Abstract

This paper presents results of the first phase of “Dielectric Elastomer Cooperative Microactuator Systems” (DECMAS), a project within the German Research Foundation Priority Program 2206, “Cooperative Multistable Multistage Microactuator Systems” (KOMMMA). The goal is the development of a soft cooperative microactuator system combining high flexibility with large-stroke/high-frequency actuation and self-sensing capabilities. The softness is due to a completely polymer-based approach using dielectric elastomer membrane structures and a specific silicone bias system designed to achieve large strokes. The approach thus avoids fluidic or pneumatic compo-nents, enabling, e.g., future smart textile applications with cooperative sensing, haptics, and even acoustic features. The paper introduces design concepts and a first soft, single-actuator demonstrator along with experimental characterization, before expanding it to a 3 × 1 system. This system is used to experimentally study coupling effects, supported by finite element and lumped parameter simulations, which represent the basis for future cooperative control methods. Finally, the paper also introduces a new methodology to fabricate metal-based electrodes of sub-micrometer thickness with high membrane-straining capability and extremely low resistance. These electrodes will enable further miniaturization towards future microscale applications.

1. Introduction

Cooperative microsystems usually rely on silicon [1], fluidic [2], shape memory alloy [3], or piezoelectric transducers [4] to implement actuation. Despite their ease of miniaturization, those solutions generally result in small strokes, low efficiency, and stiff designs. Dielectric elastomers (DEs), consisting of thin and stretchable capacitors that expand when subjected to high voltage, appear to be a suitable alternative technology for cooperative microactuators [5,6,7]. They feature properties such as large deformations, inherent flexibility, high scalability, high energy density and efficiency, as well as the ability to work as actuators and capacitive sensors at the same time (self-sensing [8]). While multistability is generally introduced in actuators to save energy, in the case of DEs (which are already low-power actuators due to their capacitive nature), multistability can be used in unconventional ways. For instance, a multistable biasing mechanism allows the magnification of the system stroke by up to an order of magnitude compared to a linear bias spring [9].

