Sustainable Dewatering of Industrial Sludges in Sludge Treatment Reed Beds: Experiences from Pilot and Full-Scale Studies under Different Climates

Abstract

:Featured Application

Abstract

1. Introduction

2. Sludge Treatment Reed Bed System and Industrial Sludge

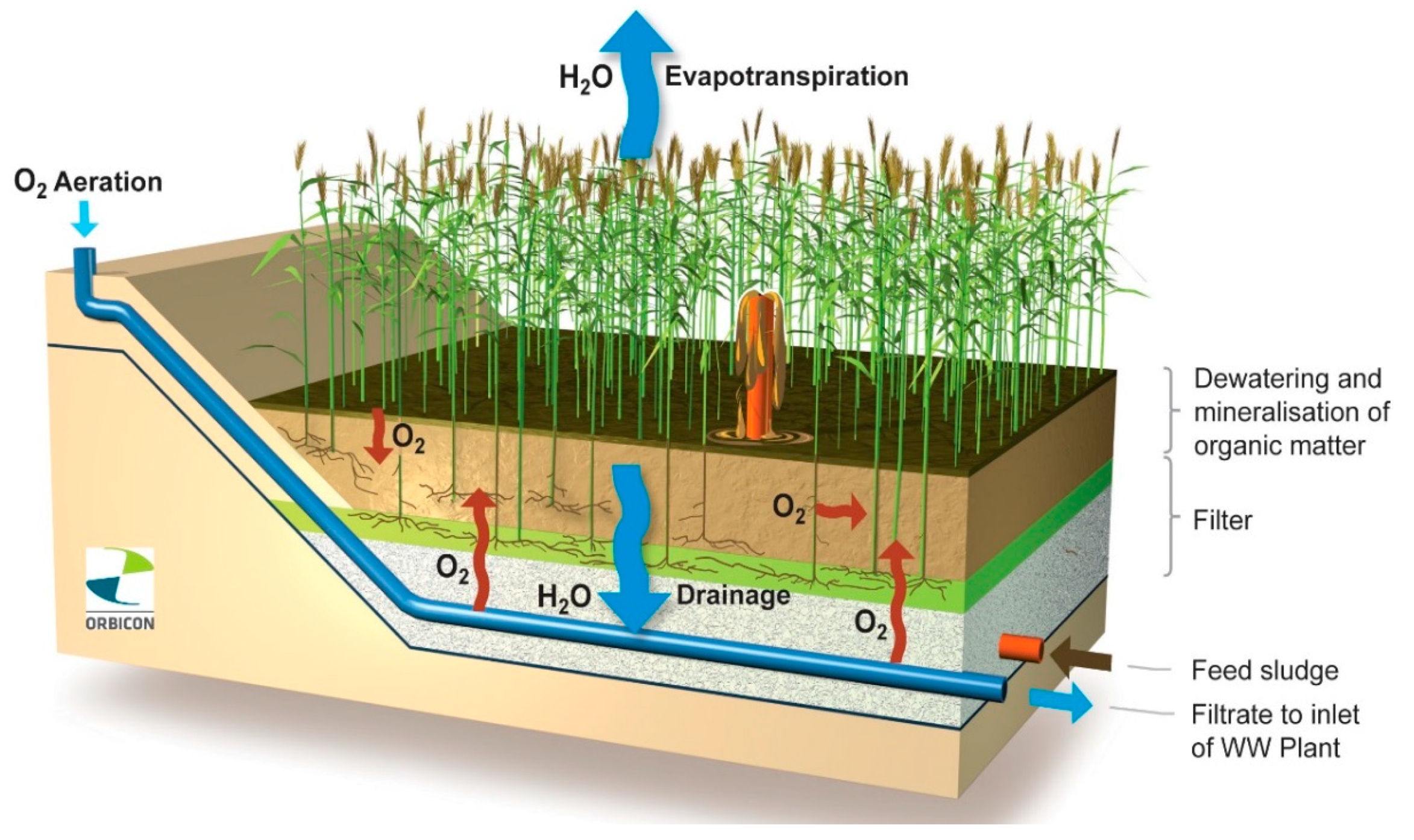

2.1. Description

2.2. Operation

2.3. Industrial Sludge in STRB

2.3.1. Organic Matter

2.3.2. Oil and Fats

