Impact of Tungsten on Thermomechanically Induced Precipitation of Laves Phase in High Performance Ferritic (HiperFer) Stainless Steels

Abstract

:1. Motivation and Introduction

2. Experimental Procedure

2.1. Alloy Modelling and Manufacturing

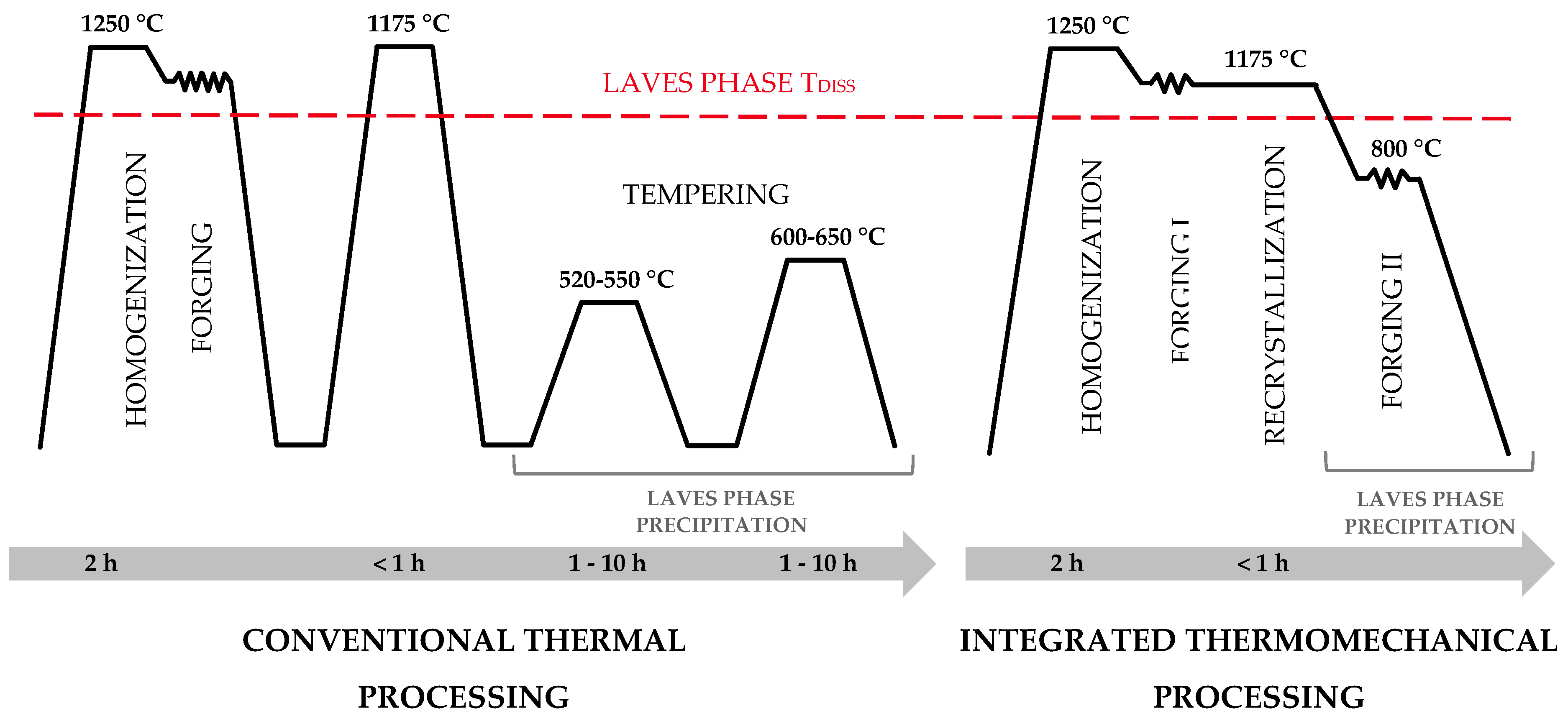

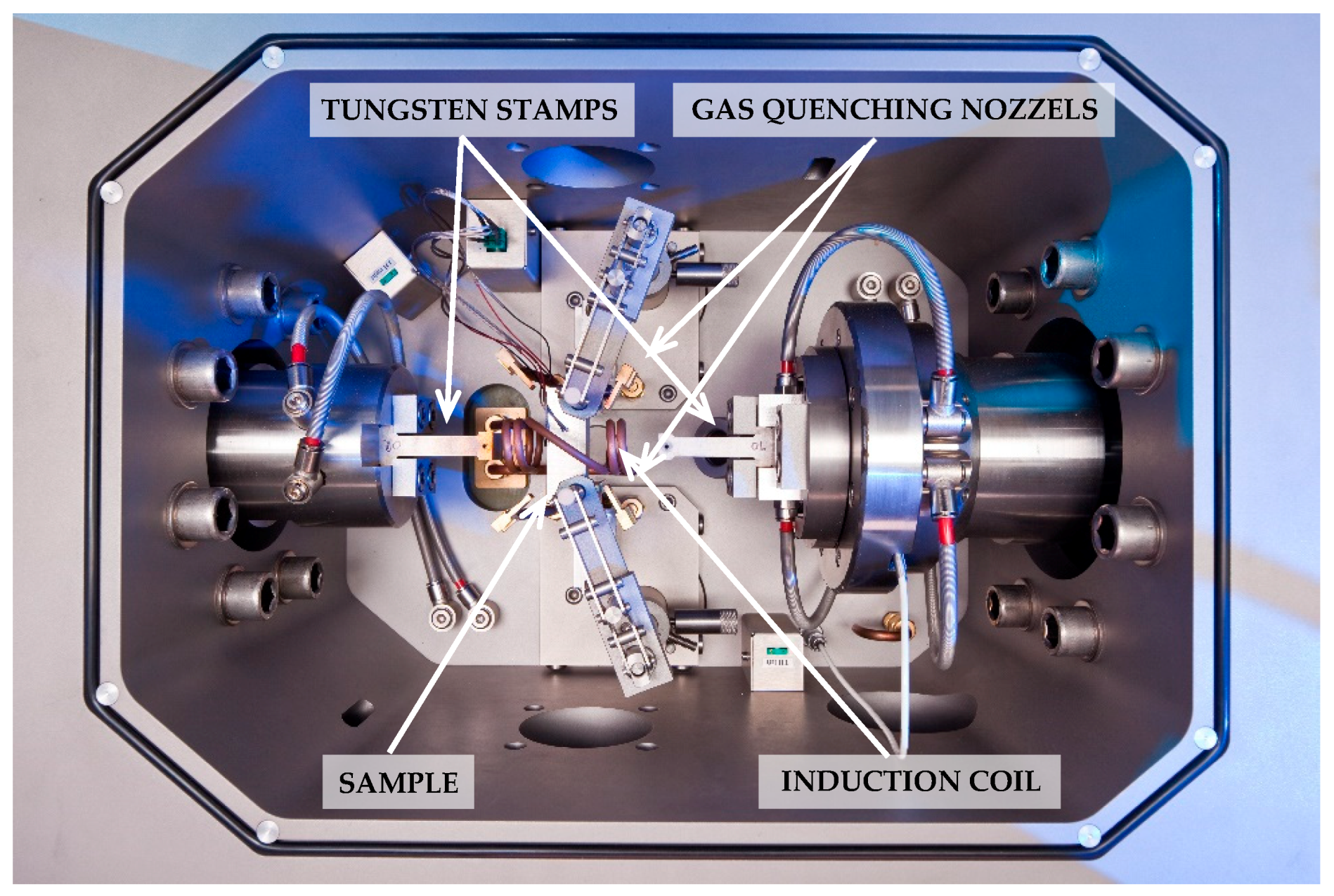

