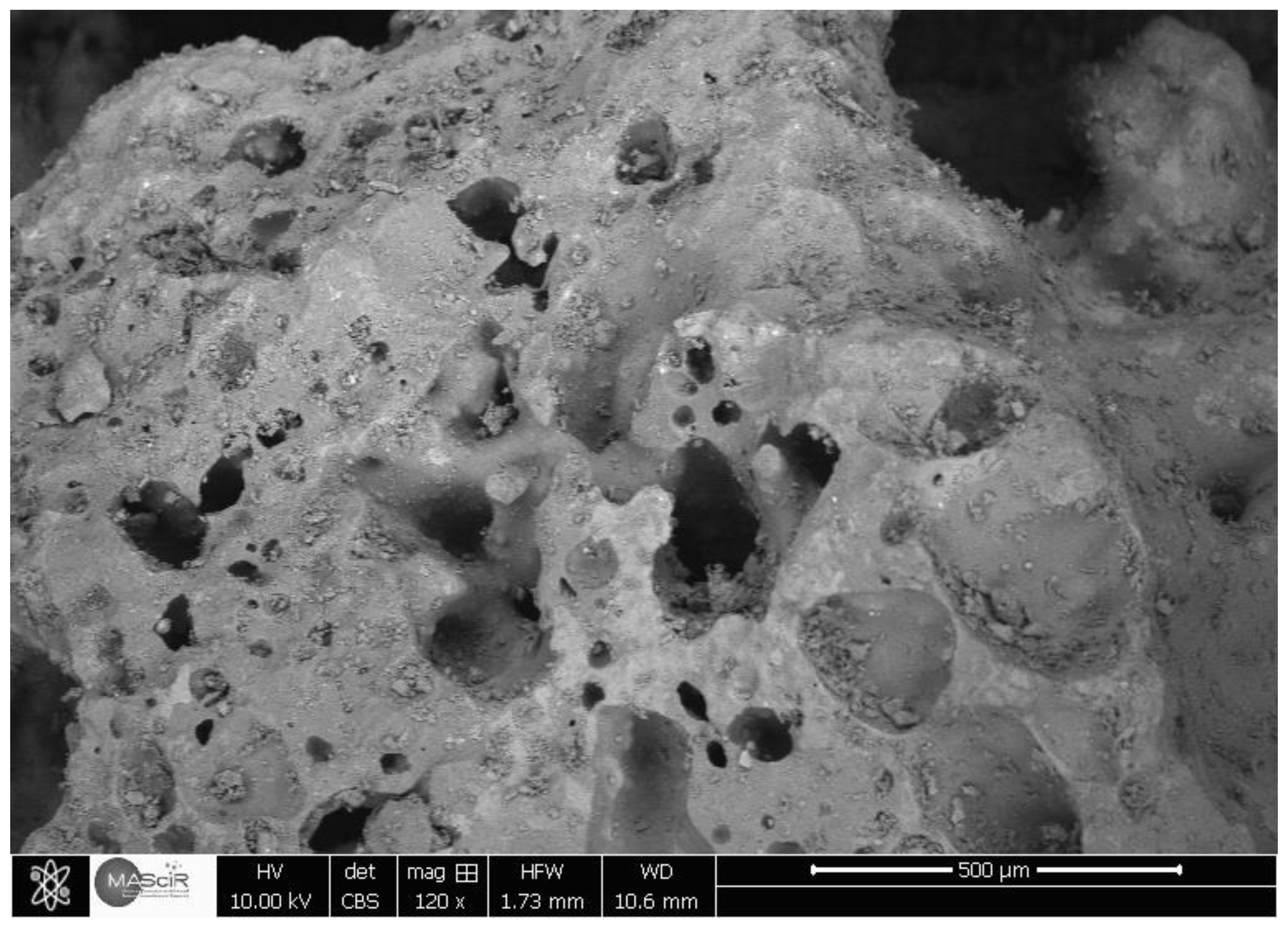

2.1.1. Natural Pozzolan

2.1.2. Cement

2.1.3. Lime

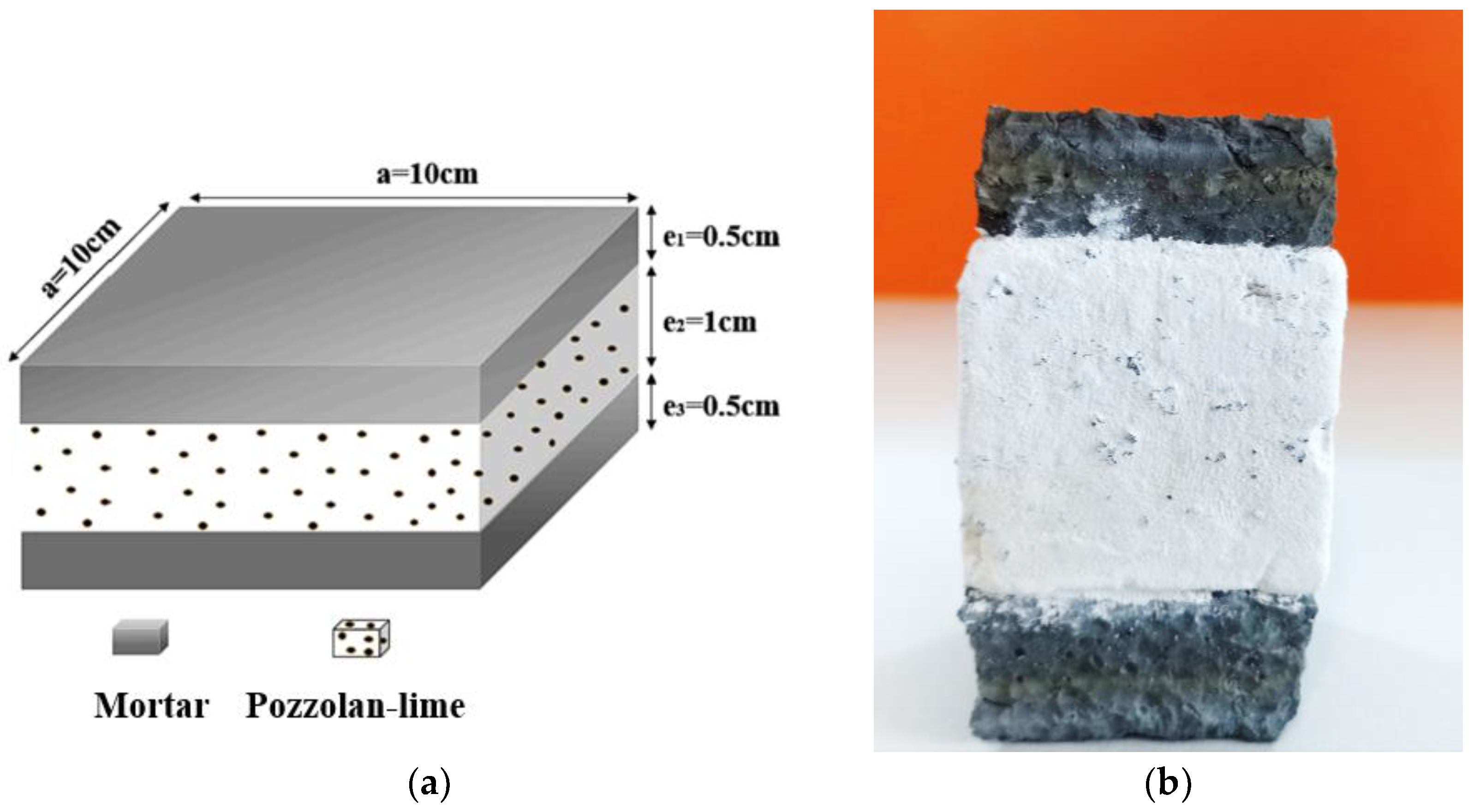

2.1.4. Procedure of Samples’ Preparation

2.2. Methods

