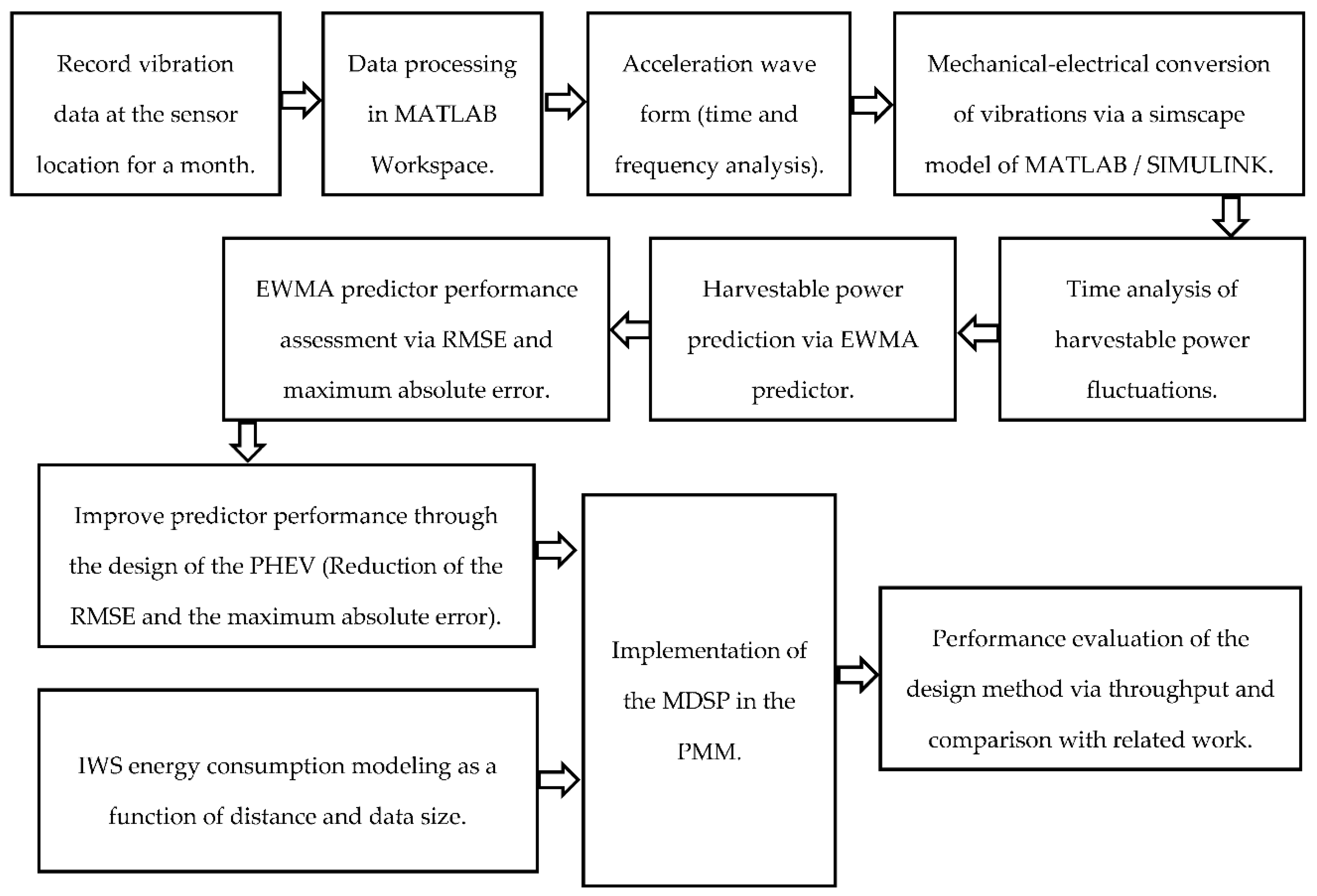

With the possibility of predicting the amount of harvestable energy, this section proposes a method of efficiently managing this energy. The method consists of defining the specifications of the IWS by integrating the amount of energy that will be harvested during the current measurement cycle. This would reduce the data queue in the IWS by maximizing the transferable data during each measurement cycle. To precisely define the node’s residual energy, an electrical energy consumption model that considers the most dissipation source in the IWS node is established. Under the basis of the harvestable energy and the energy need, the data’s maximum size is then defined. In this section, the PHEV performance is evaluated in terms of the amount of data transmitted to the BS.

4.1. IWS Energy Consumption Model

To accurately estimate the node’s specification based on the recovered energy, it is essential to consider a node consumption model that incorporates most sources of dissipation. Two main factors are involved in the definition of IWS activities, the network’s topology, and the communication protocol. Topology refers to the organization of the network; the main topologies are the star, the mesh, and the cluster. The protocol refers to techniques for accessing the channel shared by the various IWSs in the network to avoid collisions and interference. Most of the current IoT networks are star networks; therefore, each IWS directly transmits the collected data to the BS. In this work, it was assumed that the BS schedules transmission times under the Time Division Multiple Access (TDMA) to avoid collisions.

