1. Introduction

The meaning of cross-border is between different countries, or involving living beings of different countries [

1]. Cross-border can be derived from cross-border E-Commerce, cross-border cooperation, cross-border transportation, cross-border logistics, and so on [

2,

3,

4]. These concepts have very important strategic significance for promoting economic integration and trade globalization [

5,

6].

Cross-border logistics is the basis of cross-border trade and the flow of goods, and which not only links nations through foreign trade but is also a pillar of national economic development [

7]. Cross-border logistics platforms can support the comprehensive requirements of the development of modern logistics enterprises, strengthen the role of information technology, and electronic commerce in logistics enterprises [

8]. The platform also plays an important role in promoting the integration of information flow logistics resources [

9]. Through cross-border logistics platforms, government departments have also strengthened the macro and standardized management of the market and provided diversified logistics information services [

10].

In September 2013, President Xi of China proposed building the Silk Road Economic Belt to boost regional cooperation and called for the establishment of a new regional cooperation model. These proposals are collectively called the One Belt and One Road (OBOR) initiative or the Belt and Road initiative (BRI) [

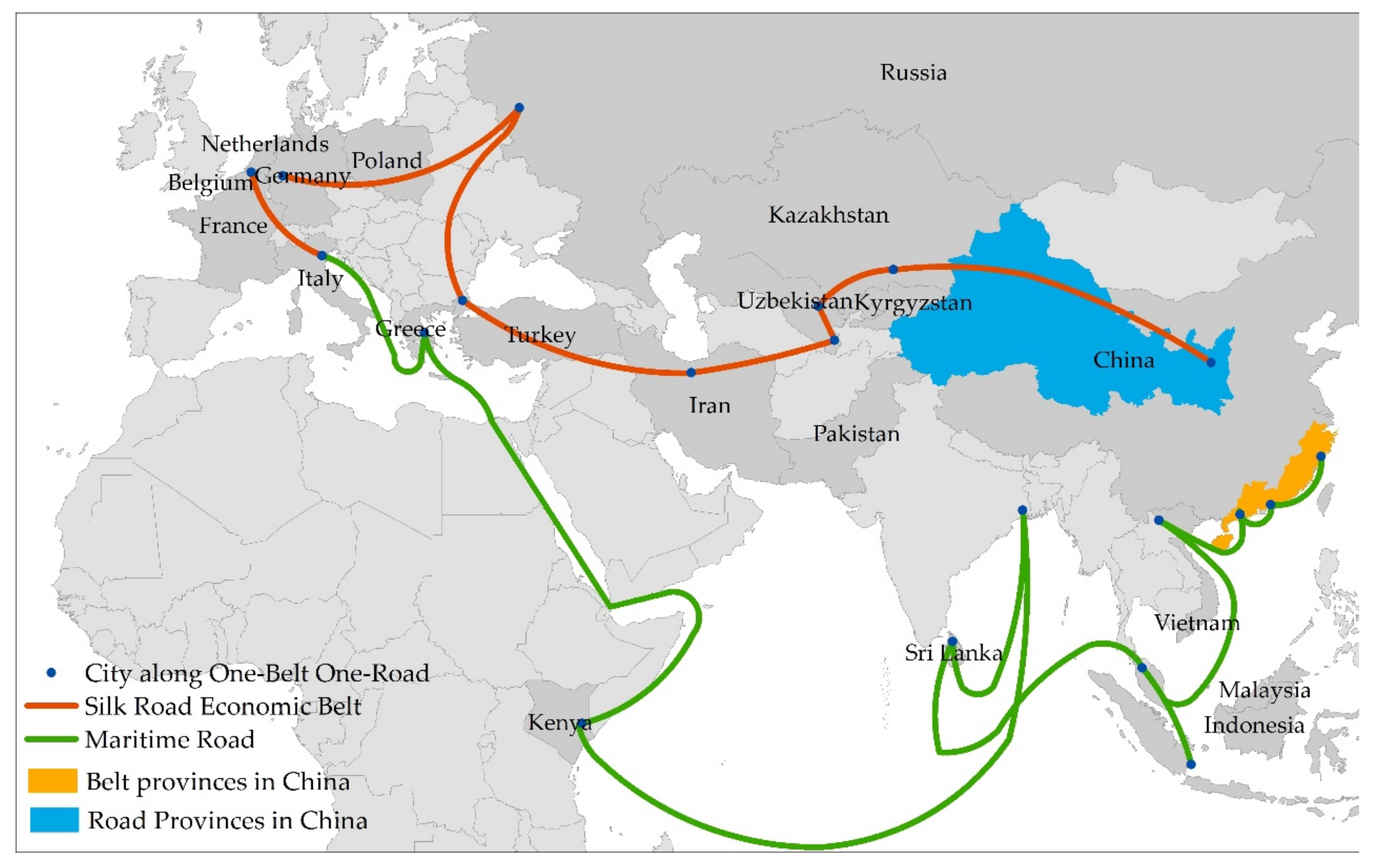

11], the geographical coverage of which is illustrated in

Figure 1. There are more than 60 countries along the Silk Road Economic Belt and the 21st Century Maritime Silk Road, covering a population of 3.2 billion, which accounts for 43.4% of the global population; the total economic aggregate is

$12 trillion (a global share of 16%) and the total trade amount is

$7,185,550 million, which accounts for 21.7% of total world trade [

12].

OBOR is an unprecedented market construction project. In accordance with the goals of the OBOR strategy, cross-border e-commerce is growing rapidly. According to reports from Alibaba [

13], half of the customers—more than 100 million—on its Business-to-Customer (B2C) platform are located within the OBOR region. International logistics cooperation is therefore essential to meeting growing regional demand. The implementation of OBOR accelerates the logistics infrastructure interconnecting Asia, Europe, and Africa, which also strengthens the construction of infrastructure such as hub ports, airports, railways, and other ports. The logistics tunnels between China and Europe include ocean shipping transport tunnels, air transport tunnels, and land transport tunnels [

12]. The CR Express is the international railway intermodal container train between China and Europe, traveling through countries along the Silk Road Economic Belt, having a fixed train number, route and other conditions [

