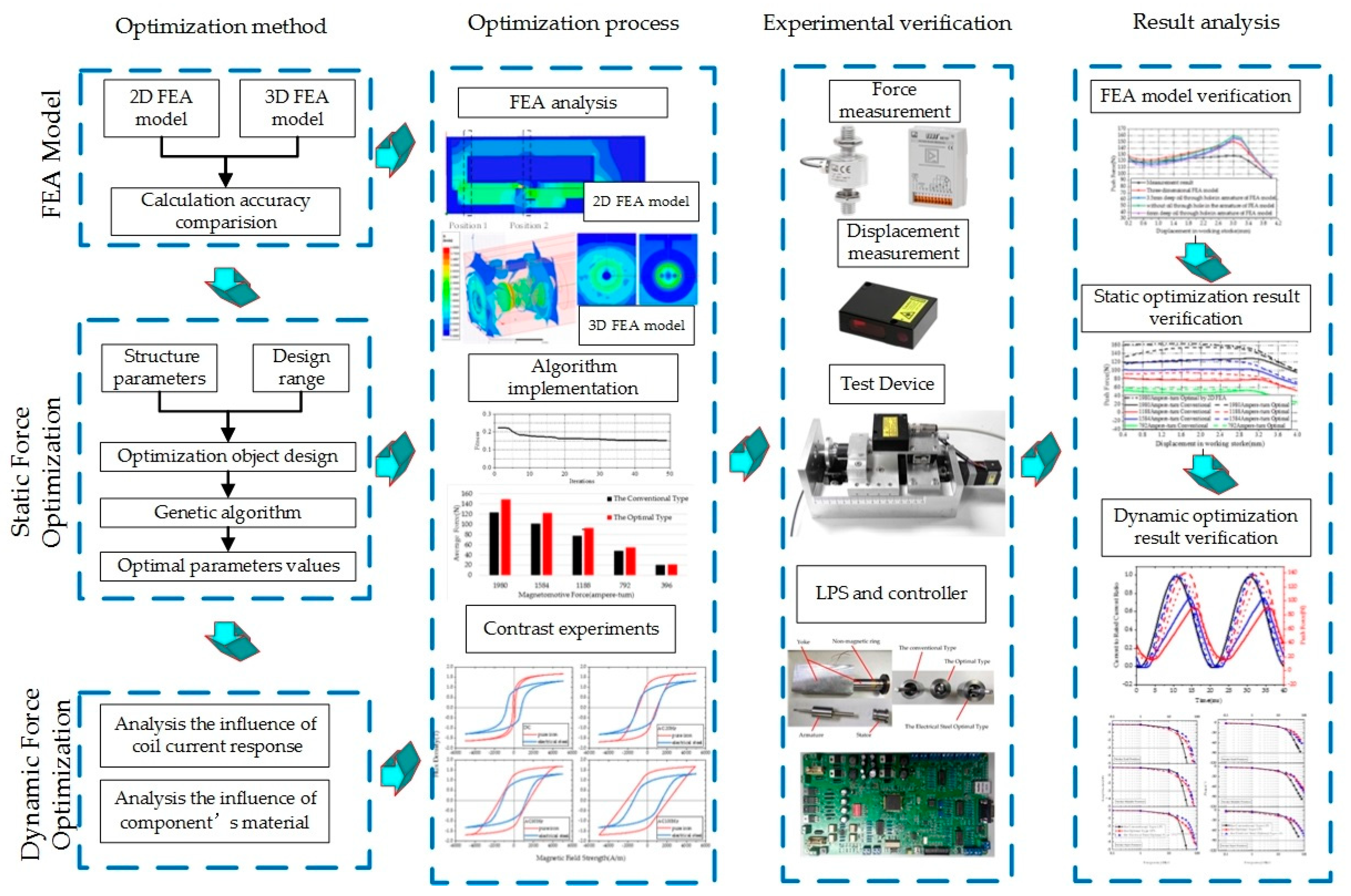

A Performance Improvement Strategy for Solenoid Electromagnetic Actuator in Servo Proportional Valve