2. System Design

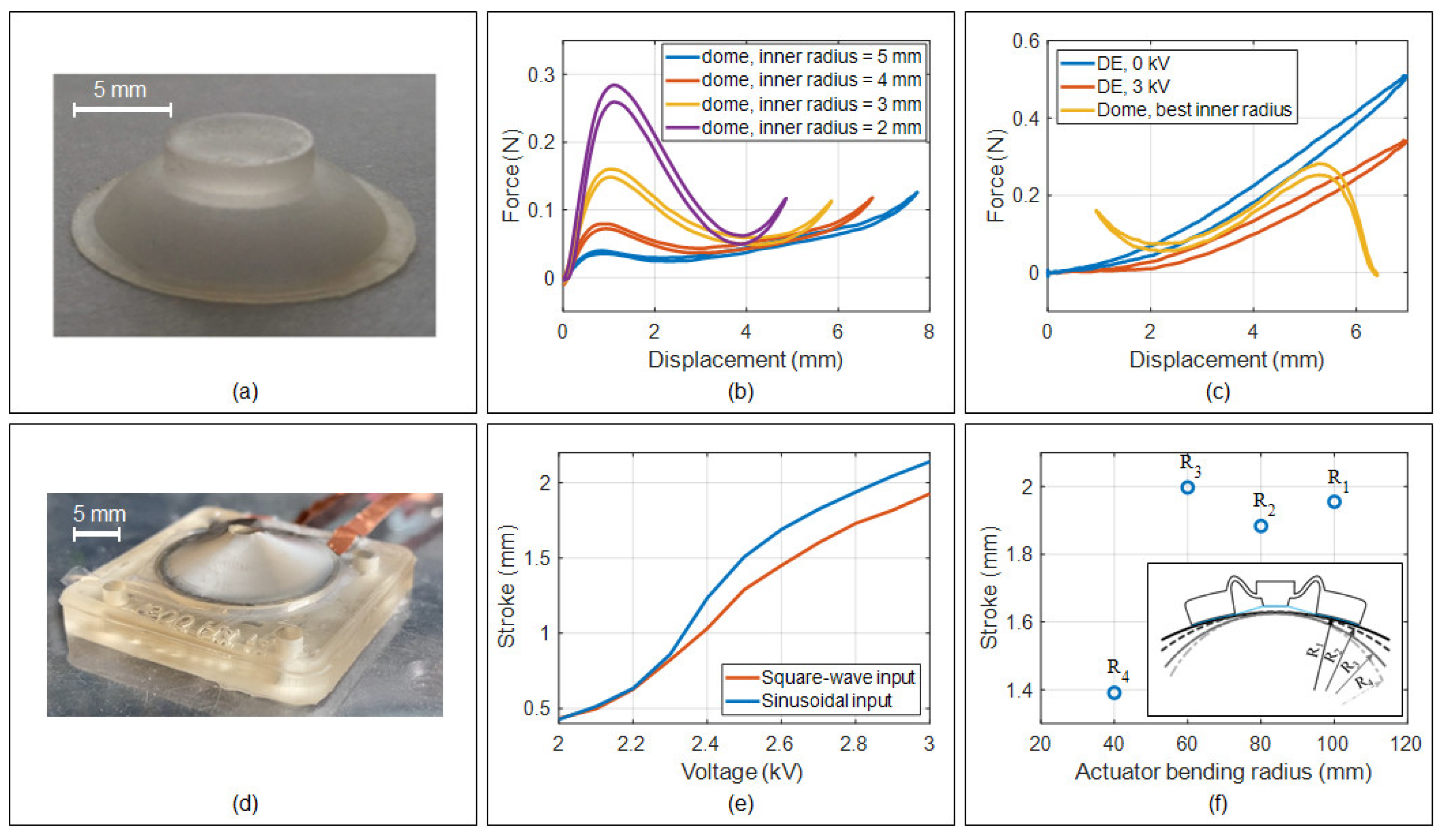

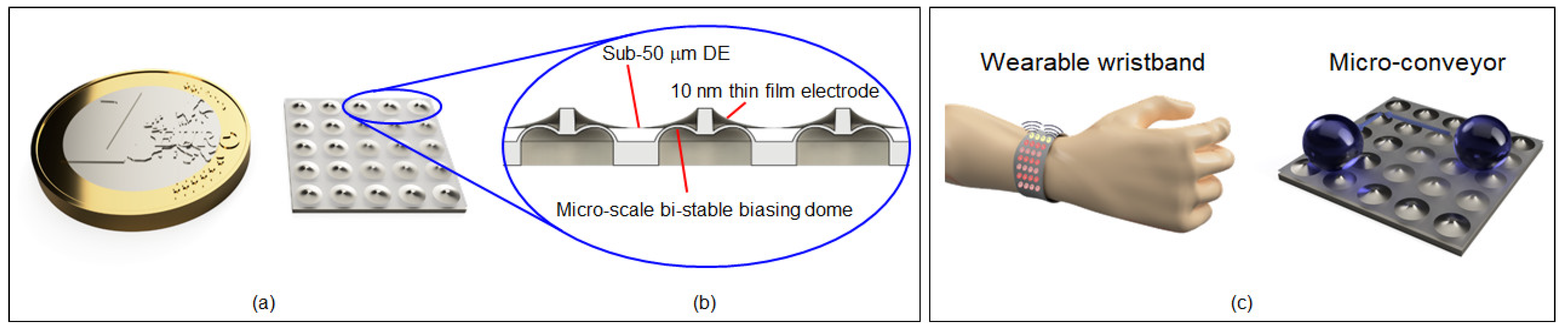

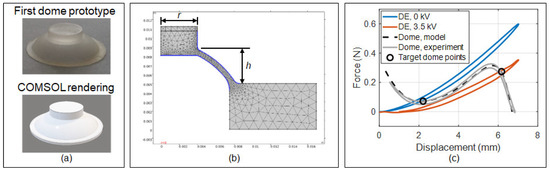

In order to achieve large strokes in dielectric elastomer membrane systems, Hodgins et al. [9] demonstrated the usefulness of so-called negative-rate bias springs based on stainless steel (NBS). This property can also be realized using soft silicone dome structures (Figure 1a). Neu et al. [10,11,12] showed that, depending on the dome geometry, the negative slope in a force–displacement curve can be tuned to match the corresponding dielectric elastomer actuator (DEA) curves (Figure 1b,c). Coupled with a 50 μm silicone film (Wacker ELASTOSIL 2030) of 10 mm diameter, the resulting DEA-NBS system (Figure 1d) could be shown to generate strokes of approximately 2 mm under various inputs while being able to adjust to different curvature configurations, thus demonstrating the flexibility of the approach.

Figure 1.

Silicone-based dome as negative-rate bias spring (a), load-deformation behavior (b,c), DE actuator (d), DEA stroke (e), stroke for different bending radii (f).

