Structural Analysis and Design of Reinforced Concrete Bridge Corbels

Abstract

:1. Introduction

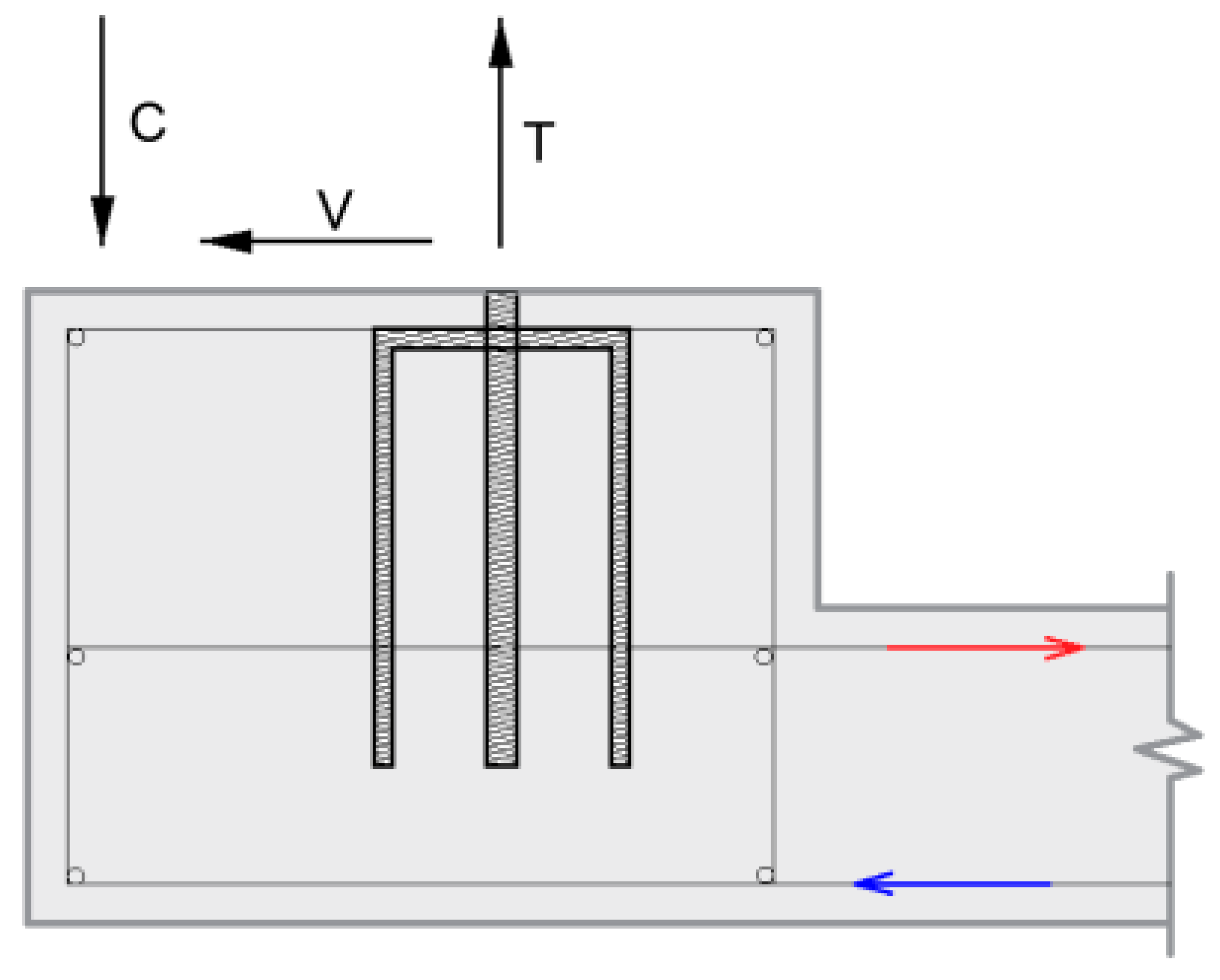

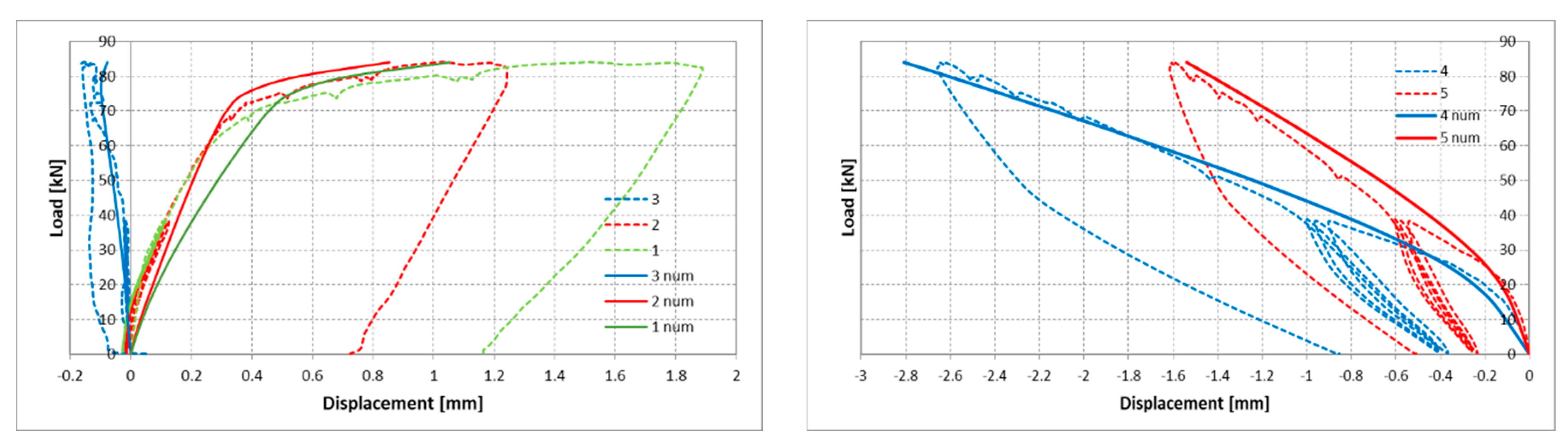

2. Experimental Research

3. Discussion

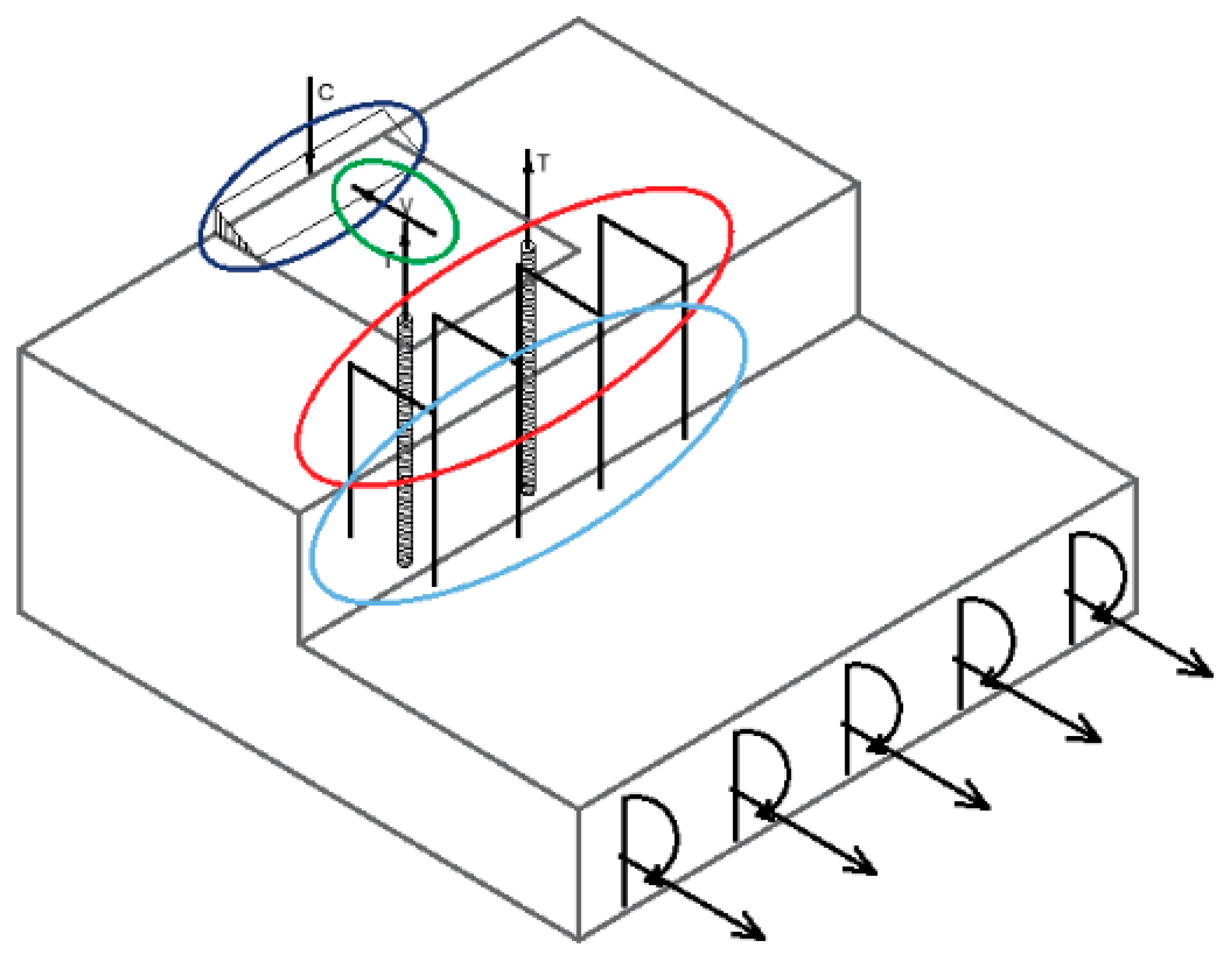

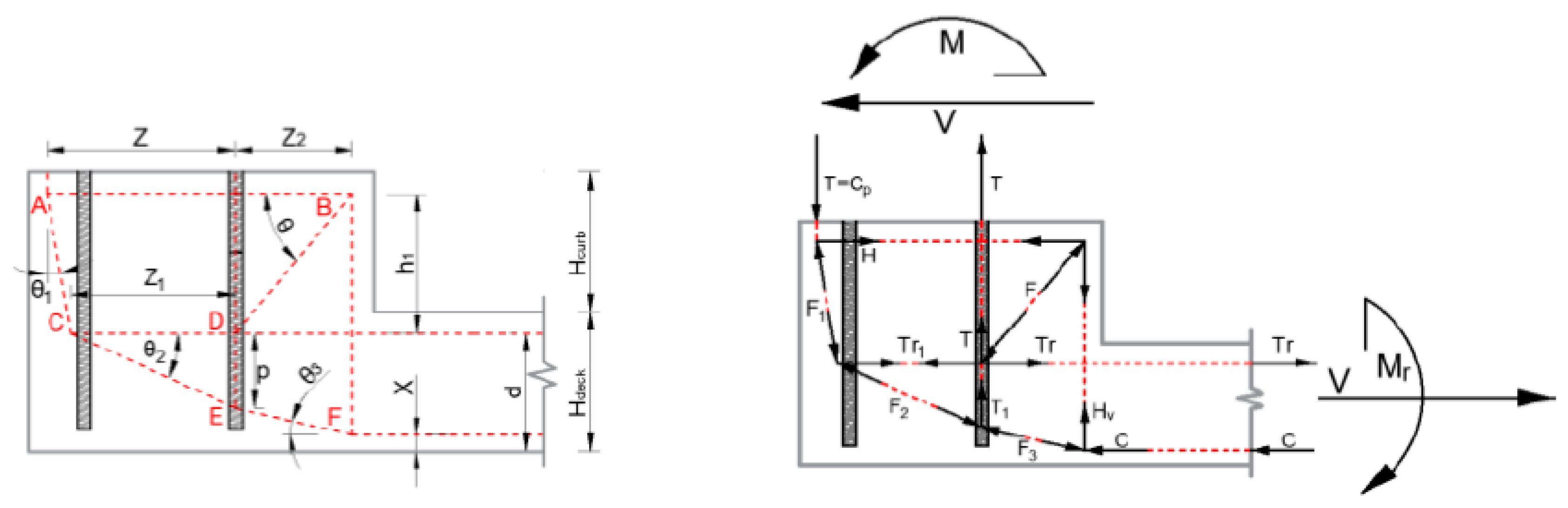

3.1. Strut-and-Tie Model

- The node located close to the external edge of the concrete element under the compressed part of the plate (A). In this node, three elements of the model are converging: Two struts in compression and the top reinforcement of the curb in tension.