Abstract

:1. Introduction

2. Static Performance Optimization of Solenoid Electromagnetic Actuator

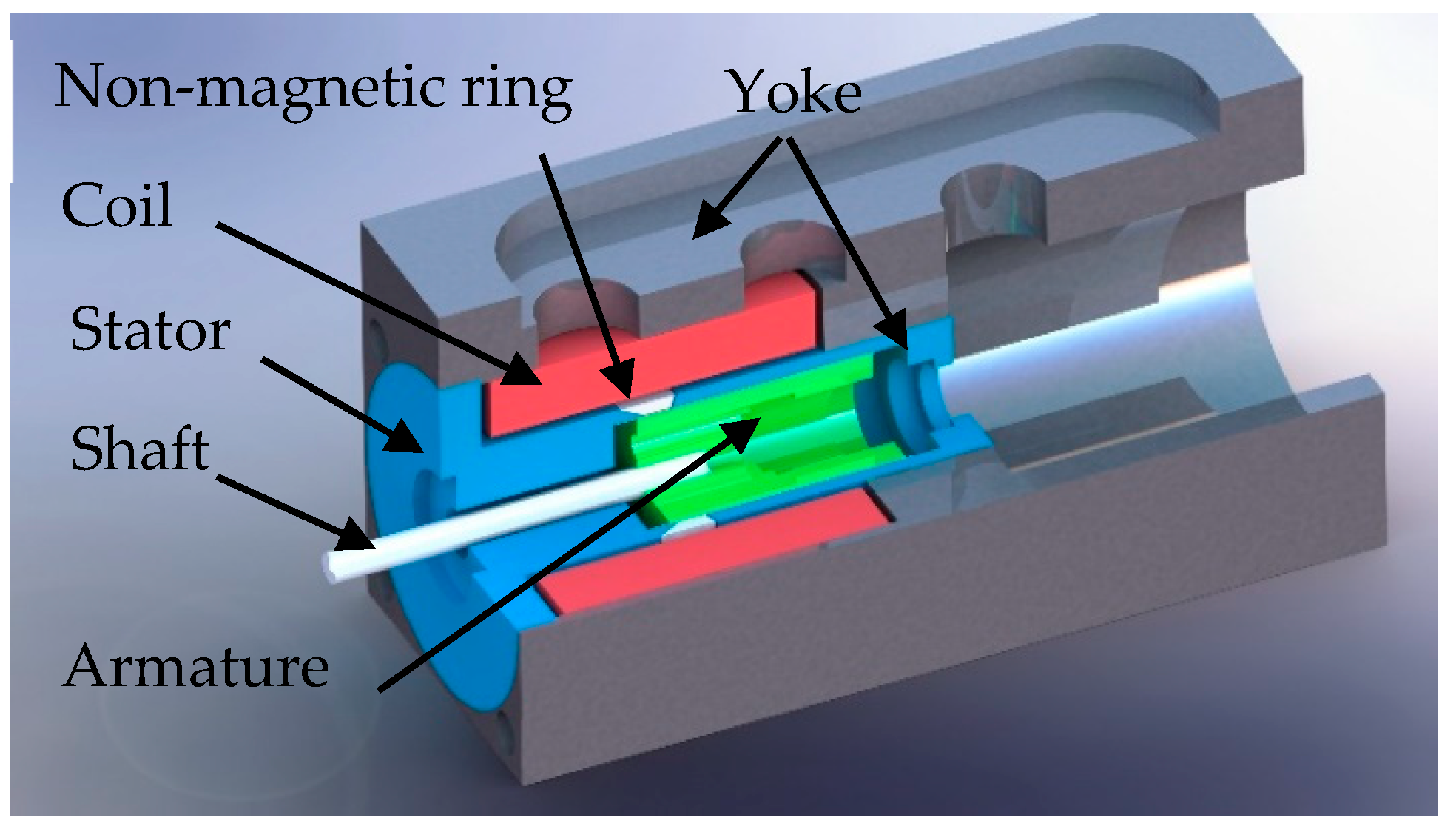

2.1. Structure and Simulation Model

2.2. Multi-Objective Genetic Algorithm Optimization for Structure Parameters of the LPS

2.3. Simulation and the Measurement Results

3. Dynamic Performance Improvement of Solenoid Electromagnetic Actuator

3.1. The Analysis of the Coil Winding Parameters

3.2. The Analysis of the Magnetic Materials

3.3. Dynamic Performance Test

4. Conclusions

- (1)

- An equal yoke cross-sectional area simplified method was proposed in this study to reduce the time cost of the 3D FEA model of the LPS. The simplified 2D FEA model was verified by the comparison of the static push-force versus displacement curves. The simulation result and the measurement result indicated that the simplified 2D FEA model showed equal calculation accuracy with 3D FEA model and the time cost of the 2D FEA model was reduced more than 99.8% by comparison with 3D FEA model.

- (2)

- A multi-objective GA static performance optimization strategy was presented in this study to optimize the shape parameters of the LPS. An optimization fitness was proposed to obtain large push force and guarantee the deviation of the push force in the working stroke and improve the output efficiency (push force to mass ratio). The global optimization result was obtained and the manufactured. According to the comparison results of the manufactured optimal-type LPS and conventional-type LPS, the push force of the optimal-type LPS was increased by 21.8% in the rated current (total 1980 Ampere-turn magnetomotive force). Moreover, in low force requirement states, the optimal-type LPS also illustrated a good static performance.

