Analysis of the Applicability of Non-Destructive Techniques to Determine In Situ Thermal Transmittance in Passive House Façades

Abstract

1. Introduction

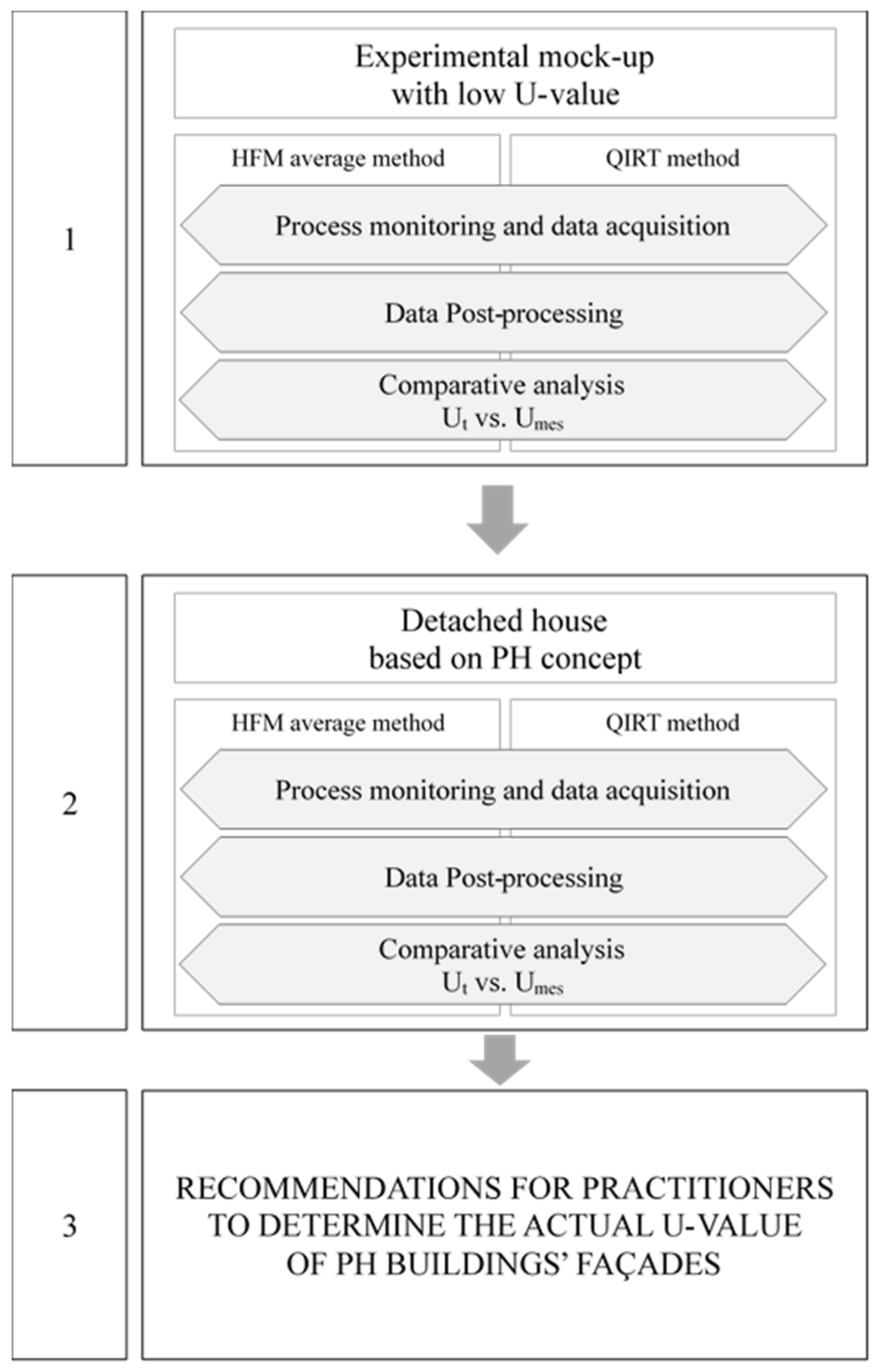

2. Materials and Methods

2.1. Measurement Setup

2.1.1. HFM Average Method

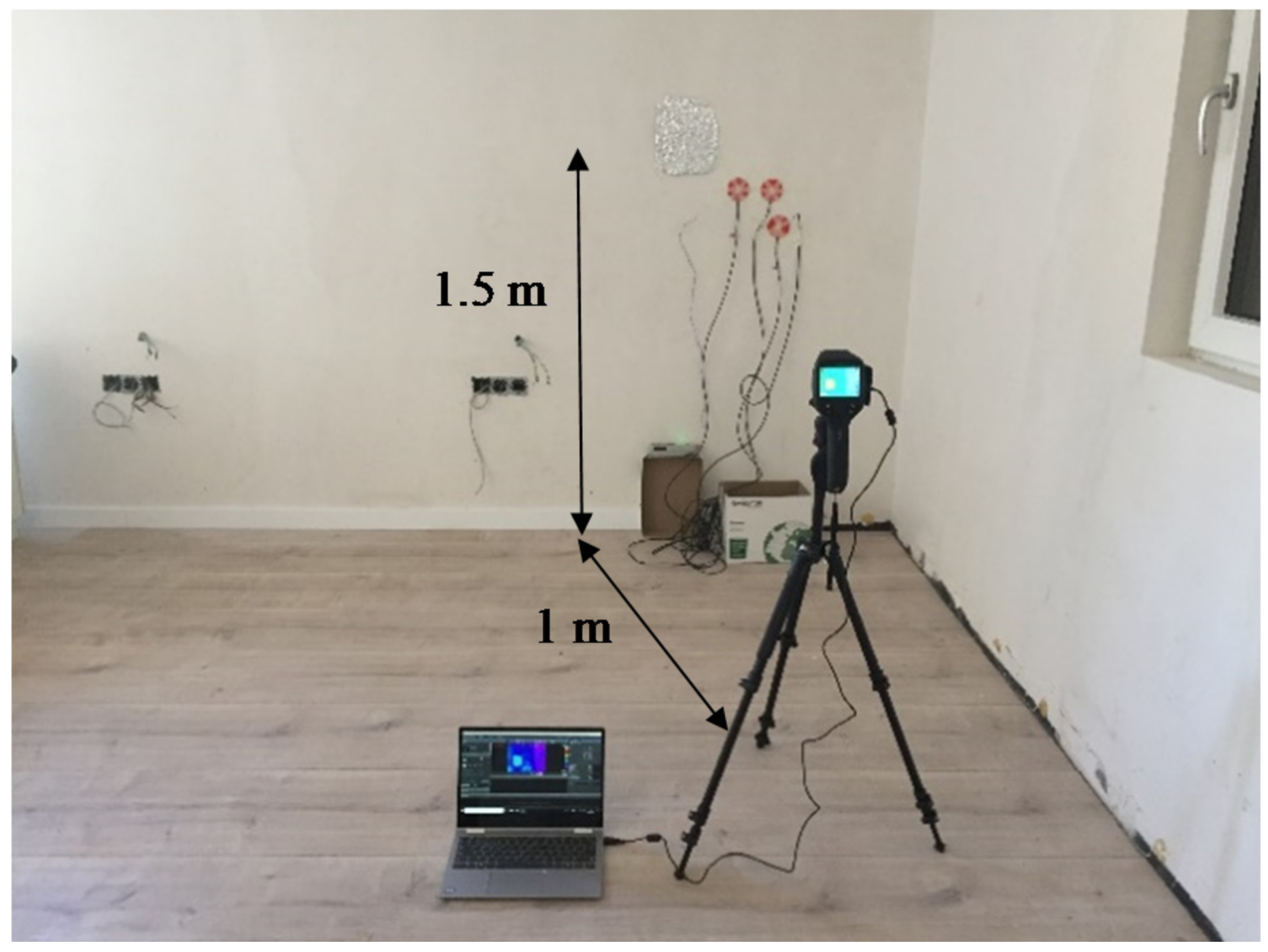

2.1.2. Quantitative Internal IRT Method

2.1.3. Validation of Methods

2.2. Measuring Equipment

2.3. Case Studies

3. Results

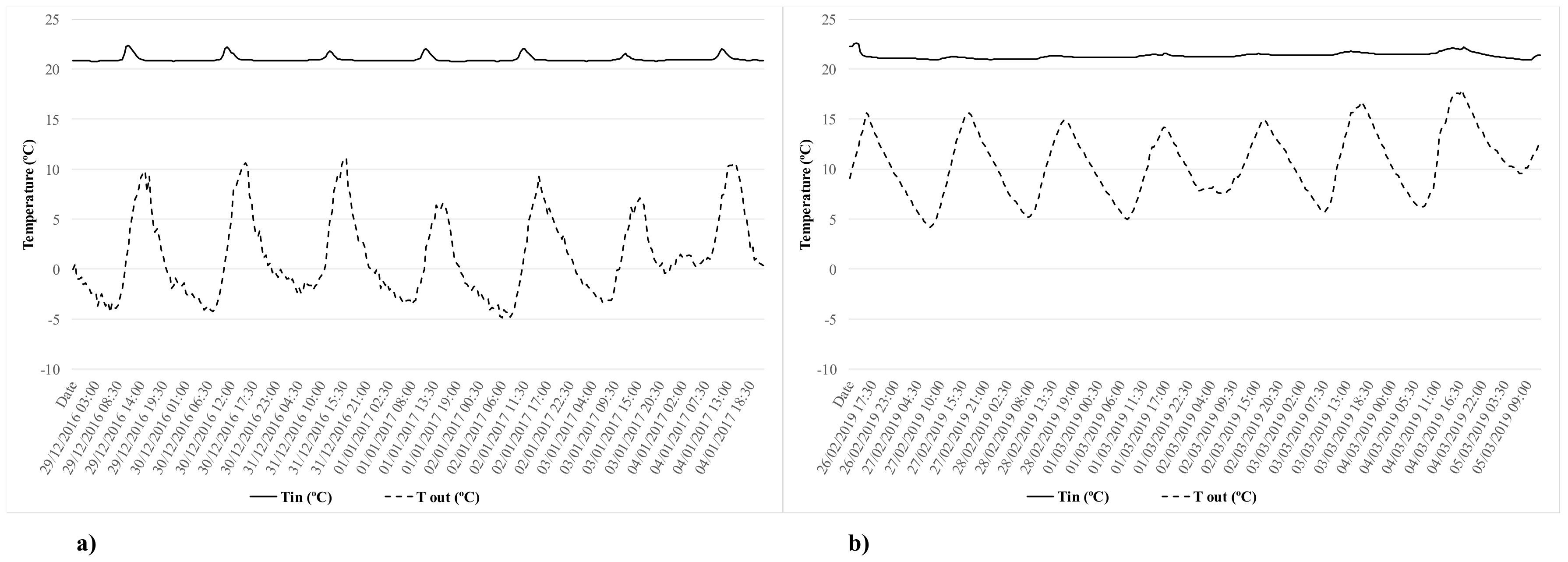

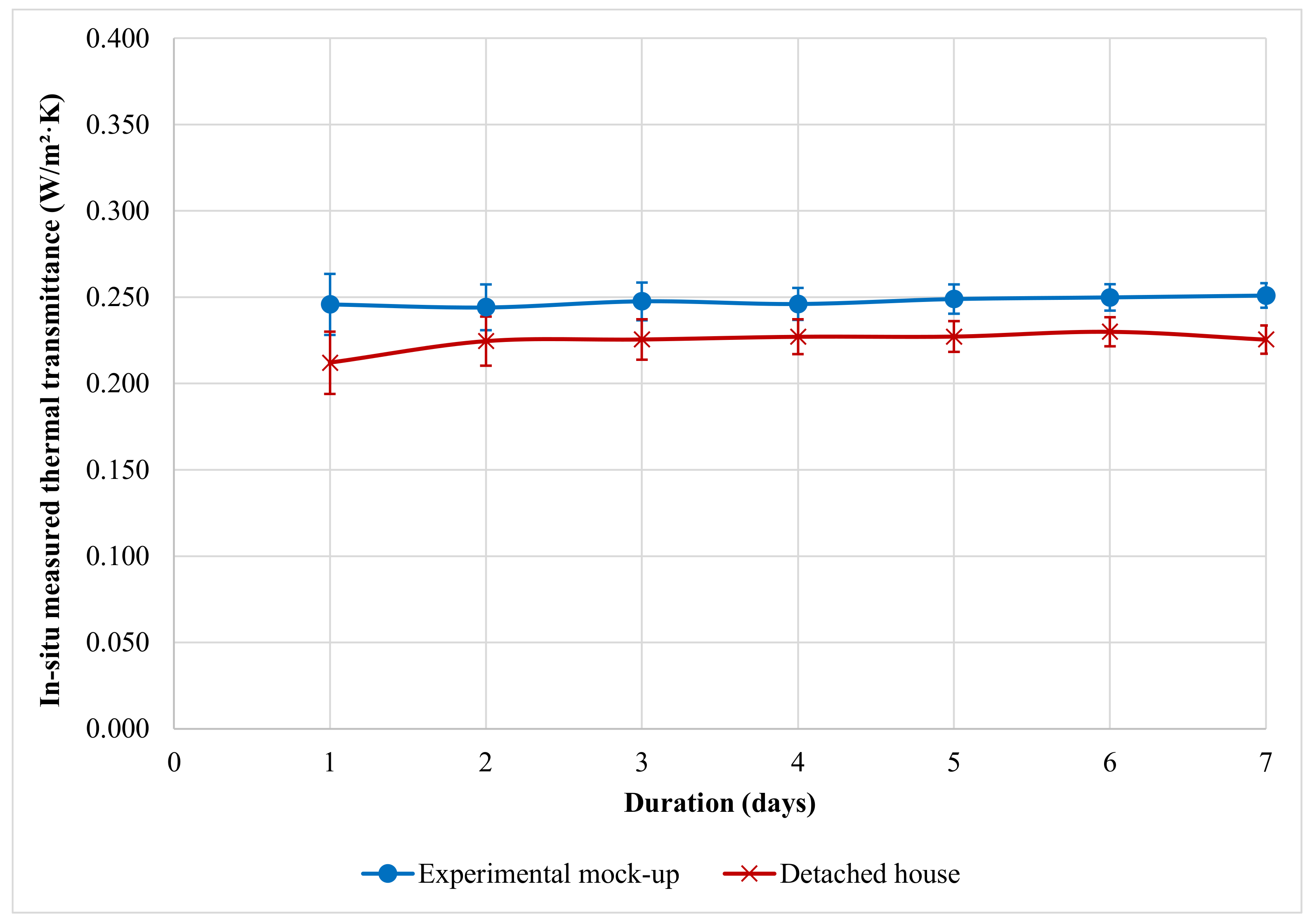

3.1. HFM Average Method

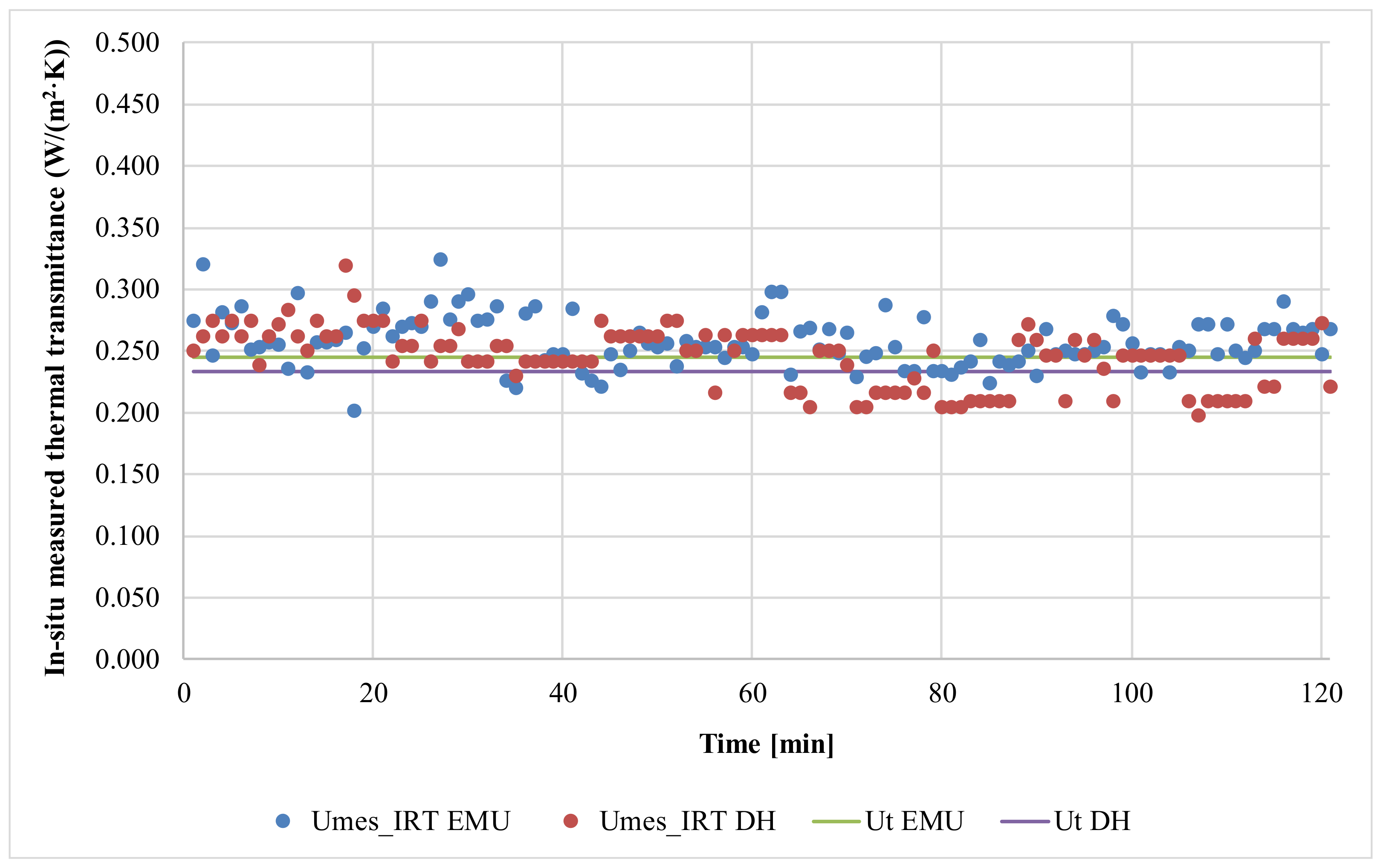