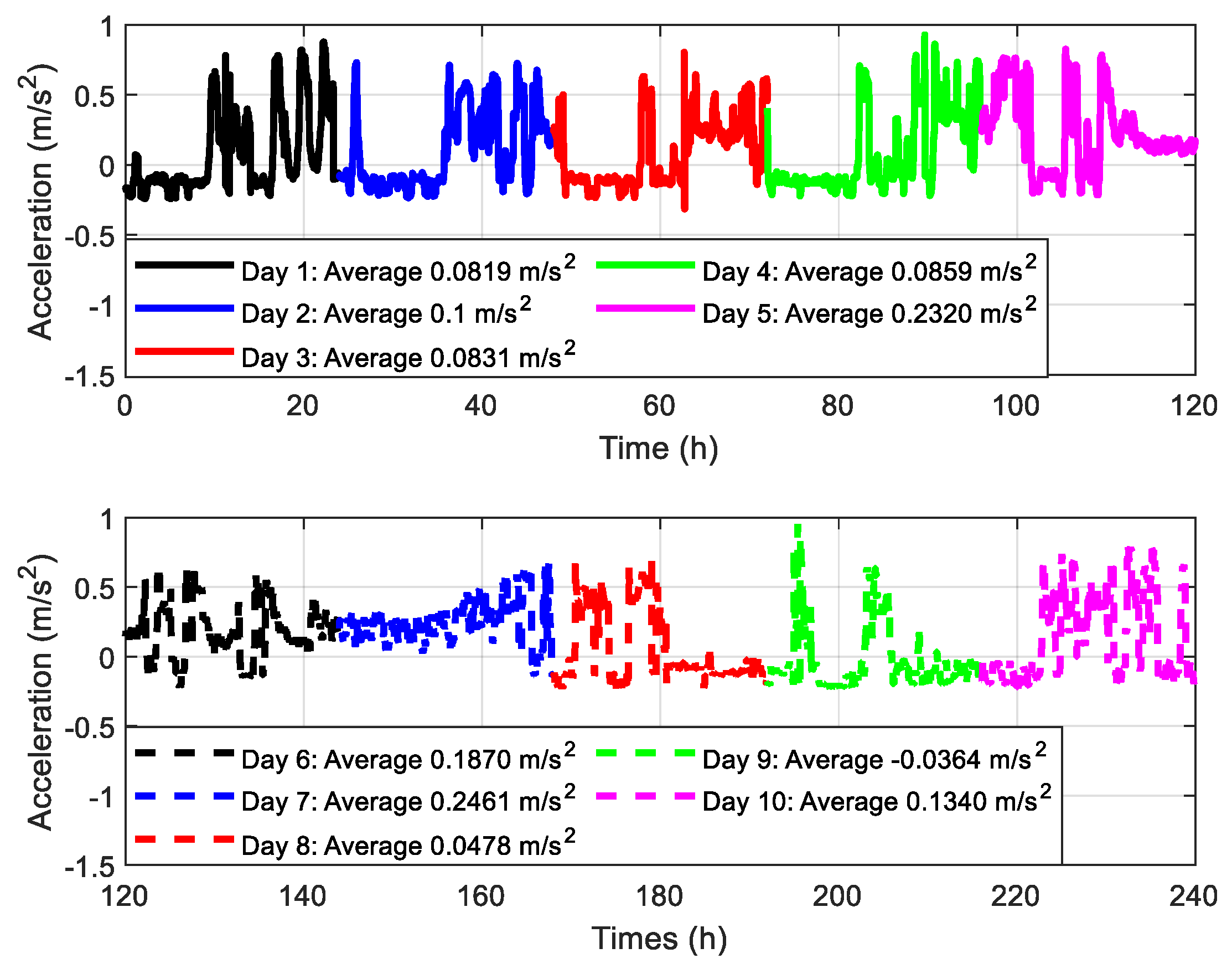

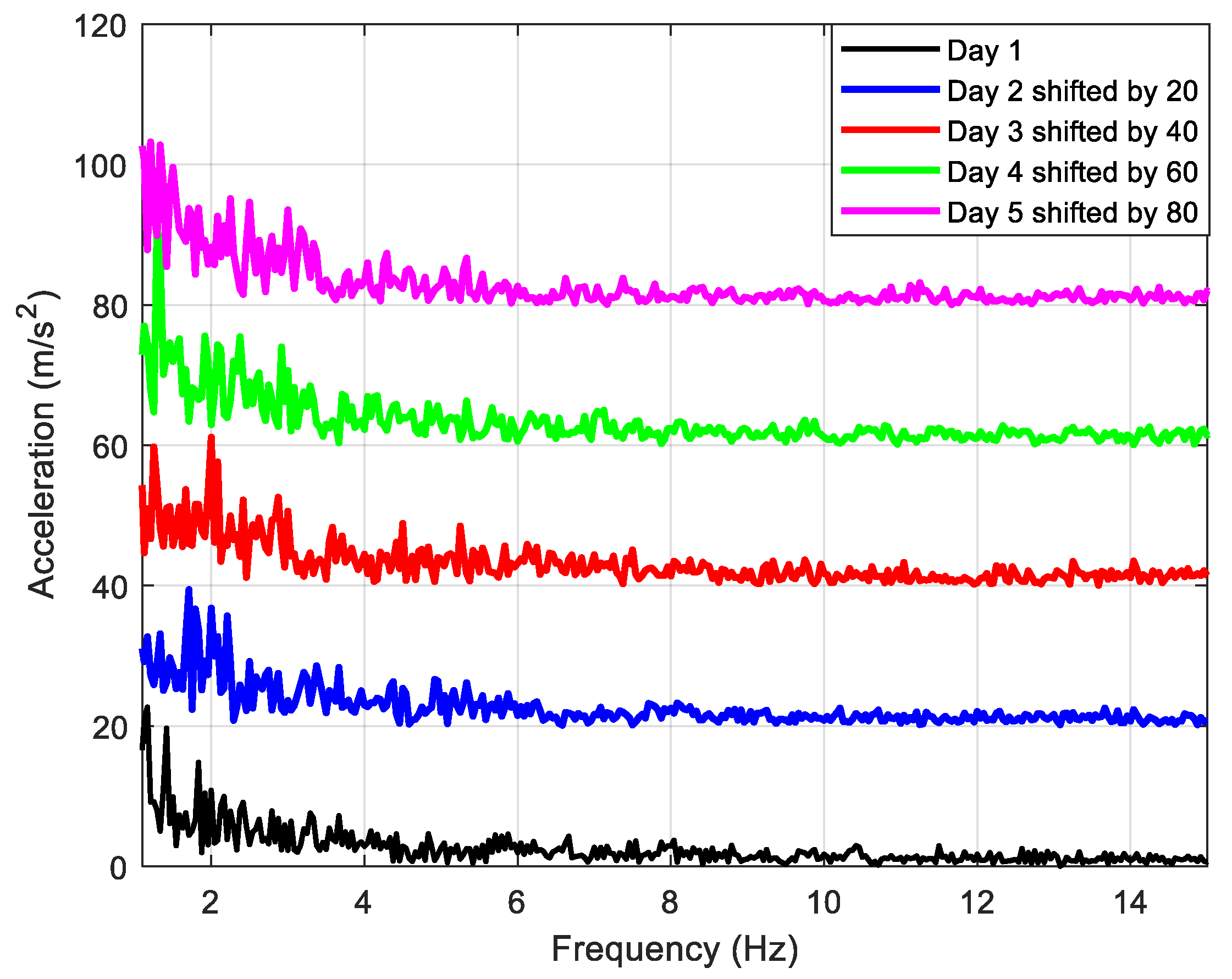

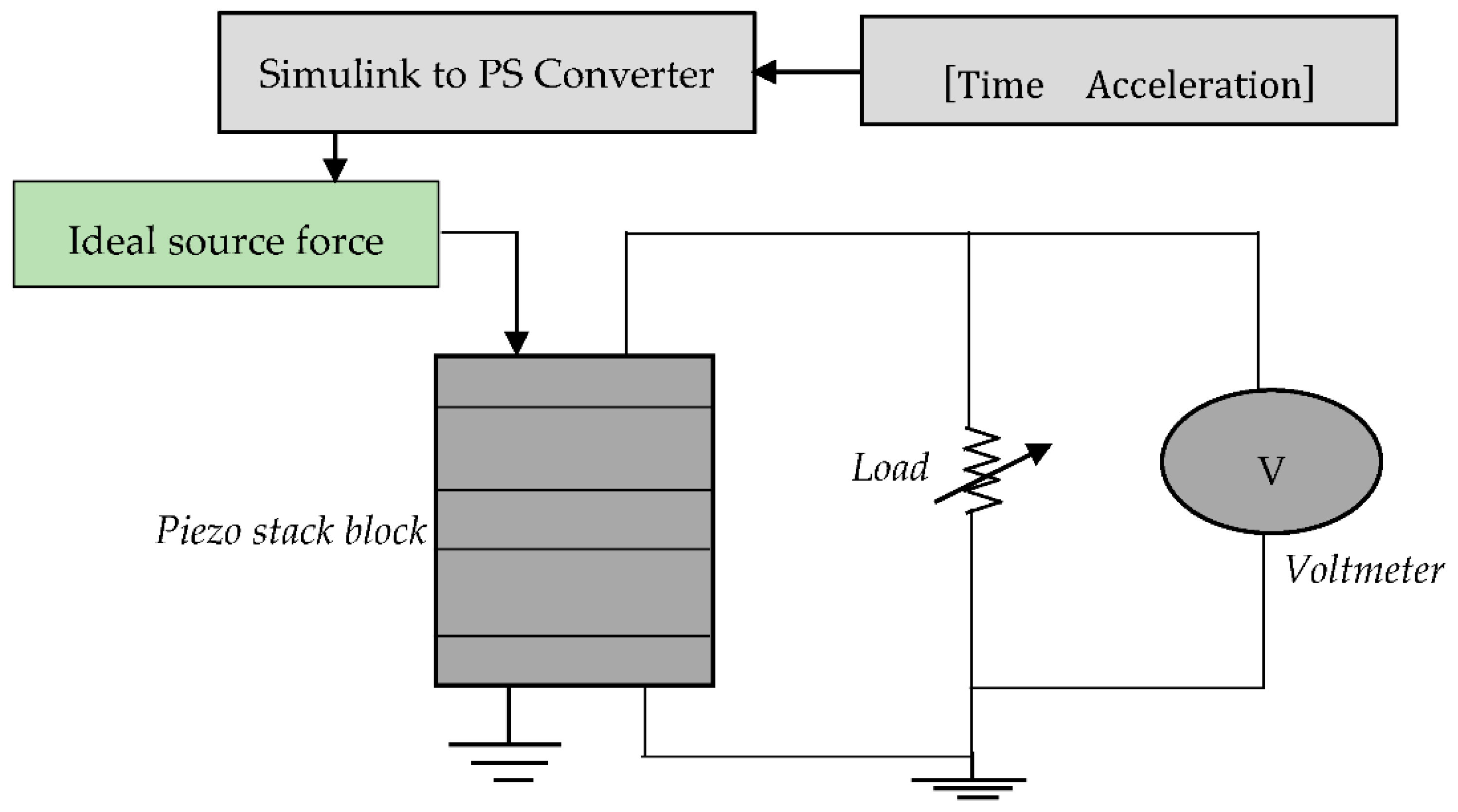

Following the star topology of the IoT networks and of the different blocks that constitute the IWS (see

Figure 1), three main sources of dissipation must be considered to estimate the energy requirement of the IWS for

bits of data. This is the energy related to data acquisition, energy due to processing, and the energy required for data transmission [

51]. According to many previous studies [

51,

52,

53,

54], and some IWs commercial off-the-shelf components (Cf

Table 1), the communication module is the biggest energy consumer in the IWS. For example, in [

52], the amounts of energy for data sensing and for data processing of an accelerometer MMA7260Q are respectively estimated to be 0.000268 times and 0.044 times the energy dissipated for data communication. In [

54], the energy dissipated for communication is evaluated at 51% of the total energy cost of the IWS in industrial processes for which the sensor must be used for the activation of a pre-actuator (contactor or speed variator, for example). Given these observations, only the energy cost associated with data transmission will be considered in this work.

In most studies, the energy consumption estimation is based on short-range communications modules like the CC2520 of Texas Instruments. Recently, thanks to advances in the field of microelectromechanical systems, many long-range communications protocols are increasingly offered to meet the current requirements of IoT applications. Among these protocols, we can mention the Long-Range Wide Area Network (LoRaWAN), the Narrowband IoT (NB-IoT), and Sigfox [