2.2. Thermomechanical Treatment

2.3. Mechanical Testing

2.4. Microstructural Investigation

3. Results and Discussion

3.1. Alloy Design

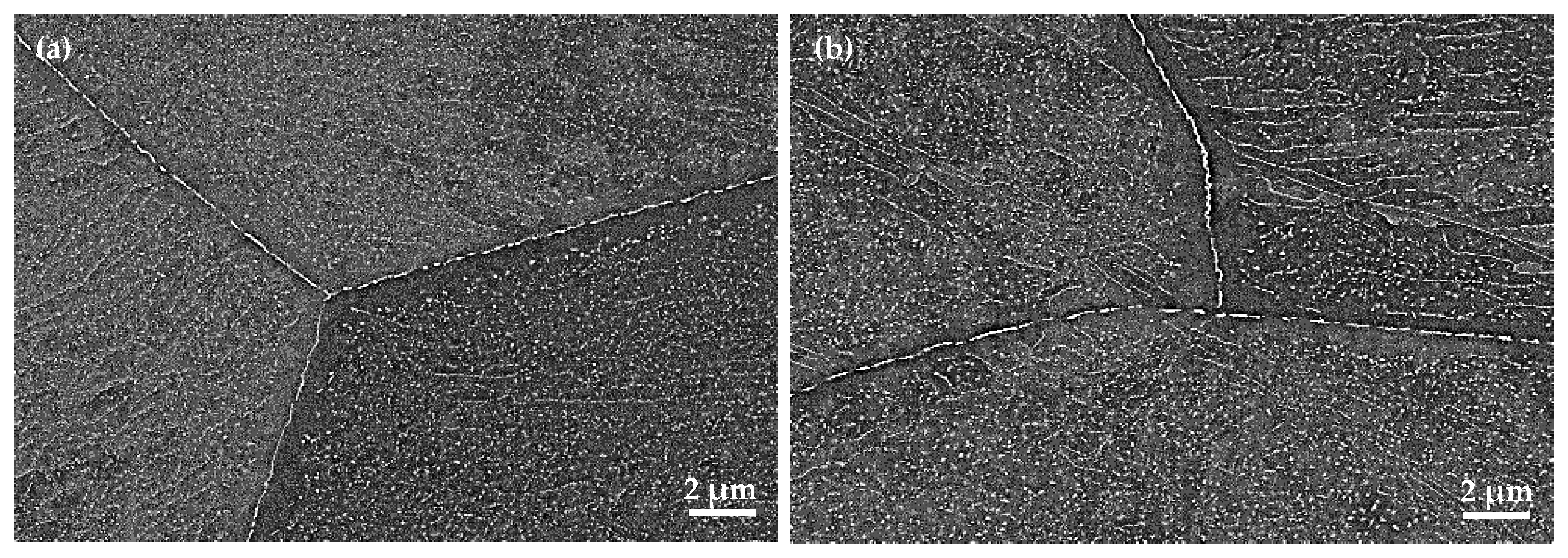

3.2. Effect of Tungsten Addition on Laves Phase Precipitation

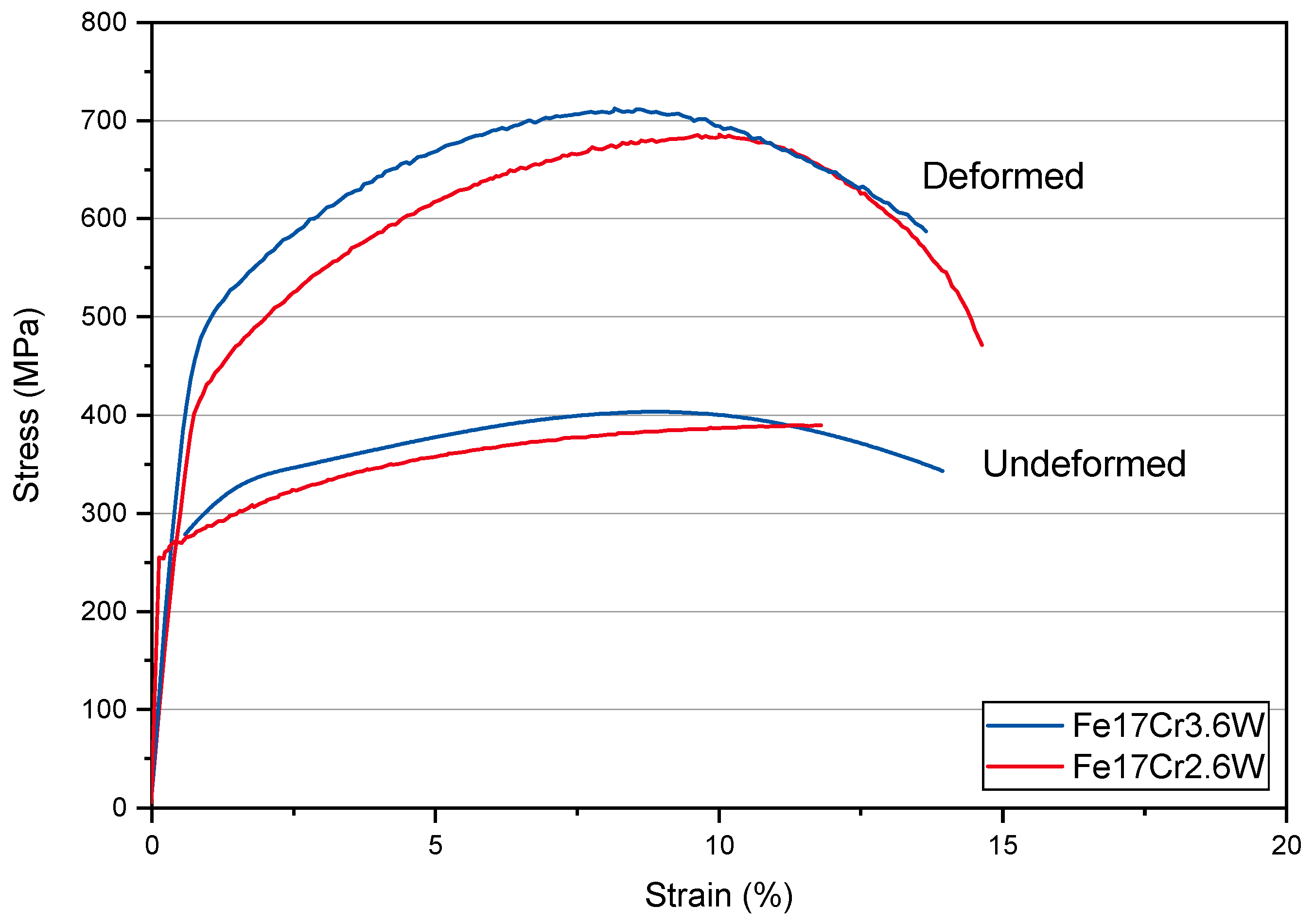

3.3. Tensile Properties

4. Conclusions

- A fine and homogeneous thermomechanically induced precipitation of the Laves phase in fully ferritic steels is possible and can be controlled by the selection of the deformation parameters. The targeted and fast precipitation within a few minutes during thermomechanical treatment could replace the conventional two-step tempering treatment to precipitate the Laves phase, which takes several hours. As a result, the integrated thermomechanical process opens up a new, more effective, and more economical processing route for high-performance ferritic (HiperFer) stainless steels.

