Mechanical Behaviour of Atrazine-Contaminated Clay

Abstract

:1. Introduction

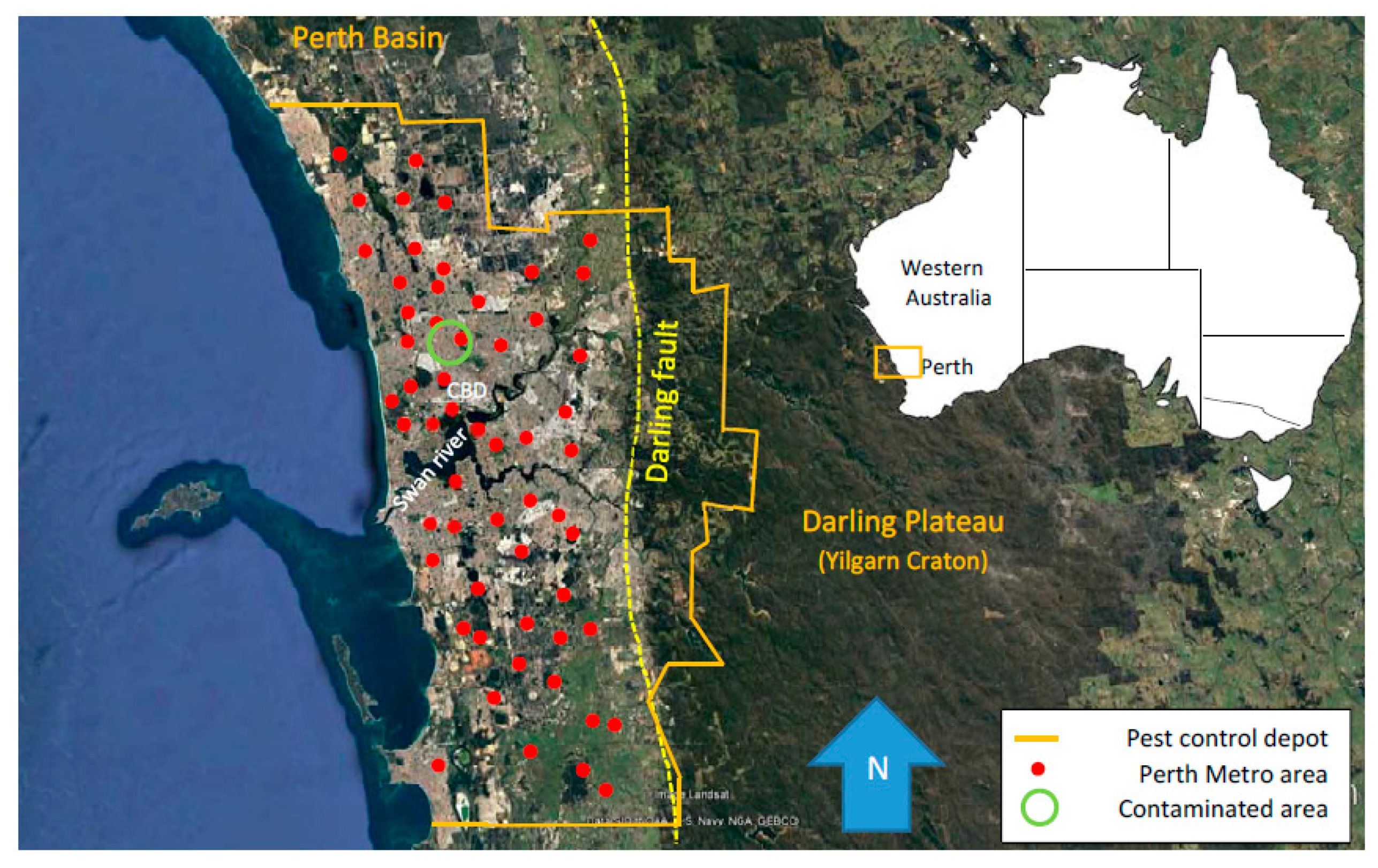

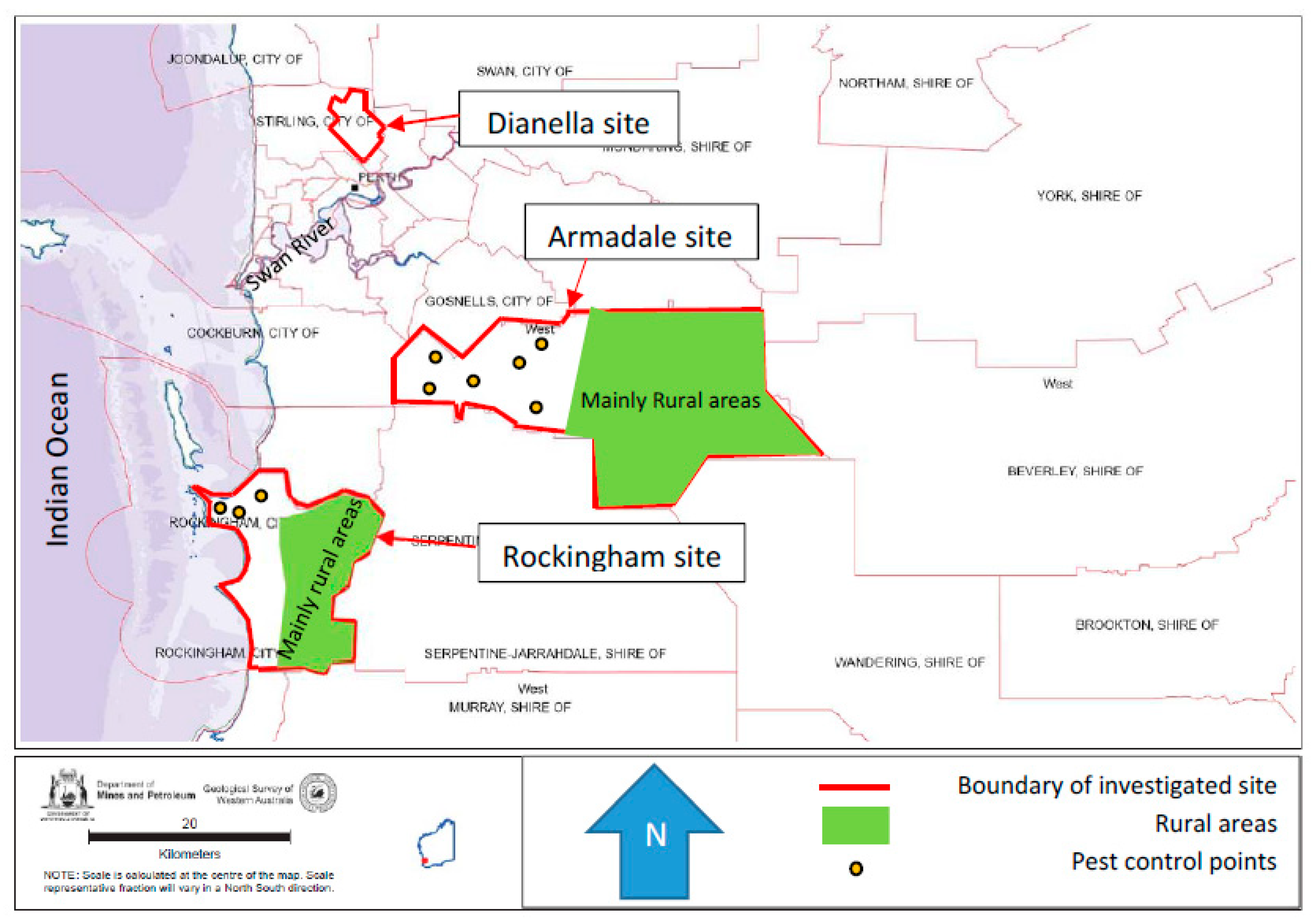

2. Study Area and Site Investigations

3. Methodology

3.1. Used Materials

3.2. Sample Preparation

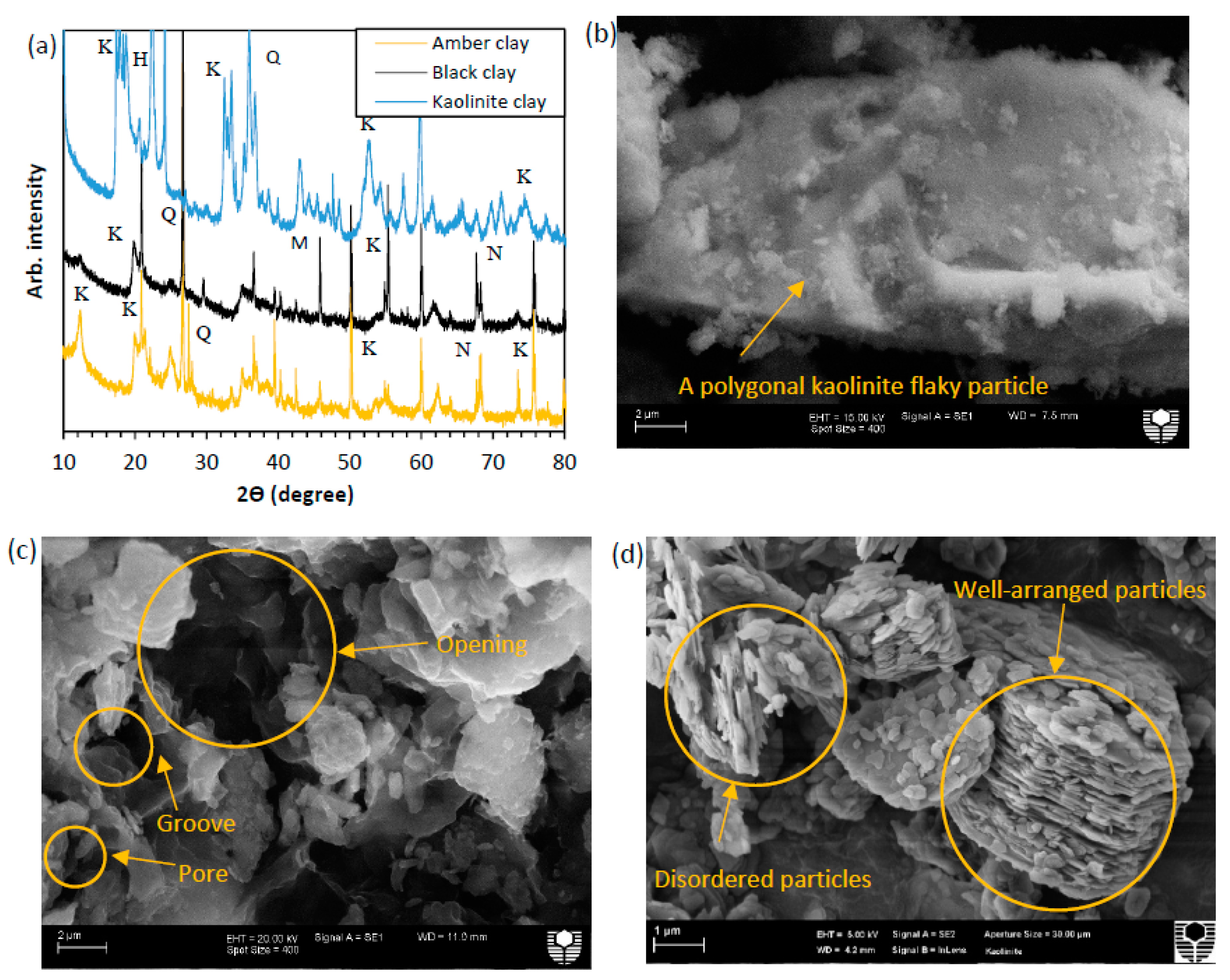

4. Microstructural Characterisations

5. Results and Discussion

5.1. Effect of Contamination on Atterberg Limit Characteristics

5.2. Effect of Contamination on Compaction Parameters

5.3. Ring Shear Results

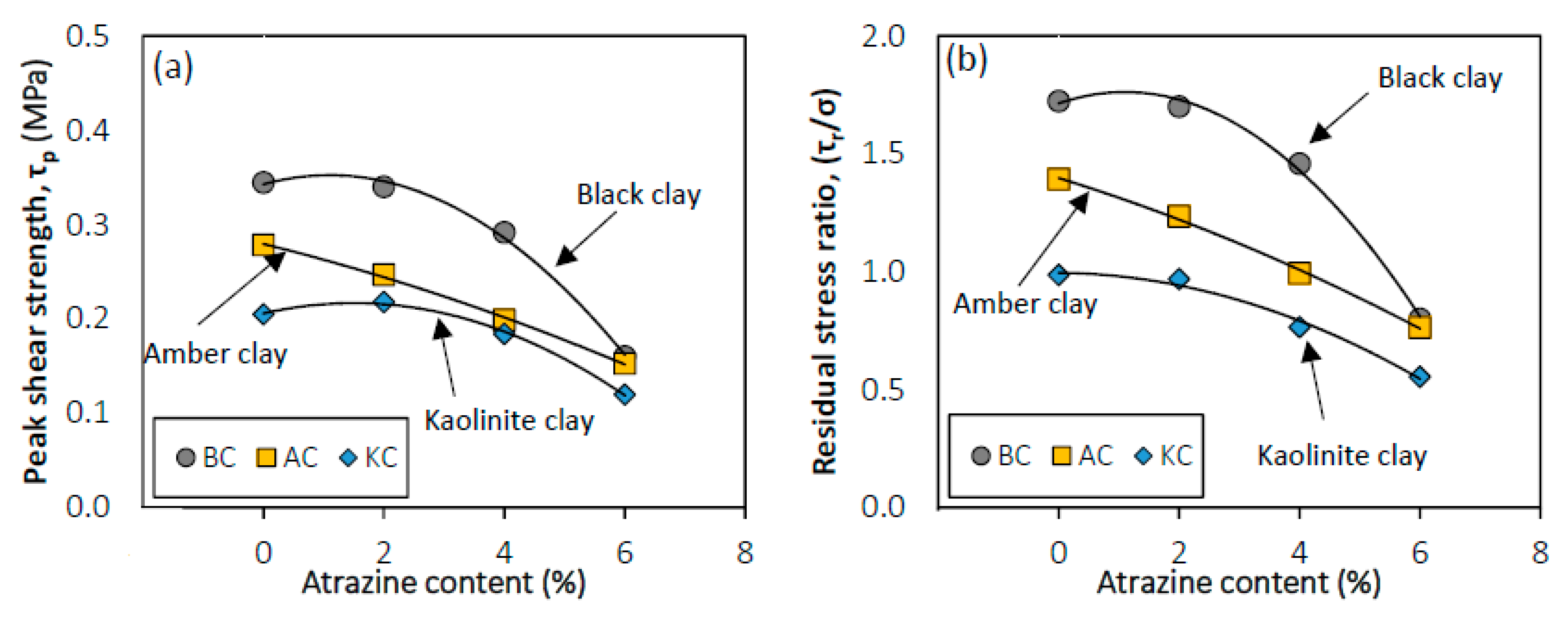

5.3.1. Effect of Contamination on Shear Strength

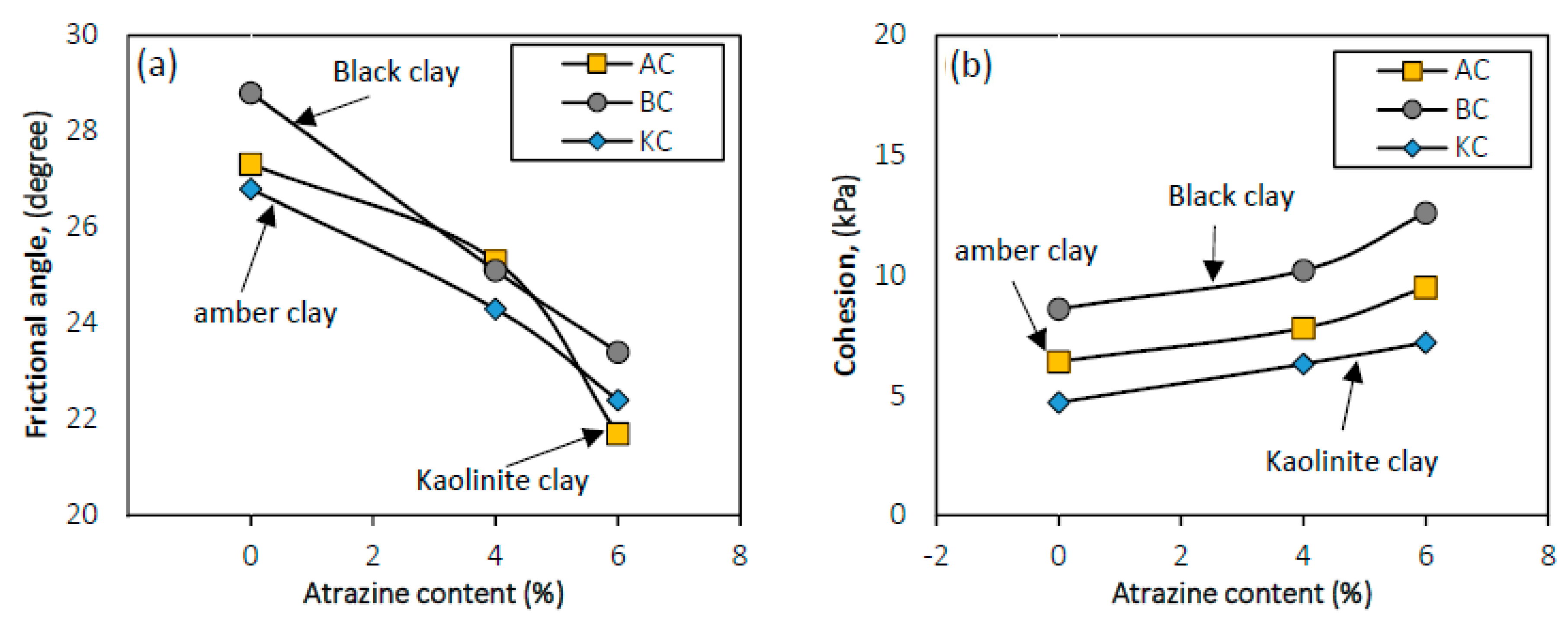

5.3.2. Effect of Contamination on Cohesion and Friction Angle

5.3.3. Effect of Duration of the Contamination

6. Conclusions

- ▯

- The results showed that enhancing atrazine content in soil increased the liquid limit (LL) and plastic limit (PL) characteristics of the tested clays due to viscous nature of the contamination agent.

