Concepts and Capabilities of In-House Built Nanosecond Pulsed Electric Field (nsPEF) Generators for Electroporation: State of Art

Abstract

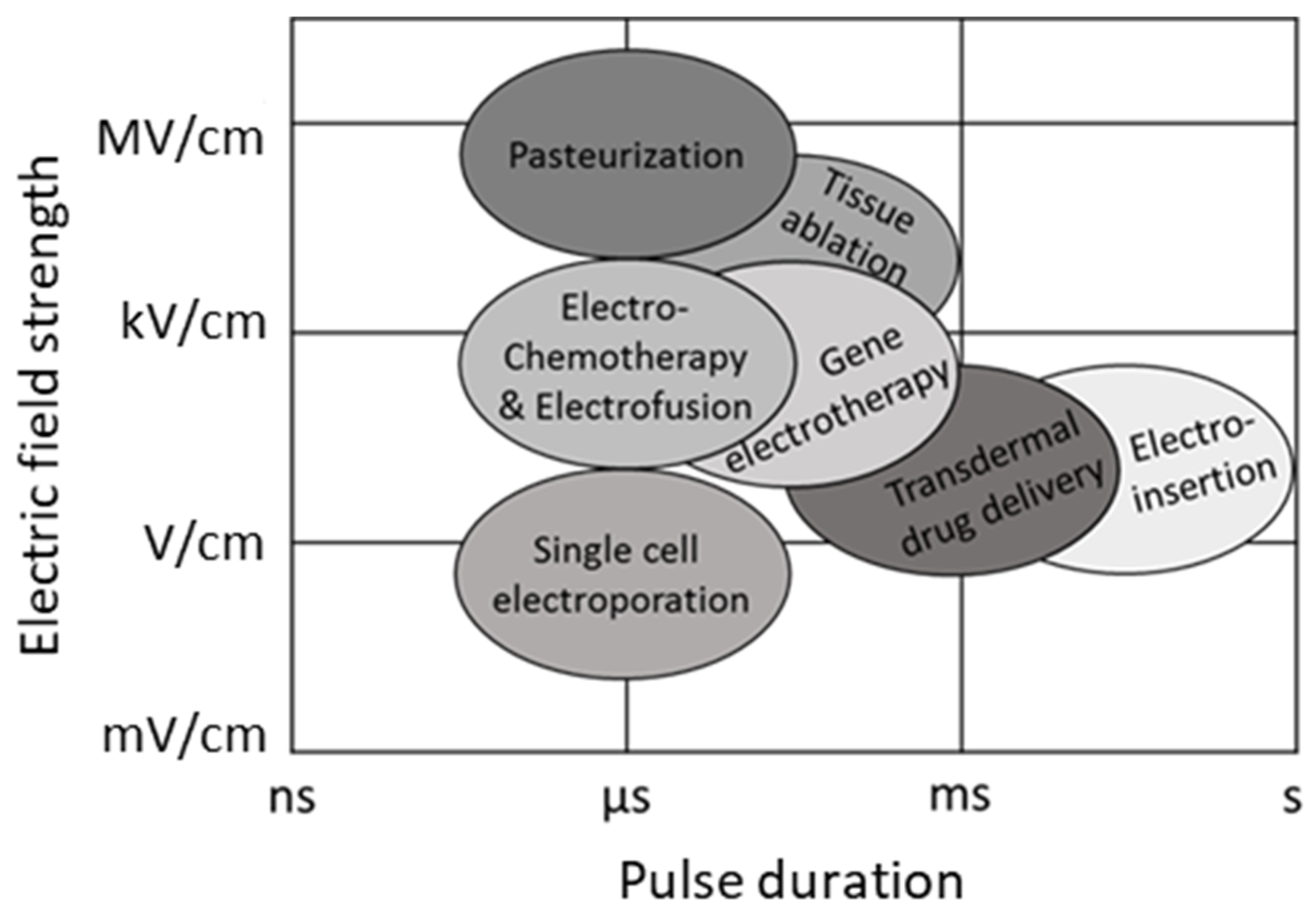

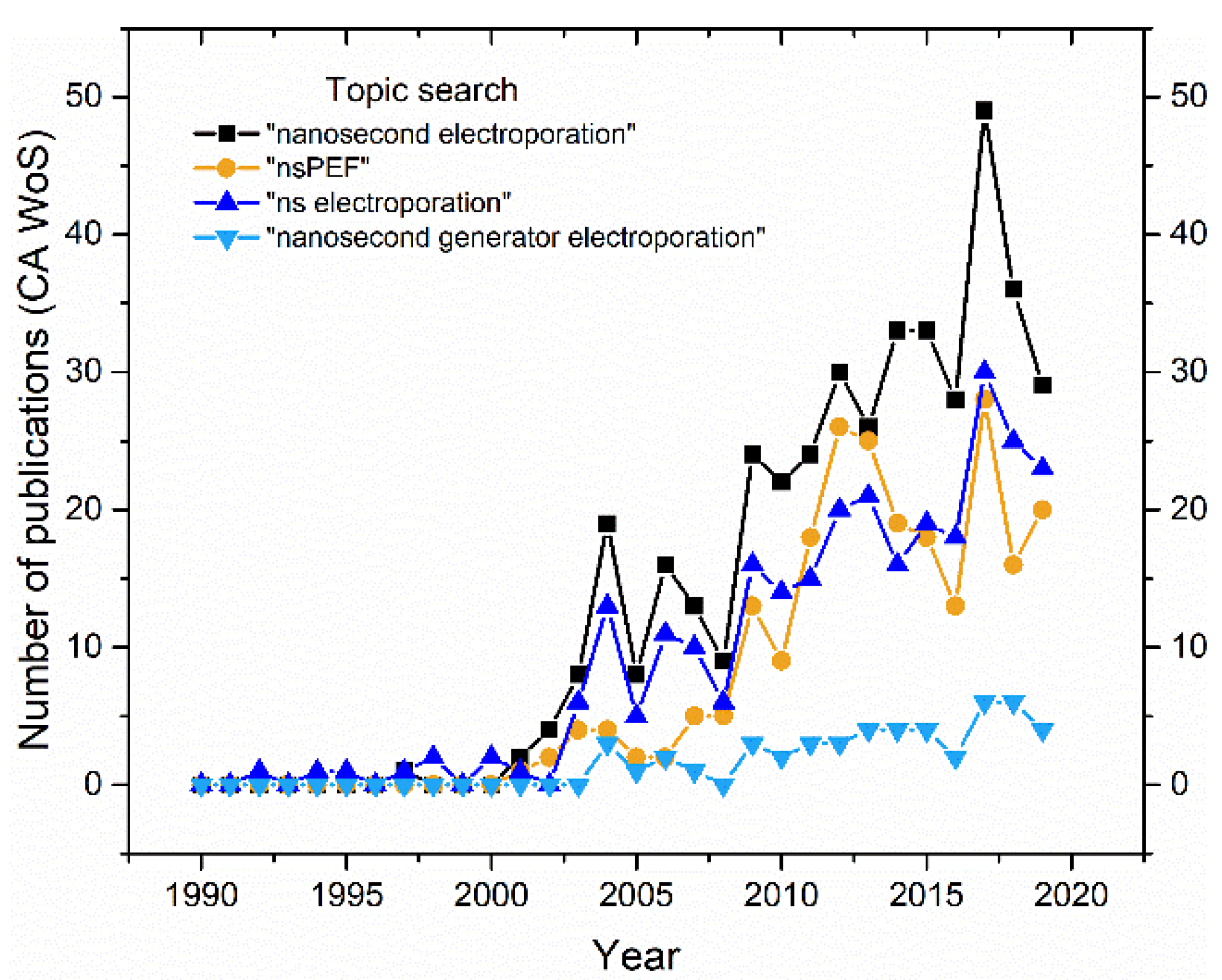

1. Introduction

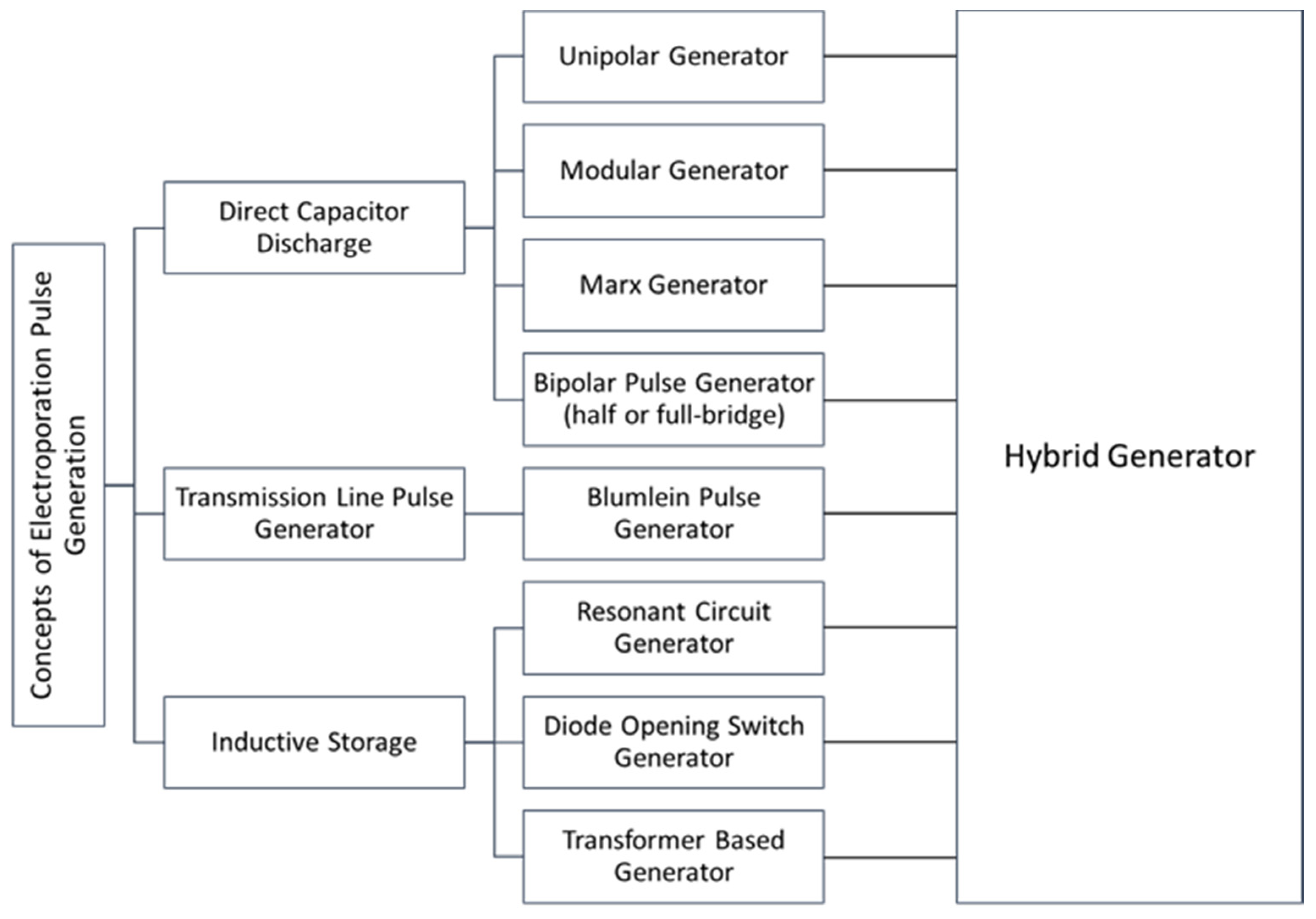

2. Basic Generator Topologies

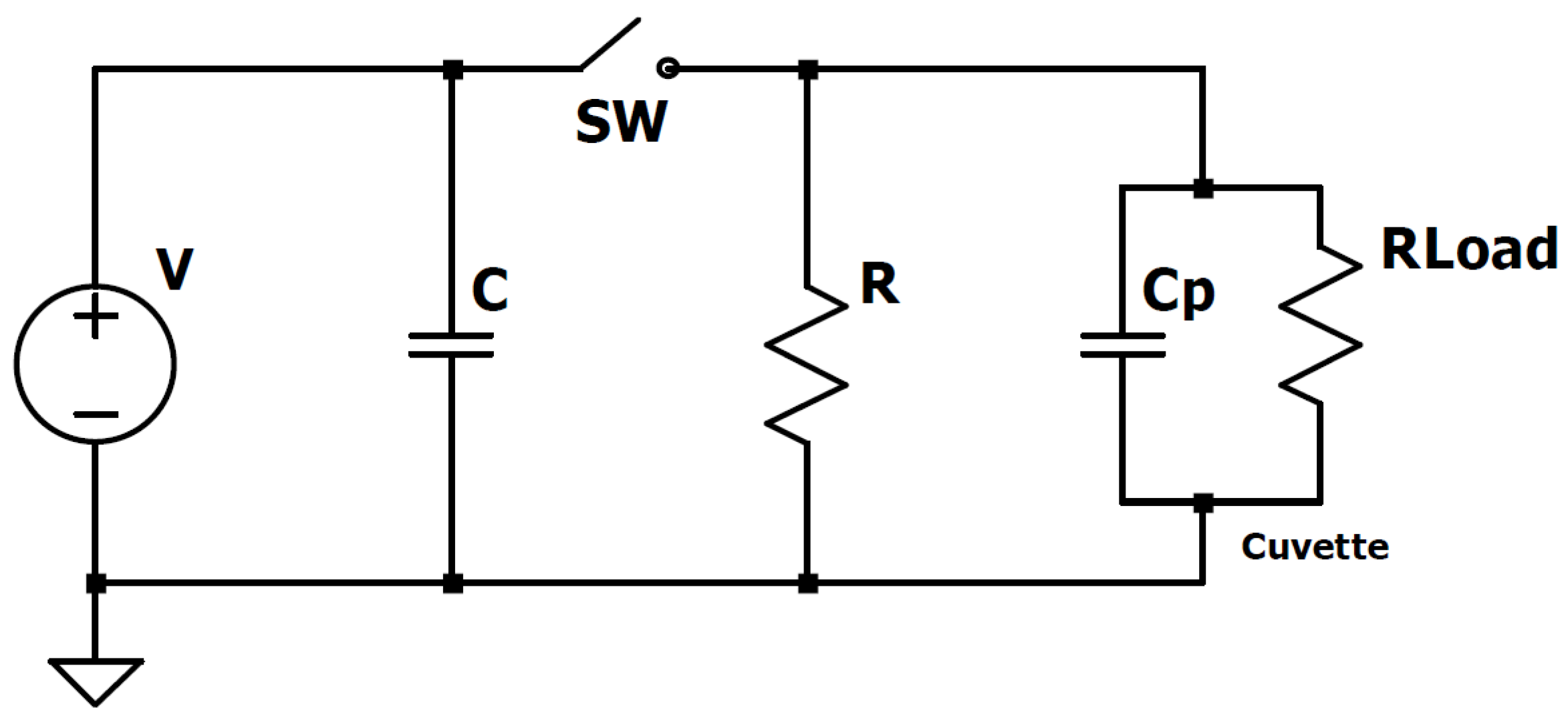

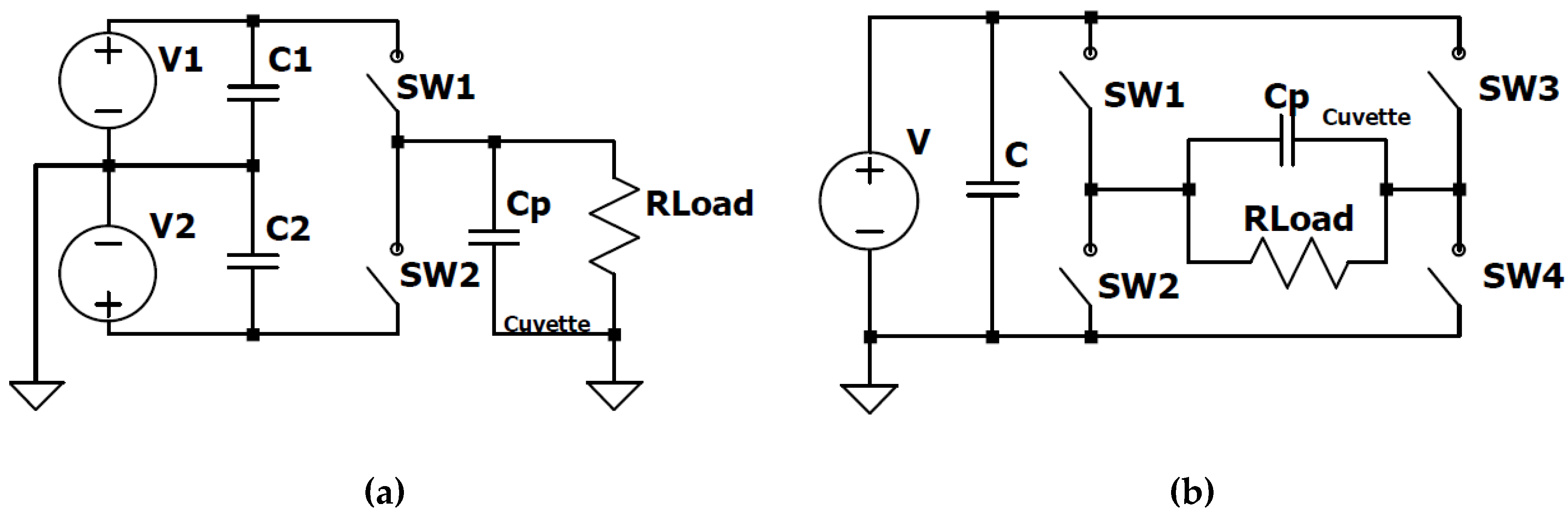

2.1. Pulse Forming Using Capacitor Discharge Circuits

2.2. Pulse Forming Circuit Topology Based on Transmission Lines

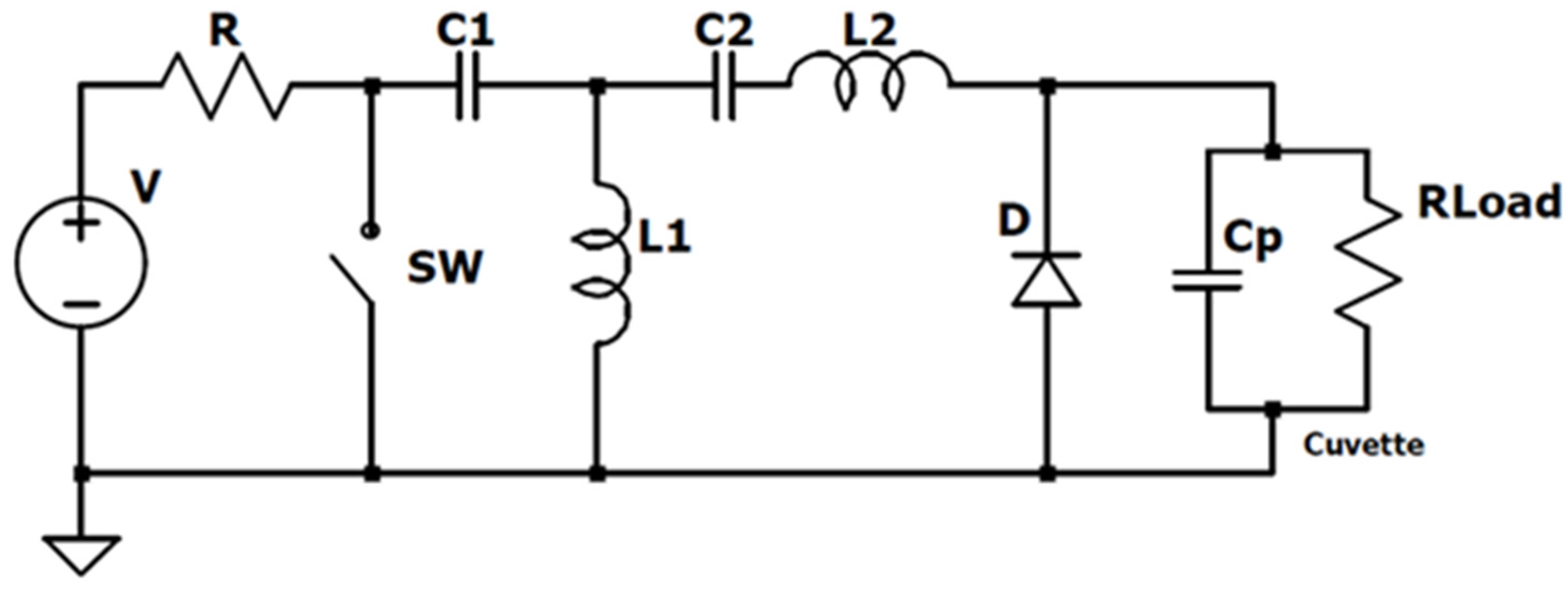

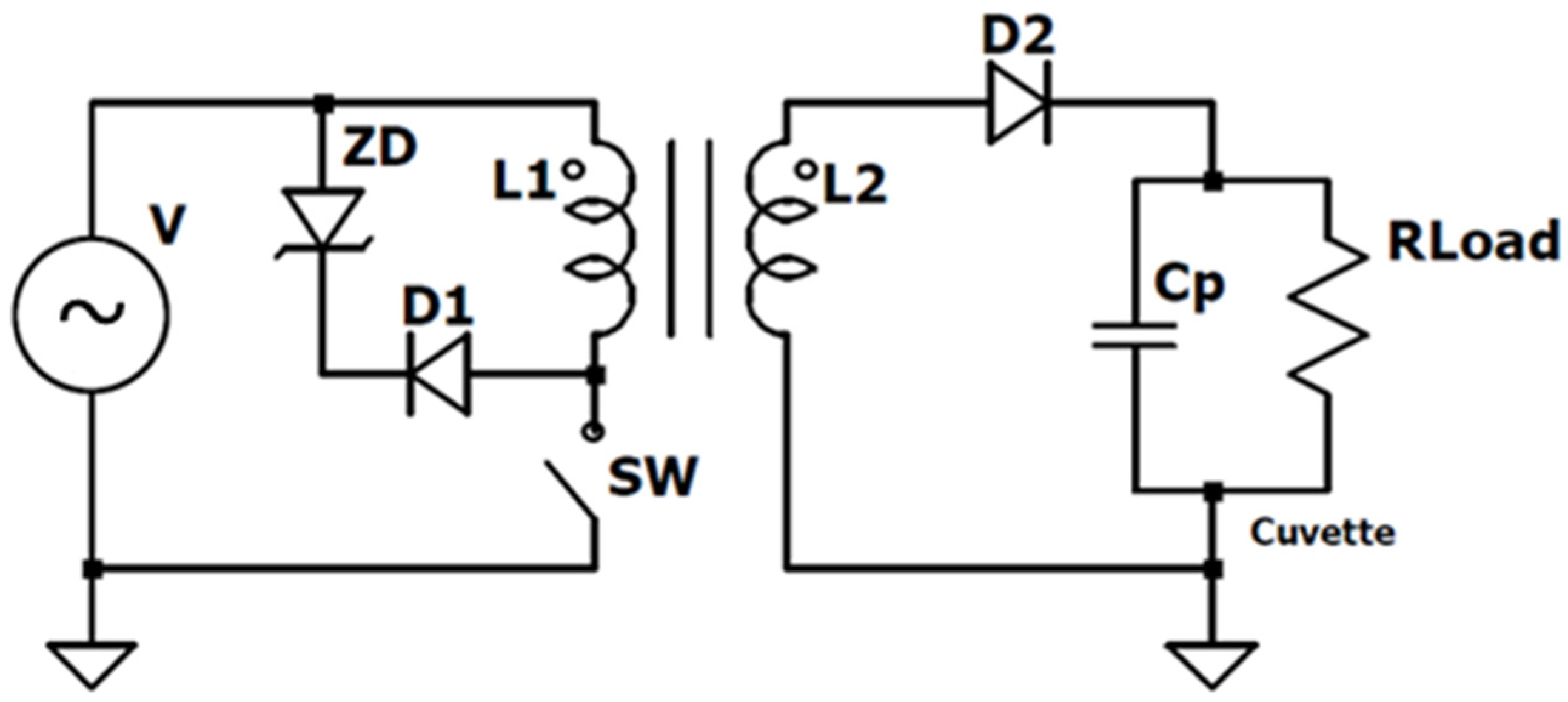

2.3. The Inductive Energy Discharge Pulse Generators

3. Overview

3.1. Advantages and Disadvantages of the Typical Electroporator Concepts

3.2. Classification of Available In-House Built Generators for nsPEF