- The node located at the internal upper corner of the curb (B): Here the stirrups are bent at 90° and the two ties, which represent the vertical and horizontal branches of the stirrups, are equilibrated by an inclined concrete strut.

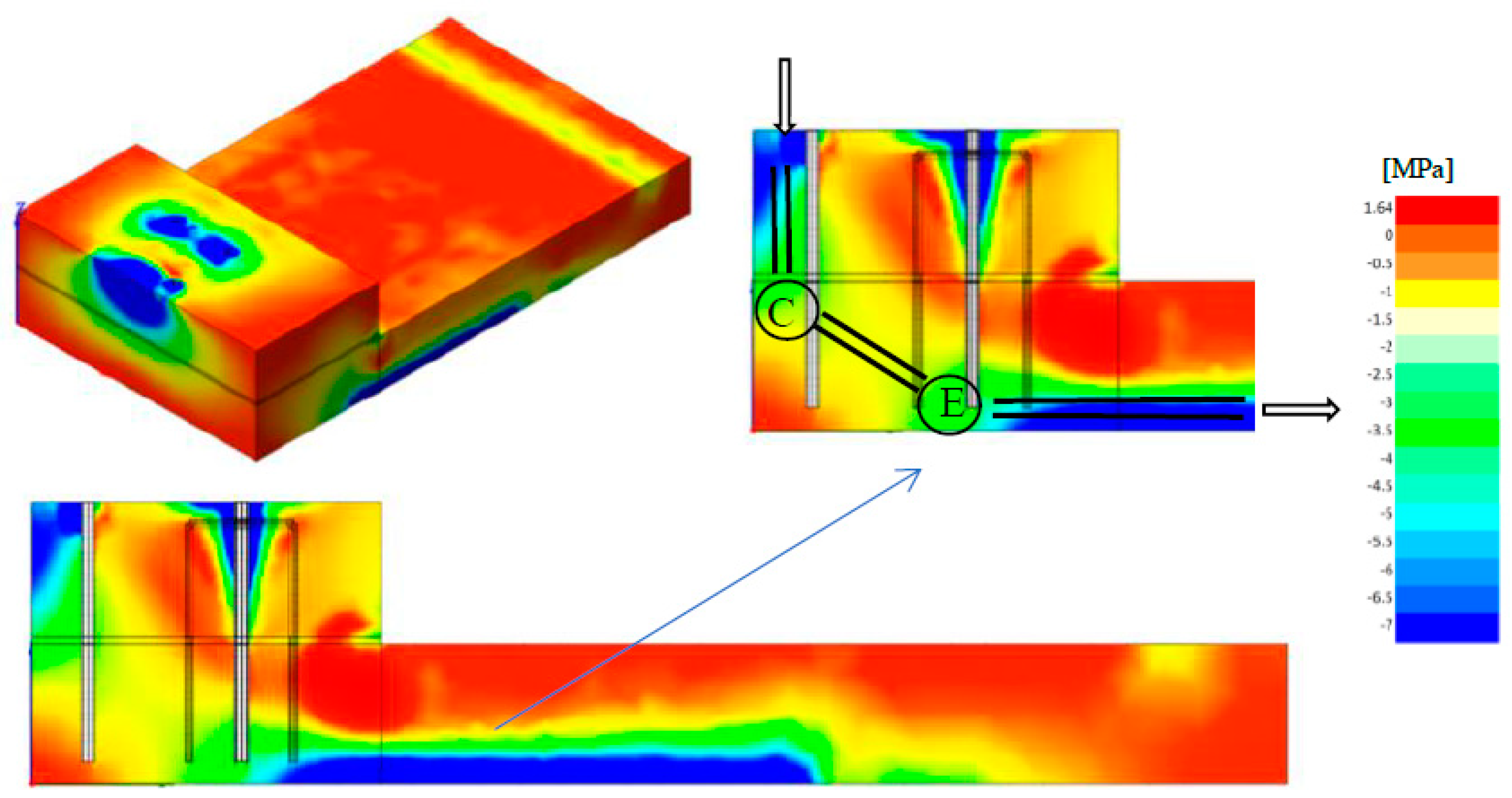

- The node between the two struts in compression deviated by the effect of the tensile force in the upper reinforcement of the deck slab (C).

- The node (D), placed where the compressed concrete strut coming from node B is equilibrated by the difference in vertical tension in the bar and the difference in horizontal tension in the upper reinforcement of the deck.

- The node (E), placed at the bottom of the bar where the tension in the bar contributes to the deviation of the compressive force in the concrete struts.

- The node (F), placed where the vertical branch of the corbel stirrups meets the two compressed struts coming, respectively, from node E and from the compressed lower chord of the deck.