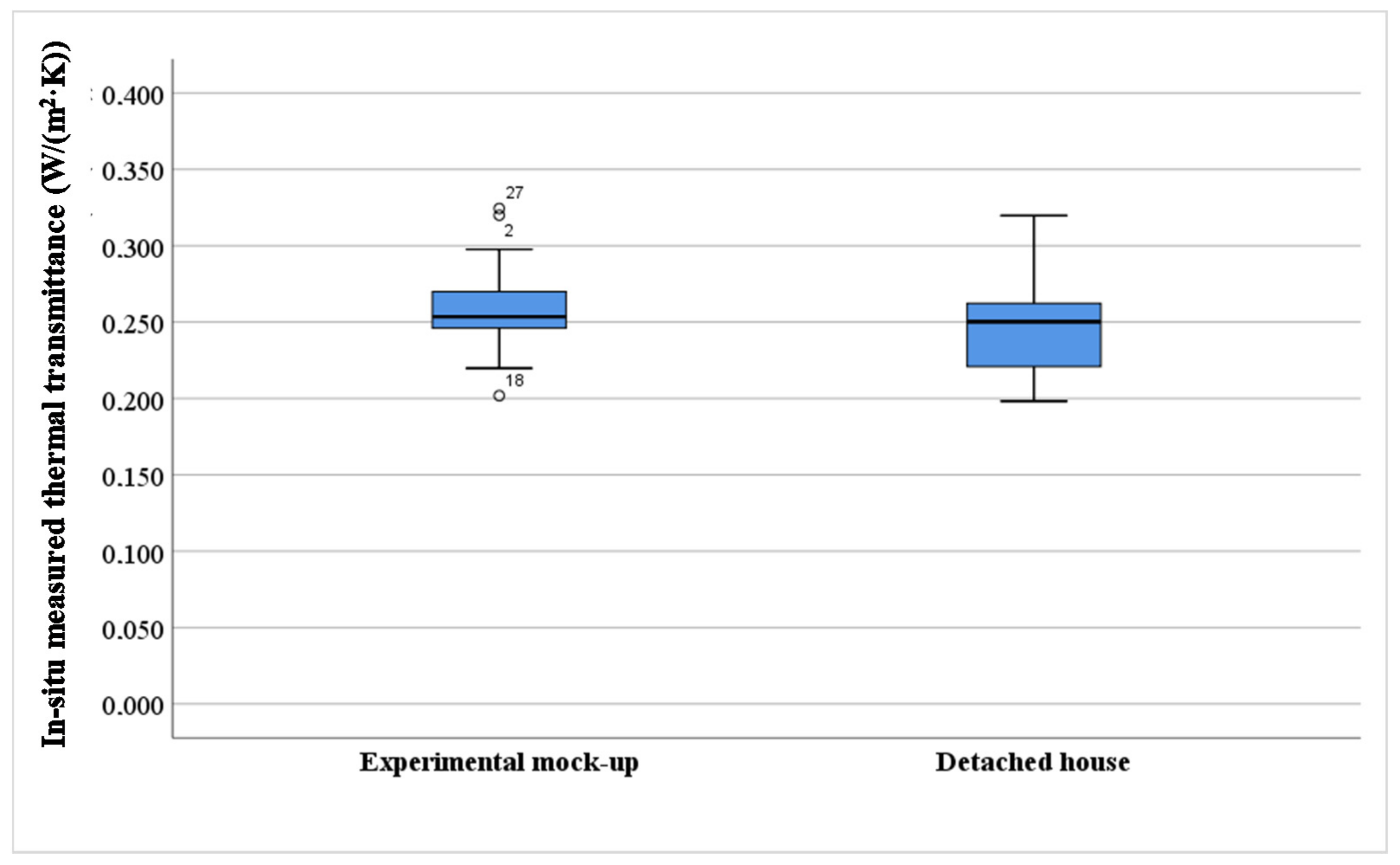

3.2. Quantitative Internal IRT Method

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kylili, A.; Fokaides, P.A.; Jimenez, P.A.L. Key Performance Indicators (KPIs) approach in buildings renovation for the sustainability of the built environment: A review. Renew. Sustain. Energy Rev. 2016, 56, 906–915. [Google Scholar] [CrossRef]

- Wang, Y.; Du, J.; Kuckelkorn, J.M.; Kirschbaum, A.; Gu, X.; Li, D. Identifying the feasibility of establishing a passive house school in Central Europe: An energy performance and carbon emissions monitoring study in Germany. Renew. Sustain. Energy Rev. 2019, 113, 109256. [Google Scholar] [CrossRef]

