Multi-Criteria Evaluation Model of Management for Weaned Piglets and Its Relations with Farm Performance and Veterinary Medicine Consumption

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Source

2.2. Methodology for Evaluating the Indices and Factors of the Quick Scan Handling and Hygiene Calculator

2.3. Evaluation of the Productive and Health Parameters of the Farms

2.4. Statistical Analysis

3. Results

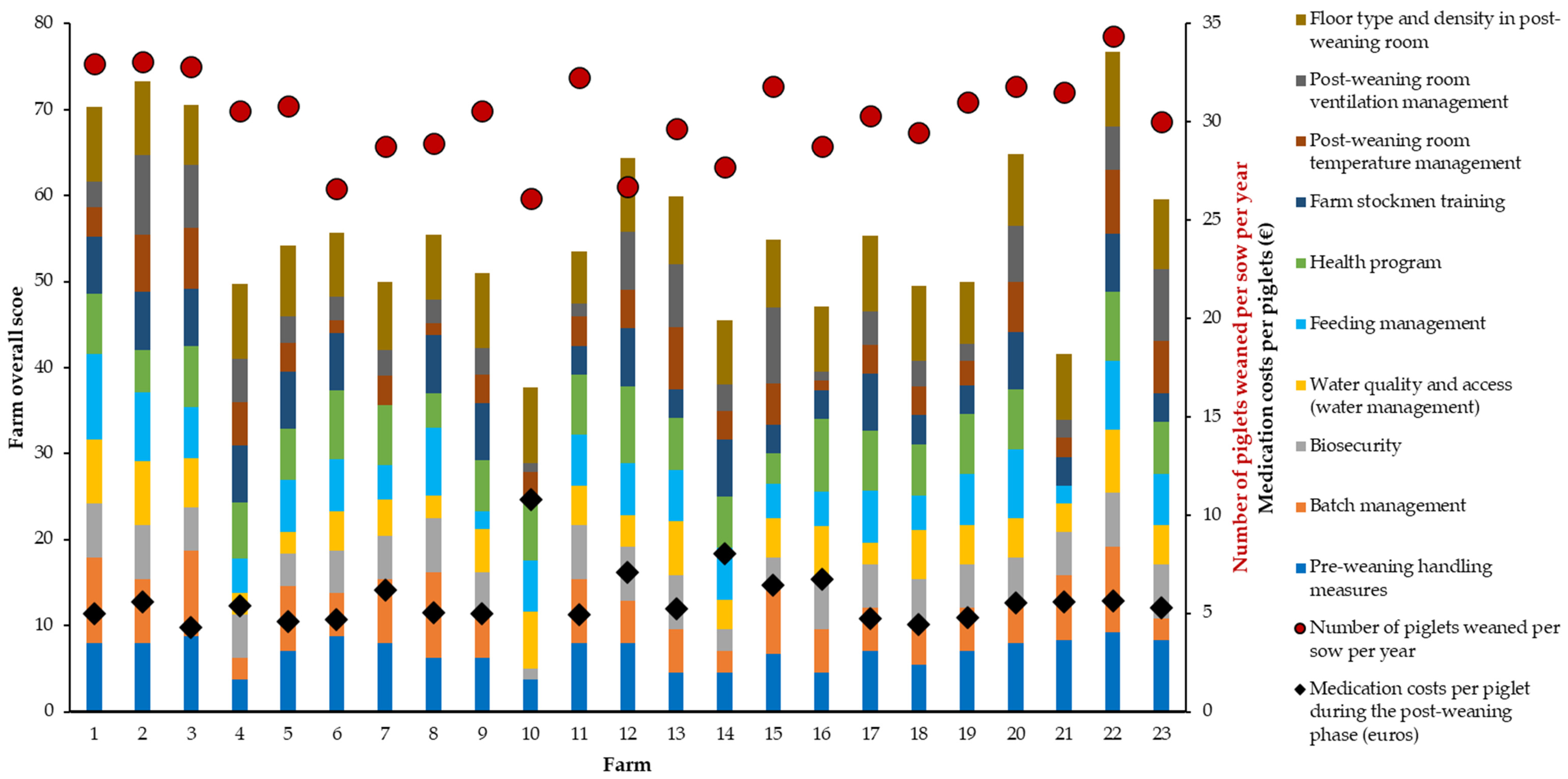

3.1. Evaluation of the Quick Scan Handling and Hygiene Calculator Indices

3.2. Correlation between Handling and Hygiene Scores and Productive Parameters

3.3. Farm Groups of Productivity

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Contreras, J.M.; Calderón, Á.; López, J.Á. La Nutrición Del Lechón En Relación Con Los Puntos Críticos En El Destete. Anaporc 2012, 9, 24–28. [Google Scholar]

- Prieto Barona, S.; Díaz Gaona, C.; Sánchez Rodríguez, M.; Rodríguez Estévez, V. El manejo de los lechones destetados. Ganadería 2017, 110, 56–59. [Google Scholar]