- ▯

- Increasing atrazine contamination content of the soil reduced maximum dry density (MDD) and optimum moisture content (OMC) of the tested clays.

- ▯

- Peak shear strength and residual stress ratio of the tested soils reduced by increasing the atrazine contents. This reduction was attributed to an increase in the viscosity of the soil which caused the pore fluid in the clay to behave like a lubricant agent and let the clay particles easily slide when external stress is applied.

- ▯

- Peak shear strength and residual stress ratio reduced even more when duration of the contaminating soil increased. This behaviour was attributed to simulation of the long-term contamination condition that caused a reduction dielectric constant and accordingly the shear strength characteristics of the tested soils.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Al-Rkaby, A.H.J.; Chegenizadeh, A.; Nikraz, H.R. Directional-dependence in the mechanical characteristics of sand: A review. Int. J. Geotech. Eng. 2016, 10, 499–509. [Google Scholar] [CrossRef]

- Al-Rkaby, A.H.J.; Chegenizadeh, A.; Nikraz, H. Anisotropic strength of large scale geogrid-reinforced sand: Experimental study. Soils Found. 2017, 57, 557–574. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Shear Test on Reinforced Clay. Adv. Mater. Res. 2011, 250, 3223–3227. [Google Scholar] [CrossRef] [Green Version]

- Chegenizadeh, A.; Nikraz, H. Composite Soil: Fiber Inclusion and Strength. Adv. Mater. Res. 2011, 308, 1646–1650. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Permeability test on reinforced clayey sand. World Acad. Sci. Eng. Technol. 2011, 54, 130–133. [Google Scholar]

- Chegenizadeh, A.; Nikraz, H. Investigation on Compaction Characteristics of Reinforced Soil. Adv. Mater. Res. 2011, 261, 964–968. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Investigation on Strength of Fiber Reinforced Clay. Adv. Mater. Res. 2011, 261, 957–963. