Abstract

Purchasing and procurement managers should make informed decisions in selecting materials at the right time, in sufficient quantities, and at affordable prices. Supplier selection and order allocation (SSOA) is a vital aspect of purchasing and procurement processes. In this research, the techniques and decision-making methods used in SSOA from peer-reviewed journals published from 2021 to 2023 are examined. This research explores the publications through three major categories, including literature reviews (LR), deterministic optimization (DO) models, and uncertain optimization (UO) models. The related operations research techniques are also discussed. Furthermore, observations, conclusions, and suggestions for future studies are provided with details.

1. Introduction

All around the world, companies rely on procurement, logistics, and supplier selection and order allocation (SSOA) to help their organizations run successfully. As such, many research studies have been conducted on various ways to best utilize the resources in a supply chain. While many papers have been published on supplier selection or order allocation individually, few research papers conjointly cover SSOA. The main research question in this paper is: What are the recent techniques and trends in the supplier selection and order allocation field? This unique literature review summarizes 43 papers published from 2021 to 2023 covering SSOA and its applications. This period was chosen because other literature reviews have covered the papers in this field up to 2020. The small volume of papers found further emphasizes the need for increased research, as there is a deficit in the number of papers incorporating quantitative and qualitative criteria in the evaluation of supply chain suppliers and their uncertain environments (Hu et al. 2022). The papers in this literature review paper have been retrieved using databases and websites such as Taylor and Francis, Google Scholar, ScienceDirect, Scopus, and Web of Science. ‘Supplier selection and order allocation’ is the main keyword used to find the related papers in this study. SSOA involves optimization models that help influence decisions in an organization, usually for maximizing profit, minimizing costs, and increasing efficiency (Bai et al. 2022).

Various multi-criteria decision-making (MCDM) methods like data envelopment analysis (DEA), fuzzy analytical hierarchy process (FAHP), and best–worst method (BWM) are used to determine the priority and usefulness of a decision in the supply chain. These techniques can be applied in various industries, such as agriculture, food and beverage, green supply chain, textile, manufacturing, and automotive. Common sources of uncertainty in SSOA may include demand, cost, supplier, availability, delivery, and quality (defect rate).

Given the ongoing climate change crisis, individuals, industries, and countries around the world are committed to achieving carbon neutrality and lessening the effects of anthropogenic activities (Bai et al. 2022). The focus of more recent SSOA papers has been on green supply chains, with multi-objective models including equations for reducing carbon emissions. In a constantly changing environment, many companies feel pressure to transition their strategies to incorporate a circular economy (CE) in their supply chains (Mirzaee et al. 2023). Due to this, procurement of resources focuses on the ability to recycle, refurbish, and remanufacture. In addition, recent socio-economic, political, and environmental factors have incentivized more research on the effects of natural calamities on uncertain parameters; the effects of COVID-19, and the higher occurrence of natural disasters like floods and earthquakes affect delivery rates and supplier availability (Ali and Zhang 2023). Natural disasters, bankruptcies, and equipment failures are also external factors affecting the supply chain and the related SSOA (Hosseini et al. 2022).

This paper will continue to discuss these fundamental ideas and will further elaborate on the types of models and solution methods to tackle SSOA problems. This paper has several research contributions. Unlike other literature review papers in this field, new papers (2021 to 2023) are considered and analyzed in this study. In addition, the related operations research techniques are categorized and discussed in detail. Another research contribution of this paper is providing unique observations and future research directions in the field of supplier selection and order allocation. Section 2 contains the taxonomy and classification, such as literature reviews and deterministic and uncertain optimization models. Then, Section 3 discusses key observations. Section 4 provides conclusions and suggestions for future avenues of research.

2. Organization of the Related Literature

In this research, papers about supplier selection and order allocation have been collected using databases and websites such as Taylor and Francis, Google Scholar, ScienceDirect, Scopus, and Web of Science. Two components are used to classify the publications. The initial component is the problem category, and the secondary component is the operations research techniques. This classification is helpful for analyzing SSOA problems based on qualitative and quantitative aspects.

2.1. Problem Category

The problem categories include the following: deterministic optimization (DO) models, uncertain optimization (UO) models, and literature reviews (LR). In Table 1, the classified papers are shown.

Table 1.

References for each problem category.

2.1.1. Literature Reviews

Within the ScienceDirect (Elsevier) and Taylor and Francis databases, using the search term ‘supplier selection and order allocation’, there were 6 literature review papers published after 2020 that were found to be relevant to SSOA. The review from de Oliveira et al. (2023) combined multi-criteria decision analysis (MCDA), cluster analysis (CA), and data envelopment analysis (DEA) methods to see future trends and existing applications. They pulled publications from Scopus, ScienceDirect, and Web of Science to find the publications that were the most impactful. It was found that 490 articles (approximately 44%) combined DEA and MCDA methods. The review also stated that there was a growing trend in hybrid decision-making techniques in the banking, energy, and operations industries.