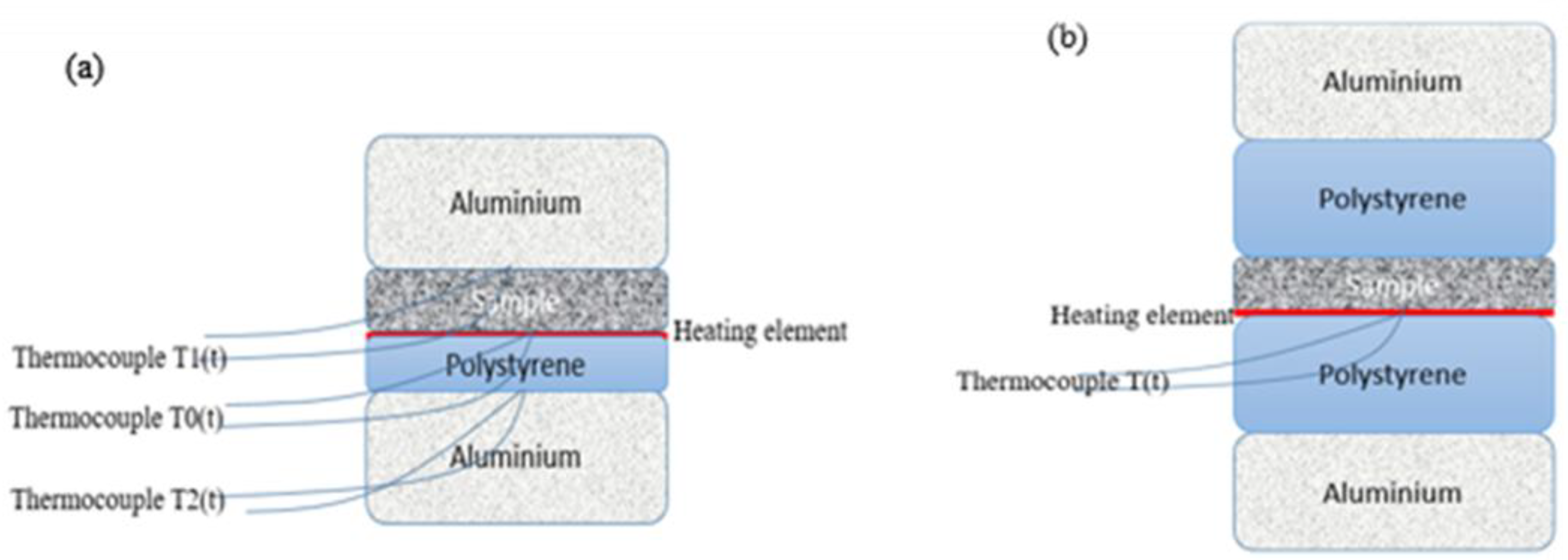

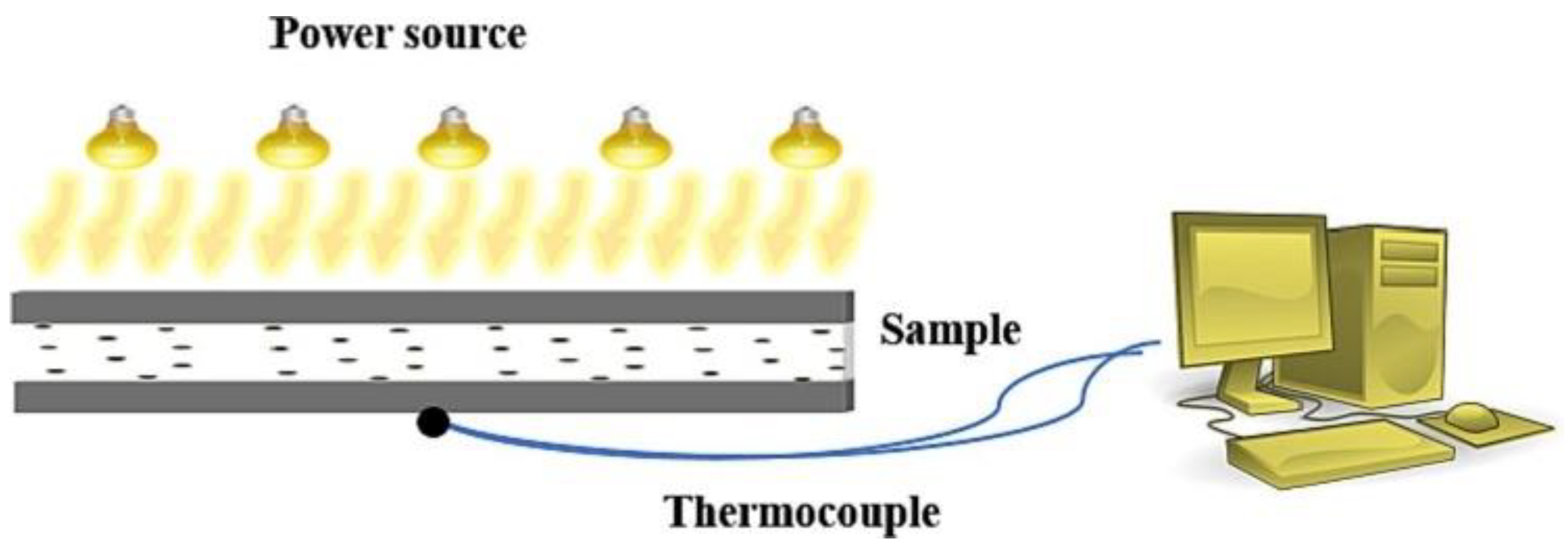

2.2.1. Thermal Characteristics

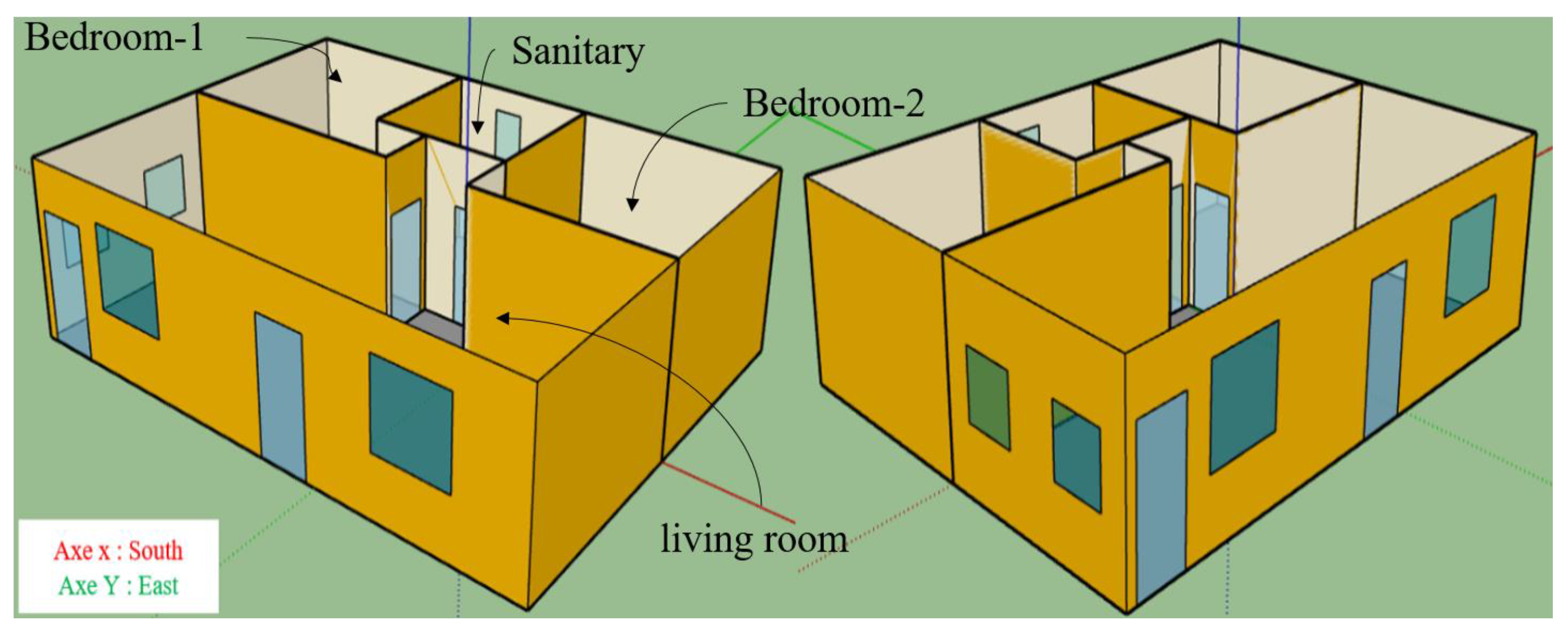

2.2.2. Thermal Simulation

- Ventilation profile (Table 5).

