Using Near-Surface-Mounted Small-Diameter Steel Wires to Improve Construction Efficiency in Strengthening Substandard Lapped Spliced Reinforced Concrete Beams

Abstract

1. Introduction

2. Aims of the Study

3. Experiments

3.1. Materials

3.1.1. Concrete

3.1.2. Internal Reinforcement

3.1.3. Steel Wires

3.1.4. Adhesive

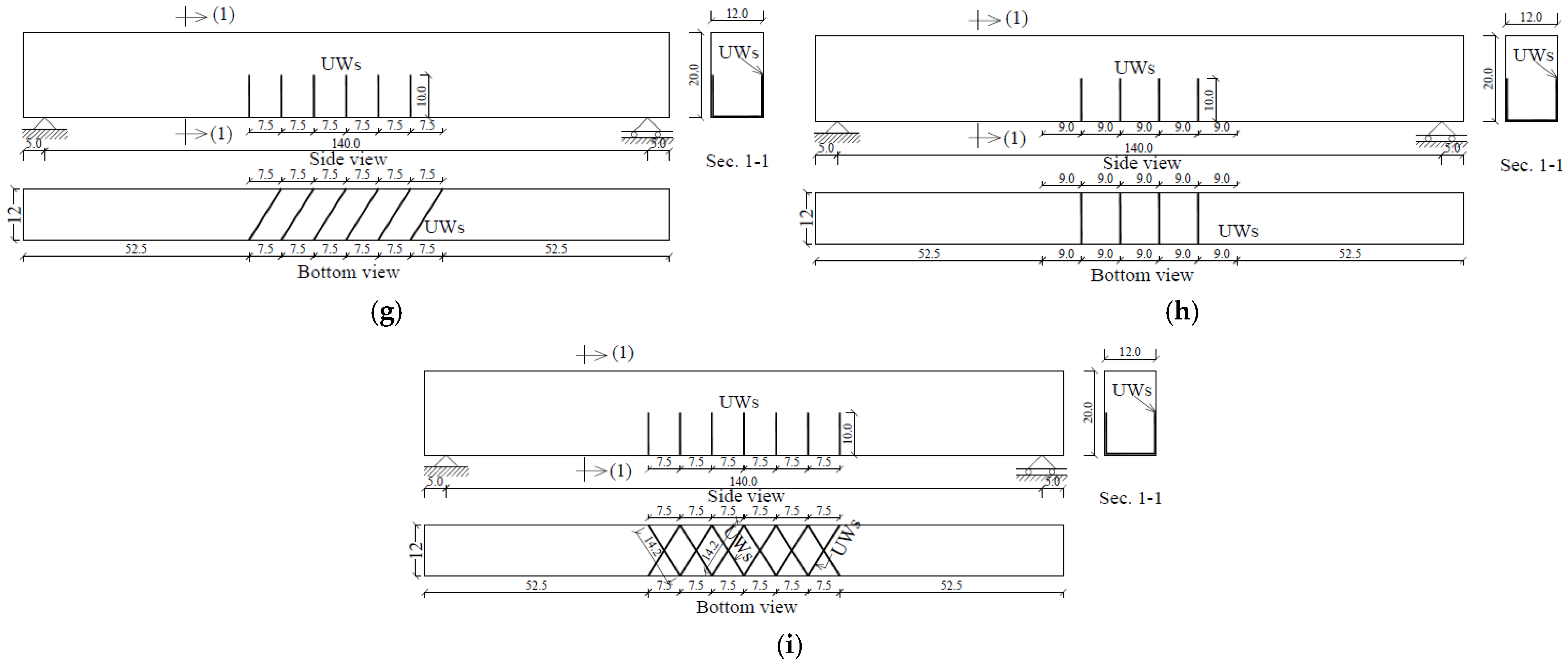