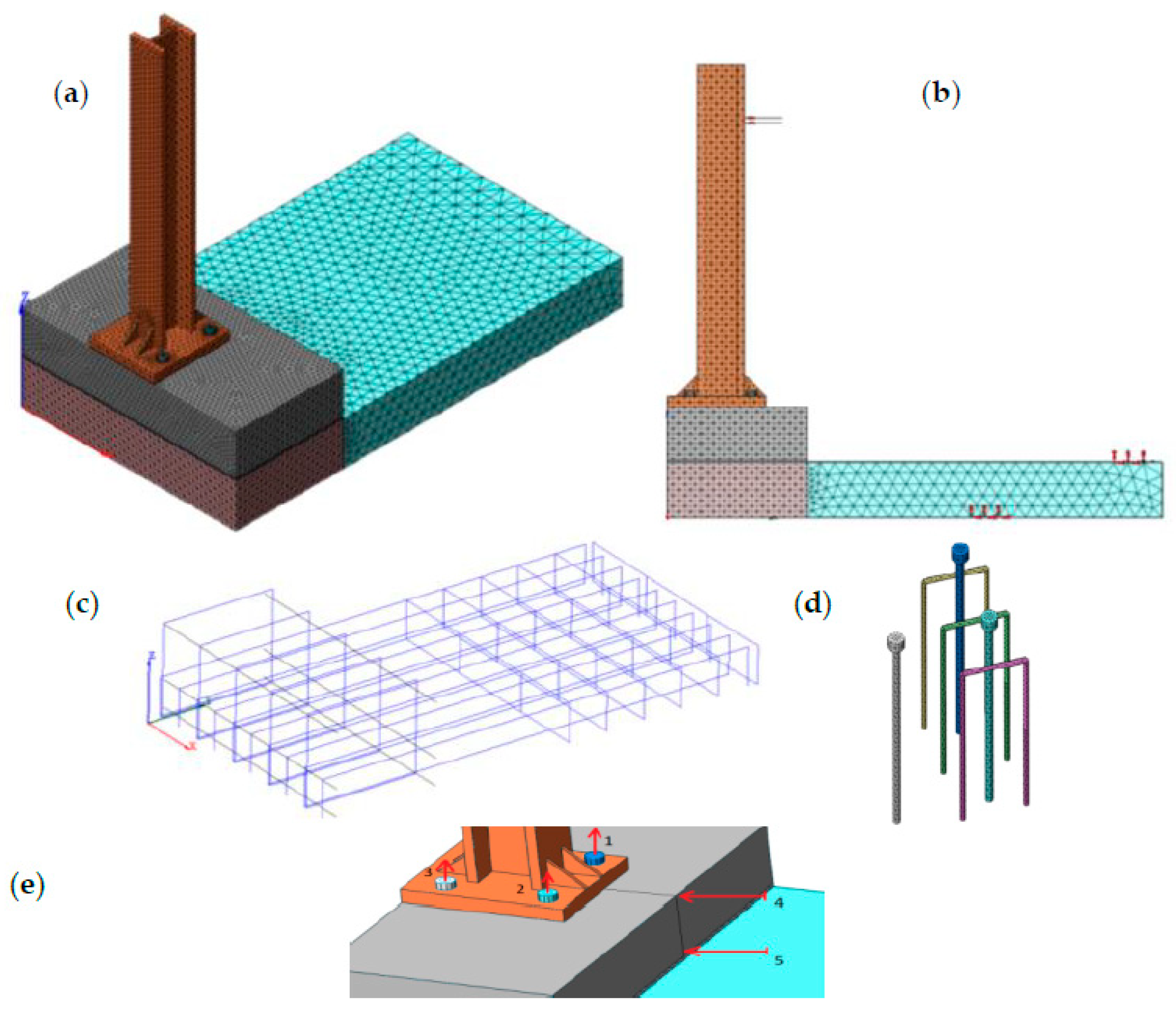

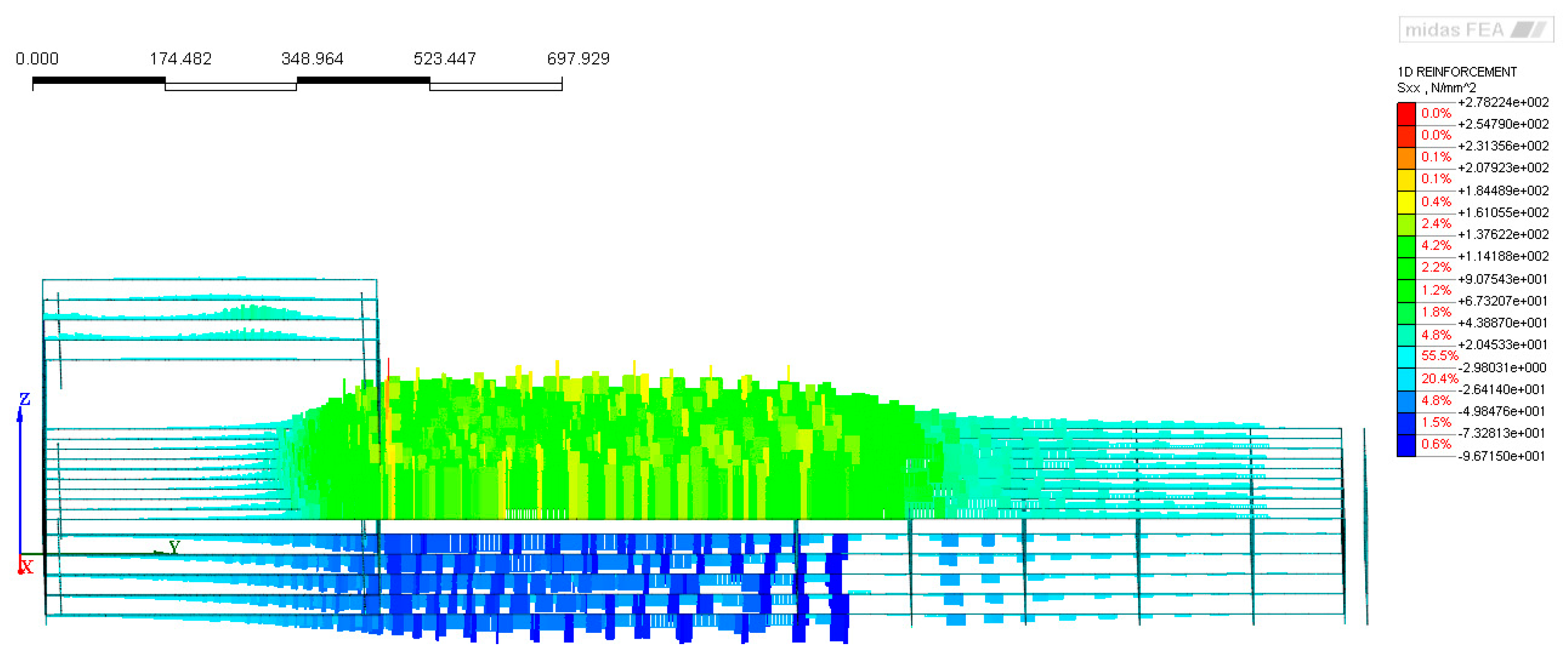

3.2. Numerical Analyses

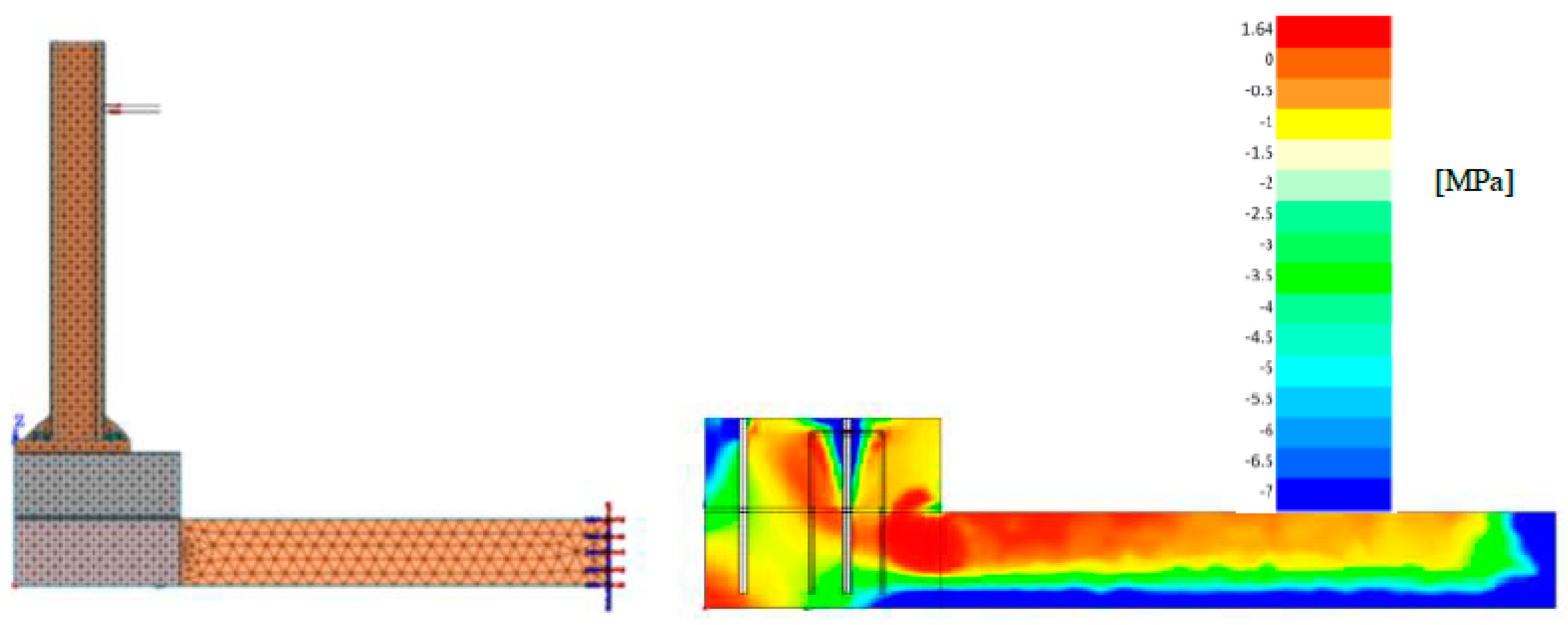

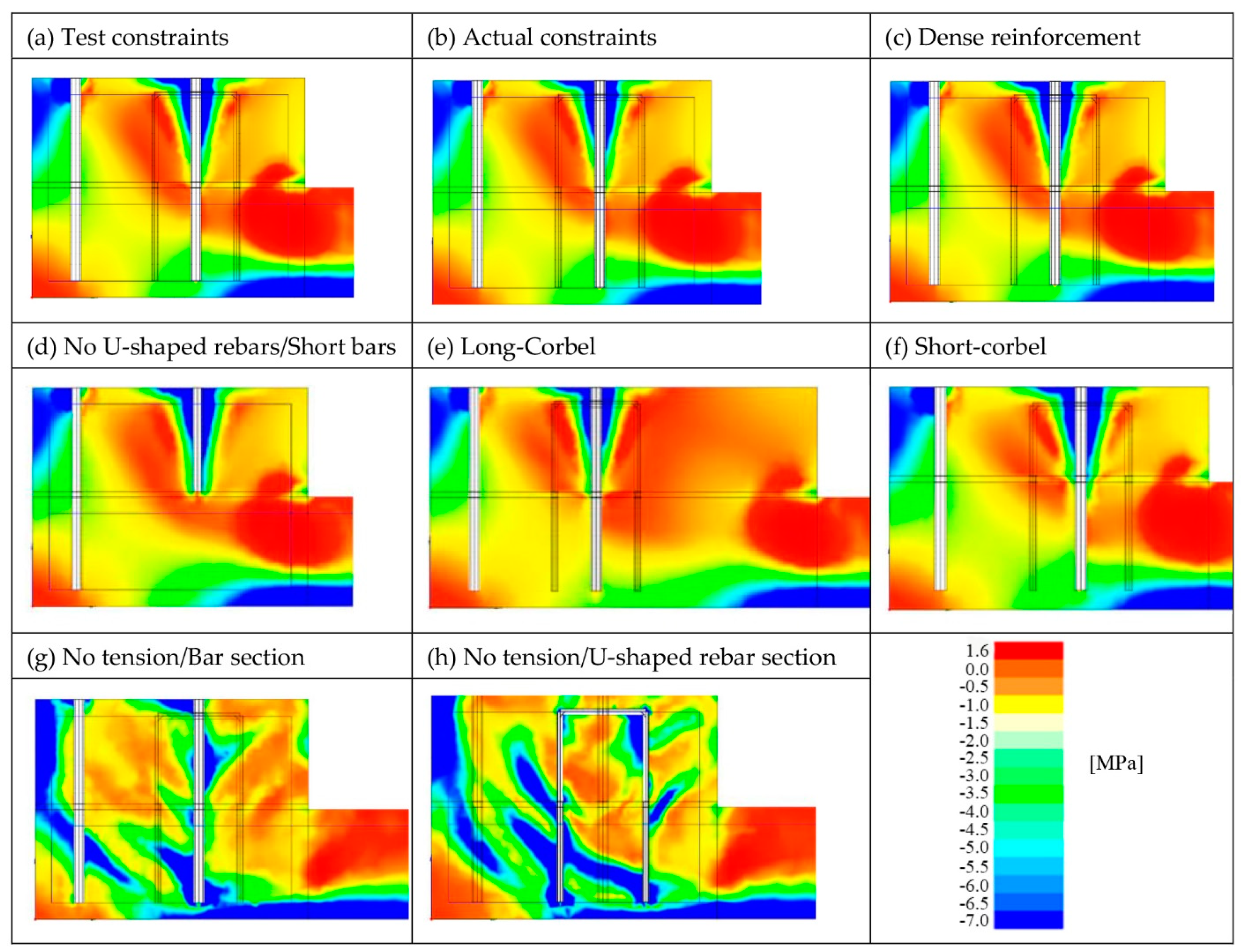

- Model with actual constraints: Substituting the two supports used to simulate the experimental tests (Figure 6b) with a clamped edge that simulates the real bridge situation. This model showed that the stress field around the anchorage group was not affected by these different boundary conditions (Figure 11).