14]. As an important part of the OBOR, the CR Express has become the backbone land transport tunnel in OBOR logistics because of its short distance, fast speed, safety record, and minimal impact to the natural environment [

12].

The opening of the China Railway Express (CR Express) is the key element in realizing the facility connectivity and unimpeded trade principles set forth in the OBOR initiative. The first CR Express (Chongqing–Duisburg) successfully opened on 19 March 2011. The CR Express had opened more than 16,000 trains by the end of June 2019, and reaches 53 cities in 16 European countries [

14]. The increase in the number of CR Express trains between 2011 and 2019 is shown in

Figure 2. In recent years, the service and operation quality of CR Express have been continuously improved, and it has good international brand effect and development prospects. It has effectively pushed China to the world and opened up economic and trade exchanges between countries along the Silk Road Economic Belt. The CR Express has become the iconic achievement of OBOR construction [

15].

Despite its success, there are many problems to be solved in the operation of the CR Express [

15]. With the increase in the number of trains, many important stations have become congested, lowering the trains’ on-schedule rate and making it difficult to guarantee delivery times. Moreover, port changes and passage capacity are insufficient for customs clearance of goods traveling by CR Express, with low rates of inspection and quarantine of goods on the trains and low clearance efficiency [

16]. In terms of freight source organization, CR Express trains are scattered throughout China and fewer trains return with international goods, resulting in the low economy of the train. There is also a low level of information interconnection, competition between each route of the CR Express is fierce, and government subsidies are now significant. Although the CR Express routes have achieved normal and stable operation, return trains are much less in demand than departure trains and almost no goods are transported by countries along the Silk Road Economic Belt [

14]. The CR Express basically serves as door-to-door transportation: Few containers need loading or unloading at freight stations in the middle of the journey, as the railway department has not cooperated well with domestic and foreign logistics enterprises and has not organized the source of goods along the line [

12]. Therefore, in addition to considering the increase of transport capacity, we must also consider improving the transport organization of the CR Express to improve the quality of service and maintain the image of the brand in the international logistics market.