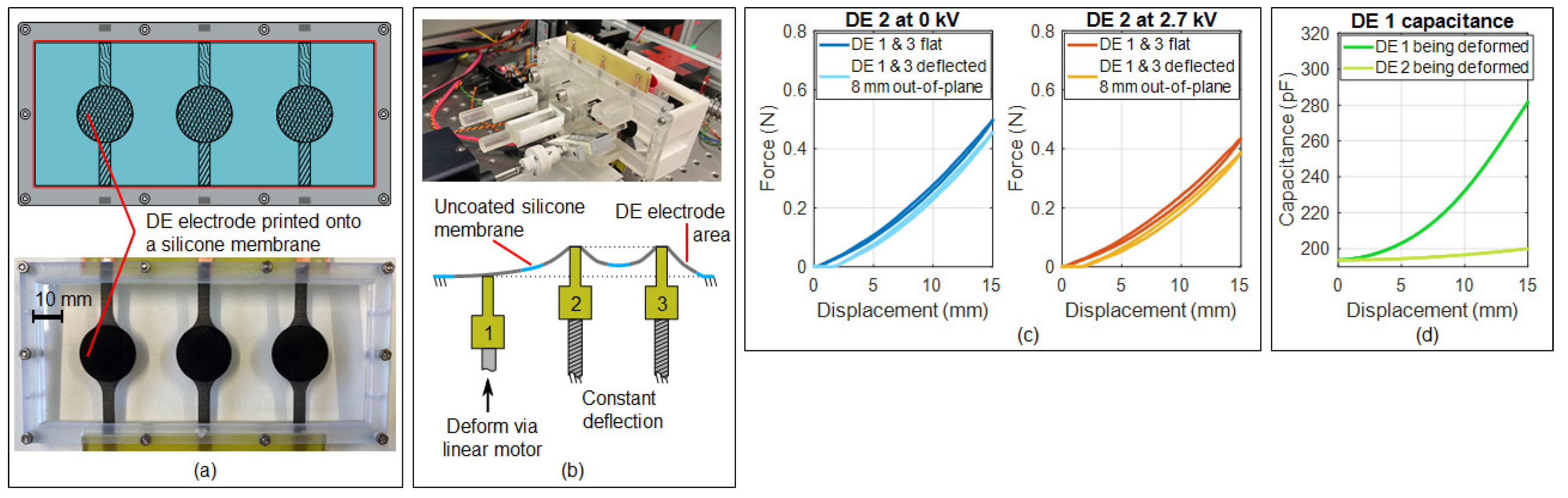

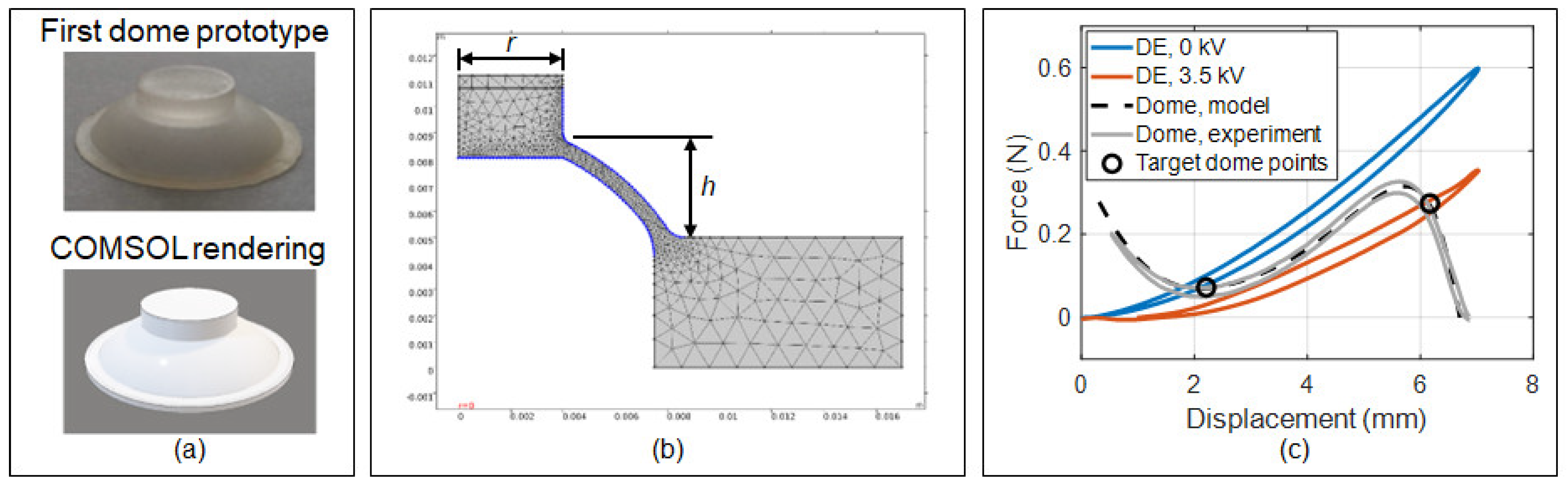

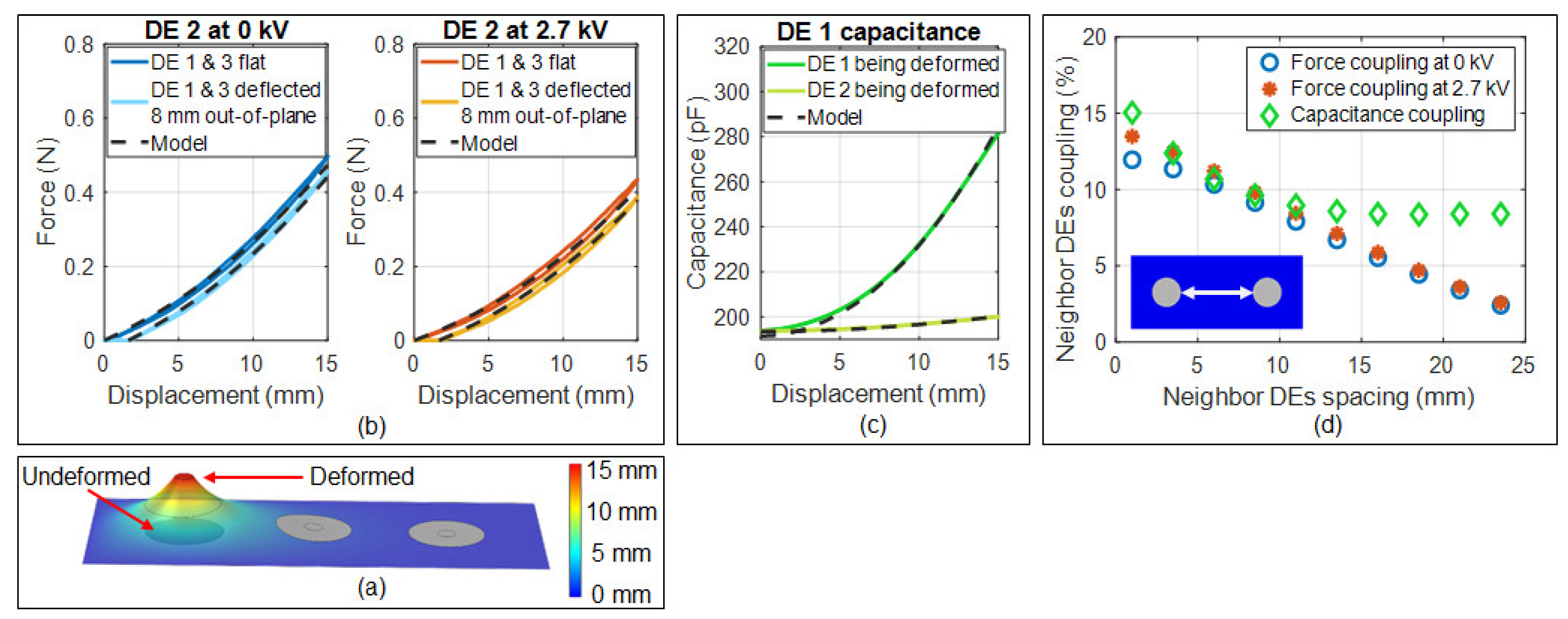

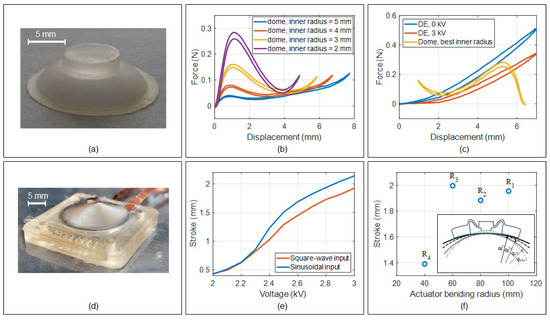

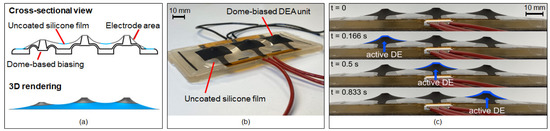

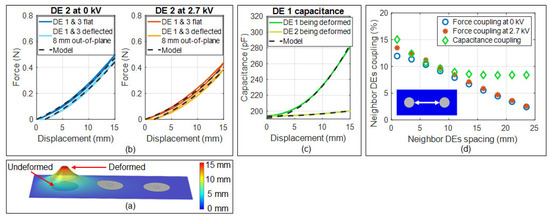

The concept was then extended to a multiactuator configuration [13,14,15]. In order to minimize fabrication and assembly efforts, future systems should ideally consist only of one DE membrane. This, however, introduces potential coupling effects that first need to be investigated for cooperative actuation. Figure 2a shows a 3 × 1 DEA system with carbon black (CB)/polydimethylsiloxane (PDMS) electrodes screen-printed on the same silicon membrane [16], which was subsequently characterized in a specifically designed test rig (Figure 2b). The plots in Figure 2c illustrate that the actuator performance of the center DE2 is not affected by a simultaneous displacement of its neighbors, while DE2 is still able to sense its own displacement as well as those of its neighbors through a capacitance measurement (Figure 2d).

Figure 2.

3 × 1 DEA membrane w/CB/PDMS electrodes (a), test rig for coupling characterization (b), center DE actuation properties unaffected by neighbor deflection (c), center DE sensing properties capable of self-detection and neighbor detection (d).

These features demonstrate the system’s potential for future cooperative behavior, as illustrated by Figure 3a,b. Figure 3c shows an example of a simple wave propagation experiment.

Figure 3.

3 × 1 DEA membrane w/polymeric dome bias, schematic side view (a), 3 × 1 DEA membrane w/ polymeric dome bias, full view (b), 3 × 1 DEA membrane w/polymeric dome bias, simple wave propagation (c).

