Design and Experiment of Dry-Ice Cleaning Mechanical Arm for Insulators in Substation

Abstract

:Featured Application

Abstract

1. Introduction

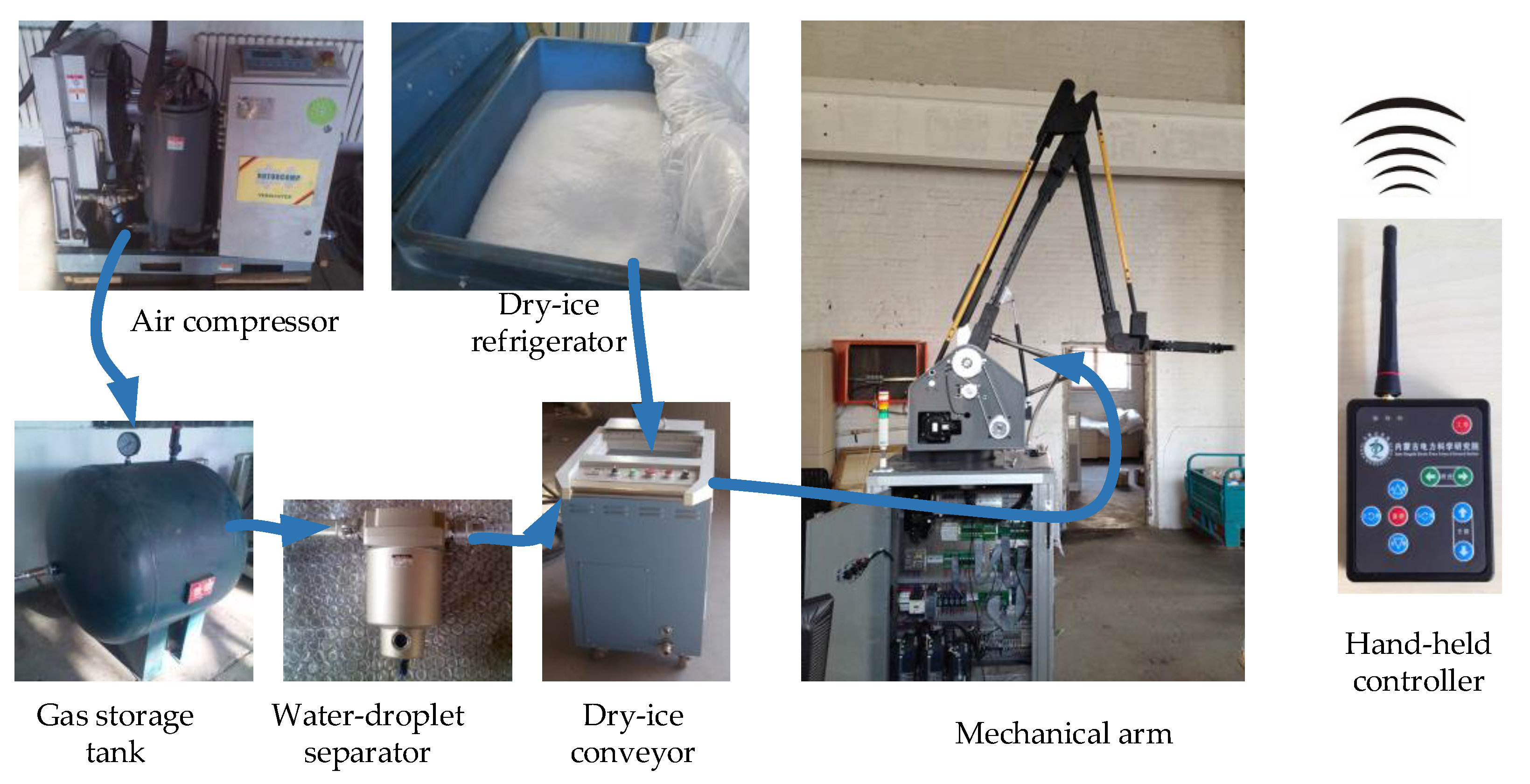

2. General Design of Dry-Ice Cleaning Mechanical Arm System

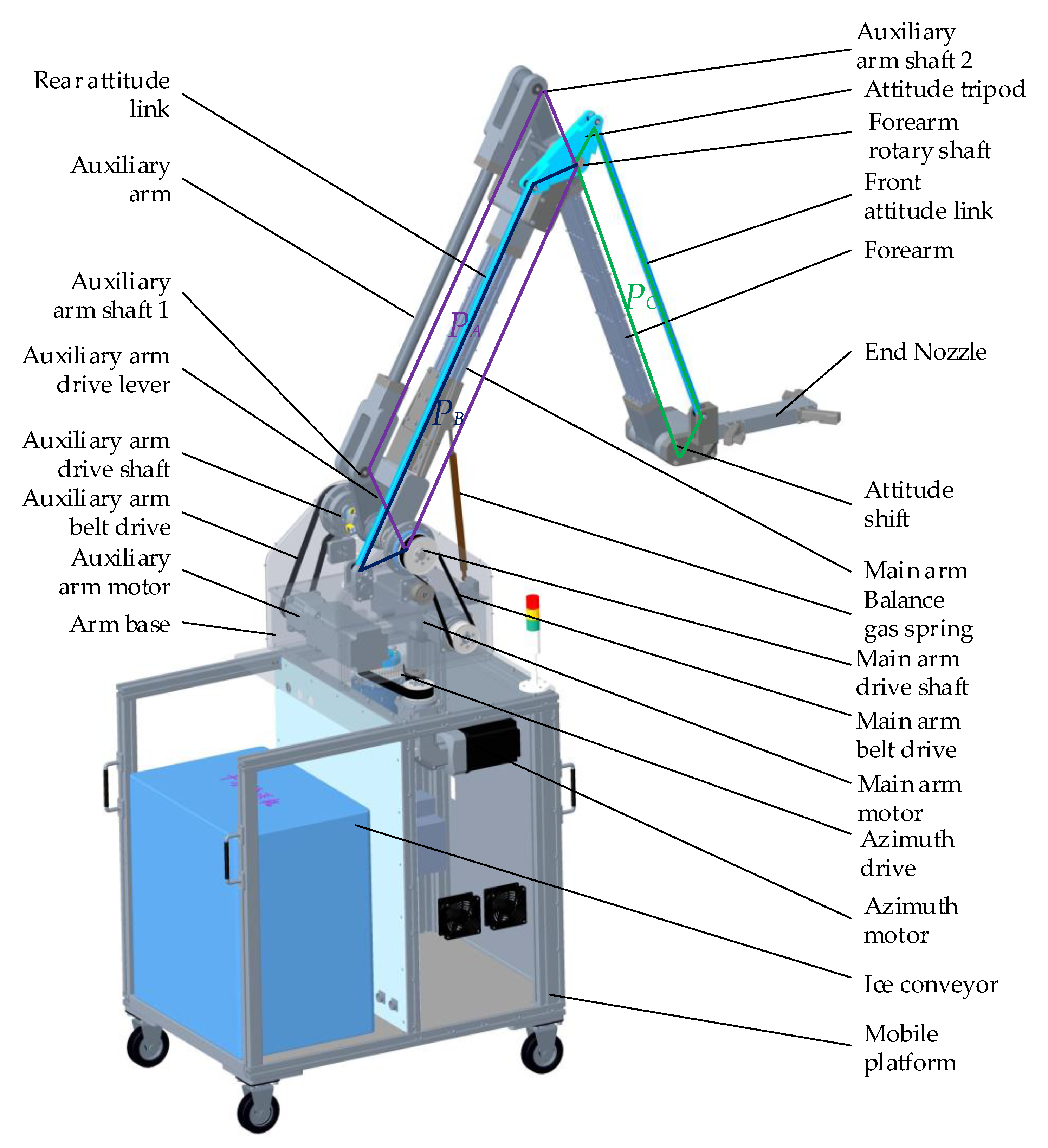

3. Mechanical System of Electrified Dry-Ice Cleaning Robotic Arm

3.1. Structural Principle of Mechanical Arm

3.2. The Nozzle Design for Dry-Ice Cleaning Insulator

3.3. The Realization of Mechanical System of Mechanical Arm

4. Kinematics and Simulation Analysis of Dry-Ice Cleaning Mechanical Arm

4.1. Kinematics Analysis of Dry-Ice Cleaning Mechanical Arm

- 1)

