Evaluating the Influence of Alfa Fiber Morphology on the Thermo-Mechanical Performance of Plaster-Based Composites and Exploring the Cost–Environmental Effects of Fiber Content

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Preparation Process

2.1.1. Local Sourcing and Sustainability Considerations

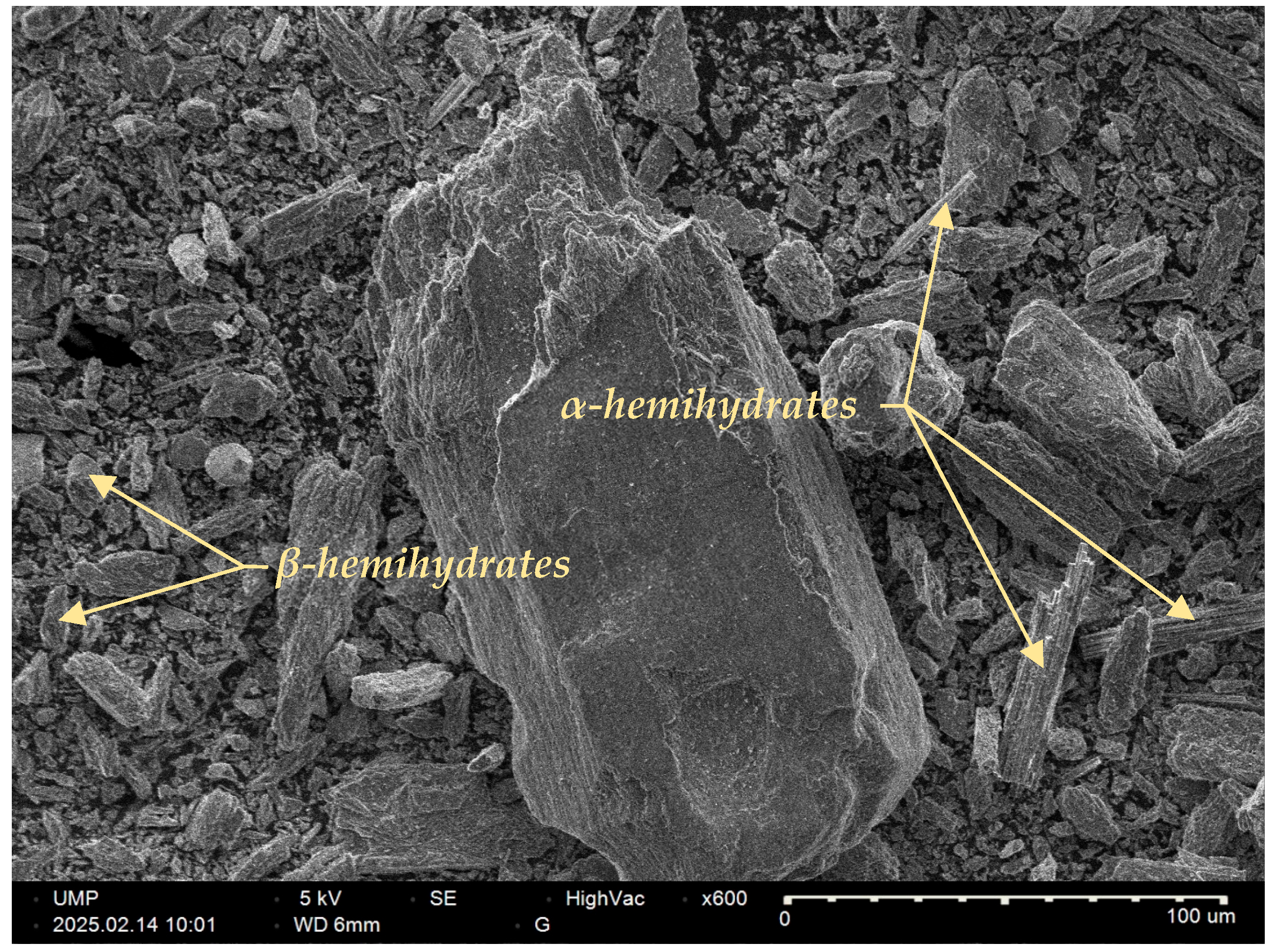