- Infiltration profile is set to 0.6 V/h for all zones.

- The initial indoor air temperature and humidity for different cities (Table 6).

- The prototype building is occupied by individuals according to Table 7.

- Equipment occupation (Table 8).

- the geometry, orientation of the building and location of the windows/doors is the same

- The sensible heating and cooling equipment power are unlimited with a radiative fraction equal to zero.

- The setpoint temperatures schedule for heating and cooling (Table 9)

3. Results

3.1. Density

3.2. Thermal Conductivity

3.3. Thermal Effusivity

3.4. Thermal Diffusivity and Specific Heat Capacity

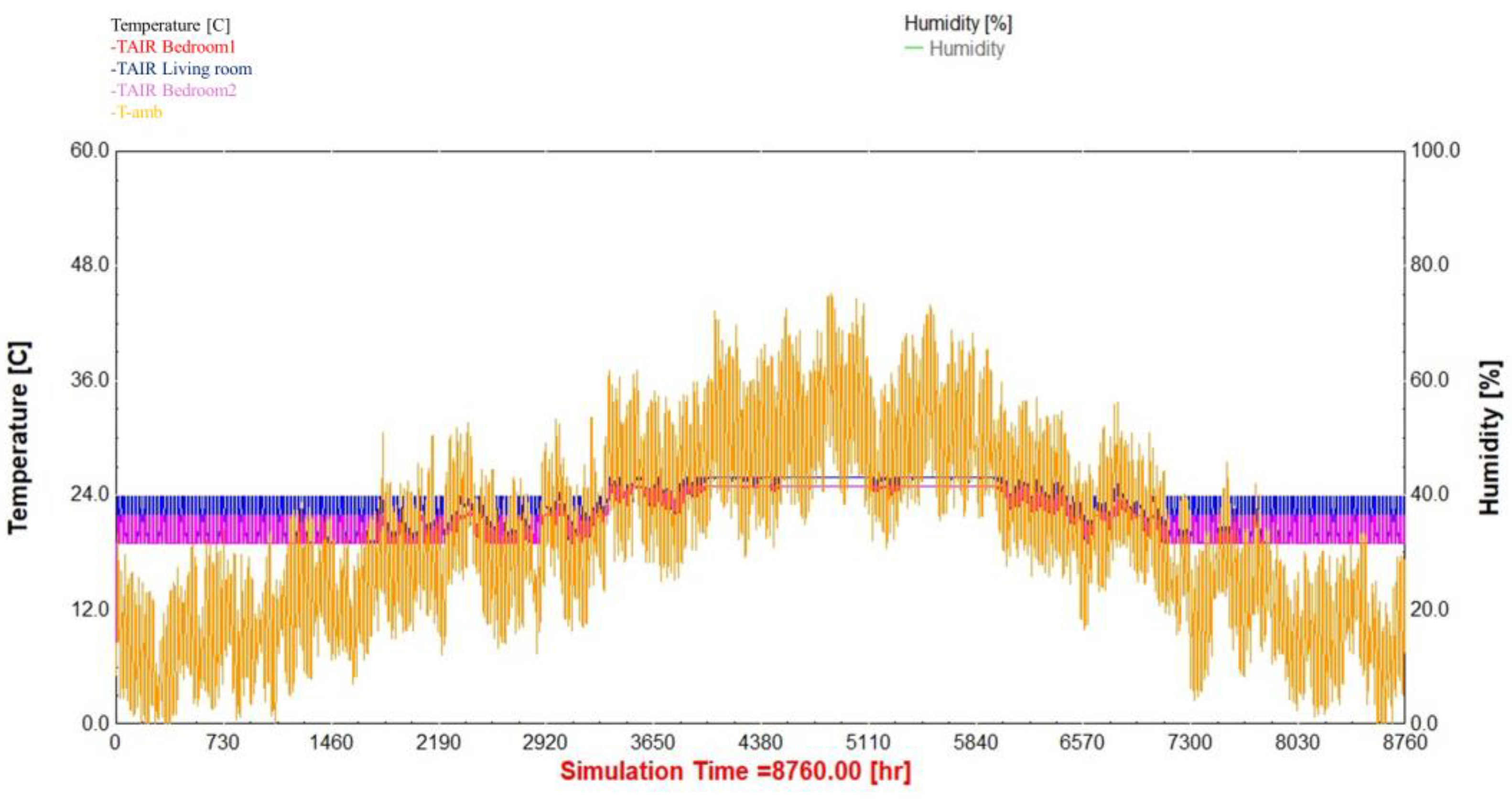

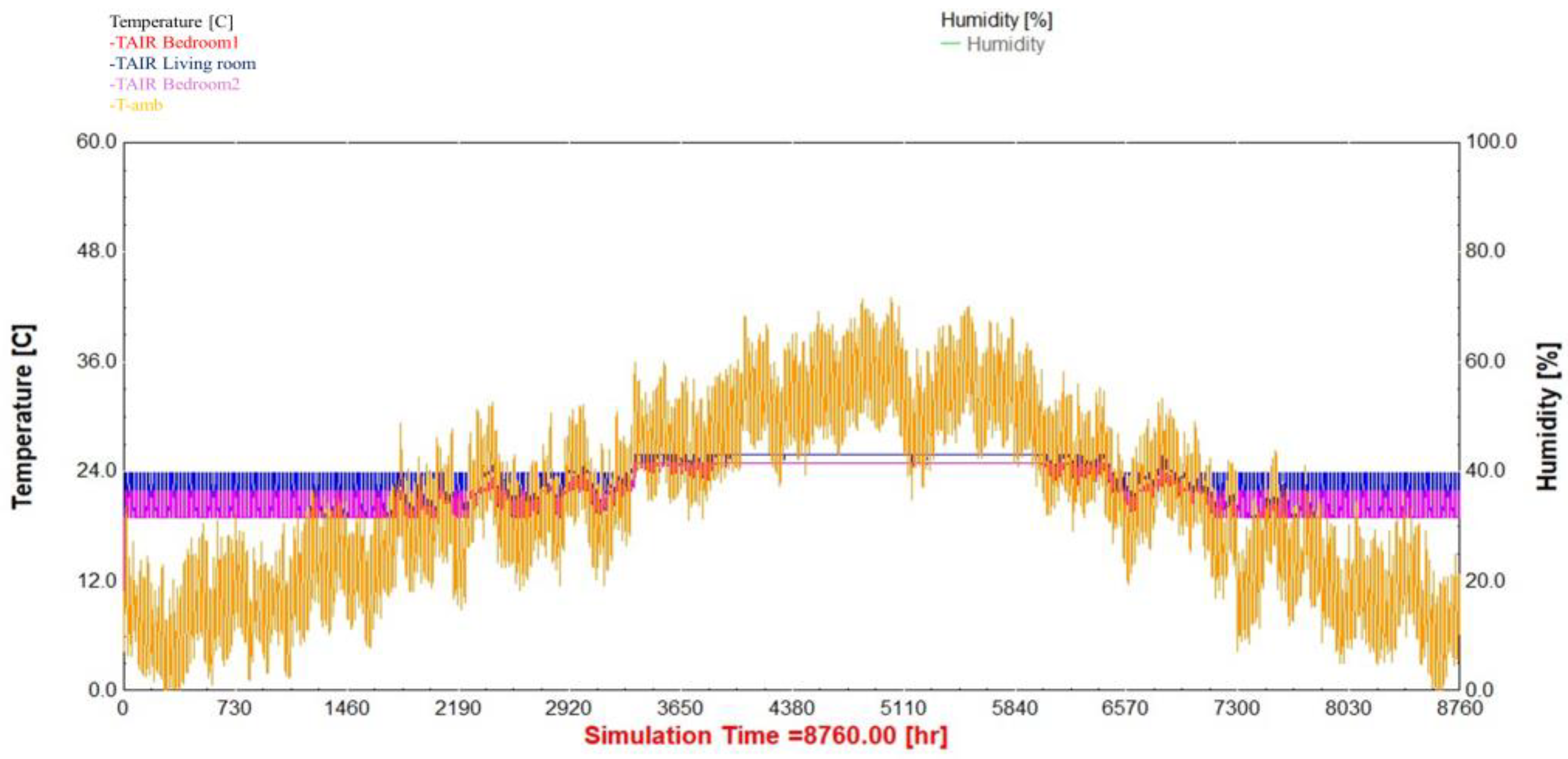

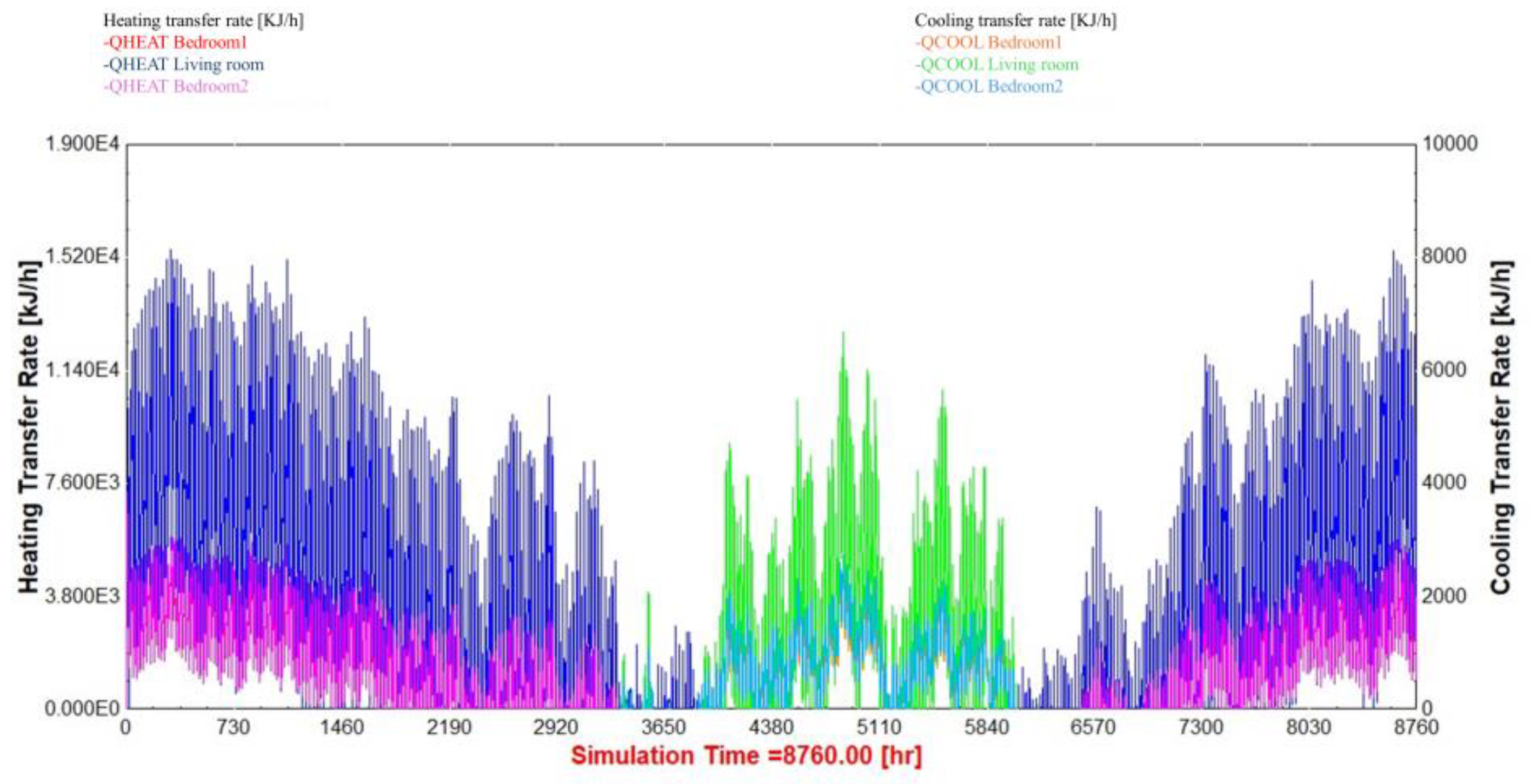