The review from Araújo et al. (2023) found a total of 29 articles that emphasized decision-making methodologies for rating technologies, such as using artificial intelligence, decision theory, and mathematical programming in the oil and gas industry. The paper reviewed a total of 29 articles with new findings of machine learning (ML) methods. For future research, the paper recommends exploring different collections of selection and ranking methods. An example can be merging different heuristic methods like using decision theory methods and fuzzy sets together to show their effectiveness.

Spyridonidou and Vagiona (2023) conducted a direct analysis and assessment of current location-scouting procedures for photovoltaics and other solar technologies. A total of 152 studies were identified based on the following criteria: (1) site selection methods, (2) exclusion criteria, (3) assessment criteria, (4) optimization modules, (5) geographic areas, (6) spatial analysis, (8) UV radiation estimation and analytics, (9) sensitivity analysis (and how it relates to location selection procedure), (10) community engagement planning approaches, (12) regulations and policies, (13) suitability records (linguistic or/and numeric), and rating procedures. The conclusions were that there was a high tendency to use the analytical hierarchy process (AHP) at the assessment stage. A suggestion was made to apply the entropy method more often at the assessment stage since it was more objective than AHP for determining the assessment criteria weights.

Jamalnia et al. (2022) reviewed the sustainability management of multi-tier supply chains. A total of 37 contingency variables were used to measure the effectiveness of sustainable supply chain approaches. The paper evaluated quantitative techniques such as mathematical optimization, simulation, and multi-criteria decision-making (MCDM) techniques. The techniques included case studies, surveys, hypothesis testing, and the Delphi method. The review focused on motivations for non-compliance to sustainability and the risks of ignoring sub-suppliers’ non-compliance to sustainability. It was found that suppliers’ non-compliance to sustainability is due to a lack of visibility and transparency from lower tiers of supply chains, and a lack of sustainable procedures, capabilities, and tools. Their conclusions stated that an in-depth analysis of the contingency variables showed that the variation in the contingency variables influences the effectiveness of each sustainable supply chain management strategy.

The review by Hu et al. (2022) summarizes past work on supplier selection as it relates to supplier selection in a disaster context. The review finds papers focusing on disaster operations management. It analyzed articles between 2010 and 2020. In this field, there was a significant research gap that showed a lack of qualitative standards and assessment of suppliers. They concluded that the models the authors proposed should incorporate more aspects related to the supply, demand, and transportation processes in uncertain environments. In addition, they should be tailored toward specific types of disasters. This is so that effective cooperation between aid organizations and suppliers can occur. The paper also emphasized focusing not only on the economic costs but on humanitarian-related operations as well.

Masudin et al. (2022) performed a bibliometric review on green purchasing using supplier selection from papers published from 1992 to 2022. A total of 220 articles were studied, and it was found that green purchasing increased in frequency around 1994. The most noticeable instances of green procurement involve an effective SSOA strategy that is sustainable, increases efficiency, and saves costs. In recent years, these factors have played a role in corporate competition and the overall role of green supply chain management. It has been increasingly attracting researcher’s interest, given the peak of 27 articles published in 2021. There is specific interest in countries like China where a large part of the industry is in manufacturing, followed by India and then Iran.

2.1.2. Deterministic Optimization Models

This section covers DO models in SSOA. Various publications are discussed regarding the different types of applications, techniques, and common topics.

Bai et al. (2022) tested SSOA policies for the procurement of electric power supplies in China by building a multi-objective model. The paper aimed to set up an SSOA model that supported carbon neutrality and optimized cost and quality goals. The model was applied empirically and analyzed with case study information using a trading platform that gives access to joint supplier selection. With this model, various sourcing policies were able to be evaluated, but the trading platform considered was a simple one-sided market situation. In various real-life scenarios, a larger two-sided market scenario is likely to be involved. The future recommendations from this study suggest including more complex and detailed models alongside economic valuations and decision-support tools.

Ahmad et al. (2022) studied a two-echelon make-to-order SSOA problem from an Indian belt conveyor company. They looked at the bills of materials to determine the shortlist of suppliers in each echelon and formulated a mixed-integer nonlinear programming (MINLP) model to determine how many manufacturers and part suppliers in the first and second echelons are required to meet the periodic demand. To ensure the robustness of the model, the Taguchi method of tolerance design (TMTD) was used. When the MINLP and TMTD were applied, the coefficient of variation of the objective function increased by 51%.

