A Workspace Visualization Method for a Multijoint Industrial Robot Based on the 3D-Printing Layering Concept

Abstract

1. Introduction

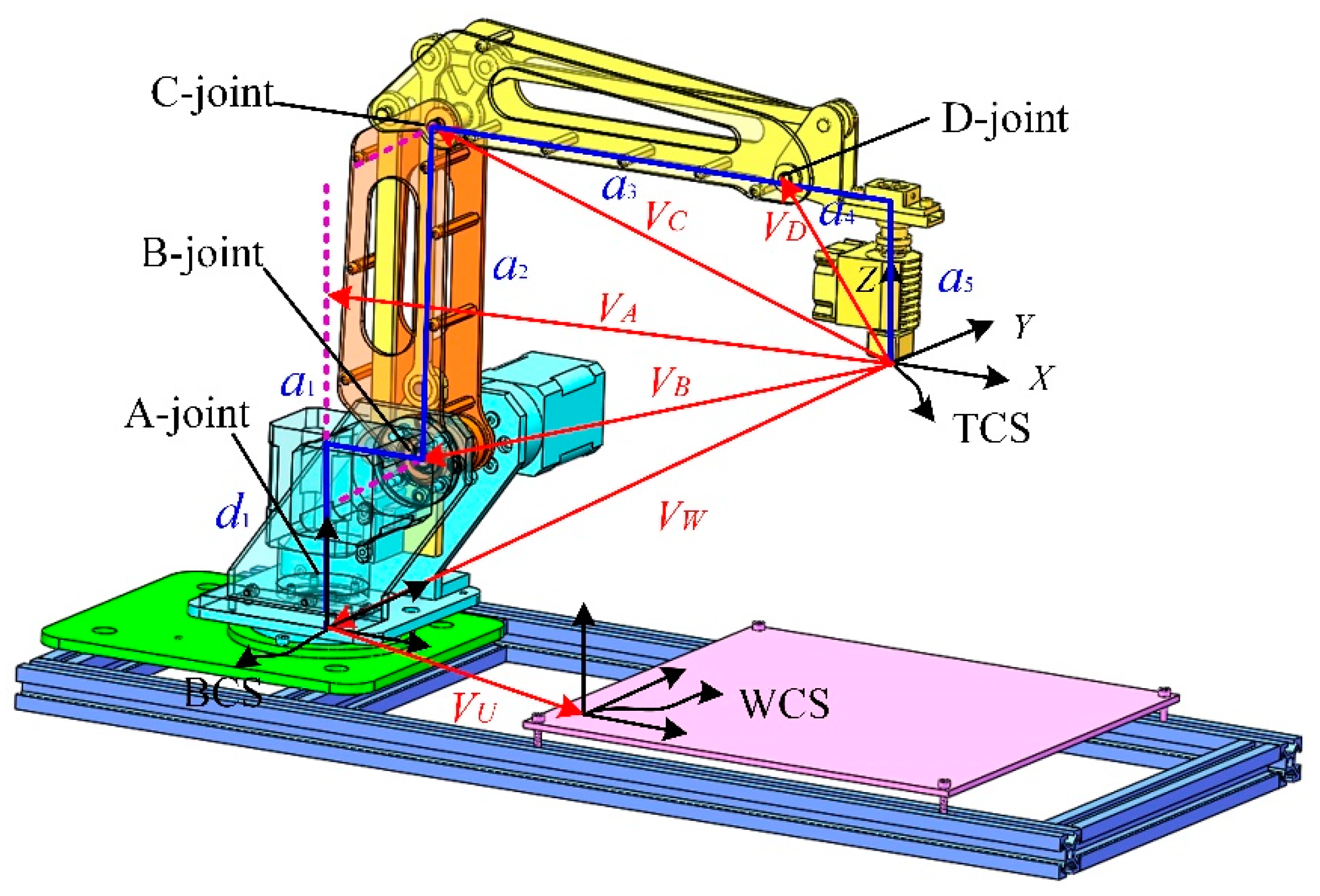

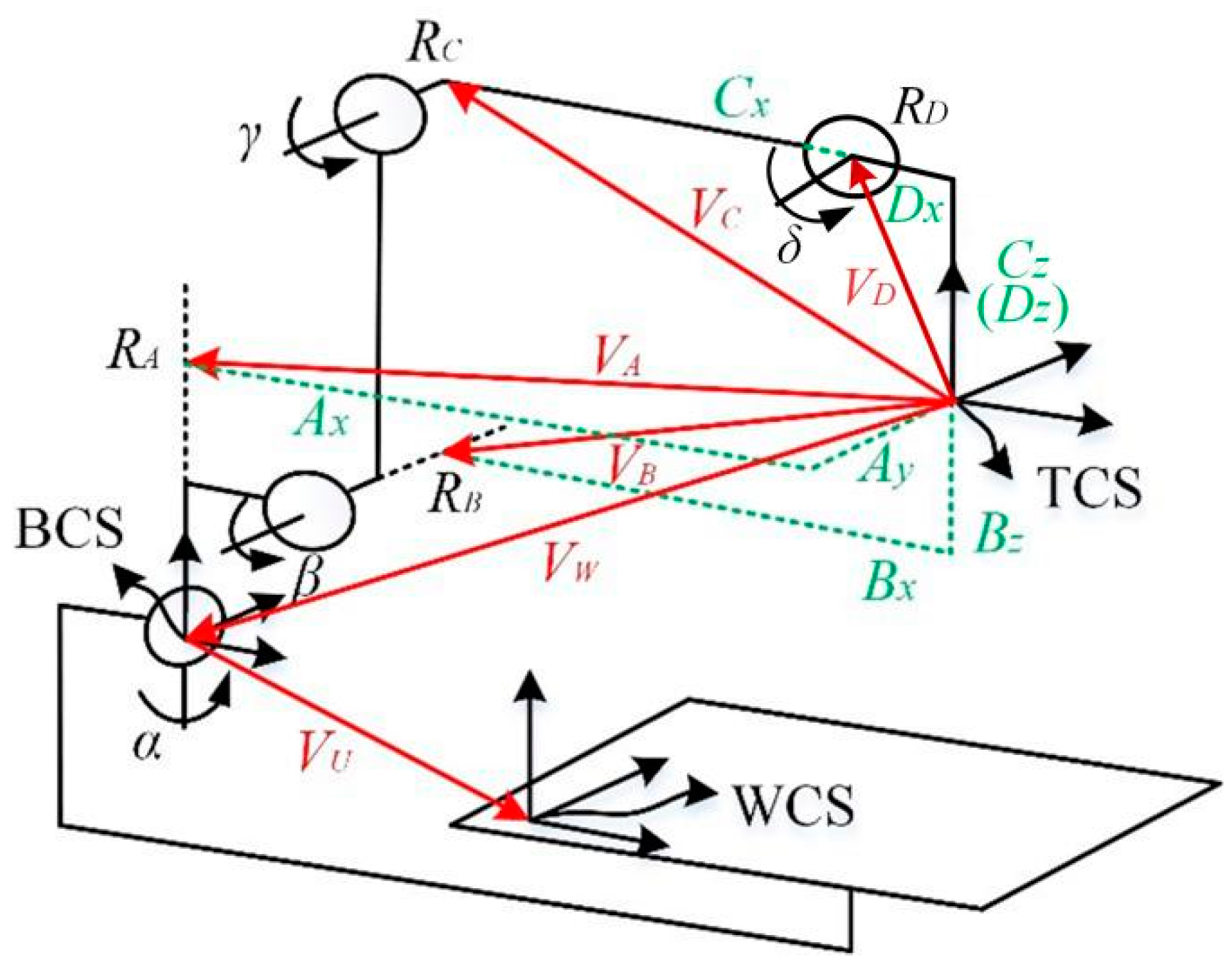

2. Kinematic Model of a Multijoint Industrial Robot

2.1. Forward Kinematics Based on POE Theory

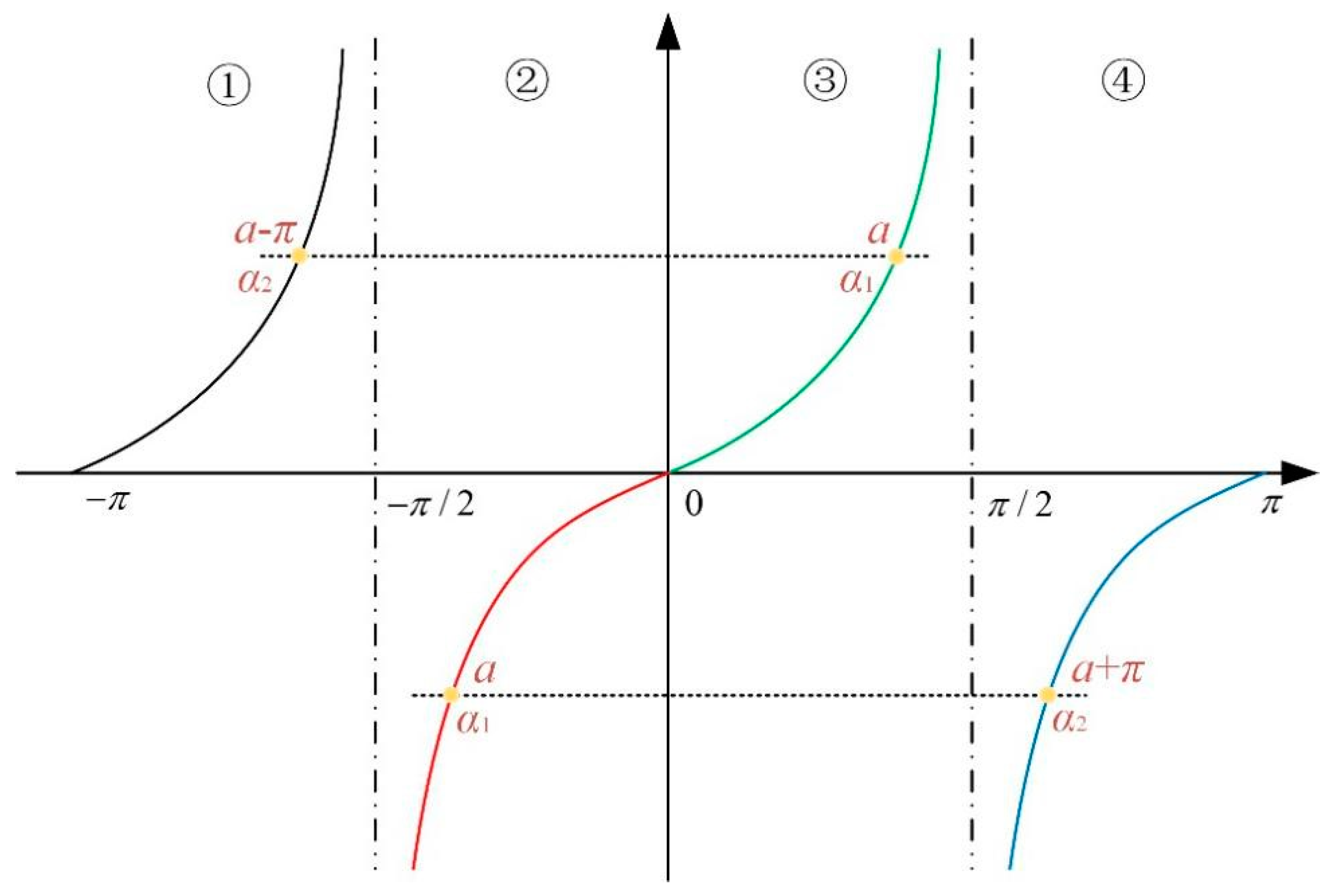

2.2. All Possible Solutions of Joint Angle in Inverse Kinematics

