Application of Impact-Echo Method to 3D SIBIE Procedure for Damage Detection in Concrete

Abstract

:1. Introduction

1.1. Non-Destructive Testing for Concrete

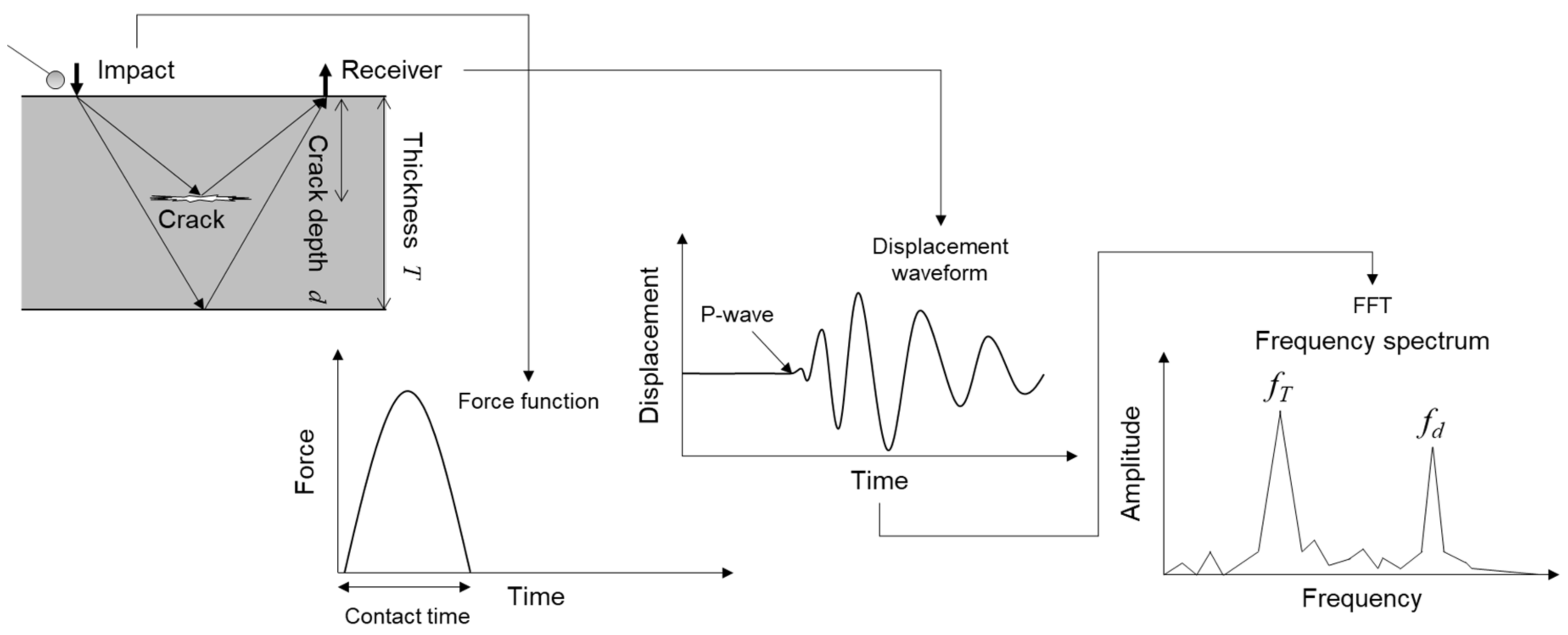

