Optimization Design of Actuator Parameters with Stepless Capacity Control System Considering the Effect of Backflow Clearance

Abstract

1. Introduction

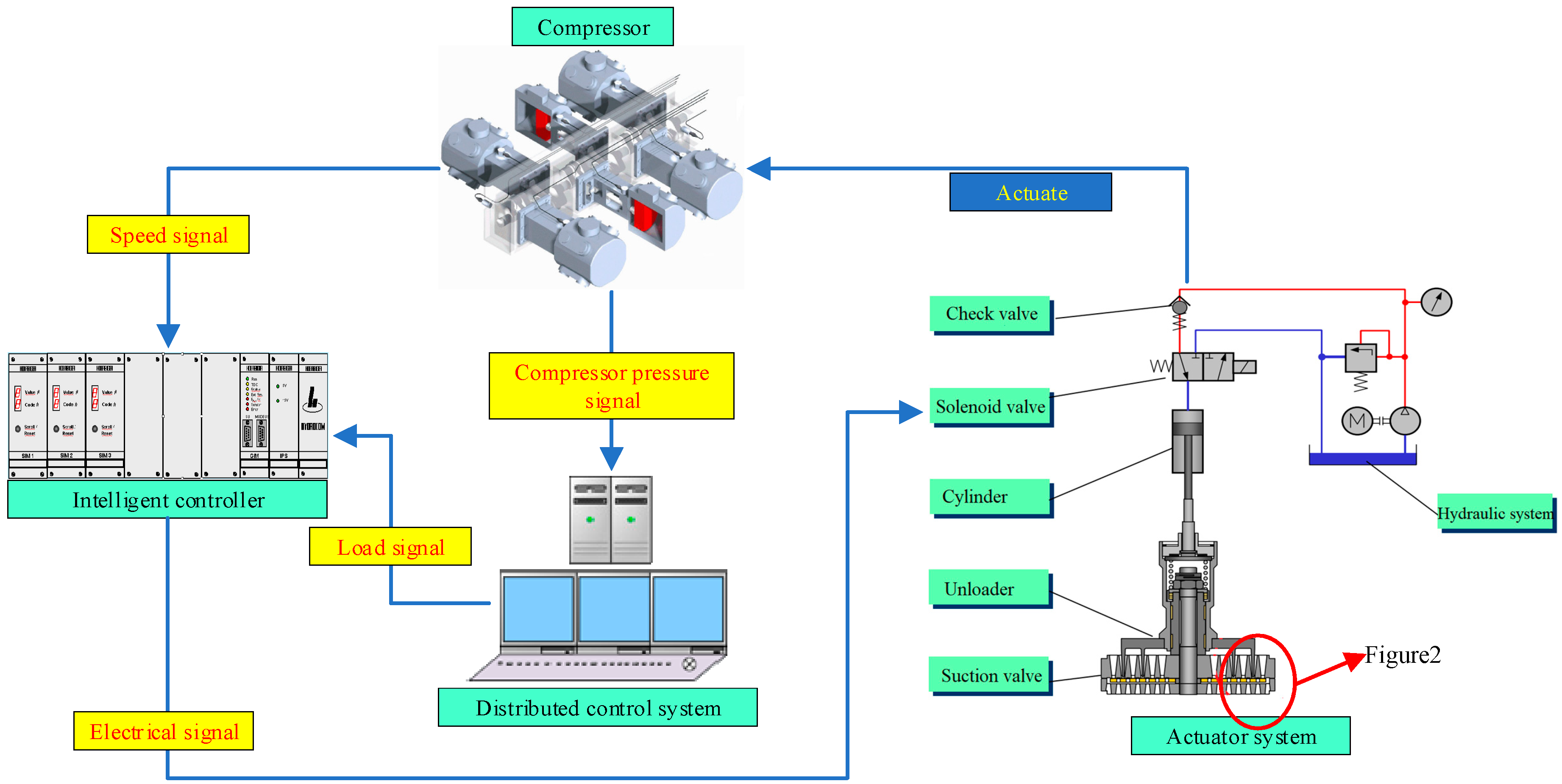

2. Mathematical Model of Stepless Capacity Control System

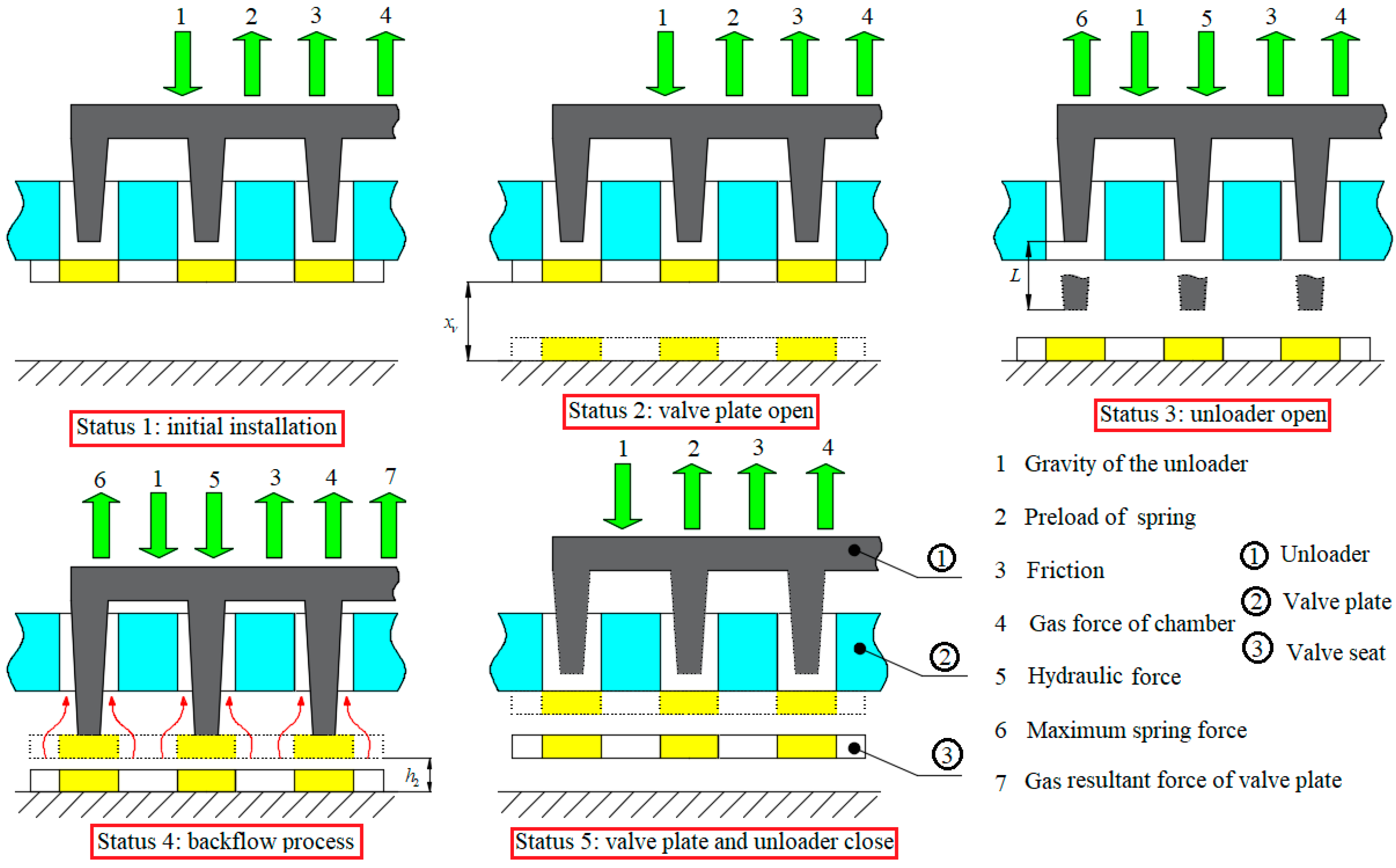

2.1. Mathematical Model of Actuator

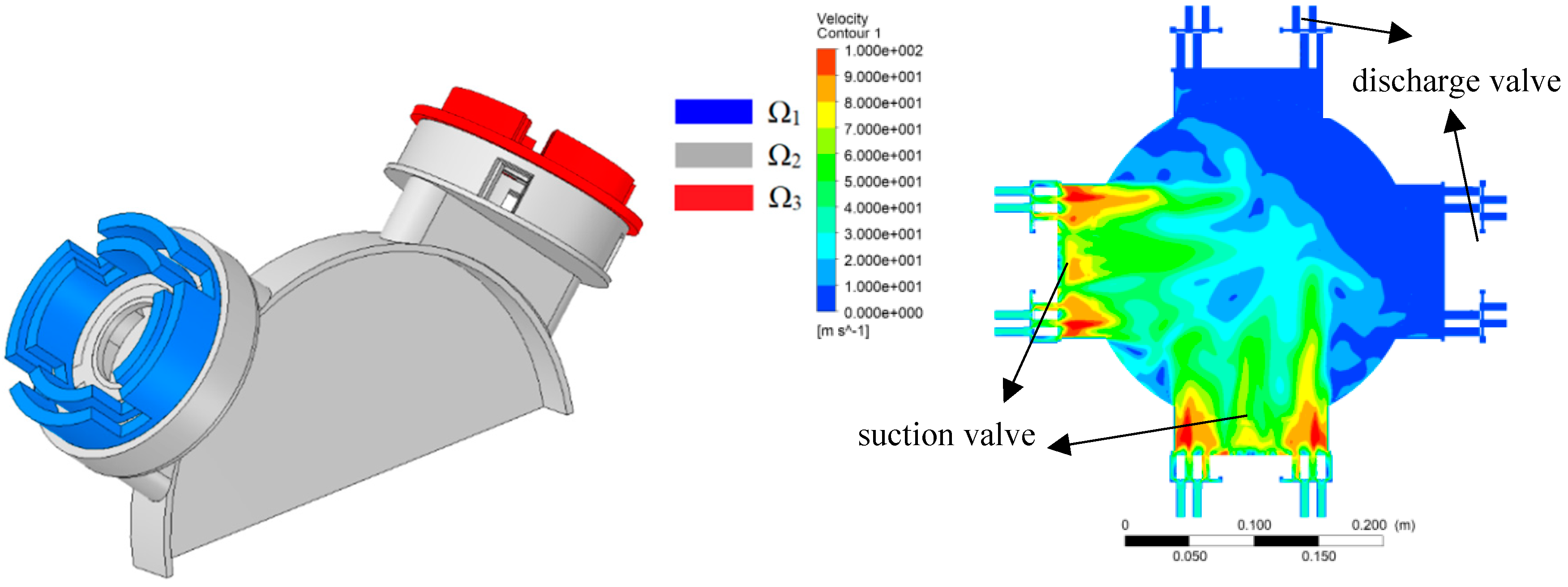

2.2. Computational Fluid Dynamics (CFD) Model of Reciprocating Compressor

2.2.1. Flow Control Equations

2.2.2. Boundary Conditions and Initial Conditions

2.2.3. CFD Model of Compressor Cylinder and Valve

2.2.4. Dynamic Mesh Control Equation of Valve Plate

3. Simulation Results and Impact Analysis

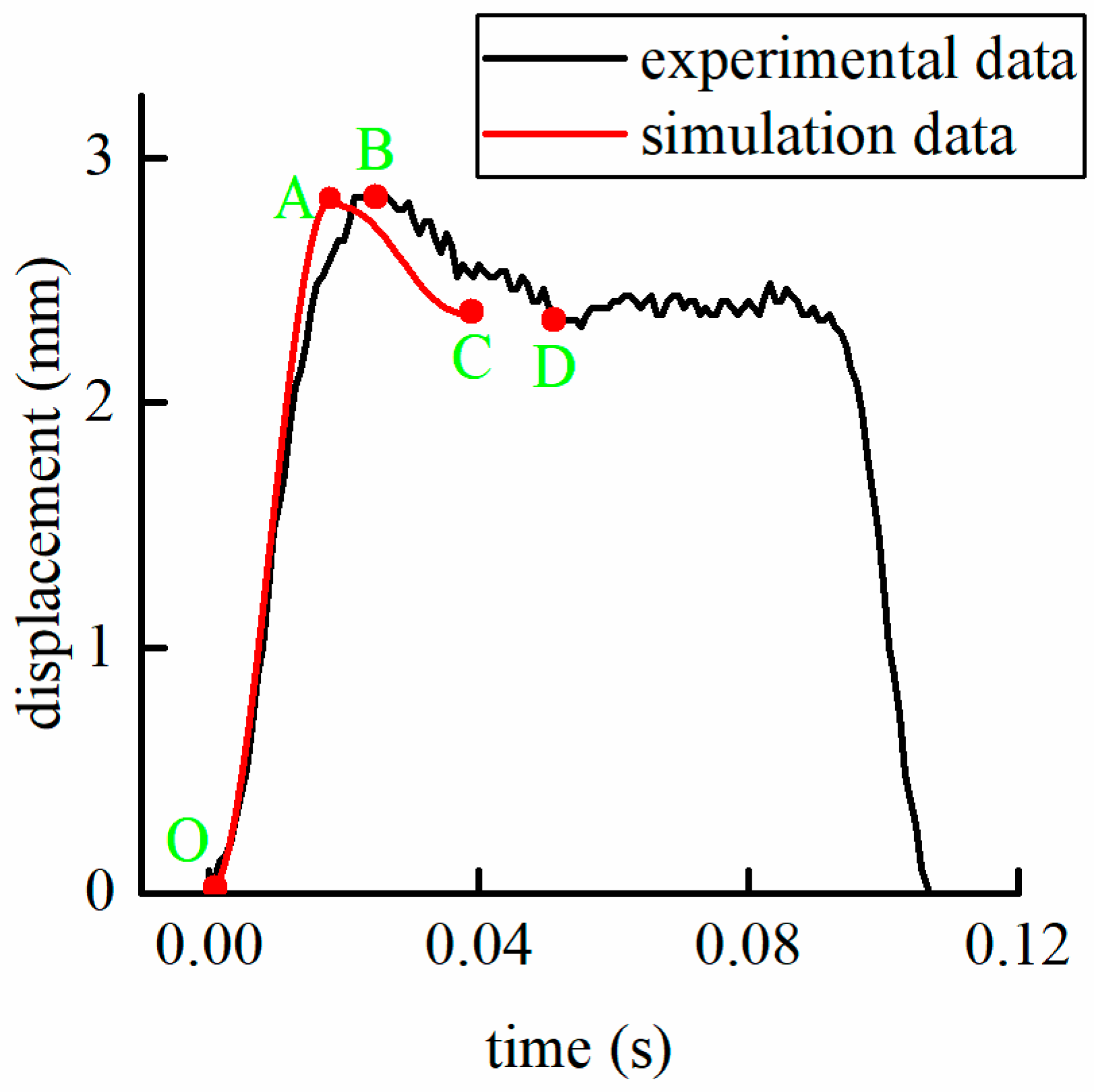

3.1. Analysis of Actuator

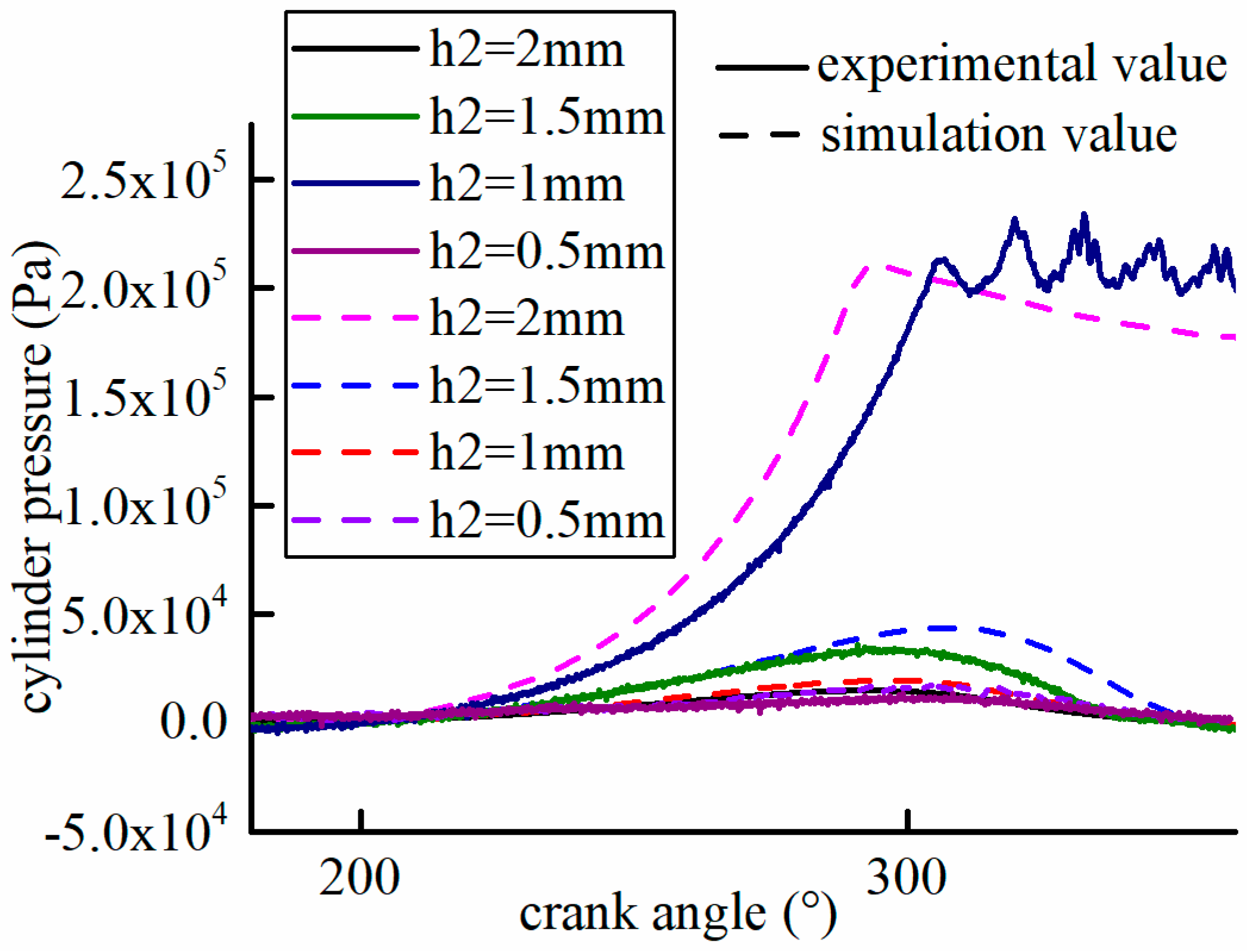