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Ghadimi, B.; Nikraz, H.; Şimşek, M. A novel two-dimensional approach to modelling functionally graded beams resting on a soil medium. Struct. Eng. Mech. 2014, 51, 727–741. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Nikraz, H. Liquefaction resistance of fibre reinforced low-plasticity silt. Soil Dyn. Earthq. Eng. 2018, 104, 372–377. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Santa, G.D.; Nikraz, H. Influence of recycled tyre amendment on the mechanical behaviour of soil-bentonite cut-off walls. J. Clean. Prod. 2018, 177, 507–515. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Panizza, S.; Nikraz, H. Effect of Powdered Recycled Tire on Sulfate Resistance of Cemented Clay. J. Mater. Civ. Eng. 2017, 29, 04017160. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. Effect of Slag on Restoration Mechanical Characteristics of Ethanol Gasoline–Contaminated Clay. J. Environ. Eng. 2018, 144, 06018001. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. Shear strength characteristics of over-consolidated clay treated with ggbfs. Aust. Geomech. 2018, 53, 141–149. [Google Scholar]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. Effect of Flyash on Post-Cyclic Behavior of Sand. J. Earthq. Eng. 2018, 15, 1–3. [Google Scholar] [CrossRef]

- Llewellyn, R.S.; Powles, S.; Powles, S.B. High Levels of Herbicide Resistance in Rigid Ryegrass (Lolium rigidum) in the Wheat Belt of Western Australia1. Weed Technol. 2001, 15, 242–248. [Google Scholar] [CrossRef]

- Powles, S.; Howat, P.D. Herbicide-resistant Weeds in Australia. Weed Technol. 1990, 4, 178–185. [Google Scholar] [CrossRef]

- Walker, S.R.; Blacklow, W.M. Adsorption and degradation of triazine herbicides in soils used for lupin production in Western-Australia-Laboratory studies and a simulation model. Soil Res. 1994, 32, 1189–1205. [Google Scholar]