Sun et al. (2022) used a numerical experiment and created a MINLP and order-splitting model. This model was solved with a Knitro commercial package in MATLAB. The order-splitting model was designed based on chosen suppliers to maximize profit, and MINLP was used to determine the top suppliers and to find the reorder point and order-split quantities for each supply chain group. The findings showed how the models allowed for simultaneous consideration of decisions, future suppliers, and inventory management policies in a warehouse and N number of identical retailers.

Esmaeili-Najafabadi et al. (2021) used MINLP to create risk-neutral and risk-averse decision-making models. Value-at-risk (VaR), conditional value-at-risk (CVaR), and particle swarm optimization (PSO) were the risk assessment tools that were used to determine the models. The MINLP models considered local and regional disruption risks. Local disruption risks occur internally with the supplier (i.e., machine breakdown), while regional disruption risks happen in the same geographical region (natural hazard).

2.1.3. Uncertain Optimization Models

In this part, some papers that used UO models and applied related techniques are mentioned and the key ideas are highlighted. Each paper and its type of uncertainty variables are shown in Table 2.

Table 2.

The references and uncertainty sources.

The latest literature review by Zhang et al. (2023) focused on the disruption of collaborative manufacturing supply chains due to cyber attacks. SSOA is used to mitigate risks that may cause disruptions. The researchers collected indicators of cyber risk from suppliers and used the fuzzy analytical hierarchy process (FAHP) to calculate their risk level, followed by the technique for order preference by similarity to ideal solution (TOPSIS) to evaluate the cyber risk and determine their rankings by risk. A two-stage hybrid mixed-integer programming (MIP) was created to support decisions on the suppliers’ order allocation and minimize supply chain costs. The first stage of decisions was based on predicted circumstances and no emergencies, while the second stage was based on unforeseen circumstances and emergencies. The conclusions of the application showed that this model helped mitigate risks by offering a quantitative and theoretical basis for cyber risk evaluation, making a significant impact on supply chain management.

Islam et al. (2022) conducted a study on juice consumption from the Canadian juice industry. They developed a long-short-term memory (LSTM) network to form accurate predictions on juice consumption choices and help managers determine future demand. A fuzzy strengths, weaknesses, opportunities, threats (SWOT) analysis was done on the qualitative and quantitative factors of selecting suppliers. The results from the LSTM network and the fuzzy SWOT analysis were combined to develop a multi-objective model to help managers restructure their SSOA in their organization.

Islam et al. (2021) published another paper applying machine learning and optimization models to data from a Canadian food grain company. They looked at the demand for flour, rye flour, wheat, and rice from 11 different suppliers and geographic locations. The parameter of uncertainty for this model was the demand, which can negatively impact results if the data are not accurate. Two methods for measuring demand were implemented. The relational regressor chain (RRC) method was used to predict future demand and form comparisons with the auto-regressive integrated moving average technique and Holt’s linear trend. The results show that RRC was more precise in forecasting demand. Then, a multi-objective programming model (MOPM) was formulated to determine the distributors and the order quantities for each distributor.

In the paper published by Ali and Zhang (2023), a real-life Pakistani textile industry was analyzed to verify the techniques and to determine the best SSOA based on neutral and risk-averse decision-making options. They considered quantity discounts with respect to foreign transportation risks (e.g., natural disasters and global pandemics). FAHP calculated the relative rates of the criteria, and then a multi-objective linear programming model (MOLPM) was created to reduce the delivery lateness rate, quality rejection rate, total procurement cost, foreign transportation risks, and carbon emissions from product procurement. Afterward, the model was converted using the fuzzy compromise programming technique to find SSOA companies that provided quantity discounts. The findings show that the suggested model and methodology are effective for managing data uncertainties compared to other existing SSOA approaches.

Hosseini et al. (2022) analyzed a composite products company within the aerospace industry. They used the BWM-evidential reasoning method to evaluate distributors under uncertainty and calculated their weights. A multi-objective mathematical model (MOMM) was used to measure the trade-off between the financial costs and the sustainability of the supply chain. The uncertainty being measured was the demand and availability of supply. They mentioned equipment failures, natural disasters, and bankruptcies as the factors affecting the availability of supply. These uncertainties were studied with a set of scenarios classified under three states: optimistic, pessimistic, and probabilistic. The second part used stochastic and dynamic programming to solve the MOMM. These results were measured against the results found from the Epsilon constraint method and the revised multi-choice goal programming technique. The findings showed that the proposed MOMM delivered faster and more accurate results.