- Pluske, J.R.; Pethick, D.W.; Hopwood, D.E.; Hampson, D.J. Nutritional Influences on Some Major Enteric Bacterial Diseases of Pig. Nutr. Res. Rev. 2002, 15, 333–371. [Google Scholar] [CrossRef] [PubMed]

- Pluske, J.R.; Turpin, D.L.; Kim, J.-C. Gastrointestinal Tract (Gut) Health in the Young Pig. Anim. Nutr. 2018, 4, 187–196. [Google Scholar] [CrossRef] [PubMed]

- Diana, A.; Boyle, L.A.; Leonard, F.C.; Carroll, C.; Sheehan, E.; Murphy, D.; Manzanilla, E.G. Removing Prophylactic Antibiotics from Pig Feed: How Does It Affect Their Performance and Health? BMC Vet. Res. 2019, 15, 67. [Google Scholar] [CrossRef]

- Pluske, J.R.; Miller, D.W.; Sterndale, S.O.; Turpin, D.L.; Pluske, J.R.; Miller, D.W.; Sterndale, S.O.; Turpin, D.L. Associations between Gastrointestinal-Tract Function and the Stress Response after Weaning in Pigs. Anim. Prod. Sci. 2019, 59, 2015–2022. [Google Scholar] [CrossRef]

- Magallón, E.; García, A.; Bautista, R.; Alonso, B.; Cano, J.I.; Almenara, S.; Prieto, P.; Magallón, P.; Ortiz, E. Manejo y Gestión del Posdestete. El Lechón Destetado—Grupo Asís; SERVET: Zaragoza, Spain, 2017; ISBN 978-84-16818-44-0. [Google Scholar]

- Walsh, C.; Fanning, S. Antimicrobial Resistance in Foodborne Pathogens—A Cause for Concern? Curr. Drug Targets 2008, 9, 808–815. [Google Scholar] [CrossRef]

- Murphy, D.; Ricci, A.; Auce, Z.; Beechinor, J.G.; Bergendahl, H.; Breathnach, R.; Bureš, J.; Silva, J.P.D.D.; Hederová, J.; Hekman, P.; et al. EMA and EFSA Joint Scientific Opinion on Measures to Reduce the Need to Use Antimicrobial Agents in Animal Husbandry in the European Union, and the Resulting Impacts on Food Safety (RONAFA). EFSA J. 2017, 15, e04666. [Google Scholar] [CrossRef]

- Temple, D.; Dalmau, A.; Ruiz de la Torre, J.L.; Manteca, X.; Velarde, A. Application of the Welfare Quality® Protocol to Assess Growing Pigs Kept under Intensive Conditions in Spain. J. Vet. Behav. 2011, 6, 138–149. [Google Scholar] [CrossRef]

- Agostini, P.S.; Gasó, J.G.; Manzanilla, E.G.; Silva, C.A.D.; de Beorlegui, C.B. Descriptive Study of Production Factors Affecting Performance Traits in Growing-Finishing Pigs in Spain. Span. J. Agric. Res. 2013, 11, 371–381. [Google Scholar] [CrossRef]

- Backhans, A.; Sjölund, M.; Lindberg, A.; Emanuelson, U. Biosecurity Level and Health Management Practices in 60 Swedish Farrow-to-Finish Herds. Acta Vet. Scand. 2015, 57, 14. [Google Scholar] [CrossRef] [PubMed]

- Black, J.L.; Giles, L.R.; Wynn, P.C.; Knowles, A.G.; Kerr, C.A.; Jones, M.R.; Strom, A.D.; Gallagher, N.L.; Eamens, G.J. Factors Limiting the Performance of Growing Pigs in Commercial Environments. In Manipulating pig production VIII. Proceedings of the Eighth Biennial Conference of the Australasian Pig Science Association (APSA), Adelaide, Australia, 25–28 November, 2001; Australasian Pig Science Association: Brisbane, Australia, 2001; pp. 9–36. [Google Scholar]

- Da Silva, C.A.; Agostini, P.D.S.; Dias, C.P.; Callegari, M.A.; dos Santos, R.d.K.S.; Novais, A.K.; Pierozan, C.R.; Gasó, J.G. Characterization and Influence of Production Factors on Growing and Finishing Pig Farms in Brazilian Cooperatives. R. Bras. Zootec. 2017, 46, 264–272. [Google Scholar] [CrossRef]

- Laine, T.M.; Lyytikäinen, T.; Yliaho, M.; Anttila, M. Risk Factors for Post-Weaning Diarrhoea on Piglet Producing Farms in Finland. Acta Vet. Scand. 2008, 50, 21. [Google Scholar] [CrossRef] [PubMed]

- Postma, M.; Stärk, K.D.C.; Sjölund, M.; Backhans, A.; Beilage, E.G.; Lösken, S.; Belloc, C.; Collineau, L.; Iten, D.; Visschers, V.; et al. Alternatives to the Use of Antimicrobial Agents in Pig Production: A Multi-Country Expert-Ranking of Perceived Effectiveness, Feasibility and Return on Investment. Prev. Vet. Med. 2015, 118, 457–466. [Google Scholar] [CrossRef]