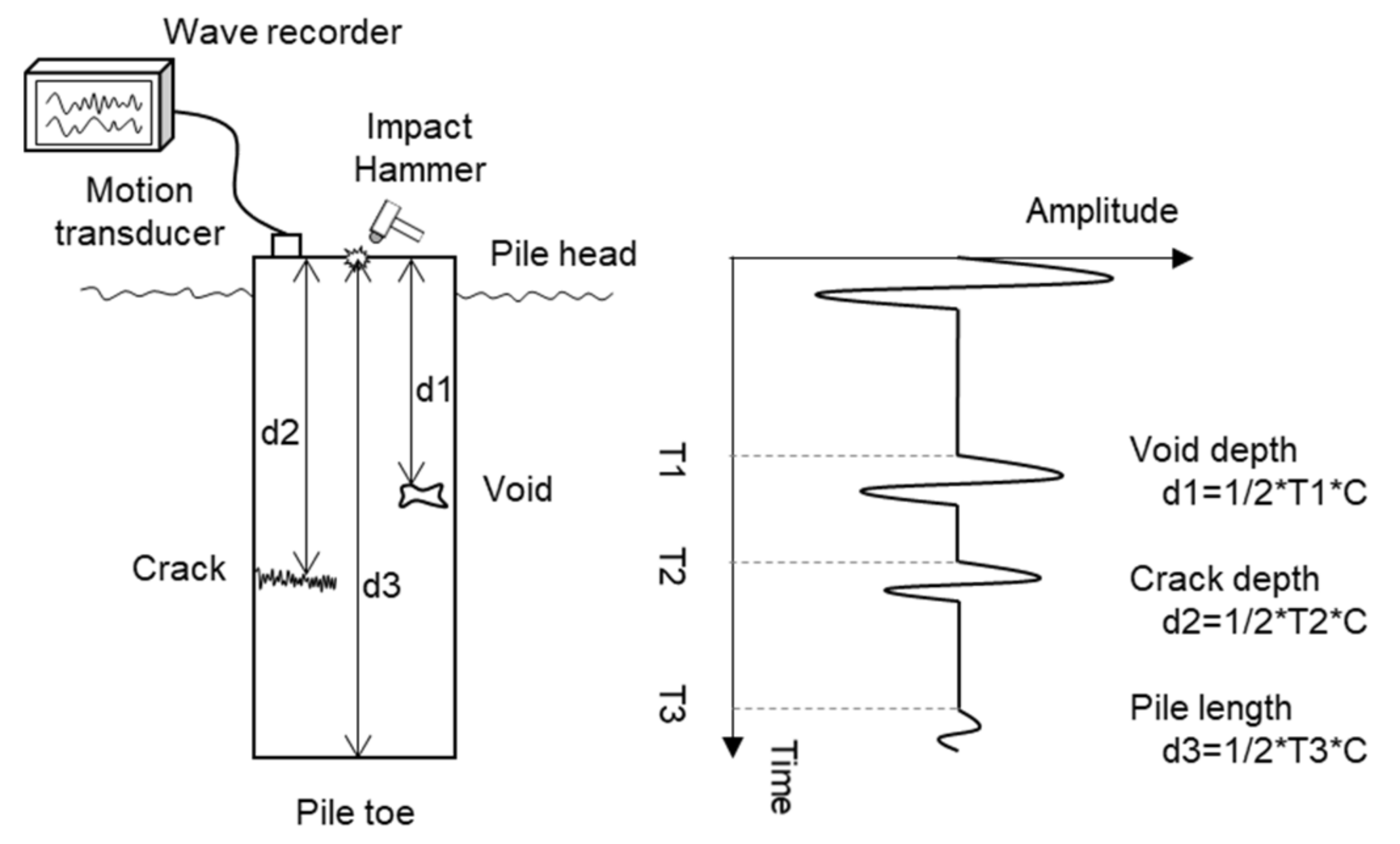

1.2. Impact-Echo Method

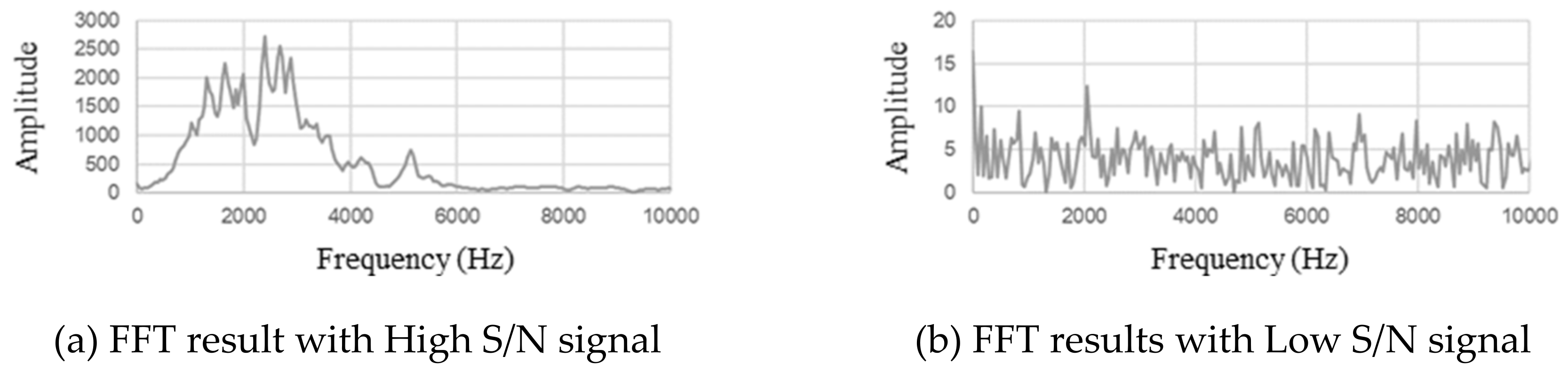