- Tungsten, as the main Laves phase-forming element, is necessary for the desired Laves phase precipitation. In both investigated model alloys with respective tungsten contents of 2.6 wt. % (Fe17Cr2.6W) and 3.6 wt. % (Fe17Cr3.6W), the precipitation of the fine and homogeneous dispersed strengthening Laves phase was achieved. Corresponding to the precipitation strengthening, an increase in yield and ultimate tensile strength of approximately 200 MPa was achieved in comparison to the particle-free, undeformed state. The 1 wt. % higher tungsten content in the Fe17Cr3.6W alloy results in approximately 30 MPa higher strength values caused by the higher phase fraction of the Laves phase.

- The amount of expensive tungsten is directly related to the total production costs of the alloy. Corresponding to the results, 2.6 wt. % of tungsten is sufficiently beneficial for the desired strengthening effect at ambient temperature. Moreover, a further increase to 3.6 wt.% did not cause significant progress in yield strength or in ultimate tensile strength.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zurek:, J.; Debruycker, E.; Huymans, S.; Quadakkers, W.J. Steam Oxidation of 9–12% Cr Steels: Critical Evaluation and Implications for Practical Applikation. In Proceedings of the 9th Liége Conference on Materials for Advanced Power Engineering, Liége, Belgium, 27–29 Septemper 2010; pp. 1182–1190. [Google Scholar]

- Quadakkers, W.J.; Ennis, P.J.; Zurek, J.; Michalik, M. Steam Oxidation of Ferritic Steels—Laboratory Test Kinetic Data. Mater. High Temp. 2004, 22, 37–47. [Google Scholar]

- Essuman, E.; Meier, G.H.; Zurek, J.; Hänsel, M.; Singheiser, L.; Quadakkers, W.J. Enhanced internal oxidation as trigger for breakaway oxidation of Fe–Cr alloys in gases containing water vapor. Scr. Mater. 2007, 57, 845–848. [Google Scholar] [CrossRef]

- Viswanathan, R.; Bakker, W. Materials for Ultrasupercritical Coal Power Plants-Boiler Materials: Part 1. J. Mater. Eng. Perform. 2001, 10, 81–95. [Google Scholar] [CrossRef]

- Cottis, B.; Graham, M.; Lindsay, R.; Lyon, S.; Richardson, T.; Scantlebury, D.; Scott, H. Shreir’s Corrosion; Elsevier: Amsterdam, The Netherlands, 2010; Volume 1, pp. 407–456. [Google Scholar]

- Mayer, K.H. Statusreport: Werkstoffentwicklung zur Effizienzsteigerung von fossilen Kraftwerken; Stahlinstitut VDEh: Düsseldorf, Germany, 2006. [Google Scholar]

- Danielsen, H.K.; Hald, J. Behaviour of Z phase in 9–12% Cr steels. Energy Mater. 2006, 1, 49–57. [Google Scholar] [CrossRef]

- Danielsen, H.K.; Hald, J. Influence of Z phase on long-term creep stability of martensitic 9 to 12% Cr-steels. VGB PowerTech 2009, 5, 68–73. [Google Scholar]

- Knežević, V.; Balun, J.; Sauthoff, G.; Inden, G.; Schneider, A. Design of martensitic/ferritic heat-resistant steels for application at 650 °C with supporting thermodynamic modelling. Mater. Sci. Eng. A 2008, 477, 334–343. [Google Scholar] [CrossRef]

- Hald, J.; Korcakova, L. Precipitate stability in creep resistant ferritic steels. In Proceedings of the MPA-NIMS-Workshop–Modern 9–12% Cr-Steels for Power Plant Application, Stuttgart, Germany, 10–11 October 2002. [Google Scholar]

- Danielsen, H.K. Precipitation process of Z phase in 9–12%Cr steels. In Proceedings of the 7th International Conference on Advances in Materials Technology for Fossil Power Plants, Waikoloa, HI, USA, 22–25 October 2013; pp. 1104–1116. [Google Scholar]

- Kern, T.; Mayer, K.H.; Donth, B.; Zeiler, G.; Digianfrancesco, A. The European Efforts in Development of New High Temperature Rotor Materials–COST 536. In Proceedings of the 9th Liége Conference on Materials for Advanced Power Engineering, Liége, Belgium, 27–29 Septemper 2010; pp. 27–36. [Google Scholar]