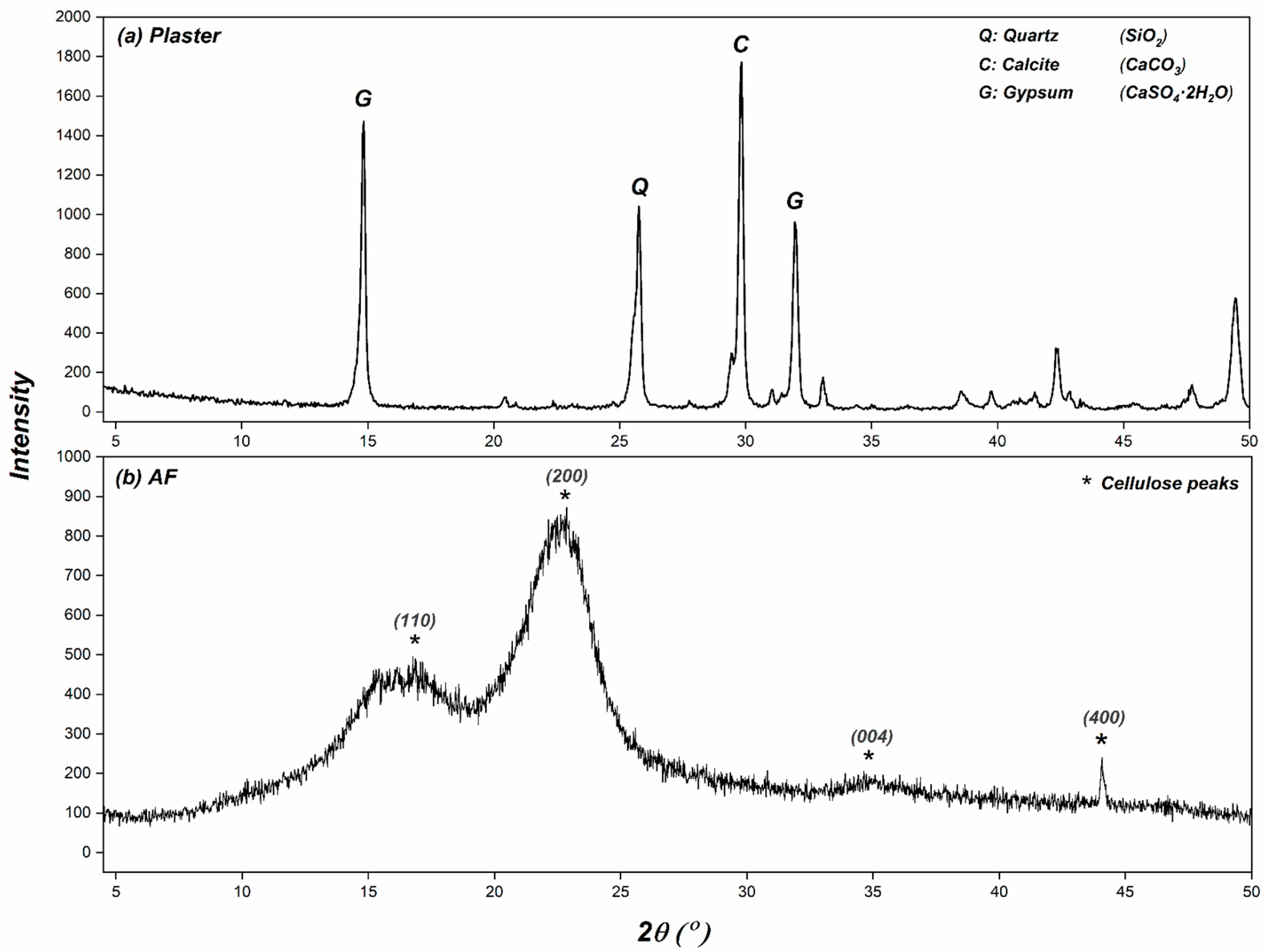

2.1.2. Plaster

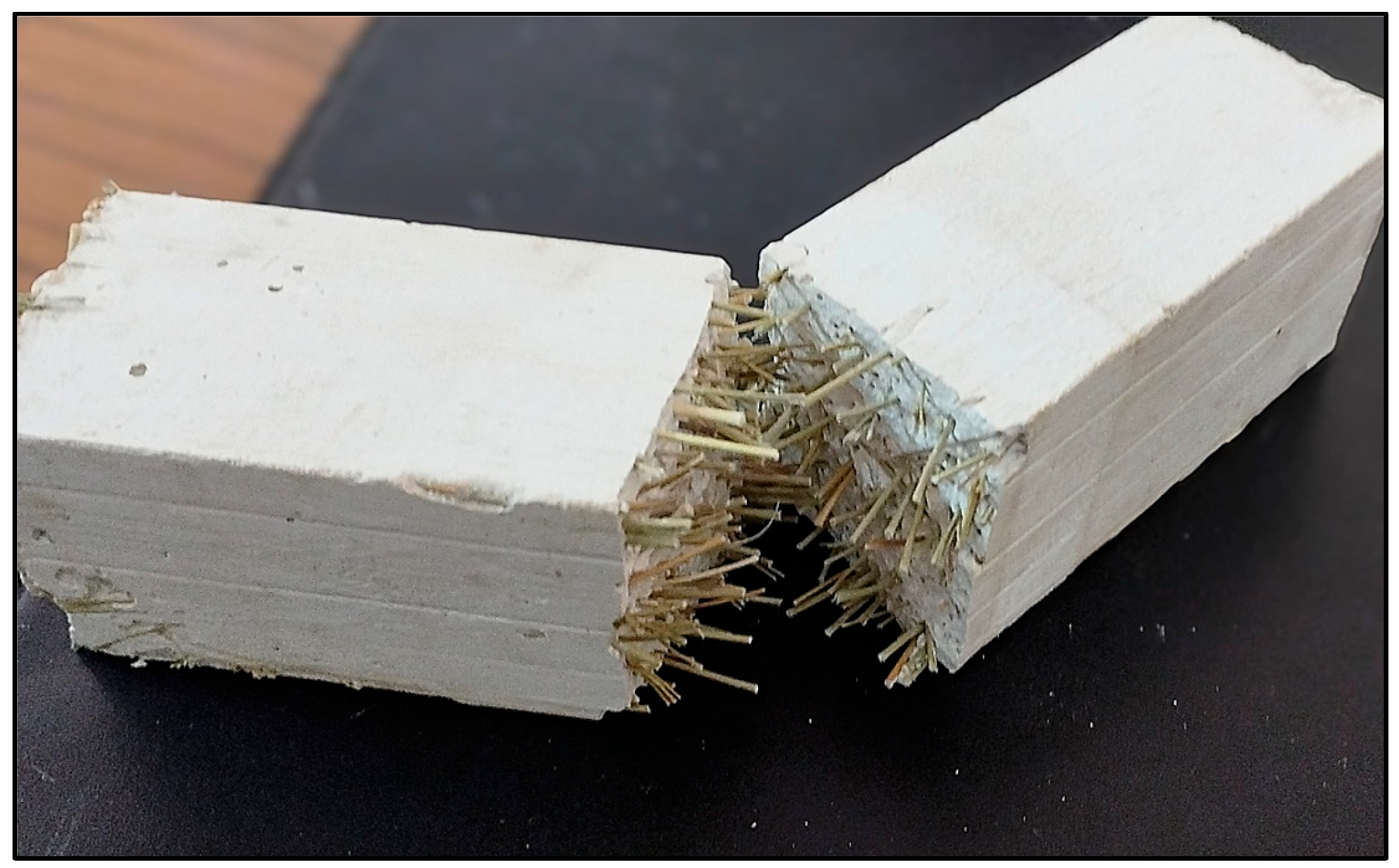

2.1.3. Alfa Fibers (AF)

2.1.4. Preliminary Characterization Tests

2.1.5. Sample Preparation

2.2. Characterization Techniques

2.2.1. Thermophysical Properties

2.2.2. Mechanical Properties

3. Results and Discussion

3.1. Density

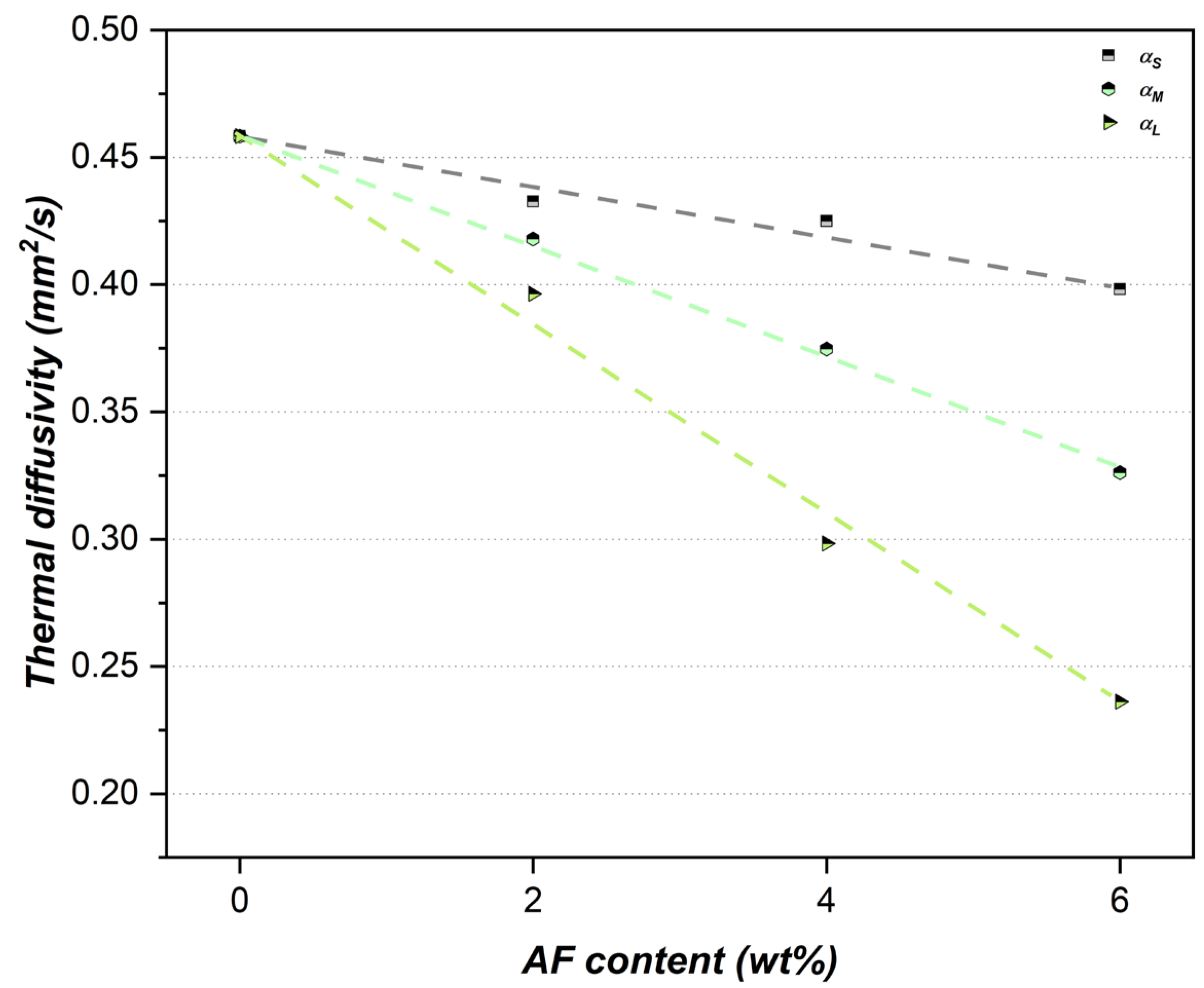