1.3. SIBIE Procedure

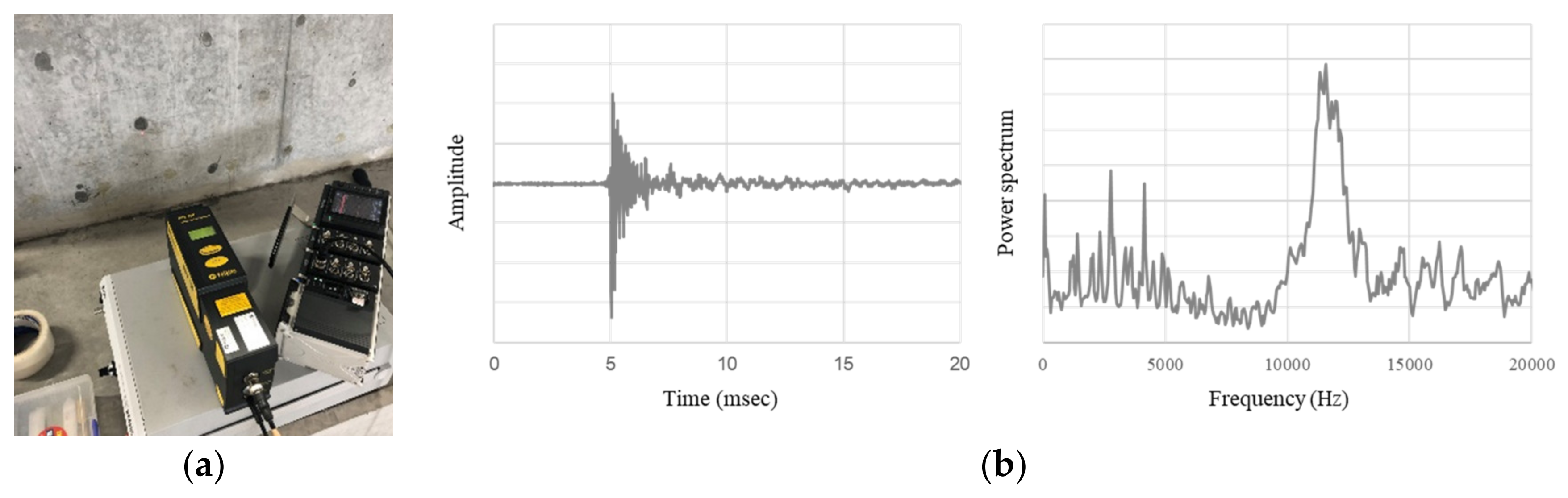

1.4. Remote Sensing for Elastic