- Forward kinematics analysis:

- 2)

- Inverse kinematics analysis

4.2. Simulation Analysis of Dry-Ice Cleaning Mechanical Arm

5. Strength Analysis of Dry-Ice Cleaning Mechanical Arm

6. Design of Control System

7. Experiments

7.1. Electrified Dry-Ice Cleaning Mechanical Arm Experiment System

7.2. High-Voltage Endurance Insulation Test of Dry-Ice Cleaning Mechanical Arm

7.3. Insulator Cleaning Test at Substation Site

8. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Ibrahim, M.E.; Abd-Elhady, A.M.; Sabiha, N.A. Dynamic flashover model considering pollution layer resistance variation for fixed washed high voltage insulators. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2960–2967. [Google Scholar] [CrossRef]

- El-Zohri, E.; Ziedan, H.; Prochazka, R. A New Proposed Dynamic Arc Model for Flashover Performance of a Non-Uniform Polluted Insulator String under HVAC Stress. Electr. Power Syst. Res. 2015, 119, 278–286. [Google Scholar] [CrossRef]

- Gorur, R.; Olsen, R.; Crane, J.; Adams, T.; Jurney, J.; Venkataraman, S. Prediction of Flashover Voltage of Insulators Using Low Voltage Surface Resistance Measurement; Final Project Report; Power System Engineering Research Center (PSERC): Phoenix, AZ, USA, 2006; pp. 154–163. [Google Scholar]

- Ibrahim, M.E.; Sabiha, N.A.; Izzularab, M.A. Nanofilled Nonlinear Coating Material for Improving Proactive Flashover Performance of High Voltage Insulators. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2156–2163. [Google Scholar] [CrossRef]

- Rizk, F.A.M. Mathematical models for pollution flashover. Electra 1981, 78, 71–103. [Google Scholar]

- Zhang, Z.; Jiang, X.; Sun, C. Research status and Prospect of flashover characteristics of polluted insulator. Grid Technol. 2006, 30, 35–40. [Google Scholar]

- Tian, Y.; Tieyuan, X.; Rui, Z. Study on the boundary conditions of the leakage current and the generation of dry band in the polluted layer of post insulator. High Volt. Technol. 2016, 42, 214–222. [Google Scholar]

- Zhang, Z.; Jiang, X.; Sun, C. Comparison of the AC Pollution Flashover Characteristics of Insulators Under Two Different Polluting Manners. Proc. CSEE 2006, 26, 124–127. [Google Scholar]

- Jia, Z.; Bai, W.; Yao, S. Influence of hydrophobic cleaning detergent on external insulation of electrical equipment. Gaodianya Jishu/High Volt. Eng. 2012, 38, 2403–2409. [Google Scholar]

- Jia, Z.; Wang, W.; Zhang, Q. Self-cleaning hard coating of insulator for the usage of anti-pollution flashover. Gaodianya Jishu/High Volt. Eng. 2012, 38, 2044–2050. [Google Scholar]

- Wang, W.; Zhang, H.; Chen, C. Performance analysis of self-cleaning hard coating on insulators after trial operation. Appl. Mech. Mater. 2013, 341, 1346–1350. [Google Scholar] [CrossRef]

- Liu, W.-X.; Quan, H.-Q.; Liu, X.-M. Preparation and properties of visible light-active self-cleaning porcelain insulators. Cailiao Gongcheng/J. Mater. Eng. 2014, 4, 46–49. [Google Scholar]

- Fan, Y.; Hu, C.; Wang, J. Comparison of Hot Water Washing Efficiency of 500 kV Post Insulator Between Normal Type and Anti-pollution Type. Gaodianya Jishu/High Volt. Eng. 2017, 43, 1500–1508. [Google Scholar]

- Wu, T.; Huang, S.; Yang, D. Effect of new insulation cleaning agent on electrical and mechanical properties of silicone rubber materials. In Proceedings of the 2018 China International Conference on Electricity Distribution, Tianjin, China, 17–19 September 2018; pp. 979–983. [Google Scholar]

- Fujimura, T.; Okayama, M.; Isozaki, T. Hot-Line Washing of Substation Insulators. IEEE Trans. Power Appar. Syst. 1970, 89, 770–774. [Google Scholar] [CrossRef]