- Gleeson, B.L.; Collins, A.M.; Gleeson, B.L.; Collins, A.M. Under What Conditions Is It Possible to Produce Pigs without Using Antimicrobials? Anim. Prod. Sci. 2015, 55, 1424–1431. [Google Scholar] [CrossRef]

- Rojo-Gimeno, C.; Postma, M.; Dewulf, J.; Hogeveen, H.; Lauwers, L.; Wauters, E. Farm-Economic Analysis of Reducing Antimicrobial Use Whilst Adopting Improved Management Strategies on Farrow-to-Finish Pig Farms. Prev. Vet. Med. 2016, 129, 74–87. [Google Scholar] [CrossRef]

- Raasch, S.; Collineau, L.; Postma, M.; Backhans, A.; Sjölund, M.; Belloc, C.; Emanuelson, U.; Beilage, E.G.; Stärk, K.; Dewulf, J.; et al. Effectiveness of Alternative Measures to Reduce Antimicrobial Usage in Pig Production in Four European Countries. Porc. Health Manag. 2020, 6, 6. [Google Scholar] [CrossRef]

- Lynegaard, J.C.; Kjeldsen, N.J.; Bache, J.K.; Weber, N.R.; Hansen, C.F.; Nielsen, J.P.; Amdi, C. Low Protein Diets without Medicinal Zinc Oxide for Weaned Pigs Reduced Diarrhea Treatments and Average Daily Gain. Animal 2021, 15, 100075. [Google Scholar] [CrossRef]

- Waluszewski, A.; Cinti, A.; Perna, A. Antibiotics in Pig Meat Production: Restrictions as the Odd Case and Overuse as Normality? Experiences from Sweden and Italy. Humanit. Soc. Sci. Commun. 2021, 8, 1–12. [Google Scholar] [CrossRef]

- Carr, J. Estándares de La Producción Porcina: Manual Técnico; Asís Veterinaria: Zaragoza, Spain, 2004. [Google Scholar]

- da Agostini, P.S.; Manzanilla, E.G.; de Blas, C.; Fahey, A.G.; da Silva, C.A.; Gasa, J. Managing Variability in Decision Making in Swine Growing-Finishing Units. Ir. Vet. J. 2015, 68, 20. [Google Scholar] [CrossRef]

- Faucitano, L.; Schaefer, A.L. Welfare of Pigs: From Birth to Slaughter; Wageningen Academic Publishers: Wageningen, The Netherlands, 2008; ISBN 978-90-8686-066-1. [Google Scholar]

- Velarde, A.; Geers, R. On Farm Monitoring of Pig Welfare; Wageningen Academic Publishers: Wageningen, The Netherlands, 2007; ISBN 978-90-8686-591-8. [Google Scholar]

- Sanz-Fernández, S.; Díaz Gaona, C.; Casas-Rosal, J.C.; Alos, N.; Tusell, L.; Quintanilla, R.; Rodríguez-Estévez, V. Pre-Weaning Piglet Survival on Commercial Farms. J. Anim. Sci. 2023; Under Review. [Google Scholar]

- Andersen, I.L.; Tajet, G.M.; Haukvik, I.A.; Kongsrud, S.; Bøe, K.E. Relationship between Postnatal Piglet Mortality, Environmental Factors and Management around Farrowing in Herds with Loose-Housed, Lactating Sows. Acta Agric. Scand. Sect. A—Anim. Sci. 2007, 57, 38–45. [Google Scholar] [CrossRef]

- Koketsu, Y.; Iida, R. Farm Data Analysis for Lifetime Performance Components of Sows and Their Predictors in Breeding Herds. Porc. Health Manag. 2020, 6, 24. [Google Scholar] [CrossRef]

- Moreira, L.P.; Menegat, M.B.; Barros, G.P.; Bernardi, M.L.; Wentz, I.; Bortolozzo, F.P. Effects of Colostrum, and Protein and Energy Supplementation on Survival and Performance of Low-Birth-Weight Piglets. Livest. Sci. 2017, 202, 188–193. [Google Scholar] [CrossRef]

- Soraci, A.L.; Amanto, F.; Tapia, M.O.; de la Torre, E.; Toutain, P.-L. Exposure Variability of Fosfomycin Administered to Pigs in Food or Water: Impact of Social Rank. Res. Vet. Sci. 2014, 96, 153–159. [Google Scholar] [CrossRef] [PubMed]

- Camp Montoro, J.; Pessoa, J.; Solà-Oriol, D.; Muns, R.; Gasa, J.; Manzanilla, E.G. Effect of Phase Feeding, Space Allowance and Mixing on Productive Performance of Grower-Finisher Pigs. Animals 2022, 12, 390. [Google Scholar] [CrossRef]

- López-Vergé, S.; Solà-Oriol; Gasa, J. Strategies to Control Piglet Weight Variability in the Nursery (1/2): Farrowing, Segregation of Animals, Environmental Comfort. Available online: https://www.pig333.com/articles/strategies-to-control-piglet-weight-variability-in-the-nursery-1-2_10964/ (accessed on 8 November 2023).