China Premier Li Keqiang first proposed the “Internet Plus” action plan in the government work report in 2015 [

17]. Internet Plus is simply “Internet plus traditional industry”. With the development of science and technology, the use of information and Internet platforms has enabled the Internet to integrate with traditional industries and take advantage of the advantages of the Internet to create new development opportunities. Through its own advantages, “Internet Plus” optimizes, upgrades and transforms traditional industries, so that traditional industries can adapt to current new developments, thereby ultimately pushing society forward [

17]. In the new Internet Plus era, the application scenarios of cloud computing and big data technology are constantly being enriched and have played a great role in many industries [

17]. Relying on the rise of the cloud platform model, the construction of cross-border logistics information cloud platforms (CLICPs) can help the logistics industry promote information construction and development to ensure the transportation safety of logistics production work and improve operation quality. CLICPs are an important means for achieving intelligent logistics. With the extension of freight demand and the development of whole-journey service, the last-mile problem has become the bottleneck restricting the development of logistics [

18]. Intermodal transportation is an important carrier and the main form of door-to-door transportation of goods. Land transportation is dominated by highway and railway transport, whereas cross-border logistics transportation is divided into trunk CR Express transportation and branch highway transportation connections [

19]. Door-to-door transportation in cross-border logistics is considered to attract and stabilize the source of goods; its purpose is to reduce costs, increase efficiency, and promote the prosperity and development of cross-border economy and trade [

12].

Several studies have addressed cross-border logistics under the OBOR initiative. Edirisinghe [

7] used the logistics performance index as a tool to analyze cross-border logistics performance in Sri Lanka. Wei and Dong [

8] studied import and export freight organization of the inland waterless port cross-border logistics network under the OBOR initiative and constructed a mathematical model for optimizing this network. Jia et al. [

9] optimized the cross-border logistics network of inland waterless ports under the BRI considering the time value generated by the early arrival of goods, synthetically analyzing the influence of cost and time factors on transportation mode in the network to better reflect the reality of the cross-border logistics network. Leung et al. [

10] proposed a robust optimization model for solving cross-border logistics problems in uncertain environments; by adjusting penalty parameters, the decision maker can use this model to determine optimal long-term transportation strategies, including the optimal transportation route and fleet composition, thus minimizing the total expenditure under different economic growth scenarios. Wong et al. [

18] proposed a performance evaluation system framework to evaluate direct and indirect cross-border logistics supply chain models. Kuzmicz and Pesch [

19] analyzed models of and a variety of solutions to empty container repositioning problems through the prism of Eurasian intermodal transportation. Liu et al. [

20] explored supply-chain coordination issues arising from the OBOR initiative.

Cloud computing can provide technical guarantees in solving big data problems because of its high computing efficiency and flexibility [

21]. Cloud computing resources are allocated and billed based on user needs and user usage, and have the advantages of wide area network interconnection, so cloud computing can reduce infrastructure investment and maintenance costs; furthermore, as basic technical support for big data services, cloud computing is also of great significance to data storage, service construction, analysis, and management [

22].

With the continuous research and promotion of cloud computing technology, many companies and enterprises began to deploy big data and cloud computing related services. For example, relevant research within Facebook has introduced and summarized the steps to moving applications to hybrid clouds [

23]. Shen et al. [

24] discussed how to migrate social network applications to the cloud and analyzed the advantages of cloud platforms in resource invocations and cost savings. Kemp et al. [

25] proposed a cloud-oriented method for managing and analyzing OpenCL acceleration point feature histogram cloud processing for railway track detection. Azizian et al. [

26] collected big data from sensors installed in vehicles. In order to improve the prediction performance of cloud services, Luo et al. [