- Johnston, D.; Siddall, M.; Ottinger, O.; Peper, S.; Feist, W. Are the energy savings of the passive house standard reliable? A review of the as-built thermal and space heating performance of passive house dwellings from 1990 to 2018. Energy Effic. 2020, 13, 1605–1631. [Google Scholar] [CrossRef]

- Rohdin, P.; Molin, A.; Moshfegh, B. Experiences from nine passive houses in Sweden—Indoor thermal environment and energy use. Build. Environ. 2014, 71, 176–185. [Google Scholar] [CrossRef]

- Dalbem, R.; Grala da Cunha, E.; Vicente, R.; Figueiredo, A.; Oliveira, R.; Baptista da Silva, A.C.S. Optimisation of a social housing for south of Brazil: From basic performance standard to passive house concept. Energy 2019, 167, 1278–1296. [Google Scholar] [CrossRef]

- Piccardo, C.; Dodoo, A.; Gustavsson, L. Retrofitting a building to passive house level: A life cycle carbon balance. Energy Build. 2020, 223, 110135. [Google Scholar] [CrossRef]

- Mihai, M.; Tanasiev, V.; Dinca, C.; Badea, A.; Vidu, R. Passive house analysis in terms of energy performance. Energy Build. 2017, 144, 74–86. [Google Scholar] [CrossRef]