- Bottoms, K.; Poljak, Z.; Dewey, C.; Deardon, R.; Holtkamp, D.; Friendship, R. Evaluation of External Biosecurity Practices on Southern Ontario Sow Farms. Prev. Vet. Med. 2013, 109, 58–68. [Google Scholar] [CrossRef]

- Laanen, M.; Persoons, D.; Ribbens, S.; de Jong, E.; Callens, B.; Strubbe, M.; Maes, D.; Dewulf, J. Relationship between Biosecurity and Production/Antimicrobial Treatment Characteristics in Pig Herds. Vet. J. 2013, 198, 508–512. [Google Scholar] [CrossRef]

- Postma, M.; Backhans, A.; Collineau, L.; Loesken, S.; Sjölund, M.; Belloc, C.; Emanuelson, U.; grosse Beilage, E.; Nielsen, E.O.; Stärk, K.D.C.; et al. Evaluation of the Relationship between the Biosecurity Status, Production Parameters, Herd Characteristics and Antimicrobial Usage in Farrow-to-Finish Pig Production in Four EU Countries. Porc. Health Manag. 2016, 2, 9. [Google Scholar] [CrossRef]

- Kummer, R.; Gonçalves, M.A.D.; Lippke, R.T. Fatores que influenciam o desempenho dos leitões na fase de creche. Acta Sci. Vet. 2009, 37, s195–s209. [Google Scholar]

- Rodríguez Estévez, V.; Díaz Gaona, C.; Arce, C.; Sánchez Rodríguez, M. Los Cuidados del lechón en el Destete. Albéitar Publicación Vet. Indep. 2016, 200, 12–14. [Google Scholar]

- Madec, F.; Bridoux, N.; Bounaix, S.; Jestin, A. Measurement of Digestive Disorders in the Piglet at Weaning and Related Risk Factors. Prev. Vet. Med. 1998, 35, 53–72. [Google Scholar] [CrossRef]

- Rhouma, M.; Fairbrother, J.M.; Beaudry, F.; Letellier, A. Post Weaning Diarrhea in Pigs: Risk Factors and Non-Colistin-Based Control Strategies. Acta Vet. Scand. 2017, 59, 31. [Google Scholar] [CrossRef] [PubMed]

- Fornós, M.; Sanz-Fernández, S.; Jiménez-Moreno, E.; Carrión, D.; Gasa, J.; Rodríguez-Estévez, V. The Feeding Behaviour Habits of Growing-Finishing Pigs and Its Effects on Growth Performance and Carcass Quality: A Review. Animals 2022, 12, 1128. [Google Scholar] [CrossRef]

- O’Connell, N.E.; Beattie, V.E.; Weatherup, R.N. Influence of Feeder Type on the Performance and Behaviour of Weaned Pigs. Livest. Prod. Sci. 2002, 74, 13–17. [Google Scholar] [CrossRef]

- Kemper, N. Optimising Pig Welfare at the Weaning and Nursery Stage. In Understanding the Behaviour and Improving the Welfare of Pigs; Burleigh Dodds Science Publishing: Cambridgeshire, UK, 2020; pp. 177–207. ISBN 978-1-00-304822-0. [Google Scholar]

- Magallón, E.; García, A.; Bautista, R.; Alonso, B.; Cano, J.I.; Prieto, P.; Magallón, P. Manejo y Gestión de Maternidades Porcinas II. La Lactación- Grupo Asís Store; SERVET: Zaragoza, Spain, 2015; ISBN 978-84-16315-08-6. [Google Scholar]

- Spoolder, H.A.M.; Ruis, M.A.W. Improving Farm Animal Productivity and Welfare, by Increasing Skills and Knowledge of Stock People. In Environment and Welfare—Proceedings of International Symposium; China Agriculture Press: Chongqing, China, 2015; pp. 269–277. ISBN 9787109234598. [Google Scholar]

- Kil, D.Y.; Stein, H.H. Board Invited Review: Management and Feeding Strategies to Ameliorate the Impact of Removing Antibiotic Growth Promoters from Diets Fed to Weanling Pigs. Can. J. Anim. Sci. 2010, 90, 447–460. [Google Scholar] [CrossRef]

- Chantziaras, I.; De Meyer, D.; Vrielinck, L.; Van Limbergen, T.; Pineiro, C.; Dewulf, J.; Kyriazakis, I.; Maes, D. Environment-, Health-, Performance- and Welfare-Related Parameters in Pig Barns with Natural and Mechanical Ventilation. Prev. Vet. Med. 2020, 183, 105150. [Google Scholar] [CrossRef]

- Ramirez, B.C.; Hayes, M.D.; Condotta, I.C.F.S.; Leonard, S.M. Impact of Housing Environment and Management on Pre-/Post-Weaning Piglet Productivity. J. Anim. Sci. 2022, 100, skac142. [Google Scholar] [CrossRef] [PubMed]

