Static Residual Tensile Strength Response of GFRP Composite Laminates Subjected to Low-Velocity Impact

Abstract

1. Introduction

2. Experimental Programme

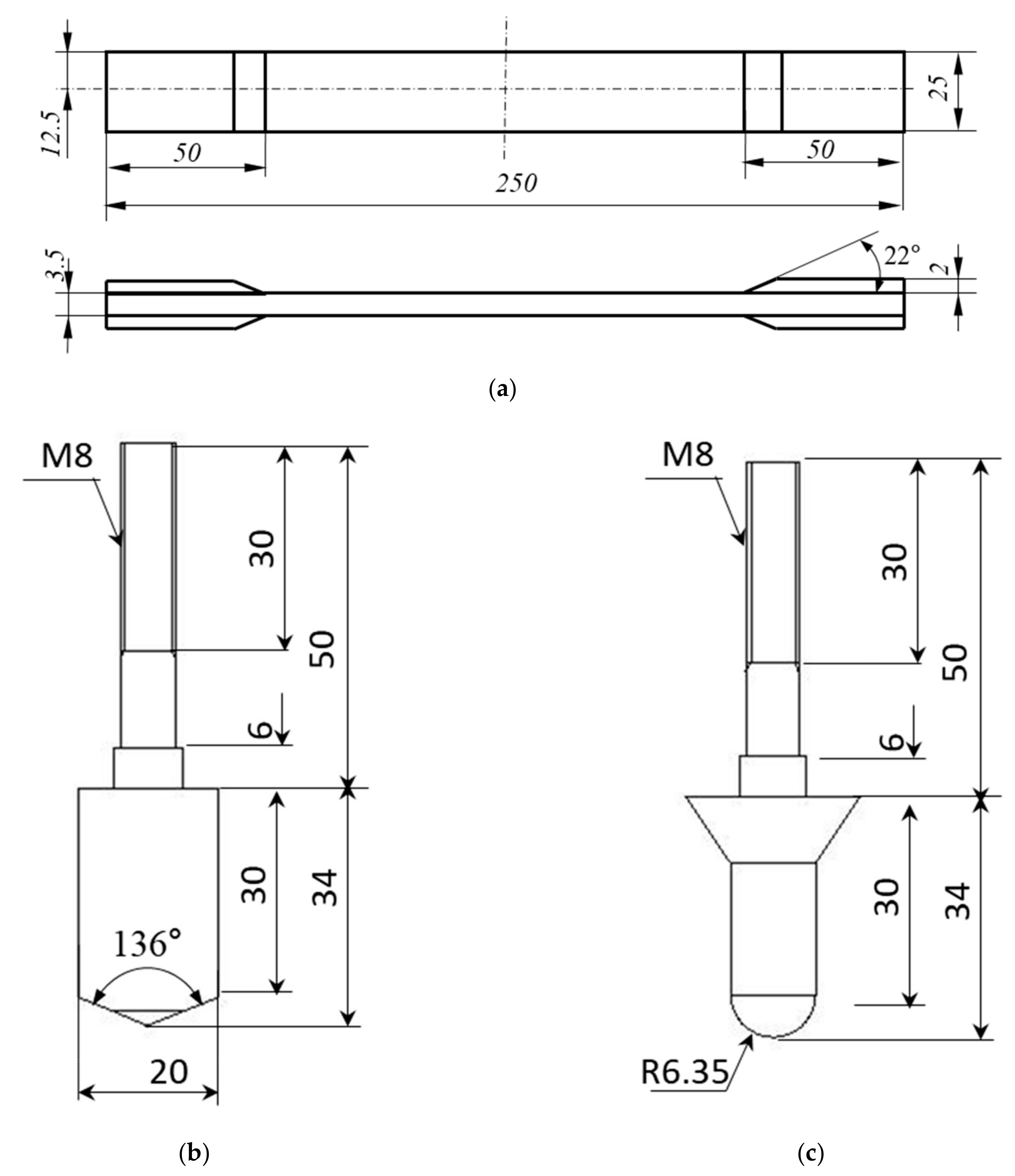

2.1. Specimen and Introduction of Impact Indent

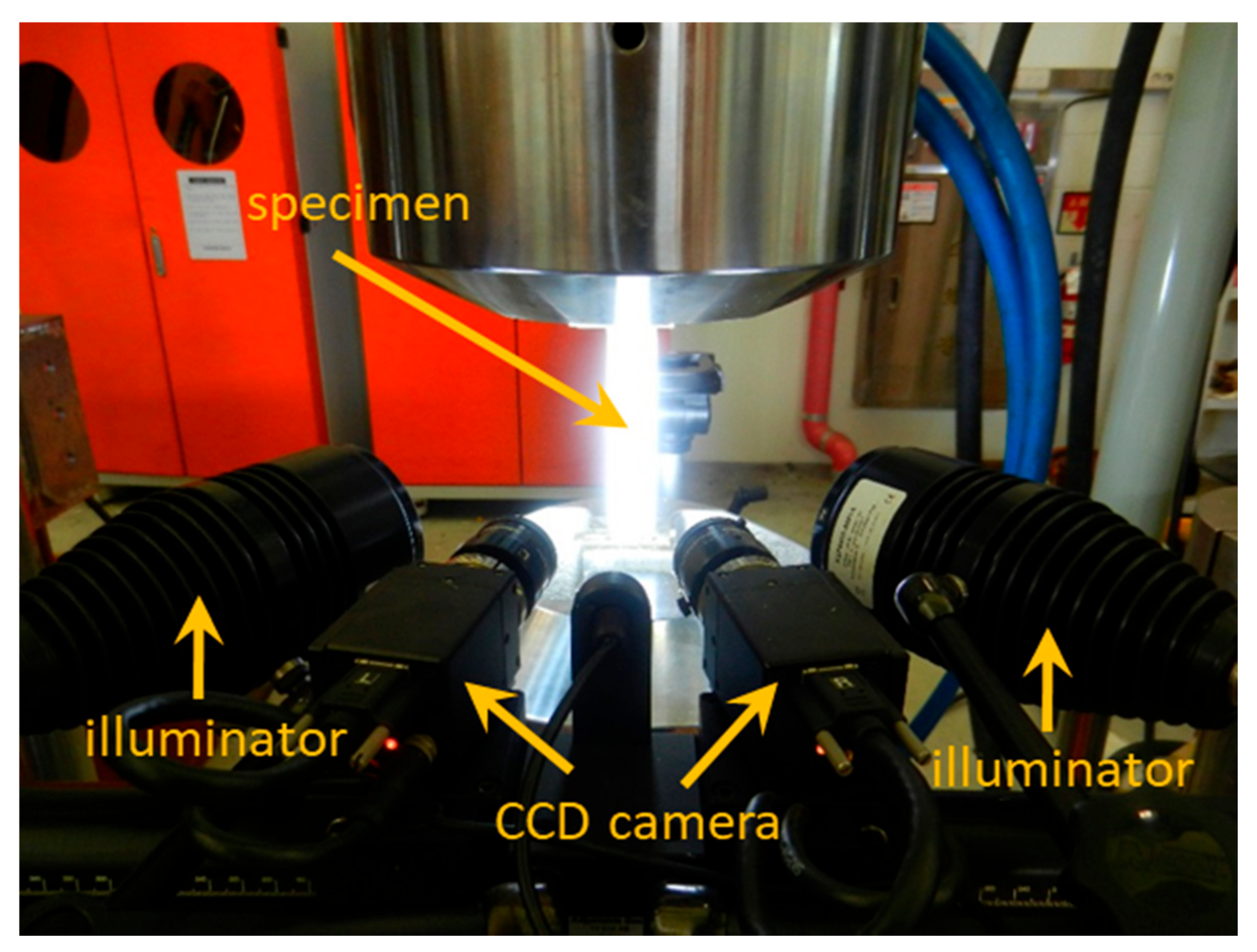

2.2. Test Method and DIC Measurement

2.3. SEM Observation