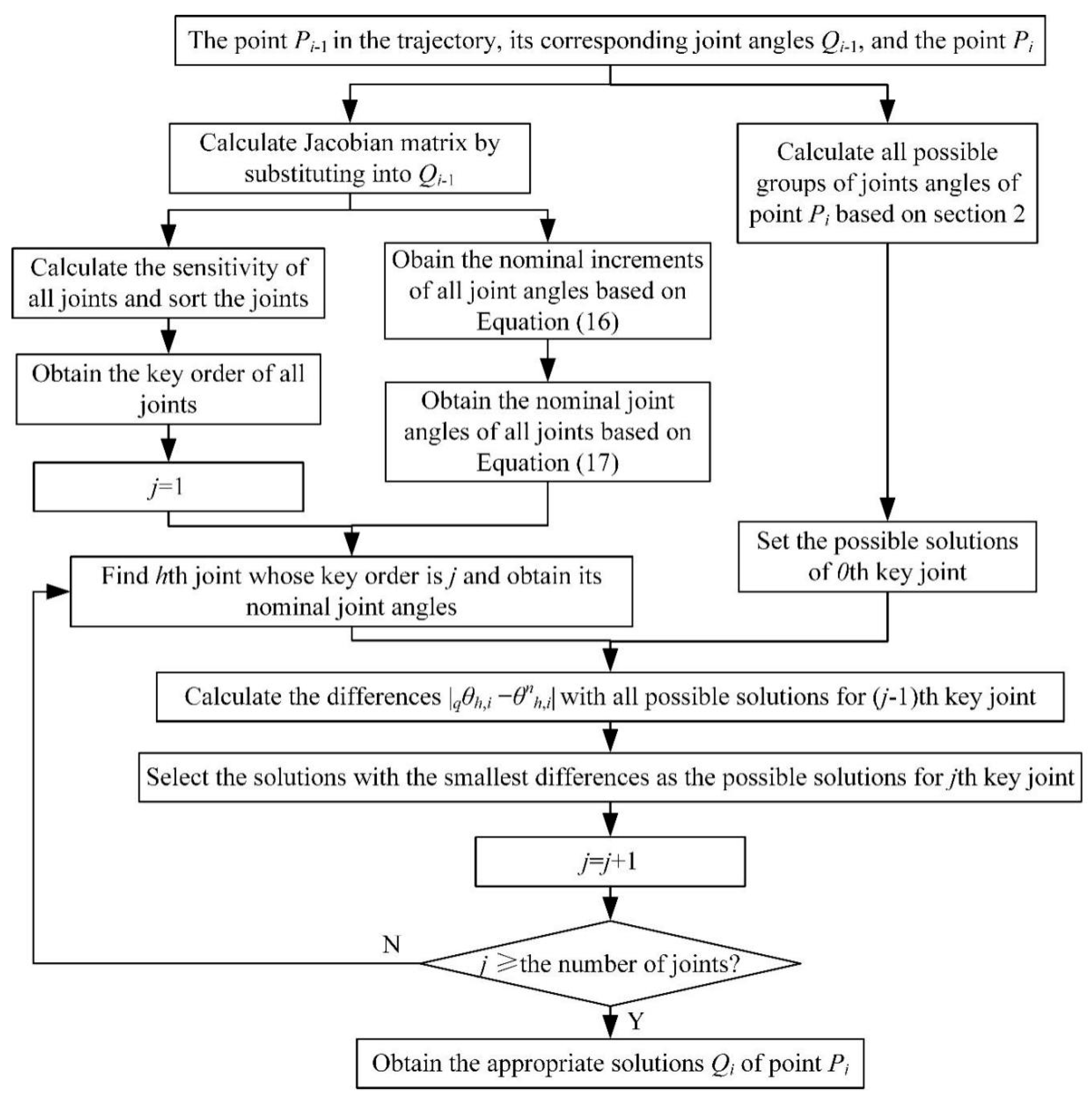

3. Multisolution Selection of Joint Angle Based on the Key Order of the Joint

3.1. Key Order of the Joint

3.2. Multisolution Selection

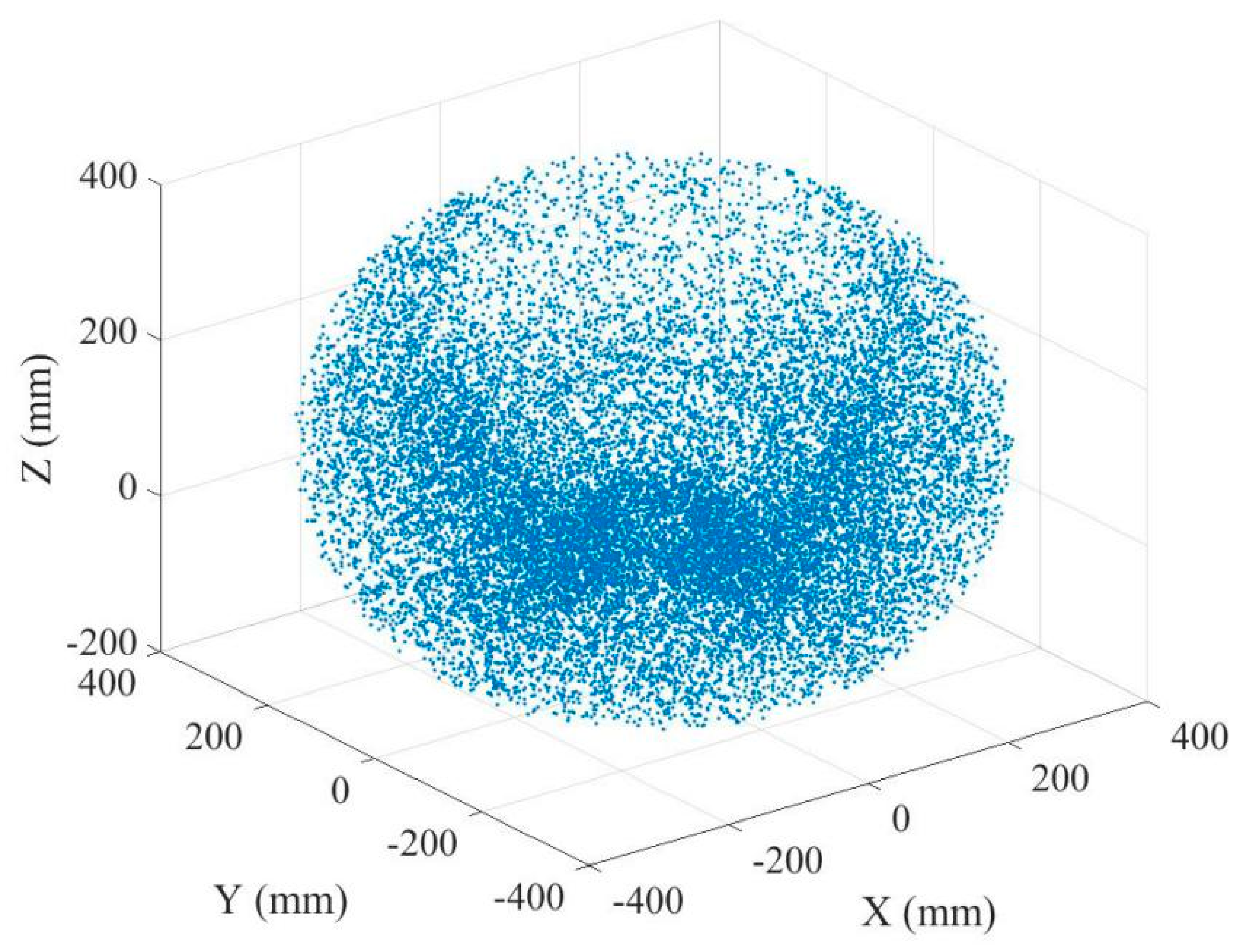

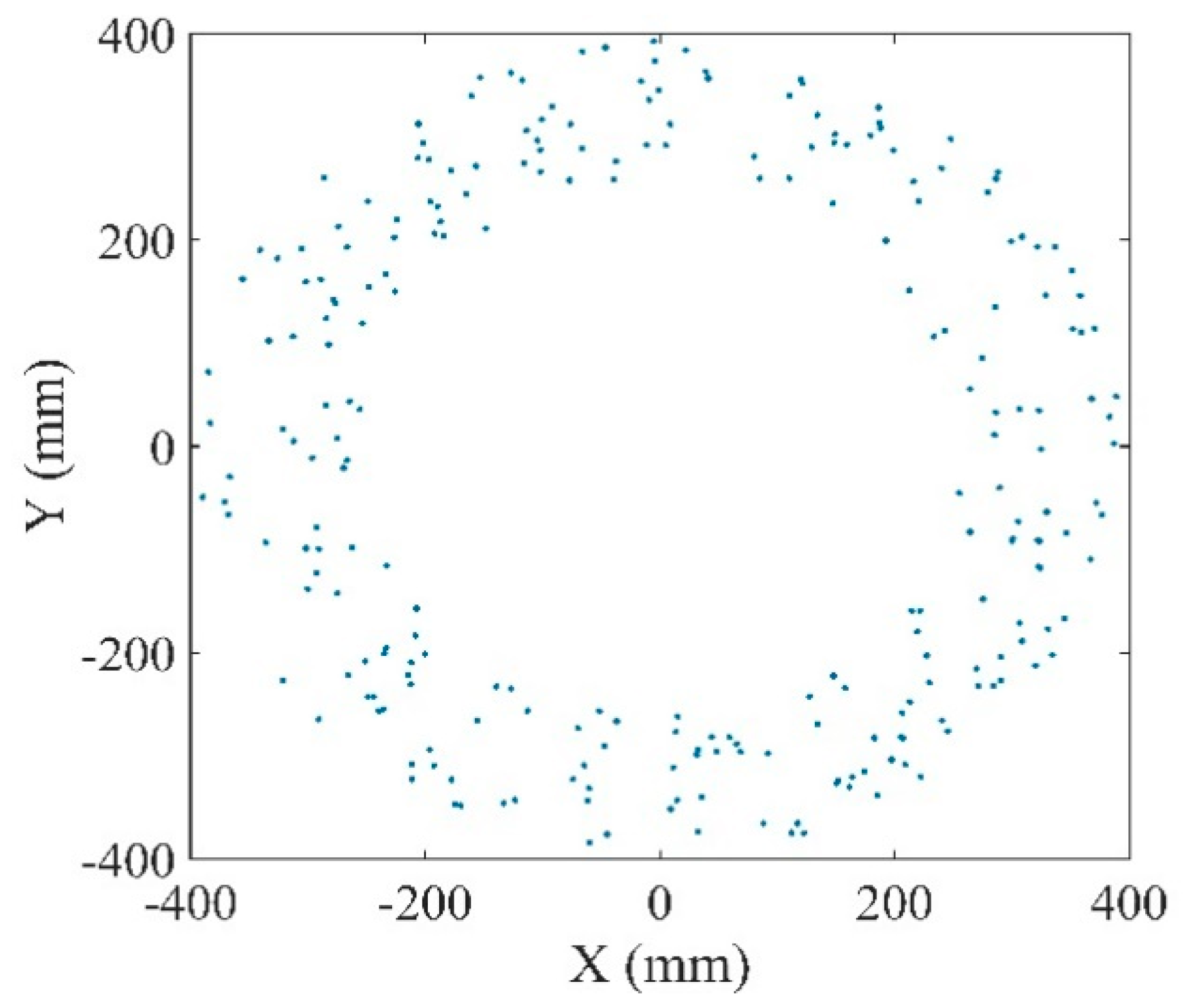

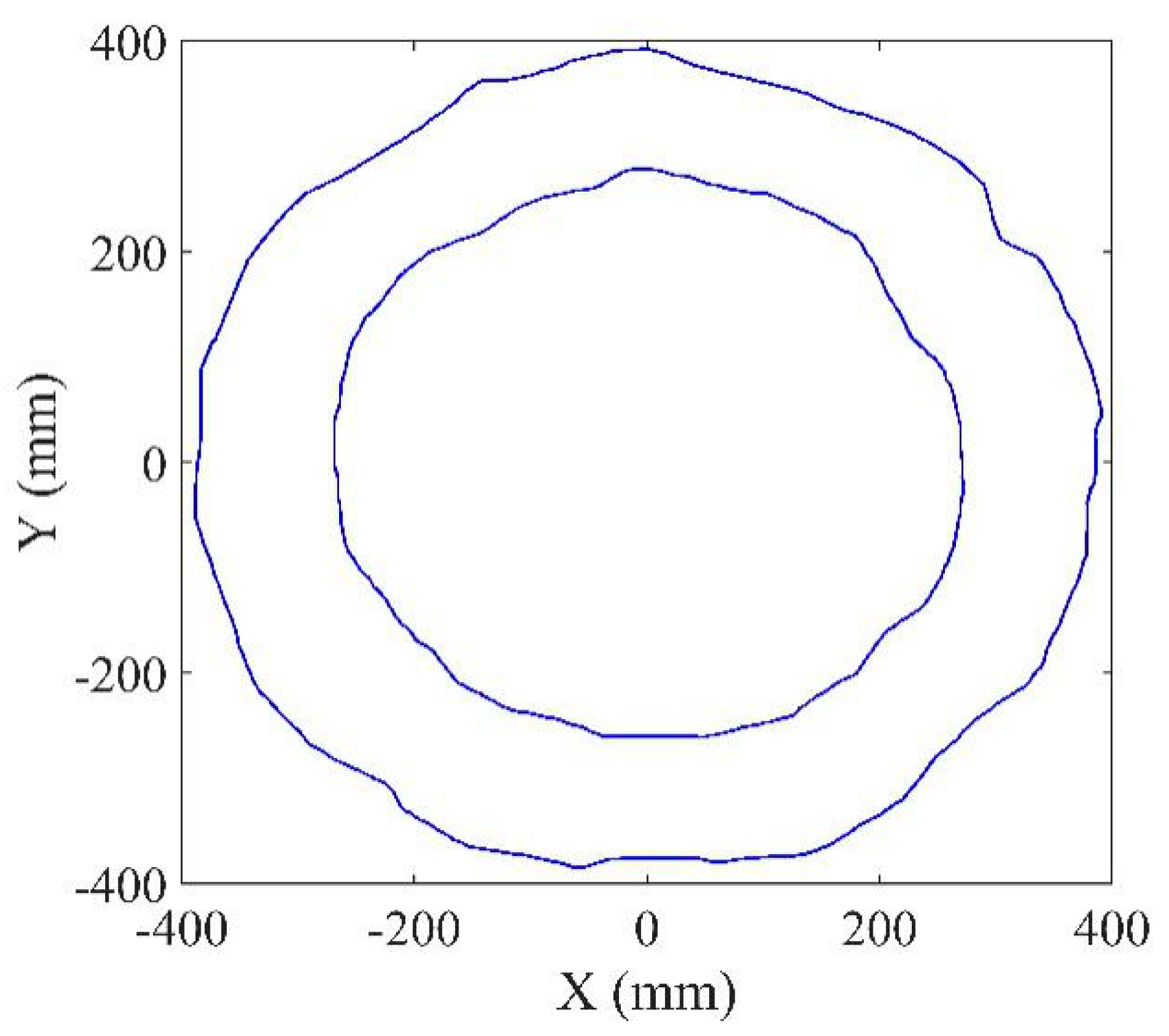

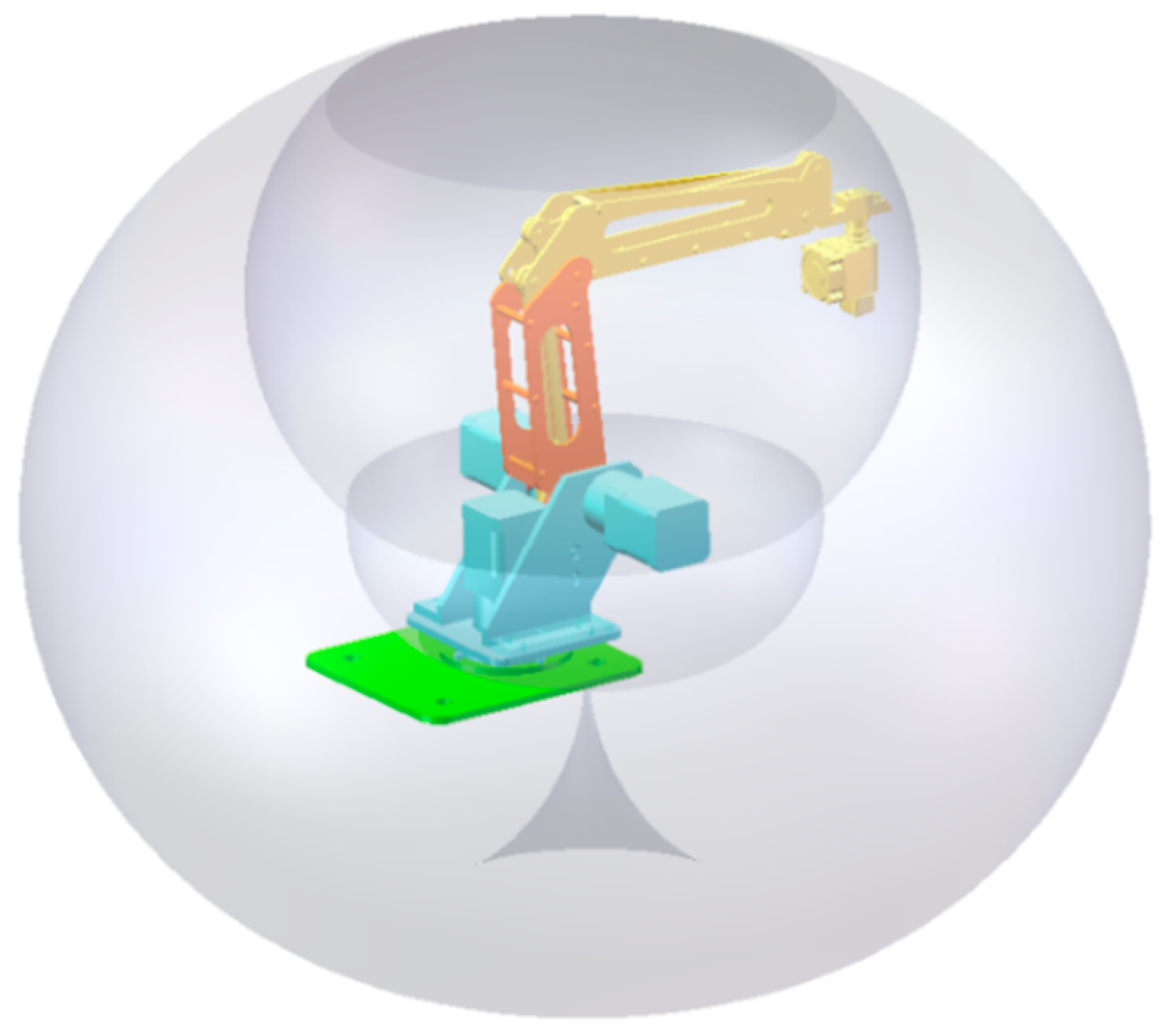

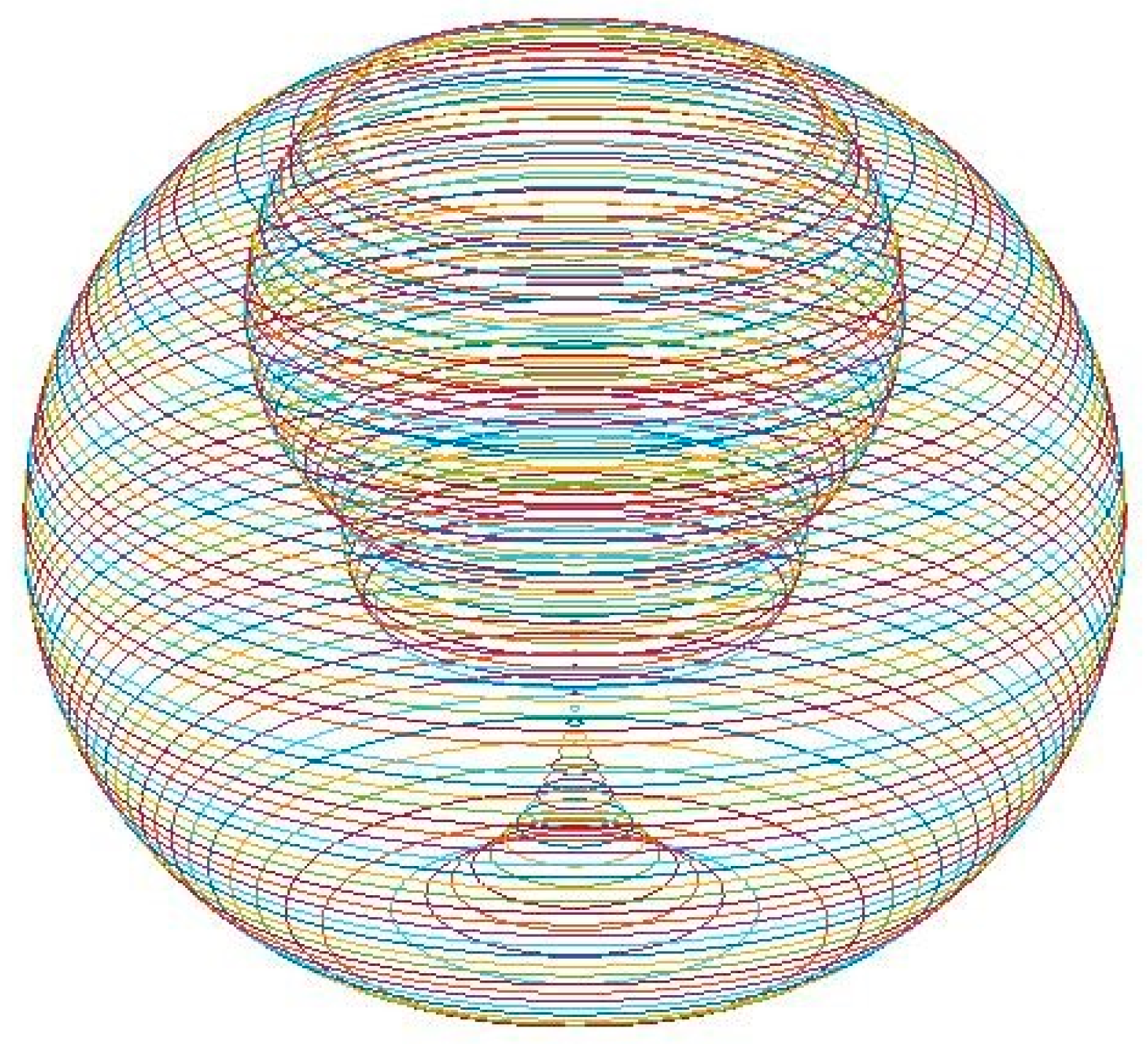