3.2. Thermal Conductivity and Diffusivity

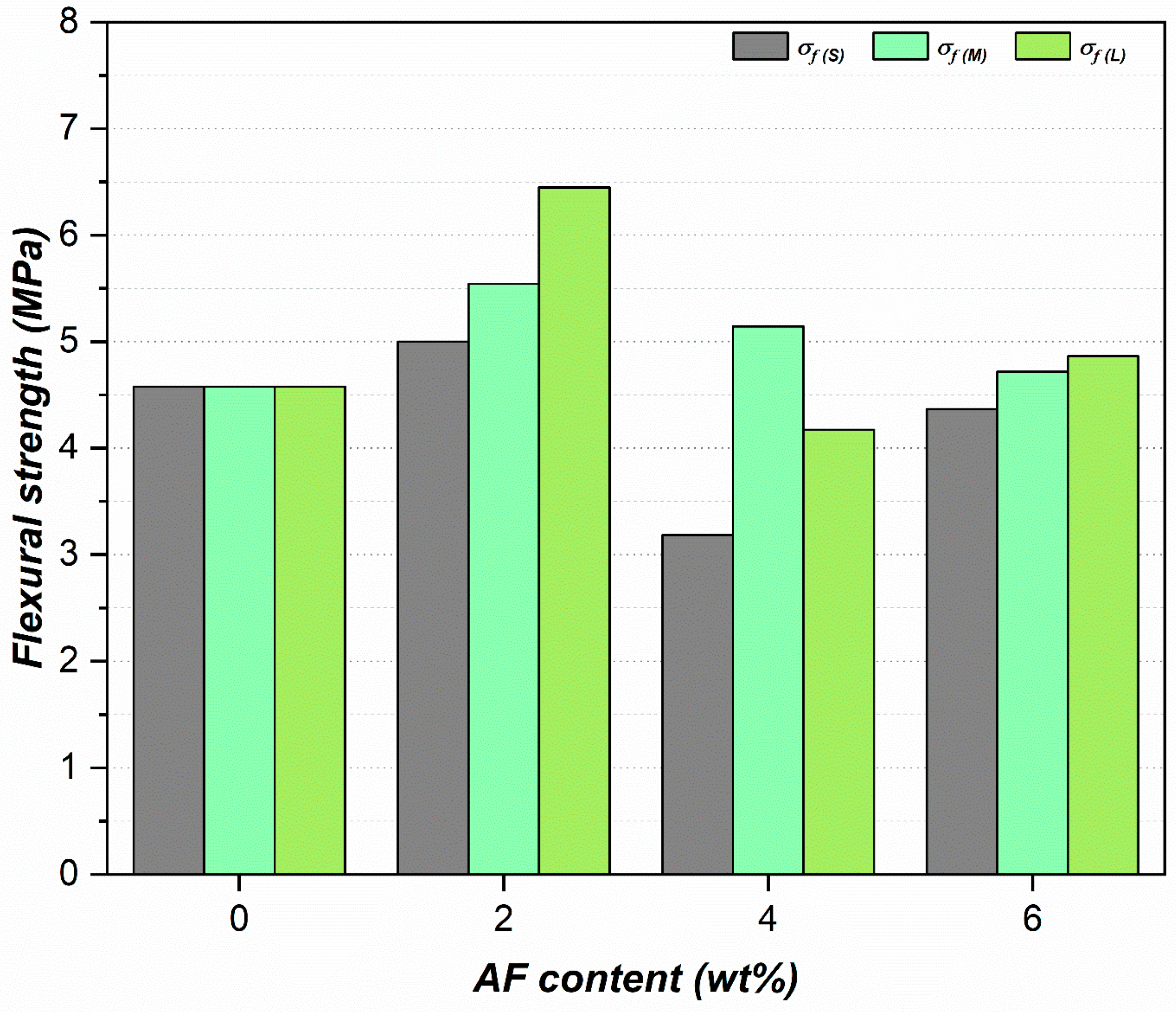

3.3. Compression and Flexural Strengths

3.4. Practical Implications

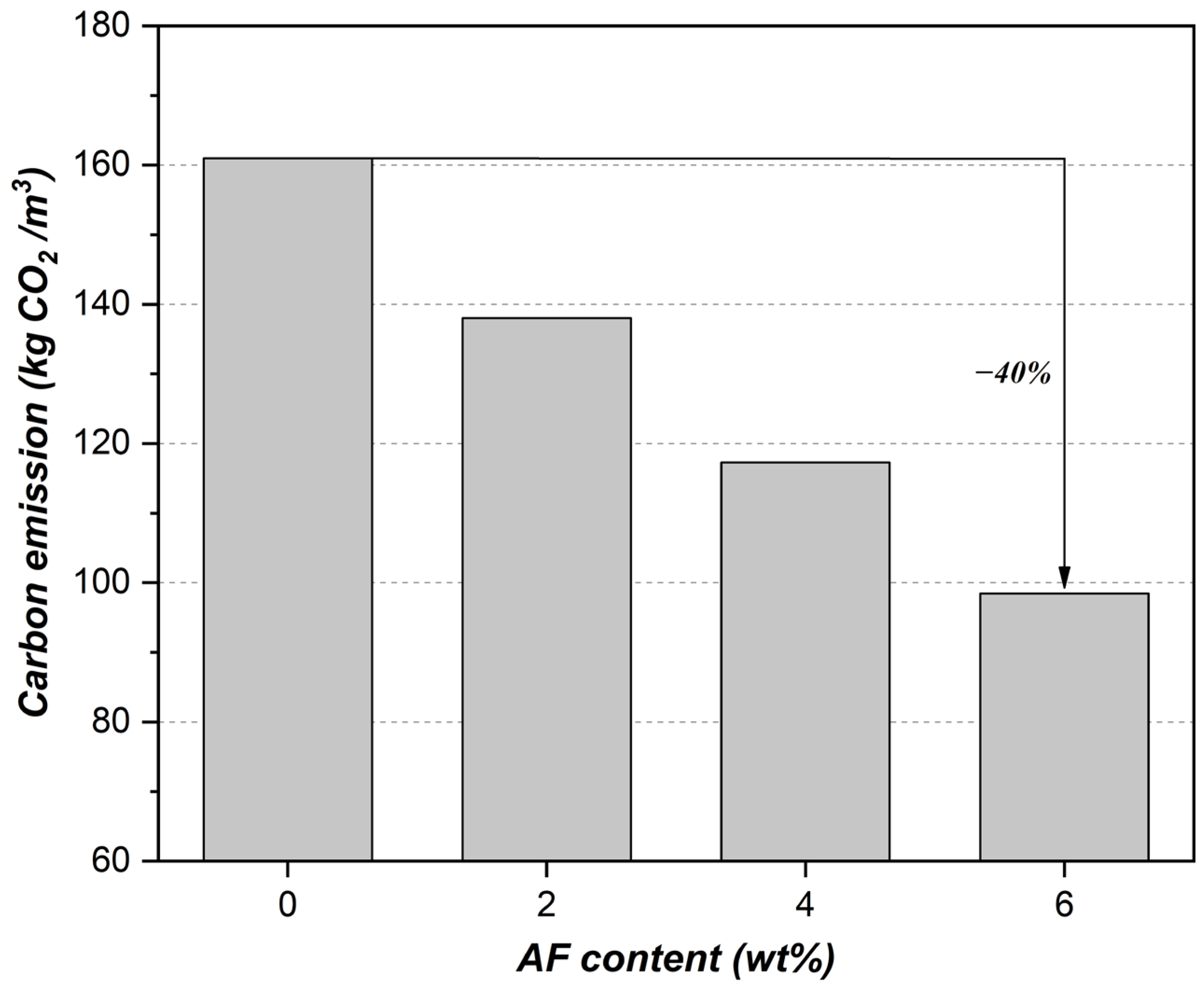

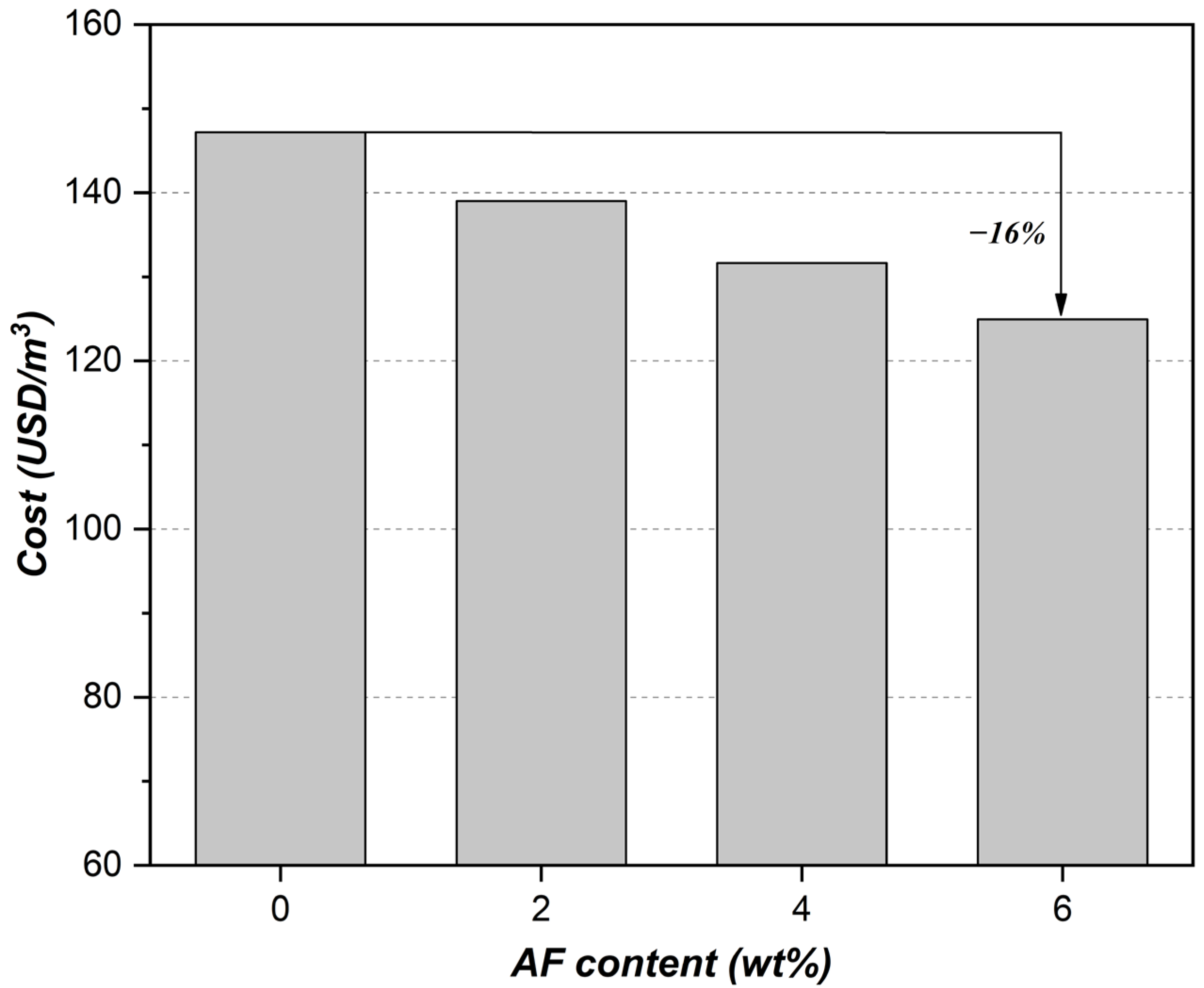

4. CO2 Emissions and Cost Analysis

4.1. Carbon Emissions Analysis

4.2. Cost Analysis

| Materials | CO2 Emission (kg·CO2/kg) [58] | Disposal Cost (USD/kg) [16,59] |

|---|---|---|

| Plaster | 0.1402 | 0.128 |

| Alfa fibers | −2.56 | 0.00403 |

4.3. Limitation and Future Directions:

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caronge, M.A.; Tjaronge, M.W.; Rahim, I.R.; Irmawaty, R.; Lapian, F.E.P. Feasibility study on the use of processed waste tea ash as cement replacement for sustainable concrete production. J. Build. Eng. 2022, 52, 104458. [Google Scholar] [CrossRef]

- Lachheb, A.; Allouhi, A.; El Marhoune, M.; Saadani, R.; Kousksou, T.; Jamil, A.; Rahmoune, M.; Oussouaddi, O. Thermal insulation improvement in construction materials by adding spent coffee grounds: An experimental and simulation study. J. Clean. Prod. 2019, 209, 1411–1419. [Google Scholar]