- Moreno, R.; Buxadé, C. Instalaciones para lechones y cerdos de cebo. Mundo Ganadero 1999, 109, 37–45. [Google Scholar]

- Ye, Z.; Zhang, G.; Seo, I.-H.; Kai, P.; Saha, C.K.; Wang, C.; Li, B. Airflow Characteristics at the Surface of Manure in a Storage Pit Affected by Ventilation Rate, Floor Slat Opening, and Headspace Height. Biosyst. Eng. 2009, 104, 97–105. [Google Scholar] [CrossRef]

- Morsing, S.; Strøm, J.S.; Zhang, G.; Kai, P. Scale Model Experiments to Determine the Effects of Internal Airflow and Floor Design on Gaseous Emissions from Animal Houses. Biosyst. Eng. 2008, 99, 99–104. [Google Scholar] [CrossRef]

- Kim, J.; Lee, I.; Lee, S.; Park, S.; Jeong, D.; Choi, Y.; Decano-Valentin, C.; Yeo, U. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System. Agriculture 2022, 12, 1139. [Google Scholar] [CrossRef]

- Friendship, R.M.; Wilson, M.R.; McMillan, I. Management and Housing Factors Associated with Piglet Preweaning Mortality. Can. Vet. J. 1986, 27, 307–311. [Google Scholar] [PubMed]

- King, V.L.; Koketsu, Y.; Reeves, D.; Xue, J.; Dial, G.D. Management Factors Associated with Swine Breeding-Herd Productivity in the United States. Prev. Vet. Med. 1998, 35, 255–264. [Google Scholar] [CrossRef] [PubMed]

- Pierozan, C.R.; Callegari, M.A.; Dias, C.P.; de Souza, K.L.; Gasa, J.; Silva, C.A. da Herd-Level Factors Associated with Piglet Weight at Weaning, Kilograms of Piglets Weaned per Sow per Year and Sow Feed Conversion. Animal 2020, 14, 1283–1292. [Google Scholar] [CrossRef]

- Koketsu, Y.; Tani, S.; Iida, R. Factors for Improving Reproductive Performance of Sows and Herd Productivity in Commercial Breeding Herds. Porc. Health Manag. 2017, 3, 1. [Google Scholar] [CrossRef]

- Davis, R.L.; Briggs, G.M. Studies with Antibiotics in Chick and Poult Starting Rations1. Poult. Sci. 1951, 30, 767–771. [Google Scholar] [CrossRef]

- Hill, D.C.; Branion, H.D.; Slinger, S.J.; Anderson, G.W. Influence of Environment on the Growth Response of Chicks to Penicillin*. Poult. Sci. 1953, 32, 462–466. [Google Scholar] [CrossRef]

- Teillant, A.; Brower, C.H.; Laxminarayan, R. Economics of Antibiotic Growth Promoters in Livestock. Annu. Rev. Resour. Econ. 2015, 7, 349–374. [Google Scholar] [CrossRef]

- Dritz, S.S.; Tokach, M.D.; Goodband, R.D.; Nelssen, J.L. Effects of Administration of Antimicrobials in Feed on Growth Rate and Feed Efficiency of Pigs in Multisite Production Systems. J. Am. Vet. Med. Assoc. 2002, 220, 1690–1695. [Google Scholar] [CrossRef]

- Miller, G.Y.; Algozin, K.A.; McNamara, P.E.; Bush, E.J. Productivity and Economic Effects of Antibiotics Used for Growth Promotion in U.S. Pork Production. J. Agric. Appl. Econ. 2003, 35, 469–482. [Google Scholar] [CrossRef]

- Zimmerman, D.R. Role of Subtherapeutic Levels of Antimicrobials in Pig Production. J. Anim. Sci. 1986, 62, 6–16. [Google Scholar] [CrossRef]

- Ardakani, Z.; Canali, M.; Aragrande, M.; Tomassone, L.; Simoes, M.; Balzani, A.; Beber, C.L. Evaluating the Contribution of Antimicrobial Use in Farmed Animals to Global Antimicrobial Resistance in Humans. One Health 2023, 17, 100647. [Google Scholar] [CrossRef]

- Pitkin, A.; Otake, S.; Dee, S. Biosecurity Protocols for the Prevention of Spread of Porcine Reproductive and Respiratory Syndrome Virus; Swine Disease Eradication Center, University of Minnesota College of Veterinary Medicine: St Paul, MN, USA, 2009. [Google Scholar]

- Pritchard, G.; Dennis, I.; Waddilove, J. Biosecurity: Reducing Disease Risks to Pig Breeding Herds. Practice 2005, 27, 230–237. [Google Scholar] [CrossRef]

- Edwards, L.; Crabb, H. Water Quality and Management in the Australian Pig Industry. Anim. Prod. Sci. 2021, 61, 637–644. [Google Scholar] [CrossRef]