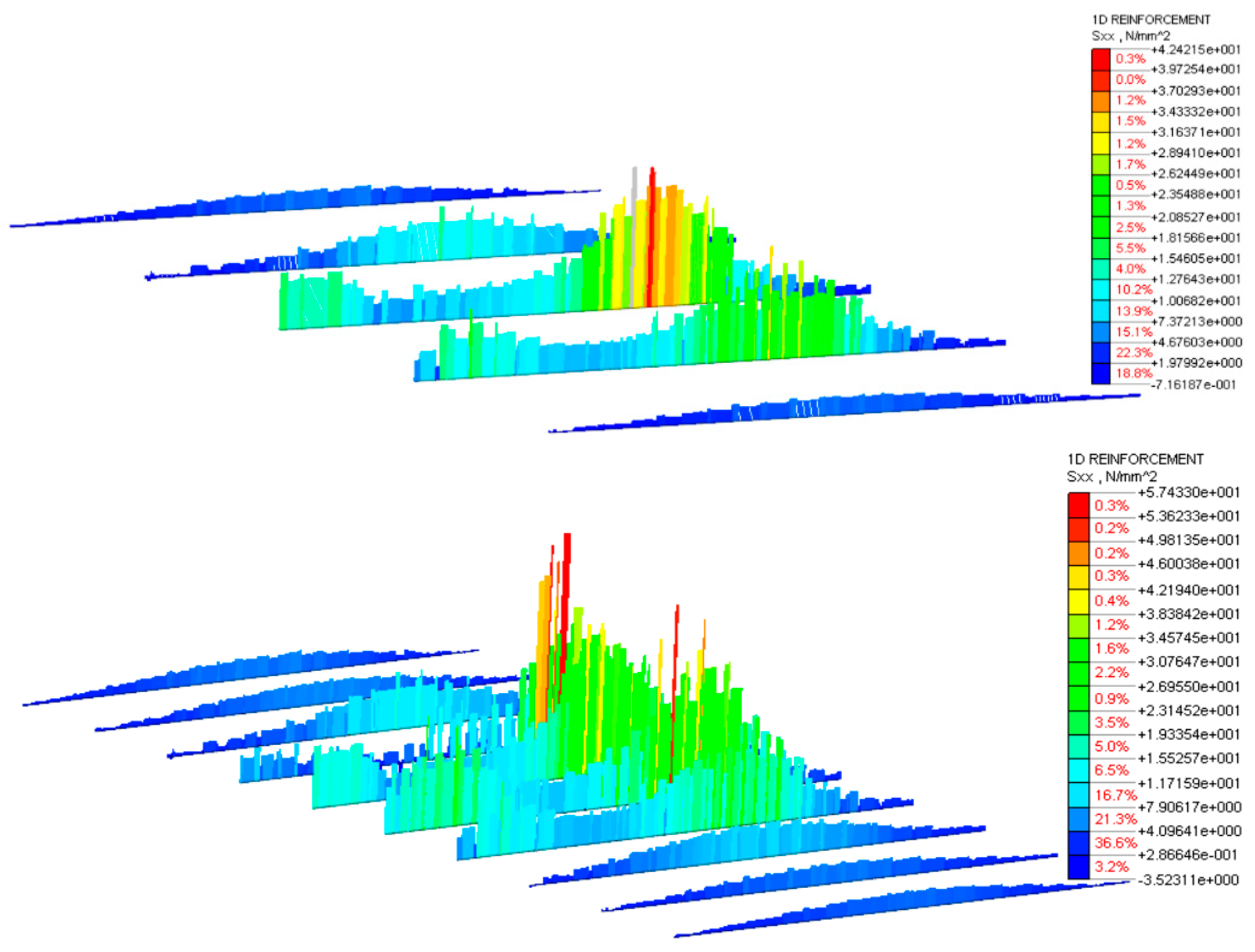

- Model with dense stirrups to verify if a lower spacing of the stirrups of the corbel affects the stress field. The spacing of the stirrups in the curb was chosen, according to the common practice considering the low reinforcement case (200 mm), while in this model the spacing was reduced to 100 mm, providing twice the area of stirrups. Consequently, only a limited decrease in the average stress of the stirrups was observed (of about 23%, Figure 12) but the overall stress distribution within the corbel did not change (Figure 13c).

- No U-shaped rebars model: The U-shaped rebars were removed and the anchoring bars in tension were shortened up to the cold joint to evaluate if the presence of the U-shaped rebars and the bars in the region E (Figure 10) had an influence on the deviation of the stress field. This solution obviously is not feasible because, in this case, the tension load cannot be properly transferred to the concrete of the underneath slab (Figure 13d).

- Short-corbel and long-corbel models, which are considered as possible geometry in practical applications. In these two models the geometry of the corbel was modified by decreasing the height of the curb from 40 cm to 35 cm (short-corbel model, Figure 13f) and by increasing the length of the curb from 50 cm to 70 cm (long-corbel model, Figure 13e). The comparison of the principal stress in compression fields (Figure 13e,f) allowed us to remark that, even if some modifications in the stresses occurred, the main flow of compression stresses remained substantially unchanged in terms of starting and ending points (Figure 10, points C and E) while changing the geometry of the curb.

- No-tension constitutive model (introduced in the 1960s by Zienkiewicz et al. [34]): With the assumption of “no-tension material”, the concrete is considered without any tensile strength. This model can help to understand the implications of the usual hypothesis of no-tension material and what is the role of concrete in this case. The stress fields for the same section passing through the two bars, and for the section passing through the central, U-shaped rebar, are represented in Figure 13g,h, respectively. In this case the stress field was strongly influenced by the anchorage system since concrete could no longer bear tensile stresses. By comparing this model (Figure 13g,h) with the previous ones (Figure 13a–f), it can be observed that the deviation of the stresses in region E was due to the tensile strength of concrete. This model (Figure 13g,h) highlighted the main role of the concrete tensile strength, usually not considered in the design phase. In defining the strut-and-tie model, this contribution cannot be disregarded when dealing with nodal equilibrium. In addition, the no-tension model did not highlight the stress concentration in the corbel/deck transition section, which appeared as the highly stressed section in other models and where cracks appeared during the experimental tests (Figure 2).