Effect of Carbonation Curing on Physical and Durability Properties of Cementitious Materials Containing AOD Slag

Abstract

:1. Introduction

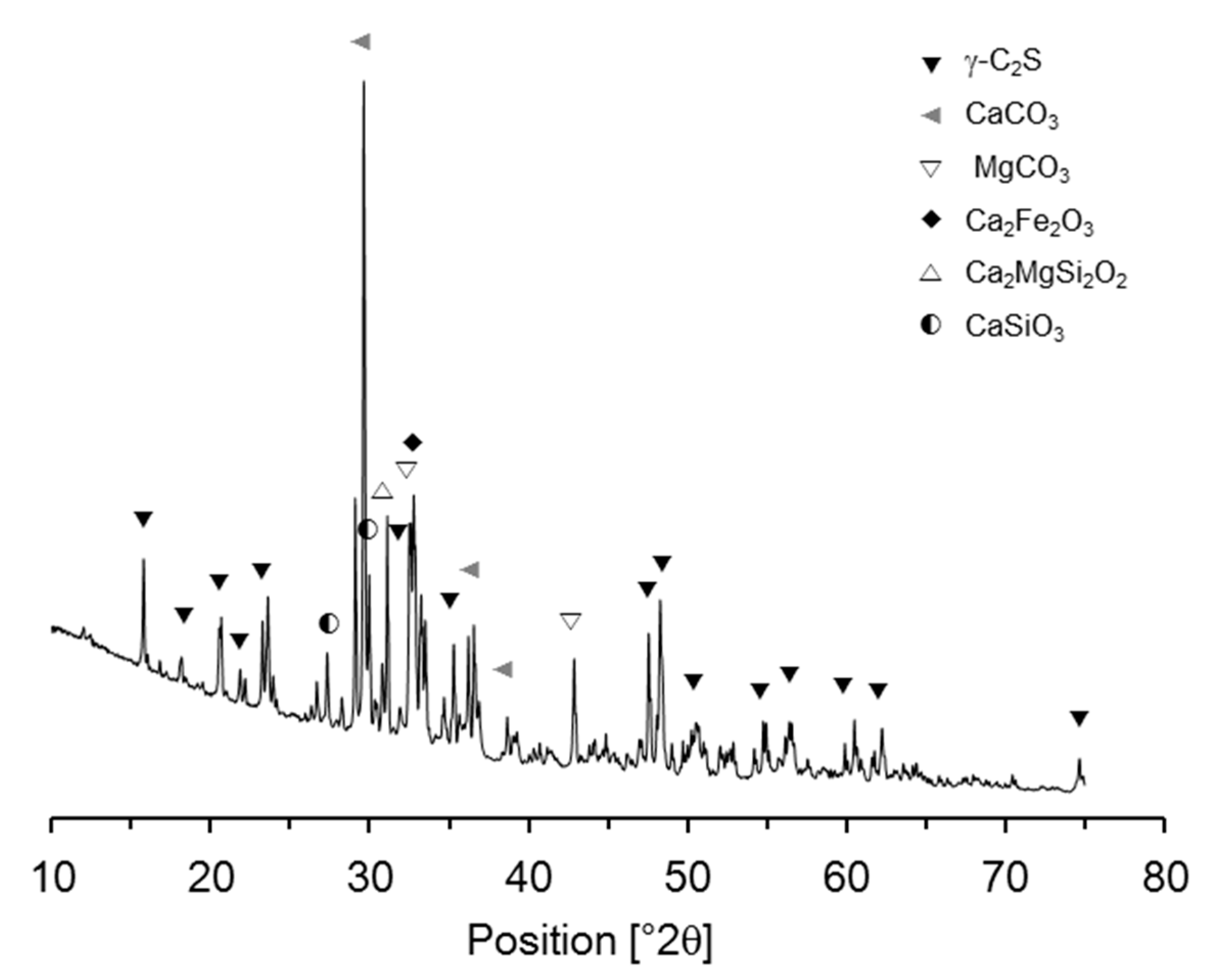

2. Materials and Methods

2.1. Materials and Mixture Proportions

2.2. Test Methods

3. Experimental Results and Discussion

3.1. Conpression Strength

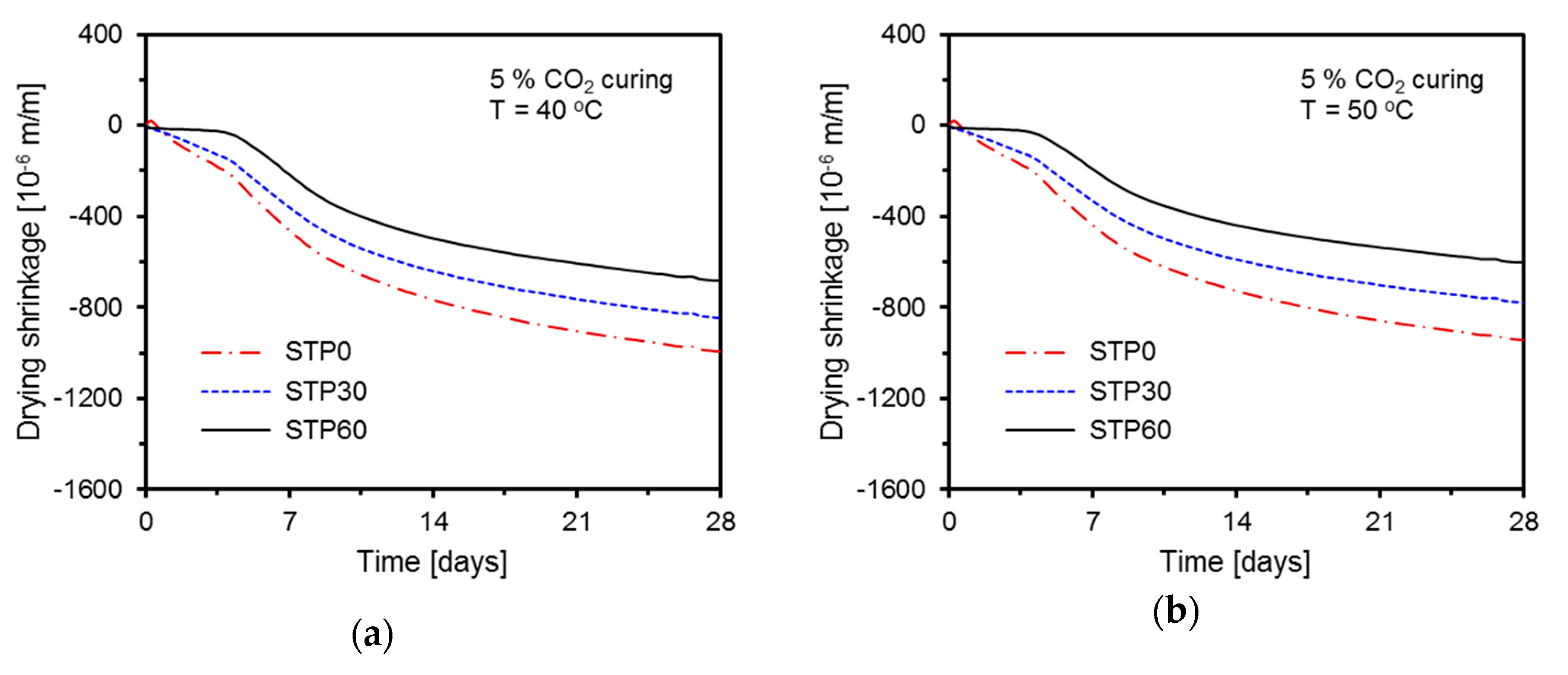

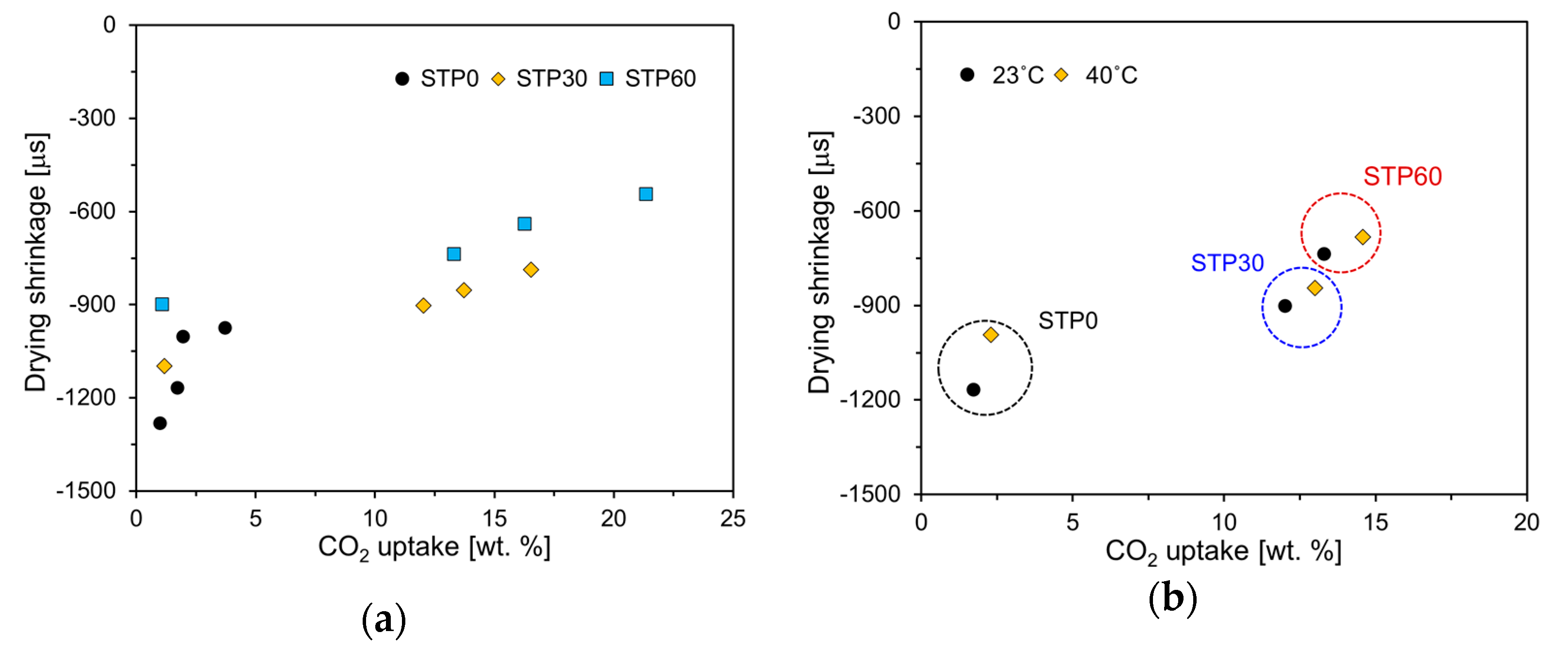

3.2. Drying Shrinkage

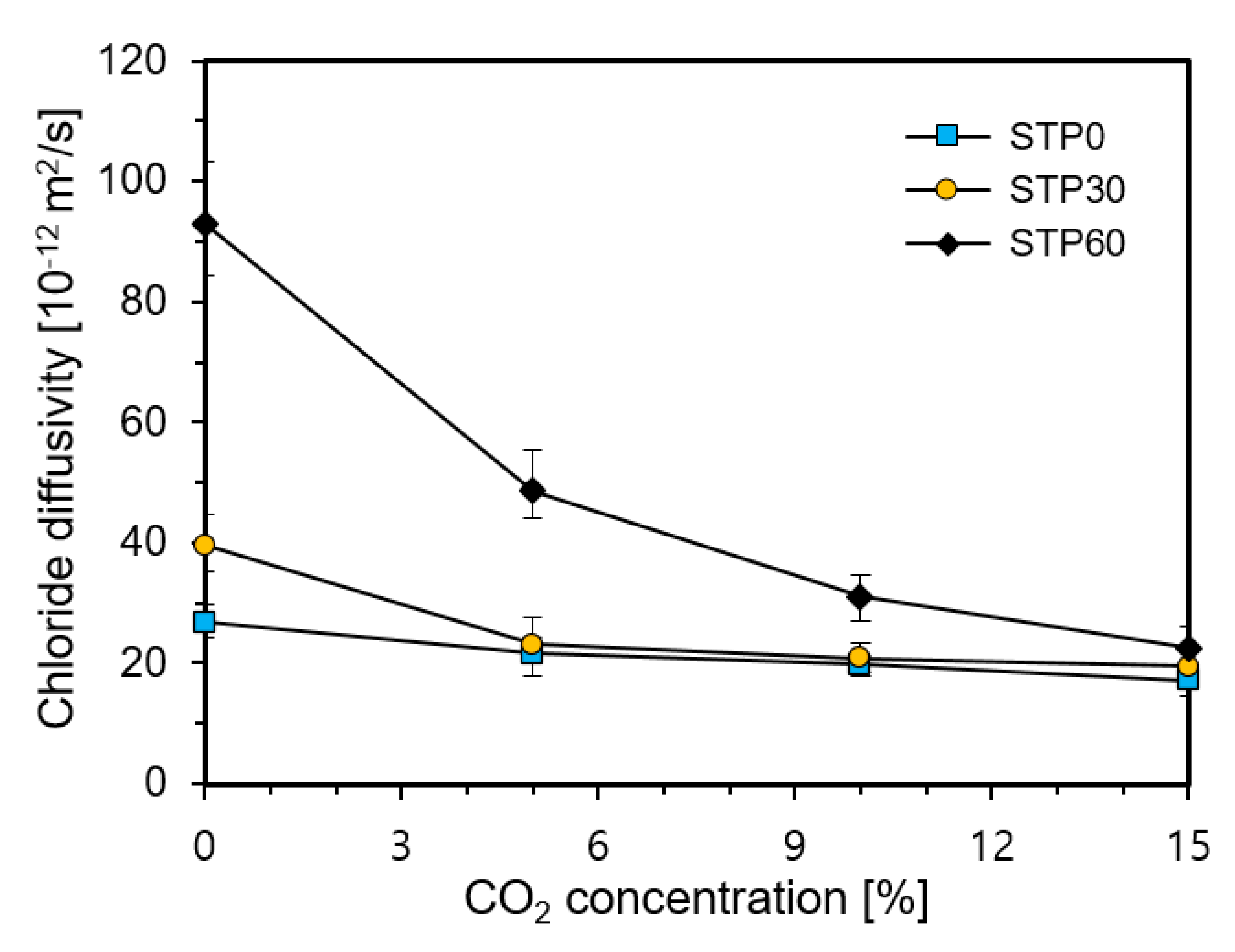

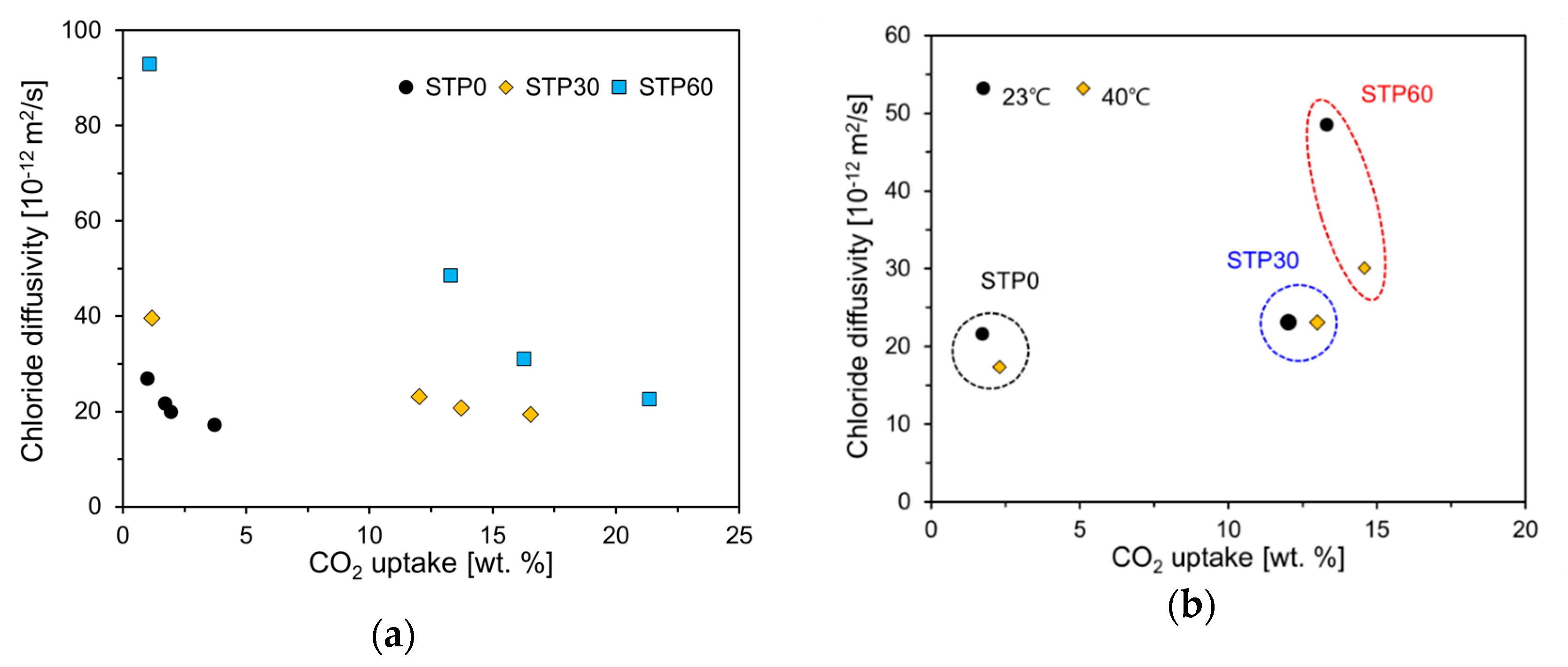

3.3. Chloride Diffusivity

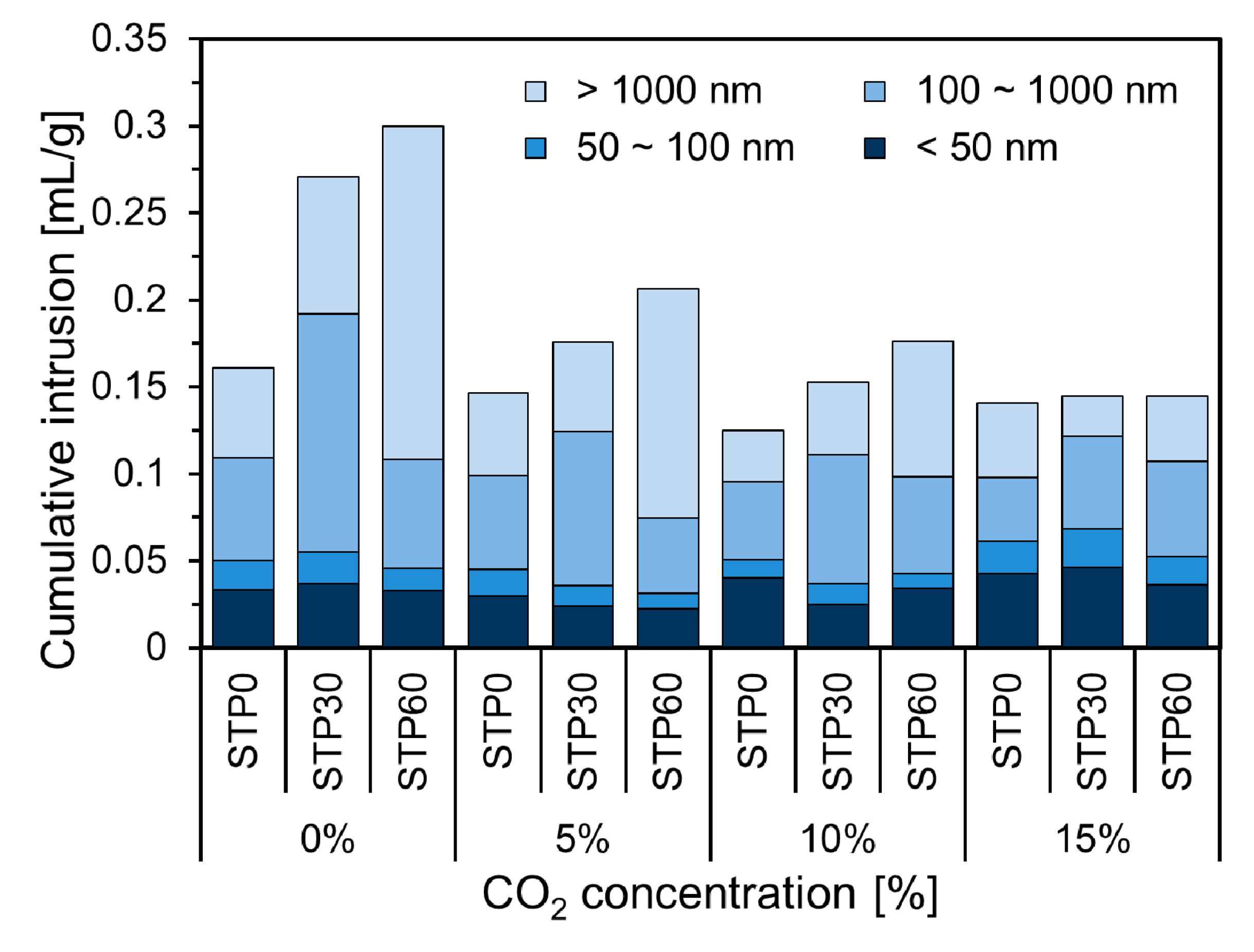