55]. From previous work [

55,

56,

57], it emerges that LoRa is the most advantageous in terms of lifespan; this technology is then considered to maximize the performance of the IWS in terms of transmission range or maximum data sizes. In LoRa technology, Chirp Spread Spectrum (CSS) modulation is used; it is based on a spectrum spread, allowing the signal to be transmitted over a spectral width greater than all the frequencies compose it. There are three operating modes in LoRa technology called classes A, B, and C [

58]; the most energy-efficient is class A in which the sensors go into sleep mode after acknowledging the data. LoRa modulation provides the ability to use multiple orthogonal spreading factors (SF) to improve spectral efficiency and network capacity. Each symbol is made up of SF bits and changes in a BandWidth (BW) window around the central frequency [

59]. The transmission time,

(for Time on Air) in ms of a number symbol

is defined by:

The SF is between 5 and 12, and the bandwidth is expressed in

. The value of

varies depending on the modulation parameters. In this work, the LoRa SX1280 of Semtech [

60] transceiver is considered, and for variable packet size, the number of symbols is defined by:

where

represents the number of bits in the payload, SF is the spreading factor, and

and

, respectively, represent the number of symbols in the preamble and the number of symbols in the header.

Considering the transmission power

and the transmission duration

, the energy dissipated for the data transmission