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Frangopol, D.M. Optimizing Bridge Network Maintenance Management under Uncertainty with Conflicting Criteria: Life-Cycle Maintenance, Failure, and User Costs. J. Struc. Eng. 2006, 132, 1835–1845. [Google Scholar] [CrossRef]

- Yehia, S.; Abudayyeh, O.; Fazal, I.; Randolph, D. A decision support system for concrete bridge deck maintenance. Adv. Eng. Softw. 2008, 39, 202–210. [Google Scholar] [CrossRef]

- Wan-Wendner, R. Aging concrete structures: A review of mechanics and concepts. Die Bodenkult. J. Land Manag. Food Environ. 2018, 69, 175–199. [Google Scholar] [CrossRef] [Green Version]

- Cardinale, G.; Orlando, M. Structural evaluation and strengthening of a reinforced concrete bridge. J. Bridge. Eng. ASCE 2004, 9, 35–42. [Google Scholar] [CrossRef]

- Mitchell, G.; Strahota, M.T.; Gokani, V.; Picón, R.; Yang, S.; Klingner, R.E.; Williamson, E.B. Performance of Retrofit Highway Barriers with Mechanical Anchors. ACI Struct. J. 2010, 107, 381–389. [Google Scholar]

- Cattaneo, S.; Crespi, P. Response of connections between concrete corbels and safety barriers. Materials 2019, 12, 4103. [Google Scholar] [CrossRef] [Green Version]

- Cattaneo, S.; Crespi, P.; Locatelli, A.; Rago, D. Safety Barriers for Bridges, Report Dept; ABC, Politecnico di Milano: Milano, Italy, 2018. [Google Scholar]

- Gesoglu, M.; Ozturan, T.; Ozel, M.; Guneyisi, E. Tensile behavior of post-installed anchors in plain and steel fiber reinforced normal and high-strength concretes. ACI Struct. J. 2005, 102, 224–231. [Google Scholar]

- Cattaneo, S. Wedge-type expansion anchors in high performance concrete. ACI Struct. J. 2007, 104, 191–198. [Google Scholar]

- Gurbuz, T.; Ilki, A. Pullout performance of fully and partially bonded retrofit anchors in low strength concrete. ACI Struct. J. 2011, 108, 61–70. [Google Scholar]

- Delhomme, F.; Brun, M. Pullout Tests on Post-Installed Bonded Anchors in Ultra-High Performance Fiber Reinforced Concrete. Struct. Eng. Int. 2019, 29, 1–8. [Google Scholar] [CrossRef]

- Eligehausen, R.; Cook, R.A.; Appl, J. Behavior and design of adhesive bonded anchors. ACI Struct. J. 2006, 103, 822–831. [Google Scholar]

- Cook, R.A.; Konz, R.C. Factors Influencing Bond Strength of Adhesive Anchors. ACI Struct. J. 2001, 98, 76–86. [Google Scholar]