3.2. Relationship between Backflow Clearance and Cylinder Pressure

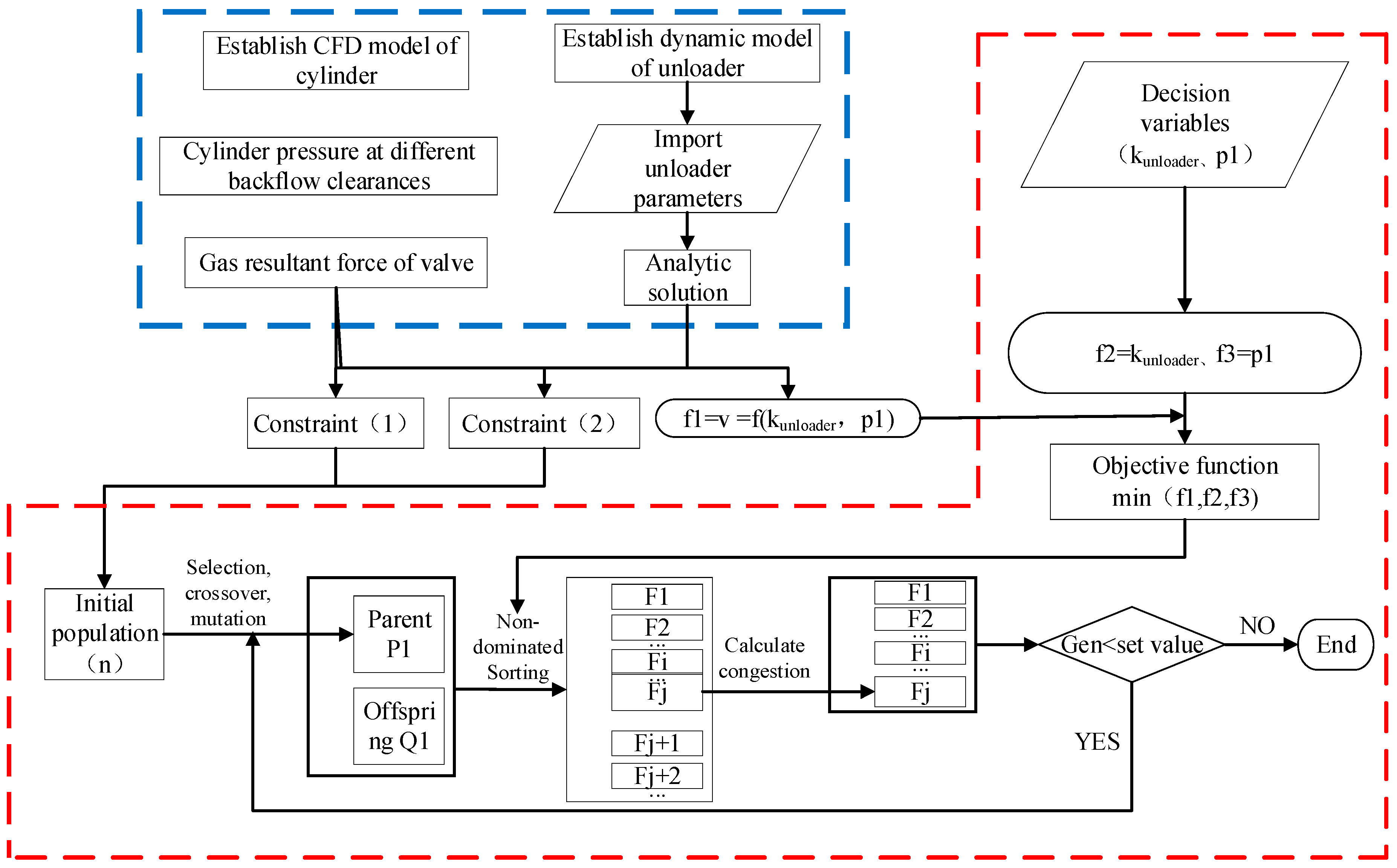

4. Multi-Objective Optimization Model of Actuator

4.1. Objective Function

(1) Impact velocity

(2) Hydraulic pressure and stiffness

(3) Backflow clearance

4.2. Constraint Condition

4.3. Optimization Algorithm Diagram

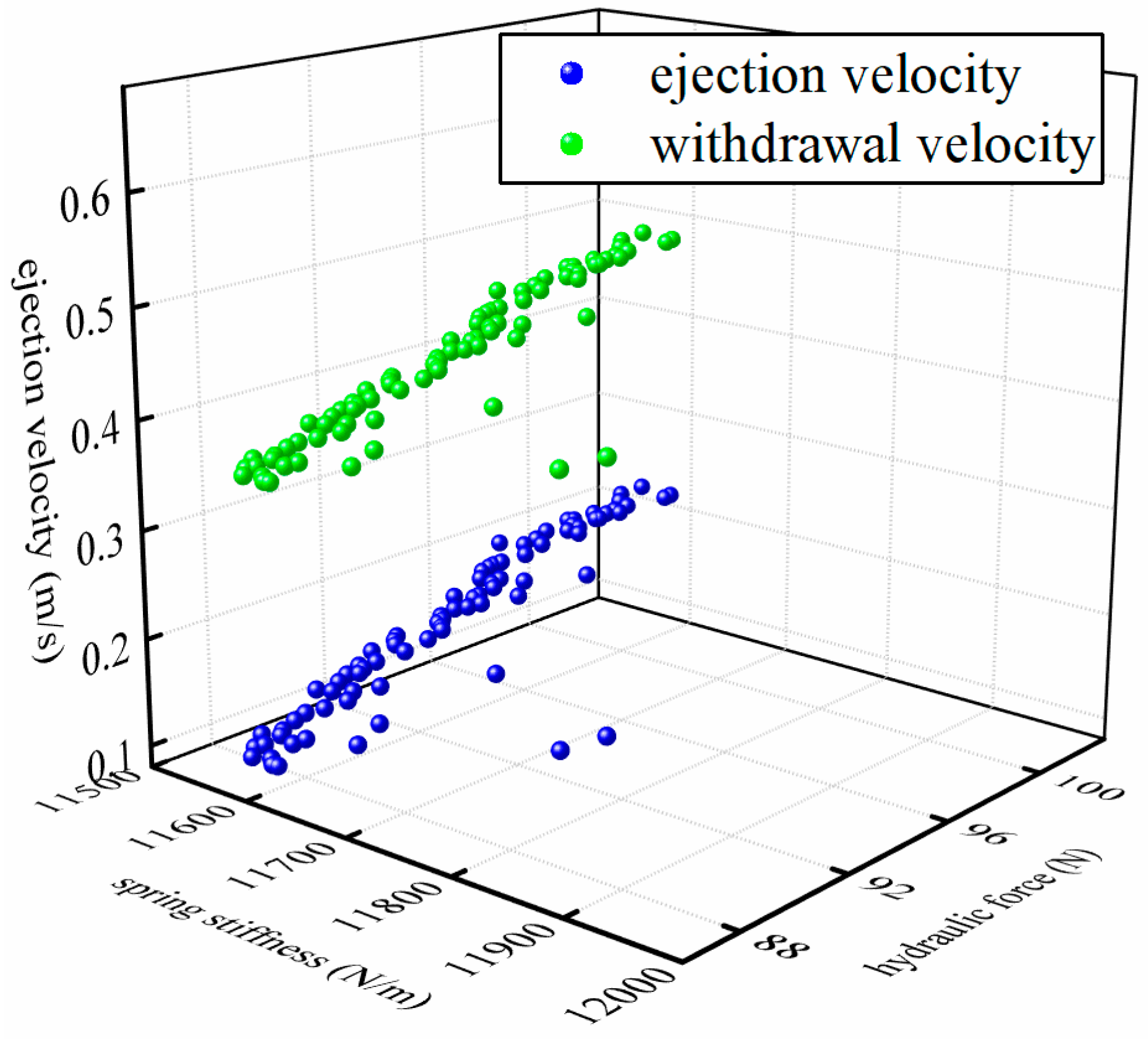

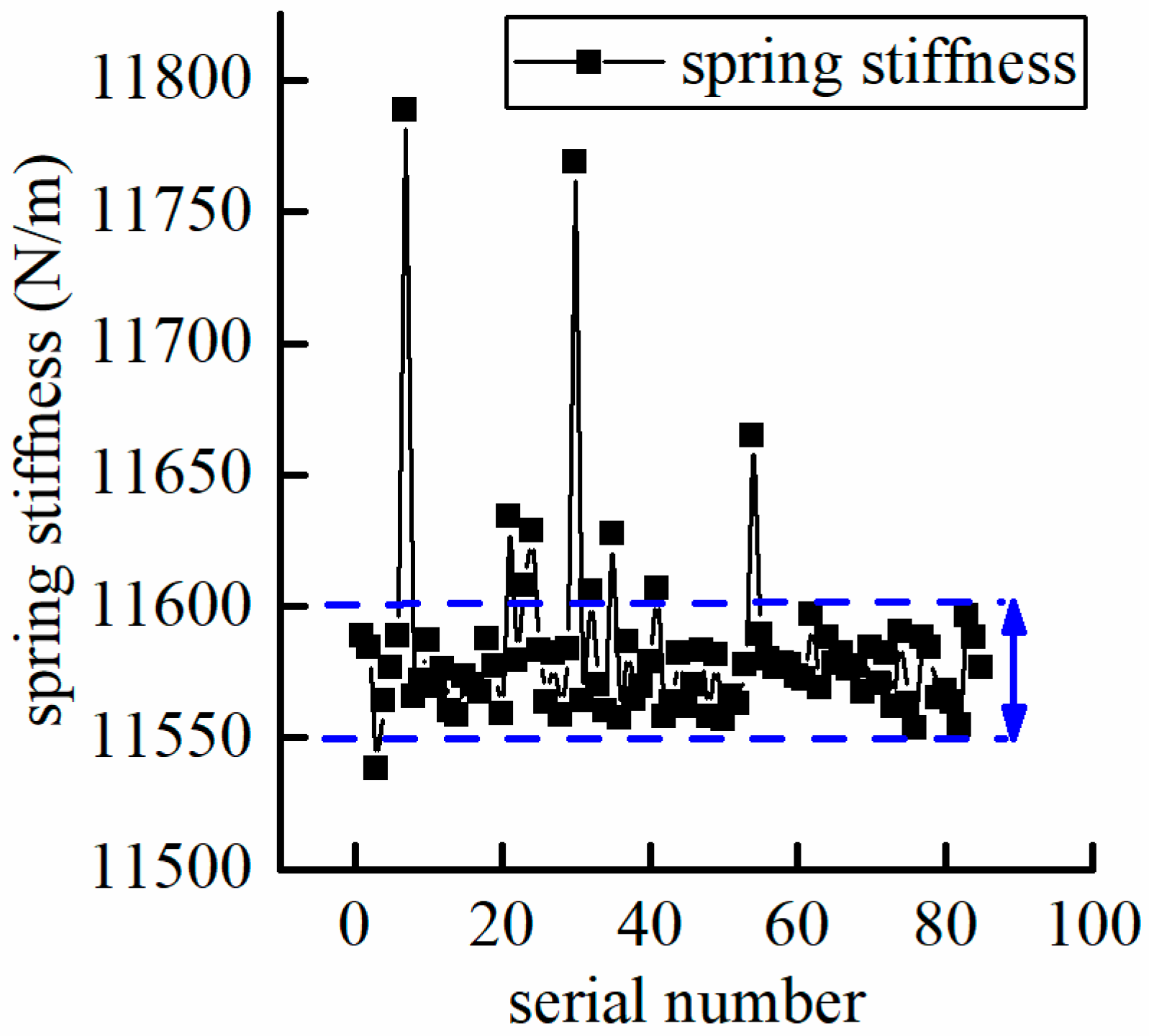

5. Optimization Results and Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bloch, H.P.; Hoefner, J.J. Reciprocating Compressors Operation & Maintenance; Gulf Publishing Company: Houston, TX, USA, 1996. [Google Scholar]

- Perreira, E.P.; Parise, J.A.R. Performance analysis of capacity control devices for heat pump reciprocating compressors. Heat Recovery Syst. CHP 1993, 13, 451–461. [Google Scholar] [CrossRef][Green Version]