- Wang, R.; Lu, S.; Feng, W. A three-stage optimization methodology for envelope design of passive house considering energy demand, thermal comfort and cost. Energy 2020, 192, 116723. [Google Scholar] [CrossRef]

- Tokarik, M.S.; Richman, R.C. Life cycle cost optimization of passive energy efficiency improvements in a Toronto house. Energy Build. 2016, 118, 160–169. [Google Scholar] [CrossRef]

- Ekström, T.; Bernardo, R.; Blomsterberg, A. Cost-effective passive house renovation packages for Swedish single-family houses from the 1960s and 1970s. Energy Build. 2018, 161, 89–102. [Google Scholar] [CrossRef]

- Kylili, A.; Ilic, M.; Fokaides, P.A. Whole-building Life Cycle Assessment (LCA) of a passive house of the sub-tropical climatic zone. Resour. Conserv. Recycl. 2017, 116, 169–177. [Google Scholar] [CrossRef]

- Wang, Y.; Kuckelborn, J.; Zhao, F.-Y.; Spliethoff, H.; Lang, W. A state of art of review on interactions between energy performance and indoor environment quality in Passive House buildings. Renew. Sustain. Energy Rev. 2017, 72, 1303–1319. [Google Scholar] [CrossRef]

- Liang, X.; Wang, Y.; Royapoor, M.; Wu, Q.; Roskilly, T. Comparison of building performance between Conventional House and Passive House in the UK. Energy Procedia 2017, 142, 1823–1828. [Google Scholar] [CrossRef]

- Guerra-Santin, O.; Tweed, C.; Jenkins, H.; Jiang, S. Monitoring the performance of low energy dwellings: Two UK case studies. Energy Build. 2013, 64, 32–40. [Google Scholar] [CrossRef]

- Johnston, D.; Farmer, D.; Brooke-Peat, M.; Miles-Shenton, D. Bridging the domestic building fabric performance gap. Build. Res. Inf. 2014, 44, 147–159. [Google Scholar] [CrossRef]

- Stamp, S. Assessing Uncertainty in Co-Heating Test: Calibrating a Whole Building Steady State Heat Loss Measurement Method. Ph.D. Thesis, University College London (UCL), London, UK, 2015. [Google Scholar]

- Johnston, D.; Siddall, M. The building fabric thermal performance of Passivhaus dwellings—Does it do what it says on the tin? Sustainability 2016, 8, 97. [Google Scholar] [CrossRef]

- Gupta, R.; Kotopouleas, A. Magnitude and extent of building fabric thermal performance gap in UK low energy housing. Appl. Energy 2018, 222, 673–686. [Google Scholar] [CrossRef]

- Baker, P. U-values and traditional buildings. In situ measurements and their comparisons to calculated values. Hist. Scotl. Alba Aosmhor Tech. Pap. 2011, 10, 70. [Google Scholar]

- Desogus, G.; Mura, S.; Ricciu, R. Comparing different approaches to in situ measurement of building components thermal resistance. Energy Build. 2011, 43, 2613–2620. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Baldinelli, G.; Bianchi, F. Evaluating in situ thermal transmittance of green buildings masonries: A case study. Case Stud. Constr. Mater. 2014, 1, 53–59. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Gori, P.; De Lieto Vollaro, R. In situ thermal transmittance measurements for investigating differences between wall models and actual building performance. Sustainability 2015, 7, 10388–10398. [Google Scholar] [CrossRef]

- Ficco, G.; Iannetta, F.; Ianniello, E.; d’Ambrosio Alfano, F.R.; Dell’Isola, M. U-value in situ measurement for energy diagnosis of existing buildings. Energy Build. 2015, 104, 108–121. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Rodríguez-Álvaro, R.; Moyano, J.J.; Rico, F.; Marín, D. Determining the U-value of façades using the thermometric method: Potentials and limitations. Energies 2018, 11, 360. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; De Lieto Vollaro, R.; Asdrubali, F. A methodological approach for heat-flow meter data post-processing under different climatic conditions and wall orientations. Energy Build. 2020, 223, 110216. [Google Scholar] [CrossRef]

- Mandilaras, I.; Atsonios, I.; Zannis, G.; Founti, M. Thermal performance of a building envelope incorporating ETICS with vacuum insulation panels and EPS. Energy Build. 2014, 85, 654–665. [Google Scholar] [CrossRef]

- Albatici, R.; Tonelli, A.M.; Chiogna, M. A comprehensive experimental approach for the validation of quantitative infrared thermography in the evaluation of building thermal transmittance. Appl. Energy 2015, 141, 218–228. [Google Scholar] [CrossRef]

- Nardi, I.; Ambrosini, D.; Rubeis, T.; de Sfarra, S.; Perilli, S.; Pasqualoni, G. A comparison between thermographic and flow-meter methods for the evaluation of thermal transmittance of different wall constructions. J. Phys. Conf. Ser. 2015, 655, 012007. [Google Scholar] [CrossRef]

- Bros-Williamson, J.; Garnier, C.; Currie, J.I. A longitudinal building fabric and energy performance analysis of two homes built to different energy principles. Energy Build. 2016, 130, 578–591. [Google Scholar] [CrossRef]

- Samardzioska, T.; Apostolska, R. Measurement of heat-flux of new type façade walls. Sustainability 2016, 8, 1031. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, P.; Zhang, W. Development and application of infrared thermography non-destructive testing techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef]

- RESNET—Residential Energy Services Network. RESNET Interim Guideline for Thermographic Inspections of Buildings. 2012. Available online: http://www.resnet.us/standards/RESNET_IR_interim_guidelines.pdf (accessed on 4 October 2020).