- Grosser, P.; Fuchs, W.; Eligehausen, R. A field study of adhesive anchor installations. Concr. Int. 2011, 33, 57–63. [Google Scholar]

- González, F.; Fernández, J.; Agranati, G.; Villanueva, P. Influence of construction conditions on strength of post installed bonded anchors. Constr. Build. Mater. 2018, 165, 272–283. [Google Scholar] [CrossRef]

- Cattaneo, S.; Locatelli, A.; Rago, D. Reliability of bonded anchors with different installation techniques: Experimental assessment. Asian J. Civ. Eng. 2019, 20, 681–692. [Google Scholar] [CrossRef]

- European Committee for Standardization (CEN). CEN/EN1992-1-1+AC. Eurocode 2: Design of Concrete Structures-Part 1-1: General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2010. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary on Building Code Requirements for Structural Concrete (ACI 318R-14); ACI: Farmington Hills, MI, USA, 2014. [Google Scholar]

- European Committee for Standardization (CEN). CEN/EN1992-4. Eurocode 2-Design of Concrete Structures-Part 4: Design of Fastenings for Use in Concrete; CEN: Brussels, Belgium, 2018. [Google Scholar]

- Eligehausen, R.; Mallée, R.; Silva, J. Anchorage in Concrete Construction; Ernst&Sohn: Hamburg, Germany, 2006. [Google Scholar]

- Charney, F.A.; Pal, K.; Silva, J. Recommended procedures for development and splicing of post-installed bonded reinforcing bars in concrete structures. ACI Struct. J. 2013, 110, 437–446. [Google Scholar] [CrossRef]

- Mahrenholtz, C.; Eligehausen, R.; Reinhardt, H. Design of post-installed reinforcing bars as end anchorage or as bonded anchor. Eng. Struct. 2015, 100, 645–655. [Google Scholar] [CrossRef]

- Kunz, J.; Hamad, B.S.; Al Hammoud, R. Evaluation of Bond Strength of Bonded-In or Post-Installed Reinforcement. ACI Struct. J. 2006, 103, 207–218. [Google Scholar] [CrossRef]

- He, Z.; Liu, Z.; Wang, J.; Ma, Z. Development of Strut-and-Tie Models Using Load Path in Structural Concrete. ASCE J. Struct. Eng. 2020, 146, 06020004. [Google Scholar] [CrossRef]

- Cai, C.S. Three-Dimensional Strut-and-Tie Analysis for Footing Rehabilitation. Pract. Period. Struct. Des. Constr. 2002, 7, 14–25. [Google Scholar] [CrossRef]

- Xia, Y.; Langelaar, M.; Hendriks, M.A.N. Automated optimization-based generation and quantitative evaluation of Strut-and-Tie models. Comput. Struct. 2020, 238, 106297. [Google Scholar] [CrossRef]

- European Organisation for Technical Assessment (EOTA). EOTA/TR048. Details of Tests for Post-Installed Fasteners in Concrete; EOTA: Brussels, Belgium, 2016. [Google Scholar]

- European Organisation for Technical Assessment (EOTA). EOTA/ETA 16/0143. Injection System Hilti HIT-RE 500 V3; EOTA: Brussels, Belgium, 2016. [Google Scholar]

- Ministero delle Infrastrutture e dei Trasporti. Aggiornamento delle Norme Tecniche per le Costruzioni (NTC2018); Ministero delle Infrastrutture e dei Trasporti: Roma, Italy, 2018. [Google Scholar]

- Russo, G.; Venir, R.; Pauletta, M.; Somma, G. Reinforced Concrete Corbels—Shear Strength Model and design Formula. ACI Struct. J. 2006, 103, 3–10. [Google Scholar]

- Fib. Model Code for Concrete Structures 2010; Fib: Lausanne, Switzerland, 2013. [Google Scholar]

- MidasFEA. Analysis and Algorithm Manual; MidasFEA: South Korea, Seongnam, 2015. [Google Scholar]

- Cattaneo, S.; Giussani, F. Shear behaviour of R.C. beams with water-stop joints. Eng. Struct. 2013, 56, 1775–1786. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Valliappan, S.; King, I.P. Stress Analysis of Rock as a ‘No Tension’ Material. Géotechnique 1968, 18, 56–66. [Google Scholar] [CrossRef]

| Geometry | Actions/Forces | Design |

|---|---|---|

| Z, Z2, h1, Hcorbel, Hdeck (see Figure 5) | T, VEd, MEd | |

| Area of stirrups within 2 steel plate width | ||

| cs concrete cover | Steel area at the top of the deck | |

| S1 =spacing between U-shaped rebars S2 =spacing between the vertical branches of the U-shaped rebars | Area of concrete under tension | |

| X (see Figure 5)—determined as the half of the neutral axis at the ultimate limit state of the slab with a width B = 3S1 | ||

| θ1 = 10° | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cattaneo, S.; Crespi, P.; Biolzi, L. Structural Analysis and Design of Reinforced Concrete Bridge Corbels. Appl. Sci. 2020, 10, 6727. https://doi.org/10.3390/app10196727

Cattaneo S, Crespi P, Biolzi L. Structural Analysis and Design of Reinforced Concrete Bridge Corbels. Applied Sciences. 2020; 10(19):6727. https://doi.org/10.3390/app10196727

Chicago/Turabian StyleCattaneo, Sara, Pietro Crespi, and Luigi Biolzi. 2020. "Structural Analysis and Design of Reinforced Concrete Bridge Corbels" Applied Sciences 10, no. 19: 6727. https://doi.org/10.3390/app10196727

APA StyleCattaneo, S., Crespi, P., & Biolzi, L. (2020). Structural Analysis and Design of Reinforced Concrete Bridge Corbels. Applied Sciences, 10(19), 6727. https://doi.org/10.3390/app10196727