4. A Workspace Visualization Method Based on a 3D-Printing Layering Concept

4.1. Existing Boundary Extraction Method

4.2. Extraction of the Workspace Boundary Based on 3D-Layering Concept

5. Example and Verification Experiment

5.1. Verification of the Extraction of Workspace Boundary Based on 3D-Layering Concept

5.2. Verification of Multisolution Selection Method Based on the Key Degrees of the Joints

- (1)

- According to the inverse kinematic formula in Section 2.2, four groups of solutions of joint angles at path point P1 were solved, and then all possible groups of joint angles were obtained according to Equation (12), as shown in Table 4. They were seen as the possible solutions for the 0th key joint.

- (2)

- According to Section 3.1, the Jacobian matrix J0 was obtainedat the path point P0. The sensitivity Sq of each joint was calculated by the Jacobian matrix J0.

- For j = 1, the joint with the key order of 1 was found to be the A-joint. Its nominal joint angles were obtained as 8.2939° based on . The differences between and qθ1,1 in Table 4 were calculated. The smallest difference of α-joint angles was 8.3025°−8.2939°=0.0086°. The possible solutions for the first key order were 1Q1 and 2Q1, and then, j = j + 1 = 2. The second key order was the C-joint, and its nominal joint angles were obtained as −117.65°. The differences of were calculated with the joint angles of the C-joint in 1Q1 and 2Q1. The possible solutions for the second key order were 1Q1, which had the smallest difference of . For the third key order, the nominal joint angles were = 99.5755 and the possible solution was also 1Q1. As a result, the appropriate solution of point P1 was Q1 = 1Q1 = [8.3025, 99.0992, −117.2420]T.