3.4. Mercury Intrusion Porosimetry (MIP)

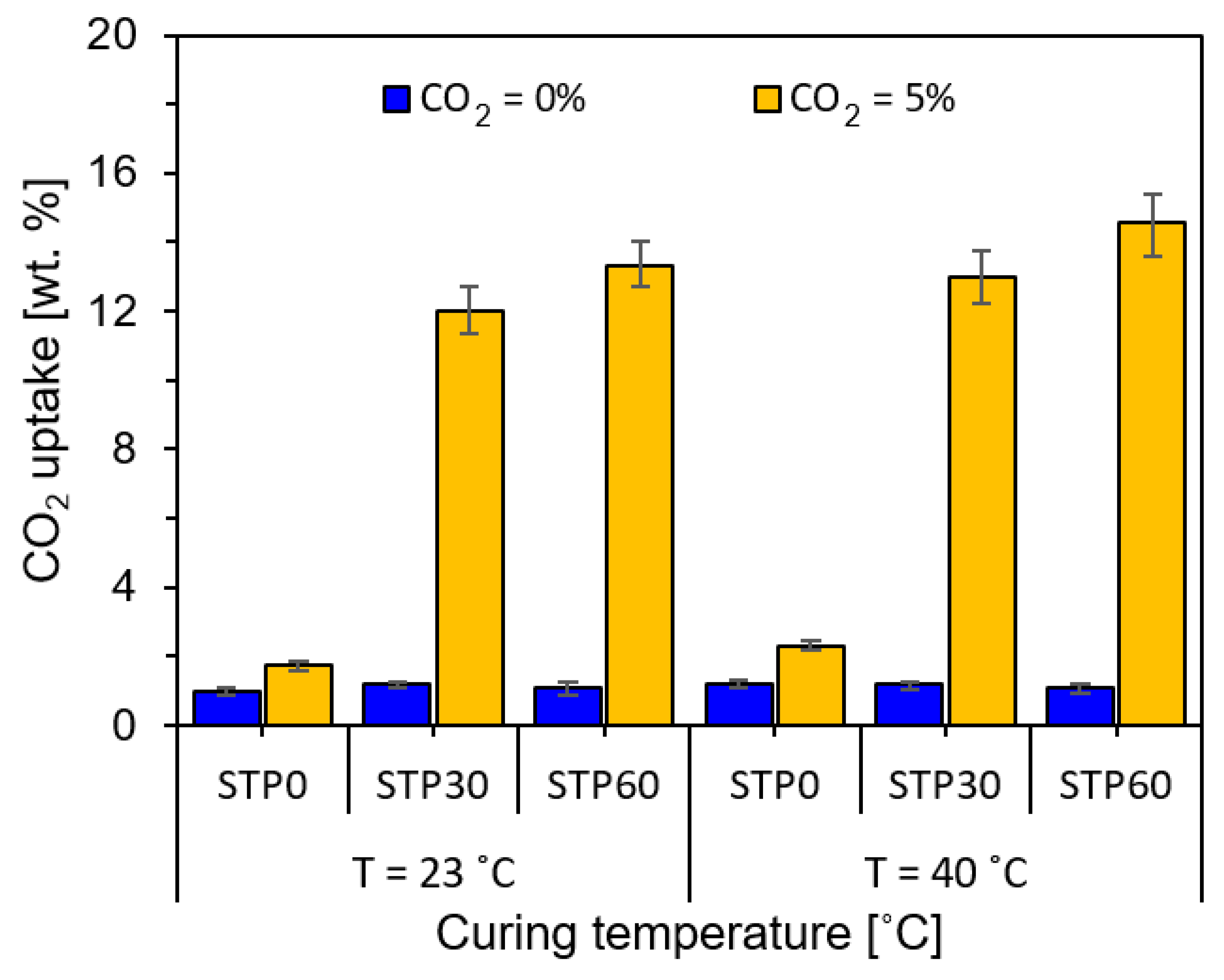

3.5. CO2 Uptake

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Naseri, H.; Jahanbakhsh, H.; Hosseini, P.; Nejad, F.M. Designing sustainable concrete mixture by developing a new machine learning technique. J. Clean. Prod. 2020, 258, 120578. [Google Scholar] [CrossRef]

- Falikman, V.; Realfonzo, R.; Coppola, L.; Hàjek, P.; Riva, P. SP-326: Durability and Sustainability of Concrete Structures (DSCS-2018). ACI Spec. Publ. 2018, 326, 1192. [Google Scholar]