Electroporation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cemazar, M.; Sersa, G.; Frey, W.; Miklavcic, D.; Teissié, J. Recommendations and Requirements for Reporting on Applications of Electric Pulse Delivery for Electroporation of Biological Samples. Bioelectrochemistry 2018, 122, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Denzi, A.; Merla, C.; Palego, C.; Paffi, A.; Ning, Y.; Multari, C.R.; Cheng, X.; Apollonio, F.; Hwang, J.C.M.; Liberti, M. Assessment of Cytoplasm Conductivity by Nanosecond Pulsed Electric Fields. IEEE Trans. Biomed. Eng. 2015, 62, 1595–1603. [Google Scholar] [CrossRef] [PubMed]

- Dutta, D.; Asmar, A.; Stacey, M. Effects of Nanosecond Pulse Electric Fields on Cellular Elasticity. Micron 2015, 72, 15–20. [Google Scholar] [CrossRef] [PubMed]

- Bennett, W.F.D.; Sapay, N.; Tieleman, D.P. Atomistic Simulations of Pore Formation and Closure in Lipid Bilayers. Biophys. J. 2014, 106, 210–219. [Google Scholar] [CrossRef] [PubMed]

- Tsong, T.Y.Y. Electroporation of Cell Membranes. Biophys. J. 1991, 60, 297–306. [Google Scholar] [CrossRef]

- Sundararajan, R. Nanosecond Electroporation: Another Look. Mol. Biotechnol. 2009, 41, 69–82. [Google Scholar] [CrossRef]

- Miklavčič, D.; Mali, B.; Kos, B.; Heller, R.; Serša, G. Electrochemotherapy: From the Drawing Board into Medical Practice. Biomed. Eng. Online 2014, 13, 29. [Google Scholar] [CrossRef]

- Shi, G.; Edelblute, C.; Arpag, S.; Lundberg, C.; Heller, R. IL-12 Gene Electrotransfer Triggers a Change in Immune Response within Mouse Tumors. Cancers 2018, 10, 498. [Google Scholar] [CrossRef]

- Sitzmann, W.; Vorobiev, E.; Lebovka, N. Applications of Electricity and Specifically Pulsed Electric Fields in Food Processing: Historical Backgrounds. Innov. Food Sci. Emerg. Technol. 2016, 37, 302–311. [Google Scholar] [CrossRef]