- Nardi, I.; Lucchi, E.; De Rubeis, T.; Ambrosini, D. Quantification of heat energy losses through the building envelope: A state-of-the-art with critical and comprehensive review on infrared thermography. Build. Environ. 2018, 146, 190–205. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Marín, D.; Fresco-Contreras, R. Review of in situ methods for assessing the thermal transmittance of walls. Renew. Sustain. Energy Rev. 2019, 102, 356–371. [Google Scholar] [CrossRef]

- Tejedor, B.; Barreira, E.; Almeida, R.M.S.F.; Casals, M. Thermographic 2D U-value map for quantifying thermal bridges in building façades. Energy Build. 2020, 224, 110176. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; Santos, C.F.; Póvoas, Y.V. Evaluation of the infrared thermography technique for capillarity moisture detection in buildings. Procedia Struct. Integr. 2018, 11, 107–113. [Google Scholar] [CrossRef]

- Nardi, I.; Perilli, S.; De Rubeis, T.; Sfarra, S.; Ambrosini, D. Influence of insulation defects on the thermal performance of walls. An experimental and numerical investigation. J. Build. Eng. 2019, 21, 355–365. [Google Scholar] [CrossRef]

- Garrido, I.; Solla, M.; Lagüela, S.; Fernández, N. IRT and GPR techniques for moisture detection and characterization in buildings. Sensors 2020, 20, 6421. [Google Scholar] [CrossRef]

- Huang, Y.; Shih, P.; Hsu, K.-T.; Chiang, C.-H. To identify the defects illustrated on building façades by employing infrared thermography under shadow. NDT & E Int. 2020, 111, 102240. [Google Scholar] [CrossRef]

- Martens, U.; Schröder, K.-U. Evaluation of infrared thermography methods for analyzing the damage behavior of adhesively bonded repair solutions. Compos. Struct. 2020, 240, 111991. [Google Scholar] [CrossRef]

- Lucchi, E. Thermal transmittance of historical stone masonries: A comparison among standard, calculated and measured data. Energy Build. 2017, 151, 393–405. [Google Scholar] [CrossRef]

- International Organization for Standardization. Performance of Buildings. Detection of Heat, Air and Moisture Irregularities in Buildings by Infrared Methods—Part 3: Qualifications of Equipment Operators, Data Analysts and Report Writers; ISO 6781-3:2015; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- International Organization for Standardization. Thermal Performance of Buildings. Qualitative Detection of Thermal Irregularities in Building Envelopes. Infrared Method; UNE EN 13187:1998; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Minimum Detectable Temperature Difference for Thermal Imaging Systems; ASTM E1311; American Society for Testing Materials: West Conshohocken, PA, USA, 2004. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Measuring and Compensating for Reflected Ambient Temperature Using Infrared Imaging Radiometers; ASTM E1862; American Society for Testing Materials: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Lucchi, E. Applications of the infrared thermography in the energy audit of buildings: A review. Renew. Sustain. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- Tejedor, B.; Casals, M.; Macarulla, M.; Giretti, A. U-value time series analyses: Evaluating the feasibility of in-situ short-lasting IRT tests for heavy multi-leaf walls. Build. Environ. 2019, 159, 1–19. [Google Scholar] [CrossRef]

- Albatici, R.; Tonelli, A. Verifica sperimentale in situ, con analisi termografiche e algoritmi di calcolo della transmittanza termica di un elemento costruttivo. In Annali Museo Civico di Rovereto. Sezione: Archeologia, Storia, Scienze Naturali, 23rd ed.; Museo Civico di Rovereto: Rovereto, Italy, 2008. [Google Scholar]

- Albatici, R.; Tonelli, A.M. Infrared thermovision technique for the assessment of thermal transmittance value of opaque building elements on site. Energy Build. 2010, 42, 2177–2183. [Google Scholar] [CrossRef]

- Vavilov, V.P. A pessimistic view of the energy auditing of building structures with the use of infrared thermography. Russ. J. Nondestruct. Test. 2010, 46, 906–910. [Google Scholar] [CrossRef]

- Dall’O, G.; Sarto, L.; Panza, A. Infrared screening of residential buildings for energy audit purposes: Results of a field test. Energies 2013, 6, 3859–3878. [Google Scholar] [CrossRef]

- Ham, Y.; Golparvar-Fard, M. Automated cost analysis of energy loss in existing buildings through thermographic inspections and CFD analysis. In Proceedings of the ISARC-30th International Symposium on Automation and Robotics in Construction and Mining, Montreal, QC, Canada, 11–15 August 2013. [Google Scholar] [CrossRef]

- Nardi, I.; Sfarra, S.; Ambrosini, D. Quantitative thermography for the estimation of the U-Value: State of art and a case study. J. Phys. Conf. Ser. 2014, 547, 012016. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Jang, C.; Jeong, H.; Song, D. Appropriate conditions for determining the temperature difference ratio via infrared camera. Build. Serv. Eng. 2015, 37, 1–16. [Google Scholar] [CrossRef]

- Ibos, L.; Monchau, J.-P.; Feuillet, V.; Candau, Y. A comparative study of in-situ measurement methods of a building wall thermal resistance using infrared thermography. Int. Conf. Qual. Control Artif. Vis. 2015. [Google Scholar] [CrossRef]

- Marino, B.M.; Muñoz, N.; Thomas, L.P. Estimation of the surface thermal resistance and heat loss by conduction using thermography. Appl. Therm. Eng. 2017, 114, 1213–1221. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Kalogirou, S.A. Application of infrared thermography for the determination of the overall heat transfer coefficient (U-Value) in building envelopes. Appl. Energy 2011, 88, 4358–4365. [Google Scholar] [CrossRef]

- Ham, Y.; Golpavard-Fard, M. 3D Visualization of thermal resistance and condensation problems using infrared thermography for building energy diagnostics. Vis. Eng. 2014, 2, 12. [Google Scholar] [CrossRef]

- Tzifa, V.; Papadakos, G.; Papadopoulou, A.G.; Marinakis, V.; Psarras, J. Uncertainty and method limitations in a short-time measurement of the effective thermal transmittance on a building envelope using an infrared camera. Int. J. Sustain. Energy 2017, 36, 28–46. [Google Scholar] [CrossRef]

- Danielski, I.; Fröling, M. Diagnosis of buildings’ thermal performance—A quantitative method using thermography under non-steady state heat flow. Energy Procedia 2015, 83, 320–329. [Google Scholar] [CrossRef]

- Tejedor, B.; Casals, M.; Gangolells, M.; Roca, X. Quantitative internal infrared thermography for determining in-situ thermal behaviour of façades. Energy Build. 2017, 151, 187–197. [Google Scholar] [CrossRef]

- Marshall, A.; Francou, J.; Fitton, R.; Swan, W.; Owen, J.; Benjaver, M. Variation of the U-value measurement of a whole dwelling using infrared thermography under controlled conditions. Buildings 2018, 8, 46. [Google Scholar] [CrossRef]