- Scarlin, B.; Kern, T.U.; Staubli, M. The European efforts in matererial development for 650 °C USC power plants–COST 522. In Proceedings of the 4th International Conference on Advances in Materials Technology for Fossil Power Plants, Hilton Head Island, SC, USA, 25–28 October 2004; pp. 80–99. [Google Scholar]

- Kotecki, D.J.; Siewert, T.A. WRC-1992 constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram. Weld. J. 1992, 71, 171–178. [Google Scholar]

- Toda, Y.; Tohyama, H.; Kushima, H.; Kimura, K.; Abe, F. Influence of Chemical Composition and Heat Treatment Condition on Impact Toughness of 15Cr Ferritic Creep Resistant Steel. JSME Int. J. Ser. A 2005, 48, 125–131. [Google Scholar] [CrossRef] [Green Version]

- Toda, Y.; Seki, K.; Kimura, K.; Abe, F. Effects of W and Co on Long-term Creep Strength of Precipitation Strengthened 15Cr Ferritic Heat Resistant Steels. ISIJ Int. 2003, 43, 112–118. [Google Scholar] [CrossRef] [Green Version]

- Froitzheim, J.; Meier, G.H.; Niewolak, L.; Ennis, P.; Hattendorf, H.; Singheiser, L.; Quadakkers, W.J. Development of high strength ferritic steel for interconnect application in SOFCs. J. Power Sour. 2008, 178, 163–173. [Google Scholar] [CrossRef]

- Kuhn, B.; Jimenez, C.A.; Niewolak, L.; Hüttel, T.; Beck, T.; Hattendorf, H.; Singheiser, L.; Quadakkers, W.J. Effects of Laves Phase Strengthening on the mechanical Properties of High Cr Ferritic Steels for Solid Oxide Fuell Cell Interconnect Application. Mater. Sci. Eng. A 2011, 528, 5888–5899. [Google Scholar] [CrossRef]

- Kuhn, B.; Talik, M.; Niewolak, L.; Zurek, J.; Hattendorf, H.; Ennis, P.; Quadakkers, W.J.; Beck, T.; Singheiser, L. Development of high chromium ferritic steels strengthened by intermetallic phases. Mater. Sci. Eng. A 2014, 594, 372–380. [Google Scholar] [CrossRef]

- Kuhn, B.; Talik, M.; Fischer, T.; Fan, X.; Yamamoto, Y.; Barrilao, J.L. Science and Technology of High Performance Ferritic (HiperFer) Stainless Steels. Metals 2020, 10, 463. [Google Scholar] [CrossRef] [Green Version]

- Lukas, H.L.; Fries, S.G.; Sundman, B. Computational Thermodynamics: The CALPHAD Method; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Thermo-Calc Software. Thermo-Calc–User’s Guide; Thermo-Calc Software: Stockholm, Sweden, 2016. [Google Scholar]

- Barrilao, J.L.; Kuhn, B.; Wessel, E.; Talík, M. Microstructure of intermetallic particle strengthened high-chromium fully ferritic steels. Mater. Sci. Technol. 2016, 33, 1056–1064. [Google Scholar] [CrossRef]

- Lopez Barrilao, J.K. Microstructure Evolution of Laves Phase Strengthened Ferritic Steels for High Temperature Application. Ph.D. Thesis, RWTH Aachen University-FZ Jülich, Aachen, Germany, 2016. [Google Scholar]

- Barrilao, J.L.; Kuhn, B.; Wessel, E. Identification, size classification and evolution of Laves phase precipitates in high chromium, fully ferritic steels. Micron 2017, 101, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Kuhn, B.; Talík, M.; Lopez Barrilao, J.; Singheiser, L.; Yamamoto, Y. Development Status of High Performance Ferritic (HiperFer) Steels. In Proceedings of the 8th International Conference on Advances in Materials Technology for Fossil Power Plants, Algarve, Portugal, 10–14 October 2016. [Google Scholar]