- Golberg, A.; Sack, M.; Teissie, J.; Pataro, G.; Pliquett, U.; Saulis, G.; Stefan, T.; Miklavcic, D.; Vorobiev, E.; Frey, W. Energy-Efficient Biomass Processing with Pulsed Electric Fields for Bioeconomy and Sustainable Development. Biotechnol. Biofuels 2016, 9, 94. [Google Scholar] [CrossRef]

- Yarmush, M.L.; Golberg, A.; Serša, G.; Kotnik, T.; Miklavčič, D. Electroporation-Based Technologies for Medicine: Principles, Applications, and Challenges. Annu. Rev. Biomed. Eng. 2014, 16, 295–320. [Google Scholar] [CrossRef] [PubMed]

- Wagstaff, P.G.K.; Buijs, M.; van den Bos, W.; de Bruin, D.M.; Zondervan, P.J.; de la Rosette, J.J.M.C.H.; Laguna Pes, M.P. Irreversible Electroporation: State of the Art. OncoTargets Ther. 2016, 9, 2437–2446. [Google Scholar] [CrossRef] [PubMed]

- Venslauskas, M.S.; Šatkauskas, S. Mechanisms of Transfer of Bioactive Molecules through the Cell Membrane by Electroporation. Eur. Biophys. J. 2015, 44, 277–289. [Google Scholar] [CrossRef] [PubMed]

- Miklavčič, D.; Reberšek, M. Development of Devices and Electrodes. In Proceedings of the Electroporation-Based Technologies and Treatments: International Scientific Workshop and Postgraduate Course, Ljubljana, Slovenia, 12–18 November 2017; pp. 85–94. [Google Scholar]

- Reberšek, M.; Miklavcic, D. Concepts of Electroporation Pulse Generation and Overview of Electric Pulse Generators for Cell and Tissue Electroporation. In Advanced Electroporation Techniques in Biology and Medicine; CRC Press: Boca Raton, FL, USA, 2010; pp. 323–339. [Google Scholar]

- Batista Napotnik, T.; Reberšek, M.; Vernier, P.T.; Mali, B.; Miklavčič, D. Effects of High Voltage Nanosecond Electric Pulses on Eucaryotic Cells (in Vitro): A Systematic Review. Bioelectrochemistry 2016, 110, 1–12. [Google Scholar] [CrossRef]

- Buchmann, L.; Mathys, A. Perspective on Pulsed Electric Field Treatment in the Bio-Based Industry. Front. Bioeng. Biotechnol. 2019, 7, 265. [Google Scholar] [CrossRef]

- Kotnik, T.; Rems, L.; Tarek, M.; Miklavčič, D. Membrane Electroporation and Electropermeabilization: Mechanisms and Models. Annu. Rev. Biophys. 2019, 48, 63–91. [Google Scholar] [CrossRef]

- Chopinet, L.; Batista-Napotnik, T.; Montigny, A.; Rebersek, M.; Teissié, J.; Rols, M.P.; Miklavčič, D. Nanosecond Electric Pulse Effects on Gene Expression. J. Membr. Biol. 2013, 246, 851–859. [Google Scholar] [CrossRef]

- Neal, R.E.; Garcia, P.A.; Robertson, J.L.; Davalos, R.V. Experimental Characterization and Numerical Modeling of Tissue Electrical Conductivity during Pulsed Electric Fields for Irreversible Electroporation Treatment Planning. IEEE Trans. Biomed. Eng. 2012, 59, 1076–1085. [Google Scholar] [CrossRef]

- Garcia, P.A.; Rossmeisl, J.H.; Neal, R.E.; Ellis, T.L.; Davalos, R.V. A Parametric Study Delineating Irreversible Electroporation from Thermal Damage Based on a Minimally Invasive Intracranial Procedure. Biomed. Eng. Online 2011, 10, 34. [Google Scholar] [CrossRef]

- Mi, Y.; Xu, J.; Tang, X.; Bian, C.; Liu, H.; Yang, Q.; Tang, J. Scaling Relationship of In Vivo Muscle Contraction Strength of Rabbits Exposed to High-Frequency Nanosecond Pulse Bursts. Technol. Cancer Res. Treat. 2018, 17, 1533033818788078. [Google Scholar] [CrossRef]

- Guenther, E.; Klein, N.; Mikus, P.; Stehling, M.K.; Rubinsky, B. Electrical Breakdown in Tissue Electroporation. Biochem. Biophys. Res. Commun. 2015, 467, 736–741. [Google Scholar] [CrossRef] [PubMed]

- Rodaite-Riseviciene, R.; Saule, R.; Snitka, V.; Saulis, G. Release of Iron Ions from the Stainless Steel Anode Occurring during High-Voltage Pulses and Its Consequences for Cell Electroporation Technology. IEEE Trans. Plasma Sci. 2014, 42, 249–254. [Google Scholar] [CrossRef]

- Das, M.; Grider, D.; Leslie, S.; Raju, R.; Schutten, M.; Hefner, A. 10 KV SiC Power MOSFETs and JBS Diodes: Enabling Revolutionary Module and Power Conversion Technologies. In Materials Science Forum; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012. [Google Scholar]

- Puc, M.; Čorović, S.; Flisar, K.; Petkovšek, M.; Nastran, J.; Miklavčič, D. Techniques of Signal Generation Required for Electropermeabilization. Survey of Electropermeabilization Devices. Bioelectrochemistry 2004, 64, 113–124. [Google Scholar] [CrossRef] [PubMed]

- Pirc, E.; Reberšek, M.; Miklavčič, D. Dosimetry in Electroporation-Based Technologies and Treatments. In Dosimetry in Bioelectromagnetics; Markov, M., Ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 233–268. [Google Scholar]

- Lucia, O.; Sarnago, H.; Garcia-Sanchez, T.; Mir, L.M.; Burdio, J.M. Industrial Electronics for Biomedicine: A New Cancer Treatment Using Electroporation. IEEE Ind. Electron. Mag. 2019, 13, 6–18. [Google Scholar] [CrossRef]

- Pirc, E.; Miklavčič, D.; Reberšek, M. Nanosecond Pulse Electroporator With Silicon Carbide MOSFETs: Development and Evaluation. IEEE Trans. Biomed. Eng. 2019, 66, 3526–3533. [Google Scholar] [CrossRef]

- Elgenedy, M.A.; Massoud, A.M.; Ahmed, S.; Williams, B.W.; McDonald, J.R. A Modular Multilevel Voltage-Boosting Marx Pulse-Waveform Generator for Electroporation Applications. IEEE Trans. Power Electron. 2019, 34, 10575–10589. [Google Scholar] [CrossRef]

- Sack, M. Marx-Generator Design and Development for Biomass Electroporation. In Handbook of Electroporation; Springer International Publishing: Cham, Switzerland, 2017; pp. 793–812. [Google Scholar]

- Elserougi, A.; Massoud, A.; Ahmed, S. Conceptual Study of a Bipolar Modular High Voltage Pulse Generator with Sequential Charging. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3450–3457. [Google Scholar] [CrossRef]

- Stankevic, V.; Simonis, P.; Zurauskiene, N.; Stirke, A.; Dervinis, A.; Bleizgys, V.; Kersulis, S.; Balevicius, S. Compact Square-Wave Pulse Electroporator with Controlled Electroporation Efficiency and Cell Viability. Symmetry (Basel) 2020, 12, 412. [Google Scholar] [CrossRef]

- Bernal, C.; Lucia, O.; Sarnago, H.; Burdio, J.M.; Ivorra, A.; Castellvi, Q. A Review of Pulse Generation Topologies for Clinical Electroporation. In Proceedings of the IECON 2015—41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 625–630. [Google Scholar]

- Elgenedy, M.A.; Massoud, A.M.; Ahmed, S.; Williams, B.W. A High-Gain, High-Voltage Pulse Generator Using Sequentially Charged Modular Multilevel Converter Submodules, for Water Disinfection Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1394–1406. [Google Scholar] [CrossRef]

- Xiao, S.; Zhou, C.; Yang, E.; Rajulapati, S.R. Nanosecond Bipolar Pulse Generators for Bioelectrics. Bioelectrochemistry 2018, 123, 77–87. [Google Scholar] [CrossRef]

- Butkus, P.; Tolvaisiene, S. The Comparison of Technical Capabilities of Six Pulse Generators for Biological Applications. In Proceedings of the 2019 IEEE 7th IEEE Workshop on Advances in Information, Electronic and Electrical Engineering (AIEEE), Liepaja, Latvia, 15–16 November 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar]

- Rebersek, M.; Miklavcic, D. Advantages and Disadvantages of Different Concepts of Electroporation Pulse Generation. ATKAFF 2011, 52, 11–19. [Google Scholar] [CrossRef]

- Redondo, L.M.S. Basic Concepts of High-Voltage Pulse Generation. In Handbook of Electroporation; Springer International Publishing: Cham, Switzerland, 2017; Volume 2, pp. 859–879. [Google Scholar]

- Behrend, M.; Kuthi, A.; Gu, X.; Vernier, P.T.; Marcu, L.; Craft, C.M.; Gundersen, M.A. Pulse Generators for Pulsed Electric Field Exposure of Biological Cells and Tissues. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 820–825. [Google Scholar] [CrossRef]