- Kaddouri, H.; Abidouche, A.; Alaoui, M.S.H.; Driouch, I.; Hamdaoui, S. Impact of Insulation using Bio-sourced Materials on the Thermal and Energy Performance of a Typical Residential Building in Morocco. J. Adv. Res. Fluid Mech. Therm. Sci. 2024, 117, 43–59. [Google Scholar]

- Touil, M.; Lachheb, A.; Saadani, R.; Kabiri, M.R.; Rahmoune, M. A new experimental strategy assessing the optimal thermo-mechanical properties of plaster composites containing Alfa fibers. Energy Build. 2022, 262, 111984. [Google Scholar]

- Boumhaout, M.; Boukhattem, L.; Hamdi, H.; Benhamou, B.; Nouh, F.A. Thermomechanical characterization of a bio-composite building material: Mortar reinforced with date palm fibers mesh. Constr. Build Mater. 2017, 135, 241–250. [Google Scholar]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Dev, V.G.; Santhanam, M. Performance evaluation of sugarcane bagasse ash blended cement in concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar]

- Tedjditi, A.K.; Ghomari, F.; Taleb, O.; Belarbi, R.; Bouhraoua, R.T. Potential of using virgin cork as aggregates in development of new lightweight concrete. Constr. Build. Mater. 2020, 265, 120734. [Google Scholar]

- Ajouguim, S.; Talibi, S.; Djelal-Dantec, C.; Hajjou, H.; Waqif, M.; Stefanidou, M.; Saadi, L. Effect of Alfa fibers on the mechanical and thermal properties of compacted earth bricks. Mater. Today Proc. 2019, 37, 4049–4057. [Google Scholar] [CrossRef]

- El-Abbassi, F.E.; Assarar, M.; Ayad, R.; Bourmaud, A.; Baley, C. A review on alfa fibre (Stipa tenacissima L.): From the plant architecture to the reinforcement of polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105677. [Google Scholar]

- Charai, M.; Mezrhab, A.; Moga, L.; Karkri, M. Hygrothermal, mechanical and durability assessment of vegetable concrete mixes made with Alfa fibers for structural and thermal insulating applications. Constr. Build. Mater. 2022, 335, 127518. [Google Scholar]

- Sair, S.; Mansouri, S.; Tanane, O.; Abboud, Y.; El Bouari, A. Alfa fiber-polyurethane composite as a thermal and acoustic insulation material for building applications. SN Appl. Sci. 2019, 1, 667. [Google Scholar]

- Bali, Y.; Kriker, A.; Abimouloud, Y.; Bouzouaid, S. Improving thermal insulation of fired earth bricks with alfa plant and glass powder additives: Effects on thermo-physical and mechanical properties. Case Stud. Therm. Eng. 2024, 53, 103778. [Google Scholar] [CrossRef]

- Benallel, A.; Tilioua, A.; Laaroussi, N.; Garoum, M. Valorization of plant waste for sustainable and ecological insulation in construction: Characterization of thermal and acoustic properties. Renew. Sustain. Energy Rev. 2025, 208, 115014. [Google Scholar] [CrossRef]

- Charai, M.; Mghazli, M.O.; Channouf, S.; Jagadesh, P.; Moga, L.; Mezrhab, A. Lightweight waste-based gypsum composites for building temperature and moisture control using coal fly ash and plant fibers. Constr. Build. Mater. 2023, 393, 132092. [Google Scholar]

- Benallel, A.; Tilioua, A.; Ettakni, M.; Ouakarrouch, M.; Garoum, M.; Hamdi, M.A.A. Design and thermophysical characterization of new thermal insulation panels based on cardboard waste and vegetable fibers. Sustain. Energy Technol. Assess. 2021, 48, 101639. [Google Scholar]

- Bourbia, S.; Kazeoui, H.; Belarbi, R. A review on recent research on bio-based building materials and their applications. Mater. Renew Sustain. Energy 2023, 12, 117–139. [Google Scholar]

- Brahim, S.B.; Cheikh, R.B. Influence of fibre orientation and volume fraction on the tensile properties of unidirectional Alfa-polyester composite. Compos. Sci. Technol. 2007, 67, 140–147. [Google Scholar]

- Tarchi, I.; Hanana, M.; Msaada, K.; Hessini, K.; Soliman, T.; Frouja, O.; Ahmed, H.B. Seasonal dynamics of alfa fibers: Comprehensive characterization of chemical, elemental, and mechanical properties in a semi-arid ecosystem. Sci. Hortic. 2024, 329, 112981. [Google Scholar] [CrossRef]

- Ajouguim, S.; Abdelouahdi, K.; Waqif, M.; Stefanidou, M.; Saâdi, L. Modifications of Alfa fibers by alkali and hydrothermal treatment. Cellulose 2019, 26, 1503–1516. [Google Scholar]

- Mouhoubi, S.; Bourahli, M.E.H.; Osmani, H.; Abdeslam, S. Effect of alkali treatment on alfa fibers behavior. J. Nat. Fibers 2017, 14, 239–249. [Google Scholar]

- Althoey, F.; Hakeem, I.Y.; Hosen, A.; Qaidi, S.; Isleem, H.F.; Hadidi, H.; Shahapurkar, K.; Ahmad, J.; Ali, E. Behavior of concrete reinforced with date palm fibers. Materials 2022, 15, 7923. [Google Scholar] [CrossRef] [PubMed]

- Çomak, B.; Bideci, A.; Bideci, Ö.S. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Suárez, C.M.; Carrillo, C.H.; Junco, O.G. Mechanical performance of mortar mixes reinforced with hemp and fique fibers treated with sodium silicate. J.Phys. Conf. Ser. IOP Publ. 2021, 2046, 012059. [Google Scholar]

- Sawsen, C.; Fouzia, K.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar]