- Gerritse, R.; Beltrán, J.; Hernández, F. Adsorption of atrazine, simazine, and glyphosate in soils of the Gnangara Mound, Western Australia. Soil Res. 1996, 34, 599–607. [Google Scholar] [CrossRef]

- Appleyard, S. Groundwater quality in the Perth region. Aust. Geomech. 2003, 38, 103–112. [Google Scholar]

- Joll, C.A.; Franzmann, P.D. A Review and Recommendations for the Remediation of Atrazine and Fenamiphos Contamination of Soil and Groundwater at Dianella; Centre for Groundwater Studies (CSIRO): Canberra, Australia, 1997; p. 79. [Google Scholar]

- Franzmann, P.D.; Zappia, L.R.; Tilbury, A.L.; Patterson, B.M.; Davis, G.B.; Mandelbaum, R.T. Bioaugmentation of Atrazine and Fenamiphos Impacted Groundwater: Laboratory Evaluation. Bioremediation J. 2000, 4, 237–248. [Google Scholar] [CrossRef]

- Chau, P.C. The Role of Pesticide Metabolites and Preferential Flow in Understanding Pesticide Fate in the Vadose Zone. Bachelor’s Thesis, University of Western Australia, Perth, Australia, 2010. [Google Scholar]

- Bell, A.L.; McCullough, L.M.; Gregory, B.J. Clay contamination in crushed rock highway sub-bases. In Proceedings of the The Second Australian Conference on Engineering Materials, Sydney, Australia, 6–38 July 1981. [Google Scholar]

- Meegoda, J.N.; Rajapakse, R.A. Short-Term and Long-Term Permeabilities of Contaminated Clays. J. Environ. Eng. 1993, 119, 725–743. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Vallejo, L.E.; Reddi, L.N. Engineered Contaminated Soils and Interaction of Soil Geomembranes; American Society of Civil Engineers, Sessions of ASCE National Convention: Washington, DC, USA, 1996. [Google Scholar]

- Ratnaweera, P.; Meegoda, J.N. Shear strength and stress-strain behaviour of contaminated soils. Geotech. Test. J. 2006, 29, 133–140. [Google Scholar]

- Khamehchiyan, M.; Charkhabi, A.H.; Tajik, M. Effects of crude oil contamination on geotechnical properties of clayey and sandy soils. Eng. Geol. 2007, 89, 220–229. [Google Scholar] [CrossRef]

- Singh, S.K.; Srivastava, R.; John, S. Studies on soil contamination due to used motor oil and its remediation. Can. Geotech. J. 2009, 46, 1077–1083. [Google Scholar] [CrossRef]

- Sunil, B.M.; Shrihari, S.; Nayak, S. Shear strength characteristics and chemical characteristics of leachate-contaminated lateritic soil. Eng. Geol. 2009, 106, 20–25. [Google Scholar] [CrossRef]

- Di Matteo, L.; Bigotti, F.; Ricco, R. Compressibility of Kaolinitic Clay Contaminated by Ethanol-Gasoline Blends. J. Geotech. Geoenvironmental Eng. 2011, 137, 846–849. [Google Scholar] [CrossRef]

- Khosravi, E.; Ghasemzadeh, H.; Sabour, M.R.; Yazdani, H. Geotechnical properties of gas oil-contaminated kaolinite. Eng. Geol. 2013, 166, 11–16. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. Experimental study on effect of fly ash on liquefaction resistance of sand. Soil Dyn. Earthq. Eng. 2017, 93, 1–6. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Pu, H. Effect of Atrazine Contamination on Compressibility and Permeability Characteristics of Clay. Geotech. Test. J. 2017, 40, 936–950. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H.; Sabbar, A.S. Effect of flyash on liquefaction behaviour of sand-bentonite mixture. Soils Found. 2018, 58, 1288–1296. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Beytolahpour, I.; Moradi, M.; Javadi, A.A. Mechanical behavior of a clay soil contaminated with glycerol and ethanol. Eur. J. Environ. Civ. Eng. 2015, 20, 1–17. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Miceli, S.; Nikraz, H.; Salih Sabbar, A. Investigation on Recycled Sawdust in Controlling Sulphate Attack in Cemented Clay. Appl. Sci. 2020, 10, 1441. [Google Scholar] [CrossRef] [Green Version]

- Moss, S.J.; Freeman, M.; George, A.D.; Marshall, A.; Dunphy, J.M. The Prider Field Trip—The Rock Cycle and Geology the Perth Metropolitan Area. A Professional Development Day for High School Geology and Science Teachers; Geological Society of Australia (WA Division): Hornsby, NSW, Australia, 1998; Volume 10, p. 72. [Google Scholar]