- Tejedor, B.; Casals, M.; Gangolells, M. Assessing the influence of operating conditions and thermophysical properties on the accuracy of in-situ measured U-values using quantitative internal infrared thermography. Energy Build. 2018, 171, 64–75. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Oliveira, M.; Rubio-Bullido, C.; Marín, D. A Comparative analysis of the international regulation of thermal properties in building envelope. Sustainability 2019, 11, 5574. [Google Scholar] [CrossRef]

- Lu, X.; Memari, A. Application of infrared thermography for in-situ determination of building envelope termal properties. J. Build. Eng. 2019, 26, 100885. [Google Scholar] [CrossRef]

- Hoyano, A.; Asano, K.; Kanamaru, T. Analysis of the heat flux from the exterior surface of buildings using time sequential thermography. Atmos. Environ. 1999, 33, 3941–3951. [Google Scholar] [CrossRef]

- Emmel, M.G.; Abadie, M.O.; Mendes, N. New external convective heat transfer coefficient correlations for isolated low-rise buildings. Energy Build. 2007, 39, 335–342. [Google Scholar] [CrossRef]

- Rabadiya, A.V.; Kirar, R. Comparative analysis of wind loss coefficient (wind heat transfer coefficient) for solar plate collector. Int. J. Emerg. Technol. Adv. Eng. (IJETAE) 2012, 2, 2250–2459. [Google Scholar]

- Sham, J.F.C.; Lo, T.Y.; Memon, S.A. Verification and application of continuous surface temperature monitoring technique for investigation of nocturnal sensible heat release characteristics by building fabrics. Energy Build. 2012, 53, 108–116. [Google Scholar] [CrossRef]

- Liu, J.; Heidarinejad, M.; Gracik, S.; Srebric, J. The impact of exterior surface convective heat transfer coefficients on the building energy consumption in urban neighbourhoods with different plan area densities. Energy Build. 2015, 86, 449–463. [Google Scholar] [CrossRef]

- Madding, R. Finding R-Values of stud frame constructed houses with IR Thermography. In Proceedings of the InfraMation Conference, Reno, NV, USA, 3–7 November 2008; Available online: https://www.researchgate.net/publication/285737245_Finding_R-values_of_Stud-Frame_Constructed_Houses_with_IR_Thermography (accessed on 10 November 2020).

- Earle, R.L.; Earle, M.D. Unit Operations in Food Processing; Elsevier: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Holman, J.P. Heat Transfer, 8th ed.; McGraw Hill: New York, NY, USA, 1997; ISBN 978-0078447860. [Google Scholar]

- Bienvenido-Huertas, D.; Bermúdez, J.; Moyano, J.J.; Marín, D. Influence of ICHTC correlations on the thermal characterization of façades using the quantitative internal infrared thermography method. Build. Environ. 2019, 149, 512–525. [Google Scholar] [CrossRef]

- Gaspar, K.; Casals, M.; Gangolells, M. A comparison of standardized calculation methods for in situ measurements of façades U-value. Energy Build. 2016, 130, 592–599. [Google Scholar] [CrossRef]

- International Organization for Standardization. Thermal Insulation. Building Elements. In Situ Measurement of Thermal Resistance and Thermal Transmittance. Part 1: Heat Flow Meter Method; ISO 9869:2014; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Atsonios, I.A.; Mandilaras, I.D.; Kontogeorgos, D.A.; Founti, M.A. A comparative assessment of the standarized methods for the in-situ measurement of the thermal resistance of buildings walls. Energy Build. 2017, 154, 198–206. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Standard Practice for Determining Thermal Resistance of Building Envelope Components from the In-Situ Data; ASTM C1155-95; American Society for Testing Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Gaspar, K.; Casals, M.; Gangolells, M. In-situ measurement of façades with a low U-value: Avoiding deviations. Energy Build. 2018, 170, 61–73. [Google Scholar] [CrossRef]

- Spain, Royal Decree 314/2006 Approving the Spanish Technical Building Code CTE-DB-HE1. 2006. Available online: http://www.boe.es/boe/dias/2006/03/28/pdfs/A11816-11831.pdf (accessed on 4 October 2020).

- International Organization for Standardization. Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; UNE EN ISO 10456:2012; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- International Organization for Standardization. Building Components and Building Elements. Thermal Resistance and Thermal Transmittance. Calculation Method; UNE EN ISO 6946:2012 (ISO 6946:2007); ISO: Geneva, Switzerland, 2012. [Google Scholar]

- FLIR Systems. FLIR TOOLS+ Software; FLIR Systems: Wilsonwille, OR, USA, 2015. [Google Scholar]

| Equipment | Output | Measuring Range | Resolution | Accuracy |

|---|---|---|---|---|

| Heat flux meter plate | q [W/m2] | ±2000 W/m2 Sensitivity of HFM1 61.68 μV/(W/m2) Sensitivity of HFM2 61.29 μV/(W/m2) Sensitivity of HFM3 63.07 μV/(W/m2) | -- | ±5% |

| Inner air temperature sensor | TIN (K) | −35 to +50 °C | 0.1 °C | ±0.5 °C |

| Inner acquisition system | Input ±5 Vdc at 0 to 40 °C | -- | ±0.06% of reading | |

| Infrared camera | TWALL (K) TREF (K) | Temperature: −20 to +120 °C CFOV: 25° × 19°; IFOV: 1.36 mrad Spectral Range: 7.5–13 μm Thermal sensitivity: <0.045 °C, at 30 °C Sensor: FPA, uncooled microbolometer | 320 × 240 pixels | ±2 °C or ±2% reading |

| Outer air temperature sensor | TOUT (K) | −35 to +55 °C | 0.1 °C | ±0.5 °C |

| N# | Material Layer | Δxi (m) | λi [W/(m·K)] | Rt i [(m2·K)/W] | L (m) | Ut [W/(m2·K)] | |