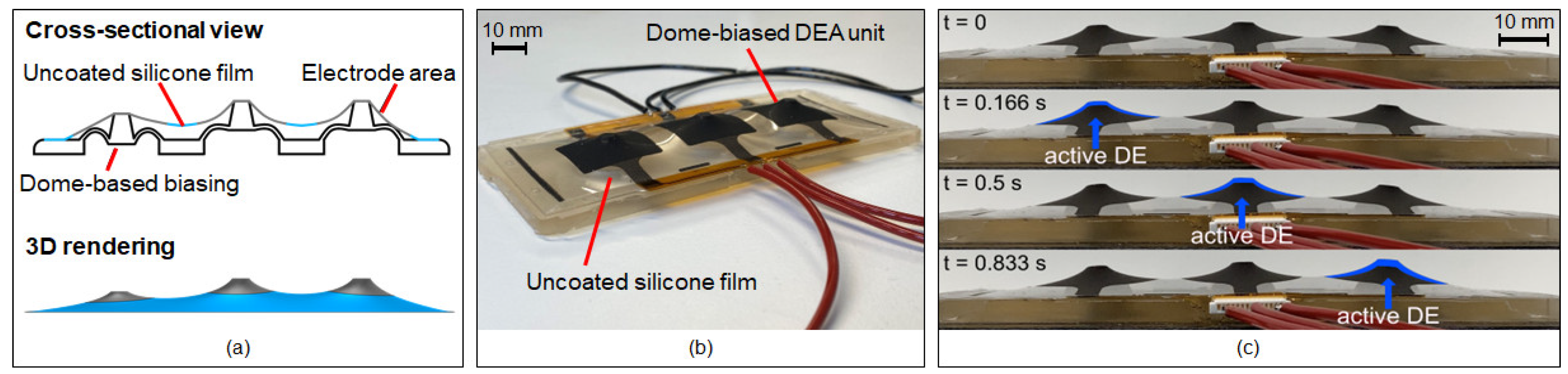

3. Modeling and Simulation

For a suitable choice of system geometries and materials, it is crucial to rely on simulations of the mechanical and electro-mechanical behavior. Figure 4 shows a finite element simulation performed with COMSOL [17,18], identifying the dome properties for the above silicone bias system.

Figure 4.

Single element polymeric dome bias, FE mesh (a,b), electro-mechanical simulation of single DEA system, experimental validation (c).

While Figure 4 illustrates the behavior of an individual dome-based DEA system, the plots in Figure 5 are the results of an electromechanical FE simulation of the 3 × 1 system above [19,20]. The simulation is able to reproduce the coupling behavior from Figure 2, while also giving an estimate of the effect of spacing between individual DEAs.

Figure 5.

3 × 1 DEA system, FE mesh (a), electro-mechanical simulation of 3 × 1 DEA system, experimental validation actuation (b), electro-mechanical simulation of 3 × 1 DEA system, experimental validation sensing (c), electro-mechanical coupling effects (d).

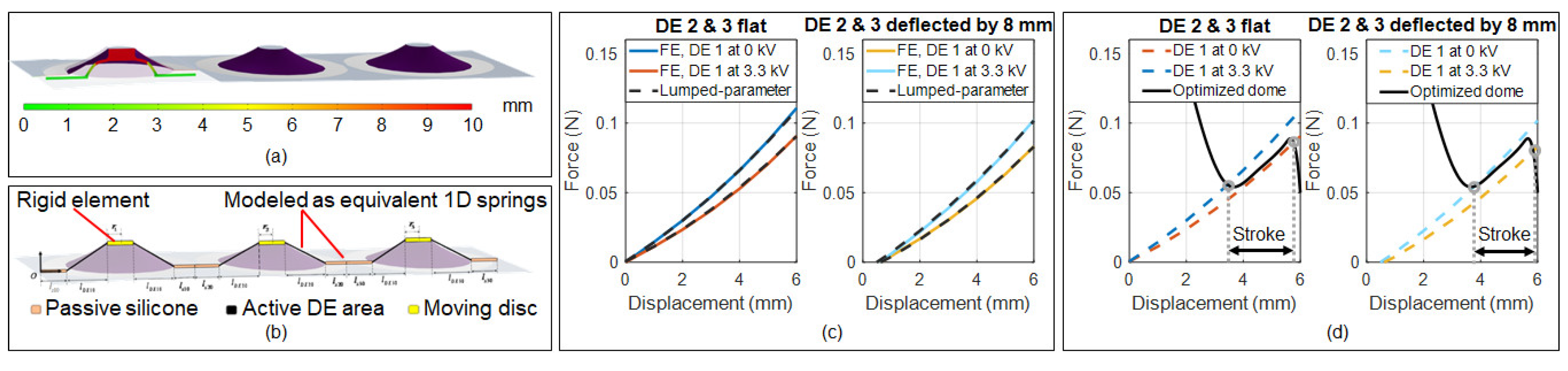

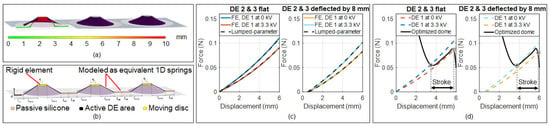

Based on the above COMSOL approach, Croce et al. also developed a lumped-parameter version of the model [21,22], which will allow for the computationally efficient implementation of future cooperative control strategies (see Figure 6).

Figure 6.

3 × 1 DEA system, lumped-parameter model for computational efficiency (a,b), electro-mechanical simulation of 3 × 1 DEA system, experimental validation actuation (c,d).