- McPherson, A.; Jones, A. Appendix D: Perth Basin geology review and site class assessment. In Natural Hazard Risk in Perth, Western Australia; 2005; pp. 313–344. Available online: https://www.researchgate.net/profile/Andrew_Mcpherson6/publication/265671763_Perth_Basin_geology_Appendix_D_PERTH_BASIN_GEOLOGY_REVIEW_and_SITE_CLASS_ASSESSMENT/links/55f0adb808ae0af8ee1d2cd9/Perth-Basin-geology-Appendix-D-PERTH-BASIN-GEOLOGY-REVIEW-and-SITE-CLASS-ASSESSMENT.pdf (accessed on 2 April 2020).

- Appleyard, S.J. Investigation of Ground Water Contamination by Fenamiphos and Atrazine in a Residential Area: Source and Distribution of Contamination. Ground Water Monit. Remediat. 1995, 15, 110–113. [Google Scholar] [CrossRef]

- Google Earth. Perth, Western Australia 32°02’46.63″S, 116°08’37.44″E, elevation 289m. 2016. Available online: https://www.google.com/maps/@-31.9738665,115.8327241,11.21z (accessed on 15 August 2016).

- Geological Survey of Western Australia. Extracted from GeoVIEW.WA extracted from GeoVIEW WA, Perth. Department of Mines and Petroleum. 2016. Available online: https://dasc.dmp.wa.gov.au/dasc/ (accessed on 28 March 2020).

- Gratchev, I.; Sassa, K. Shear Strength of Clay at Different Shear Rates. J. Geotech. Geoenvironmental Eng. 2015, 141, 06015002. [Google Scholar] [CrossRef] [Green Version]

- Sibelco Australia. Material Safety Data Sheet for Clay Prestige NY. 2011. Available online: http://wc.strategyonline.com/documents/msds/WC-BA214-MSDS.pdf (accessed on 2 April 2020).

- ASTM. Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM. Standard Test Method for Dispersive Characteristics of Clay Soil by Double Hydrometer; ASTM D4221; ASTM: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Singh, S.K.; Srivastava, R.; John, S. Settlement Characteristics of Clayey Soils Contaminated with Petroleum Hydrocarbons. Soil Sediment Contam. Int. J. 2008, 17, 290–300. [Google Scholar] [CrossRef]

- Meehan, C.L.; Brandon, T.L.; Duncan, J.M. Measuring drained residual strengths in the Bromhead ring shear. Geotech. Test. J. 2007, 30, 466–473. [Google Scholar]

- ASTM. Standard Test Method for Torsional Ring Shear Test to Determine Drained Residual Shear Strength of Cohesive Soils; ASTM D6467; ASTM: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Stark, T.D.; Eid, H.T. Modified Bromhead ring shear apparatus. Geotech. Test. J. 1993, 16, 100–107. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A. Effect of Particle Shape on Monotonic Liquefaction: Natural and Crushed Sand. Exp. Mech. 2017, 57, 1341–1348. [Google Scholar] [CrossRef]

- Stark, T.D.; Contreras, I.A. Constant volume ring shear apparatus. Geotech. Test. J. 1996, 19, 3–11. [Google Scholar] [CrossRef]

- Eid, H.; Doerfler, C. Effect of Shear Displacement Rate on Internal Shear Strength of a Reinforced Geosynthetic Clay Liner. Geosynth. Int. 1999, 6, 219–239. [Google Scholar] [CrossRef]

- Sabbar, A.S.; Chegenizadeh, A.; Nikraz, H. Static liquefaction of very loose sand–slag–bentonite mixtures. Soils Found. 2017, 57, 341–356. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Yilmaz, Y.; Nikraz, H. Effect of Lime Treatment on Static Liquefaction Behavior of Sand–Bentonite Mixtures. J. Mater. Civ. Eng. 2018, 30, 06018017. [Google Scholar] [CrossRef]

- Sridharan, A.; Rao, G.V. Shear strength behaviour of saturated clays and the role of the effective stress concept. Géotechnique 1979, 29, 177–193. [Google Scholar] [CrossRef]

- Sridharan, A.; Rao, G.V. Mechanisms controlling volume change of saturated clays and the role of the effective stress concept. Géotechnique 1973, 23, 359–382. [Google Scholar] [CrossRef]

- Meegoda, N.J.; Ratnaweera, P. Compressibility of contaminated fine-grained soils. Geotech. Test. J. 1994, 17, 101–112. [Google Scholar] [CrossRef]