2.2. Operations Research Techniques

The references in Table 3 are divided based on the operations research (optimization) techniques. Multiple authors adopted hybrid techniques in this area of study. Table 4 includes various types of objective functions that were collected from different publications.

Table 3.

Sorting papers according to their operations research techniques.

Table 4.

Single-objective and multi-objective models.

3. Observations

In this section, recommendations and observations are made based on the 43 collected publications.

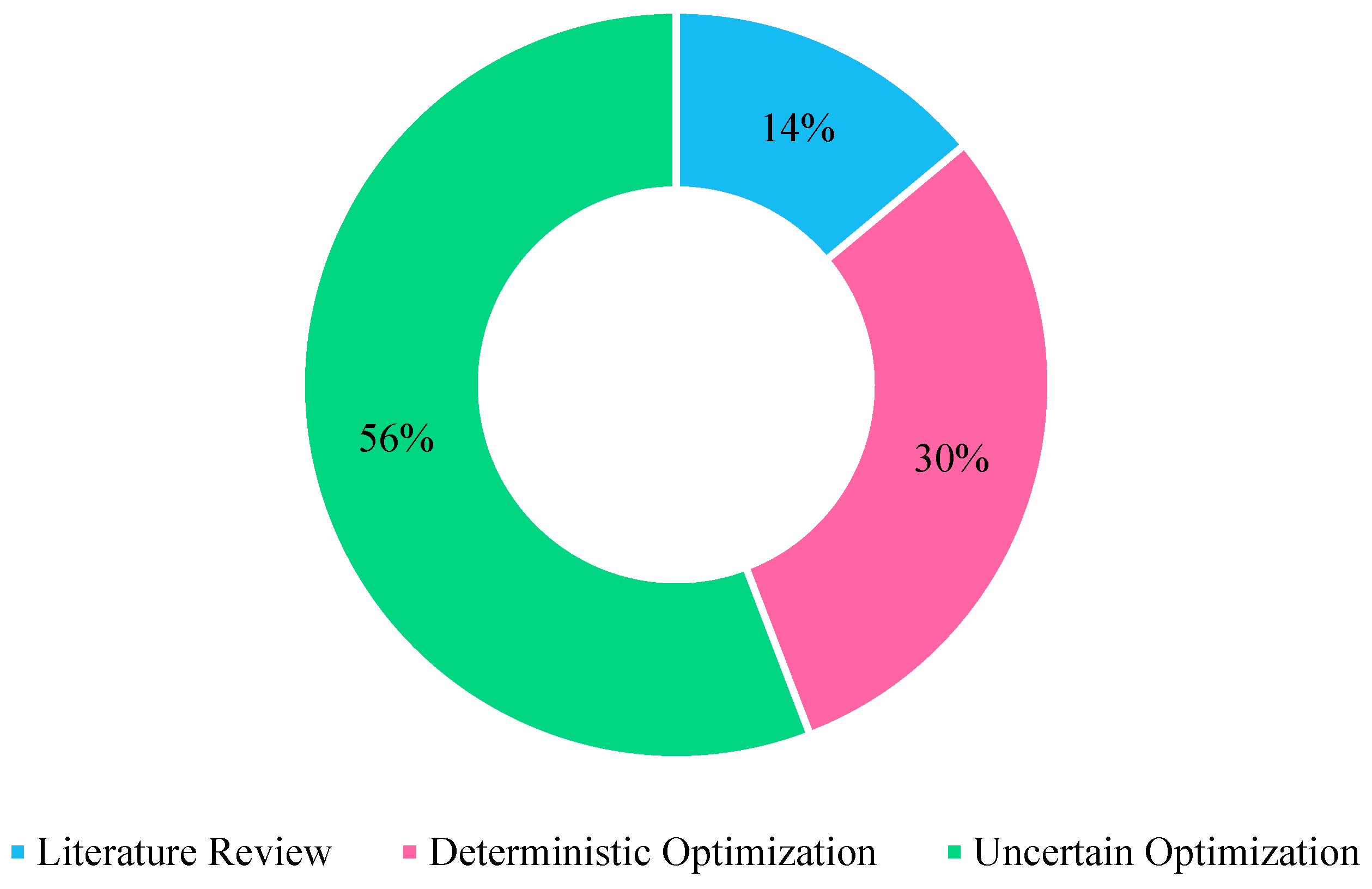

3.1. The Most Popular Category

Three elements were categorized for optimization models in the papers related to SSOA: LR, DO, and UO. Based on Figure 1, the most popular domain was UO, taking up 56% of the distribution of papers, followed by DO and LR at 30% and 14%, respectively.

Figure 1.

Distribution of domain categories.