- PIC. Wean to Finish Guidelines. Environment: Heat and Humidity Removal. 2009. Available online: https://gb.pic.com/wp-content/uploads/sites/9/2018/12/Wean_To_Finish_Manual_2019_A4_UK_LowRes.pdf (accessed on 1 November 2023).

| Indices | Management Factors |

|---|---|

| 1. Pre-weaning or lactation handling | Handling practices to ensure adequate piglet colostrum intake |

| Age of piglets during weaning (three categories) | |

| Early water and feed intake during lactation | |

| Viability of weaned piglets to have a good performance in the post-weaning phase | |

| 2. Batch management | Homogeneous batches (same number of farrowings/week ±5%) |

| Careful attention to smaller piglets | |

| Piglets are segregated by weight into different pens | |

| All-in/all-out system | |

| 3. Biosecurity | Foot baths at the weaning room entrance or boot change |

| Quarantine for external replacements | |

| Independent isolation pen or sickbay with special conditions for sick animals | |

| Proper cleaning, disinfection, and sanitary breaks between different batches | |

| Independent slurry pit for each post-weaning room | |

| Change in clothing and boots for visitors | |

| The distance to other farms or roads is greater than 2 km | |

| Adequate rodent control program | |

| 4. Water quality and access (water management) | Adequate water flow (drinkers: minimum 1l/min) |

| Chlorinated water or water with potabilization treatment | |

| Periodic pipe cleaning (biofilm removal) | |

| Cleaning water tanks as part of the all-in all-out process in each post-weaning department or room | |

| Annual microbiological water analysis | |

| Acidification of water in the first days of post-weaning | |

| Correct number of drinkers (≥1 drinker per 10 piglets) | |

| 5. Feed management | Morning weaning to reduce piglet stress and facilitate feed intake in the first hours |

| Adequate feeders for early feed intake after weaning (for instance, plate feeders) | |

| Appropriate feeder design and space per pig | |

| Gruel feeding during weaning (to create a liquid feed) | |

| Rehydrating sources for piglets during weaning | |

| 6. Health program | Swine dysentery negative |

| PRRS status of breeding sows’ herd (negative or positive with piglet vaccination) | |

| Monitoring and control of causes of death | |

| Adequate adaptation program for gilts | |

| Piglet vaccination against Mycoplasma | |

| Piglet vaccination against Circovirus | |

| 7. Farm stockmen training | Clear instructions and objectives are provided |

| There is a performance-based incentive policy | |

| Periodic training activities are conducted | |

| The stockmen regularly receive information on weaning results and assess these | |

| 8. Post-weaning room temperature management | Adequate thermal insulation |

| Type of heating systems | |

| There are temperature regulators (three possible categories are considered) and records | |

| 9. Post-weaning room ventilation management | Type of ventilation |

| A ventilation control system exists | |

| Minimum (5–10%) ventilation of air is ensured or programmed | |

| Homogeneous air distribution exists | |

| 10. Floor type and density in post-weaning rooms | Percentage of slat surface and bedding |

| Material of slat floor (three possible categories are considered) | |

| Correct densities (≥0.1 m2/10 kg live weight) | |

| There is an available area of solid floor without roughness |

| Productive and Health Traits | Mean | SD | Min | Max | Percentiles | ||

|---|---|---|---|---|---|---|---|

| 25 | 50 | 75 | |||||

| Number of reproductive sows | 704.30 | 364.42 | 187.00 | 1502.00 | 404.00 | 690.00 | 862.00 |

| Number of post-weaning rooms | 10.52 | 5.48 | 3.00 | 26.00 | 6.00 | 9.00 | 14.00 |

| Number of piglets weaned per sow per year | 24.60 | 3.20 | 15.32 | 28.72 | 22.61 | 25.38 | 26.31 |

| Pre-weaning piglet mortality rate (%) | 10.28 | 4.37 | 0.78 | 18.27 | 6.78 | 9.39 | 14.49 |

| Piglet weight during weaning (kg) | 5.67 | 0.18 | 5.47 | 6.06 | 5.51 | 5.60 | 5.77 |

| Cost of weaned piglet (EUR) | 24.69 | 3.60 | 21.43 | 38.19 | 22.37 | 23.66 | 26.37 |

| Average daily gain during the post-weaning phase (g/day) | 310.78 | 38.71 | 257.80 | 395.01 | 279.51 | 310.69 | 342.77 |

| Feed conversion ratio during the post-weaning phase | 1.76 | 0.16 | 1.20 | 1.95 | 1.67 | 1.78 | 1.89 |

| Medication costs per piglet during the post-weaning phase (EUR) | 5.69 | 1.44 | 4.28 | 10.79 | 4.77 | 5.27 | 6.17 |

| Post-weaning piglet mortality rate (%) | 3.46 | 1.47 | 1.35 | 7.49 | 2.60 | 3.00 | 4.05 |

| Total cost per piglet during the post-weaning phase (EUR) | 45.14 | 4.70 | 39.69 | 56.94 | 41.90 | 44.10 | 46.74 |