3.2. Lap-Spliced Beam Samples

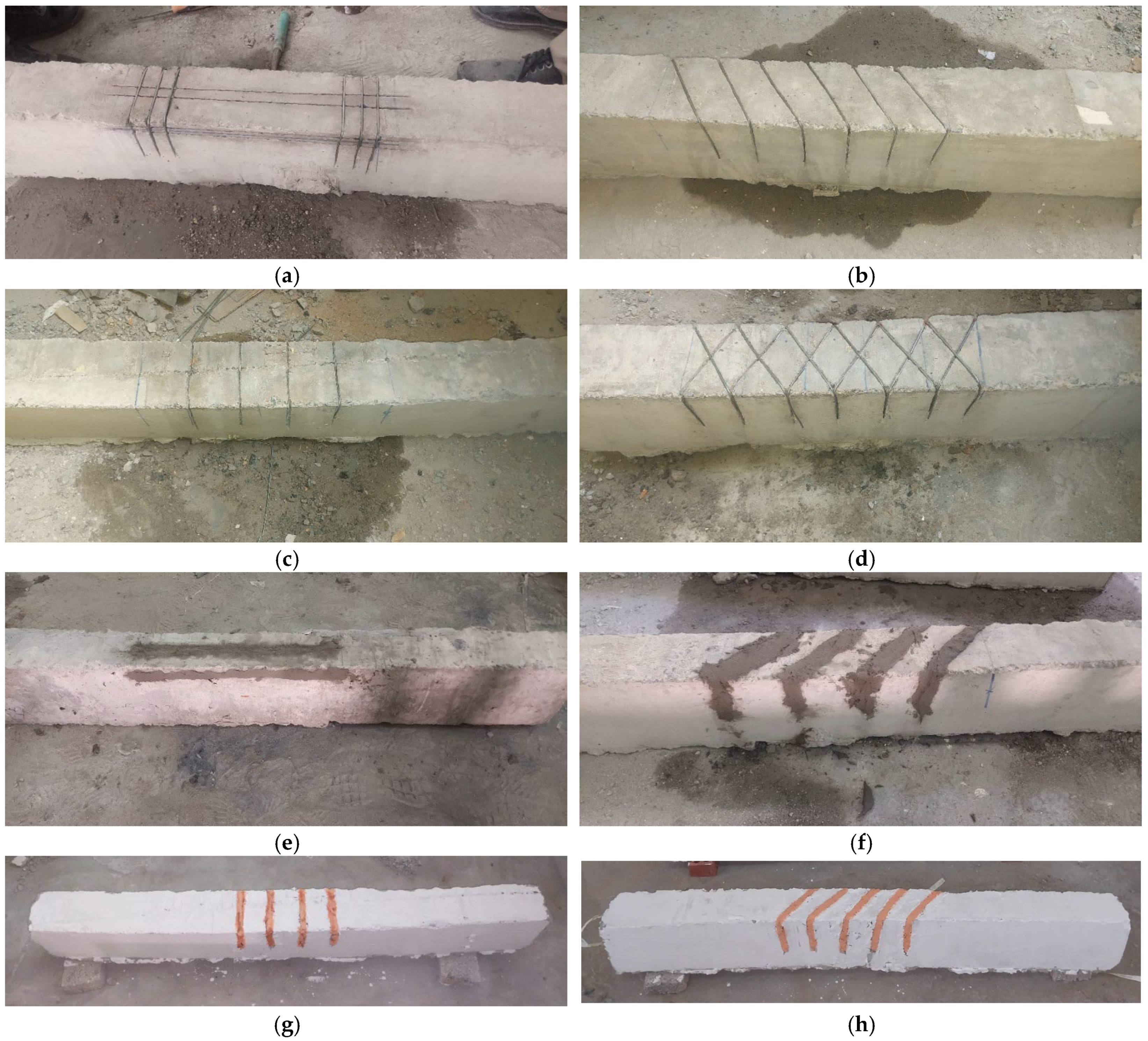

3.3. Implementing NSM

3.4. Loading Device

4. Results and Analysis

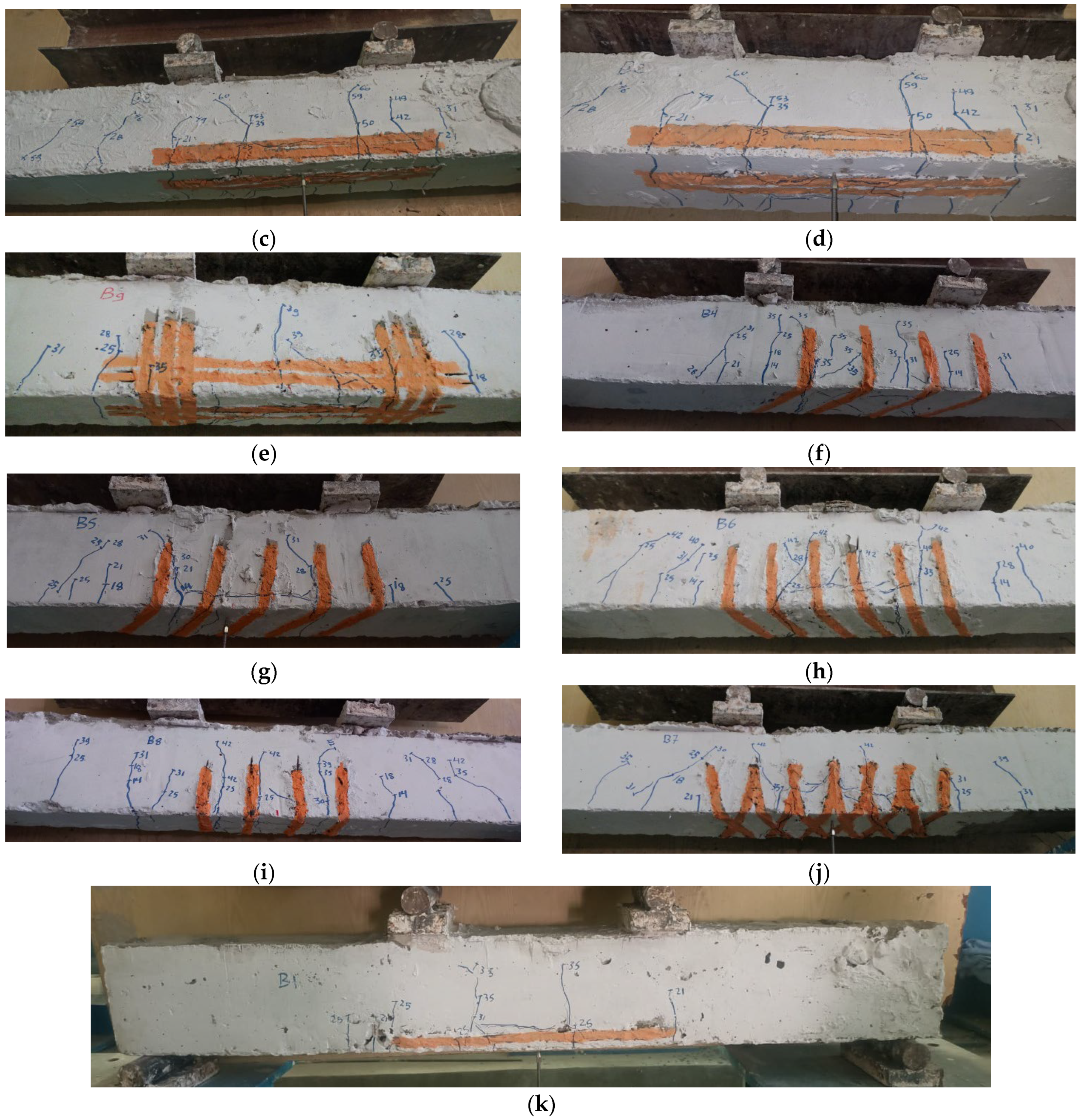

4.1. Failure and Cracking Analysis

4.2. Crack Load

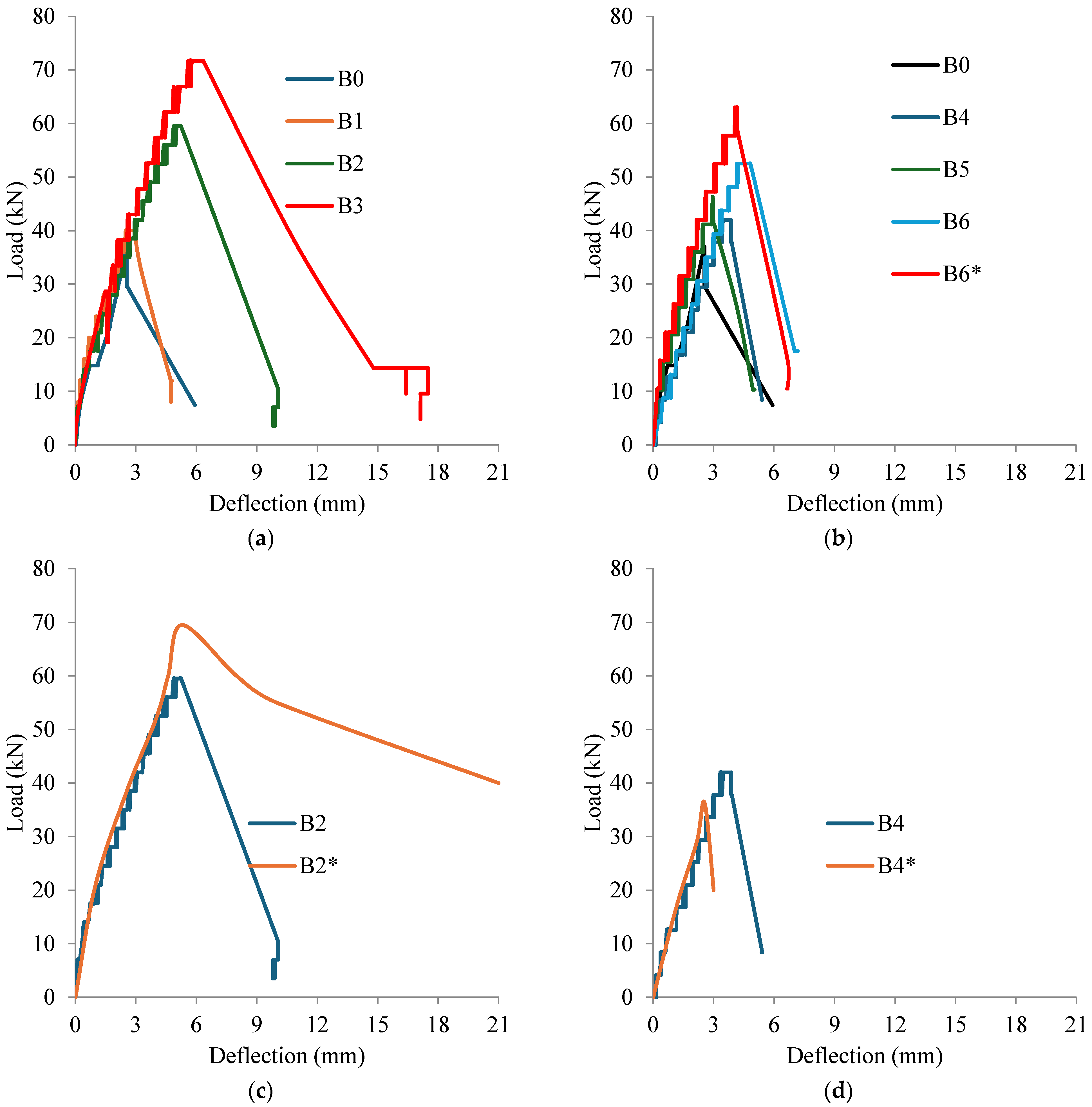

4.3. Load–Deflection Relationships