3.2. The Most Popular Source of Uncertainty

Based on the results, the greatest source of uncertainty was demand. A total of 32% of the selected papers considered demand as an uncertainty source. This parameter was commonly used to determine the demand of customers to procure supplies. A few examples include the demand for juice beverages (Islam et al. 2022), part suppliers in the manufacturing industry (Ahmad et al. 2022), demand for food produce (Islam et al. 2021), and demand for supplier parts in the aerospace industry (Hosseini et al. 2022).

3.3. Common Objective Functions

Referring to Table 4, the most popular single-objective functions involve models related to minimizing costs and maximizing profit, while multi-objective models have many objectives related to minimizing costs and reducing carbon emissions or negative environmental impacts.

3.4. Most and Least Popular Techniques

Based on Table 3, the commonly used methods for solving optimization models were various types of mixed-integer linear programming (MILP) and mixed-integer nonlinear programming (MINLP). A common linear programming technique was data envelopment analysis (DEA), which evaluates suppliers based on selected criteria (Kaur and Singh 2021). Multiple papers also employed the techniques of the analytical hierarchy process (AHP) or fuzzy analytical hierarchy process (FAHP) to calculate weights, assign importance to supplier selection criteria, and analyze factors for decision-making attitudes (Ali and Zhang 2023). TOPSIS was used in conjunction with AHP/FAHP to verify and reinforce the criteria defined in that method. Another popular MCDM was the fuzzy and non-fuzzy best–worst method (BWM) mentioned in papers by Nayeri et al. (2023) and Wu et al. (2022). Nasr et al. (2021) used BWM to select suppliers based on factors such as environmental, social, economic, and circular criteria. Another used technique is particle swarm optimization (PSO), employed by Wu et al. (2022), Esmaeili-Najafabadi et al. (2021), and Alejo-Reyes et al. (2021). Less popular methods included by Nayeri et al. (2023) used the seasonal autoregressive integrated moving average (SARIMA) and the utility function (CMCGP-UF) technique with Chebyshev multi-choice goal programming.

3.5. Popular Applications

Table 5 classifies the papers based on the applications of the techniques. Most papers applied their objective functions to a general SSOA application, but the second-highest applications were both in the green supply chain industry and the material/equipment manufacturing industry. The green supply chain industry included applications of models that incorporated reducing carbon footprint in their supply chain. The material/equipment manufacturing industry includes papers that cover manufacturing industries such as steel, medical equipment, and AC units.

Table 5.

Industry applications of the models.

3.6. The List of Publications

Table 6 includes the list of publications and the names of their respective journals. Some common journals include Computers & Industrial Engineering, International Journal of Production Economics, and Expert Systems with Applications.

Table 6.

The publications list.

3.7. Classification of the Articles Based on Year

Table 7 presents the grouping of the publications by the year of publication and their respective domain. For this review, papers published after 2020 were included. The number of articles reviewed is based on the number of articles collected at the time of this publication.

Table 7.

Grouping of the papers by the year.

4. Discussion and Conclusions

Overall, this paper addresses LR, DO, and UO models related to supplier selection and order allocation. A total of 43 papers published from 2021 to 2023 were collected. The papers were classified based on their operation research methods. This paper has several research contributions. New papers were considered and analyzed in this study. In addition, the related operations research techniques were categorized and discussed in detail.

Observations on the most popular methods show the use of MILP and MINLP to solve DO and UO models. FAHP/AHP were the common decision-making techniques for determining specific criteria for SSOA. Recent publications have significantly modeled more multi-objective functions than single-objective ones; many of the multi-objective models include functions that maximize profit, minimize costs, and minimize carbon emissions. This can be due to a rise in company interest to save costs and government incentives, policies, and attitudes to reduce carbon footprint (Bai et al. 2022). This point also becomes evident when there was a significant prevalence of green supply chain applications followed by an expected high number of SSOA application uses in the manufacturing industry. For future study, a few recommendations on the topics that should be explored are as follows:

- (i)

- Simultaneously consider multiple sources of uncertainty in the objective function. Many papers focused on one factor for uncertainty and used that as a basis to help determine their fuzzy or stochastic model. In real cases, multiple factors should be measured under uncertainty and incorporated into the optimization models.

- (ii)

- Increased research on SSOA in the healthcare industry other than how it relates to manufacturing equipment. Sudden events like COVID-19 show how disruptive events can significantly impact the supply of medical supplies and staff to meet in-hospital care. SSOA can be used to improve existing hospital systems that can prevent short staffing and insufficient medical supply in predictable and unpredictable situations.

- (iii)

- Overall, more research should be conducted in the field of supplier selection and as a result, extra literature reviews can be written. Many papers cover the topics on solely supplier selection or order allocation. Increasing studies on SSOA can provide a more comprehensive view of the topic of SSOA and the implementation of its techniques in real-world situations.