- Mukharjee, B.B.; Barai, S.V. Statistical techniques to analyze properties of nanoengineered concrete using recycled coarse aggregates. J. Clean. Prod. 2014, 83, 273–285. [Google Scholar] [CrossRef]

- Rajamane, N.P.; Nataraja, M.C.; Dattatreya, J.K.; Lakshmanan, N.; Sabitha, D. Sulphate resistance and ecofriendliness of geopolymer concretes. Indian Concr. J. 2012, 86, 13–22. [Google Scholar]

- Singh, M.; Srivastava, A.; Bhunia, D. Long term strength and durability parameters of hardened concrete on partially replacing cement by dried waste marble powder slurry. Constr. Build. Mater. 2019, 198, 553–569. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Cabeza, L.F.; Labrincha, J.; De Magalhaes, A.G. Eco-efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing Limited: Cambridge, UK, 2014. [Google Scholar]

- Sharma, R.; Khan, R.A. Sustainable use of copper slag in self compacting concrete containing supplementary cementitious materials. J. Clean. Prod. 2017, 151, 179–192. [Google Scholar] [CrossRef]

- Naghizadeh, A.; Ekolu, S.O. Method for comprehensive mix design of fly ash geopolymer mortars. Constr. Build. Mater. 2019, 202, 704–717. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Vollpracht, A. Pervious concrete made of alkali activated slag and geopolymers. Constr. Build. Mater. 2018, 189, 797–803. [Google Scholar] [CrossRef]

- BS: 6699. Specification for Ground Granulated Blast Furnace Slag for Use with Portland Cement; British Standard Institution: London, UK, 1992. [Google Scholar]

- EN 15743. Supersulfated Cement—Composition, Specification and Conformity Criteria; European Committee for Standardization (CEN): Brussels, Belgium, 2009. [Google Scholar]

- Huaiwei, Z.; Xin, H. An overview for the utilization of wastes from stainless steel industries. Resour. Conserv. Recycl. 2011, 55, 745–754. [Google Scholar] [CrossRef]

- Adegoloye, G.; Beaucour, A.L.; Ortola, S.; Noumowe, A. Concretes made of EAF slag and AOD slag aggregates from stainless steel process: Mechanical properties and durability. Constr. Build. Mater. 2015, 76, 313–321. [Google Scholar] [CrossRef]

- Adegoloye, G.; Beaucour, A.-L.; Ortola, S.; Noumowe, A. Mineralogical composition of EAF slag and stabilised AOD slag aggregates and dimensional stability of slag aggregate concretes. Constr. Build. Mater. 2016, 115, 171–178. [Google Scholar] [CrossRef]