- Reberšek, M.; Miklavčič, D.; Bertacchini, C.; Sack, M. Cell Membrane Electroporation-Part 3: The Equipment. IEEE Electr. Insul. Mag. 2014, 30, 8–18. [Google Scholar] [CrossRef]

- Joshi, R.P.; Schoenbach, K.H. Bioelectric Effects of Intense Ultrashort Pulses. Crit. Rev. Biomed. Eng. 2010, 38, 255–304. [Google Scholar]

- Schmitt, M.A.; Friedrich, O.; Gilbert, D.F. Portoporator ©: A Portable Low-Cost Electroporation Device for Gene Transfer to Cultured Cells in Biotechnology, Biomedical Research and Education. Biosens. Bioelectron. 2019, 131, 95–103. [Google Scholar] [CrossRef]

- Rubin, A.E.; Levkov, K.; Usta, O.B.; Yarmush, M.; Golberg, A. IGBT-Based Pulsed Electric Fields Generator for Disinfection: Design and In Vitro Studies on Pseudomonas Aeruginosa. Ann. Biomed. Eng. 2019, 47, 1314–1325. [Google Scholar] [CrossRef]

- Ping, W.; Jiali, B.; Hong, W.; Huiping, W. Multi-Pulse Generator for Electroporation. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology, Cancun, Mexico, 17–21 September 2003. [Google Scholar]

- Elserougi, A.A.; Massoud, A.M.; Ahmed, S. A Modular High-Voltage Pulse-Generator with Sequential Charging for Water Treatment Applications. IEEE Trans. Ind. Electron. 2016, 63, 7898–7907. [Google Scholar] [CrossRef]

- Camp, J.T.; Xiao, S.; Schoenbach, K.H. Development of a High Voltage, 150 Ps Pulse Generator for Biological Applications. In Proceedings of the 2008 IEEE International Power Modulators and High Voltage Conference, PMHVC, Las Vegas, NV, USA, 27–31 May 2008; pp. 338–341. [Google Scholar]

- Foshee, W.G.; Kirkici, H.; Hung, J.Y.; Blythe, E.K.; Goel, A.; Wehtje, G.R. Seedling Emergence of Smallflower Morningglory and Green Foxtail Subjected to a Pulsed Electric Field. Int. J. Veg. Sci. 2007, 13, 61–72. [Google Scholar] [CrossRef]

- Hahn, U.; Herrmann, M.; Leipold, F.; Schoenbach, K.H. Nanosecond, Kilovolt Pulse Generators. In Proceedings of the PPPS 2001—Pulsed Power Plasma Science 2001, Las Vegas, NV, USA, 17–22 June 2001; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2001; Volume 2, pp. 1575–1578. [Google Scholar]

- Sack, M.; Sigler, J.; Frenzel, S.; Eing, C.; Arnold, J.; Michelberger, T.; Frey, W.; Attmann, F.; Stukenbrock, L.; Müller, G. Research on Industrial-Scale Electroporation Devices Fostering the Extraction of Substances from Biological Tissue. Food Eng. Rev. 2010, 2, 147–156. [Google Scholar] [CrossRef]

- Sack, M.; Mueller, G. Design Considerations for Electroporation Reactors. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1992–2000. [Google Scholar] [CrossRef]

- Sack, M.; Sigler, J.; Eing, C.; Stukenbrock, L.; Stängle, R.; Wolf, A.; Müller, G. Operation of an Electroporation Device for Grape Mash. IEEE Tran. Plasma Sci. 2010, 38, 1928–1934. [Google Scholar] [CrossRef]

- Muratori, C.; Pakhomov, A.G.; Xiao, S.; Pakhomova, O.N. Electrosensitization Assists Cell Ablation by Nanosecond Pulsed Electric Field in 3D Cultures. Sci. Rep. 2016, 6, 23225. [Google Scholar] [CrossRef] [PubMed]

- Wandel, A.; Ben-David, E.; Ulusoy, B.S.; Neal, R.; Faruja, M.; Nissenbaum, I.; Gourovich, S.; Goldberg, S.N. Optimizing Irreversible Electroporation Ablation with a Bipolar Electrode. J. Vasc. Interv. Radiol. 2016, 27, 1441–1450.e2. [Google Scholar] [CrossRef] [PubMed]

- Kurcevskis, S.; Grainys, A.; Tolvaisiene, S.; Ustinavicius, T. High Power Electroporation System in Food Treatment—Review. In Proceedings of the 2019 IEEE 7th IEEE Workshop on Advances in Information, Electronic and Electrical Engineering (AIEEE), Liepaja, Latvia, 15–16 November 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar]

- Cronjé, T.F.; Gaynor, P.T. High Voltage and Frequency Bipolar Pulse Generator Design for Electroporation-Based Cancer Therapy. In Proceedings of the 2013 Australasian Universities Power Engineering Conference, AUPEC 2013, Hobart, TAS, Australia, 29 September–3 October 2013; pp. 1–7. [Google Scholar]

- Abdelsalam, I.; Elgenedy, M.A.; Ahmed, S.; Williams, B.W. Full-Bridge Modular Multilevel Submodule-Based High-Voltage Bipolar Pulse Generator with Low-Voltage DC, Input for Pulsed Electric Field Applications. IEEE Trans. Plasma Sci. 2017, 45, 2857–2864. [Google Scholar] [CrossRef]

- Dong, S.; Yao, C.; Mi, Y.; Li, C.; Zhao, Y.; Lv, Y.; Liu, H. Design of Bipolar Pulse Generator Topology Based on Marx Supplied by Double Power. In Proceedings of the 2016 IEEE International Power Modulator and High Voltage Conference, IPMHVC 2016, San Francisco, CA, USA, 6–9 July 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 26–31. [Google Scholar]

- Deshpande, A.; Prakash, G.V.; Goswami, U.; Singh, R.; Anitha, V.P. Implementation of Line Type High Voltage Nanosecond Rectangular Pulse Generator with Adjustable Pulse Widths for Liquid Discharge Applications. In Proceedings of the IEEE International Pulsed Power Conference, Orlando, FL, USA, 23–29 June 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019. [Google Scholar]

- Mi, Y.; Zhang, Y.; Wan, J.; Yao, C.; Li, C. Nanosecond Pulse Generator Based on an Unbalanced Blumlein-Type Multilayered Microstrip Transmission Line and Solid-State Switches. IEEE Trans. Plasma Sci. 2016, 44, 795–802. [Google Scholar] [CrossRef]

- Mi, Y.; Wan, J.; Bian, C.; Zhang, Y.; Yao, C.; Li, C. A Multiparameter Adjustable, Portable High-Voltage Nanosecond Pulse Generator Based on Stacked Blumlein Multilayered PCB Strip Transmission Line. IEEE Trans. Plasma Sci. 2016, 44, 2022–2029. [Google Scholar] [CrossRef]

- Mi, Y.; Bian, C.; Wan, J.; Xu, J.; Yao, C.; Li, C. A Modular Solid-State Nanosecond Pulsed Generator Based on Blumlein-Line and Transmission Line Transformer with Microstrip Line. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2196–2202. [Google Scholar] [CrossRef]

- Romeo, S.; D’Avino, C.; Zeni, O.; Zeni, L. A Blumlein-Type, Nanosecond Pulse Generator with Interchangeable Transmission Lines for Bioelectrical Applications. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1224–1230. [Google Scholar] [CrossRef]

- Kolb, J.F.; Kono, S.; Schoenbach, K.H. Nanosecond Pulsed Electric Field Generators for the Study of Subcellular Effects. Bioelectromagnetics 2006, 27, 172–187. [Google Scholar] [CrossRef]

- Warindi, H.S.P.; Suharyanto, H.G. Impedance Measurement System of a Biological Material Undergoing Pulsed Electric Field Exposed. In Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 170, pp. 410–415. [Google Scholar]

- Rebersek, M.; Kranjc, M.; Pavliha, D.; Batista-Napotnik, T.; Vrtanik, D.; Amon, S.; Miklavi, D. Blumlein Configuration for High-Repetition-Rate Pulse Generation of Variable Duration and Polarity Using Synchronized Switch Control. IEEE Trans. Biomed. Eng. 2009, 56, 2642–2648. [Google Scholar] [CrossRef]

- Lindblom, A. Inductive Pulse Generation. Digit. Compr. Summ. Uppsala Diss. Fac. Sci. Technol. 2006, 159, 93. [Google Scholar]

- Darwish, A.; Elgenedy, M.A.; Finney, S.J.; Williams, B.W.; McDonald, J.R. A Step-up Modular High-Voltage Pulse Generator Based on Isolated Input-Parallel/Output-Series Voltage-Boosting Modules and Modular Multilevel Submodules. IEEE Trans. Ind. Electron. 2019, 66, 2207–2216. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, R.; Zhang, X.; Tu, Z.; Zhang, J. Bipolar High Voltage Pulse Generator without H-Bridge Based on Cascade of Positive and Negative Marx Generators. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 476–483. [Google Scholar] [CrossRef]

- Zeng, W.; Yao, C.; Dong, S.; Wang, Y.; Ma, J.; He, Y.; Yu, L. Self-Triggering High-Frequency Nanosecond Pulse Generator. IEEE Trans. Power Electron. 2020, 35, 8002–8012. [Google Scholar] [CrossRef]