- Holdack-Janssen, H.; Kruse, H. Continuous and discontinuous capacity control for high speed refrigeration compressors. Proc. Purdue Comp. Tech. Conf. 1984, 67–75. [Google Scholar]

- Verma, J.C. Optimum utilization of capacity control devices in reciprocating compressors. Proc. Purdue Comp. Tech. Conf. 1986, 509–520. [Google Scholar]

- Steinruck, P. Method and Apparatus for Controlling Compressor Valves in a Piston Compressor. U.S. Patent 08/851934, 1999. [Google Scholar]

- Steinruck, P. Device and Method for Influencing the Periodic Stroke Movement of the Closing Element of a Valve. U.S. Patent 08/508 453, 1998. [Google Scholar]

- Bin, T.; Yuanyang, Z.; Liansheng, L.; Guangbin, L.; Le, W.; Qichao, Y. Thermal performance analysis of reciprocating compressor with stepless capacity control system. Appl. Therm. Eng. 2013, 54, 380–386. [Google Scholar] [CrossRef]

- Li, D.; Wu, H.; Gao, J. Experimental study on stepless capacity regulation for reciprocating compressor based on novel rotary control valve. Int. J. Refrig. 2013, 36, 1701–1715. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Z.; Zhang, J.; Zhou, C.; Liu, W. Performance analysis and optimization of reciprocating compressor with stepless capacity control system under variable load conditions. Int. J. Refrig. Rev. Int. Froid 2018, 94, 174–185. [Google Scholar] [CrossRef]

- Liu, G.; Zhao, Y.; Tang, B.; Li, L. Dynamic performance of suction valve in stepless capacity regulation system for large-scale reciprocating compressor. Appl. Therm. Eng. 2016, 96, 167–177. [Google Scholar] [CrossRef]