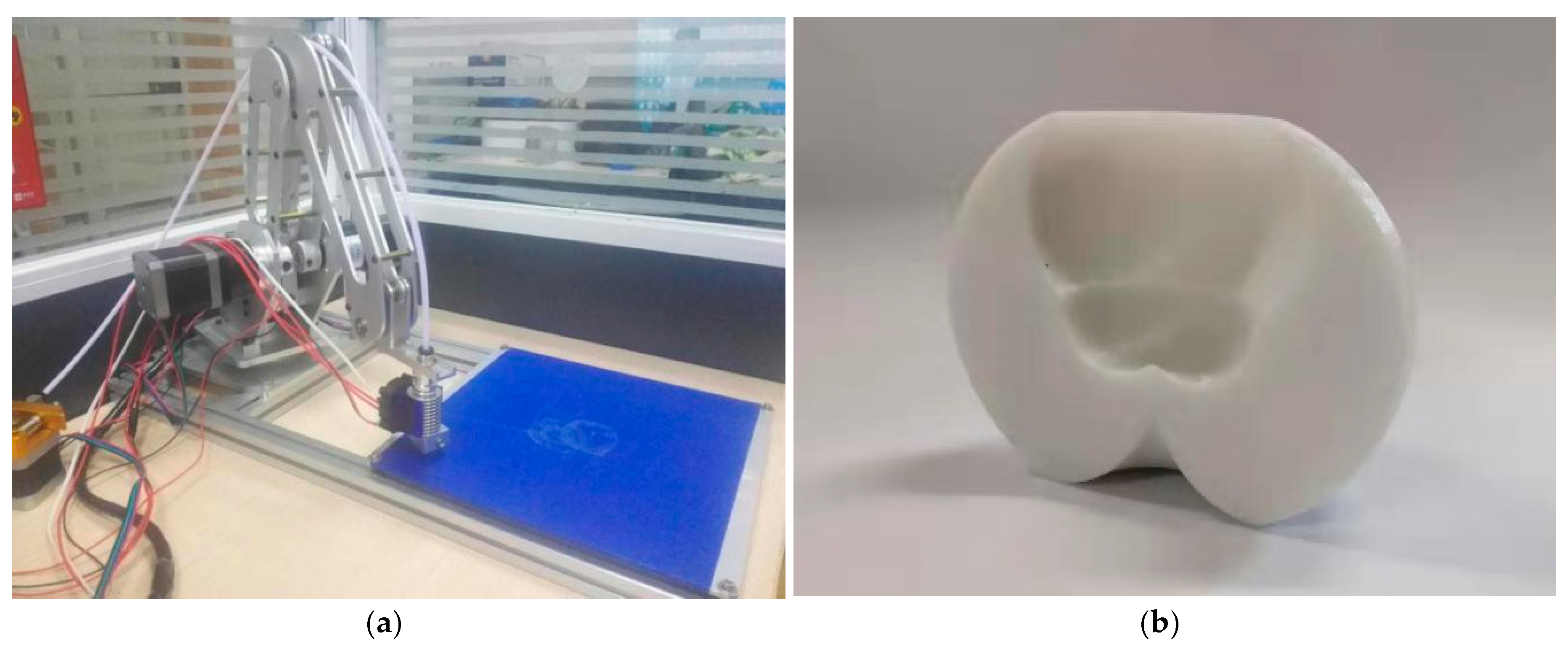

5.3. Experiments

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, D.; Calderon, C.A.A.; Gan, J.Q.; Hu, H. An analysis of the inverse kinematics for a 5-dof manipulator. Int. J. Autom. Comput. 2005, 2, 114–124. [Google Scholar] [CrossRef]

- Iliukhin, V.N.; Mitkovskii, K.B.; Bizyanova, D.A.; Akopyan, A.A. The modeling of inverse kinematics for 5 dof manipulator. Procedia Eng. 2017, 176, 498–505. [Google Scholar] [CrossRef]

- Lee, C.S.G.; Ziegler, M. Geometric approach in solving inverse kinematics of puma robots. IEEE Trans. Aerosp. Electron. Syst. 1984, 20, 695–706. [Google Scholar] [CrossRef]

- Fu, G.; Fu, J.; Shen, H.; Xu, Y.; Jin, Y.A. Product-of-exponential formulas for precision enhancement of five-axis machine tools via geometric error modeling and compensation. Int. J. Adv. Manuf. Technol. 2015, 81, 289–305. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, S.; Zhang, X. Improved inverse kinematics algorithm using screw theory for a six-dof robot manipulator. Int. J. Adv. Robot. Syst. 2015, 12, 140–148. [Google Scholar] [CrossRef]

- Fu, G.; Gao, H.; Gu, T. A universal postprocessor of general table-tilting type of five-axis machine tools without rotational tool center point function for actual nc code generation. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018. [Google Scholar]

- Fu, G.; Gong, H.; Fu, J.; Gao, H.; Deng, X. Geometric error contribution modeling and sensitivity evaluating for each axis of five-axis machine tools based on poe theory and transforming differential changes between coordinate frames. Int. J. Mach. Tools Manuf. 2019, 147, 103455. [Google Scholar] [CrossRef]

- An, H.S.; Seo, T.W.; Lee, J.W. Generalized solution for a sub-problem of inverse kinematics based on product of exponential formula. J. Mech. Sci. Technol. 2018, 32, 2299–2307. [Google Scholar] [CrossRef]

- Ayiz, C.; Kucuk, S. The kinematics of industrial robot manipulators based on the exponential rotational matrices. In Proceedings of the IEEE International Symposium on Industrial Electronics, Seoul, Korea, 5–8 July 2009. [Google Scholar]

- Yahya, S.; Mohamed, H.A.F.; Moghavvemi, M.; Yang, S.S. A geometrical inverse kinematics method for hyper-redundant manipulators. In Proceedings of the 2008 10th Intl. Conf. on Control, Automation, Robotics and Vision 2008, Hanoi, Vietnam, 17–20 December 2008; pp. 1954–1958. [Google Scholar]

- Ananthanarayanan, H.; Ordóñez, R. Real-time inverse kinematics of (2n+1) dof hyper-redundant manipulator arm via a combined numerical and analytical approach. Mech. Mach. Theory 2015, 91, 209–226. [Google Scholar] [CrossRef]

- Beheshti, M.T.H.; Tehrani, A.K.; Ghanbari, B. An optimized adaptive fuzzy inverse kinematics solution for redundant manipulators. In Proceedings of the International Symposium on Intelligent Control 2003, Houston, TX, USA, 8 October 2003; pp. 924–929. [Google Scholar]

- Ayyıldız, M.; Cetinkaya, K. Comparison of four different heuristic optimization algorithms for the inverse kinematics solution of a real 4-dof serial robot manipulator. Neural Comput. Appl. 2015, 27, 825–836. [Google Scholar] [CrossRef]

- Guang, W.-D.; Yin, L.-Z.; Wei, S.-T. Inverse kinematics of robot based on weighted optimization. Modul. Mach. Tool Autom. Manuf. Tech. 2016, 5, 1–8. [Google Scholar]