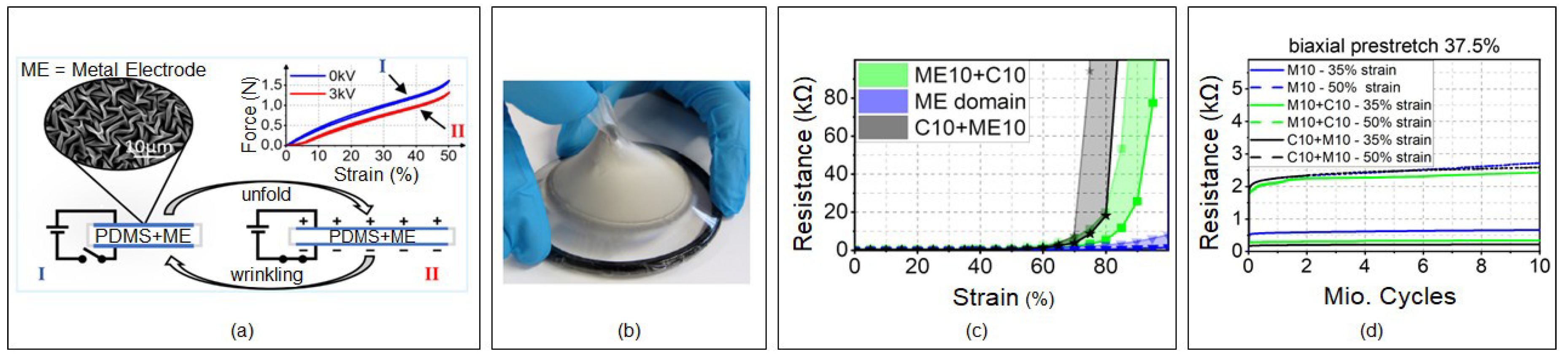

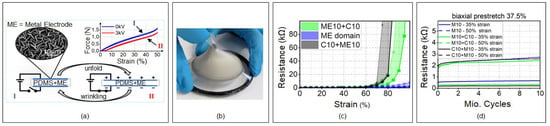

4. Electrodes

While the CB/PDMS electrodes from above have been successfully used for a number of macro-scale applications, their miniaturization potential is somewhat limited due to the resolution of the underlying screen-printing technology. To address this issue, Hubertus et al. [23,24] developed a technology based on the sputter deposition of Ni-based electrodes. One of the key features of the approach is pre-stretching the PDMS membrane prior to the electrode deposition. Unloading of the membrane after sputtering then leads to a strongly wrinkled surface; see the top left of Figure 7a. Operating the DE afterwards in a strain range below the pre-stretch level unfolds the wrinkles, which, coupled with the extremely low electrode thickness of <20 nm, does not impact the stiffness of the DEA negatively (Figure 7a, top right), hence allowing for efficient actuation.

Figure 7.

Single element DEA with Ni-sputtered nano-scale electrode (a), strong adhesion between electrode and silicone membrane (b), low resistance over large strain range (c), high cycle fatigue with stable resistance behavior (d).

Figure 7b displays the strong adhesion between the electrode and the PDMS membrane. Furthermore, despite the low layer thickness, the electrode features a very small electric resistance in the operation range up to the pre-stretch level (Figure 7c), remaining stable over several million cycles (Figure 7d).

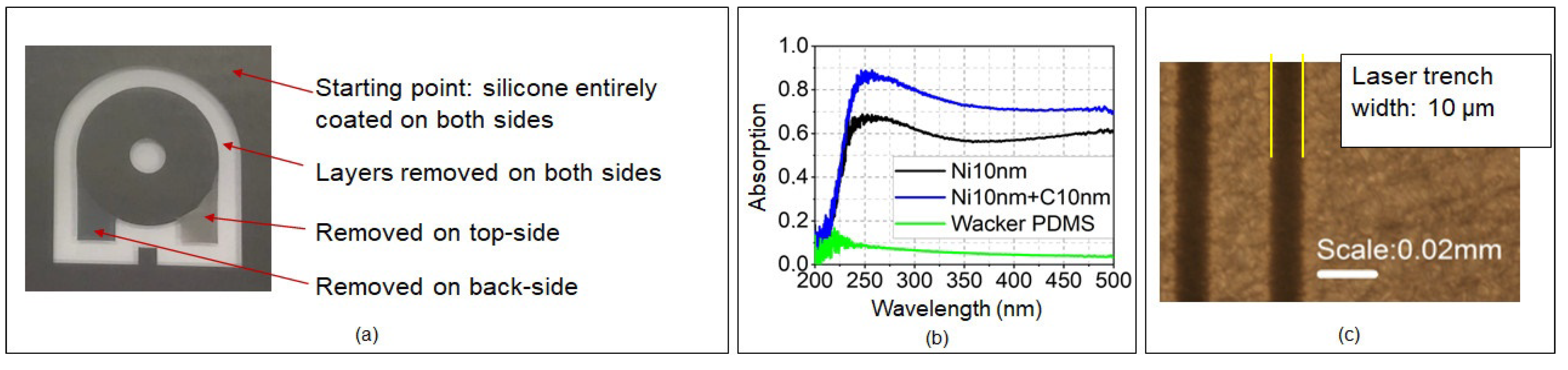

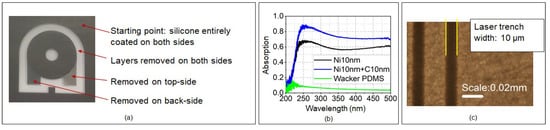

Additionally, the authors developed a highly efficient way of structuring the electrodes on the DEA’s top and bottom sides (Figure 8a) to obtain desired shapes for a broad range of target applications [25]. Tuning the wavelength and other laser operation parameters, they could utilize metal and polymer absorption behavior (Figure 8b) such that top and bottom electrode layers could be simultaneously removed with a single laser with high precision from one side only (Figure 8c).

Figure 8.

Simultaneous two-side electrode structuring technique (a), based on optimal absorption properties (b), high resolution suitable for future MEMS applications (c).