2.3.3. Heavy Metals

2.3.4. Nutrients

2.3.5. Hazardous Organic Compounds

3. Case Studies of Pilot and Full-Scale STRBs

3.1. Industrial Sludge with High Fat Content (Denmark and Sweden)

3.2. Industrial Sludge with High Nickel Content (Denmark)

3.3. Sewage Sludge with High Chromium Content (Greece)

3.4. Water Works Sludge (England)

3.4.1. WW Sludge and Drained Water Quality

3.4.2. Sedimentation and Capillary Suction Time

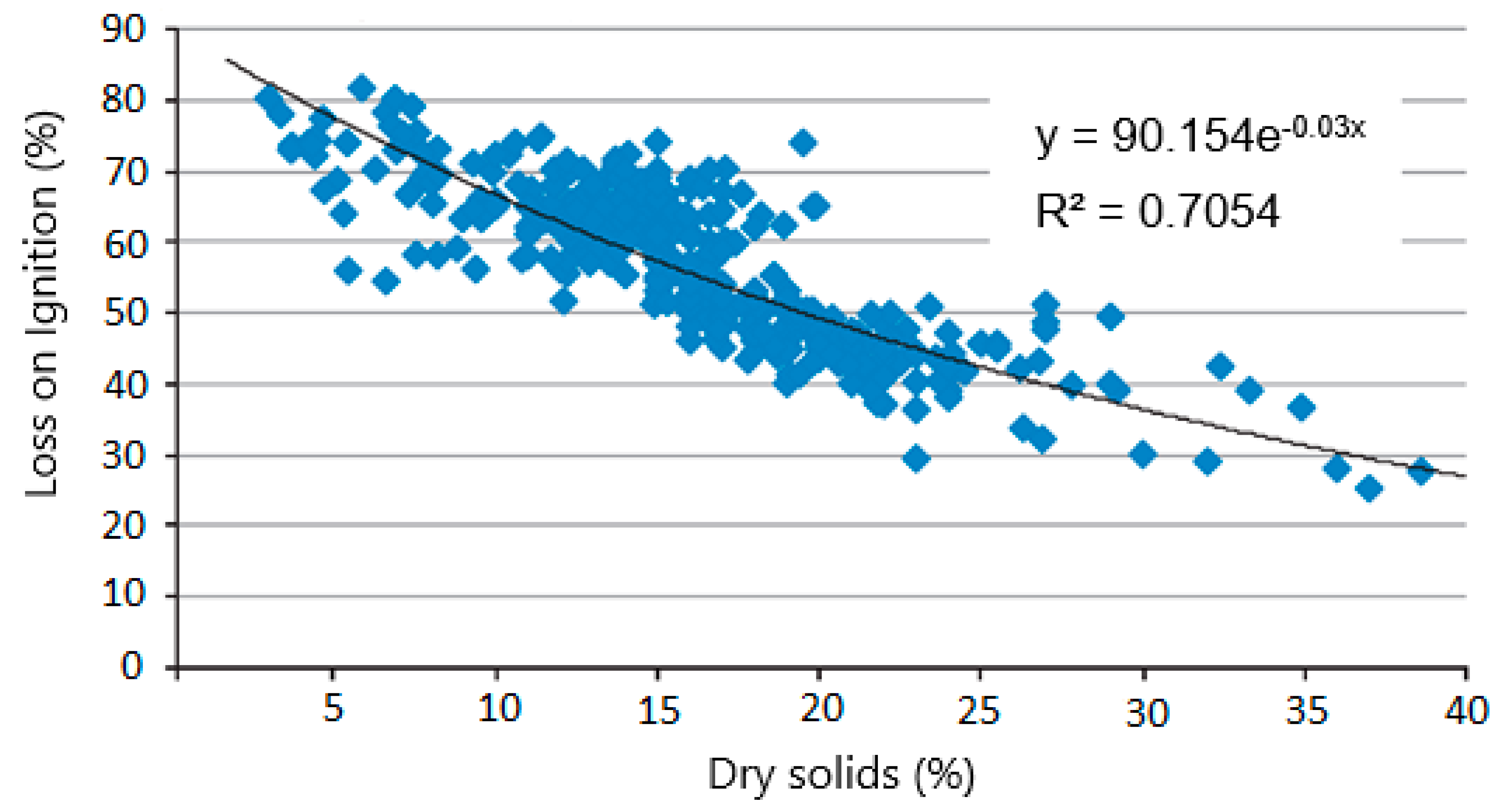

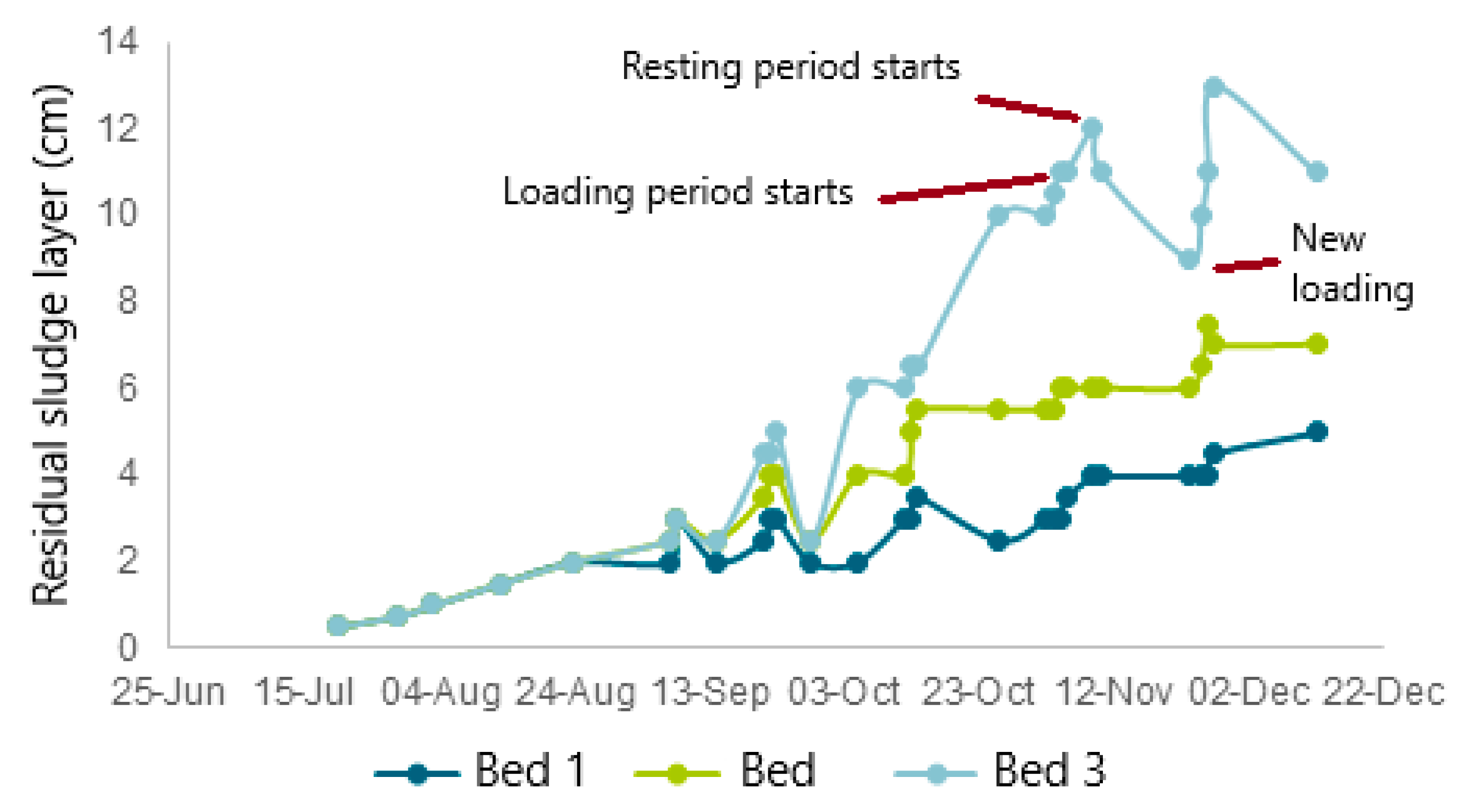

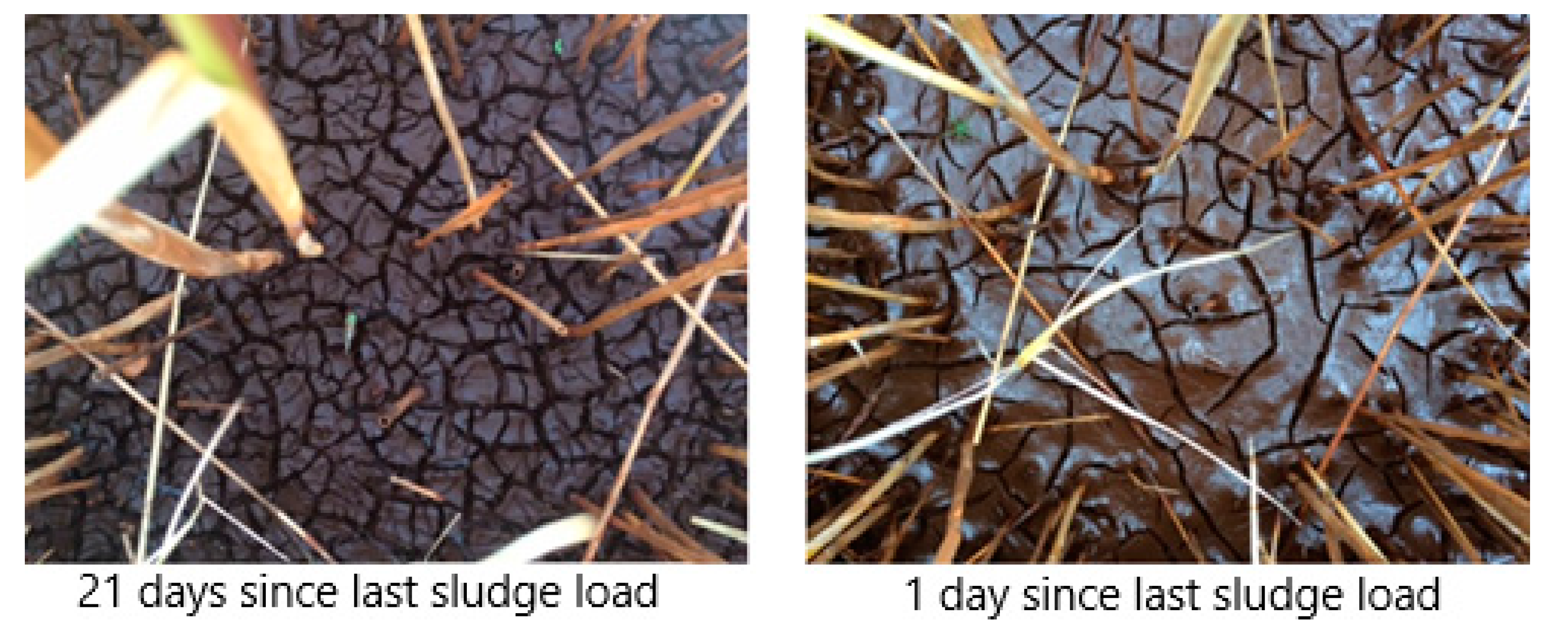

3.4.3. Water Works Sludge Volume Reduction and Residual Sludge Development

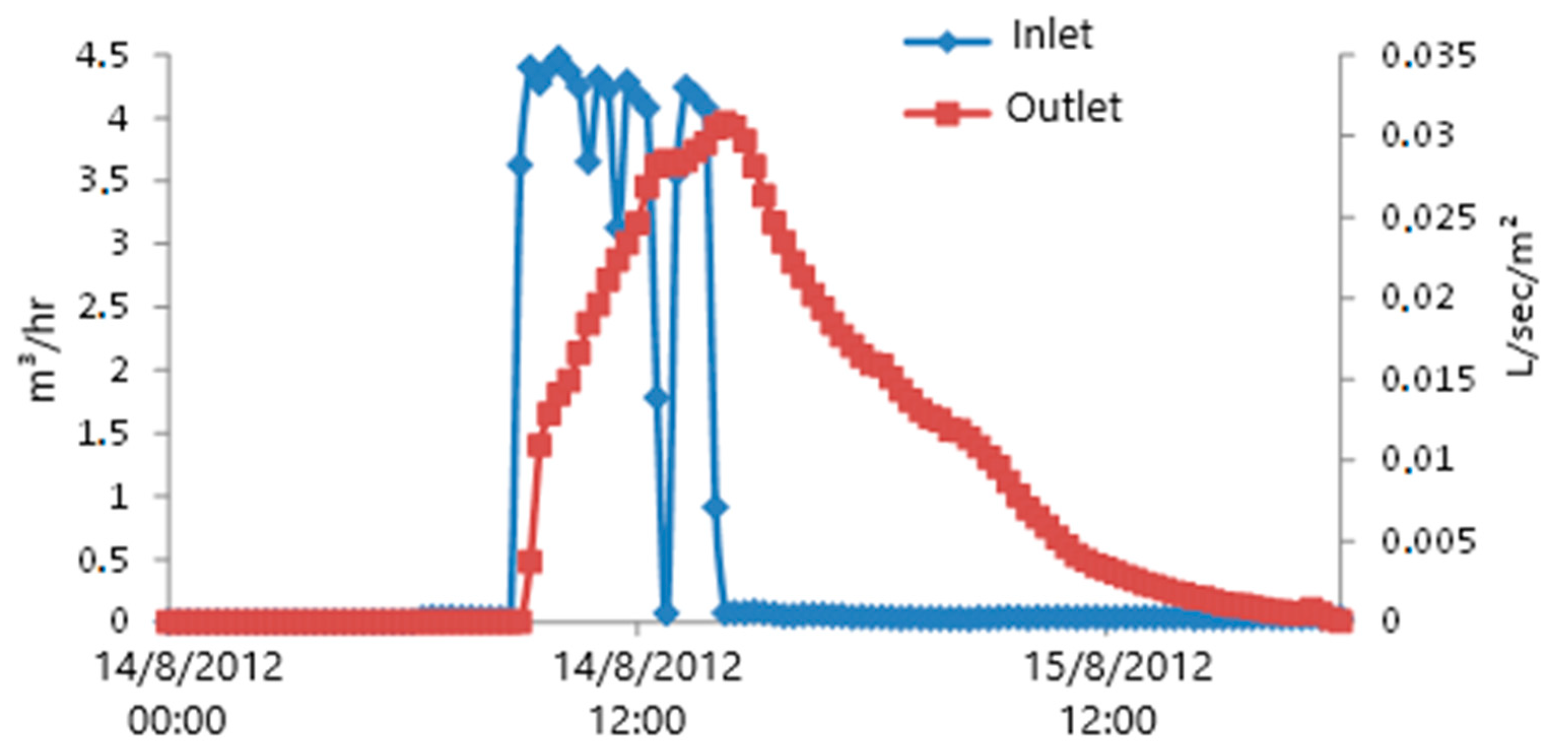

3.4.4. Infiltration Rate

3.5. Overall Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stefanakis, A.I.; Akratos, C.S.; Tsihrintzis, V.A. Vertical Flow Constructed Wetlands. In Eco-Engineering Systems for Wastewater and Sludge Treatment, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage sludge management in Europe: A critical analysis of data quality. Int. J. Environ. Waste Manag. 2016, 18, 226–238. [Google Scholar] [CrossRef]

- EC (European Commission). Sewage Sludge. Available online: https://ec.europa.eu/environment/waste/sludge (accessed on 14 September 2020).