- (iv)

- There are several future opportunities to explore the applications of data science techniques, such as machine learning methods in SSOA. For instance, neural networks can be combined (e.g., Yang et al. (2008a, 2008b); Zhang et al. 2005).

Author Contributions

Conceptualization, T.N., S.H.A. and B.S.; methodology, T.N., S.H.A. and B.S.; software, T.N. and S.H.A.; validation, T.N. and S.H.A.; formal analysis, T.N. and S.H.A.; investigation, T.N. and S.H.A.; resources, T.N. and S.H.A.; data curation, T.N. and S.H.A.; writing—original draft preparation, T.N., S.H.A. and B.S; writing—review and editing, T.N., S.H.A. and B.S; visualization, T.N. and S.H.A.; supervision, S.H.A.; project administration, S.H.A.; funding acquisition, S.H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmad, Md. Tanweer, Mohammad Firouz, and Sandeep Mondal. 2022. Robust supplier-selection and order-allocation in two-echelon supply networks: A parametric tolerance design approach. Computers and Industrial Engineering 171: 108394. [Google Scholar] [CrossRef]

- Alejo-Reyes, Avelina, Abraham Mendoza, and Elias Olivares-Benitez. 2021. A heuristic method for the supplier selection and order quantity allocation problem. Applied Mathematical Modelling 90: 1130–42. [Google Scholar] [CrossRef]

- Ali, Hassan, and Jingwen Zhang. 2023. A fuzzy multi-objective decision-making model for global green supplier selection and order allocation under quantity discounts. Expert Systems with Applications 225: 120119. [Google Scholar] [CrossRef]

- Arabsheybani, Amir, and Alireza Khasmeh Arshadi. 2021. Robust and resilient supply chain network design considering risks in food industry: Flavour industry in Iran. International Journal of Management Science and Engineering Management 16: 197–208. [Google Scholar] [CrossRef]

- Araújo, Lavínia Maria Mendes, Caio Souto Maior, Isis Didier Lins, and Marcio Moura. 2023. Technology selection and ranking: Literature review and current applications in oil and gas industry. Geoenergy Science and Engineering 226: 211771. [Google Scholar] [CrossRef]

- Bai, Chunguang, Qingyun Zhu, and Joseph Sarkis. 2022. Supplier portfolio selection and order allocation under carbon neutrality: Introducing a “Cool”ing model. Computers and Industrial Engineering 170: 108335. [Google Scholar] [CrossRef]

- Beiki, Hossein, Mohammad Seyedhosseini, Vadim Ponkratov, Angelina Olegovna Zekiy, and Sergei Anatolyevich Ivanov. 2021. Addressing a sustainable supplier selection and order allocation problem by an integrated approach: A case of automobile manufacturing. Journal of Industrial and Production Engineering 38: 239–53. [Google Scholar] [CrossRef]

- Chauhan, Vinod Kumar, Stephen Mak, Ajith Kumar Parlikad, Muhannad Alomari, Linus Casassa, and Alexandra Brintrup. 2023. Real-time large-scale supplier order assignments across two-tiers of a supply chain with penalty and dual-sourcing. Computers and Industrial Engineering 176: 108928. [Google Scholar] [CrossRef]

- de Oliveira, Maiquiel Schmidt, Vilmar Steffen, Antonio Carlos de Francisco, and Flavio Trojan. 2023. Integrated data envelopment analysis, multi-criteria decision making, and cluster analysis methods: Trends and perspectives. Decision Analytics Journal 8: 100271. [Google Scholar] [CrossRef]

- Dobos, Imre, and Gyöngyi Vörösmarty. 2021. Green supplier selection using a common weights analysis of DEA and EOQ types of order allocation. Managerial and Decision Economics 42: 612–21. [Google Scholar] [CrossRef]

- Ebrahim Qazvini, Zahra, Alireza Haji, and Hassan Mina. 2021. A fuzzy solution approach to supplier selection and order allocation in green supply chain considering the location-routing problem. Scientia Iranica 28: 446–64. [Google Scholar] [CrossRef]

- Esmaeili-Najafabadi, Elham, Nader Azad, and Mohammad Saber Fallah Nezhad. 2021. Risk-averse supplier selection and order allocation in the centralized supply chains under disruption risks. Expert Systems with Applications 175: 114691. [Google Scholar] [CrossRef]

- Esteso, Ana, M. M. E. Alemany, and Angel Ortiz. 2023. Sustainable agri-food supply chain planning through multi-objective optimisation. Journal of Decision Systems, 1–25. [Google Scholar] [CrossRef]