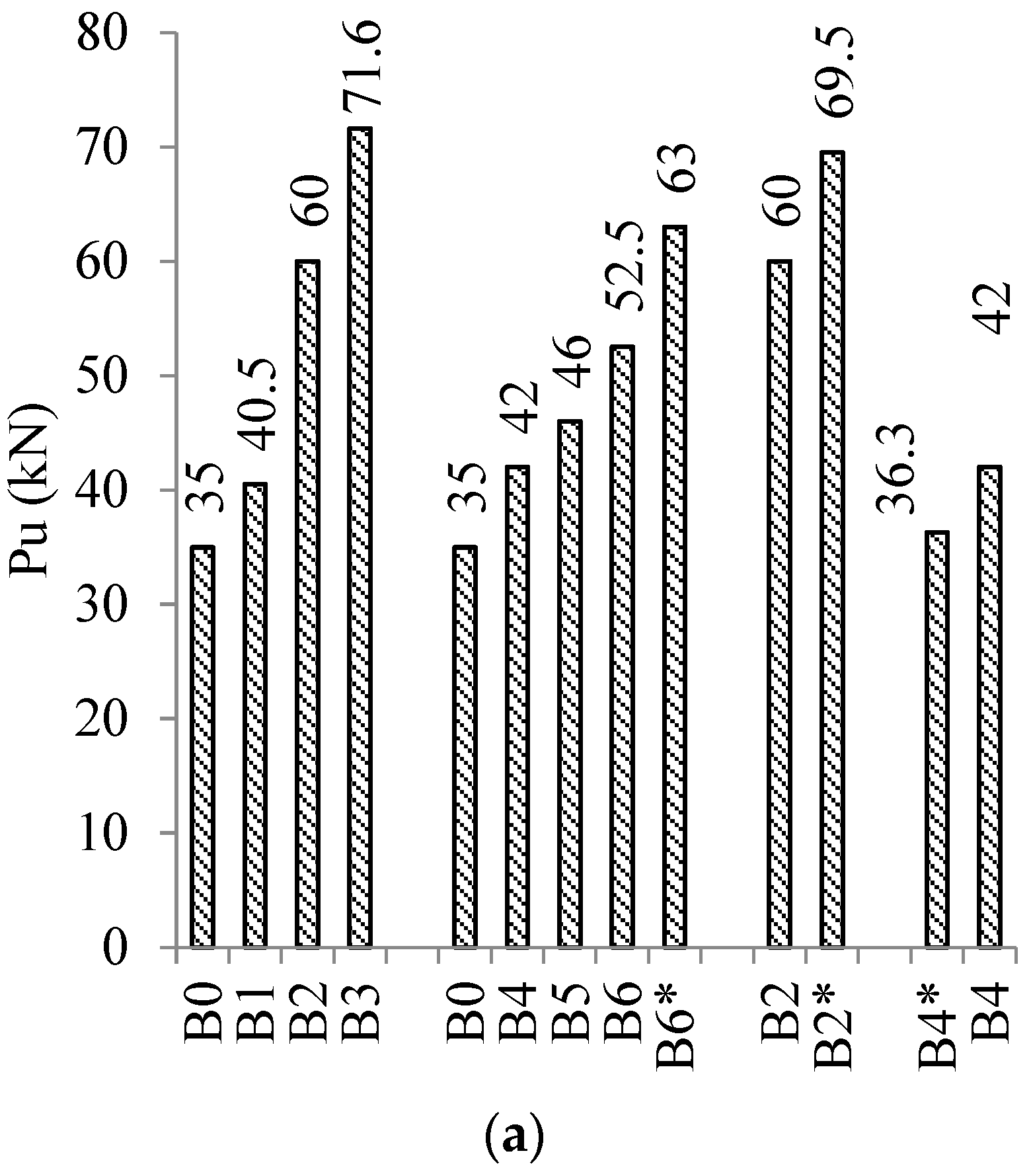

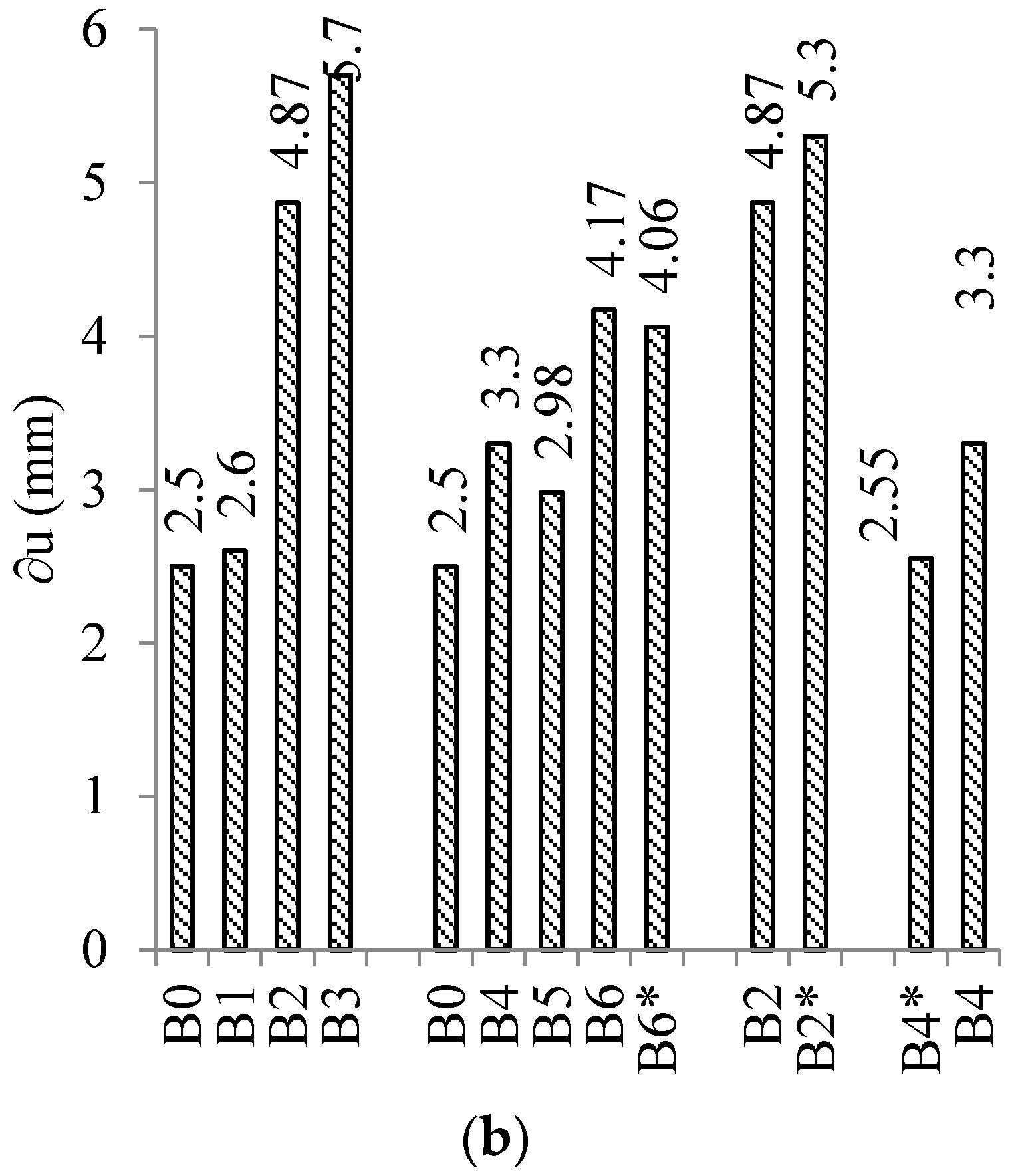

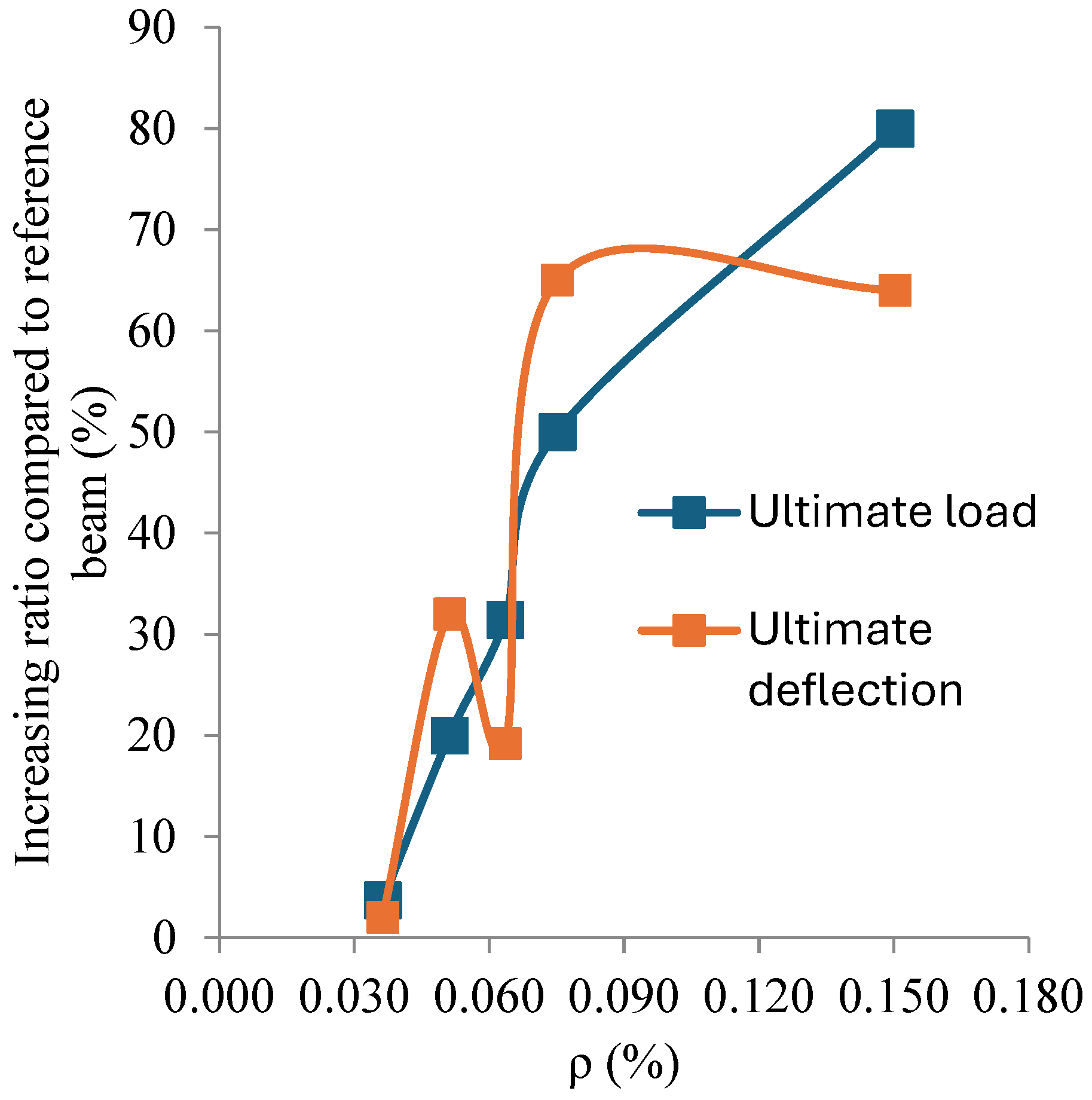

4.4. Ultimate Load and Corresponding Deflection

5. Cost of the Presented NSM Strengthening

6. Conclusions

- Most strengthened beams failed due to concrete splitting at the splice region accompanied by partial debonding at the wires–epoxy interface;

- The cracking load of the three-longitudinal-wire beam was 60% more than that of the control beam;

- When the longitudinal wire reinforcement-to-lapped rebars area ratio was 9.4%, 18.7%, and 28%, the ultimate load of the beams was improved by 15.71%, 71.43%, and 104.57%, respectively, and the ultimate deflection was enhanced by 4%, 94%, and 128% compared to the control beam;

- When the transverse U-shaped wire reinforcement ratio was 0.036%, 0.051%, 0.064%, 0.075%, and 0.150%, the ultimate load of the beams was improved by 3.7%, 20%, 31.4%, 50%, and 80%, respectively, and the ultimate deflection was enhanced by 2%, 32%, 19%, 67%, and 62.4% compared to the control beam;

- When compared to a comparable beam without ties, adding end ties to the beam resulted in a minor improvement in the ultimate load (15.8%) and ultimate deflection (8.8%);

- When compared to a comparable beam with perpendicular U-shaped wires, inclined U-shaped wires improved both the ultimate load (15.7%) and ultimate deflection (29.4%).