- Novickij, V.; Stankevic, V.; Zurauskiene, N.; Balevicius, S.; Stirke, A.; Dervinis, A.; Bleizgys, V. Nanosecond Square-Wave Pulse Generator for Pulsed Electric Field Treatment of Biological Objects. In Proceedings of the 5th Euro-Asian Pulsed Power Conference, Kumamoto, Japan, 8–12 September 2014; pp. 157–160. [Google Scholar]

- Davies, I.W.; Merla, C.; Casciati, A.; Tanori, M.; Zambotti, A.; Mancuso, M.; Bishop, J.; White, M.; Palego, C.; Hancock, C.P. Push-Pull Configuration of High-Power MOSFETs for Generation of Nanosecond Pulses for Electropermeabilization of Cells. Int. J. Microw. Wirel. Technol. 2019, 11, 645–657. [Google Scholar] [CrossRef]

- Deng, J.; Stark, R.H.; Schoenbach, K.H. Nanosecond Pulse Generator for Intracellular Electromanipulation. In Proceedings of the IEEE Conference Record of Power Modulator Symposium IEEE, Norfolk, VA, USA, 26–29 June 2000; pp. 47–50. [Google Scholar]

- Kolb, J.F.; Scarlett, S.; Cannone, J.; Zhuang, J.; Osgood, C.; Schoenbach, K.H.; De Angelis, A.; Zeni, L. Nanosecond Pulse Generator with Variable Pulse Duration for the Study of Pulse Induced Biological Effects. In Proceedings of the 2008 IEEE International Power Modulators and High-Voltage Conference, Las Vegas, NV, USA, 28–31 May 2008; pp. 61–64. [Google Scholar]

- Pavliha, D.; Reberšek, M.; Miklavčič, D. Design and Quality Assessment of the Graphical User Interface Software of a High-Voltage Signal Generator. Elektroteh. Vestn. 2011, 78, 281–286. [Google Scholar]

- Chuan, L.; Wenchuan, W.; Lin, Z.; Mingjia, L.; Jianhua, Z. Development of 650 KV 2 Ns High Voltage Pulse Generator. High Power Laser Part. Beams 2014, 26, 3–7. [Google Scholar]

- Mi, Y.; Bian, C.; Li, P.; Yao, C.; Li, C. A Modular Generator of Nanosecond Pulses with Adjustable Polarity and High Repetition Rate. IEEE Trans. Power Electron. 2018, 33, 10654–10662. [Google Scholar] [CrossRef]

- Achour, Y.; Starzyński, J.; Kasprzycka, W.; Trafny, E.A. Compact Low-Cost High-Voltage Pulse Generator for Biological Applications. Int. J. Circuit Theory Appl. 2019, 47, 1948–1962. [Google Scholar] [CrossRef]

- He, Y.; Ma, J.; Yu, L.; Dong, S.; Gao, L.; Zeng, W.; Yao, C. 10 MHz High-Power Pulse Generator on Boost Module. IEEE Trans. Ind. Electron. 2020. [Google Scholar] [CrossRef]

- Merla, C.; El Amari, S.; Kenaan, M.; Liberti, M.; Apollonio, F.; Arnaud-Cormos, D.; Couderc, V.; Leveque, P. A 10-Ω High-Voltage Nanosecond Pulse Generator. IEEE Trans. Microw. Theory Tech. 2010, 58, 4079–4085. [Google Scholar] [CrossRef]

- Balevicius, S.; Stankevic, V.; Zurauskiene, N.; Shatkovskis, E.; Stirke, A.; Bitinaite, A.; Saule, R.; Maciuleviciene, R.; Saulis, G. System for the Nanoporation of Biological Cells Based on an Optically-Triggered High-Voltage Spark-Gap Switch. IEEE Trans. Plasma Sci. 2013, 41, 2706–2711. [Google Scholar] [CrossRef]

- Chaney, A.; Sundararajan, R. Simple MOSFET-Based High-Voltage Nanosecond Pulse Circuit. IEEE Trans. Plasma Sci. 2004, 32, 1919–1924. [Google Scholar] [CrossRef]

- Yao, C.; Sun, C.; Mi, Y.; Xiong, L.; Wang, S. Experimental Studies on Killing and Inhibiting Effects of Steep Pulsed Electric Field (SPEF) to Target Cancer Cell and Solid Tumor. IEEE Trans. Plasma Sci. 2004, 32, 1626–1633. [Google Scholar] [CrossRef]

- Sunkam, R.K.; Selmic, R.R.; Haynie, D.T.; Hill, J.S. Solid-State Nanopulse Generator: Application in Ultra-Wideband Bioeffects Research. In Proceedings of the Conference Proceedings—IEEE Southeastcon, Greensboro, NC, USA, 26–29 March 2004; pp. 281–284. [Google Scholar]

- Leveque, P.; Arnaud-Cormos, D. Generators and Applicators for Nanosecond Pulsed Electric Field. In Proceedings of the 6th European Conference on Antennas and Propagation, EuCAP 2012, Prague, Czech Republic, 26–30 March 2012; pp. 351–355. [Google Scholar]

- Krishnaveni, R.S.; Veeraraghavalu, R.; Rangarajan, R. Development of Pef Source in Nanosecond Range for Food Sterilization. J. Electr. Syst. 2015, 11, 407–419. [Google Scholar]

- Novickij, V.; Grainys, A.; Butkus, P.; Tolvaišienė, S.; Švedienė, J.; Paškevičius, A.; Novickij, J. High-Frequency Submicrosecond Electroporator. Biotechnol. Biotechnol. Equip. 2016, 30, 607–613. [Google Scholar] [CrossRef]

- Zajc, A.; Miklavcic, D.; Rebersek, M. Expanding the Power Pulse Duration Range for Electroporation. In Proceedings of the 28th International Conference Electrotechnical and Computer Science, Portorož, Slovenia, 23–24 September 2019. [Google Scholar]

- Krishnaswamy, P.; Kuthi, A.; Vernier, P.T.; Gundersen, M.A. Compact Subnanosecond Pulse Generator Using Avalanche Transistors for Cell Electroperturbation Studies. IEEE Transa. Dielectr. Electr. Insul. 2007, 14, 871–877. [Google Scholar] [CrossRef]

- Mendes, J.P.M.; Canacsinh, H.; Redondo, L.M.; Rossi, J.O. Solid State Marx Modulator with Blumlein Stack for Bipolar Pulse Generation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1199–1204. [Google Scholar] [CrossRef]

- Yao, C.; Zhang, X.; Guo, F.; Dong, S.; Mi, Y.; Sun, C. FPGA-Controlled All-Solid-State Nanosecond Pulse Generator for Biological Applications. IEEE Trans. Plasma Sci. 2012, 40, 2366–2372. [Google Scholar] [CrossRef]

- Sakamoto, T.; Akiyama, H. Solid-State Dual Marx Generator with a Short Pulsewidth. IEEE Trans. Plasma Sci. 2013, 41, 2649–2653. [Google Scholar] [CrossRef]

- Yao, C.; Zhao, Z.; Dong, S.; Zuo, Z. High-Voltage Subnanosecond Pulsed Power Source with Repetitive Frequency Based on Marx Structure. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1896–1901. [Google Scholar] [CrossRef]

- Dong, S.; Yao, C.; Yang, N.; Luo, T.; Zhou, Y.; Wang, C. Solid-State Nanosecond-Pulse Plasma Jet Apparatus Based on Marx Structure with Crowbar Switches. IEEE Trans. Plasma Sci. 2016, 44, 3353–3360. [Google Scholar] [CrossRef]

- Li, C.; Zhang, R.; Yao, C.; Mi, Y.; Tan, J.; Dong, S.; Gong, L. Development and Simulation of a Compact Picosecond Pulse Generator Based on Avalanche Transistorized Marx Circuit and Microstrip Transmission Theory. IEEE Trans. Plasma Sci. 2016, 44, 1907–1913. [Google Scholar] [CrossRef]

- Redondo, L.M.; Kandratsyeu, A.; Barnes, M.J.; Calatroni, S.; Wuensch, W. Solid-State Marx Generator for the Compact Linear Collider Breakdown Studies. In Proceedings of the 2016 IEEE International Power Modulator and High Voltage Conference, IPMHVC 2016, San Francisco, CA, USA, 6–9 July 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 187–192. [Google Scholar]

- Yao, C.; Dong, S.; Zhao, Y.; Mi, Y.; Li, C. A Novel Configuration of Modular Bipolar Pulse Generator Topology Based on Marx Generator with Double Power Charging. IEEE Trans. Plasma Sci. 2016, 44, 1872–1878. [Google Scholar] [CrossRef]

- Yao, C.; Dong, S.; Zhao, Y.; Zhou, Y.; Mi, Y.; Li, C. High-Frequency Composite Pulse Generator Based on Full-Bridge Inverter and Soft Switching for Biological Applications. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2730–2737. [Google Scholar] [CrossRef]

- Li, C.; Wang, E.; Yao, C.; Mi, Y.; Tan, J.; Zhang, R. Compact Solid-State Marx-Bank Sub-Nanosecond Pulse Generator Based on Gradient Transmission Line Theory. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2181–2188. [Google Scholar] [CrossRef]