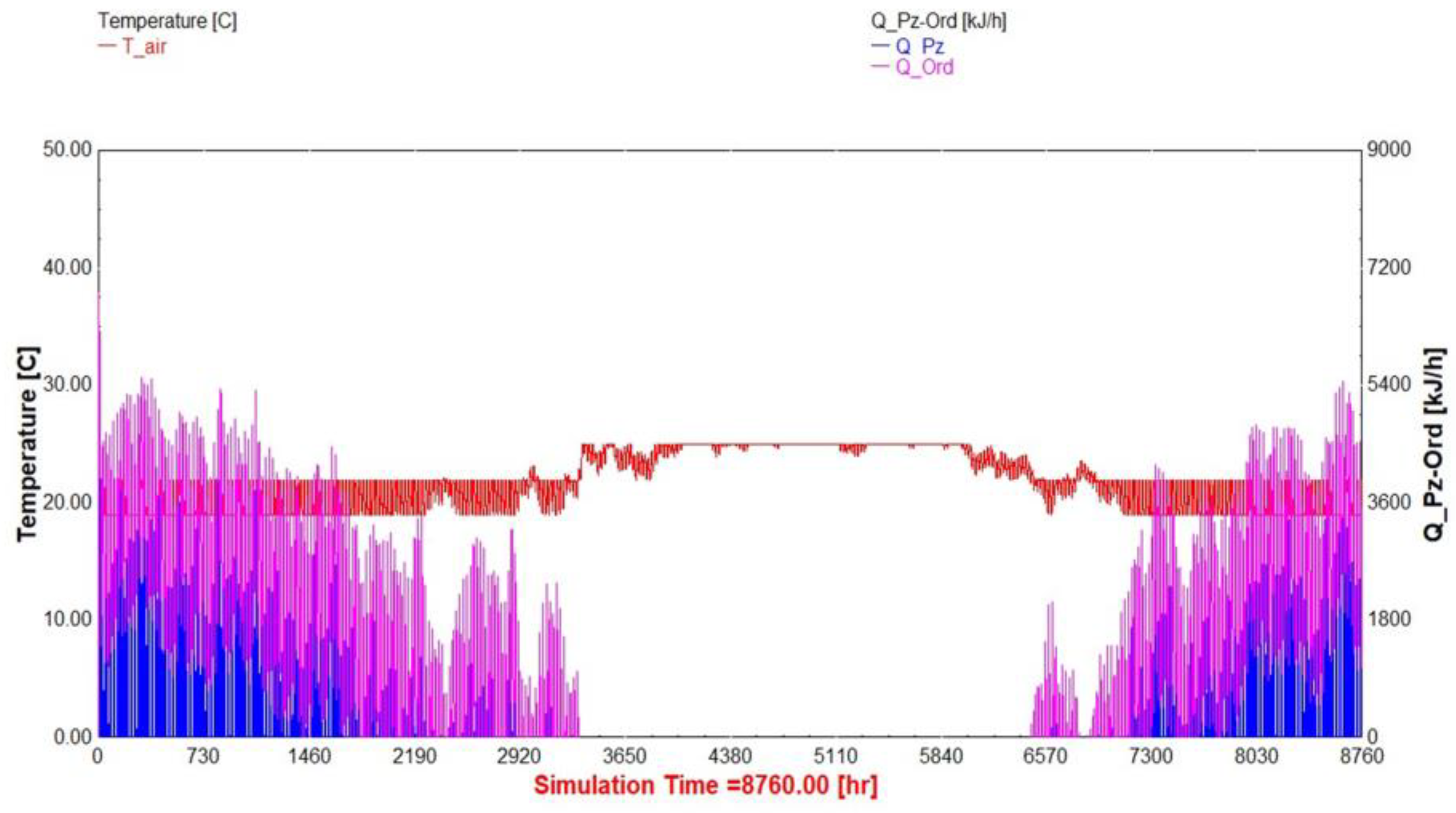

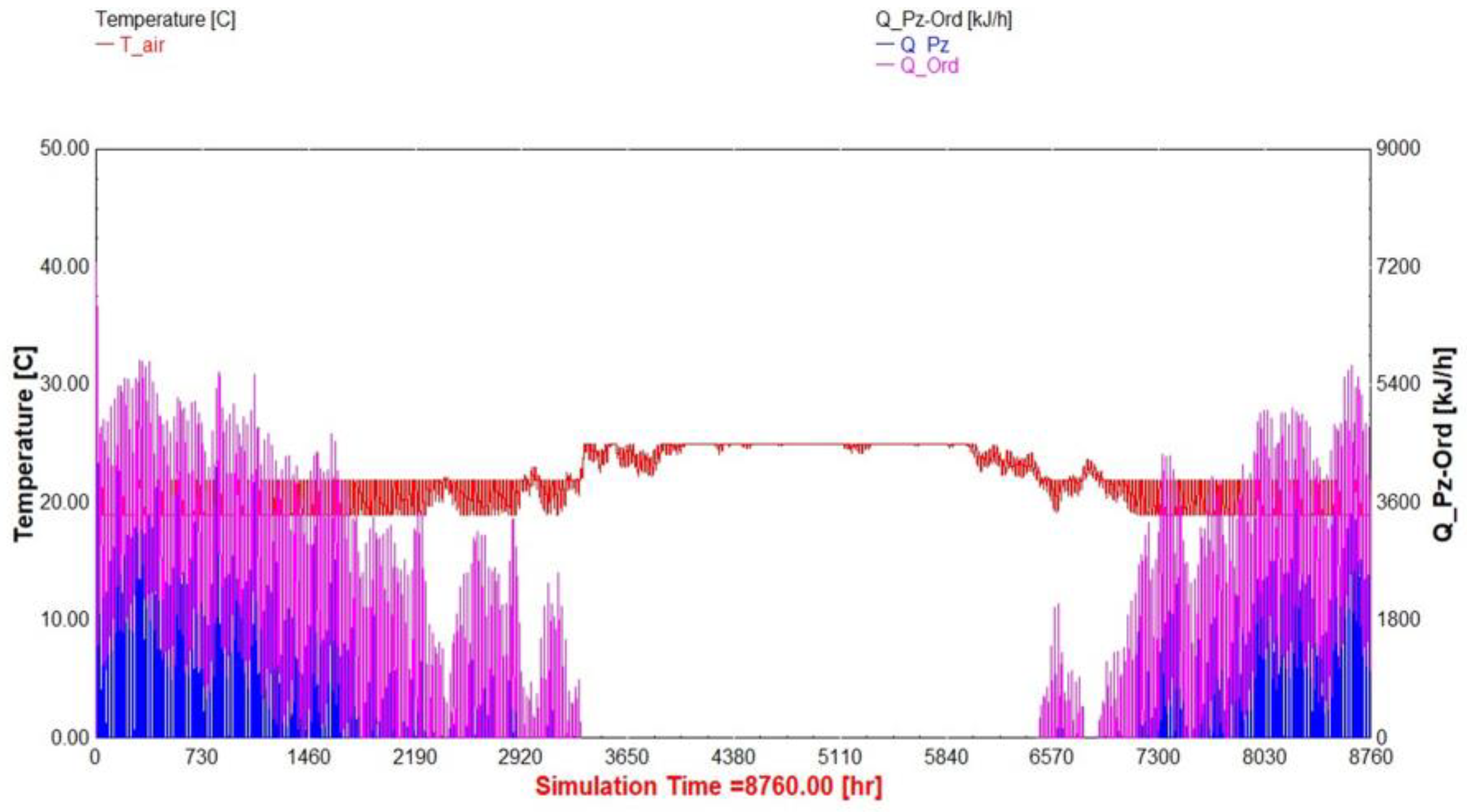

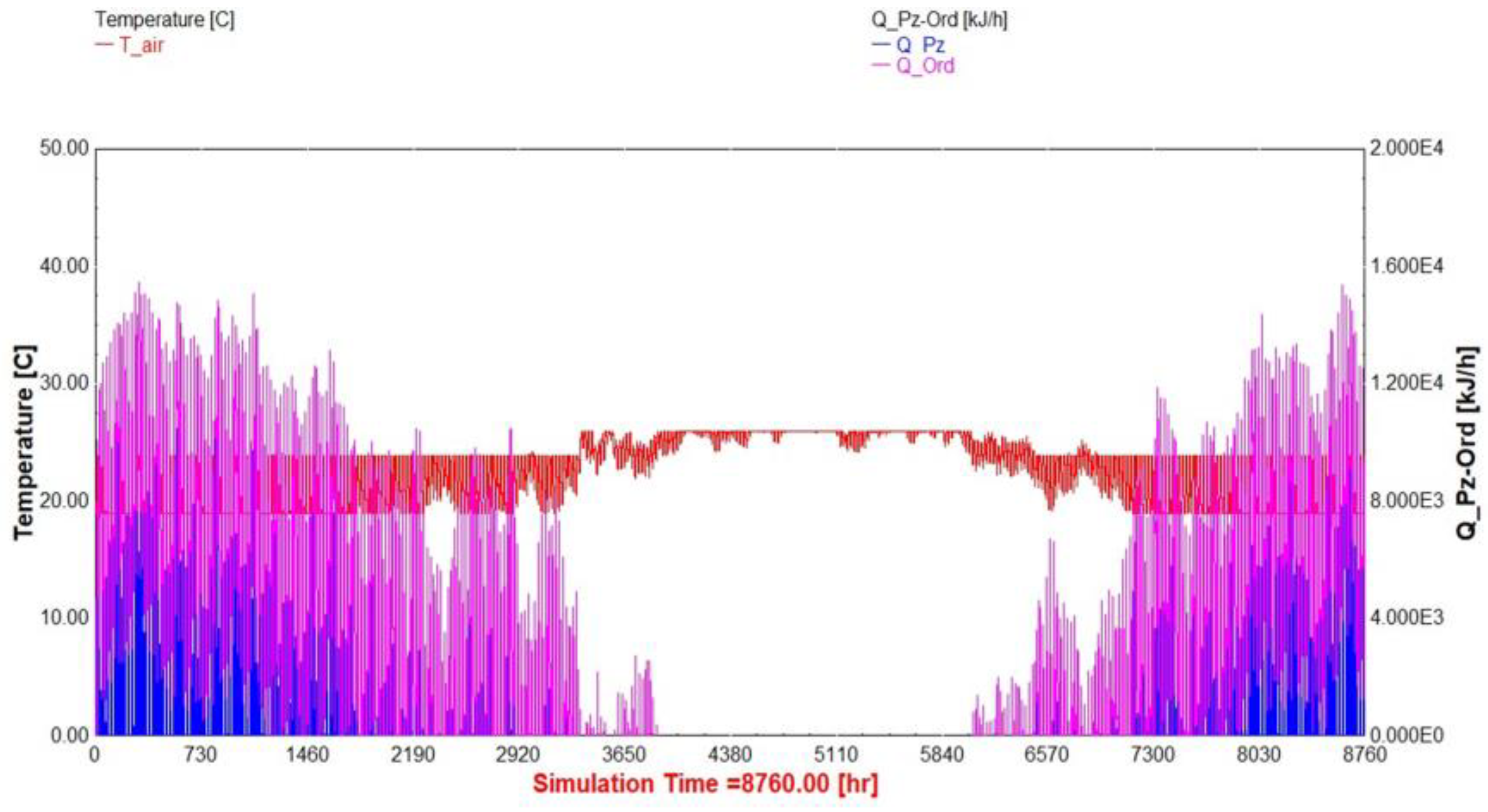

3.5. Thermal Simulation Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mariane, T.; Antonio, C.; Neto, F.; Wurtz, F.; Delinchant, B. The Evolution of Knowledge and Trends within the Building Energy Efficiency Field of Knowledge. Energies 2022, 15, 691. [Google Scholar] [CrossRef]