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 408R-03; Bond and Development of Straight Reinforcing Bars in Tension (Reapproved 2012). American Concrete Institute: Farmington Hill, MI, USA, 2012.

- FIB. Model Code for Concrete Structures 2010, 1st ed.; Ernst & Sohn GmbH & Co.: Berlin, Germany, 2013. [Google Scholar]

- FIB. Bond and Anchorage of Embedded Reinforcement: Background to the FIB Model Code for Concrete Structures 2010; Bulletin No 72; FIB: Lausanne, Switzerland, 2014. [Google Scholar]

- Haavisto, J.; Alho, H.; Laaksonen, A. Behavior of lap splices in reinforced concrete beams after bar yielding. Struct. Concr. 2023, 24, 5245. [Google Scholar] [CrossRef]

- Ali, H.M.Y.; Sheikh, M.N.; Hadi, M.N.S. Flexural strengthening of RC beams with NSM-GFRP technique incorporating innovative anchoring system. Structures 2022, 38, 251–264. [Google Scholar] [CrossRef]

- Michels, J.; Sta’skiewicz, M.; Czaderski, C.; Lasek, K.; Kotynia, R.; Motavalli, M. Anchorage resistance of CFRP strips externally bonded to various cementitious substrates. Compos. Part B Eng. 2014, 63, 50–60. [Google Scholar] [CrossRef]

- Dias, S.J.E.; Barros, J.A.O.; Janwaen, W. Behavior of RC beams flexurally strengthened with NSM CFRP laminates. Compos. Struct. 2018, 201, 363–376. [Google Scholar] [CrossRef]

- Berardi, U.; Dembsey, N. Thermal and Fire Characteristics of FRP Composites for Architectural Applications. Polymers 2015, 7, 2276–2289. [Google Scholar] [CrossRef]

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2017.

- Zhang, S.S.; Yu, T.; Chen, G.M. Reinforced concrete beams strengthened in flexure with near-surface mounted (NSM) CFRP strips: Current Status and Research needs. Compos. Part B 2017, 131, 30–42. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.D.A.; Ferdous, W.; Alyousef, R. Performances, challenges and opportunities in strengthening reinforced concrete structures by using FRPs—A state-of-the-art review. Eng. Fail. Anal. 2020, 111, 104480. [Google Scholar] [CrossRef]

- Lorenzis, L.D.; Teng, J.G. Near-surface Mounted FRP Reinforcement: An Emerging Technique for Strengthening Structures. Compos. Part B 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Hassan, T.K.; Rizkalla, S.H. Bond mechanism of near surface mounted fiber reinforced polymer bars for flexural strengthening of concrete structures. ACI Struct. J. 2004, 6, 830–839. [Google Scholar]

- Fayed, S.; Ghalla, M.; Hu, J.W.; Mlybari, E.A.; Albogami, A.; Yehia, S.A. Shear strengthening of RC beams using prestressed near-surface mounted bars reducing the probability of construction failure risk. Materials 2024, 17, 5701. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.B.; Lin, D.J.; Fu, B.; Liu, S.H.; Han, Z.J. Flexural performance of reinforced concrete beams strengthened using near-surface-mounted carbon-fiber-reinforced polymer bars: Effects of bonding patterns. Compos. Struct. 2024, 335, 117985. [Google Scholar] [CrossRef]

- Khol, S.; Seo, S.Y.; Van Tran, H.; Hanif, M.U. Shear Strengthening of RC Beams Using Partial-Length Near-Surface Mounted (PLNSM) CFRP Strips. Int. J. Concr. Struct. Mater. 2024, 18, 90. [Google Scholar] [CrossRef]

- Aljidda, O.; Alnahhal, W.; El Refai, A. Flexural strengthening of one-way reinforced concrete slabs using near surface-mounted BFRP bars. Eng. Struct. 2024, 303, 117507. [Google Scholar] [CrossRef]

- Saadah, M.; Ashteyat, A.; Murad, Y. Shear strengthening of RC beams using side near surface mounted CFRP ropes and strips. Structures 2021, 32, 380–390. [Google Scholar] [CrossRef]