- Wang, R.; Sun, L. Safety and technique of hot washing. In Proceedings of the 6th International Conference on Transmission &Distribution Construction & Live Line Maintenance, Las Vegas, NV, USA, 12–17 September 1993; pp. 225–239. [Google Scholar]

- Goto, S.; Nakamura, M.; Watanabe, T. Automatic decision making of timing of insulator washing in coastal substations by pollution prediction through event matching model. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Millbrae, CA, USA, 23 October 1996; pp. 412–415. [Google Scholar]

- Daha, M.M.; Ibrahim, M.E.; Izzularab, M.A. Effect of washing water flow rate and pollution level on leakage current of a fixed washed high voltage insulator. In Proceedings of the 18th International Middle-East Power Systems Conference, Cairo, Egypt, 27–29 December 2016; pp. 234–239. [Google Scholar]

- Dengguo, W.; Xiaoming, L.; Zhensheng, L. Safety protection technology of electrified water flushing device for transmission line. Power Syst. Autom. 2014, 38, 171–177. [Google Scholar]

- Xin, L. Research and Development of Control System of Insulator Charged Water Flushing Device; Southwest Jiaotong University: Chengdu, China, 2009. [Google Scholar]

- Pei, W. Study on the Overall Scheme of Wheel Washing with Charged Water; Southwest Jiaotong University: Chengdu, China, 2013. [Google Scholar]

- Zulin, W.; Jianguo, W.; Songbo, H. Washing of polluted insulator strings with live water for 4 sets of 500 kV transmission lines. High Volt. Technol. 2014, 40, 3688–3694. [Google Scholar]

- Lin, S. Application prospect of live water flushing technology for 500 kV power equipment. Grid Technol. 2015, 39, 2297–2302. [Google Scholar]

- Ying, Z.; Shouyin, L.; Jianjun, S. Research on Hot Washing Robot System for High Voltage Substation Equipment. High Volt. Eng. 2017, 43, 1326–1332. [Google Scholar]

- Deming, Y.; Jian, S.; Jun, W. Research and application of helicopter in power grid operation and maintenance. Power Grid Technol. 2009, 33, 107–112. [Google Scholar]

- Pelacchi, P. Automatic hot line insulator washing device positioned by helicopter. In Proceedings of the ESMO’98–1998 IEEE 8th International Conference on Transmission and Distribution Construction, Orlando, FL, USA, 26–30 April 1998; p. 133. [Google Scholar]

- Perin, D.; Pigini, A.; Visintainer, I. Live-line insulator washing: experimental investigation to assess safety and efficiency requirements. IEEE Trans. Power Deliv. 1995, 10, 518–525. [Google Scholar] [CrossRef]

- Yong, D.; Yong, P.; Tie, L. Experimental study on safe clearance distance of helicopter live working on UHV AC transmission line platform. High Volt. Technol. 2015, 41, 1292–1298. [Google Scholar]

- Cheng, Z.; Jia, J.; Zhong, L. Development of insulator cleaning robot. In Proceedings of the 4th International Conference on Applied Robotics for the Power Industry, Jinan, China, 11–13 October 2016; pp. 1–3. [Google Scholar]

- Wang, L.; Wang, H.-G.; Song, Y.-F. Behavior planning of a suspension insulator cleaning robot for power transmission lines. Jilin Daxue Xuebao/J. Jilin Univ. 2018, 48, 518–525. [Google Scholar]

- Sun, B.; Xu, W.; Yang, R.-Q. Trajectory optimization for a cleaning robot for a hotline insulator. J. Harbin Inst. Technol. 2005, 12, 696–699. [Google Scholar]

- Zhang, J.; Yang, R.-Q. 3D object visual tracking for the 220 kV/330 kV high-voltage live-line insulator cleaning robot. J. Donghua Univ. 2009, 26, 264–269. [Google Scholar]

- Byun, S.-H.; Cho, B.-H.; Park, J.-Y. Implementation of control system for insulator cleaning robot. In Proceedings of the 2006 SICE-ICASE International Joint Conference, Busan, Korea, 18–21 October 2006; pp. 3044–3047. [Google Scholar]

- Park, J.-Y.; Cho, B.-H.; Byun, S.-H. Development of cleaning robot system for live-line suspension insulator strings. Int. J. Control Autom. Syst. 2009, 7, 211–220. [Google Scholar] [CrossRef]