- Cao, J.L.; Hong, W.R.; Li, Y.; He, Z.K. Study on flow field in capacity regulating actuator for reciprocating compressor. IOP Conf. Ser. Mater. Sci. Eng. 2013, 52. [Google Scholar] [CrossRef]

- Hong, W.; Jin, J.; Wu, R.; Zhang, B. Theoretical analysis and realization of stepless capacity regulation for reciprocating compressors. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2009, 223, 205–213. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Jiang, Z.; Zhou, C.; Liu, W. Investigation on thermodynamic state and valve dynamics of reciprocating compressors with capacity regulation system and parameter optimization. Eng. Appl. Comput. Fluid Mech. 2019, 13, 923–937. [Google Scholar] [CrossRef]

- Jin, J.; Hong, W. Valve dynamic and thermal cycle model in stepless capacity regulation for reciprocating compressor. Chin. J. Mech. Eng. 2012, 25, 1151–1160. [Google Scholar] [CrossRef]

- Wang, L.; Liu, G.B.; Zhao, Y.Y.; Li, L.L. Performance comparison of capacity control methods for reciprocating compressors. In Proceedings of the 9th International Conference on Compressors and their Systems, London, UK, 7–9 September 2015; Volume 90. [Google Scholar]

- Xu, Q.; Hong, W. Dynamic performance of reciprocating compressor with capacity regulation system. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2019, 233, 526–535. [Google Scholar] [CrossRef]

- Yuanyang, Z.; Bin, T.; Guangbin, L.; Liansheng, L.; Huaide, Y.; Wenhui, M.; Haiping, X. Experimental research on dynamic response of capacity control system in reciprocating compressor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 358–365. [Google Scholar] [CrossRef]

- Tang, B.; Zhao, Y.; Li, L.; Wang, L.; Liu, G.; Yang, Q.; Meng, W. Dynamic characteristics of suction valves for reciprocating compressor with stepless capacity control system. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 104–114. [Google Scholar] [CrossRef]

- He, Z.; Jian, Z.; Wang, T.; Li, D.; Peng, X. Investigation on the variation of pressure in the cylinder of the refrigerator compressor based on fsi model. IOP Conf. Ser. Mater. Sci. Eng. 2017, 232, 012005. [Google Scholar] [CrossRef]

- Lacerda, J.F.; Takemori, C.K. CFD Approach to Evaluate Heat Transfer in Reciprocating Compressors. In Proceedings of the International Compressor Engineering Conference, Purdue, 11–14 July 2016; Available online: https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=3486&context=icec (accessed on 11 April 2020).