Wave Detection with Laser Doppler Vibrometer

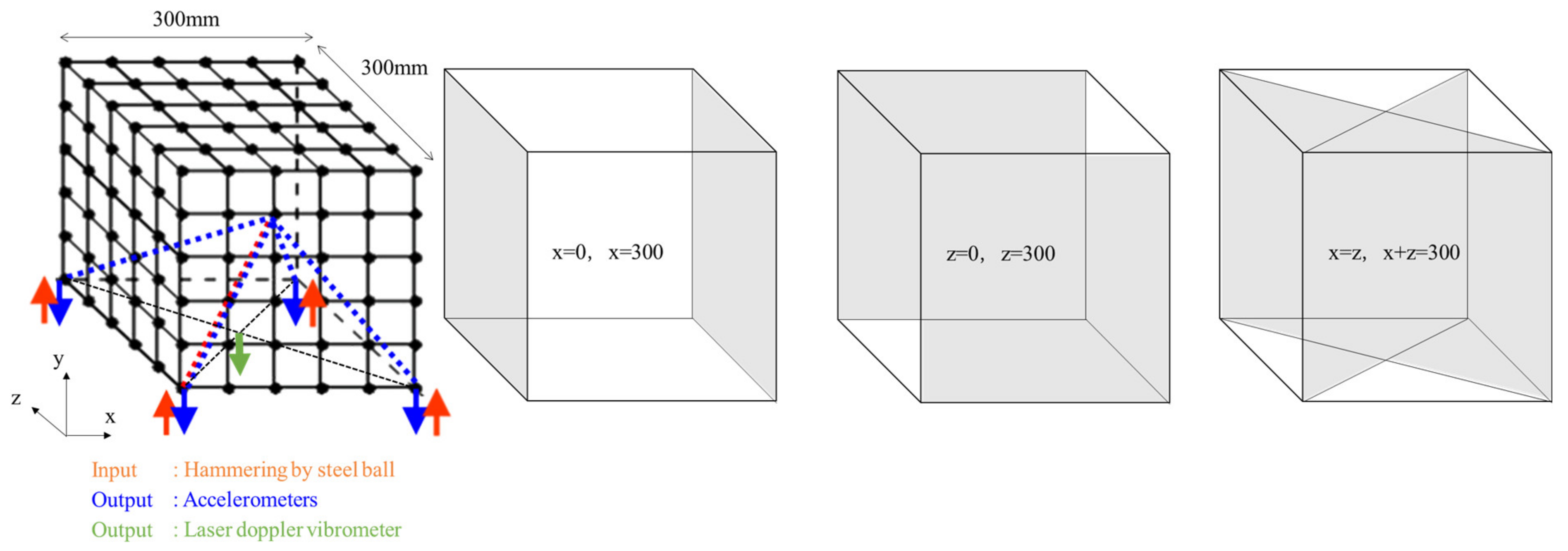