- Salado, R.; Vencovsky, D.; Daly, E.; Zamparutti, T.; Palfrey, R. Part II: Report on Options and Impacts. In Environmental, Economic and Social Impacts of the Use of Sewage Sludge on Land; Report by RPA; European Commission, DG Environment: Brussels, Belgium, 2010. [Google Scholar]

- Nielsen, S.; Willoughby, N. Sludge treatment and drying reed bed systems in Denmark. Water Environ. J. 2005, 19, 296–305. [Google Scholar] [CrossRef]

- Uggetti, E.; Ferrer, I.; Llorens, E.; Garcia, J. Sludge treatment wetlands: A review on the state of the art. Bioresour. Technol. 2010, 101, 2905–2912. [Google Scholar] [CrossRef] [PubMed]

- Brix, H. Sludge dewatering and mineralization in Sludge Treatment Reed Beds. Water 2017, 9, 160. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, S. Economic assessment of sludge handling and environmental impact of sludge treatment in a reed bed system. Water Sci. Technol. 2015, 71, 1286–1292. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, S.; Larsen, J.D. Operational strategy, economic and environmental performance of sludge treatment reed bed systems—based on 28 years of experience. Water Sci. Technol. 2016, 74, 1793–1799. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, S. Mineralisation of hazardous organic compounds in a sludge reed bed and sludge storage. Water Sci. Technol. 2005, 51, 109–117. [Google Scholar] [CrossRef]

- Boruszko, D. Changes of the content of heavy metals and PAH’s in sewage sludge treatment with Reed Bed Lagoons. J. Ecol. Eng. 2018, 19, 75–87. [Google Scholar] [CrossRef]

- Stefanakis, A.I. The Role of Constructed Wetlands as Green Infrastructure for Sustainable Urban Water Management. Sustainability 2019, 11, 6981. [Google Scholar] [CrossRef] [Green Version]

- Olsson, L.; Larsen, J.D.; Ye, S.; Brix, H. Emissions of CO2 and CH4 from sludge treatment reed beds depend on system management and sludge loading. J. Environ. Manag. 2014, 141, 51–60. [Google Scholar] [CrossRef] [PubMed]

- Mantovi, P.; Baldoni, G.; Toderi, G. Reuse of liquid, dewatered, and composted sewage sludge on agricultural land: Effects of long-term application on soil and crop. Water Res. 2005, 39, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Langergraber, G.; Dotro, G.; Nivala, J.; Rizzo, A.; Stein, O.R. Wetland Technology: Practical Information on the Design and Application of Treatment Wetlands, 1st ed.; IWA Publishing: London, UK, 2019. [Google Scholar]

- Stefanakis, A.I.; Becker, J.A. A review of emerging contaminants in water: Classification, sources, and potential risk. In Impact of Water Pollution on Human Health and Environmental Sustainability; McKeown, A.E., Bugyi, G., Eds.; IGI Global: Hershey, PA, USA, 2015; pp. 55–80. [Google Scholar]

- Harrison, E.Z.; Oakes, S.R.; Hysell, M.; Hay, A. Organic chemicals in sewage sludges. Sci. Total Environ. 2006, 367, 481–497. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kołecka, K.; Gajewska, M.; Stepnowski, P.; Caban, M. Spatial distribution of pharmaceuticals in conventional wastewater treatment plant with Sludge Treatment Reed Beds technology. Sci. Total Environ. 2019, 647, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Cui, Y.; Li, A.; Wang, D.; Zhang, W.; Chen, Z. Seasonal dynamics of bacterial communities associated with antibiotic removal and sludge stabilization in three different sludge treatment wetlands. J. Environ. Manag. 2019, 240, 231–237. [Google Scholar] [CrossRef]

- Ma, J.; Cui, Y.; Li, A.; Zhang, W.; Ma, C.; Chen, Z. Occurrence and distribution of five antibiotic resistance genes during the loading period in sludge treatment wetlands. J. Environ. Manag. 2020, 274, 111190. [Google Scholar] [CrossRef]

- European Union. Council Directive 86/278/EEC on the Protection of the Environment, and in Particular of the Soil, when Sewage Sludge is used in Agriculture. Off. J. Eur. Union 1986, L181, 6–12. [Google Scholar]

- European Commission-DG Environment. Working Document on Sludge; 3rd Draft; European Commission-DG Environment: Brussels, Belgium, 2000; Available online: http://ec.europa.eu/environment/waste/sludge/pdf/sludge_en.pdf (accessed on 13 July 2020).

- Stefanakis, A.I. Constructed Wetlands for Industrial Wastewater Treatment, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Nielsen, S. Sludge treatment reed bed facilities-organic load and operation problems. Water Sci. Technol. 2011, 63, 942–948. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Tsihrintzis, V.A. Effects of loading, resting period, temperature, porous media, vegetation and aeration on performance of pilot-scale Vertical Flow Constructed Wetlands. Chem. Eng. J. 2012, 181–182, 416–430. [Google Scholar] [CrossRef]

- Kołecka, K.; Obarska-Pempkowiak, H.; Gajewska, M. Polish experience in operation of sludge treatment reed beds. Ecol. Eng. 2018, 120, 405–410. [Google Scholar] [CrossRef]

- Mennerich, A.; Niebuhr, L.; Ezzo, H. Full scale sludge treatment in reed beds in moderate climate—A case study. Water 2017, 9, 741. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.; Bel, T.; Bourdoncle, P.; Dimare, J.; Troesch, S.; Molle, P. Septage unit treatment by sludge treatment reed beds for easy management and reuse: Performance and design considerations. Water Sci. Technol. 2018, 77, 279–285. [Google Scholar] [CrossRef] [PubMed]

- Stefanakis, A.I.; Akratos, C.S.; Melidis, P.; Tsihrintzis, V.A. Surplus activated sludge dewatering in pilot-scale Sludge Drying Reed Beds. J. Hazard Mater. 2009, 172, 1122–1130. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Tsihrintzis, V.A. Effect of various design and operation parameters on performance of pilot-scale Sludge Drying Reed Beds. Ecol. Eng. 2012, 38, 65–78. [Google Scholar] [CrossRef]