- Abdel-Jaber, M.; Abdel-Jaber, M.; Katkhuda, H.; Shatarat, N.; El-Nimri, R. Influence of Compressive Strength of Concrete on Shear Strengthening of Reinforced Concrete Beams with Near Surface Mounted Carbon Fiber-Reinforced Polymer. Buildings 2021, 11, 563. [Google Scholar] [CrossRef]

- Allam, S.M. Flexural strengthening of RC beams with lap splices. Int. Rev. Civ. Eng. 2013, 4, 256–273. [Google Scholar]

- Garcia, R.; Guadagnini, M.; Pilakoutas, K.; Pech Poot, L.A. FRP strengthening of substandard lap-spliced RC members: A comprehensive survey. Adv. Struct. Eng. 2017, 20, 976–1001. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Sohrabi, M.R.; Moodi, Y.; Gholamhosseini, E. Strengthening of Lap-Spliced RC Beams Using Near-Surface Mounting Method. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 251–259. [Google Scholar] [CrossRef]

| Group | Parameter | Beam ID | Pu (kN) | Increase in Pu (%) | ∂u (mm) | Increase in ∂u (%) |

|---|---|---|---|---|---|---|

| GI | Amount of longitudinal wires | B0 | 35 | 0.00 | 2.5 | 0.00 |

| B1 | 40.5 | 15.71 | 2.6 | 4.00 | ||

| B2 | 60 | 71.43 | 4.87 | 94.80 | ||

| B3 | 71.6 | 104.57 | 5.7 | 128.00 | ||

| GII | Amount of italic cross wires | B0 | 35 | 0.00 | 2.5 | 0.00 |

| B4 | 42 | 20.00 | 3.3 | 32.00 | ||

| B5 | 46 | 31.43 | 2.98 | 19.20 | ||

| B6 | 52.5 | 50.00 | 4.17 | 66.80 | ||

| B6* | 63 | 80.00 | 4.06 | 62.40 | ||

| GIII | End tie | B2 | 60 | 0.00 | 4.87 | 0.00 |

| B2* | 69.5 | 15.83 | 5.3 | 8.83 | ||

| GVI | Direction of cross wires | B4* | 36.3 | 0.00 | 2.55 | 0.00 |

| B4 | 42 | 15.70 | 3.3 | 29.41 |

| Beam | Aw (mm2) | L (mm) | b (mm) | Nt | β | ρ (%) | |

|---|---|---|---|---|---|---|---|

| B4* | 4.9 | 450 | 120 | 4 | N/A | 1 | 0.036 |

| B4 | 4.9 | 450 | 120 | 4 | 52 | 1.41 | 0.051 |

| B5 | 4.9 | 450 | 120 | 5 | 59 | 1.4 | 0.064 |

| B6 | 4.9 | 450 | 120 | 6 | 64 | 1.38 | 0.075 |

| B6* | 4.9 | 450 | 120 | 12 | 64 | 1.38 | 0.150 |

| Item | Wires | Epoxy | Labor | Total Cost |

|---|---|---|---|---|

| Amount | 5 kg | 3 kg | 3 people | |

| Cost | 250 EGP | 1200 EGP | 900 EGP | 2350 EGP |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fayed, S.; Ghalla, M.; Mlybari, E.A.; Bazuhair, R.W.; Madenci, E.; Özkılıç, Y.O. Using Near-Surface-Mounted Small-Diameter Steel Wires to Improve Construction Efficiency in Strengthening Substandard Lapped Spliced Reinforced Concrete Beams. Buildings 2025, 15, 957. https://doi.org/10.3390/buildings15060957

Fayed S, Ghalla M, Mlybari EA, Bazuhair RW, Madenci E, Özkılıç YO. Using Near-Surface-Mounted Small-Diameter Steel Wires to Improve Construction Efficiency in Strengthening Substandard Lapped Spliced Reinforced Concrete Beams. Buildings. 2025; 15(6):957. https://doi.org/10.3390/buildings15060957

Chicago/Turabian StyleFayed, Sabry, Mohamed Ghalla, Ehab A. Mlybari, Rabeea W. Bazuhair, Emrah Madenci, and Yasin Onuralp Özkılıç. 2025. "Using Near-Surface-Mounted Small-Diameter Steel Wires to Improve Construction Efficiency in Strengthening Substandard Lapped Spliced Reinforced Concrete Beams" Buildings 15, no. 6: 957. https://doi.org/10.3390/buildings15060957

APA StyleFayed, S., Ghalla, M., Mlybari, E. A., Bazuhair, R. W., Madenci, E., & Özkılıç, Y. O. (2025). Using Near-Surface-Mounted Small-Diameter Steel Wires to Improve Construction Efficiency in Strengthening Substandard Lapped Spliced Reinforced Concrete Beams. Buildings, 15(6), 957. https://doi.org/10.3390/buildings15060957