- (3)

- A dynamic performance improvement strategy of increasing coil rated current was proposed. To certify the performance influence of the coil rated current, a theoretical analysis and an experimental test were employed. Both the theoretical results and test results could validate the advantage of increasing rated current. According to the comparison result of the manufactured optimal-type LPS and conventional-type LPS, the force response frequency of the optimal-type LPS were increased by 73.4%, 52.2% and 57.5%, respectively at start, middle and end position in the working stroke.

- (4)

- In addition, a dynamic performance improvement strategy of replacing magnetic material of the armature was proposed. To verify the influence of the magnetic materials, a theoretical analysis and an experimental test were also employed. Both the theoretical analysis and the experimental tests also validated the advantage of electric steel. According to the comparison results of the manufactured electrical steel optimal-type LPS and conventional-type LPS, the force response frequency of the electrical steel optimal type increased by 129.1%, 79.6% and 74.3%, respectively at start, middle and end position in the working stroke.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sefkat, G. The design optimization of the electromechanical actuator. Struct. Multidisc. Optim. 2009, 37, 635–644. [Google Scholar] [CrossRef]

- Meng, F.; Chen, H.; Liu, H.; Han, B.; Nie, X. The optimisation of a proportional solenoid valve design for heavy vehicle active suspension system. Int. J. Vehicle Des. 2015, 68, 180–200. [Google Scholar] [CrossRef]

- Wang, L.; Li, G.; Xu, C.; Xi, X.; Wu, X.; Sun, S.P. Effect of characteristic parameters on the magnetic properties of solenoid valve for high-pressure common rail diesel engine. Energy Convers. Manag. 2016, 127, 656–666. [Google Scholar] [CrossRef]

- Chen, C.; Chiang, M. Development of Proportional Pressure Control Valve for Hydraulic Braking Actuator of Automobile ABS. Appl. Sci. 2018, 8, 639. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Liu, J.; Ye, D.; Chen, Y.; Lu, P. Multiobjective optimal design and soft landing control of an electromagnetic valve actuator for a camless engine. IEEE-ASME Trans. Mechatron. 2013, 18, 963–972. [Google Scholar] [CrossRef]

- Yoon, S.; Hur, J.; Chun, Y.; Hyun, D. Shape optimization of solenoid actuator using the finite element method and numerical optimization technique. IEEE Trans. Ind. Electron. 1997, 33, 4140–4142. [Google Scholar] [CrossRef]

- Yang, W.; Guo, J.; Liu, Y.; Zhai, G. Multi-Objective Optimization of Contactor’s Characteristics Based on RBF Neural Networks and Hybrid Method. IEEE Trans. Magn. 2019, 99, 1–4. [Google Scholar] [CrossRef]

- Shin, Y.; Lee, S.; Choi, C. Shape Optimization to Minimize the Response Time of Directacting Solenoid Valve. J. Magn. 2015, 20, 193–200. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Fan, L.; Zhou, W.; Ma, X.; Song, E. Dynamic performances analysis and optimization of novel high-speed electromagnetic actuator for electronic fuel injection system of diesel engine. J. Mech. Sci. Technol. 2017, 31, 4019–4028. [Google Scholar] [CrossRef]

- Plavec, E. Genetic Algorithm Based Plunger Shape Optimization of DC Solenoid Electromagnetic Actuator. In Proceedings of the IEEE TELFOR, Belgrade, Serbia, 22–23 November 2016. [Google Scholar] [CrossRef]

- Park, C.; Lim, B.; Chung, K. Design verification methodology for a solenoid valve for industrial applications. J. Mech. Sci. Technol. 2015, 29, 677–686. [Google Scholar] [CrossRef]

- Yamada, H.; Kihara, S.; Yamaguchi, M.; Nakagawa, H.; Hagiwara, K. Static thrust improvement of a linear proportional solenoid. J. Magn. Soc. Jpn. 1994, 9, 117–121. [Google Scholar] [CrossRef]

- Hung, N.; Lim, O. Improvement of Electromagnetic Force and Dynamic Response of a Solenoid Injector Based on the Effects of Key Parameters. Int. J. Automot. Technol. 2019, 20, 949–960. [Google Scholar] [CrossRef]

- Li, S.; Nehl, T.; Gopalakrishnan, S.; Omekanda, A.; Namuduri, C.; Prasad, R. A Dynamic Solenoid Model for Fuel Injectors. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018. [Google Scholar] [CrossRef]

- Tao, G.; Chen, H.; J, Y.; He, Z. Optimal design of the magnetic field of a high-speed response solenoid valve. J. Mater. Process. Tech. 2002, 129, 555–558. [Google Scholar] [CrossRef]

- Cai, B.; Liu, Y.; Tian, X.; Wang, Z.; Wang, F.; Li, H.; Ji, R. Optimization of Submersible Solenoid Valves for Subsea Blowout Preventers. IEEE Trans. Magn. 2011, 47, 451–458. [Google Scholar] [CrossRef]