- Ajouguim, S.; Page, J.; Djelal, C.; Saâdi, L. Effect of treated Alfa fibers on hydration kinetics, mechanical, and adhesion properties of fiber cement composite. J. Build. Eng. 2023, 71, 106558. [Google Scholar]

- Ajouguim, S.; Page, J.; Djelal, C.; Waqif, M.; Saâdi, L. Impact of Alfa fibers morphology on hydration kinetics and mechanical properties of cement mortars. Constr. Build. Mater. 2021, 293, 123514. [Google Scholar] [CrossRef]

- Garrouri, S.; Lakhal, W.; Benazzouk, A.; Sediki, E. Potential use of Alfa fibers in construction material: Physico-mechanical and thermal characterisation of reinforced specimen. Constr. Build. Mater. 2022, 342, 127787. [Google Scholar] [CrossRef]

- Sakami, S.; Boukhattem, L.; Boumhaout, M.; Benhamou, B. Development of alfa fiber-based mortar with improved thermo-mechanical properties. Appl. Sci. 2020, 10, 8021. [Google Scholar] [CrossRef]

- Messas, T.; Achoura, D.; Abdelaziz, B.; Mamen, B. Experimental investigation on the mechanical behavior of concrete reinforced with Alfa plant fibers. Frat. Ed IntegritàStrutt. 2022, 16, 102–113. [Google Scholar] [CrossRef]

- Ajouguim, S.; Page, J.; Djelal, C.; Waqif, M.; Saâdi, L. Investigation on the use of ground alfa fibres as reinforcement of cement mortars. Proc. Inst. Civ. Eng.-Constr. Mater. 2021, 174, 161–171. [Google Scholar] [CrossRef]

- Charai, M.; Sghiouri, H.; Mezrhab, A.; Karkri, M. Thermal insulation potential of non-industrial hemp (Moroccan cannabis sativa L.) fibers for green plaster-based building materials. J. Clean. Prod. 2021, 292, 126064. [Google Scholar] [CrossRef]

- EN 13279-2:2014; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- Zavadskaya, L.V.; Ilich, G. Berdov Change of Structure and Strength of Gypsum at Adding Disperse Mineral Additives. Res. J. Appl. Sci. Eng. Technol. 2016, 12, 86–93. [Google Scholar] [CrossRef]

- Liang, J.; Yang, W.; Yuen, A.C.Y.; Long, H.; Qiu, S.; Cordeiro, I.M.D.C.; Wang, W.; Chen, T.B.Y.; Hu, Y.; Yeoh, G.H. Peanut shell derived carbon combined with nano cobalt: An effective flame retardant for epoxy resin. Molecules 2021, 26, 6662. [Google Scholar] [CrossRef]

- Horma, O.; El Hammouti, A.; El Hassani, S.; Kırgız, M.S.; Channouf, S.; Moussaoui, M.A.; Mezrhab, A. A sustainable approach to mortar production using mint stem aggregates: Investigating the thermal, mechanical and physical performance. Mater. Civ. Eng. 2024, 36, 04024330. [Google Scholar] [CrossRef]

- Verma, N.; Kumar, V.; Bansal, M.C. Comparative view on microbial consumption of agro-based lignocellulosic waste biomass in sustainable production of cellulases. Biomass. Convers. Biorefinery 2021, 11, 2669–2679. [Google Scholar] [CrossRef]

- Jelle, B.P. Nano-based thermal insulation for energy-efficient buildings. In Start-Up Creation: The Smart Eco-Efficient Built Environment; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 129–181. [Google Scholar] [CrossRef]

- I. 22007-2; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. The International Organization for Standardization (ISO): Geneva, Switzerland, 2015. Available online: https://www.iso.org/obp/ui/#iso:std:iso:22007:-2:ed-2:v1:en (accessed on 22 January 2025).

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2011.

- ASTM-C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM: West Conshohocken, PA, USA, 2018. Available online: https://www.astm.org/c0348-14.html (accessed on 9 March 2025).

- El Hammouti, A.; Charai, M.; Channouf, S.; Horma, O.; Mezrhab, A.; Karkri, M.; Tankari, M.A. Application analysis and environmental impact of straw reinforced gypsum plaster for improving the energy efficiency in buildings in the six climate zones of Morocco. J. Build. Eng. 2023, 74, 106829. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Karkri, M.; Moga, L. Thermal performance study of plaster reinforced with Alfa fibers. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2021. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Rodríguez-Liñán, C.; Flores-Colen, I.; de Brito, J. Use of polycarbonate waste as aggregate in recycled gypsum plasters. Materials 2020, 13, 3042. [Google Scholar] [CrossRef]

- Singh, S.; Dalbehera, M.M.; Kumar, A.A.; Maiti, S.; Balam, N.B.; Bisht, R.S.; Panigrahi, S.K. Elevated temperature and performance behaviour of rice straw as waste bio-mass based foamed gypsum hollow blocks. J. Build. Eng. 2023, 69, 106220. [Google Scholar] [CrossRef]

- Horma, O.; Charai, M.; El Hassani, S.; El Hammouti, A.; Mezrhab, A. Thermo-physical and mechanical characterization of cement-based mortar incorporating spent tea. J. Build. Eng. 2022, 52, 104392. [Google Scholar] [CrossRef]

- Horma, O.; Channouf, S.; El Hammouti, A.; El Hassani, S.; Miri, H.; Moussaoui, M.A.; Mezrhab, A. Enhancing concrete sustainability using crushed peanut shells: An analysis of thermophysical properties, durability, and application potential in construction. J. Build.Eng. 2024, 90, 109434. [Google Scholar] [CrossRef]

- Mustapha, K.; Azeko, S.T.; Annan, E.; Kana, M.G.Z.; Daniel, L.; Soboyejo, W.O. Pull-out behavior of natural fiber from earth-based matrix. J. Compos. Mater. 2016, 50, 3539–3550. [Google Scholar] [CrossRef]