5. Conclusions and Outlook

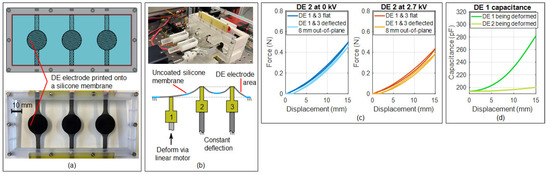

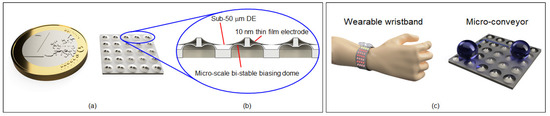

The paper presented first steps towards future cooperative dielectric-elastomer-based microactuator systems, detailing design, simulation, and system fabrication including a novel electrode technology. Based on a fully polymeric approach without fluidics or pneumatics, these systems (Figure 9a,b) will be suitable for, e.g., wearable and other mobile applications in the future. They will be able to generate a multitude of complex cooperative motion patterns such as self-organized transport processes for microconveyor systems or wave propagation signals in wearable haptics devices, potentially combining these with hapto-acoustic features [26,27]; see Figure 9c.

Figure 9.

Future fluidics-free and highly flexible cooperative DEA-MEMS system (a,b), potential applications in smart textiles or self-organizing microconveyor systems (c).

The next steps in Phase 2 of the DECMAS project will address a systematic study on the miniaturization and subsequent fabrication of the developed system with sub-50 µm PDMS membranes and microstructured Ni-sputtered electrodes. These steps will make use of further simulations and will particularly develop novel cooperative model-based control methods. In addition, an extension to a 3 × 3 design is planned to generate 2D arrays such as the ones proposed in, e.g., [28].

Author Contributions

Conceptualization, S.S., G.R. and G.S.; methodology, S.S., G.R. and G.S.; simulations, S.C.; hardware and experimental validation, J.N.; electrode development, J.H.; writing—original draft preparation, S.S.; writing—review and editing, S.S.; supervision, S.S., G.R. and G.S.; project administration, S.S., G.R. and G.S.; funding acquisition, S.S., G.R. and G.S. All authors have read and agreed to the published version of the manuscript.

Funding

The German Research Foundation (DFG) through the three DECMAS projects (RI3030/2-1, SCHU1609/7-1, SE704/9-1) within the Priority Program SPP 2206—Cooperative Multistage Mul-tistable Microactuator Systems (KOMMMA).

Acknowledgments

We would like to thank Wacker Chemie AG for providing the ELASTOSIL 2030 silicone films used in the projects.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bohringer, K.-F.; Donald, B.R.; MacDonald, N.C. Single-crystal silicon actuator arrays for micro manipulation tasks. In Proceedings of the Ninth International Workshop on Micro Electromechanical Systems, San Diego, CA, USA, 11–15 February 1996; pp. 7–12. [Google Scholar]

- Vandelli, N.; Wroblewski, D.; Velonis, M.; Bifano, T. Development of a MEMS Microvalve Array for Fluid Flow Control. J. Microelectromech. Syst. 1998, 7, 395–403. [Google Scholar] [CrossRef]

- Mineta, T.; Yanatori, H.; Hiyoshi, K.; Tsuji, K.; Ono, Y.; Abe, K. Tactile display MEMS device with SU8 micro-pin and spring on SMA film actuator array. IEEE Transducers 2017, 2017, 2031–2034. [Google Scholar]

- Hishinuma, Y.; Yang, E.-H. Piezoelectric Unimorph Microactuator Arrays for Single-Crystal Silicon Continuous-Membrane Deformable Mirror. J. Microelectromech Syst. 2006, 15, 370–379. [Google Scholar] [CrossRef]

- Kornbluh, R.D.; Pelrine, R.; Prahlad, H.; Heydt, R. Electroactive polymers: An emerging technology for MEMS. SPIE Mems/Moems Compon. Appl. 2004, 5344, 13–27. [Google Scholar]

- Balakrisnan, B.; Smela, E. Challenges in the microfabrication of dielectric elastomer actuators. SPIE Eapad 2010, 2010, 76420K. [Google Scholar]

- Akbari, S.; Shea, H.R. An array of 100 μm × 100 μm dielectric elastomer actuators with 80% strain for tissue engineering applications. Sens. Actuator A Phys. 2012, 186, 236–241. [Google Scholar] [CrossRef]

- Rizzello, G.; Naso, D.; York, A.; Seelecke, S. A Self-Sensing Approach for Dielectric Elastomer Actuators Based on Online Estimation Algorithms. IEEE/ASME Trans. Mechatron. 2017, 22, 728–738. [Google Scholar] [CrossRef]

- Hodgins, M.; York, A.; Seelecke, S. Experimental comparison of bias elements for out-of-plane DEAP actuator system. Smart Mater. Struct. 2013, 22, 094016. [Google Scholar] [CrossRef]

- Neu, J.; Hubertus, J.; Croce, S.; Schultes, G.; Seelecke, S.; Rizzello, G. Fully Polymeric Domes as High-Stroke Biasing System for Soft Dielectric Elastomer Actuators. Front. Robot. AI 2021, 8, 171. [Google Scholar] [CrossRef]