- Feng, Yuqiang, Yanju Chen, and Yankui Liu. 2022. Optimising two-stage robust supplier selection and order allocation problem under risk-averse criterion. International Journal of Production Research 61: 6356–80. [Google Scholar] [CrossRef]

- Firouzi, Fatameh, and Omid Jadidi. 2021. Multi-objective model for supplier selection and order allocation problem with fuzzy parameters. Expert Systems with Applications 180: 115129. [Google Scholar] [CrossRef]

- Goodarzi, Fariba, Vahid Abdollahzadeh, and Masoomeh Zeinalnezhad. 2022. An integrated multi-criteria decision-making and multi-objective optimization framework for green supplier evaluation and optimal order allocation under uncertainty. Decision Analytics Journal 4: 100087. [Google Scholar] [CrossRef]

- Hamdi, Faiza, Laila Messaoudi, and Jalel Euchi. 2023. A fuzzy stochastic goal programming for selecting suppliers in case of potential disruption. Journal of Industrial and Production Engineering 40: 677–91. [Google Scholar] [CrossRef]

- Hosseini, Zahra Sadat, Simme Douwe Flapper, and Mohammadali Pirayesh. 2022. Sustainable supplier selection and order allocation under demand, supplier availability and supplier grading uncertainties. Computers and Industrial Engineering 165: 107811. [Google Scholar] [CrossRef]

- Hu, Shaolung, Zhijie Sasha Dong, and Benjamin Lev. 2022. Supplier selection in disaster operations management: Review and research gap identification. Socio-Economic Planning Sciences 82: 101302. [Google Scholar] [CrossRef]

- Islam, Samiul, Saman Hassanzadeh Amin, and Leslie J. Wardley. 2021. Machine learning and optimization models for supplier selection and order allocation planning. International Journal of Production Economics 242: 108315. [Google Scholar] [CrossRef]

- Islam, Samiul, Saman Hassanzadeh Amin, and Leslie J. Wardley. 2022. Supplier selection and order allocation planning using predictive analytics and multi-objective programming. Computers and Industrial Engineering 174: 108825. [Google Scholar] [CrossRef]

- Islam, Samiul, Saman Hassanzadeh Amin, and Leslie. J. Wardley. 2023. A Supplier Selection and Order Allocation Planning Framework by Integrating Deep Learning, Principal Component Analysis, and Optimization Techniques. Expert Systems with Applications 235: 121121. [Google Scholar] [CrossRef]

- Jamalnia, Aboozar, Yu Gong, and Kannan Govindan. 2022. Sub-supplier’s sustainability management in multi-tier supply chains: A systematic literature review on the contingency variables, and a conceptual framework. International Journal of Production Economics 225: 108671. [Google Scholar] [CrossRef]

- Kaur, Harpreet, and Surya Prakash Singh. 2021. Multi-stage hybrid model for supplier selection and order allocation considering disruption risks and disruptive technologies. International Journal of Production Economics 231: 107830. [Google Scholar] [CrossRef]

- Liaqait, Raja Awais, Salman Warsi, Mujtaba Agha, Taiba Zahid, and Till Becker. 2022. A multi-criteria decision framework for sustainable supplier selection and order allocation using multi-objective optimization and fuzzy approach. Engineering Optimization 54: 928–48. [Google Scholar] [CrossRef]

- Liu, Dengzhou, and Zhongkai Li. 2021. Joint decision-making of product family configuration and order allocation by coordinating suppliers under disruption risks. Journal of Engineering Design 32: 213–46. [Google Scholar] [CrossRef]

- Masudin, Ilyas, Sabila Zahra Umamy, Al-Imron Cynthia Novel, and Restuputri Dian. 2022. Green procurement implementation through supplier selection: A bibliometric review. Cogent Engineering 9: 2119686. [Google Scholar] [CrossRef]

- Mirzaee, Hossein, Hamed Samarghandi, and Keith Willoughby. 2023. A robust optimization model for green supplier selection and order allocation in a closed-loop supply chain considering cap-and-trade mechanism. Expert Systems with Applications 228: 120423. [Google Scholar] [CrossRef]

- Mohammed, Ahmed, Chunguang Bai, Nabil Channouf, Teejan Al Ahmed, and Shaymaa Maher Mohamed. 2023. G-resilient multi-tier supplier selection and order allocation in food industry: A hybrid methodology. International Journal of Systems Science: Operations and Logistics 10: 2195055. [Google Scholar] [CrossRef]

- Mohammed, Ahmed, Irina Harris, Anthony Soroka, Mohamed Naim, Tim Ramjaun, and Morteza Yazdani. 2021. Gresilient supplier assessment and order allocation planning. Annals of Operations Research 296: 335–62. [Google Scholar] [CrossRef]