- Tossavainen, M.; Engstrom, F.; Yang, Q.; Menad, N.; Lidstrom Larsson, M.; Bjorkman, B. Characteristics of steel slag under different cooling conditions. Waste Manag. 2007, 27, 1335–1344. [Google Scholar] [CrossRef] [PubMed]

- Kriskova, L.; Pontikes, Y.; Cizer, O.; Mertens, G.; Veulemans, W.; Geysen, D.; Jones, P.; Vandewalle, L.; Balen, K.V.; Blanpain, B. Effect of mechanical activation on the hydraulic properties of stainless steel slags. Cem. Concr. Res. 2012, 42, 778–788. [Google Scholar] [CrossRef]

- Moon, E.-J.; Choi, Y.C. Development of carbon-capture binder using stainless steel argon-oxygen decarburization slag activated by carbonation. J. Clean. Prod. 2018, 180, 642–654. [Google Scholar] [CrossRef]

- Zhao, H.Q.; Qi, Y.H.; Shi, Y.L.; Na, X.Z.; Feng, H.L. Mechanism and prevention of disintegration of AOD stainless steel slag. J. Iron. Steel. Res. 2013, 20, 26–30. [Google Scholar] [CrossRef]

- Young, J.F.; Berger, R.L.; Breese, J. Accelerated curing of compacted calcium silicate mortars on exposure to CO2. J. Am. Ceram. Soc. 1974, 57, 394–397. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997. [Google Scholar] [CrossRef]

- Guan, X.; Liu, S.; Feng, C.; Qiu, M. The hardening behavior of γ-C2S binder using accelerated carbonation. Constr. Build. Mater. 2016, 114, 204–207. [Google Scholar] [CrossRef]

- Salman, M.; Cizer, Ö.; Pontikes, Y.; Santos, R.M.; Snellings, R.; Vandewalle, L.; Blanpain, B.; Balen, K.V. Effect of accelerated carbonation on AOD stainless steel slag for its valorisation as a CO2-sequestering construction material. Chem. Eng. J. 2014, 246, 39–52. [Google Scholar] [CrossRef] [Green Version]

- Moon, E.-J.; Choi, Y.C. Carbon dioxide fixation via accelerated carbonation of cement-based materials: Potential for construction materials applications. Constr. Build. Mater. 2019, 199, 676–687. [Google Scholar] [CrossRef]

- ISO 679. Cement—Test Methods—Determination of Strength; International Organization of Standards: Geneva, Switzerland, 2009. [Google Scholar]

- Park, B.; Moon, E.-J.; Choi, Y.C. Investigation of microstructure and mechanical performance of carbon-capture binder using AOD stainless steel slag. Constr. Build. Mater. 2020, 242, 118174. [Google Scholar] [CrossRef]

- NT Build 492. Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; Nordtest: Espoo, Finland, 1999. [Google Scholar]

- Kim, J.-K.; Moon, Y.-H.; Eo, S.-H. Compressive strength development of concrete with different curing time and temperature. Cem. Concr. Res. 1998, 28, 1761–1773. [Google Scholar] [CrossRef]

- Barnett, S.J.; Soutsos, M.N.; Millard, S.G.; Bungey, J.H. Strength development of mortars containing ground granulated blast-furnace slag: Effect of curing temperature and determination of apparent activation energies. Cem. Concr. Res. 2006, 36, 434–440. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. A maturity approach to estimate compressive strength development of CO2-cured concrete blocks. Cem. Concr. Comp. 2018, 85, 153–160. [Google Scholar] [CrossRef]

- Brue, F.N.G.; Davy, C.A.; Burlion, N.; Skoczylas, F.; Bourbon, X. Five year drying of high performance concretes: Effect of temperature and cement-type on shrinkage. Cem. Concr. Res. 2017, 99, 70–85. [Google Scholar] [CrossRef]

- Mo, L.; Zhang, F.; Deng, M. Mechanical performance and microstructure of the calcium carbonate binders produced by carbonating steel slag paste under CO2 curing. Cem. Concr. Res. 2016, 88, 217–226. [Google Scholar] [CrossRef]

- Shah, V.; Scrivener, K.; Bhattacharjee, B.; Bishnoi, S. Changes in microstructure characteristics of cement paste on carbonation. Cem. Concr. Res. 2018, 109, 184–197. [Google Scholar] [CrossRef]

- Nielsen, P.; Boone, M.A.; Horckmans, L.; Snellings, R.; Quaghebeur, M. Accelerated carbonation of steel slag monoliths at low CO2 pressure—microstructure and strength development. J. CO2 Util. 2020, 36, 124–134. [Google Scholar] [CrossRef]