27] introduced intelligent technology into quality of service prediction to improve its performance. The gradual development of cloud computing has also had a great effect on large-scale data processing technology and tools. The main driving force of this development has come from Internet enterprises including Google, Microsoft, Amazon, and Alibaba Cloud, which not provide users with big data storage and analysis functions that help enterprises to tap deeply into the value of data. For example, Google offers a Google Big Query product to meet undefined customer data analytics service [

28], Microsoft developed Windows Azure Marketplace [

29], Amazon’s large data analytics service is based on the Amazon Web Services Marketplace [

30]; Alibaba Cloud has launched a big data solution to meet the needs of various user-processed data [

31].

Table 1 lists some current big data processing technologies and tools. By flexibly invoking cloud services, users can not only make use of big data computing and mining functions, but also provide strong technical support to users by encapsulating data resources from big data technical services.

Cloud computing technology is closely related to the development of CLICP technology. Tan and Ai [

32] analyzed the security of cloud computing in a railway environment and proposed a cloud computing security reference framework. Jiang et al. [

33] gave an overview of intelligent railway transportation systems—including cloud computing technology—and analyzed the future of such systems. Markovi et al. [

34] applied support vector machines to the prediction of train delays.

The majority of publications on cross-border logistics and information platform cover issues related to intermodal transportation; existing research has not considered the significance of the CR Express to cross-border logistics and the importance of cloud technology to its information platforms.

Ultimately, research on cross-border logistics has focused less on the modes of public, rail, and land transport; traditional logistics is still based on road transportation’s high cost and limited transportation capacity, which is based on the trunk railway transportation form of CR Express. Trends indicate the necessity of understanding a future in which receiving and delivery services with door-to-door transportation are completed by road and railway transportation.

Moreover, cloud computing technology is developing quickly, with governments and Internet companies actively promoting the upgrading of related technologies. However, cross-border logistics has not yet been introduced into cloud computing and big data technology. A small number of studies have excavated the massive operation data from the business work accumulated over the years. Research on the transformation of cross-border logistics service models from traditional to information and digitization must be further carried out using cloud computing technology.

In this paper, we focus on CLICP construction and design. The remainder of the paper is structured as follows. The following section contains a technology analysis of the proposed CLICP, and its construction scheme is designed in the fourth section. Our final section outlines the conclusion from the research in this paper.

3. The CLICP Construction Scheme

The CLICP Construction Scheme is different from the research of CLICP technology analysis. CLICP technology analysis mainly conducts a research from the perspective of platform construction technology and engineering background. The research of CLICP technology analysis focuses on the interrelationship of each part of the platform architecture, related systems, functions, and algorithm performance. The research of CLICP Construction Scheme mainly focus on the concrete realization of each component of platform.

3.1. CLICP Architecture Design

After putting forward the transport scheme of the CLICP, its basic architecture needs to be designed. The CLICP can rely on the mature 95,306 freight system of the CNRP and the railway transportation information integration platform. The CLICP can depend on the railway to account for its long-distance cargo transportation advantages, and expand the logistics market in the medium- and short-term.

With the help of the OBOR initiative background development, the CLICP not only has a huge market, but also conforms to the national macro-control policy for the development of the logistics industry. As mentioned earlier, CLICP uses a hybrid cloud platform mobile application model to connect transportation, and integrates the railway department, cargo owners, carriers, drivers, and consignees in a logistics link on one platform. In order to create a transparent, open, and universally beneficial online ecosystem, CLICP is a platform based on the core process of open and credit system-based. All platform members have the opportunity to find better resources or new businesses while better managing their existing businesses. Such a platform system creates unparalleled business opportunities.