- Garner, A.L.; Caiafa, A.; Jiang, Y.; Klopman, S.; Morton, C.; Torres, A.S.; Loveless, A.M.; Neculaes, V.B. Design, Characterization and Experimental Validation of a Compact, Flexible Pulsed Power Architecture for Ex Vivo Platelet Activation. PLoS ONE 2017, 12, e0181214. [Google Scholar] [CrossRef]

- Li, C.; Wang, E.; Tan, J.; Zhang, R.; Wang, S.; Yao, C.; Mi, Y. Design and Development of a Compact All-Solid-State High-Frequency Picosecond-Pulse Generator. IEEE Trans. Plasma Sci. 2018, 46, 3249–3256. [Google Scholar] [CrossRef]

- Ke, Q.; Li, C.; Yao, C.; Du, J.; Yao, C.; Mi, Y. Development of Bipolar Nano/Microsecond Pulse Generator. In Proceedings of the 2018 IEEE International Power Modulator and High Voltage Conference, IPMHVC, Jackson, WY, USA, 3–7 June 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 13–16. [Google Scholar]

- Redondo, L.M.; Zahyka, M.; Kandratsyeu, A. Solid-State Generation of High-Frequency Burst of Bipolar Pulses for Medical Applications. IEEE Trans. Plasma Sci. 2019, 47, 4091–4095. [Google Scholar] [CrossRef]

- Zeng, W.; Yu, L.; Dong, S.; Ma, J.; Wang, Y.; He, Y.; Wang, X.; Yao, C. A Novel High Frequency Bipolar Pulsed Power Generator for Biological Applications. IEEE Trans. Power Electron. 2020. [Google Scholar] [CrossRef]

- Kuthi, A.; Gabrielsson, P.; Behrend, M.R.; Vernier, P.T.; Gundersen, M.A. Nanosecond Pulse Generator Using Fast Recovery Diodes for Cell Electromanipulation. IEEE Trans. Plasma Sci. 2005, 33, 1192–1197. [Google Scholar] [CrossRef]

- Tang, T.; Wang, F.; Kuthi, A.; Gundersen, M. Nanosecond Pulse Generator Using Diode Opening Switch for Cell Electroperturbation Studies. In Proceedings of the Digest of Technical Papers-IEEE International Pulsed Power Conference, Monterey, CA, USA, 13–15 June 2007; pp. 1258–1261. [Google Scholar]

- Sanders, J.M.; Kuthi, A.; Wu, Y.H.; Vernier, P.T.; Gundersen, M.A. A Linear, Single-Stage, Nanosecond Pulse Generator for Delivering Intense Electric Fields to Biological Loads. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1048–1054. [Google Scholar] [CrossRef]

- Akiyama, M.; Sakugawa, T.; Hosseini, S.H.R.; Shiraishi, E.; Kiyan, T.; Akiyama, H. High-Performance Pulsed-Power Generator Controlled by FPGA. IEEE Trans. Plasma Sci. 2010, 38, 2588–2592. [Google Scholar] [CrossRef]

- Kranjc, M.; Rebersek, M.; Miklavcic, D. Numerical Simulations Aided Development of Nanosecond Pulse Electroporators. In Proceedings of the 6th European Conference on Antennas and Propagation, EuCAP 2012, Prague, Czech Republic, 26–30 March 2012; pp. 344–347. [Google Scholar]

- Ma, J.; Dong, S.; Liu, H.; Yu, L.; Yao, C. A High-Gain Nanosecond Pulse Generator Based on Inductor Energy Storage and Pulse Forming Line Voltage Superposition. In Proceedings of the IEEE International Pulsed Power Conference, Orlando, FL, USA, 23–29 June 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019. [Google Scholar]

- Dermol-Černe, J.; Pirc, E.; Miklavčič, D. Mechanistic View of Skin Electroporation–Models and Dosimetry for Successful Applications: An Expert Review. Exp. Opin. Drug Deliv. 2020, 17, 689–704. [Google Scholar] [CrossRef]

| Concept | Advantage | Disadvantage | ||

|---|---|---|---|---|

| Direct Capacitor | Non-Modular | Unipolar | Simple and inexpensive construction for systems up to 1 kV; Very flexible pulse shape control in the sub-microsecond–millisecond range; Can operate in a high frequency range. | High-voltage supply required; Amplitude droop during the pulse; High capacity capacitor banks are required for rectangular wave delivery into high loads; Switch must withstand full voltage amplitude or complex synchronization circuits are required in case of array of switches; Not suitable for sub-100 ns pulses. |

| Bipolar | Positive and/or negative high-voltage pulses; Highest pulse forming flexibility; Capability to use asymmetrical pulses; Specific electrotransfer mechanisms can be triggered. | Switch synchronization is needed; Complex control systems; Limited voltage handling capability; Not suitable for sub-100 ns pulses. | ||

| Modular | Applicable with low voltage switches and voltage supplies; Wide flexibility of pulse parameters; Arbitrary signal shape; Easy to achieve high currents; Can operate in high frequency range. | Limited amplitude resolution; Complex control system; Switch synchronization is needed; Not suitable for sub-100 ns pulses. | ||

| Marx Generator | Applicable with low voltage switches and voltage supplies; High voltages up to hundreds of kV; High currents; Can generate sub-100 ns pulses. | Bulky structure; Voltage droop is common when high loads are used; Limited high frequency capability; Electrode degradation in case of spark-gaps. | ||

| Transmission line | Blumlein | Simple design; Commonly used for short pulse generation (sub-100 ns); High-voltages and currents; Can be used for bipolar pulses | Load impedance matching requirement; Pulse width inflexibility (limited to transmission line); Relatively short lifetime; Most of the usual concepts operate in low repetition rate; Big dimensions of the generator. | |

| Inductive Storage | Resonant Circuit | High energy density pulsing can be ensured. | Not applicable for electroporation directly; Parasitic parameters affect the waveform; Switch synchronization is needed; Complex control system. | |

| Diode Opening Switch | High energy density; Accessible electrical components; Variable load impedance; Commonly used for short pulse generation (sub-100 ns); Fast repetition frequency. | Complicated design; Low output power; Switch synchronization is needed; Complex control system; Complex switching and poor control of pulse durations. | ||

| Transformer based | High pulse amplitude; Applicable with low voltage switches; Flexible pulse amplitude. | Transient processes affect pulse waveform; Core saturation and reset after pulse. | ||

| Circuit | Reference | Pulse Form | Pulse Polarity | Pulse Duration | Maximum Amplitude | Repetition Frequency | Switch | Switch Model | Pulse Form and Topology Remarks |

|---|---|---|---|---|---|---|---|---|---|

| Blumlein-type | 2000 [73] | Gaussian | Unipolar | 8 ns | 30 kV | - | Spark gap | - | Pressurized spark gap |

| 2003 [40] | Gaussian | Unipolar | 3–15 ns | >10 kV | - | Spark gap | - | Distorted pulse shape | |

| 2006 [64] | Rectangular | Unipolar | 10 ns | 40 kV | - | Spark gap | - | Distorted pulse shape | |

| 2006 [64] | Rectangular | Unipolar | 10–300 ns | 1 kV | 0–50 MHz | MOSFET | DE375-102N12A | - | |

| 2007 [48] | Gaussian | Unipolar | 50 ns | 65 kV | 10 Hz | Spark gap | - | Distorted pulse shape | |

| 2008 [74] | Rectangular | Unipolar | 8–300 ns | 1 kV | - | MOSFET | DE275-102N06A | - | |

| 2009 [66] | Rectangular | Unipolar and bipolar | 20, 50, 75, 150, and 230 ns | <0.3 kV | 0–1.1 MHz | MOSFET | DE275-102N06A | High pulse amplitude droop | |

| 2011 [75] | - | - | 40–200 ns | 1 kV | 0–100 kHz | - | - | Pulse shape not specified | |

| 2013 [63] | Gaussian | Unipolar and bipolar | 10, 20, 60 ns | 2 kV | - | Transistor | HTS-UF | Distorted pulse shape | |

| 2014 [76] | Gaussian | Bipolar | 2 ns | 650 kV | - | Oil switch | - | Hybrid with resonant | |

| 2016 [60] | Rectangular | Unipolar | 50–100 ns | 2 kV | 0–(~3) kHz | MOSFET | DE475-102N21A | Distorted pulse shape | |

| 2016 [61] | Rectangular | Unipolar | 100 ns | 1.7 kV | 0–(~3) kHz | MOSFET | - | Distorted pulse shape; Modular circuit | |

| 2017 [62] | Gaussian | Unipolar | 20 ns | 2.5 kV | 0–10 kHz | MOSFET | DE475-102N21A | - | |

| 2018 [77] | Gaussian | Unipolar and bipolar | 30 ns | 10 kV | 0–200 kHz | MOSFET | DE475-102N21A | Modular | |

| 2019 [78] | Rectangular | Unipolar | 30 ns | 4 kV | 1 kHz | IGBT and spark gap | IRG4PH50K | Distorted pulse shape; With transformer | |