- Sun, Z.; Li, G.; Wang, L. Effects of structure parameters on the static electromagnetic characteristics of solenoid valve for an electronic unit pump. Energy Convers. Manag. 2016, 113, 119–130. [Google Scholar] [CrossRef]

- Lee, H.; Ahn, J.; Kim, H. Design of a Solenoid Actuator for a Cylinder Valve in a Fuel Cell Vehicle. Appl. Sci. 2016, 6, 288. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Wang, M.; Wang, Z.; Grekhov, L.; Qiu, T.; Ma, X. Different boost voltage effects on the dynamic response and energy losses of high-speed solenoid valves. Appl. Therm. Eng. 2017, 123, 1494–1503. [Google Scholar] [CrossRef]

- Lee, S.; Yi, H.; Han, K.; Kim, J. Genetic Algorithm-Based Design Optimization of Electromagnetic Valve Actuators in Combustion Engines. Energies 2015, 8, 13222–13230. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, X.; Li, C.; Jiao, Z.; Qu, Y. Multiobjective optimization of a hollow plunger type solenoid for high speed on/off valve. IEEE Trans. Ind. Electron. 2017, 65, 3115–3124. [Google Scholar] [CrossRef]

- Wang, X.; Quan, L.; Luan, S. Dynamic and Static Characteristics of Double Push Rods Electromechanical Converter. Chin. J. Mech. Eng. 2019, 32, 62. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Q.; Zhang, Z.; Xie, N. Power losses and dynamic response analysis of ultra-high speed solenoid injector within different driven strategies. Appl. Therm. Eng. 2015, 91, 611–621. [Google Scholar] [CrossRef]

| Key Parameter and Key Characteristic | Range of the Design Parameter (mm) | Conventional Type LPS | Optimal Type LPS | Electrical Steel Optimal Type LPS |

|---|---|---|---|---|

| length of the armature—a1 | 25 mm–34.4 mm | 31.4 mm | 32.3 mm | 33.2 mm |

| radius of the armature—a2 | correlated to c2 and y6 | 9.02 mm | 9.65 mm | 10.15 mm |

| depth of the spring hole—a3 | 4 mm–20 mm | 16.9 mm | 4.7 mm | 8 mm |

| thickness of the spring hole sleeve—a4 | 3 mm–8 mm | 4.5 mm | 5.2 mm | 4.5 mm |

| thickness of the stator—y1 | 4 mm–8 mm | 5.5 mm | 5.5 mm | 4.9 mm |

| non-magnetic ring—y2 | 3.5 mm–3.9 mm | 3.7 mm | 3.6 mm | 3.7 mm |

| non-magnetic ring—y3 | 1.5 mm–5 mm | 3 mm | 2.5 mm | 3.3 mm |

| non-magnetic ring—y4 | 3 mm–6 mm | 3.9 mm | 3.4 mm | 3.3 mm |

| non-magnetic ring—y5 | 1 mm–3 mm | 1 mm | 2.6 mm | 2.2 mm |

| thickness of the armature sleeve—y6 | 1.5 mm–3 mm | 2 mm | 2.3 mm | 1.9 mm |

| length of the coil—c1 | correlated to c1 | 8.2 mm | 7.7 mm | 7.6 mm |

| thickness of the coil—c2 | 6 mm–8.5 mm | 41.5 mm | 43.8 mm | 44.6 mm |

| moving mass | 85.8 g | 99.1 g | 112.1 g | |

| rated average force | 123.4 N | 149.6 N | 131.3 N | |

| force response frequency | 32.7 Hz | 52.8 Hz | 57.0 Hz |

| Position | Conventional Type LPS | Optimal Type LPS | Electrical Steel Optimal Type LPS |

|---|---|---|---|

| start position | 31.6 Hz | 54.8 Hz | 72.4 Hz |

| middle position | 34.7 Hz | 52.8 Hz | 62.3 Hz |

| end position | 32.7 Hz | 51.5 Hz | 57.0 Hz |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Weng, Z.; Jin, B. A Performance Improvement Strategy for Solenoid Electromagnetic Actuator in Servo Proportional Valve. Appl. Sci. 2020, 10, 4352. https://doi.org/10.3390/app10124352

Wang S, Weng Z, Jin B. A Performance Improvement Strategy for Solenoid Electromagnetic Actuator in Servo Proportional Valve. Applied Sciences. 2020; 10(12):4352. https://doi.org/10.3390/app10124352

Chicago/Turabian StyleWang, Shijie, Zhidan Weng, and Bo Jin. 2020. "A Performance Improvement Strategy for Solenoid Electromagnetic Actuator in Servo Proportional Valve" Applied Sciences 10, no. 12: 4352. https://doi.org/10.3390/app10124352