- Bing, W.U.; Jiang, Z.N. The force analysis of reciprocating compressor valve using cfd. Compress. Technol. 2011, 4, 24–26. [Google Scholar]

- Mi, X.; Li, Q.; Wang, F.; Zhao, X. Flow field simulation of reciprocating compressor based on dynamic mesh technology. In Proceedings of the 2017 IEEE 21st International Conference on Computer Supported Cooperative Work in Design (CSCWD), Wellington, New Zealand, 26–28 April 2017. [Google Scholar]

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Rotational speed | n | r/min | 300 |

| Radius of the crankshaft | r | m | 0.09 |

| connecting rod length | l | m | 0.45 |

| Radius of the cylinder | rc | m | 100 |

| suction pressure | pi | kPa | 100 |

| Exhaust Pressure | pd | kPa | 200 |

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Mass | kg | 1.5 | |

| Friction | N | 30 | |

| Maximum compression of spring | m | 0.0075 | |

| Stroke | m | 0.003 | |

| Spring stiffness | N/m | 18,425 | |

| Maximum action time | s | 0.012 |

| Rebound Coefficient | p1 = 4 MPa | p1 = 3 MPa | ||

|---|---|---|---|---|

| Experiment Value | Simulation Value | Experiment Value | Simulation Value | |

| −0.2 | 0.05 | 0.282 | 0.05 | 0.194 |

| −0.1 | 0.085 | 0.052 | ||

| −0.05 | 0.044 | 0.025 | ||

| Gap Value (mm) | 0.25 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 |

|---|---|---|---|---|---|---|---|

| Maximum pressure in backflow (Pa) | 1.37 × 104 | 1.49 × 104 | 1.63 × 104 | 1.96 × 104 | 2.61 × 104 | 4.37 × 104 | 1.07 × 105 |

| Pressure increase amplitude | 13.67% | 14.88% | 16.26% | 19.58% | 26.10% | 43.72% | 107.19% |

| Parameter | Value |

|---|---|

| Population size | 100 |

| Generation | 1000 |

| Mutation fraction | 0.7 |

| Crossover fraction | 0.4 |

| Variation ratio | 0.02 |

| Crossover ratio | 0.02 |

| Parameter | Design 1 | Design 2 | Decrease Percentage | Design 3 | Decrease Percentage | Design 4 | Decrease Percentage |

|---|---|---|---|---|---|---|---|

| Spring stiffness (N/m) | 18,425 | 11,588.82 | 37.10% | 11,575.84 | 37.17% | 11,606.55 | 37.01% |

| Hydraulic force (N) | 190.9 | 87.44 | 54.20% | 94.25 | 50.63% | 101.82 | 46.66% |

| Ejection impact velocity (m/s) | 0.836 | 0.093 | 88.83% | 0.17 | 79.48% | 0.23 | 72.83% |

| Withdrawal impact velocity (m/s) | 0.752 | 0.354 | 52.91% | 0.42 | 44.22% | 0.48 | 35.55% |

| Backflow clearance (mm) | 0 | 0.00125 | — — | 0.00065 | — — | 2.00 × 10−5 | — — |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhou, C.; Jiang, Z.; Wang, Y.; Sun, X. Optimization Design of Actuator Parameters with Stepless Capacity Control System Considering the Effect of Backflow Clearance. Appl. Sci. 2020, 10, 2703. https://doi.org/10.3390/app10082703

Zhang J, Zhou C, Jiang Z, Wang Y, Sun X. Optimization Design of Actuator Parameters with Stepless Capacity Control System Considering the Effect of Backflow Clearance. Applied Sciences. 2020; 10(8):2703. https://doi.org/10.3390/app10082703

Chicago/Turabian StyleZhang, Jinjie, Chao Zhou, Zhinong Jiang, Yao Wang, and Xu Sun. 2020. "Optimization Design of Actuator Parameters with Stepless Capacity Control System Considering the Effect of Backflow Clearance" Applied Sciences 10, no. 8: 2703. https://doi.org/10.3390/app10082703

APA StyleZhang, J., Zhou, C., Jiang, Z., Wang, Y., & Sun, X. (2020). Optimization Design of Actuator Parameters with Stepless Capacity Control System Considering the Effect of Backflow Clearance. Applied Sciences, 10(8), 2703. https://doi.org/10.3390/app10082703