| Cost per kg of live weight of piglet during the post-weaning phase (EUR) | 2.33 | 0.31 | 2.05 | 3.07 | 2.12 | 2.22 | 2.40 |

| Mean | SD | Min | Max | Percentiles | |||

|---|---|---|---|---|---|---|---|

| 25 | 50 | 75 | |||||

| Pre-weaning handling measures | 6.87 | 1.67 | 3.75 | 9.17 | 5.42 | 7.08 | 7.92 |

| Batch management | 5.98 | 2.69 | 0.00 | 10.00 | 5.00 | 5.00 | 7.50 |

| Biosecurity | 5.11 | 1.30 | 1.25 | 6.25 | 5.00 | 5.00 | 6.25 |

| Water quality and access (water management) | 4.81 | 1.78 | 2.80 | 8.40 | 2.80 | 4.20 | 5.60 |

| Feeding management | 5.74 | 1.94 | 2.00 | 10.00 | 4.00 | 6.00 | 6.00 |

| Health program | 6.28 | 1.87 | 0.00 | 9.00 | 6.00 | 7.00 | 7.00 |

| Farm stockmen training | 4.93 | 2.22 | 0.00 | 6.67 | 3.33 | 6.67 | 6.67 |

| Post-weaning room temperature management | 4.08 | 1.89 | 1.19 | 7.50 | 3.33 | 3.33 | 5.83 |

| Post-weaning room ventilation management | 4.32 | 2.59 | 1.00 | 9.27 | 2.75 | 3.00 | 6.83 |

| Floor type and density in post-weaning rooms | 8.03 | 0.73 | 6.02 | 8.75 | 7.50 | 8.04 | 8.75 |

| Farm overall score for the quick scan handling and hygiene calculator | 56.12 | 10.12 | 37.65 | 76.76 | 49.73 | 54.88 | 64.36 |

| Number of Piglets Weaned Per Sow per Year | Cost of Weaned Piglet | ADG 2 during Post-Weaning | FCR 2 during Post-Weaning | Medication Costs per Piglet during Post-Weaning | Post-Weaning Piglet Mortality Rate | Total Cost of Piglet during Post-Weaning | Cost per kg of Live Weight of Piglet during Post-Weaning | |

|---|---|---|---|---|---|---|---|---|

| Pre-weaning handling measures | 0.531 ** | −0.396 | 0.036 | −0.322 | −0.473 * | −0.490 * | −0.515 * | −0.561 ** |

| Batch management | 0.679 *** | −0.494 * | 0.14 | −0.283 | −0.536 ** | −0.477 * | −0.656 *** | −0.557 ** |

| Biosecurity | 0.547 ** | −0.134 | 0.065 | −0.453 * | −0.619 ** | −0.455 * | −0.473 * | −0.273 |

| Water quality and access (water management) | 0.157 | −0.204 | −0.168 | −0.124 | 0.141 | 0.309 | −0.179 | 0.024 |

| Feeding management | 0.19 | −0.107 | 0.254 | −0.26 | −0.049 | −0.11 | −0.177 | −0.071 |

| Health program | −0.199 | 0.295 | 0.308 | −0.325 | 0.089 | 0.108 | 0.213 | 0.175 |

| Farm stockmen training | 0.389 | 0.012 | 0.344 | −0.137 | −0.432 * | −0.436 * | −0.147 | −0.169 |

| Post-weaning room temperature management | 0.393 | −0.055 | −0.167 | −0.195 | −0.097 | −0.239 | −0.21 | 0.122 |

| Post-weaning room ventilation management | 0.301 | 0.078 | −0.304 | −0.218 | −0.162 | −0.286 | −0.152 | 0.095 |

| Floor type and density in post-weaning rooms | −0.085 | 0.236 | −0.173 | −0.063 | 0.167 | −0.058 | 0.248 | 0.219 |

| Farm overall score for the quick scan handling and hygiene calculator | 0.592 ** | −0.182 | 0.086 | −0.442 * | −0.414 * | −0.437 * | −0.435 * | −0.228 |

| Q1. 25% of Farms with the Highest Annual Productivity | Q2 and Q3 (50% of the Farms) | Q4. 25% of Farms with the Lowest Annual Productivity | Total | |

|---|---|---|---|---|

| Number of piglets weaned per sow per year | 27.73 a (0.88) | 25.29 b (0.74) | 20.20 c (2.70) | 24.60 (3.20) |

| Farm overall score for the quick scan handling and hygiene calculator | 68.23 a (8.22) | 52.83 b (5.22) | 50.04 b (9.16) | 56.12 (10.12) |

| Mean number of reproductive sows | 714.83 (512.55) | 808.00 (318.39) | 503.67 (216.32) | 704.30 (364.42) |

| Pre-weaning piglet mortality rate | 7.42 a (3.74) | 9.54 a (3.43) | 14.51 b (3.73) | 10.28 (4.37) |

| Piglet weight during weaning (kg) | 5.63 (0.16) | 5.65 (0.17) | 5.74 (0.24) | 5.67 (0.18) |