- Xiao, L.-G.; Feng, T.-R. Algorithm for the inverse kinematics calculation of 6-dof serial welding robots based on geometry. Mach. Des. Manuf. 2015, 2, 29–35. [Google Scholar]

- Sen, D.; Singh, B.N. A geometric approach for determining inner and exterior boundaries of workspaces of planar manipulators. J. Mech. Des. 2008, 130, 022306. [Google Scholar] [CrossRef]

- Abdel, K.-M.; Yang, J. Workspace boundaries of serial manipulators using manifold stratification. Int. J. Adv. Manuf. Technol. 2006, 28, 1211–1229. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Ding, Y.-M. Method for workspace calculation of 6r serial manipulator based on surface enveloping and overlaying. J. Shanghai Jiaotong Univ. Sci. 2010, 15, 556–562. [Google Scholar] [CrossRef]

- Gan, Y.; Yu, W.; He, W.; Wang, J.; Sun, F. The research about prescribed workspace for optimal design of 6r robot. Mod. Mech. Eng. 2014, 4, 154–163. [Google Scholar] [CrossRef]

- Liu, X.-J.; Jinsongwang, W.; Oh, K.-K.; Kim, J. A new approach to the design of a delta robot with a desiredworkspace. J. Intell. Robot. Syst. 2004, 39, 209–225. [Google Scholar] [CrossRef]

- Bergamaschi, P.R.; Nogueira, A.C.; de Fátima Pereira Saramago, S. Design and optimization of 3r manipulators using the workspace features. Appl. Math. Comput. 2006, 172, 439–463. [Google Scholar] [CrossRef]

- Kohli, D.; Spanos, J. Workspace analysis of mechanical manipulators using polynomial discriminants. J. Mech. Transm. Autom. Des. 1985, 107, 209–215. [Google Scholar] [CrossRef]

- Kohli, D.; Hsu, M.-S. The jacobian analysis of workspaces of mechanical manipulators. Mech. Mach. Theory 1987, 22, 265–275. [Google Scholar] [CrossRef]

- Yang, J.; Abdel-Malek, K.; Zhang, Y. On the workspace boundary determination of serial manipulators with non-unilateral constraints. Robot. Comput. -Integr. Manuf. 2008, 24, 60–76. [Google Scholar] [CrossRef]

- Cao, Y.; Lu, K.; Li, X.; Zang, Y. Accurate numerical methods for computing 2d and 3d robot workspace. Int J. Adv. Robot. Syst. 2011, 8, 1–13. [Google Scholar] [CrossRef]

- Peidró, A.; Reinoso, Ó.; Gil, A.; Marín, J.M.; Payá, L. An improved monte carlo method based on gaussian growth to calculate the workspace of robots. Eng. Appl. Artif. Intell. 2017, 64, 197–207. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, H.; Luo, Z.; Zhang, X. Improvement on monte carlo method for robot workspace determination. Trans. Chin. Soc. Agric. Mach. 2013, 44, 230–235. [Google Scholar]

- Merlet, J.P. An Improved Design Algorithm Based on Interval Analysis for Spatial Parallel Manipulator with Specified Workspace. In Proceedings of the IEEE International Conference on Robotics & Automation, Seoul, Korea, 21–26 May 2001; pp. 1289–1294. [Google Scholar]

- Chablat, D.; Wenger, P.; Merlet, J.P. Workspace Analysis of the Orthoglide Using Interval Analysis. In Advances in Robot Kinematics; Lenarcic, J., Thomas, F., Eds.; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Kaloorazi, M.H.F.; Masouleh, M.T.; Caro, S. Determining the Maximal Singularity-free Circle or Sphere of Parallel Mechanisms Using Interval Analysis. Robotica 2014, 34, 1–15. [Google Scholar] [CrossRef]

- Viegas, C.; Daney, D.; Tavakoli, M.; de Almeida, T. Performance analysis and design of parallel kinematic machines using interval analysis. Mech. Mach. Theory 2017, 115, 218–236. [Google Scholar] [CrossRef]

- Yi, C.; Xiujuan, L.; Yi, N.; Guanying, Y. Computation and geometrical error analysis of a 3d robot’s workspace. Mech. Sci. Technol. 2006, 25, 1458–1461. [Google Scholar]

| Solution of Rotation Angles | Range of Inverse Trigonometric Functions | Stroke of A-Joint, B-Joint, or C-Joint |

|---|---|---|

| Double Solutions of α | Region Belonged to | |

|---|---|---|

| a > 0 | ③ ① | |

| a < 0 | ② ④ | |

| a = 0 | - - |

| The Scope of the Pz | The Value of β when rmin | The Value of β when rmax |

|---|---|---|

| Num. | α (qθ1,1) (°) | β (qθ2,1) (°) | γ (qθ2,1) (°) |

|---|---|---|---|

| 1Q1 | 8.3025 | 99.0992 | −117.2420 |

| 2Q1 | 8.3025 | −32.0948 | 117.2420 |

| 3Q1 | −171.6975 | 99.0992 | −117.2420 |

| 4Q1 | −171.6975 | −32.0948 | 117.2420 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, G.; Tao, C.; Gu, T.; Lu, C.; Gao, H.; Deng, X. A Workspace Visualization Method for a Multijoint Industrial Robot Based on the 3D-Printing Layering Concept. Appl. Sci. 2020, 10, 5241. https://doi.org/10.3390/app10155241

Fu G, Tao C, Gu T, Lu C, Gao H, Deng X. A Workspace Visualization Method for a Multijoint Industrial Robot Based on the 3D-Printing Layering Concept. Applied Sciences. 2020; 10(15):5241. https://doi.org/10.3390/app10155241

Chicago/Turabian StyleFu, Guoqiang, Chun Tao, Tengda Gu, Caijiang Lu, Hongli Gao, and Xiaolei Deng. 2020. "A Workspace Visualization Method for a Multijoint Industrial Robot Based on the 3D-Printing Layering Concept" Applied Sciences 10, no. 15: 5241. https://doi.org/10.3390/app10155241

APA StyleFu, G., Tao, C., Gu, T., Lu, C., Gao, H., & Deng, X. (2020). A Workspace Visualization Method for a Multijoint Industrial Robot Based on the 3D-Printing Layering Concept. Applied Sciences, 10(15), 5241. https://doi.org/10.3390/app10155241