- Kim, K.G.; Choi, H.S. Market Mechanisms in the Building Sector from an Urban Perspective: Creative Building Solutions; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Reindl, K.; Palm, J. Energy Efficiency in the Building Sector: A Combined Middle-Out and Practice Theory Approach. Int. J. Sustain. Energy Plan. Manag. 2020, 28, 3426. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F. Toward Building Sector Energy Transition. In Handbook of Energy Transitions, 1st ed.; Taylor & Francis: Oxford, UK, 2022; pp. 127–150. [Google Scholar] [CrossRef]

- Asif, M. Buildings for Sustainable Energy Future. In Handbook of Energy and Environmental Security; Elsevier: Amsterdam, The Netherlands, 2022; pp. 171–181. [Google Scholar] [CrossRef]

- Kasseh, Y.; Touzani, A.; EL Majaty, S. Exemplarity of the State for the Energy Efficiency of Buildings Institutional—Case of Morocco. Nat. Environ. Pollut. Technol. 2023, 22, 169–177. [Google Scholar] [CrossRef]

- El Alaoui, H.; Bazzi, A.; El Hafdaoui, H.; Khallaayoun, A.; Lghoul, R. Sustainable Railways for Morocco: A Comprehensive Energy and Environmental Assessment. J. Umm Al-Qura Univ. Eng. Archit. 2023, 14, 271–283. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A Review on Insulation Materials for Energy Conservation in Buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of Agricultural and Forest Industry Waste and Residues in Natural Fiber-Polymer Composites: A Review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Dubois, M.-C.; Blomsterberg, Å. Energy Saving Potential and Strategies for Electric Lighting in Future North European Low Energy Office Buildings: A Literature Review. Energy Build. 2011, 43, 2572–2582. [Google Scholar] [CrossRef]

- Fang, Z.; Li, N.; Li, B.; Luo, G.; Huang, Y. The Effect of Building Envelope Insulation on Cooling Energy Consumption in Summer. Energy Build. 2014, 77, 197–205. [Google Scholar] [CrossRef]

- Mirrahimi, S.; Mohamed, M.F.; Haw, L.C.; Ibrahim, N.L.N.; Yusoff, W.F.M.; Aflaki, A. The Effect of Building Envelope on the Thermal Comfort and Energy Saving for High-Rise Buildings in Hot–Humid Climate. Renew. Sustain. Energy Rev. 2016, 53, 1508–1519. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A Review on Buildings Energy Consumption Information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Sutcu, M.; Akkurt, S. The Use of Recycled Paper Processing Residues in Making Porous Brick with Reduced Thermal Conductivity. Ceram. Int. 2009, 35, 2625–2631. [Google Scholar] [CrossRef]

- Annaba, K.; Elourdi, F.Z.; Ibaaz, K.; Bouyahyaoui, A.; Cherkaoui, M.; Ouaki, B.; Oubanmouh, S. Thermomechanical Characterization and Thermal Simulation of a New Multilayer Mortar and a Light-Weight Pozzolanic Concrete for Building Energy Efficiency. Constr. Build. Mater. 2022, 346, 128479. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Al-Malah, K. Jordanian Clay-Based Heat Insulator Composites: Mechanical Properties. J. Reinf. Plast. Compos. 2008, 27, 1559–1568. [Google Scholar] [CrossRef]

- Abdel-illah, A.; Seyed Soheil, M.A.; Mohsen, S.P.; Jamal-Eddine, S.; Abdelkarim, D. An Investigation towards Optimizing the Construction Materials and Configurations of Buildings for Improving Energy Efficiency and Consumption in Morocco. Buildings 2023, 13, 1705. [Google Scholar] [CrossRef]

- Cherki, A.B.; Khabbazi, A.; Mounir, S.; Maaloufa, Y. Thermal Properties of a New Ecological Building Material: Granular Cork Embedded in White Cement. Int. Congr. Mater. Struct. Stab. 2014, 11, 01017. [Google Scholar] [CrossRef][Green Version]

- El Kafazi, I.; Bannari, R.; Boubii, C.; Elbhiri, B. Energy Efficiency for Laboratory Building: A Case Study. In Proceedings of the 2022 4th Global Power, Energy and Communication Conference (GPECOM), Nevsehir, Turkey, 14–17 June 2022. [Google Scholar] [CrossRef]

- Juimo Tchamdjou, W.; Cherradia, T.; Abidi, L.; Pereira-de-Oliveira, L. Mechanical Properties of Lightweight Aggregates Concrete Made with Cameroonian Volcanic Scoria: Destructive and Non-Destructive Characterization. J. Build. Eng. 2018, 16, 134–145. [Google Scholar] [CrossRef]

- Mouli, M.; Khelafi, H. Performance Characteristics of Lightweight Aggregate Concrete Containing Natural Pozzolan. Build. Environ. 2008, 43, 31–36. [Google Scholar] [CrossRef]

- Salazar, R.A.R.; de Gutiérrez, R.M. Natural Volcanic Pozzolans as an Available Raw Material for Alkali-Activated Materials in the Foreseeable Future: A Review. Constr. Build. Mater. 2018, 189, 109–118. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hossain, M.K.; Islam, M.N.; Zain, M.F.M. Durability of Mortar and Concrete Containing Alkali-Activated Binder with Pozzolans: A Review. Constr. Build. Mater. 2013, 93, 95–109. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Wang, K.; Tang, Q.; Nzeukou, A.N.; Billong, N.; Chinje Melo, U.; Cui, X.-M. Review on the Use of Volcanic Ashes for Engineering Applications. Resour. Conserv. Recycl. 2018, 137, 177–190. [Google Scholar] [CrossRef]

- Yin, K.; Ahamed, A.; Lisak, G. Environmental Perspectives of Recycling Various Combustion Ashes in Cement Production—A Review. Waste Manag. 2018, 80, 401–416. [Google Scholar] [CrossRef] [PubMed]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.-H.; Mehta, P.K.; Monteiro, P.J.M. High-Volume Natural Volcanic Pozzolan and Limestone Powder as Partial Replacements for Portland Cement. Cem. Concr. Compos. 2013, 45, 136–147. [Google Scholar] [CrossRef]

- Hamadache, M.; Mouli, M.; Bouhamou, N.; Benosman, A.S.; Dif, F.; Chaib, O. The Thermal Properties of Natural Pozzolan-Based Cement Mortar. Energy Procedia 2017, 139, 201–207. [Google Scholar]

- Meddah, M.S.; Benkari, N.; Al-Saadi, S.N.; Al Maktoumi, Y. Sarooj Mortar: From a Traditional Building Material to an Engineered Pozzolan—Mechanical and Thermal Properties Study. J. Build. Eng. 2020, 32, 101754. [Google Scholar] [CrossRef]

- Al-Rbaihat, R.; Eayal Awwad, K.Y. Thermal and Mechanical Characteristics of Pozzolana Concrete. IOSR J. Mech. Civ. Eng. 2021, 18, 28–35. [Google Scholar] [CrossRef]

- Bariş, K.E.; Tanaçan, L. Performance of Natural Pozzolan-Based Geopolymer Reinforced with Banana Fibers. J. Green Build. 2024, 19, 51–76. [Google Scholar] [CrossRef]

- Hamadache, M.; Mouli, M.; Bouhamou, N.; Benosman, A.S.; Dif, F.; Chaib, O.; Berrabah, H.M. Use of Pozzolanic Mortars for the Thermal Comfort of Buildings. J. Adv. Res. Mater. Sci. 2017, 34, 1–7. [Google Scholar]