- Neu, J.; Croce, S.; Hubertus, J.; Rizzello, G.; Schultes, G.; Seelecke, S. Design and characterization of polymeric domes as biasing elements for dielectric elastomer membrane actuators. Actuator 2021, 2021, 442–445. [Google Scholar]

- Neu, J.; Croce, S.; Hubertus, J.; Schultes, G.; Rizzello, G.; Seelecke, S. Assembly and characterization of a DE actuator based on polymeric domes as biasing element. Proceedings 2020, 64, 24. [Google Scholar]

- Neu, J.; Croce, S.; Willian, T.; Hubertus, J.; Schultes, G.; Seelecke, S.; Rizzello, G. Distributed Electro-Mechanical Coupling Effects in Dielectric Elastomer Membrane Arrays: System Design and Experimental Characterization. Exp. Mech. 2023, 63, 79–95. [Google Scholar] [CrossRef]

- Neu, J.; Croce, S.; Hubertus, J.; Schultes, G.; Seelecke, S.; Rizzello, G. Characterization and Modeling of an Array of Dielectric Elastomer Taxels. SPIE Eapad 2021, XXIII, 115870R. [Google Scholar]

- Neu, J.; Croce, S.; Hubertus, J.; Schultes, G.; Seelecke, S.; Rizzello, G. Experimental characterization of the mechanical coupling in a DE-array. SPIE Eapad 2022, XXIV, 120420H. [Google Scholar]

- Fasolt, B.; Hodgins, M.; Rizzello, G.; Seelecke, S. Effect of screen printing parameters on sensor and actuator performance of dielectric elastomer (DE) membranes. Sens. Actuator A Phys. 2017, 265, 10–19. [Google Scholar] [CrossRef]

- Croce, S.; Neu, J.; Hubertus, J.; Seelecke, S.; Schultes, G.; Rizzello, G. Model-Based Design Optimization of Soft Polymeric Domes Used as Nonlinear Biasing Systems for Dielectric Elastomer Actuators. Actuators 2021, 10, 209. [Google Scholar] [CrossRef]

- Croce, S.; Neu, J.; Hubertus, J.; Rizzello, G.; Seelecke, S.; Schultes, G. Modeling and simulation of compliant biasing systems for dielectric elastomer membranes based on polymeric domes. Actuator 2021, 2021, 446–449. [Google Scholar]

- Croce, S.; Neu, J.; Moretti, G.; Hubertus, J.; Schultes, G.; Rizzello, G. Finite element modeling and validation of a soft array of spatially coupled dielectric elastomer transducers. Smart Mater. Struct. 2022, 31, 084001. [Google Scholar] [CrossRef]

- Croce, S.; Neu, J.; Hubertus, J.; Schultes, G.; Seelecke, S.; Rizzello, G. Finite Element Modeling and Parameter Study of a Fully-Polymeric Array of Coupled Dielectric Elastomers. SPIE Eapad 2022, XXIV, 120420B. [Google Scholar]

- Croce, S.; Neu, J.; Hubertus, J.; Seelecke, S.; Schultes, G.; Rizzello, G. Modeling and simulation of an array of Dielectric Elestomeric Actuator Membranes. Proceedings 2020, 64, 28. [Google Scholar]

- Croce, S.; Moretti, G.; Neu, J.; Hubertus, J.; Seelecke, S.; Schultes, G.; Rizzello, G. Finite Element Modeling and Simulation of a Soft Array of Dielectric Elastomer Actuators. ASME Smasis 2021, 85499, V001T07A003. [Google Scholar]

- Hubertus, J.; Fasolt, B.; Linnebach, P.; Seelecke, S.; Schultes, G. Electromechanical evaluation of sub-micron NiCr-carbon thin films as highly conductive and compliant electrodes for dielectric elastomers. Sens. Actuators A Phys. 2020, 315, 112243. [Google Scholar] [CrossRef]

- Hubertus, J.; Croce, S.; Neu, J.; Seelecke, S.; Rizzello, G.; Schultes, G. Laser Structuring of Thin Metal Films of Compliant Electrodes on Dielectric Elastomers. Adv. Funct. Mater. 2023, 2214176. [Google Scholar] [CrossRef]

- Hubertus, J.; Neu, J.; Croce, S.; Rizzello, G.; Seelecke, S.; Schultes, G. Nanoscale nickel-based thin films as highly conductive electrodes for dielectric elastomer applications with extremely high stretchability up to 200%. ACS Appl. Mater. Interfaces 2021, 13, 39894–39904. [Google Scholar] [CrossRef]

- Gratz-Kelly, S.; Rizzello, G.; Fontana, M.; Seelecke, S.; Moretti, G. A Multi-Mode, Multi-Frequency Dielectric Elastomer Actuator. Adv. Funct. Mater. 2020, 32, 2201889. [Google Scholar] [CrossRef]

- Gratz-Kelly, S.; Krüger, T.; Rizzello, G.; Seelecke, S.; Moretti, G. An audio-tactile interface based on dielectric elastomer actuators. Smart Mater. Struct. 2023; accepted. [Google Scholar] [CrossRef]

- Chen, F.; Cao, J.; Zhang, H.; Wang, M.Y.; Zhu, J.; Zhang, Y.F. Programmable Deformations of Networked Inflated Dielectric Elastomer Actuators. IEEE/ASME Trans. Mechatron. 2019, 24, 45–55. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).