in

, is evaluated as follows:

By substituting Equation (5) in Equation (7), the expression of

becomes:

with

, which is the number of symbols in the packet and evaluated by one of the equations defined in the system of Equations (6).

is the bandwidth in

and

is the spreading factor.

The transmission power

is related to the maximum range of the LoRa transmitter. To assess the maximum range of the LoRa transmitter, one must consider the sensitivity

of the receiver, which represents the minimum power necessary to detect the transmitted signal. The sensitivity value is provided in the datasheet, and in the case of the LoRa SX1280 transceiver, it is −99 dBm [

60]. The sensitivity corresponds to the power received in a link budget between the LoRa transmitter and the LoRa receiver. Considering the path-loss propagation model and assuming the unit gains antenna, the attenuation factor

is defined as follows:

where

, and

, represent the used frequency, the speed of light, the path loss exponent, and the distance between the LoRa transmitter and the LoRa receiver, respectively.

Depending on the attenuation factor

and the transmission power

, the sensitivity

will be expressed as follows:

Thus, the transmission power in LoRa is linked to the transmission range

as follows:

Finally, the substitution of Equation (11) in Equation (8) makes it possible to express the energy cost associated with data transmission as follows:

The parameters for evaluating the energy cost of the IWS are reported in

Table 5 below; the values considered are those of a LoRa SX1280 transmitter from Semtech [

60].