- Alraddadi, S. The Impact of Thermal Treatment on the Mechanical Properties and Thermal Insulation of Building Materials Enhanced with Two Types of Volcanic Scoria Additives. Heliyon 2023, 9, e20814. [Google Scholar] [CrossRef]

- Kaplan, M.M. Performance Assessment of Lime-Pozzolan Mortars with Straw Aggregate for Sound and Thermal Insulation Purposes. Master’s Thesis, Building Science in Architecture, Middle East Technical University, Ankara, Turkey, 2019. [Google Scholar]

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavgic, M. Mechanical, Thermal, and Moisture Buffering Properties of Novel Insulating Hemp-Lime Composite Building Materials. Materials 2020, 13, 5000. [Google Scholar] [CrossRef]

- Doughmi, K.; Baba, K. Eco-Friendly Isolant Composite Mortars Based on Natural Pozzolan, Fly Ash, and Plastic Fibers. In Proceedings of the International Conference on Innovation in Modern Applied Science, Environment, Energy and Earth Studies (ICIES’11 2023), E3S Web Conf., Rabat, Morocco, 27–28 August 2023; Volume 412. [Google Scholar] [CrossRef]

- ASTM C618-15; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- El Wardi, F.Z.; Cherki, A.; Mounir, S.; Khabbazi, A.; Maaloufa, Y. Thermal Characterization of a New Multilayer Building Material Based on Clay, Cork, and Cement Mortar. Energy Procedia 2019, 157, 480–491. [Google Scholar] [CrossRef]

- Cherki, A.; Remy, B.; Khabbazi, A.; Jannot, Y.; Baillis, D. Experimental Thermal Properties Characterization of Insulating Cork–Gypsum Composite. Constr. Build. Mater. 2014, 54, 202–209. [Google Scholar] [CrossRef]

- Jannot, Y.; Felix, V.; Degiovanni, A. A Centered Hot Plate Method for Measurement of Thermal Properties of Thin Insulating Materials. Meas. Sci. Technol. 2010, 21, 035106. [Google Scholar] [CrossRef]

- El Wardi, F.Z.; Khabbazi, A.; Bencheikh, C.; Ennaceri, H.; Khaldoun, A. Insulation Material for a Model House in Zaouiat Sidi Abdessalam. In Proceedings of the 2017 International Renewable and Sustainable Energy Conference (IRSEC), Tangier, Morocco, 4–7 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Jannot, Y.; Cherki, A.-B.; Khabbazi, A.; Remy, B.; Baillis, D. Granular Cork Content Dependence of Thermal Diffusivity, Thermal Conductivity and Heat Capacity of the Composite Material/Granular Cork Bound with Plaster. Energy Procedia 2013, 42, 83–92. [Google Scholar] [CrossRef]

- Mounir, S.; Maaloufa, Y.; Cherki, A.B.; Khabbazi, A. Thermal Properties of the Composite Material Clay/Granular Cork. Constr. Build. Mater. 2014, 70, 183–190. [Google Scholar] [CrossRef]

- Jannot, Y. Théorie et Pratique de la Métrologie Thermique; LEMTA: Sumeru City, Sumeru, 2011; Volume 26, p. 29. [Google Scholar]

- Degiovanni, A.; Batsale, J.C.; Maillet, D. Mesure de la Diffusivité Longitudinale de Matériaux Anisotropes. Rev. Générale Therm. 1996, 35, 141–147. [Google Scholar] [CrossRef]

- Mesure Automatique de la Diffusivité Thermique—Archive Ouverte HAL. Available online: https://hal.archives-ouvertes.fr/jpa-00244681/ (accessed on 13 April 2022).

- Bae, Y.; Yoon, Y.; Malhotra, M.; Jung, S.; Im, P. Prototype College Building Energy Model: Building Characteristics and Energy Simulation Results. In Technical Report: Prototype College Building Energy Model: Building Characteristics and Energy Simulation Results; OSTI: Colorado Springs, CO, USA, 2022. [Google Scholar] [CrossRef]

- Oumar, A.A.; Soultan, M.; Ali, A.; Togdjim, J.; Saleh, M.S.A. Physico-Chemical and Mechanical Characterization of Local Building Materials in Chad. Int. J. Adv. Res. 2023, 11, 744–754. [Google Scholar] [CrossRef]

- Annaba, K.; El Mendili, Y.; Stout, H.; Ech-chebab, A.; Ouaki, B.; Cherkaoui, M.; Florence, C. Mechanical, Electrochemical (EIS), and Microstructural Characterization of Reinforced Concrete Incorporating Natural Volcanic Pozzolan. Case Stud. Constr. Mater. 2023, 19, e02620. [Google Scholar] [CrossRef]

- Mahomed, M.A.; Moundi, A.; Dawai, D.; Ntieche, B.; Ganou, B.M.; Koungang, G.; Michel, F. Effect of the Use of Volcanic Pozzolan from Mbepit Massif (West-Cameroon) on the Mechanical Properties of Mortar and Composite Cements Production. Eng. Res. Express 2021, 3, 015034. [Google Scholar] [CrossRef]

- El Wardi, F.Z.; Ladouy, S.; Khabbazi, A.; Ibaaz, K.; Khaldoun, A. Unfired Clay-Cork Granules Bricks Reinforced with Natural Stabilizers: Thermomechanical Characteristics Assessment. Civ. Eng. J. 2021, 7, 2068–2082. [Google Scholar] [CrossRef]

- El Wardi, F.Z.; Mounir, S.; Atbir, A.; Khabbazi, A.; Ibaaz, K. Effect of Artificial Porosity on the Thermal Behavior and the Lightness of an Eco-Friendly Building Material Based on Clay and Granular Cork. AIP Conf. Proc. 2021, 2345, 020008. [Google Scholar] [CrossRef]

- Maaloufa, Y.; Mounir, S.; Khabbazi, A.; Kettar, J.; Khaldoun, A. Thermal Characterization of Materials Based on Clay and Granular: Cork or Perlite. Energy Procedia 2015, 74, 1150–1161. [Google Scholar] [CrossRef]

- El Wardi, F.Z.; Khabbazi, A.; Cherki, A.-B.; Khaldoun, A. Thermomechanical Study of a Sandwich Material with Ecological Additives. Constr. Build. Mater. 2020, 252, 119093. [Google Scholar] [CrossRef]

- Lamrani, M.; Laaroussi, N.; Khabbazi, A.; Khalfaoui, M.; Garoum, M. Experimental Study of Thermal Properties of a New Ecological Building Material Based on Peanut Shells and Plaster. Case Stud. Constr. Mater. 2017, 7, 294–304. [Google Scholar] [CrossRef]

- Atbir, A.; Khabbazi, A.; Cherkaoui, M.; Ibaaz, K.; El Wardi, F.Z.; Chebli, S. Improvement of Thermomechanical Properties of Porous Plaster Reinforced with a Network of Morocco Sheep Wool Skeletons for Energy Efficiency. Build. Environ. 2023, 234, 110171. [Google Scholar] [CrossRef]