|---|---|---|---|---|---|---|---|

| W1 Experimental mock-up | 1 | Mortar | 0.015 | 0.550 | 0.027 | 2.64 | 0.245 |

| 2 | Lightweight concrete | 0.060 | 0.160 | 0.375 | |||

| 3 | PIR insulation | 0.080 | 0.028 | 2.857 | |||

| 4 | Non-ventilated air cavity | 0.060 | --- | 0.180 | |||

| 5 | Lightweight concrete | 0.070 | 0.160 | 0.438 | |||

| 6 | Gypsum plaster | 0.015 | 0.430 | 0.035 |

| No. | Material Layer | Δxi (m) | λi [W/(m·K)] | Rt i [(m2·K)/W] | L (m) | Ut [W/(m2·K)] | |

|---|---|---|---|---|---|---|---|

| W2 Detached house | 1 | Mortar | 0.015 | 0.550 | 0.027 | 2.50 | 0.233 |

| 2 | Lightweight concrete (EVOin) | 0.045 | 0.160 | 0.281 | |||

| 3 | PIR insulation | 0.080 | 0.028 | 2.857 | |||

| 4 | Cavity (EPS + EVOin) | 0.060 | 0.140 | 0.429 | |||

| 5 | Lightweight concrete (EVOin) | 0.080 | 0.160 | 0.500 | |||

| 6 | Gypsum plaster | 0.015 | 0.430 | 0.035 |

| Experimental Mock-Up | Detached House | ||||||

|---|---|---|---|---|---|---|---|

| UmHFM ± [W/m2·K] | (%) | CV (%) | UmHFM ± [W/m2·K] | (%) | CV (%) | ||

| Number of cycles (duration) | 1 (24 h) | 0.246 ± 0.018 | 0.33 | -- | 0.212 ± 0.018 | 8.84 | -- |

| 2 (48 h) | 0.244 ± 0.013 | 0.35 | -- | 0.225 ± 0.014 | 3.47 | -- | |

| 3 (72 h) | 0.248 ± 0.011 | 1.05 | 1.39 | 0.225 ± 0.012 | 3.06 | 6.80 | |

| 4 (96 h) | 0.246 ± 0.009 | 0.44 | 1.40 | 0.227 ± 0.010 | 2.37 | 1.15 | |

| 5 (120 h) | 0.249 ± 0.008 | 1.59 | 1.13 | 0.227 ± 0.009 | 2.33 | 0.84 | |

| 6 (144 h) | 0.250 ± 0.008 | 1.98 | 1.57 | 0.230 ± 0.008 | 1.13 | 1.43 | |

| 7 (168 h) | 0.251 ± 0.007 | 2.41 | 0.81 | 0.225 ± 0.008 | 3.09 | 2.02 | |

| Measurement period | From 29 December 2016 to 4 January 2017 | From 26 February 2019 to 4 March 2019 | |||||

| ΔT average (°C) | 19.7 | 10.8 | |||||

| Number of Cycle Evaluated | Related Cycles in the Evaluation | Deviation in Um-HFM (%) | |

|---|---|---|---|

| Experimental Mock-Up | Detached House | ||

| 3 (72 h) | 3 vs. 2 | 1.4 | 0.4 |

| 4 (96 h) | 4 vs. 3 | −0.6 | 0.7 |

| 5 (120 h) | 5 vs. 4 | 1.1 | 0.0 |

| 6 (144 h) | 6 vs. 5 | 0.4 | 1.2 |

| 7 (168 h) | 7 vs. 6 | 0.4 | −2.0 |

| Experimental Mock-UP | Detached House | |||||

|---|---|---|---|---|---|---|

| Number of Cycle Evaluated | Duration of the Analysis Period (Days) | Analysis Period | Um-HFM [W/m2·K] | Deviation of Um-HFM between Periods of Analysis (%) | Um-HFM [W/m2·K] | Deviation of Um-HFM between Periods of Analysis (%) |

| 3 (72 h) | 2 | Initial test period | 2.34 | 2.3 | 2.34 | 1.5 |

| Final test period | 2.40 | 2.37 | ||||

| 4 (96 h) | 2 | Initial test period | 2.34 | 0.8 | 2.34 | 0.6 |

| Final test period | 2.33 | 2.35 | ||||

| 5 (120 h) | 3 | Initial test period | 2.36 | 0.3 | 2.35 | 1.1 |

| Final test period | 2.37 | 2.37 | ||||

| 6 (144 h) | 4 | Initial test period | 2.33 | 2.4 | 2.34 | 1.7 |

| Final test period | 2.39 | 2.38 | ||||

| 7 (168 h) | 4 | Initial test period | 2.33 | 2.2 | 2.34 | 2.0 |

| Final test period | 2.39 | 2.39 | ||||

| Parameters | Experimental Mock-Up | Detached House |

|---|---|---|

| Ut [W/m2·K] | 0.245 | 0.233 |

| Umes_IRT [W/m2·K] | 0.257 | 0.245 |

| Test duration (hours) | 2 | 2 |

| ΔT Range (°C) | 8.2–10.4 | 13.17–15.76 |

| SD [W/m2·K] | 0.021 | 0.024 |

| CV (%) | 8.06 | 9.69 |

| ΔUIRT/Ut (%) | 4.90 | 5.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tejedor, B.; Gaspar, K.; Casals, M.; Gangolells, M. Analysis of the Applicability of Non-Destructive Techniques to Determine In Situ Thermal Transmittance in Passive House Façades. Appl. Sci. 2020, 10, 8337. https://doi.org/10.3390/app10238337

Tejedor B, Gaspar K, Casals M, Gangolells M. Analysis of the Applicability of Non-Destructive Techniques to Determine In Situ Thermal Transmittance in Passive House Façades. Applied Sciences. 2020; 10(23):8337. https://doi.org/10.3390/app10238337

Chicago/Turabian StyleTejedor, Blanca, Kàtia Gaspar, Miquel Casals, and Marta Gangolells. 2020. "Analysis of the Applicability of Non-Destructive Techniques to Determine In Situ Thermal Transmittance in Passive House Façades" Applied Sciences 10, no. 23: 8337. https://doi.org/10.3390/app10238337

APA StyleTejedor, B., Gaspar, K., Casals, M., & Gangolells, M. (2020). Analysis of the Applicability of Non-Destructive Techniques to Determine In Situ Thermal Transmittance in Passive House Façades. Applied Sciences, 10(23), 8337. https://doi.org/10.3390/app10238337