| Cost of weaned piglet (EUR) | 22.31 a (1.24) | 24.38 ab (1.63) | 27.64 b (5.73) | 24.69 (3.60) |

| ADG 1 during the post-weaning phase (g/d) | 322.84 (44.70) | 300.16 (32.56) | 318.19 (44.58) | 310.78 (38.71) |

| FCR 2 during the post-weaning phase | 1.70 (0.06) | 1.80 (0.11) | 1.73 (0.28) | 1.76 (0.16) |

| Medication costs per piglet during the post-weaning phase (EUR) | 5.16 a (0.53) | 5.13 a (0.56) | 7.25 b (2.06) | 5.69 (1.44) |

| Post-weaning piglet mortality rate | 2.91 a (0.79) | 2.96 a (0.89) | 4.93 b (1.94) | 3.46 (1.47) |

| Total cost per piglet during the post-weaning phase | 42.12 a (2.49) | 44.38 a (2.31) | 49.56 b (6.69) | 45.14 (4.70) |

| Cost per kg of live weight of the piglet during the post-weaning phase | 2.14 a (0.11) | 2.31 ab (0.28) | 2.57 b (0.38) | 2.33 (0.31) |

| Q1. 25% of Farms with the Highest Cost of Medications per Piglet during Post-Weaning | Q2 and Q3 (50% of the Farms) | Q4. 25% of Farms with the Lowest Cost of Medications per Piglet during Post-Weaning | Total | |

|---|---|---|---|---|

| Medication costs per piglet during the post-weaning phase (EUR) | 7.54 a (1.72) | 5.29 b (0.27) | 4.58 b (0.19) | 5.69 (1.44) |

| Farm overall score for the quick scan handling and hygiene calculator | 49.90 (9.07) | 59.64 (10.85) | 55.88 (7.67) | 56.12 (10.12) |

| Mean number of reproductive sows | 565.33 (263.65) | 793.00 (434.40) | 680.67 (310.28) | 704.30 (364.42) |

| Number of piglets weaned per sow per year | 20.78 a (3.42) | 26.15 b (1.57) | 25.59 b (2.16) | 24.60 (3.20) |

| Pre-weaning piglet mortality rate | 13.03 (3.70) | 8.60 (3.74) | 10.61 (5.19) | 10.28 (4.37) |

| Piglet weight during weaning (kg) | 5.72 (0.26) | 5.68 (0.16) | 5.61 (0.15) | 5.67 (0.18) |

| Cost of weaned piglet (EUR) | 28.02 a (5.42) | 23.78 b (2.03) | 23.02 b (1.05) | 24.69 (3.60) |

| 1 ADG during the post-weaning phase (g/day) | 312.73 (48.45) | 313.27 (43.45) | 304.26 (20.01) | 310.78 (38.71) |

| 2 FCR during the post-weaning phase | 1.72 (0.27) | 1.76 (0.10) | 1.79 (0.14) | 1.76 (0.16) |

| Post-weaning piglet mortality rate | 4.74 a (2.13) | 3.07 b (0.90) | 2.91 b (0.83) | 3.46 (1.47) |

| Total cost per piglet during the post-weaning phase | 50.31 a (5.83) | 43.81 b (2.72) | 42.41 b (1.92) | 45.14 (4.70) |

| Cost per kilogram of live weight of the piglet during the post-weaning phase | 2.59 a (0.36) | 2.30 ab (0.29) | 2.14 b (0.08) | 2.33 (0.31) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanz-Fernández, S.; Díaz-Gaona, C.; Borge, C.; Quintanilla, R.; Rodríguez-Estévez, V. Multi-Criteria Evaluation Model of Management for Weaned Piglets and Its Relations with Farm Performance and Veterinary Medicine Consumption. Animals 2023, 13, 3508. https://doi.org/10.3390/ani13223508

Sanz-Fernández S, Díaz-Gaona C, Borge C, Quintanilla R, Rodríguez-Estévez V. Multi-Criteria Evaluation Model of Management for Weaned Piglets and Its Relations with Farm Performance and Veterinary Medicine Consumption. Animals. 2023; 13(22):3508. https://doi.org/10.3390/ani13223508

Chicago/Turabian StyleSanz-Fernández, Santos, Cipriano Díaz-Gaona, Carmen Borge, Raquel Quintanilla, and Vicente Rodríguez-Estévez. 2023. "Multi-Criteria Evaluation Model of Management for Weaned Piglets and Its Relations with Farm Performance and Veterinary Medicine Consumption" Animals 13, no. 22: 3508. https://doi.org/10.3390/ani13223508

APA StyleSanz-Fernández, S., Díaz-Gaona, C., Borge, C., Quintanilla, R., & Rodríguez-Estévez, V. (2023). Multi-Criteria Evaluation Model of Management for Weaned Piglets and Its Relations with Farm Performance and Veterinary Medicine Consumption. Animals, 13(22), 3508. https://doi.org/10.3390/ani13223508