- Nasr, Arash Khalili, Madjid Tavana, Behrouz Alavi, and Hassan Mina. 2021. A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. Journal of Cleaner Production 287: 124994. [Google Scholar] [CrossRef]

- Nayeri, Sina, Mohammed Amin Khoei, Mohammed Reza Rouhani-Tazangi, Mohssen GhanavatiNejad, Mohammad Rahmani, and Erfan Babaee Tirkolaee. 2023. A data-driven model for sustainable and resilient supplier selection and order allocation problem in a responsive supply chain: A case study of the healthcare system. Engineering Applications of Artificial Intelligence 124: 106511. [Google Scholar] [CrossRef]

- Nguyen, Van Hop. 2023. A hierarchical heuristic algorithm for multi-objective order allocation problem subject to supply uncertainties. Journal of Industrial and Production Engineering 40: 343–59. [Google Scholar] [CrossRef]

- Sarfaraz, Amir Homayoun, Amir Karbassi Yazdi, Peter Wanke, Elaheh Ashtari Nezhad, and Raheleh Sadat Hosseini. 2022. A novel hierarchical fuzzy inference system for supplier selection and performance improvement in the oil and gas industry. Journal of Decision Systems 32: 356–83. [Google Scholar] [CrossRef]

- Sharifi, Ebrahim, Liping Fang, and Saman Hassanzadeh Amin. 2023. A novel two-stage multi-objective optimization model for sustainable soybean supply chain design under uncertainty. Sustainable Production and Consumption 40: 297–317. [Google Scholar] [CrossRef]

- Spyridonidou, Sofia, and Dimitra G. Vagiona. 2023. A systematic review of site-selection procedures of PV and CSP technologies. Energy Reports 9: 2947–79. [Google Scholar] [CrossRef]

- Sun, Yulin, Simon Cong Guo, and Xueping Li. 2022. An order-splitting model for supplier selection and order allocation in a multi-echelon supply chain. Computers and Operations Research 137: 105515. [Google Scholar] [CrossRef]

- Ventura, Jose A., Kevin A. Bunn, Bárbara Venegas Venegas, and Lisha Duan. 2021. A coordination mechanism for supplier selection and order quantity allocation with price-sensitive demand and finite production rates. International Journal of Production Economics 233: 108007. [Google Scholar] [CrossRef]

- Wu, Chong, Jing Gao, and David Barnes. 2022. Sustainable partner selection and order allocation for strategic items: An integrated multi-stage decision-making model. International Journal of Production Research 61: 1076–100. [Google Scholar] [CrossRef]

- Yang, Xinying, Gong Gong, and Yuan Tian. 2008a. Optimal game theory in complicated virtual-modeling and CGF decision-making with multi-granularities. Presented at the 2008 International Conference on Smart Manufacturing Application, Goyangi, Republic of Korea, April 9–11; Piscataway: IEEE, pp. 95–99. [Google Scholar]

- Yang, Xinying, Guanghong Gong, Yuan Tian, and Xiaoxia Yu. 2008b. Generalized optimal game theory in virtual decision-makings. Presented at the 2008 Chinese Control and Decision Conference, Yantai, China, July 2–4; Piscataway: IEEE, pp. 1960–64. [Google Scholar]

- Yang, Yi, and Chen Peng. 2023. A prediction-based supply chain recovery strategy under disruption risks. International Journal of Production Research 61: 7670–84. [Google Scholar] [CrossRef]

- Yousefi, Samuel, Mustafa Jahangoshai Rezaee, and Maghsud Solimanpur. 2021. Supplier selection and order allocation using two-stage hybrid supply chain model and game-based order price. Operational Research 21: 553–88. [Google Scholar] [CrossRef]

- Zaretalab, Arash, Mani Sharifi, Pedram Pourkarim Guilani, Sharareh Taghipour, and Seyed Taghi Akhavan Niaki. 2022. A multi-objective model for optimizing the redundancy allocation, component supplier selection, and reliable activities for multi-state systems. Reliability Engineering and System Safety 222: 108394. [Google Scholar] [CrossRef]

- Zhang, Ping, Xinying Yang, and Zongji Chen. 2005. Neural network gain scheduling design for large envelope curve flight control law. Journal of Beijing University of Aeronautics and Astronautics 31: 604–8. [Google Scholar]

- Zhang, Yueran, Zhanwen Niu, Yaqing Zuo, and Chao-Chao Liu. 2023. Two-stage hybrid model for supplier selection and order allocation considering cyber risk. INFOR: Information Systems and Operational Research 61: 530–58. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).