- Kato, Y.; Ito, M.; Kato, Y.; Furukimi, O. Effect of Si on Precipitation Behaviour of Nb-Laves Phase and Amount of NB in Solid Solution at Elevated Temperature in High Purity 17%Cr-0.5%Nb Steels. Mater. Trans. 2010, 51, 1531–1535. [Google Scholar] [CrossRef] [Green Version]

- Aghajani, A.; Richter, F.; Somsen, C.; Fries, S.; Steinbach, I.; Eggeler, G. On the formation and growth of Mo-rich Laves phase particles during long-term creep of a 12% chromium tempered martensite ferritic steel. Scr. Mater. 2009, 61, 1068–1071. [Google Scholar] [CrossRef]

- Kuhn, B.; Talík, M.; Li, C.; Zurek, J.; Quadakkers, W.J.; Beck, T.; Singheiser, L. Development of Creep- and Corrosion-Resistance Steels for Future Steam Power Plants. In Proceedings of the International VDI Conference on “Alloys in Power Plant Technology”, Berlin, Germany, 12–13 June 2012. [Google Scholar]

- Isik, M.; Kostka, A.; Eggeler, G. On the nucleation of Laves phase particles during high-temperature exposure and creep of tempered martensite ferritic steels. Acta Mater. 2014, 81, 230–240. [Google Scholar] [CrossRef]

- Nabiran, N.; Klein, S.; Weber, S.; Theisen, W. Evolution of the Laves Phase in Ferritic Heat-Resistant Steels During Long-term Annealing and its Influence on the High-Temperature Strength. Metall. Mater. Trans. A 2014, 46, 102–114. [Google Scholar] [CrossRef]

- Talík, M. Influence of Initial Thermomechanical Treatment on High Temperature Properties of Laves Phase Strengthened Ferritic Steels. Ph.D. Thesis, RWTH Aachen University-FZ Jülich, Aachen, Germany, 2016. [Google Scholar]

| Model Alloy | C | Si | Mn | Cr | Nb | W |

|---|---|---|---|---|---|---|

| Fe17Cr2.6W | 0.0021 | 0.25 | 0.19 | 17.1 | 0.99 | 2.6 |

| Fe17Cr3.6W | 0.0043 | 0.25 | 0.21 | 17.1 | 1.01 | 3.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pöpperlová, J.; Fan, X.; Kuhn, B.; Bleck, W.; Krupp, U. Impact of Tungsten on Thermomechanically Induced Precipitation of Laves Phase in High Performance Ferritic (HiperFer) Stainless Steels. Appl. Sci. 2020, 10, 4472. https://doi.org/10.3390/app10134472

Pöpperlová J, Fan X, Kuhn B, Bleck W, Krupp U. Impact of Tungsten on Thermomechanically Induced Precipitation of Laves Phase in High Performance Ferritic (HiperFer) Stainless Steels. Applied Sciences. 2020; 10(13):4472. https://doi.org/10.3390/app10134472

Chicago/Turabian StylePöpperlová, Jana, Xiuru Fan, Bernd Kuhn, Wolfgang Bleck, and Ulrich Krupp. 2020. "Impact of Tungsten on Thermomechanically Induced Precipitation of Laves Phase in High Performance Ferritic (HiperFer) Stainless Steels" Applied Sciences 10, no. 13: 4472. https://doi.org/10.3390/app10134472

APA StylePöpperlová, J., Fan, X., Kuhn, B., Bleck, W., & Krupp, U. (2020). Impact of Tungsten on Thermomechanically Induced Precipitation of Laves Phase in High Performance Ferritic (HiperFer) Stainless Steels. Applied Sciences, 10(13), 4472. https://doi.org/10.3390/app10134472