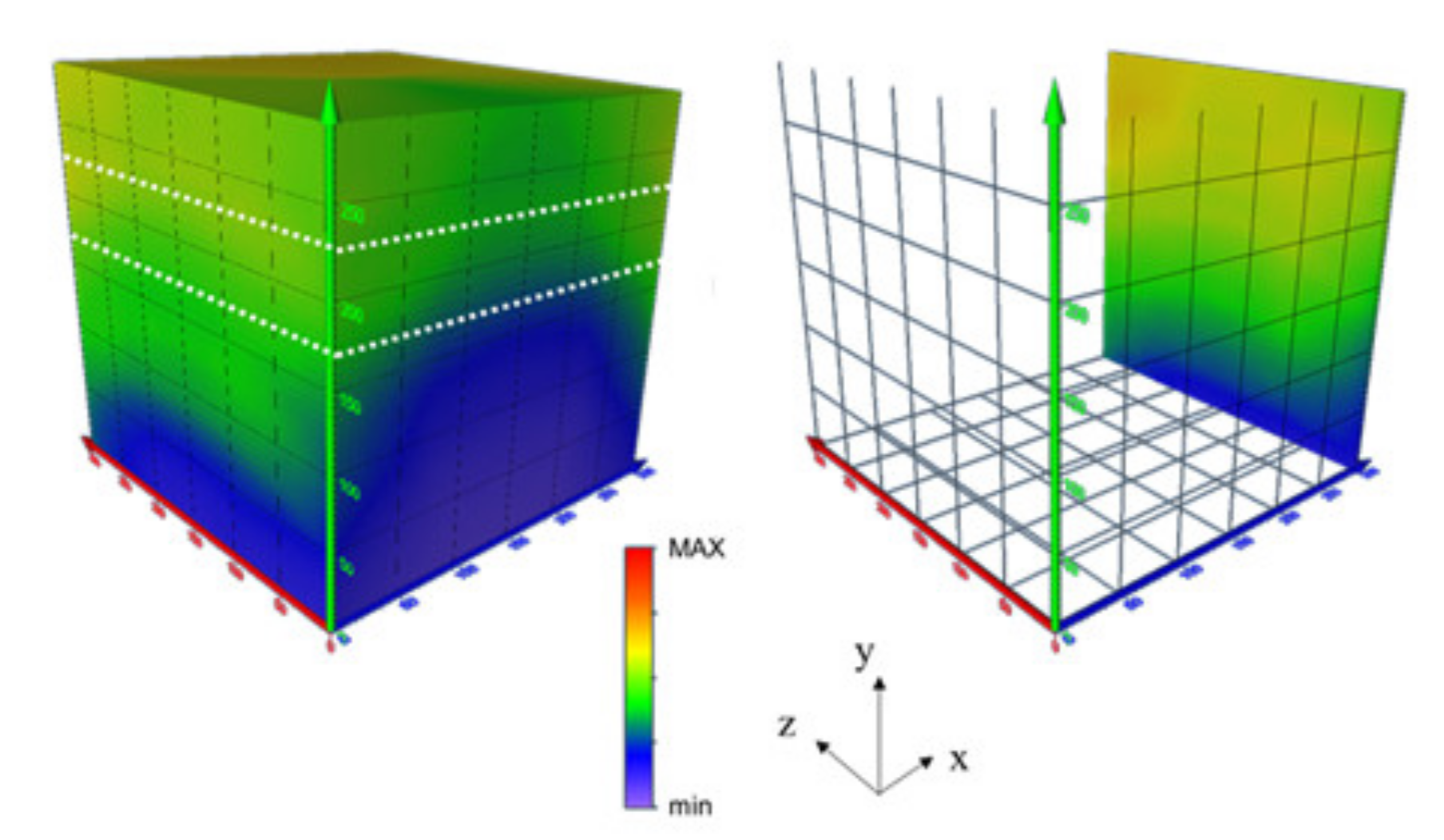

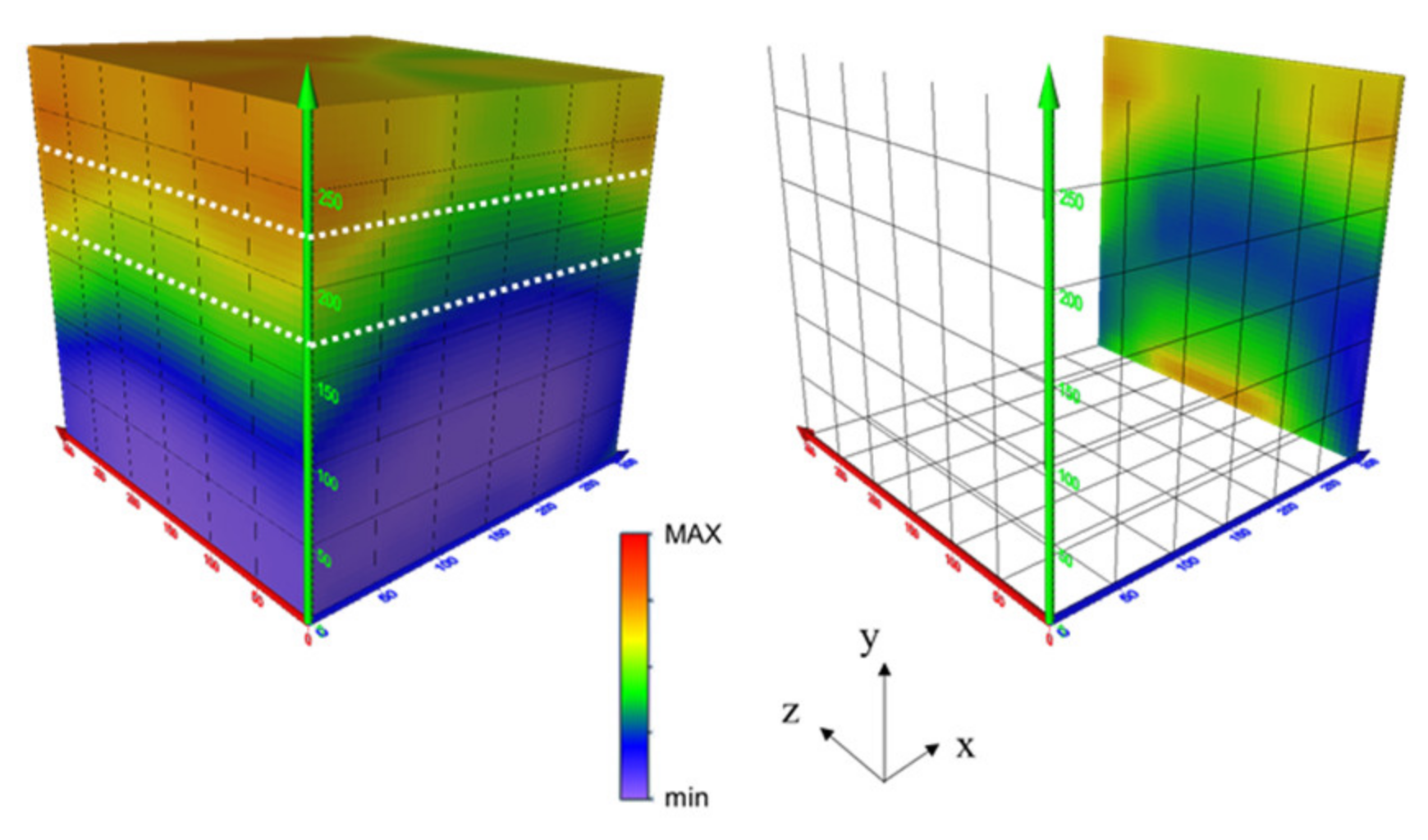

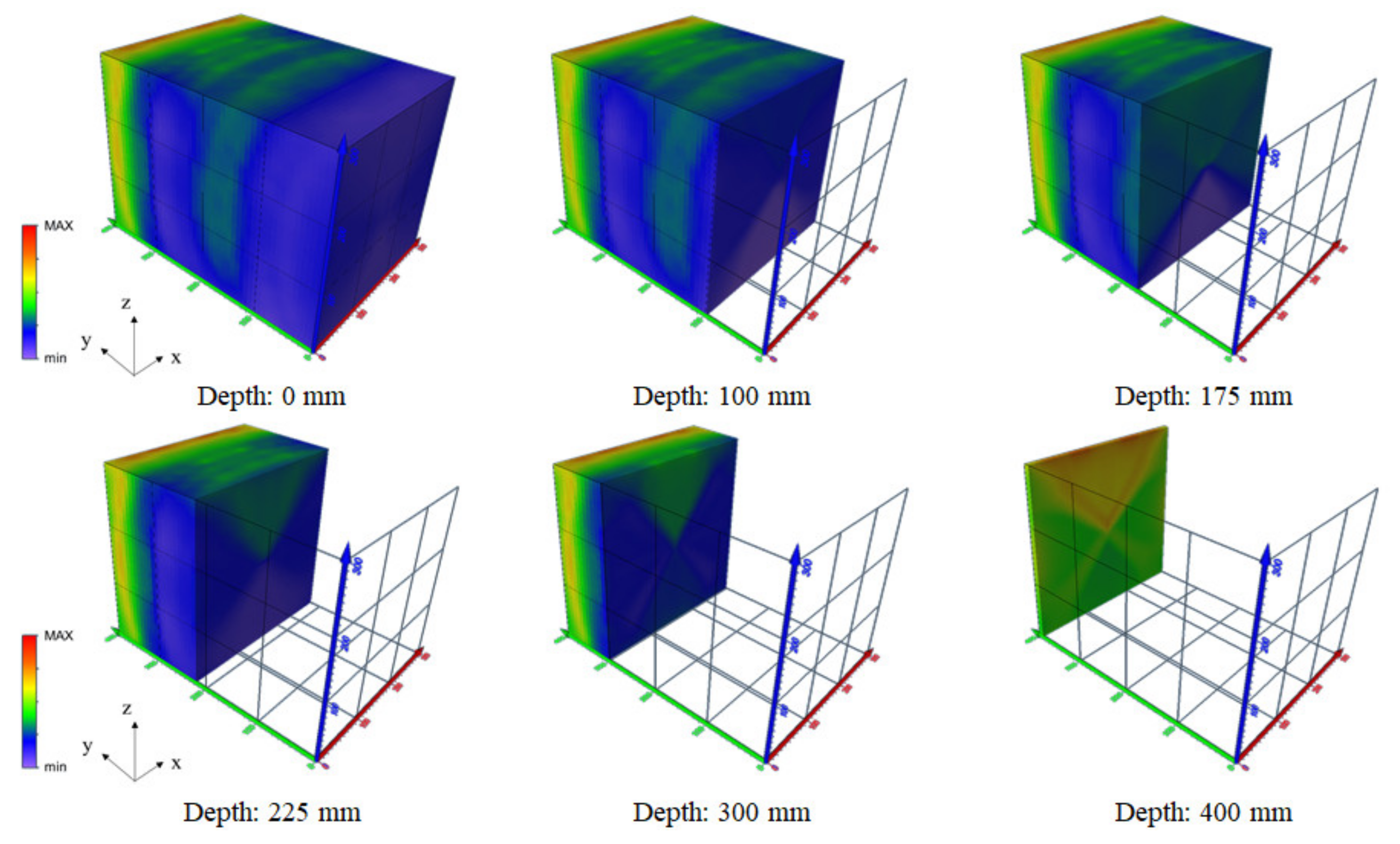