- Uggetti, E.; Ferrer, I.; Carretero, J.; Garcia, J. Performance of sludge treatment wetlands using different plant species and porous media. J. Hazard Mater. 2012, 217–218, 263–270. [Google Scholar] [CrossRef] [PubMed]

- Peruzzi, E.; Nielsen, S.; Macci, C.; Doni, S.; Iannelli, R.; Chiarugi, M.; Masciandaro, G. Organic matter stabilization in reed bed systems: Danish and Italian examples. Water Sci. Technol. 2013, 68, 1888–1894. [Google Scholar] [CrossRef] [PubMed]

- Peruzzi, E.; Macci, C.; Doni, S.; Iannelli, R.; Masciandaro, G. Stabilization process in reed bed systems for sludge treatment. Ecol. Eng. 2017, 102, 381–389. [Google Scholar] [CrossRef]

- Hu, S.; She, X.; Wei, X.; Hu, B.; Hu, C.; Qian, Y.; Fang, Y.; Zhang, X.; Bashir, S.; Chen, Z. Surplus sludge treatment in two sludge treatment beds under subtropical condition in China. Int. Biodeter. Biodegrad. 2017, 119, 377–386. [Google Scholar] [CrossRef]

- Stefanakis, A.I. Constructed wetlands for sustainable wastewater treatment in hot and arid climates: Opportunities, challenges and case studies in the Middle East. Water 2020, 12, 1665. [Google Scholar] [CrossRef]

- Stefanakis, A.I. Constructed Wetlands: Description and benefits of an eco-tech water treatment system. In Impact of Water Pollution on Human Health and Environmental Sustainability, 1st ed.; McKeown, A., Bugyi, G., Eds.; IGI Global: Hershey, PA, USA, 2015; pp. 281–303. [Google Scholar]

- Nielsen, S. Sludge drying reed beds. Water Sci. Technol. 2003, 48, 101–108. [Google Scholar] [CrossRef]

- Meng, D.; Wu, J.; Xu, Z.; Xu, Y.; Li, H.; Jin, W.; Zhang, J. Effect of passive ventilation on the performance of unplanted sludge treatment wetlands: Heavy metal removal and microbial community variation. Environ. Sci. Pollut. Res. 2020, 27, 31665–31676. [Google Scholar] [CrossRef]

- Nielsen, S.; Peruzzi, E.; Macci, C.; Doni, S.; Masciandaro, G. Stabilisation and mineralisation of sludge in reed bed systems after 10–20 years of operation. Water Sci. Technol. 2014, 69, 539–545. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, S. Sludge treatment and drying reed bed systems. 2007. Wastewater treatment in wetlands: Theoretical and practical aspects. Water Sci. Technol. 2007, 3–4, 223–234. [Google Scholar]

- Nielsen, S. Helsinge sludge reed bed system: Reduction of pathogenic microorganisms. Water Sci. Technol. 2007, 56, 175–182. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, G.; La Rosa, A.D. Design of a constructed wetland for wastewater treatment in a Sicilian town and environmental evaluation using the emergy analysis. Ecol. Model. 2006, 197, 490–497. [Google Scholar] [CrossRef]

- Zhou, J.B.; Jiang, M.M.; Chen, B.; Chen, G.Q. Emergy evaluations for constructed wetland and conventional wastewater treatments. Commun. Nonlinear Sci. Numer Simul. 2009, 14, 1781–1789. [Google Scholar] [CrossRef]

- Nielsen, S.; Bruun, E.W. Sludge quality after 10–20 years of treatment in reed bed systems. Environ. Sci. Pollut. Res. 2015, 22, 12885–12891. [Google Scholar] [CrossRef]

- Dixon, A.; Simon, M.; Burkitt, T. Assessing the environmental impact of two options for small-scale wastewater treatment: Comparing a reedbed and an aerated biological filter using a life cycle approach. Ecol. Eng. 2003, 20, 297–308. [Google Scholar] [CrossRef]

- Rosli, F.A.; Lee, K.E.; Goh, C.T.; Mokhtar, M.; Latif, M.T.; Hog, T.L.; Simon, N. The use of constructed wetlands in sequestrating carbon: An overview. Nat. Environ. Pollut. Technol. 2017, 16, 813–819. [Google Scholar]

- De Klein, J.J.M.; van der Werf, A.K. Balancing carbon sequestration and GHG emissions in a constructed wetland. Ecol. Eng. 2014, 66, 36–42. [Google Scholar] [CrossRef]

- Tuncal, T.; Uslu, O. A review of dehydrations of various industrial sludges. Drying Tech. 2014, 32, 1642–1654. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Tsihrintzis, V.A. Heavy metal fate in pilot-scale Sludge Drying Reed Beds under various design and operation conditions. J. Hazard. Mater. 2012, 213–214, 393–405. [Google Scholar] [CrossRef] [PubMed]

- Kołecka, K.; Nielsen, S.; Obarska-Pempkowiak, H. The speciation of selected heavy metals of sewage sludge stabilized in reed basins. In Proceedings of the 11th International IWA Specialist Group Conference on Wetland Systems for Water Pollution Control, Indore, India, 1–7 November 2008. [Google Scholar]