3. Results and Discussion

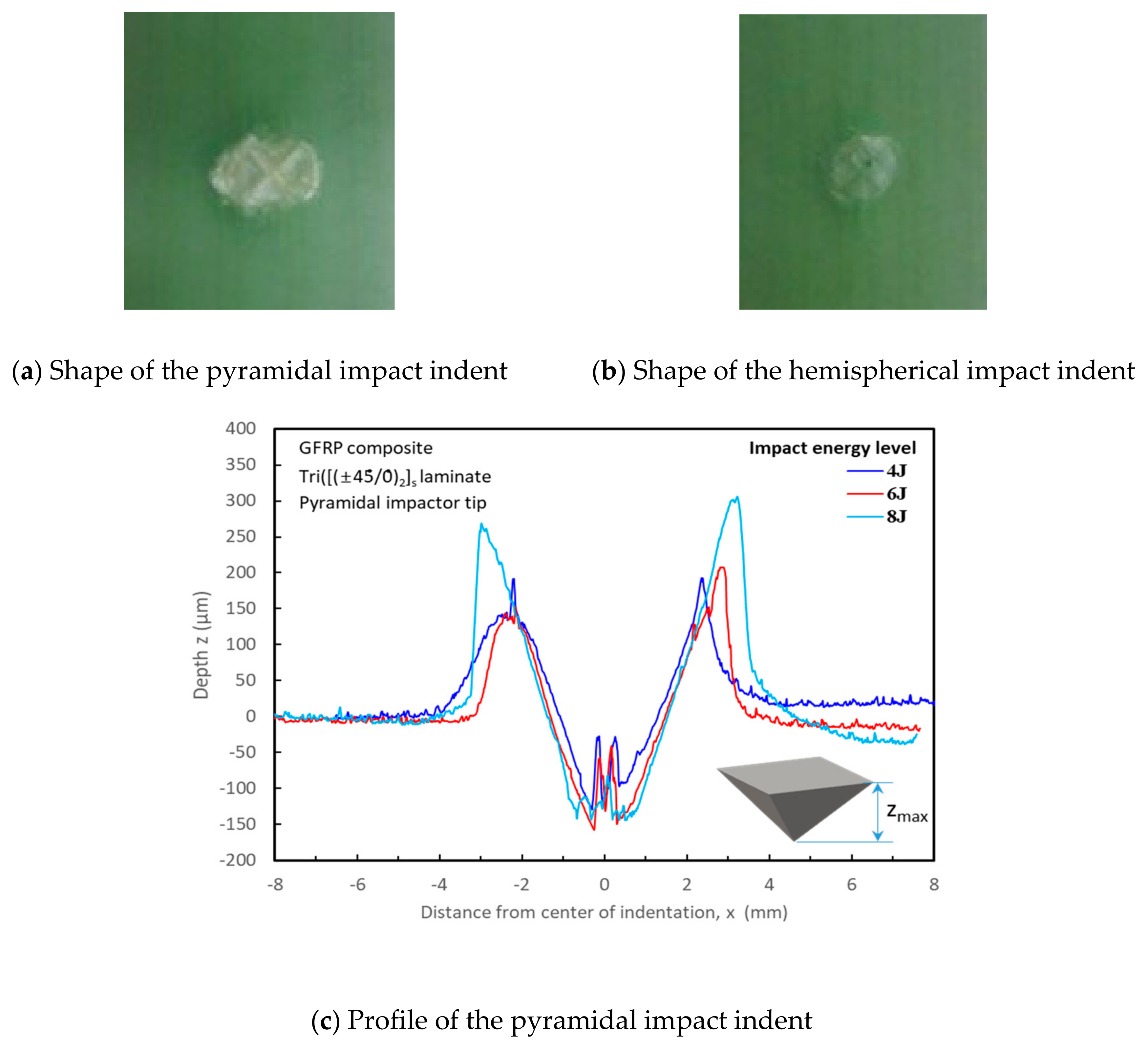

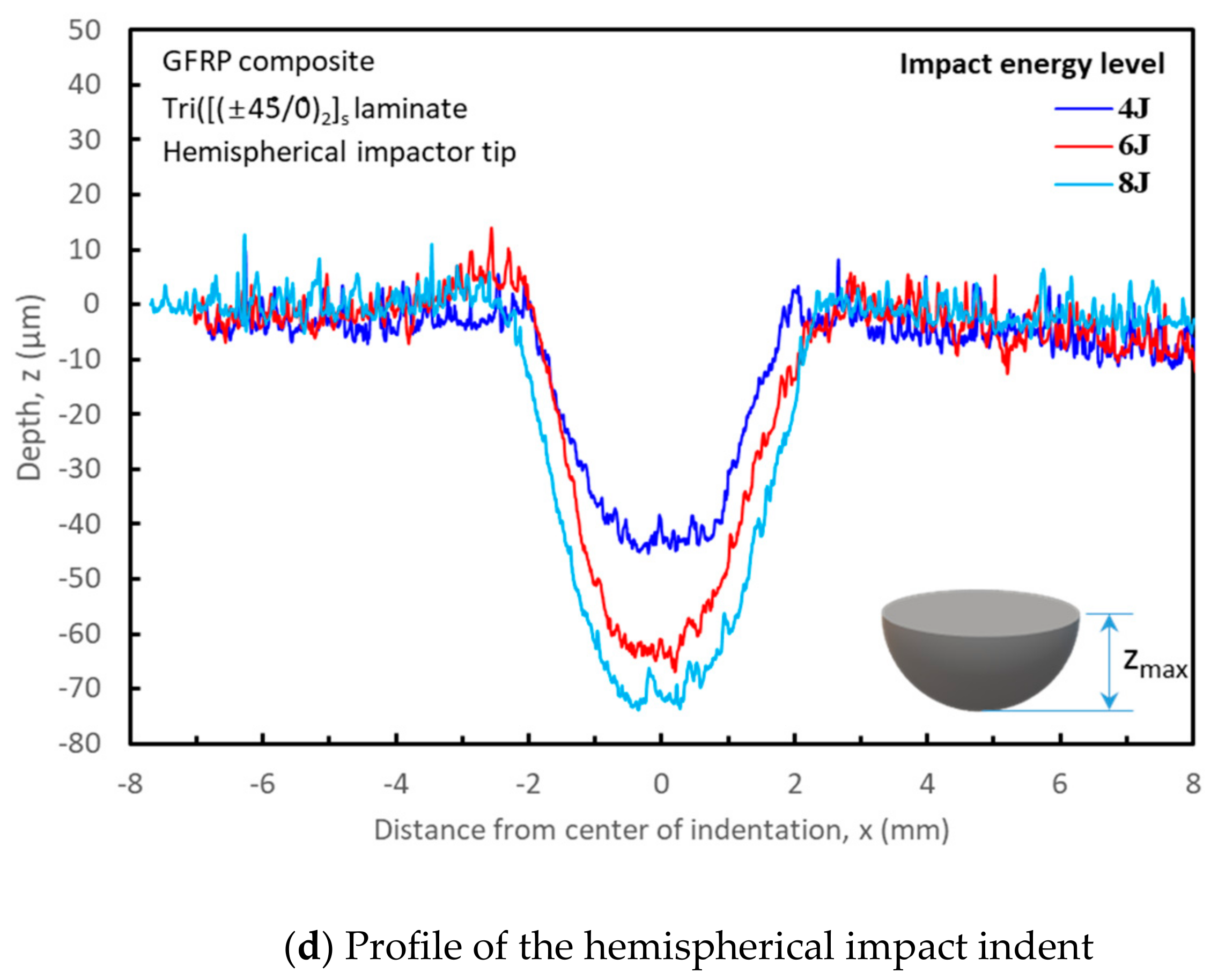

3.1. Impact Indent Geometry

3.2. Observation of Low-Velocity Impact Damage Pattern

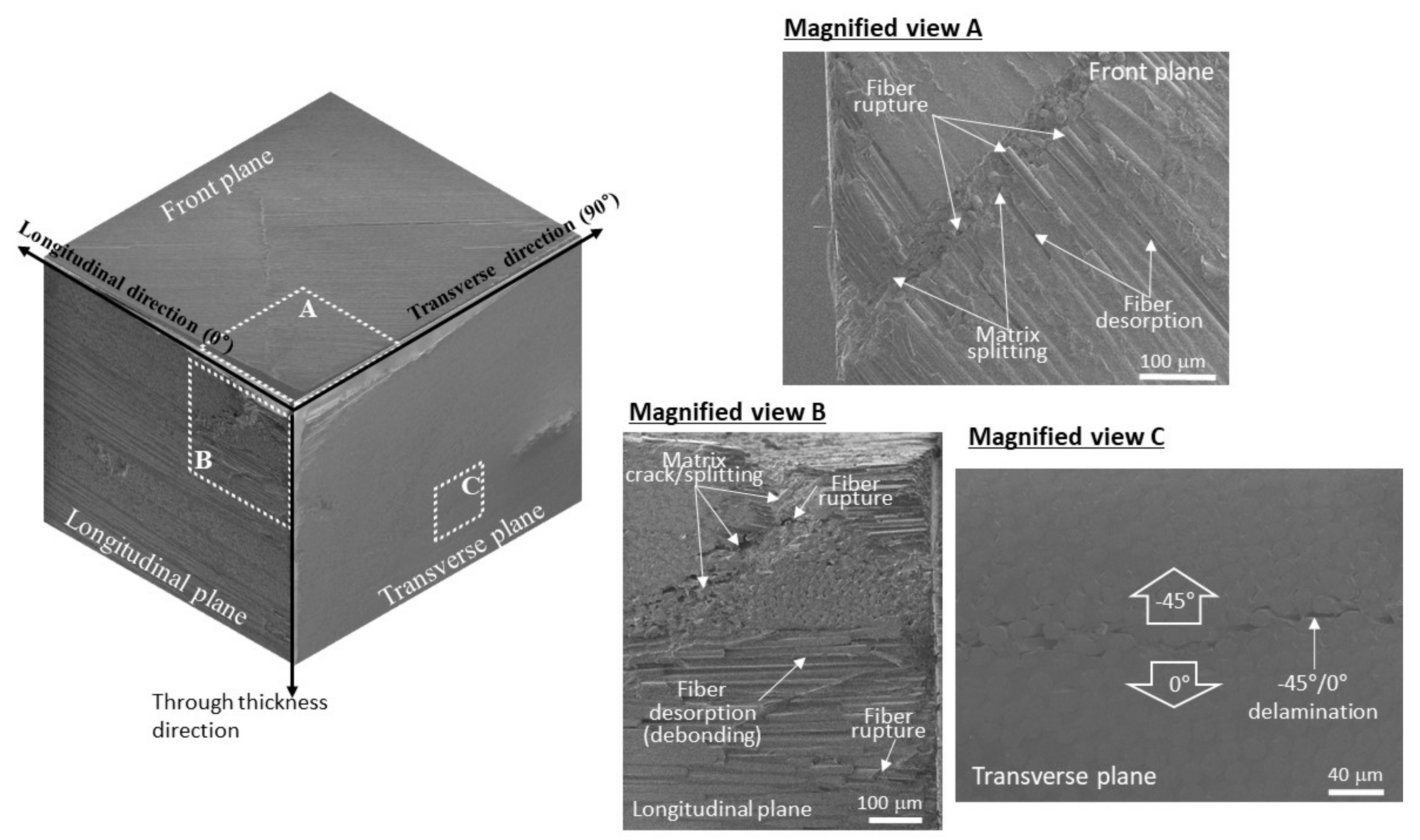

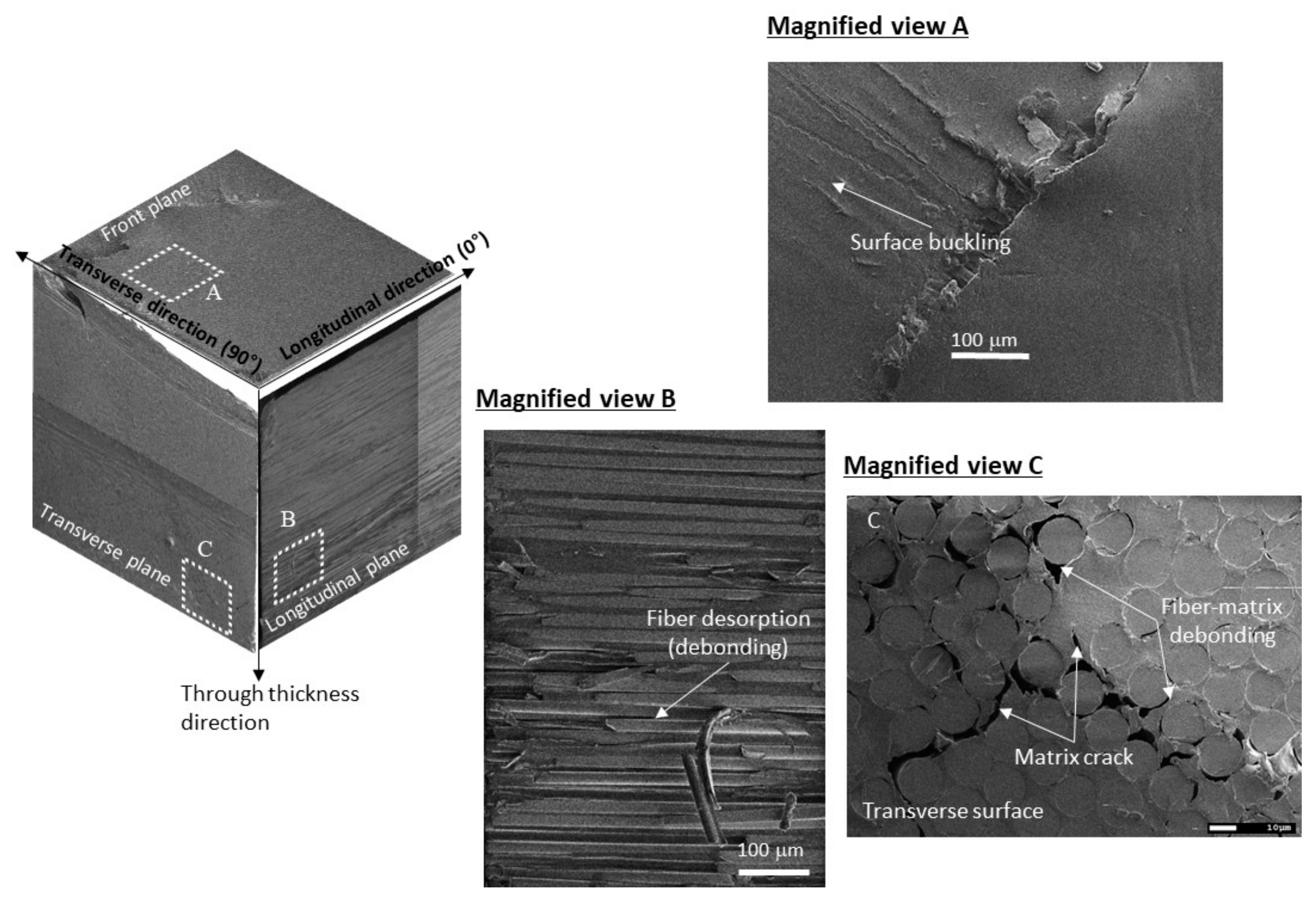

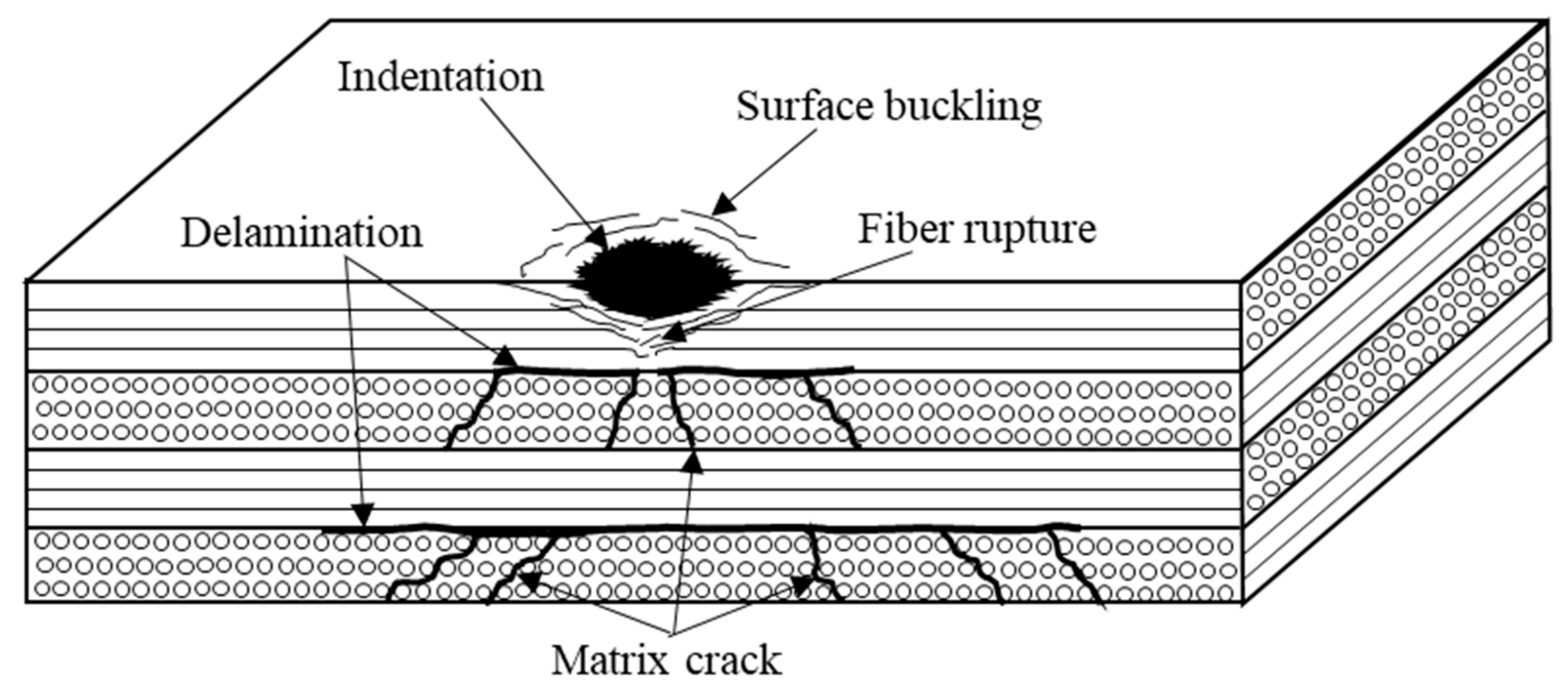

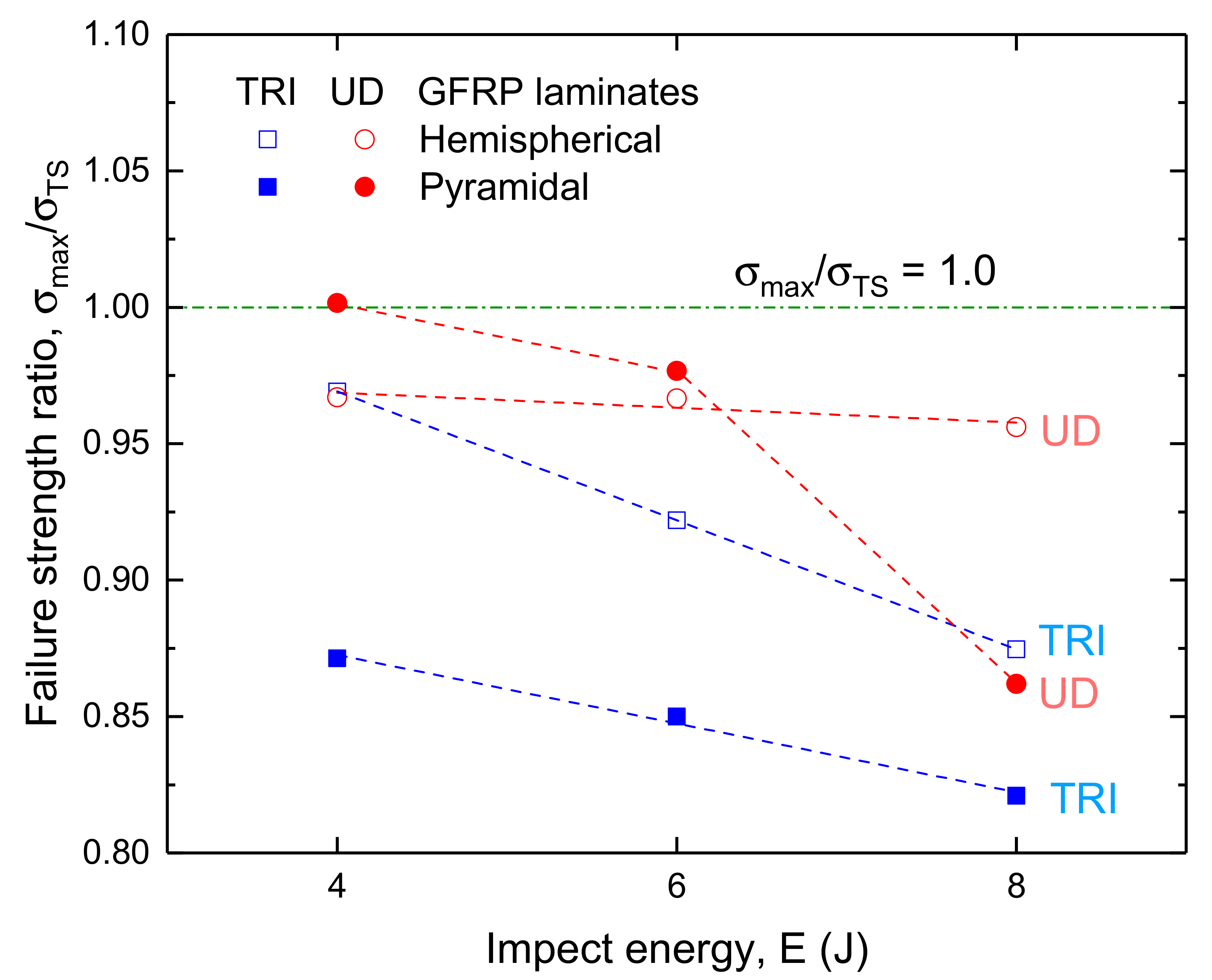