- Belkhir, Z.; Merzoud, M. Improvement of the Mechanical Behavior of Composite Materials with Different Binders Based on Local Plant Fibers Alfa and Diss. Civ. Environ. Eng. Rep. 2021, 31, 130–147. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: Mechanical and morphological studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Bernat-Masoa, E.; Puigvertb, F.; Abdelmoulac, H.; Gild, L. Additioning alfa fibres in cement mortar. Rev. De La Constr. 2018, 17, 72–84. [Google Scholar] [CrossRef]

- Blakemore, R. Humic Carbon to Fix Food, Climate and Health. Preprints 2019, 2019040109. [Google Scholar] [CrossRef]

- Drissi, M.; Horma, O.; Mezrhab, A.; Karkri, M. Exploring Raw Red Clay as a Supplementary Cementitious Material: Composition, Thermo-Mechanical Performance, Cost, and Environmental Impact. Buildings 2024, 14, 3906. [Google Scholar] [CrossRef]

- Agossou, O.G.; Amziane, S. Analysis of Mechanical and Thermal Performance and Environmental Impact of Flax-Fiber-Reinforced Gypsum Boards. Buildings 2023, 13, 3098. [Google Scholar] [CrossRef]

- Junior, J.L.L.; Brabo, D.R.; Amaral, E.L.S.; da Cruz Reis, A.W.; Amarante, C.B.D.; Dias, C.G.B.T. Characterization of the natural fibers extracted from the aninga’s stem and development of a unidirectional polymeric sheet. Sci. Rep. 2024, 14, 24780. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Santos, P.; Chamasemani, N.F. Enhancing the Mechanical Properties of Ultra-High-Performance Concrete (UHPC) Through Silica Sand Replacement with Steel Slag. Buildings 2024, 14, 3520. [Google Scholar] [CrossRef]

- Fořt, J.; Černý, R. Carbon footprint analysis of calcined gypsum production in the Czech Republic. J. Clean. Prod. 2018, 177, 795–802. [Google Scholar]

- Alves, A.B.M.; Miller, A.P.R.R.; Junior, J.E.D.L.; Miranda, L.F.R.; De Medeiros, M.H.F. Economic evaluation to recycling plaster. Int. J. Env. Waste Manag. 2017, 19, 338–352. [Google Scholar]

| Sample Designation | AF | Plaster (wt%) | Water-to-Binder Ratio | ||

|---|---|---|---|---|---|

| wt% | kg/m3 | wt% | kg/m3 | ||

| P | 0 | 0 | 100 | 1150 | 0.5 |

| PAFS2 | 2 | 5.45 | 98 | 1085.96 | 0.5 |

| PAFS4 | 4 | 10.38 | 96 | 1028.13 | 0.5 |

| PAFS6 | 6 | 14.85 | 94 | 975.65 | 0.5 |

| PAFM2 | 2 | 545 | 98 | 1085.96 | 0.5 |

| PAFM4 | 4 | 10.38 | 96 | 1028.13 | 0.5 |

| PAFM6 | 6 | 14.85 | 94 | 975.65 | 0.5 |

| PAFL2 | 2 | 5.45 | 98 | 1085.96 | 0.5 |

| PAFL4 | 4 | 10.38 | 96 | 1028.13 | 0.5 |

| PAFL6 | 6 | 14.85 | 94 | 975.65 | 0.5 |

| Composites | P | PAFS6 | PAFM6 | PAFL6 |

|---|---|---|---|---|

| Specific heat capacity (J/kgK) | 833 | 792 | 750 | 916 |

| Composite | ρ (kg/m3) | λ (W/mK) | α (mm2/s) | (MPa) | (MPa) |

|---|---|---|---|---|---|

| P | 1246 ± 24 | 0.476 ± 0.019 | 0.458 ± 0.028 | 7.22 ± 0.81 | 4.57 ± 0.49 |

| PAFL2 | 1167 ± 21 | 0.390 ± 0.023 | 0.396 ± 0.020 | 2.69 ± 0.22 | 6.45 ± 0.62 |

| PAFL6 | 1043 ± 15 | 0.225 ± 0.012 | 0.236 ± 0.017 | 1.06 ± 0.14 | 4.86 ± 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horma, O.; Drissi, M.; Laaouar, B.; El Hassani, S.; El Hammouti, A.; Mezrhab, A. Evaluating the Influence of Alfa Fiber Morphology on the Thermo-Mechanical Performance of Plaster-Based Composites and Exploring the Cost–Environmental Effects of Fiber Content. Buildings 2025, 15, 1187. https://doi.org/10.3390/buildings15071187

Horma O, Drissi M, Laaouar B, El Hassani S, El Hammouti A, Mezrhab A. Evaluating the Influence of Alfa Fiber Morphology on the Thermo-Mechanical Performance of Plaster-Based Composites and Exploring the Cost–Environmental Effects of Fiber Content. Buildings. 2025; 15(7):1187. https://doi.org/10.3390/buildings15071187

Chicago/Turabian StyleHorma, Othmane, Mohammed Drissi, Boutahar Laaouar, Sara El Hassani, Aboubakr El Hammouti, and Ahmed Mezrhab. 2025. "Evaluating the Influence of Alfa Fiber Morphology on the Thermo-Mechanical Performance of Plaster-Based Composites and Exploring the Cost–Environmental Effects of Fiber Content" Buildings 15, no. 7: 1187. https://doi.org/10.3390/buildings15071187

APA StyleHorma, O., Drissi, M., Laaouar, B., El Hassani, S., El Hammouti, A., & Mezrhab, A. (2025). Evaluating the Influence of Alfa Fiber Morphology on the Thermo-Mechanical Performance of Plaster-Based Composites and Exploring the Cost–Environmental Effects of Fiber Content. Buildings, 15(7), 1187. https://doi.org/10.3390/buildings15071187