- Matamoros, V.; Nguyen, L.X.; Arias, C.A.; Nielsen, S.; Laugen, M.M.; Brix, H. Musk fragrances, DEHP and heavy metals in a 20 years old sludge treatment reed bed system. Water Res. 2012, 46, 3889–3896. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, S.; Bruun, E.W. Dewatering of industrial sludge in Sludge Treatment Reed Bed systems. In Constructed Wetlands for Industrial Wastewater Treatment, 1st ed.; Stefanakis, A.I., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018; Volume 1, pp. 429–451. [Google Scholar]

- Kołecka, K.; Obarska-Pempkowiak, J. Potential fertilizing properties of sewage sludge treated in the sludge treatment reed beds (STRB). Water Sci. Technol. 2013, 68, 1412–1418. [Google Scholar] [CrossRef] [PubMed]

- Federle, T.W.; Itrich, N.R. Comprehensive approach for assessing the kinetics of Primary and Ultimate Biodegradation of Chemicals in activated sludge: Application to Liniear Alkylbenzene Sulfonate. Environ. Sci. Technol. 1997, 31, 1178–1184. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Tsihrintzis, V.A. Dewatering mechanisms in pilot-scale Sludge Drying Reed Beds: Effect of design and operational parameters. Chem. Eng. 2011, 172, 430–443. [Google Scholar] [CrossRef]

- Stefanakis, A.I.; Komilis, D.; Tsihrintzis, V.A. Stability and maturity of thickened wastewater sludge treated in pilot-scale Sludge Treatment Wetlands. Water Res. 2011, 45, 6441–6452. [Google Scholar] [CrossRef]

- Nielsen, S.; Sellers, T.C.P. Dewatering sludge originating in water treatment works in reed bed systems—5 years of experience. In Proceeding of the 17th European Biosolids and Organic residuals Conference and Exhibition, Leeds, UK, 19 November 2012. [Google Scholar]

- Nielsen, S.; Cooper, D.J. Dewatering sludge originating in water treatment works in reed bed systems. Water Sci. Technol. 2011, 64, 361–366. [Google Scholar] [CrossRef]

- Nielsen, S. Sludge treatment in reed beds systems—Development, design, experiences. Sustain. Sanit. Pract. 2012, 12, 33–39. [Google Scholar]

- Collard, M.; Teychene, B.; Lemée, L. Comparison of three different wastewater sludge and their respective drying processes: Solar, thermal and reed beds—Impact on organic matter characteristics. J. Environ. Manag. 2017, 203, 760–767. [Google Scholar] [CrossRef]

- Water Environment Federation (WEF). Industrial Wastewater Management, Treatment, and Disposal, 3rd ed.; WEF Manual of Practice No. FD-3; WEF Press: Alexandria, VA, USA, 2008. [Google Scholar]

- Chen, W. Optimization of sludge dewatering through pretreatment, equipment selection, and testing. Drying Technol. 2013, 31, 193–201. [Google Scholar] [CrossRef]

- Kudra, T.; Mujumdar, A.S. Advanced Drying Technologies, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Swasdisevi, T.; Devahastin, S.; Thanasookprasert, S.; Soponronnarit, S. Comparative evaluation of hot-air and superheated-steam impinging stream drying as novel alternatives for paddy drying. Drying Technol. 2013, 31, 717–725. [Google Scholar] [CrossRef]

| Parameter | EU | Denmark | ||

|---|---|---|---|---|

| Directive 86/278/EC [22] | EC Working Document on Sludge, 3rd Draft [23] | BEK No. 1001 of 27/06/2018 | ||

| Metals | mg/kg ds | mg/kg ds | mg/kg ds | mg/kg TP 1 |

| Cadmium (Cd) | 20–40 | 10 | 0.8 | 100 |

| Copper (Cu) | 1000–1750 | 1000 | 1000 | - |

| Nickel (Ni) | 300–400 | 300 | 30 | 2500 |

| Lead (Pb) | 750–1500 | 750 | 120 | 10,000 |

| Zinc (Zn) | 2500–4000 | 2500 | 4000 | - |

| Mercury (Hg) | 16–25 | 10 | 0.8 | 200 |

| Chromium (Cr) | - | 1000 | 100 | - |

| Organic compounds CONTAMINANTS | mg/kg ds | mg/kg ds | mg/kg ds | mg/kg TP |

| LAS | - | 2600 | 1300 | - |

| PAH | - | 6 | 3 | - |

| NPE | - | 50 | 10 | - |

| DEHP | - | 100 | 50 | - |

| STRB | Main Wastewater Origin | Infiltration Rate (L/s/m2) | Fat Content in Feed Sludge (g/kg ds) | Dry Solids (ds) (%) | Loss on Ignition (LOI) (%) | ||