- Naeini, S.A.; Jahanfar, M.A. Effect of salt solution and plasticity index on undrain shear strength of clays. World Acad. Sci. Eng. Technol. 2011, 49, 982–986. [Google Scholar]

- Akinwumi, I.I.; Diwa, D.; Obianigwe, N. Effects of crude oil contamination on the index properties, strength and permeability of lateritic clay. Int. J. Appl. Sci. Eng. Res. 2014, 3, 816–824. [Google Scholar]

- Sherif, M.A.; Burrous, C.M. Temperature Effects on the Unconfined Shear Strength of Saturated, Cohesive Soil; Highway Research Board Special Report, Proceedings of an International Conference Held at Washington, D.C., January 16 1969 With the Support of the National Science Foundation; Washington DC, United States, January 16 1969; On-Line Publishers, Inc: Lancaster, PA, USA, 1969. [Google Scholar]

- Nazir, A.K. Effect of motor oil contamination on geotechnical properties of over consolidated clay. Alex. Eng. J. 2011, 50, 331–335. [Google Scholar] [CrossRef]

- Alhassan, H.M.; Fagge, S.A. Effects of crude oil, low point pour fuel oil and vacuum gas oil contamination on the geotechnical properties sand, clay and laterite soils. Int. J. Eng. Res. Appl. 2013, 3, 1947–1954. [Google Scholar]

- Ghadyani, M.; Hamidi, A.; Hatambeigi, M. Triaxial shear behaviour of oil contaminated clays. Eur. J. Environ. Civ. Eng. 2016, 23, 112–135. [Google Scholar] [CrossRef]

- Moore, C.A.; Mitchell, J.K. Electromagnetic forces and soil strength. Géotechnique 1974, 24, 627–640. [Google Scholar] [CrossRef]

| No. | Collection Site | ID | Gs | LL | PL | PI | Percent Passing | CF (%) 0.002 mm | USCS | |

|---|---|---|---|---|---|---|---|---|---|---|

| Sieve Sizing (mm) | ||||||||||

| 0.075 No. 200 | 0.150 No. 40 | |||||||||

| 1 | Armadale | Amber clay | 2.72 | 62 | 31 | 31 | 70 | 100 | 10 | CH |

| 2 | Rockingham | Black clay | 2.81 | 88 | 37 | 51 | 90 | 100 | 5 | CH |

| 3 | Commercial type | Kaolinite clay | 2.58 | 58 | 28 | 30 | 100 | 100 | 65 | CH |

| Test No. | Clay Type | Test ID | Atrazine (%) | σ’n, (kPa) | Aging (d) |

|---|---|---|---|---|---|

| 1 | Amber clay | AC | 0 | 100, 150, 200 | 7 |

| 2 | AC-2A | 2 | 200 | 7 | |

| 3 | AC-4A | 4 | 100, 150, 200 | 7 | |

| 4 | AC-6A | 6 | 100, 150, 200 | 7, 14, 21 | |

| 5 | Black clay | BC | 0 | 100, 150, 200 | 7 |

| 6 | BC-2A | 2 | 200 | 7 | |

| 7 | BC-4A | 4 | 100, 150, 200 | 7 | |

| 8 | BC-6A | 6 | 100, 150, 200 | 7, 14, 21 | |

| 9 | Kaolinite clay | KC | 0 | 100, 150, 200 | 7 |

| 10 | KC-2A | 2 | 200 | 7 | |

| 11 | KC-4A | 4 | 100, 150, 200 | 7 | |

| 12 | KC-6A | 6 | 100, 150, 200 | 7, 14, 21 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H.; Yilmaz, Y. Mechanical Behaviour of Atrazine-Contaminated Clay. Appl. Sci. 2020, 10, 2457. https://doi.org/10.3390/app10072457

Keramatikerman M, Chegenizadeh A, Nikraz H, Yilmaz Y. Mechanical Behaviour of Atrazine-Contaminated Clay. Applied Sciences. 2020; 10(7):2457. https://doi.org/10.3390/app10072457

Chicago/Turabian StyleKeramatikerman, Mahdi, Amin Chegenizadeh, Hamid Nikraz, and Yuksel Yilmaz. 2020. "Mechanical Behaviour of Atrazine-Contaminated Clay" Applied Sciences 10, no. 7: 2457. https://doi.org/10.3390/app10072457

APA StyleKeramatikerman, M., Chegenizadeh, A., Nikraz, H., & Yilmaz, Y. (2020). Mechanical Behaviour of Atrazine-Contaminated Clay. Applied Sciences, 10(7), 2457. https://doi.org/10.3390/app10072457