Using the parameters in

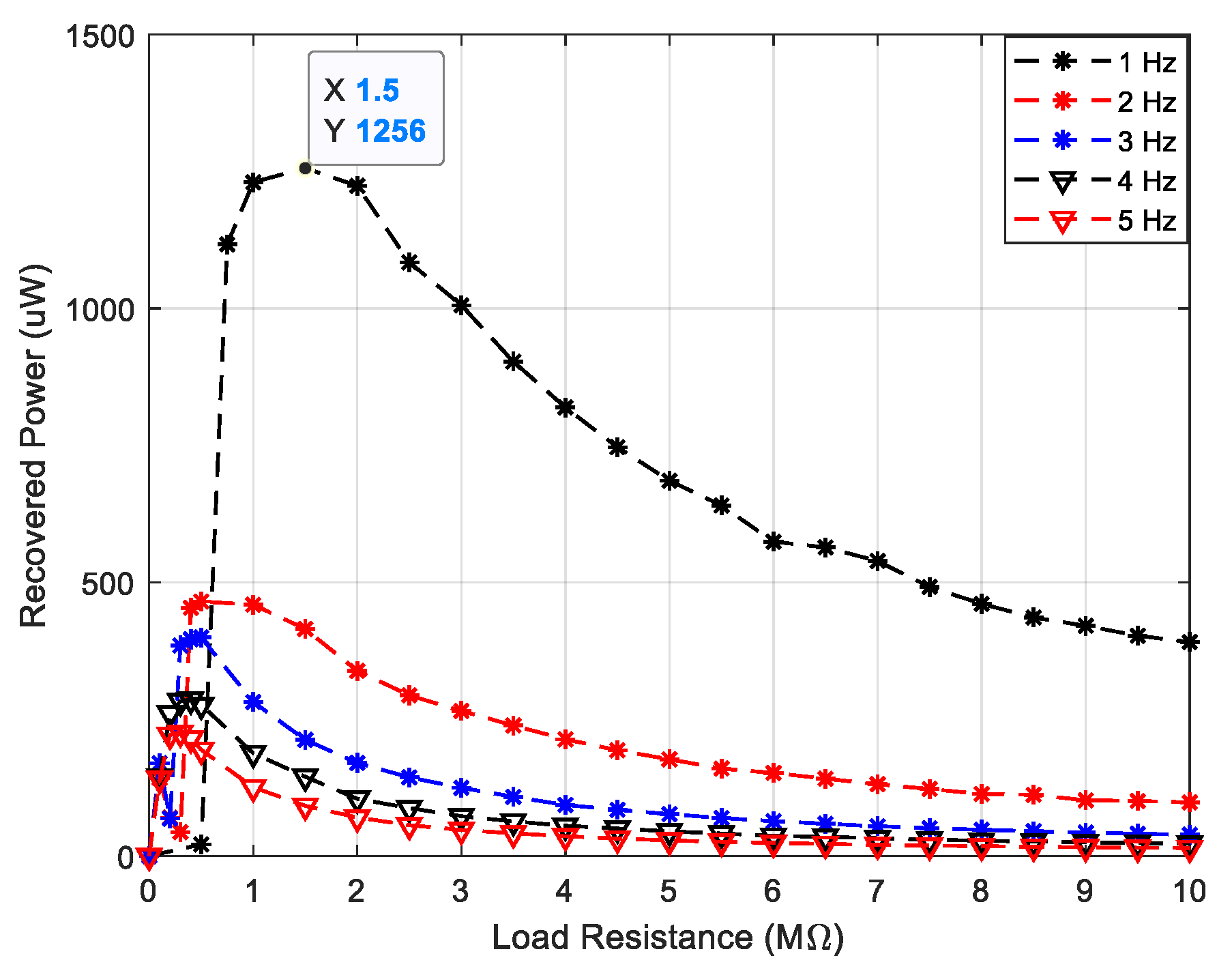

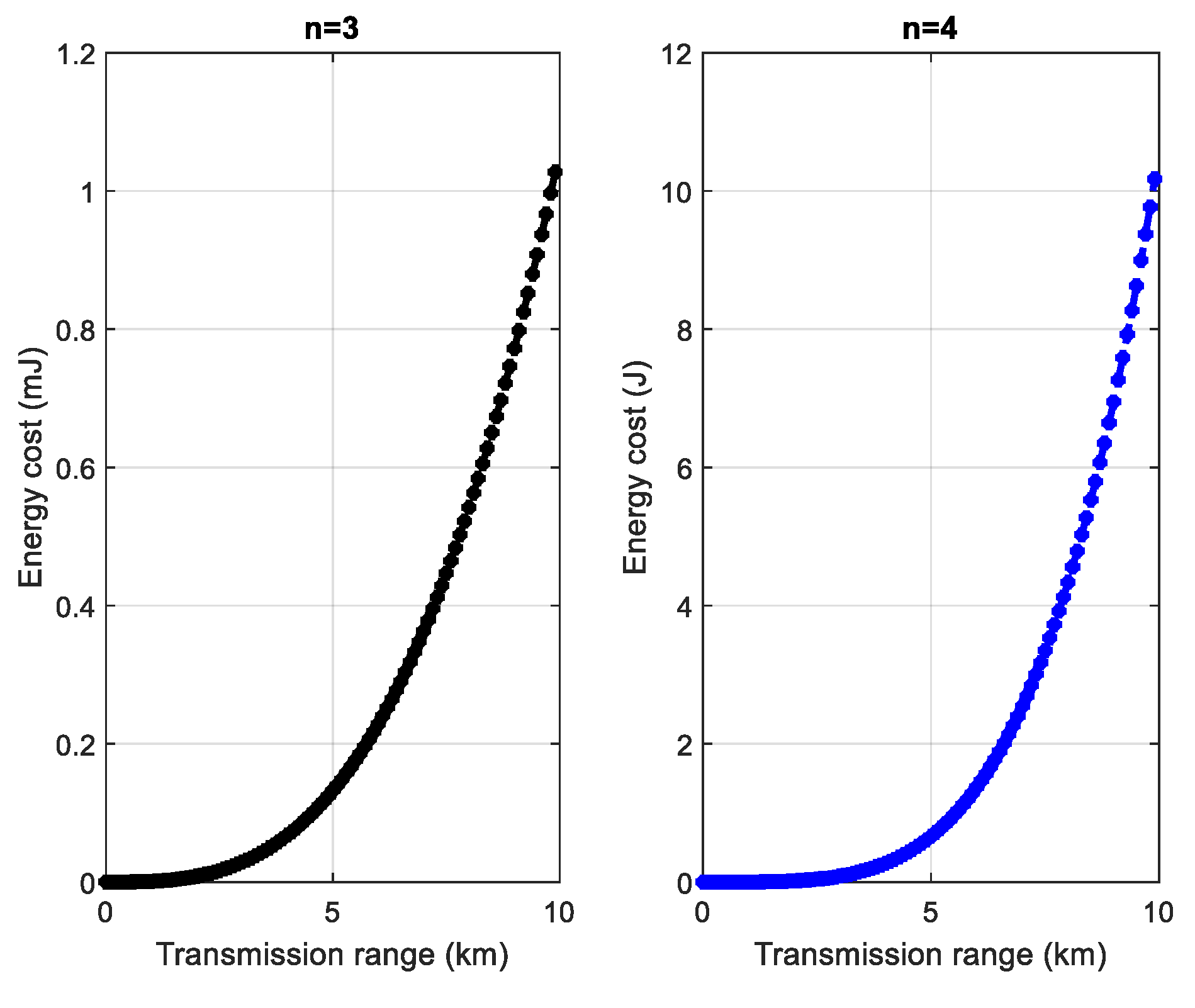

Table 5, it was obtained as a function of the loss exponent (3 or 4), the energy levels shown in

Figure 14. The results showed for transmission ranges up to 10 km, the maximum energy demand was 1.02 mJ in an environment with a loss exponent of 3 (which was the case of obstructed factories [

61]), while the energy demand is above 10 J for n = 4 which would be the case with obstructed buildings [

61]. In the rest of this paper, an exponent path loss of 3 was considered.

4.2. Management of the Harvested Energy

Equation (12) offers three possibilities of slaving the performance of the node to the energy harvested. These are the size