The CLICP’s business system is designed as a Brower/Server architecture system and the server deployment mode is a hybrid cloud deployment mode. Five types of users—the platform builder (railway head office and road bureau), carrier, cargo owner, driver, and consignee—log on to the logistics information cloud platform system under different permissions through a unified server. The CLICP system is based on a software as a service (SaaS) layer cloud platform. At present, the Internet in the field of logistics information is almost equivalent to SaaS. Users realize logistics management services through cloud computing, mobile Internet, social platform technology, and so on. In SaaS services, enterprises do not need to buy software, but instead rent Web-based software from providers to manage business activities according to their own needs. Not only that, users pay the supplier according to how much and how long the rental service is, and there is no need to maintain the software.

The logical architecture design of CLICP is shown in

Figure 5. It is divided into infrastructure, platform, and application layers, with a cloud management platform layer in which the operation support system and business support system are integrated to form the background management of the CLICP. The infrastructure layer realizes the distributed deployment and allocation of resources through virtualization technology. The platform layer builds a big data service platform based on distributed computing and distributed storage to realize the functions of cloud data storage, business management, search, communication, and computing. The application layer mainly develops the CLICP’s application function modules, including the central monitoring, order management, real-time tracking, Business Intelligent (BI) report, financial management, price monitoring, real-time bidding, user management, carrier one-stop management, financial service management, online payment, and logistics solution management modules.

3.2. CLICP Function Design

As shown in

Figure 5, the CLICP functions include both core business functions and extended service functions. This section focuses on the design and analysis of extended service functions. The basic functions of CLICP are not analyzed in detail, as they are similar to those of most current transportation platforms. Instead, we examine the research and design of custom value-added functions. Real-time bidding function, freight information push function and carrier one-stop service management are as follows. The essential difference between these three functions is the different usage scenarios of the service objects. The real-time bidding function can improve the efficiency of matching vehicles and goods. Freight information push function can expand the scope of information sharing and improve the transparency of work. Carrier one-stop service management can reduce additional work costs of the carrier and can improve convenience on the way.

3.2.1. Real-Time Bidding Function

Based on the traditional bidding method, in the CLICP’s real-time bidding function module, the consignor issues freight demand orders through the platform, including the name, type, transportation information, and settlement information of the goods. Transportation information includes cargo weight, vehicle type, loading and unloading time, loading place, and unloading place. Settlement information includes intended transportation price and settlement method. The owner can also upload photos of the goods through the app, with the PC side automatically synchronizing. In the car and cargo matching link, the cloud platform selects a carrier with the appropriate model, transportation time, and transportation line according to the order requirements and sends the freight order information to the corresponding carrier by push notification. After that, carriers who are willing to accept the order launch an anonymous bidding function through the platform. Within the specified time, the carrier will have to provide the transportation cost and required transportation time to the consignor; the carrier will not be able to see information provided to the consignor by other bidders, so as not to cause vicious price reductions and compression of the required transportation time, resulting in the ultimate inability to complete the transport service in accordance with the cost and time provided. The freight and transportation time scheme of each carrier is compared and selected by the consignor. If there is a satisfactory scheme with a suitable performance–price ratio, the consignor may confirm the order with the carrier; that is, the carrier who confirms the freight order by the consignor enters into a transaction. If the consignor is not satisfied with the quote or time of any carrier, he can communicate and negotiate with the platform and modify the requirements of the freight demand order in order to further screen for a carrier who can meet the needs of the consignor. If the negotiation is successful, the platform will once again push the order to the corresponding carrier and bidding can occur. If the negotiation is not successful, the platform will abandon the consignor order. Once the carrier participates in real-time bidding, it should complete the transportation business according to the cost and time provided in the winning bid. If the order is not completed on time or the order is accepted and abandoned, the platform will deduct its bidding margin accordingly to compensate the consignor. When the carrier receives the source information, the platform will also push the relevant return source information in order to facilitate the carrier to consider transportation costs and make a reasonable bid.

In the CLICP’s real-time bidding trading mode, there is no inquiry link, shippers directly according to freight, freight time to multi-choice carrier, the transaction is open and transparent, through bidding for freight, freight time for market pricing. At the same time, it solves problems that are difficult for carriers, such as using logistics express enterprises to find goods, and difficult for shippers, such as locating freight and freight time, which can greatly reduce logistics costs and has the advantage of integrating resources.