3.3. Reduction of Residual Static Strength

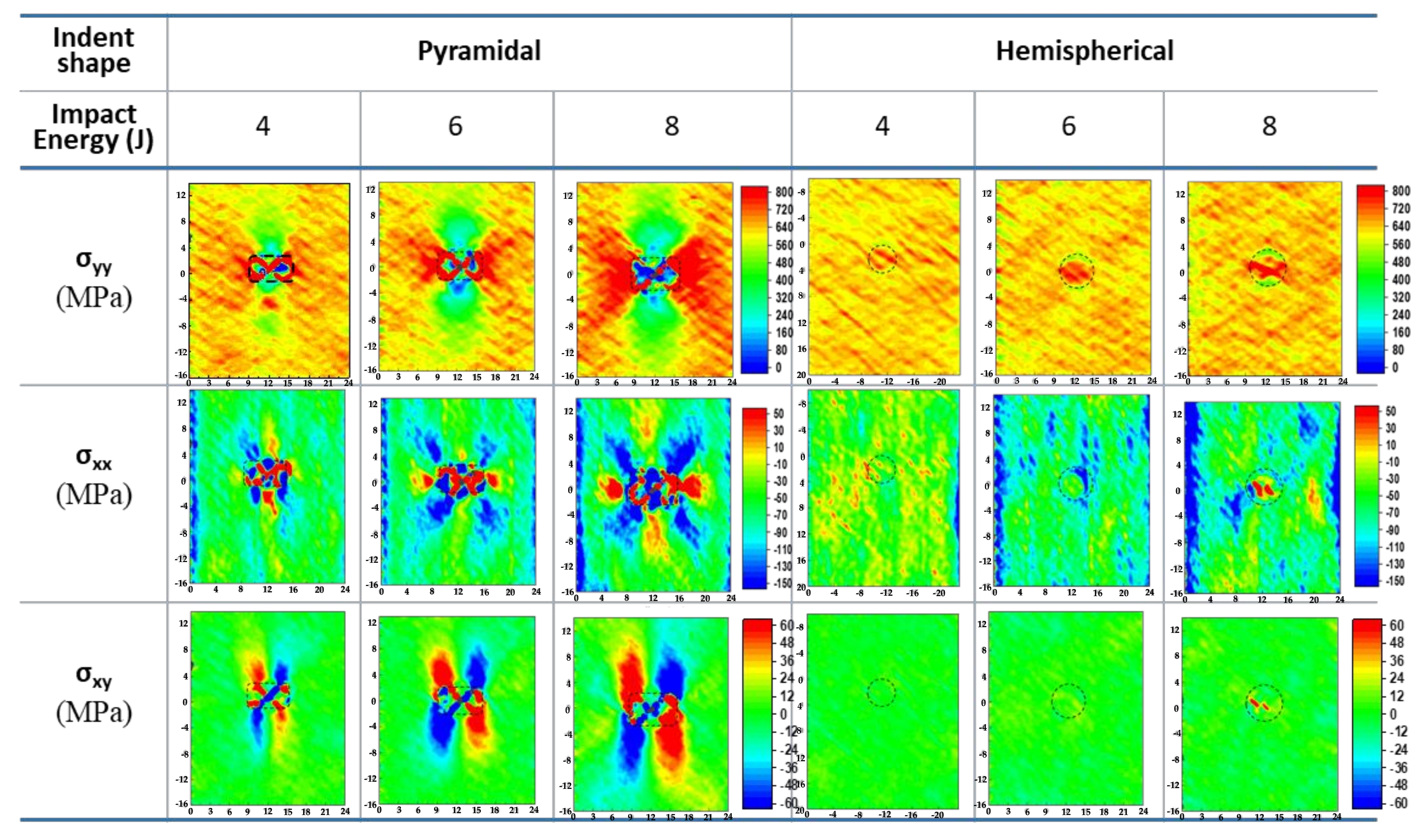

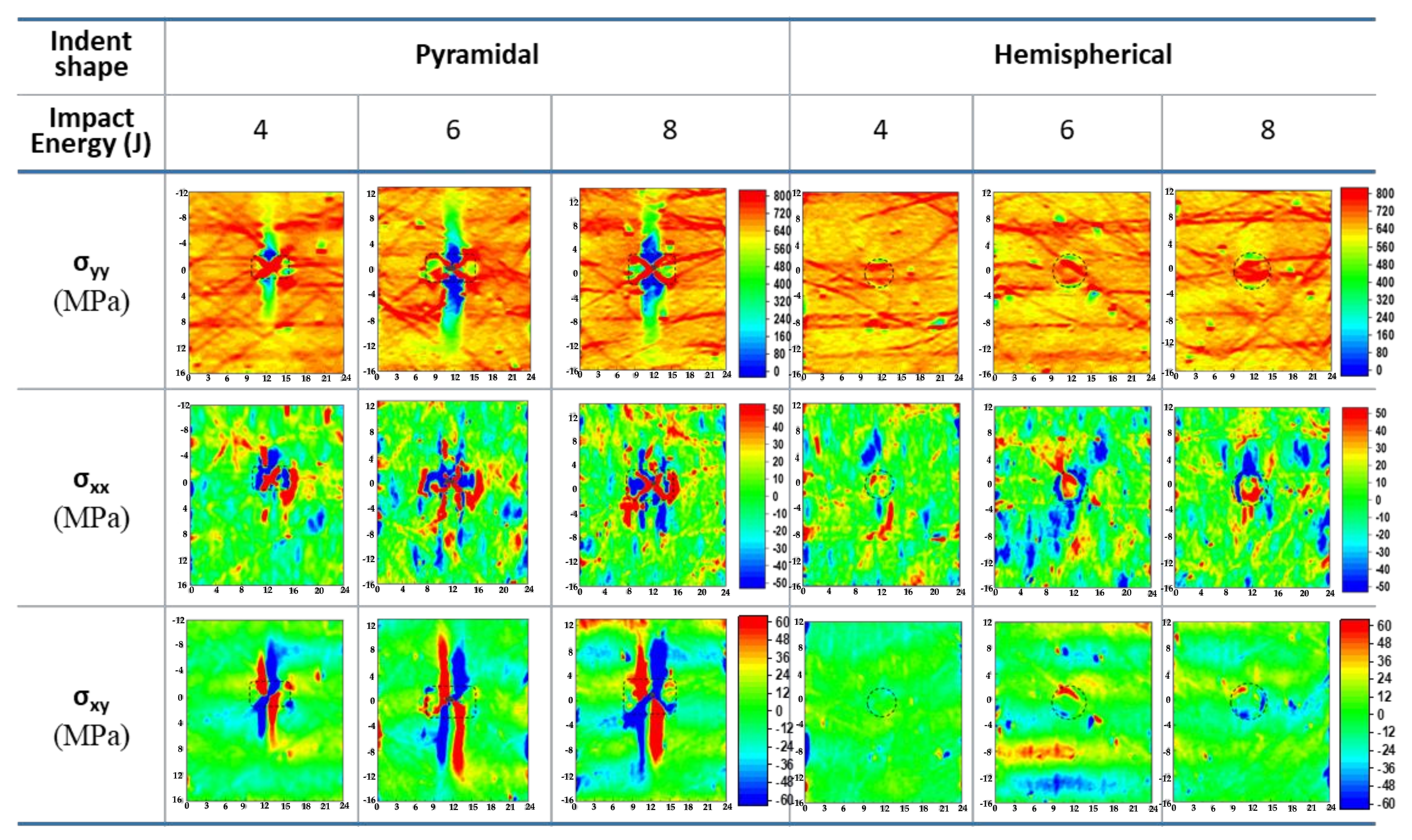

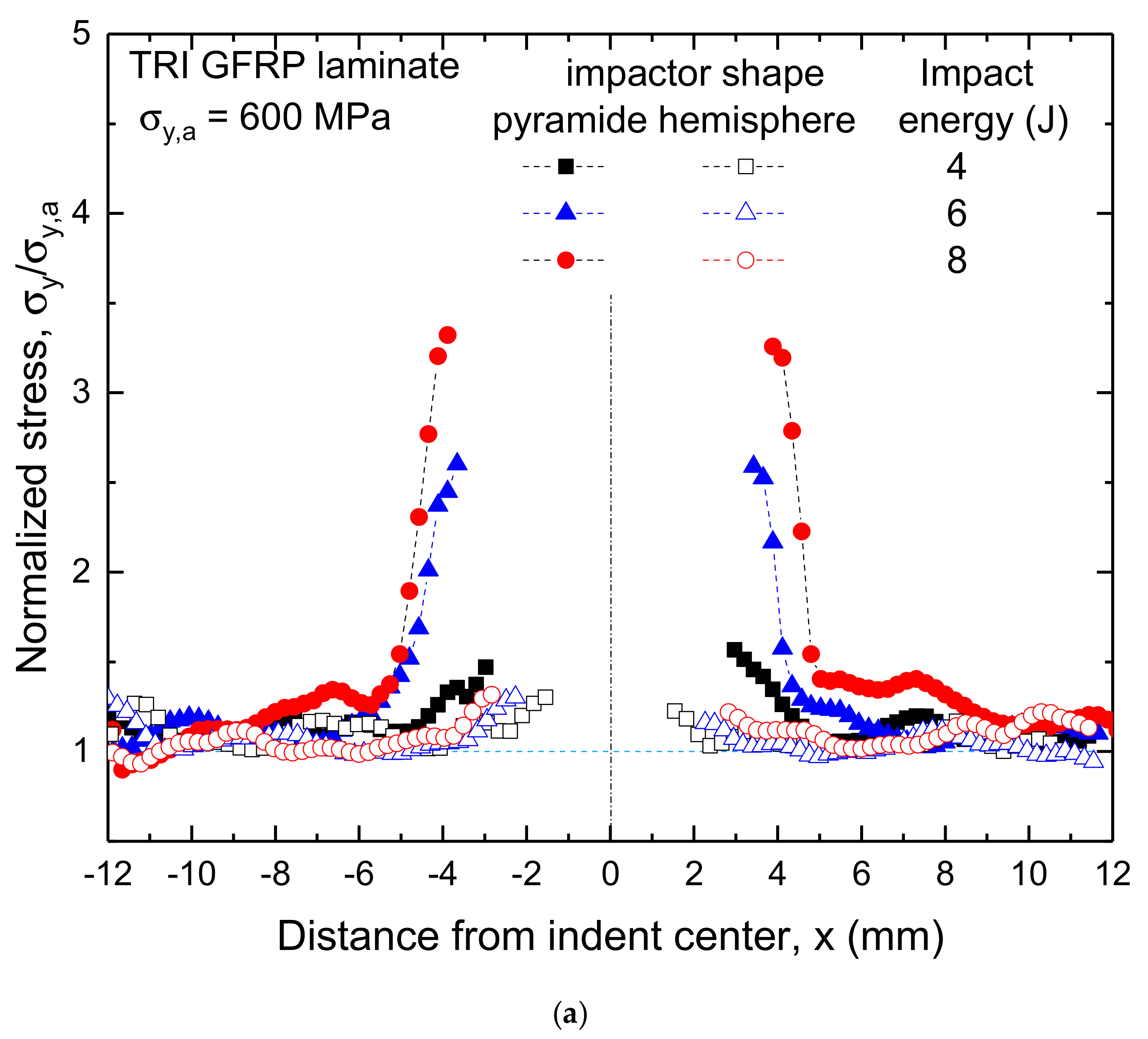

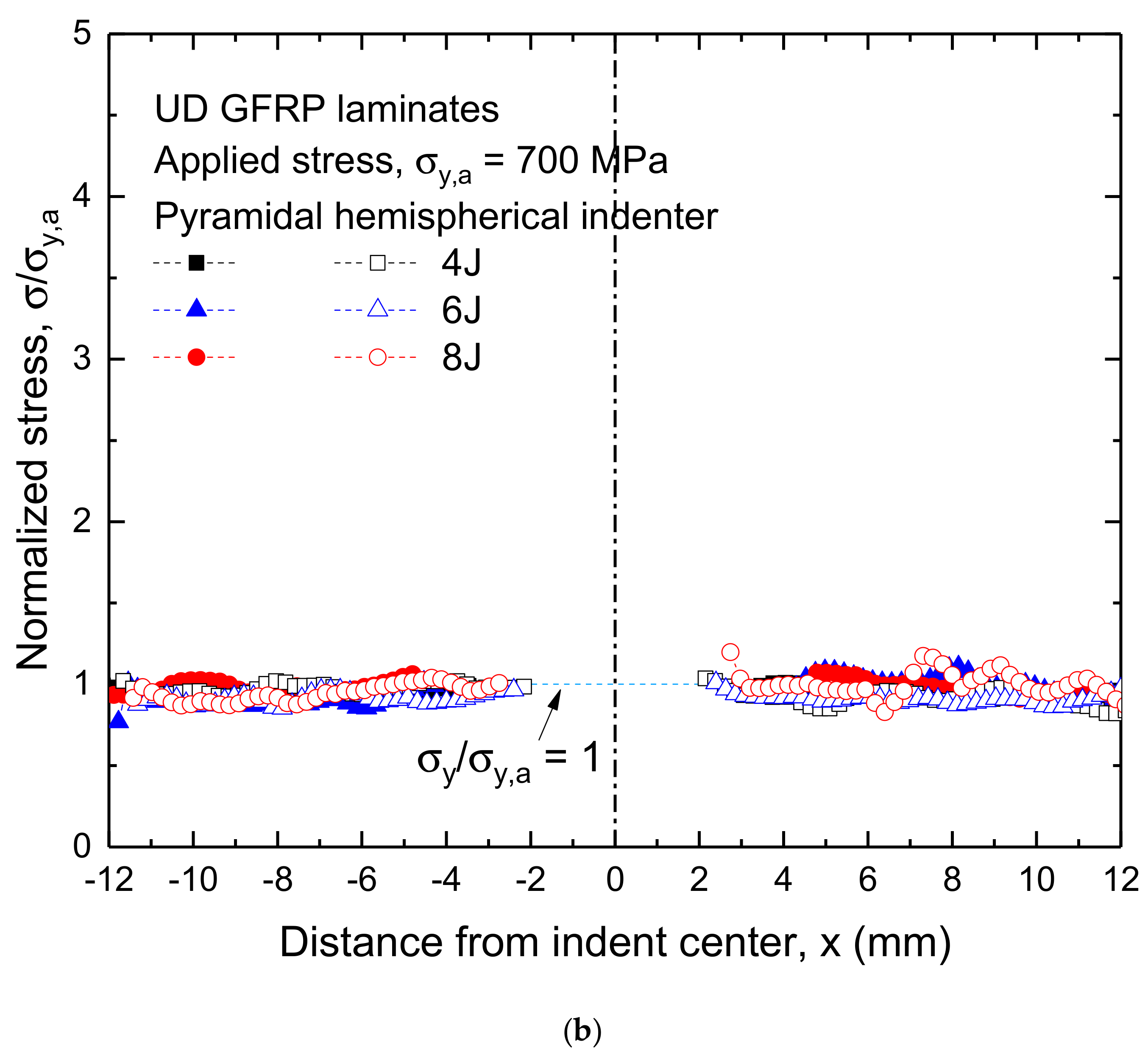

3.4. Stress Concentration Around the Impact Indent

4. Summary and Conclusions

- (1)

- The TRI GFRP laminate was remarkably more susceptible to the impact indentation than the UD laminate. Reduction of residual in-plane tensile strength for the impacted TRI laminate was relatively more severe than that for the impacted UD laminate.

- (2)

- Reduction of residual in-plane tensile strength for the TRI and UD GFRP laminates was dependent on the impact energy level and indent shape. The strength reduction became greater with increasing impact energy level, and the pyramidal indent had a relatively greater influence on the residual strength reduction than the hemispherical indent.

- (3)

- Full-field directional stress, including longitudinal (σyy), transverse (σxx) and shear (σxy) stress, distributions in the vicinity of the pyramidal and hemispherical indents for the TRI and UD GFRP laminates were determined from the DIC measurement using a linear elastic orthotropic relationship. These stresses were relatively significantly concentrated in the vicinity of the pyramidal indent for the TRI laminate, compared to those for UD laminate. Stress concentrations in the vicinity of the pyramidal and hemispherical indents for the TRI laminate were relatively higher than those for the UD laminate. Furthermore, the stress concentration became higher with increasing impact energy levels.

- (4)

- The residual strength reduction of the impacted GFRP laminates may be considerably closely associated with the stress concentration in the vicinity of the indent.