| 2020 [79] | Rectangular | Unipolar | 5 ns | 0.5 kV | 0–10 MHz | MOSFET | IXZ631DF12N100 | Fixed pulse duration; | |

| Transmission line | 2003 [40] | Gaussian | Unipolar | 150 ns | 12 kV | - | Spark gap | - | Distorted pulse shape |

| 2010 [80] | Rectangular | Bipolar | 2 ns | 1.6 kV | 0–10 Hz | PCSS 1 | - | Distorted pulse shape and laser triggering | |

| 2013 [81] | Rectangular | Bipolar | 10, 40, 60, 92 ns | 12.5 kV | - | Spark gap | - | Laser triggering | |

| 2018 [36] | Rectangular | Bipolar | 10, 60, 300 ns | 10 kV | - | Spark gap | - | Distorted pulse shape; Hybrid with resonant circuit | |

| 2019 [59] | Rectangular | Unipolar | 120, 160, 200, 300, 400 ns | 10 kV | - | Spark gap | - | Distorted pulse shape | |

| Direct capacitor discharge | 2001 [49] | Gaussian | Unipolar | 2 ns | 2.6 kV | - | Spark gap | - | Distorted pulse shape |

| 2003 [40] | Rectangular | Unipolar | 12 ns | 1 kV | - | MOSFET | DE275-501N16A | Distorted pulse shape | |

| 2004 [82] | Rectangular | Unipolar | 75 ns to 10 ms | 0.400 kV | 600 kHz | MOSFET | IXYSRF DE275-501N16A | - | |

| 2004 [83] | Exponential | Unipolar | 100 ns to 100 μs | 0.3 kV | 0–2 kHz | IGBT | - | - | |

| 2004 [84] | Exponential | Unipolar | - | 3.4 kV | 0–1 kHz | BJTs | ZTX415 | Pulse rise time to 2 ns | |

| 2012 [85] | Gaussian | Bipolar | 2.5 ns | 1.66 kV | - | Optoelectronic | - | - | |

| 2014 [71] | Rectangular | Unipolar | 200 ns to 5 μs | 8 kV | 0–30 Hz | MOSFET | HTS 91-12 | - | |

| 2015 [86] | Rectangular | Unipolar | 38 ns to 7 μs | 0.5 kV | - | MOSFET | IRF740 | - | |

| 2016 [87] | Rectangular | Unipolar | 100 ns to 1 ms | 3 kV | 0–1 MHz | MOSFET | C2M0080120D | - | |

| 2019 [72] | Rectangular | Unipolar | 80 ns to 1 μs | 1.4 kV | 0–50 Hz | MOSFET | C2M1000170D | - | |

| 2019 [88] | Rectangular | Unipolar | 80 ns | 0.5 kV | - | MOSFET | - | - | |

| Marx-bank/Modular | 2001 [49] | Gaussian | Unipolar | 6 ns | 6 kV | - | Spark gap and MOSFET | 40N160 | Distorted pulse shape |

| 2007 [48] | Gaussian | Unipolar | 200 ns | 6 kV | - | Spark gap | - | Single pulse | |

| 2007 [89] | Gaussian | Unipolar | 1.3 ns | 1.1 kV | 0–200 kHz | Diode opening | SOT-23 Zetex FMMT417 | - | |

| 2008 [47] | Gaussian | Unipolar | 135–220 ps | 20–120 kV | 0–15 Hz | Peaking | - | - | |

| Marx-bank/Modular (continue) | 2011 [90] | Rectangular | Bipolar | 100 ns | 1 kV | 1 kHz | MOSFET and JFET 2 | - | Hybrid with Blumlein; Distorted pulse shape |

| 2012 [91] | Rectangular | Unipolar | 200 ns to 1 μs | 8 kV | 0–1 kHz | MOSFET | - | - | |

| 2013 [92] | Rectangular | Bipolar | 300 ns to 10 μs | 4 kV | 0–40 kHz | IGBT | IRGPS60B120KDP | - | |

| 2015 [93] | Gaussian | Unipolar | 600 ps | 31.2 kV | - | Spark gap | - | Distorted pulse shape | |

| 2016 [94] | Rectangular | Unipolar | 100 ns to 1 μs | 8 kV | 0–1 kHz | MOSFET | C2M0080120D | - | |

| 2016 [95] | Gaussian | Unipolar | 620 ps | 1 kV | 10 kHz | Avalanche transistors | FMMT417 | Hybrid with microstrip transmission line | |

| 2016 [96] | Rectangular | Unipolar | 200 ns to 100 μs | 10 kV | 0–1 kHz | MOSFET | C2M0280120D | - | |

| 2016 [97] | Rectangular | Bipolar | 100 ns to 1 μs | 3 kV | 0–1 kHz | MOSFET | C2M0080120D | Voltage droop | |

| 2016 [98] | Rectangular | Unipolar and bipolar | 100 ns to 100 μs | 3 kV | 0–2 MHz | MOSFET | C2M0080120D | - | |

| 2017 [99] | Gaussian | Unipolar | 300 ps | 1.6 kV | 0–10 kHz | Avalanche transistors | FMMT417 | Marx with gradient transmission | |

| 2017 [58] | Rectangular | Bipolar | 100 ns to 1 μs | 3 kV | 1 kHz | MOSFET | C2M0080120D | - | |

| 2017 [100] | Gaussian | Unipolar | 400 ns to 20 μs | 6 kV | 0–100 MHz | IGBT | IXYK 120N120C | - | |

| 2018 [101] | Gaussian | Unipolar | 350 ps | 3.1 kV | 0–10 kHz | Avalanche transistors | FMMT417 | - | |

| 2018 [102] | Rectangular | Bipolar | 200 ns to 1 μs | 2 kV | 0–1 kHz | MOSFET | - | - | |

| 2019 [69] | Rectangular | Bipolar | 500 ns to 1 ms | 15 kV | 10 kHz | MOSFET | C2M0160120D | - | |

| 2019 [29] | Gaussian | Unipolar and bipolar | 8 ns | 6 kV | 0–3.5 kHz | MOSFET | IXDD609SI andC2M0025120D | Fixed pulse duration | |

| 2019 [103] | Rectangular | Bipolar | 500 ns to 10 s | 5 kV | 0–0.5 MHz | MOSFET | - | - | |

| 2020 [104] | Rectangular | Bipolar | 500 ns to 5 μs | 10 kV | 0–0.5 MHz | MOSFET | C2M0080120 | - | |

| 2020 [70] | Rectangular | Unipolar | 200 ns to 1 μs | 15.3 kV | 0–10 kHz | MOSFET | C3M0065090J | Integrated with DOS circuit | |

| Inductive storage | 2005 [105] | Gaussian | Unipolar and bipolar | 3.5 ns | 1.2 kV | 0–100 kHz | MOSFET | APT10035JLL | DOS |

| 2007 [106] | Gaussian | Unipolar | 20 ns | 4.5 kV | 20 Hz | IGBT | CM300HA-12H | Distorted pulse shape; DOS with transformers | |

| 2007 [106] | Gaussian | Unipolar | 5 ns | 7.5 kV | 20 Hz | MOSFET | APT10035 | - | |

| 2009 [107] | Gaussian | Unipolar | 5 ns | 4.4 kV | 0–3 MHz | MOSFET | - | Resonant circuit | |

| 2009 [107] | Gaussian | Unipolar | 2.6 ns | 1 kV | 0–3 MHz | MOSFET | - | Resonant circuit | |

| 2010 [108] | Gaussian | Unipolar | 50 ns | 30 kV | 0–0.5 kHz | Magnetic | - | - | |

| 2012 [109] | Gaussian | Unipolar | 50 ns | 1 kV | - | MOSFET | APT37M100L | DOS | |

| 2019 [110] | Rectangular | Unipolar | 23 ns | 8.2 kV | - | MOSFET | C3M0120090J | Hybrid with Blumlein |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butkus, P.; Murauskas, A.; Tolvaišienė, S.; Novickij, V. Concepts and Capabilities of In-House Built Nanosecond Pulsed Electric Field (nsPEF) Generators for Electroporation: State of Art. Appl. Sci. 2020, 10, 4244. https://doi.org/10.3390/app10124244

Butkus P, Murauskas A, Tolvaišienė S, Novickij V. Concepts and Capabilities of In-House Built Nanosecond Pulsed Electric Field (nsPEF) Generators for Electroporation: State of Art. Applied Sciences. 2020; 10(12):4244. https://doi.org/10.3390/app10124244

Chicago/Turabian StyleButkus, Paulius, Arūnas Murauskas, Sonata Tolvaišienė, and Vitalij Novickij. 2020. "Concepts and Capabilities of In-House Built Nanosecond Pulsed Electric Field (nsPEF) Generators for Electroporation: State of Art" Applied Sciences 10, no. 12: 4244. https://doi.org/10.3390/app10124244

APA StyleButkus, P., Murauskas, A., Tolvaišienė, S., & Novickij, V. (2020). Concepts and Capabilities of In-House Built Nanosecond Pulsed Electric Field (nsPEF) Generators for Electroporation: State of Art. Applied Sciences, 10(12), 4244. https://doi.org/10.3390/app10124244