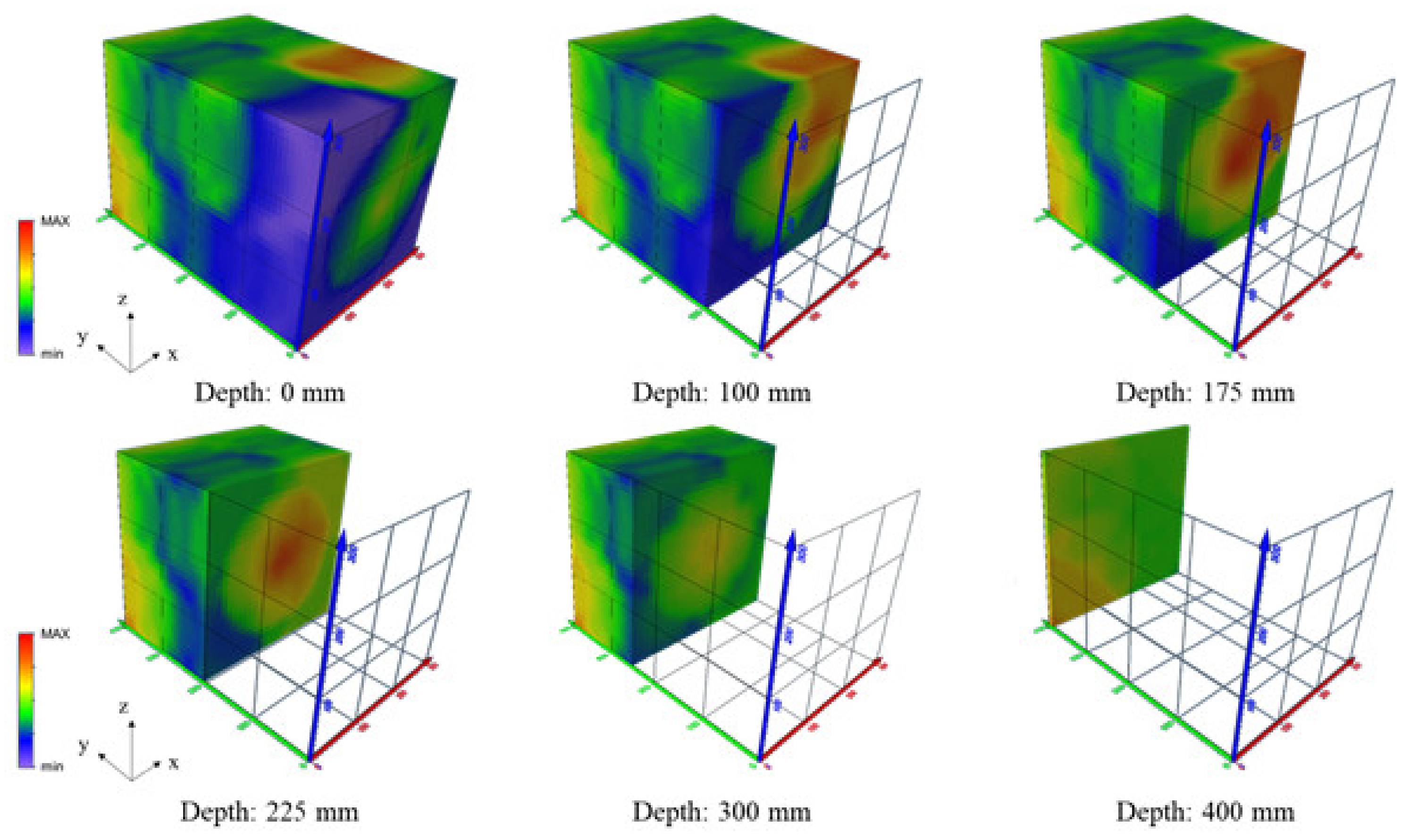

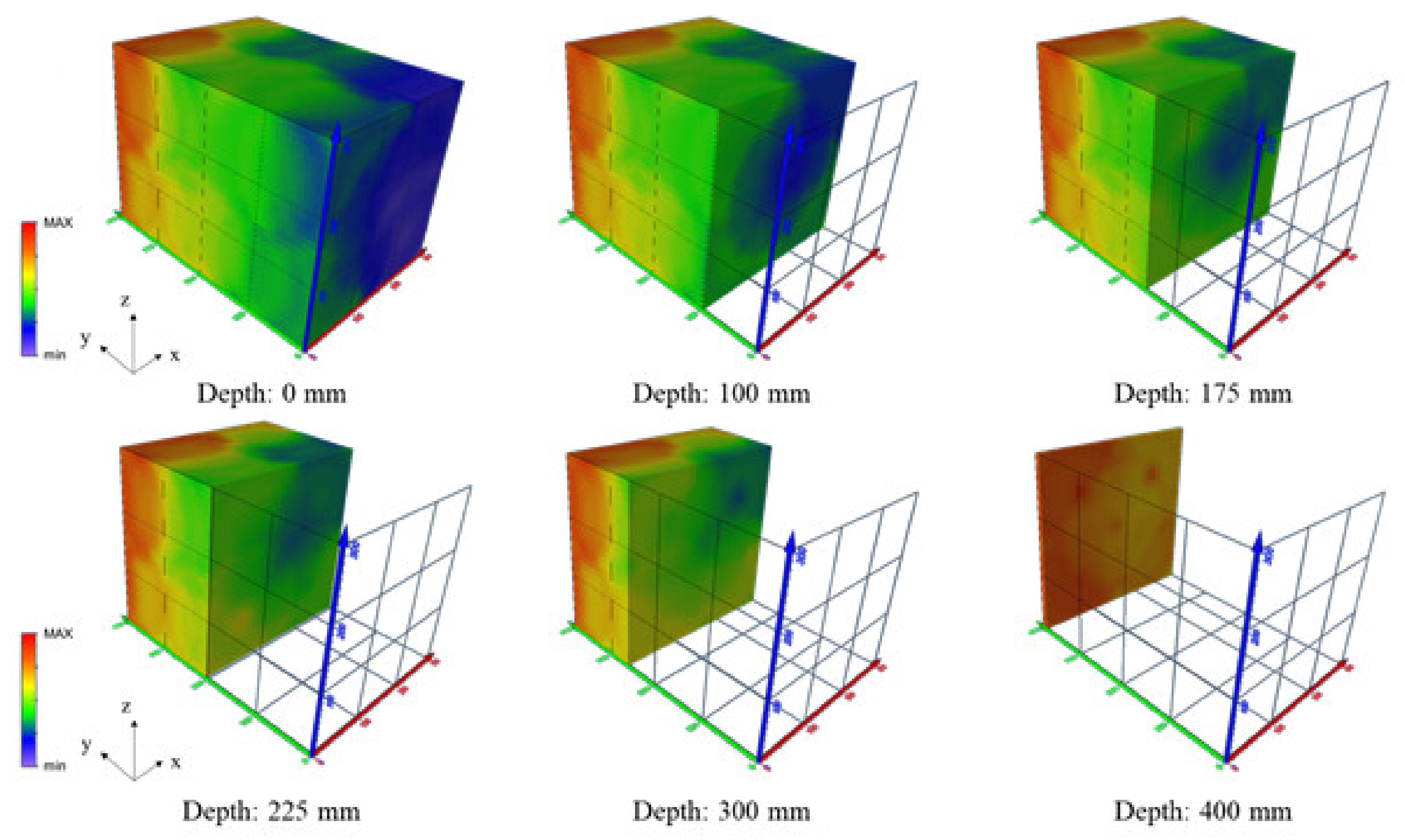