- (5)

- The impact damage patterns created in the TRI and UD GFRP laminates were dependent on the impactor head shape, but the dominant patterns were matrix cracking, delamination, debonding and fiber breakage.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shyr, T.W.; Pan, Y.H. Impact resistance and damage characteristics of composite laminates. Compos. Struct. 2003, 62, 192–203. [Google Scholar] [CrossRef]

- Arikan, V.; Sayman, O. Comparative study on repeated impact response of E-glass fiber reinforced polypropylene & epoxy matrix composites. Compos. Part B Eng. 2015, 83, 1–6. [Google Scholar]

- Panettieri, E.; Fanteria, D.; Montemurro, M.; Froustey, C. Low-velocity impact tests on carbon/epoxy composite laminates: A benchmark study. Compos. Part B Eng. 2016, 107, 9–21. [Google Scholar] [CrossRef]

- Elias, A.; Laurin, F.; Kaminski, M.; Gornet, L. Experimental and numerical investigations of low energy/velocity impact damage generated in 3D woven composite with polymer matrix. Compos. Struct. 2017, 159, 228–239. [Google Scholar] [CrossRef]

- Mitrevski, T.; Marshall, I.; Thomson, R. The influence of impactor shape on the damage to composite laminates. Compos. Struct. 2006, 76, 116–122. [Google Scholar] [CrossRef]

- Rawat, P.; Singh, K.K.; Singh, N.K. Numerical investigation of damage area due to different shape of impactors at low velocity impact of GFRP laminate. Mater. Today Proc. 2017, 4, 8731–8738. [Google Scholar] [CrossRef]

- Gaudenzi, P.; Bernabei, M.; Dati, E.; Angelis, G.D.; Marrone, M.; Lampani, L. On the evaluation of impact damage on composite materials by comparing different NDI techniques. Compos. Struct. 2014, 118, 257–266. [Google Scholar] [CrossRef]

- Tuo, H.; Lu, Z.; Ma, X.; Xing, J.; Zhang, C. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions. Compos. Part B 2019, 163, 642–654. [Google Scholar] [CrossRef]

- Tuo, H.; Lu, Z.; Ma, X.; Zhang, C.; Chen, S. An experimental and numerical investigation on low-velocity impact damage and compression-after-impact behavior of composite laminates. Compos. Part B 2019, 167, 329–341. [Google Scholar] [CrossRef]

- Prato, A.; Longana, M.L.; Hussain, A.; Wisnom, M.R. Post-Impact Behaviour of Pseudo-Ductile Thin-Ply Angle-Ply Hybrid Composites. Materials 2019, 12, 579. [Google Scholar] [CrossRef] [PubMed]

- Husman, G.E.; Whitney, J.M.; Halpin, J.C. Residual strength characterisation of laminated composites subjected to impact loading. ASTM STP 568 1975, 92–113. [Google Scholar] [CrossRef]

- Caprino, G.; Lopresto, V. The significance of indentation in the inspection of carbon fibre-reinforced plastic panels damaged by low-velocity impact. Compos. Sci. Technol. 2000, 60, 1003–1012. [Google Scholar] [CrossRef]

- Koo, J.M.; Choi, J.J.; Seok, C.S. Prediction of residual strength of CFRP after impact. Compos. Part B 2013, 54, 28–33. [Google Scholar] [CrossRef]

- Kounain, M.A.; Al-Sulaiman, F.; Khan, Z. Low velocity impact and post impact tensile properties of plain weave woven GFRP composite laminates. IJEAT 2015, 5, 92–99. [Google Scholar]

- Sanchez-Saez, S.; Barbero, E.; Zaera, R.; Navarro, C. Compression after impact of thin composite laminates. Comp. Sci. Tech. 2005, 65, 1911–1919. [Google Scholar] [CrossRef]

- ASTM D 5083. Standard Test Method for Tensile Properties of Reinforced Thermosetting Plastics Using Straight-Sided Specimens; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ISO 527-4. Plastics–Determination of Tensile Properties–Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites; International Organization for Standardization (ISO): Geneva, Switzerland, 1997. [Google Scholar]

- Hazell, P.J.; Kister, G.; Stennett, C.; Bourque, P.; Cooper, G. Normal and oblique penetration of woven CFRP laminates by a high velocity steel sphere. Compos. Part A 2008, 39, 866–874. [Google Scholar] [CrossRef]

- Hazell, P.J.; Appleby-Thomas, G. A study on the energy dissipation of several different CFRP-based targets completely penetrated by a high velocity projectile. Compos. Struct. 2009, 91, 103–109. [Google Scholar] [CrossRef]

| Laminate | Tensile Strength, σTS (MPa) | Elastic Modulus, E (GPa) | Poisson’s Ratio, ν | |||

|---|---|---|---|---|---|---|

| Longitudinal Direction | Transverse Direction | E11 | E22 | ν12 | ν21 | |

| UD | 903.4 ± 40.47 | 39.7 ± 2.25 | 41.7 | 15.4 | 0.27 | 0.11 |

| TRI | 611.6 ±19.01 | 133.7 ± 2.85 | 28.6 | 15.6 | 0.46 | 0.21 |

| Laminate Type | TRI | UD | |||

|---|---|---|---|---|---|

| Head Shape | Hemispherical | Pyramidal | Hemispherical | Pyramidal | |

| Impact Energy (J) | |||||

| Width, wmax (mm) | 4 | 4.64 ± 0.25 | 4.39 ± 0.15 | 4.36 ± 0.09 | 3.82 ± 0.55 |

| 6 | 5.27 ± 0.06 | 5.05 ± 0.3 | 4.93 ± 0.16 | 4.84 ± 0.8 | |

| 8 | 5.56 ± 0.09 | 5.94 ± 0.56 | 5.07 ± 0.18 | 6.45 ± 0.7 | |

| Depth, zmax (μm) | 4 | 45.6 ± 1.6 | 110.9 ± 15.5 | 63.3 ± 4.9 | 163.8 ± 6.7 |

| 6 | 59.6 ± 6.9 | 113 ± 18.9 | 80.9 ± 12.6 | 172.4 ± 10.2 | |

| 8 | 77.2 ± 10.6 | 117.3 ± 18.5 | 101.7 ± 5.5 | 206.8 ± 5.2 | |

| Laminate Type | TRI | UD | |||

|---|---|---|---|---|---|

| Head Shape | Hemispherical | Pyramidal | Hemispherical | Pyramidal | |

| Impact Energy (J) | |||||

| 4 | 0.97 | 0.87 | 0.97 | 1.00 | |

| 6 | 0.92 | 0.85 | 0.97 | 0.98 | |

| 8 | 0.87 | 0.82 | 0.96 | 0.86 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-I.; Huh, Y.-H.; Kim, Y.-H. Static Residual Tensile Strength Response of GFRP Composite Laminates Subjected to Low-Velocity Impact. Appl. Sci. 2020, 10, 5480. https://doi.org/10.3390/app10165480

Kim J-I, Huh Y-H, Kim Y-H. Static Residual Tensile Strength Response of GFRP Composite Laminates Subjected to Low-Velocity Impact. Applied Sciences. 2020; 10(16):5480. https://doi.org/10.3390/app10165480

Chicago/Turabian StyleKim, Jong-Il, Yong-Hak Huh, and Yong-Hwan Kim. 2020. "Static Residual Tensile Strength Response of GFRP Composite Laminates Subjected to Low-Velocity Impact" Applied Sciences 10, no. 16: 5480. https://doi.org/10.3390/app10165480

APA StyleKim, J.-I., Huh, Y.-H., & Kim, Y.-H. (2020). Static Residual Tensile Strength Response of GFRP Composite Laminates Subjected to Low-Velocity Impact. Applied Sciences, 10(16), 5480. https://doi.org/10.3390/app10165480