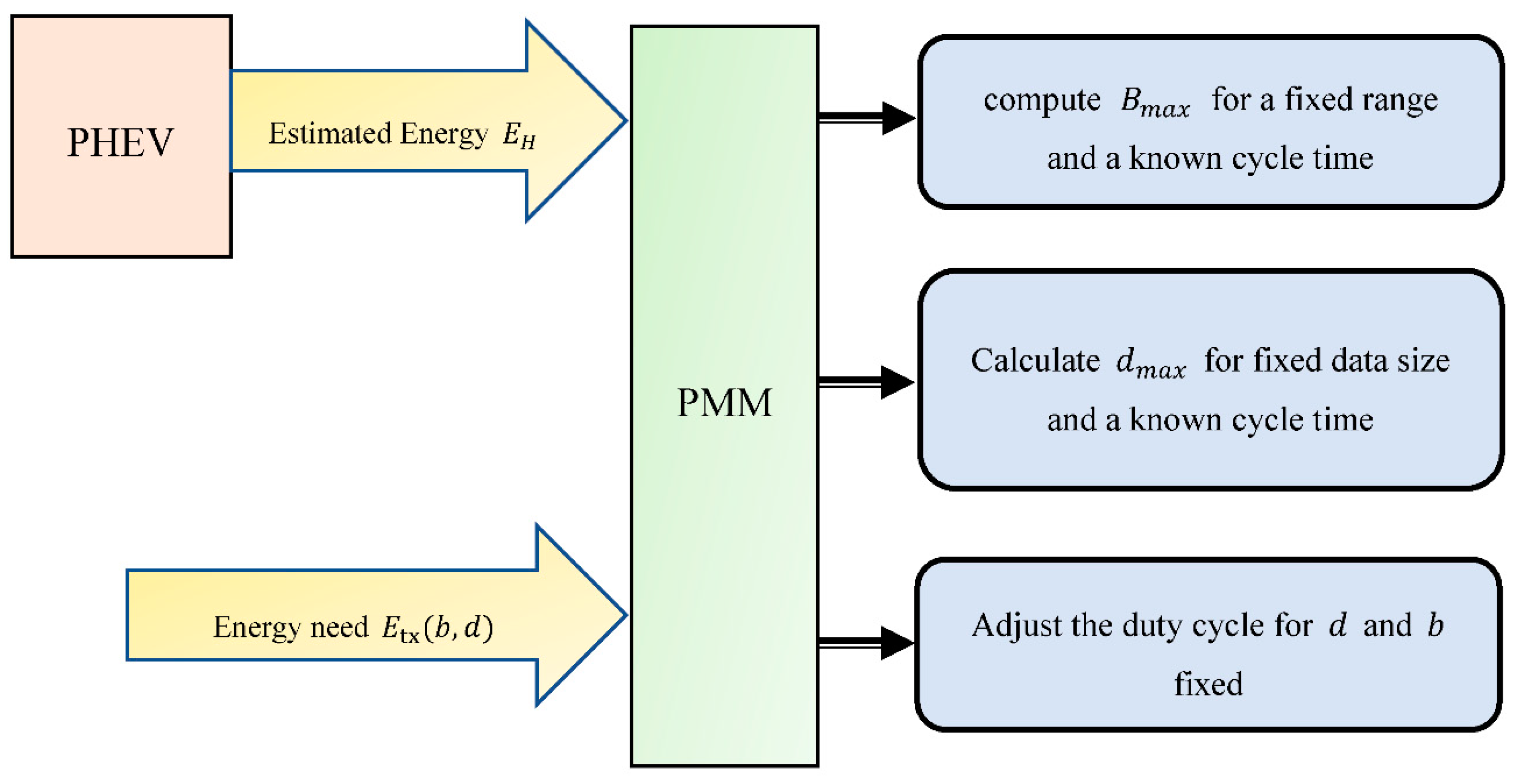

of the data in the payload and the IWS’s transmission range. The third possibility is the transmission frequency in the case of a duty cycle adaptation strategy. Assuming that all the energy harvested is dedicated to the operation of the IWS (i.e., we consider an ideal case of a lossless harvesting circuit), the energy management module will then work as shown in

Figure 15 below.

As shown in this figure, the objective is to transmit the maximum amount of data at the end of the cycle for a known measurement cycle time and distance. This first scenario makes it possible to reduce the length of the queue of data stored in the sensor [

62]. In the second case, it is considered that the transmission of a data size is fixed in advance at the greatest possible distance; this strategy would be suitable for fairly dense mesh networks and minimize transmission delays due to multi-hop communications [

63]. The duty cycle strategy is the third case dealt with; it applies when the data size and transmission range are previously defined. To simplify writing, for maximizing the data size, the used protocol will be abbreviated as MDSP. It will be a question for the PMM to use all of the harvested energy (estimated by the PHEV) during the current cycle to transmit data at the end of the cycle. Regarding the harvested energy stored during the measurement cycle, it is designated by

and is defined as follows:

where

is the duration of a cycle,

is the harvestable power during the current measurement cycle; the PHEV predicts it, and

is the instant marking the start of the current cycle.

The problem of optimizing energy management by the PMM is then the problem P1 formulated as follows:

This problem boils down to minimizing the residual energy of the IWS at the end of each cycle while preventing it from going through a value less than 0. The node’s actual residual energy at the end of each measurement cycle, considering its accumulated energy, is defined as follow:

where

is the power actually accumulated during the measurement cycle; the other parameters of the equation are defined as previously.

For data size analysis, it is assumed that the network is deployed at a fixed distance,

from the base station. The measurement cycle is one minute, corresponding to the initial sampling of the vibration data.

Figure 16 shows the operational flowchart of the PMM.

In

Figure 16,

is the minimum energy required to transmit a bit. At the start of the cycle, the range of data variations is defined, and the ranged and the duration

of the cycle;

represents the number of samples taken during the month. The operation of PMM comes down to transmitting as much data as possible at the end of the cycle under the basis of the energy harvested during the cycle. The duty cycle adaptation is also considered in this algorithm because the IWS stays on standby mode if it has not accumulated the energy necessary to transmit a data bit. The transmission range was firstly set at 1 km, and the maximum data size that can be transmitted was 1500 bits. The results obtained in terms of cumulative data over one month are shown in

Figure 17.