- Wang, D.; Noguchi, T.; Nozaki, T. Increasing efficiency of carbon dioxide sequestration through high temperature carbonation of cement-based materials. J. Clean. Prod. 2019, 238, 117980. [Google Scholar] [CrossRef]

| Chemical Compositions (wt. %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Cr2O3 | K2O | Na2O | SO3 | |

| OPC | 62.4 | 20.8 | 4.9 | 3.5 | 1.6 | - | 0.9 | 0.3 | 2.2 |

| AOD slag | 54.3 | 17.7 | 6.4 | 3.0 | 9.2 | 2.8 | 0.2 | 0.1 | 0.4 |

| Water (g) | OPC (g) | AOD Slag (g) | |

|---|---|---|---|

| STP0 | 50 | 100 | - |

| STP30 | 50 | 70 | 30 |

| STP60 | 50 | 40 | 60 |

| Variables | 28-Day Drying Shrinkage | Drying Shrinkage Reduction | |||||

|---|---|---|---|---|---|---|---|

| (× 10−6 m/m) | ((SH(0) 1-SH(x) 2)/SH(0),%) | ||||||

| STP0 | STP30 | STP60 | STP0 | STP30 | STP60 | ||

| T = 23 °C | CO2 = 0% | −1283 | −1097 | −900 | - | - | - |

| CO2 = 5% | −1169 | −903 | −737 | 8.9 | 17.7 | 18.1 | |

| CO2 = 10% | −1003 | −853 | −640 | 21.8 | 22.2 | 28.9 | |

| CO2 = 15% | −975 | −787 | −545 | 24.0 | 28.2 | 39.4 | |

| T = 40 °C | CO2 = 5% | −993 | −844 | −682 | 22.6 | 23.1 | 24.2 |

| T = 50 °C | CO2 = 5% | −943 | −776 | −600 | 26.5 | 29.3 | 33.3 |

| Variables | Voltage (V) | Test Duration (h) | Temperature (K) | Thickness (mm) | Penetration Depth (mm) | Chloride Diffusivity (m2/s) | |

|---|---|---|---|---|---|---|---|

| T = 23 °C | STP0 | 10 | 8 | 293 | 50.12 | 7.72 | 26.80 × 10−12 |

| CO2 = 0% | STP30 | 10 | 8 | 293 | 50.05 | 10.54 | 39.60 × 10−12 |

| STP60 | 10 | 8 | 293 | 49.85 | 21.78 | 92.91 × 10−12 | |

| T = 23 °C | STP0 | 10 | 8 | 293 | 50.24 | 6.54 | 21.60 × 10−12 |

| CO2 = 0% | STP30 | 10 | 8 | 293 | 50.25 | 6.88 | 23.10 × 10−12 |

| STP60 | 10 | 8 | 293 | 50.15 | 12.44 | 48.52 × 10−12 | |

| T = 23 °C | STP0 | 10 | 8 | 293 | 50.14 | 6.13 | 19.78 × 10−12 |

| CO2 = 10% | STP30 | 10 | 8 | 293 | 50.23 | 6.35 | 20.76 × 10−12 |

| STP60 | 10 | 8 | 293 | 50.24 | 8.65 | 31.04 × 10−12 | |

| T = 23 °C, | STP0 | 10 | 8 | 293 | 50.25 | 5.52 | 17.16 × 10−12 |

| CO2 = 15% | STP30 | 10 | 8 | 293 | 49.98 | 6.05 | 19.39 × 10−12 |

| STP60 | 10 | 8 | 293 | 50.14 | 6.75 | 22.49 × 10−12 | |

| T = 40 °C, | STP0 | 10 | 8 | 293 | 50.12 | 5.57 | 17.35 × 10−12 |

| CO2 = 5% | STP30 | 10 | 8 | 293 | 50.20 | 6.88 | 23.09 × 10−12 |

| STP60 | 10 | 8 | 293 | 50.22 | 8.44 | 30.08 × 10−12 | |

| T = 50 °C, | STP0 | 10 | 8 | 293 | 50.12 | 5.42 | 16.72 × 10−12 |

| CO2 = 5% | STP30 | 10 | 8 | 293 | 50.20 | 5.88 | 18.68 × 10−12 |

| STP60 | 10 | 8 | 293 | 50.22 | 7.58 | 26.05 × 10−12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, B.; Choi, Y.C. Effect of Carbonation Curing on Physical and Durability Properties of Cementitious Materials Containing AOD Slag. Appl. Sci. 2020, 10, 6646. https://doi.org/10.3390/app10196646

Park B, Choi YC. Effect of Carbonation Curing on Physical and Durability Properties of Cementitious Materials Containing AOD Slag. Applied Sciences. 2020; 10(19):6646. https://doi.org/10.3390/app10196646

Chicago/Turabian StylePark, Byoungsun, and Young Cheol Choi. 2020. "Effect of Carbonation Curing on Physical and Durability Properties of Cementitious Materials Containing AOD Slag" Applied Sciences 10, no. 19: 6646. https://doi.org/10.3390/app10196646

APA StylePark, B., & Choi, Y. C. (2020). Effect of Carbonation Curing on Physical and Durability Properties of Cementitious Materials Containing AOD Slag. Applied Sciences, 10(19), 6646. https://doi.org/10.3390/app10196646