3.2.2. Freight Information Push Function

At present, most of the information cues for goods orders in relevant logistics distribution websites are static cues, which are simple and monotonous, lack communication and interaction between consignors and carriers, and have slow information flow. With the increasing degree of freight information and vehicle ownership, existing information prompt methods can no longer meet the needs of carriers to find suitable goods orders efficiently and quickly.

For this purpose, we designed the CLICP’s freight information push module, which mainly pushes the freight demand order information issued by a consignor to the carrier side. This function is divided into two submodules: the screening module and the intelligent push module. The main implementation of the screening module is to eliminate redundant information and carry out appropriate vehicle and cargo matching functions. First, the order contents issued by the consignor, such as the weight and category of the goods or the distribution mode, are set to corresponding rules; then, the freight information is automatically screened according to the set rules and redundant or unnecessary information is excluded. At the same time, using the carrier’s basic information, the function analyzes the carrier’s history, vehicle type, and performance, and orders and feedback carriers that are not suitable for shipping are excluded from re-evaluation, so as to reduce the consignor’s waiting time and reduce redundant system data.

3.2.3. Carrier One-Stop Service Management

The one-stop service management function module is provided by the CLICP. This function module provides many convenient services for carriers, consists of four categories: life, finance, transaction, and freight car. The life convenience service is aimed at the truck driver under the carrier, mainly providing good-quality meal ordering, reliable accommodations, and shopping directly through the CLICP client. The platform can also direct the driver to a nearby convenience store, supermarket, or other commercial area, greatly facilitating the driver’s ability to live normally while transporting goods. The platform also provides financial services, including freight insurance and loans, to assist carriers in resolving possible funding shortfalls and damage to goods. In the trading module, the platform provides second-hand car trading and new car group purchase services for carriers, and provides concessions to carriers who want to buy freight car vehicles. Freight car convenience services mainly provide a variety of services for freight vehicles, including pushing nearby parking locations (including parking fees), gas station locations, and cargo transport route GPS navigation, as well as rapid rescue and maintenance in the event of vehicle damage.

One-stop service management is a convenient value-added service provided by CLICPs for carriers, in addition to the establishment of a social capacity pool, which greatly facilitates the freight transportation of carriers and simplifies the long and difficult process of freight transport.

3.3. CLICP Deployment Model

The CLICP deployment model is shown in

Figure 6; the CLICP adopts a hybrid cloud mode, with the data and core business information stored on private clouds belonging to the railway enterprise for core asset management and monitoring. Non-core business functions, such as value-added services, can be placed on the public cloud of the cloud service provider. The elastic computing resources of the public cloud are shared, minimizing the operational cost of the platform and improving its working efficiency. Cross-border logistics transport schemes can be determined quickly by using cloud resources, and the order and dispatching order are distributed to the production department and third-party branch highway carrier enterprise.

The purpose of CLICP is to attract more third-party carriers and attract more third-party carriers. In the promotion stage, the platform can distribute orders to carriers or individual drivers free of charge, attract carriers, and cultivate usage habits. At a macro level, the operation of CLICP will go through early, mid-term, and final stages. At present, the CLICP’s operation focuses on introducing the platform into the market and successfully gaining a foothold; in the mid-term, it will quickly occupy the corresponding market share and resources. As soon as possible, it will enter a stable final stage with an active user base and profitable income.