|---|---|---|---|---|---|---|---|

| Feed Sludge | Residual Sludge | Feed Sludge | Residual Sludge | ||||

| Tinglev (F) | Abattoirs | 0.002–0.005 | 21 | 0.4–0.6 | 10–15 | 75 | 70 |

| Kolding (F) | Abattoirs | 0.002–0.008 | 30 | 0.5–1.0 | 15–25 | 65 | 60 |

| Skive (F) | Abattoirs | 0.001–0.004 | 15 | 0.8–1.2 | 2.9–7.1 | 76 | - |

| Skagen (P) | Fish industry | 0.001–0.003 | 16 | 0.5–3.0 | 5–14 | 75 | 80 |

| Kristianstad (P) | Dairies, abattoirs, chicken farm and others | 0.003–0.020 | 29 | 0.5–2.5 | 8–14 | 70 | 75 |

| Water Works Facility | Period | No. of Beds | Total Treatment Area (m2) | Sludge Type |

|---|---|---|---|---|

| Hanningfield WW (P) | 2008–2013 | 6 | 120 | FS |

| Hanningfield WW (F) | 2012–2014 | 16 | 42,500 | FS |

| Lumley WW (P) | 2010 | 3 | 3 | AS |

| Whitacre WW (P) | 2015–2016 | 3 | 3 | FS |

| Feed Sludge | Whitacre WW (P) | Hanningfield WW (P + F) | Range | |

|---|---|---|---|---|

| Monitoring Period: | Autumn 2015 | 2008–2013 | ||

| Parameter | Unit | Aver. (n = 2) | Aver. (n > 25) | |

| Dry solids | % | 0.3 | 0.2 | 0.1–0.5 |

| Suspended solids | mg/L | 2630 | 1262 | 100–8000 |

| Loss on ignition | % | 40 | 23 | 10–40 |

| pH | - | 7.3 | 7.4 | 6.8–8.7 |

| Fat and oil | g/kg ds | 0.60 | 0.010–2.4 | |

| Total iron as Fe | g/kg ds | 259 | 233 | 100–400 |

| Total aluminium | g/kg ds | 0.43 | 0.41 | 0.1–3 |

| Total nitrogen (TN) | g/kg ds | 2.3 | 1–14 | |

| Total phosphorous (TP) | g/kg ds | 6.96 | 1.5–11 | |

| Phosphate (as P) | g/kg ds | 7.24 | 2000–8000 | |

| Chloride | g/kg ds | 16,30 | 41.6 | 15–45 |

| Total calcium | g/kg ds | 33.6 | 98.1 | 32–290 |

| Drained Water | Whitacre WW (P) | Hanningfield WW (P + F) | Range | |

|---|---|---|---|---|

| Monitoring Period: | Autumn 2015 | 2008–2013 | ||

| Parameter | Unit | Aver. (n = 3) | Aver. (n > 25) | |

| Dry solids | % | 0.06 | 0.05 | 0.001–0.06 |

| Suspended solids | mg/L | 93 | 0.01 | 0.001–0.05 |

| pH | - | 7.9 | 7.7 | 7.0–8.0 |

| BOD5 | mg/L | 5 | 2.4 | 1–36 |

| COD | mg/L | 44 | 33 | 3–380 |

| Total iron as Fe | mg/L | 29 | 4.5 | 0–120 |

| Total phosphorous as P | mg/L | 0.1 | 0.2 | 0–4.6 |

| Total nitrogen as N | mg/L | - | 3.3 | 0–10 |

| Chloride | mg/L | 52 | 74 | 50–100 |

| Criterion | STRB | Mechanical Systems |

|---|---|---|

| Land area demand | High | Low |

| Investment cost | Moderate/high | Moderate |

| Operation and maintenance cost | Low | High |

| Power input demand | Minimum | High |

| Use of chemicals, e.g., polymers | No | Typically required |

| Quality of final biosolids | High | Low |

| Life expectancy of main components (re-investment interval) | 20–30 years | 5–10 years |

| Need for skilled operators | No | Yes |

| Nuisance (mosquitos and odour) | No/minimum | Moderate/high |

| Downtime due to, for example, failure or repair | None | To be expected/frequent |

| Climate change impact | Positive (carbon sink) | Negative |

| Aesthetic appeal | High | Low |

| Biodiversity enhancement | Yes | No |

| Corporate social responsibility value | High | Low |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nielsen, S.; Stefanakis, A.I. Sustainable Dewatering of Industrial Sludges in Sludge Treatment Reed Beds: Experiences from Pilot and Full-Scale Studies under Different Climates. Appl. Sci. 2020, 10, 7446. https://doi.org/10.3390/app10217446

Nielsen S, Stefanakis AI. Sustainable Dewatering of Industrial Sludges in Sludge Treatment Reed Beds: Experiences from Pilot and Full-Scale Studies under Different Climates. Applied Sciences. 2020; 10(21):7446. https://doi.org/10.3390/app10217446

Chicago/Turabian StyleNielsen, Steen, and Alexandros I. Stefanakis. 2020. "Sustainable Dewatering of Industrial Sludges in Sludge Treatment Reed Beds: Experiences from Pilot and Full-Scale Studies under Different Climates" Applied Sciences 10, no. 21: 7446. https://doi.org/10.3390/app10217446

APA StyleNielsen, S., & Stefanakis, A. I. (2020). Sustainable Dewatering of Industrial Sludges in Sludge Treatment Reed Beds: Experiences from Pilot and Full-Scale Studies under Different Climates. Applied Sciences, 10(21), 7446. https://doi.org/10.3390/app10217446