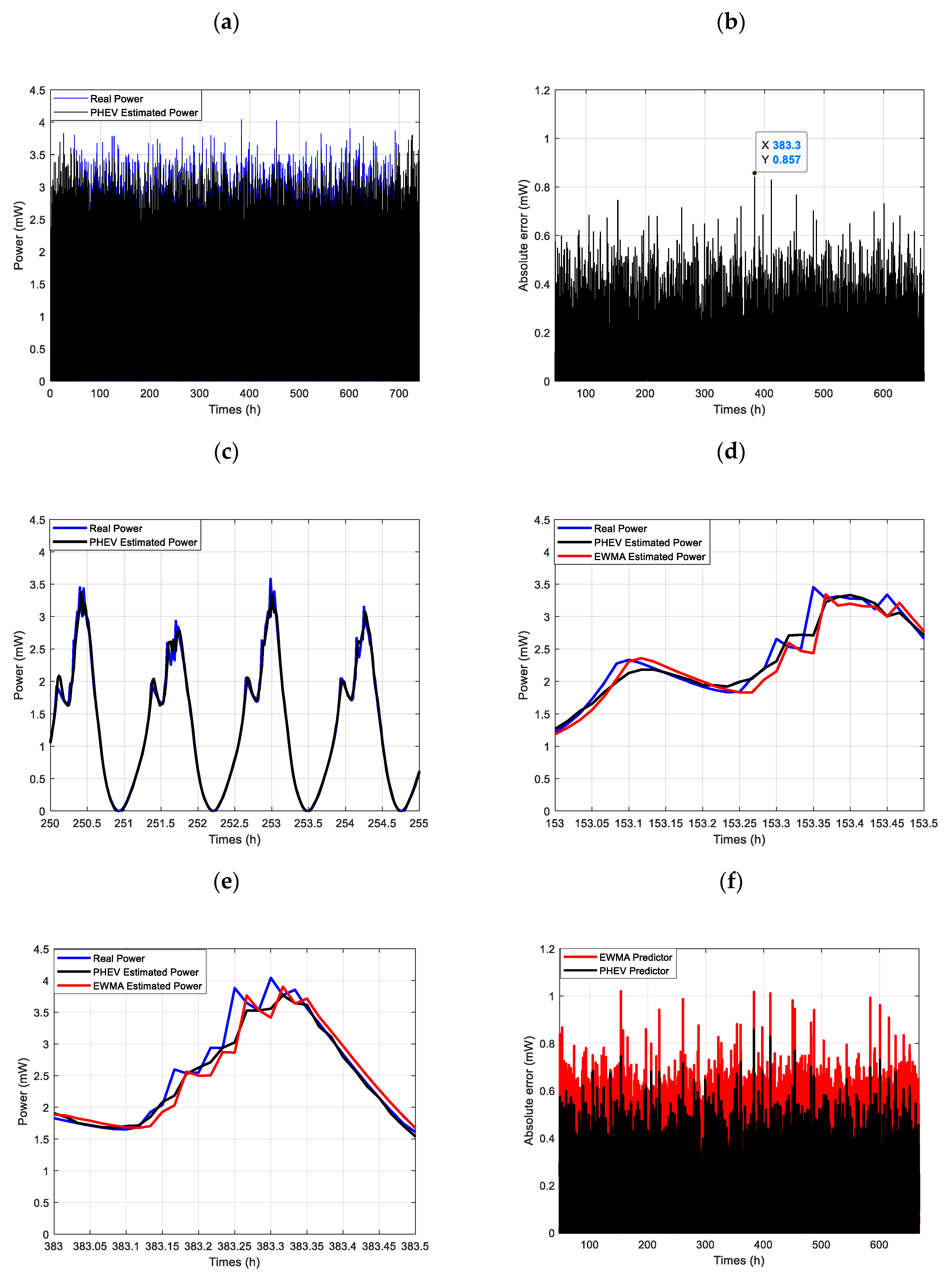

Figure 17a shows the transmitted data accumulated over the month for a transmission range of

. The result also highlights the frequency of transmission of the IWS. Overall, it was achieved that the IWS depletes its energy reserve during the first hours of measurement. For example, for a transmission with a maximum size of

, the average throughput at the start of the month was 4.36 bits / s, unlike 0.5 bits / s observed towards the end of the month.

In

Figure 17b, the maximum range was increased to 3 km, and it is observed that the amount of data transmitted over the whole month decreases, which was an expected result since the energy cost of the IWS has increased.

In

Figure 17c, the transmission range varies from 100 to 5000 km, with a data size set to the legend’s values. The amount of data transmitted over the month increases with increasing packet size. For example, for packets of size 4096 bits, it was obtained that 94.21 kbits of data were transmitted during the month under the basis of the energy harvested from the vibrations. This amount of data corresponds to an average throughput of 2.15 bits per second.

For different packet sizes (512 bits, 1024 bits, 2048 bits, and 4096 bits), the evolution of the residual energy of the IWS is shown in

Figure 17d. The evolution of the residual energy agrees with the previous results, in which it was noted that the transmission frequency is higher in the first hours of the month. It was also observed that the residual energy of the IWS increased after each transmission. This was justified because the harvestable energy calculation during each measurement cycle is based on the PHEV’s predicted power. This power was less than or equal to the real power, as shown in

Figure 13a. This is another advantage of PHEV, which avoids overestimating the harvestable power, as is the EWMA predictor.

Overall, the achieved throughput based on the harvested energy can be satisfactory for monitoring temperature data, which varies very slowly due to thermal inertia. Note that the real throughput can also be improved if the residual energy of the IWS is updated after each transmission since, in most of the results obtained, the predicted energy is below the actual energy.