- Yu, H.Y.; Xu, W.C. Anti-contamination flashover technical analysis. Electr. Saf. Technol. 2005, 7, 28–30. [Google Scholar]

- Ren, J.X. Physical Cleansing; Chemical Industry Press: Beijing, China, 2000. [Google Scholar]

- John, S.R.; Walter, W. Dry surface cleaning using CO2 snow. J. Vac. Sci. Technol. B 1991, 9, 1970–1977. [Google Scholar]

- Hoenig, S.A. Cleaning surface with dry ice. Compress. Air Mag. 1986, 8, 22–24. [Google Scholar]

- Hoenig, S.A. Dry ice snow as a cleaning media for hybrids and integrated circuits. Hybrids Circuit Technol. 1990, 7, 34–37. [Google Scholar]

- Zhao, J.H.S.L.; Lu, A. Study on cleaning technique of dry ice and application. J. Harbin Univ. Commer. 2005, 21, 588–591. [Google Scholar]

- Zhou, W.; Liu, M.; Liu, S. On the mechanism of insulator cleaning using dry ice. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1715–1722. [Google Scholar] [CrossRef]

- Huili, Z. Design about Electric Safety of High-Voltage Testing Room. Low Volt. Appar. 2008, 6, 42–44. [Google Scholar]

- Rahman, N.; Carbonari, L.; Caldwell, D.; Cannella, F. Kinematic Analysis, Prototypation and Control of a Novel Gripper for Dexterous Applications. J. Intell. Robot. Syst. 2018, 91, 193–206. [Google Scholar] [CrossRef]

- Soriano, E.; Rubio, H.; Castejón, C.; García-Prada, J. Design of a low-cost manipulator arm for industrial fields. In New Trends in Mechanism and Machine Science; Springer: Berlin, Germany, 2015; pp. 839–847. [Google Scholar]

| Experimental Voltage (kV) | 50 | 100 | 200 | 500 | 750 | 1000 |

|---|---|---|---|---|---|---|

| Safe distance (m) | 1.0 | 1.2 | 1.5 | 3 | 4.5 | 7.2 |

| Item | Parameters | Item | Parameters |

|---|---|---|---|

| Azimuth angle range | ± 120° | Pressure of dry-ice gas | 0.5~0.6 MPa |

| Azimuth velocity | ≤ 5 °/s | Angle control accuracy | ≤ ± 0.5° |

| Working distance | 1.2~1.5 m | Terminal control accuracy | ≤ ± 5 mm |

| Working height range | 2 m | Wireless transmission distance | ≥ 100 m |

| Up, down/front, rear velocity | ≤ 100 mm/s | Wireless transmission delay | ≤ 30 ms |

| Diameter of cleaning insulator | ≤ 250 mm | Weight | ≈ 150 kg |

| Arm material | MC nylon 66 | Closing size (L × W × H) | 2000 × 800 × 2900 mm |

| Pedestal material | LY12 | Expanded maximum envelope size (Diameter × Height) | Φ 3400 × 3400 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, S.; Zhou, P.; Wang, X.; Yu, Y.; Li, H. Design and Experiment of Dry-Ice Cleaning Mechanical Arm for Insulators in Substation. Appl. Sci. 2020, 10, 2461. https://doi.org/10.3390/app10072461

Tang S, Zhou P, Wang X, Yu Y, Li H. Design and Experiment of Dry-Ice Cleaning Mechanical Arm for Insulators in Substation. Applied Sciences. 2020; 10(7):2461. https://doi.org/10.3390/app10072461

Chicago/Turabian StyleTang, Shufeng, Pengfei Zhou, Xu Wang, Yue Yu, and Hualei Li. 2020. "Design and Experiment of Dry-Ice Cleaning Mechanical Arm for Insulators in Substation" Applied Sciences 10, no. 7: 2461. https://doi.org/10.3390/app10072461

APA StyleTang, S., Zhou, P., Wang, X., Yu, Y., & Li, H. (2020). Design and Experiment of Dry-Ice Cleaning Mechanical Arm for Insulators in Substation. Applied Sciences, 10(7), 2461. https://doi.org/10.3390/app10072461