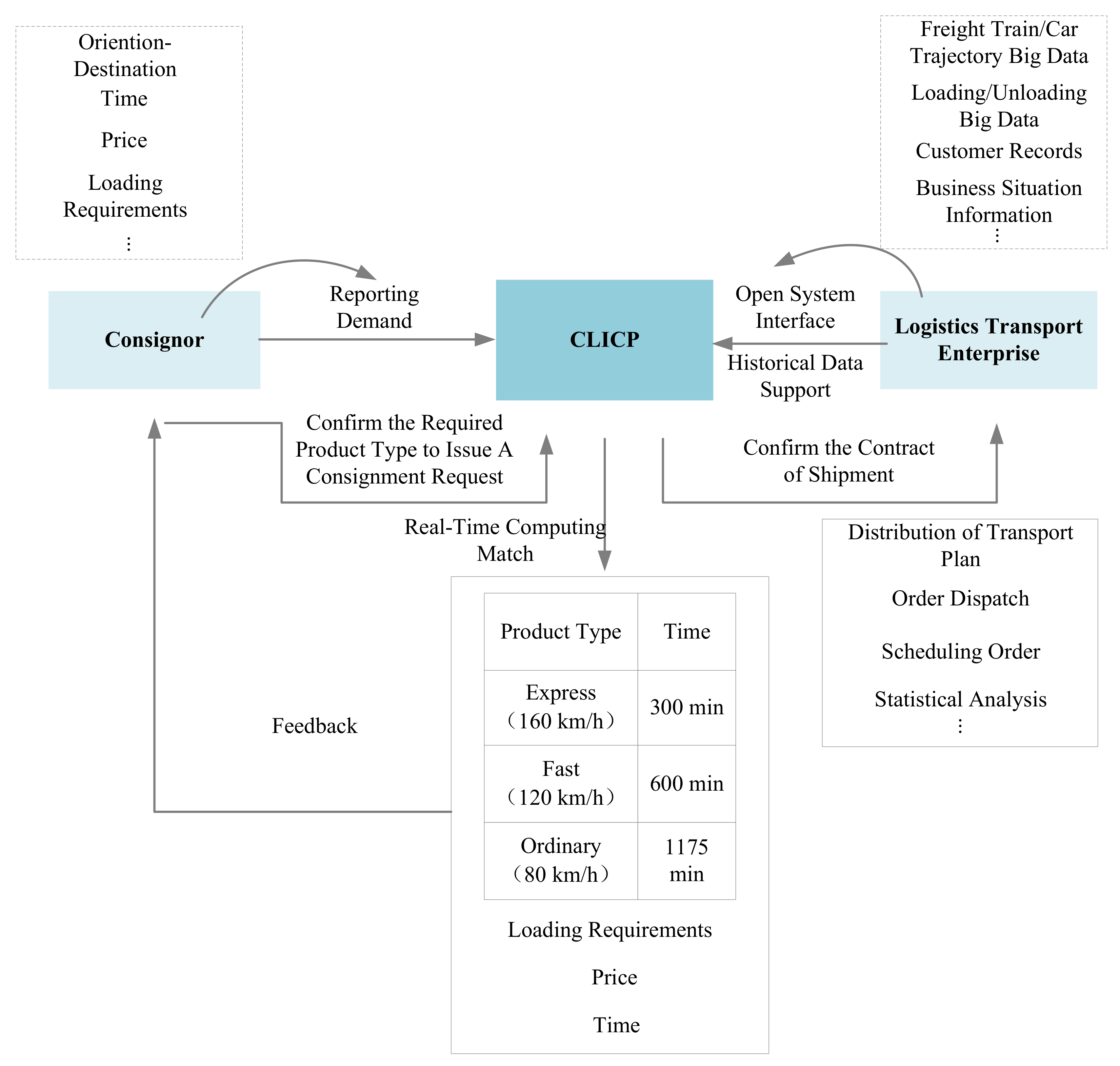

As shown in

Figure 7, the CLICP acquires historical transportation production data through the opening of the ports of its own production information system by railway and highway transportation enterprises as data support for sending transportation schemes, dispatching instructions, order distribution, and statistical analysis. According to actual transportation demand, the consignor can obtain a door-to-door logistics freight product and its corresponding attribute information from the CLICP, including price and time, and then choose the optimal freight product within the acceptable price or transportation time range. The cloud-based cross-border logistics transport scheme has the advantages of accurate marketing, efficient feedback, and mutual benefit.