- Atbir, A.; El Wardi, F.Z.; Khabbazi, A.; Cherkaoui, M. Thermophysical Study of a Multi-Layer Brick of Grids Made of Sheep’s Wool Yarn and Clay. AIP Conf. Proc. 2019, 2123, 30002. [Google Scholar] [CrossRef]

| Chemical Element | Mass Composition (%) |

|---|---|

| SiO2 | 46.48 |

| Al2O3 | 10.01 |

| Fe2O3 | 17.29 |

| CaO | 10.71 |

| MgO | 9.16 |

| SO3 | 0.47 |

| Na2O | 1.52 |

| K2O | 1.64 |

| PAF | 2.71 |

| Chemical Element | Mass Composition (%) | |

|---|---|---|

| Lime | Cement | |

| SiO2 | 0.89 | 15.17 |

| Al2O3 | 0.46 | 4.11 |

| Fe2O3 | 0.17 | 4.17 |

| CaO | 97.41 | 68.69 |

| MgO | 0.7 | 1.9 |

| SO3 | - | 4.33 |

| K2O | - | 1 |

| SrO | - | 0.09 |

| TiO2 | 0.06 | 0.34 |

| Building Component | Material | Thickness (cm) | λ (kJ/h.m.K) | Cp (kJ/kg.K) | ρ (kg/m3) | Uglobal |

|---|---|---|---|---|---|---|

| External Wall | Mortar/P | 2 | 1.44 | 0.615 | 1450 | 0.498 W/m2K |

| red brick | 10 | 0.84 | 0.76 | 925 | ||

| insulation-1 | 5 | 0.198 | 1.03 | 8.5 | ||

| red brick | 10 | 0.84 | 0.76 | 925 | ||

| Mortar/P | 2 | 1.98 | 1 | 1125 | ||

| Ground Floor | Concrete | 20 | 5.94 | 1 | 2150 | 2.916 W/m2K |

| Mortar/P | 2 | 1.98 | 1 | 1125 | ||

| tile | 2 | 4.68 | 0.84 | 2300 | ||

| Adjacent Wall | Mortar/P | 2 | 1.98 | 1 | 1125 | 0.909 W/m2K |

| red brick | 20 | 1.2 | 1 | 1100 | ||

| Mortar/P | 2 | 1.98 | 1 | 1125 | ||

| External Roof | bitumen | 2 | 0.83 | 0.96 | 2400 | 2.069 W/m2K |

| hollow core slab | 25 | 4.73 | 1 | 1327.3 | ||

| Mortar/P | 2 | 1.98 | 1 | 1125 |

| Building Component | Material | Thickness (cm) | λ (kJ/h.m.K) | Cp (kJ/kg.K) | ρ (kg/m3) | Uglobal |

|---|---|---|---|---|---|---|

| External Wall | Mortar/Ord | 2 | 2.646 | 1.033 | 1880 | 0.502 W/m2K |

| red brick | 10 | 0.84 | 0.76 | 925 | ||

| insolation-1 | 5 | 0.198 | 1.03 | 8.5 | ||

| red brick | 10 | 0.84 | 0.76 | 925 | ||

| Mortar/Ord | 2 | 2.646 | 1.033 | 1880 | ||

| Ground Floor | concrete | 20 | 5.94 | 1 | 2150 | 2.996 W/m2K |

| Mortar/Ord | 2 | 2.646 | 1.033 | 1880 | ||

| tile | 2 | 4.68 | 0.84 | 2300 | ||

| Adjacent Wall | Mortar/Ord | 2 | 2.646 | 1.033 | 1880 | 0.925 W/m2K |

| red brick | 20 | 1.2 | 1 | 1100 | ||

| Mortar/Ord | 2 | 2.646 | 1.033 | 1880 | ||

| External Roof | bitumen | 2 | 0.83 | 0.96 | 2400 | 2.109 W/m2K |

| hollow core slab | 25 | 4.73 | 1 | 1327.3 | ||

| Mortar/Ord | 2 | 2.646 | 1.033 | 1880 |

| Name | Type | Value | Specific Fan Power | Supply Air Conditioning | T_Suplply Air Flow | Air Flow Humidity |

|---|---|---|---|---|---|---|

| Sanitary Vent | air change rate | 2/h | 300 | external by other component | Outside air | relative humidity with outside air |

| Temperature (°C) | Humidity (%) | |

|---|---|---|

| Azilal | 6.5 | 65 |

| Errachidia | 5.2 | 45 |

| Zone | 00h–8h | 8h–12h | 12h–13h | 13h–14h | 14h–20h | 20h–22h | 22h–00h |

|---|---|---|---|---|---|---|---|

| Bedroom-1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 |

| Bedroom-2 | 2 | 0 | 1 | 0 | 0 | 0 | 2 |

| living room | 0 | 1 | 1 | 3 | 1 | 3 | 0 |

| Zone | Type | Schedules | Energie |

|---|---|---|---|

| Bedroom-1 | Lighting | Sched- Bedroom 1 | 7 W |

| PC with monitor | ---- | 180 W | |

| People | ----- | 185 W | |

| Bedroom-2 | Lighting | Sched- Bedroom 2 | 5 W |

| TV | Sched- Bedroom 2 | 250 W | |

| People | ----- | 185 W | |

| Living room | Lighting | All day | 3 W |

| People | ----- | 185 W | |

| TV | 9 h à 18 h | 300 W |

| Zone | Profil | 00h00–08h00 | 08h00–12h00 | 12h00–14h00 | 14h00–18h00 | 18h00–24h00 |

|---|---|---|---|---|---|---|

| Bedroom-1 | Heating (°C) | 19 | 22 | 22 | 22 | 19 |

| Cooling (°C) | 25 | |||||

| Bedroom-2 | Heating (°C) | 19 | 22 | 22 | 22 | 19 |

| Cooling (°C) | 25 | |||||

| Living room | Heating (°C) | 19 | 24 | 24 | 24 | 19 |

| Cooling (°C) | 25 | |||||

| Samples | Density ρ (Kg m−3) | Thermal Conductivity λ (W m−1 K−1) | Thermal Effusivity E (J m−2 K−1 s−1/2) | Thermal Diffusivity a 10−7(m2 s−1) | Specific Heat Capacity C (J kg−1 K−1) |

|---|---|---|---|---|---|

| Reference material (Ordinary mortar) | 1880 | 0.735 | 730 | 3.78 | 1033 |

| Multilayer material | 1450 | 0.4 | 604 | 2.23 | 1237 |

| Intermediate layer | ------ | 0.28 | ---- | ----- | 1252 |

| Gain | 23% | 46% | 17% | 41% | 40% |

| City | Energy Consumption (kWh/year) | |||

|---|---|---|---|---|

| Type of Mortar | Heating Needs | Cooling Needs | Total Energy Consumption | |

| Azilal city | Ordinary | 12,830.06 | 1893.75 | 14,723.81 |

| Pozzolan | 9603.85 | 1455.11 | 11,058.96 | |

| gain | 25% | 23% | 25% | |

| Errachidia city | Ordinary | 11,836.49 | 3032.96 | 14,869.45 |

| Pozzolan | 11,247.40 | 3004.73 | 14,252.13 | |

| gain | 5% | 1% | 4% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Annaba, K.; Belarouf, S.; El Wardi, F.Z.; Ibaaz, K.; Cherkaoui, M.; Florence, C.; Colin, J.; Mege, R.; Mendili, Y.E. Harnessing Natural Pozzolan for Sustainable Heating and Cooling: Thermal Performance and Building Efficiency in Moroccan Climates. Buildings 2024, 14, 2633. https://doi.org/10.3390/buildings14092633

Annaba K, Belarouf S, El Wardi FZ, Ibaaz K, Cherkaoui M, Florence C, Colin J, Mege R, Mendili YE. Harnessing Natural Pozzolan for Sustainable Heating and Cooling: Thermal Performance and Building Efficiency in Moroccan Climates. Buildings. 2024; 14(9):2633. https://doi.org/10.3390/buildings14092633

Chicago/Turabian StyleAnnaba, Khadija, Sara Belarouf, Fatima Zohra El Wardi, Khalid Ibaaz, Mouha Cherkaoui, Céline Florence, Johan Colin, Romain Mege, and Yassine El Mendili. 2024. "Harnessing Natural Pozzolan for Sustainable Heating and Cooling: Thermal Performance and Building Efficiency in Moroccan Climates" Buildings 14, no. 9: 2633. https://doi.org/10.3390/buildings14092633

APA StyleAnnaba, K., Belarouf, S., El Wardi, F. Z., Ibaaz, K., Cherkaoui, M., Florence, C., Colin, J., Mege, R., & Mendili, Y. E. (2024). Harnessing Natural Pozzolan for Sustainable Heating and Cooling: Thermal Performance and Building Efficiency in Moroccan Climates. Buildings, 14(9), 2633. https://doi.org/10.3390/buildings14092633