2. 3D SIBIE Procedure

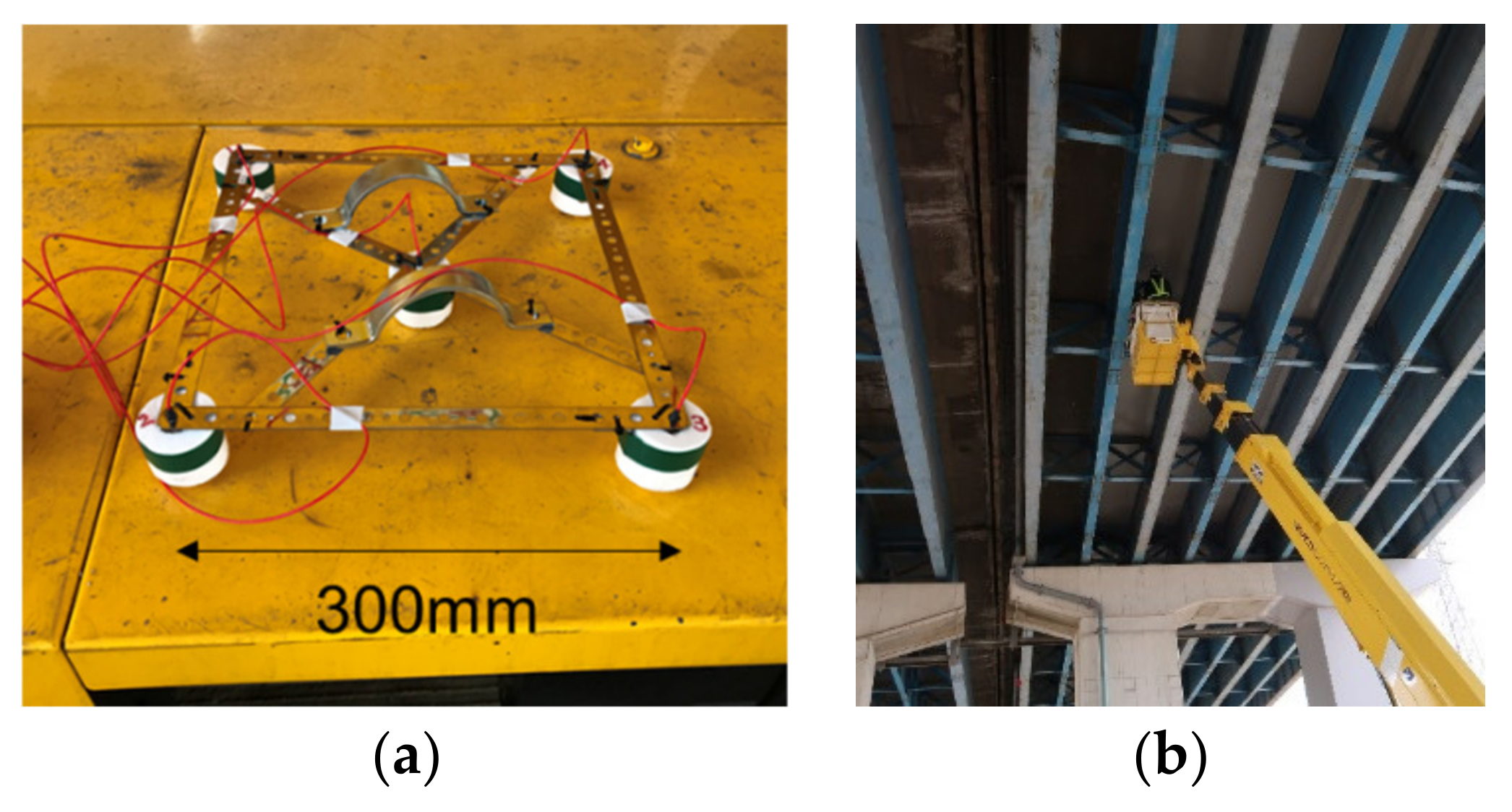

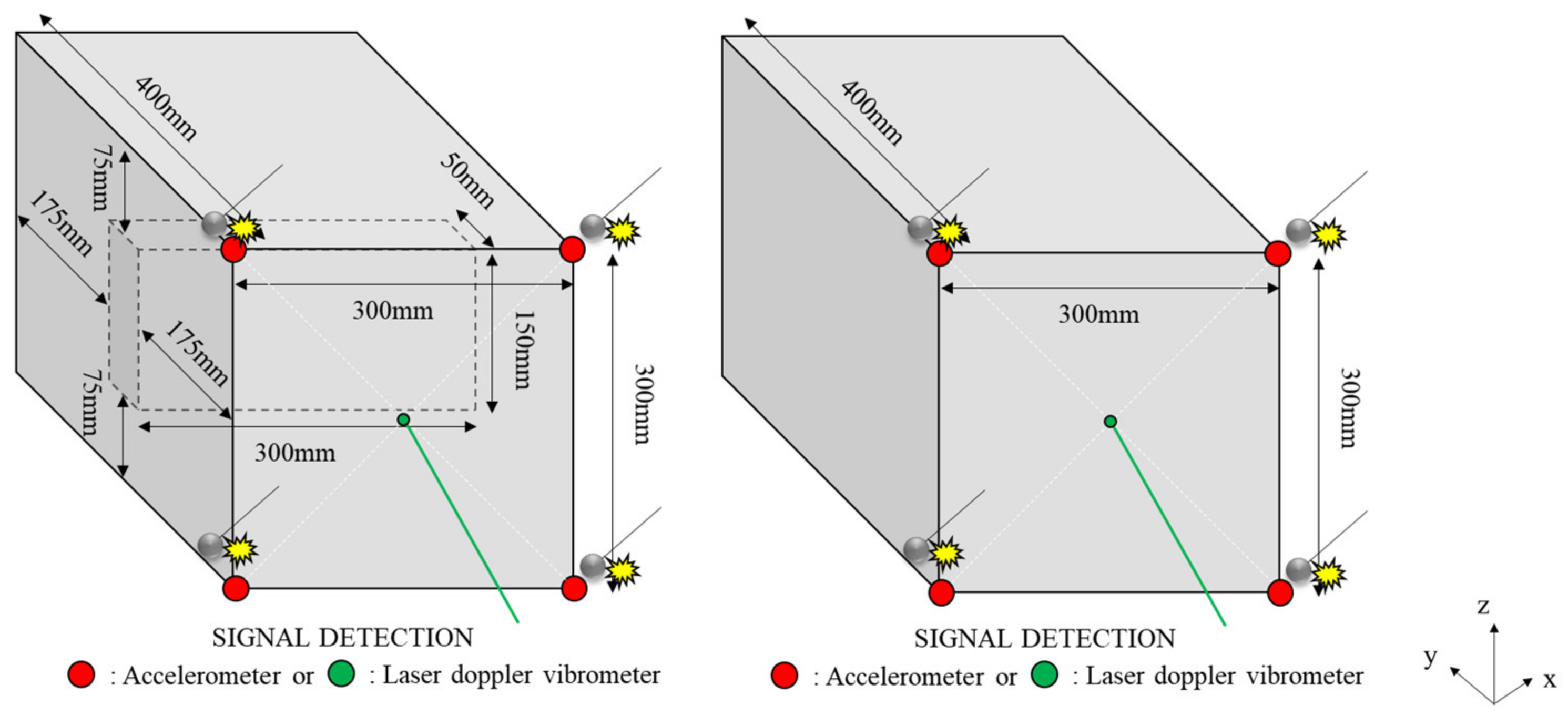

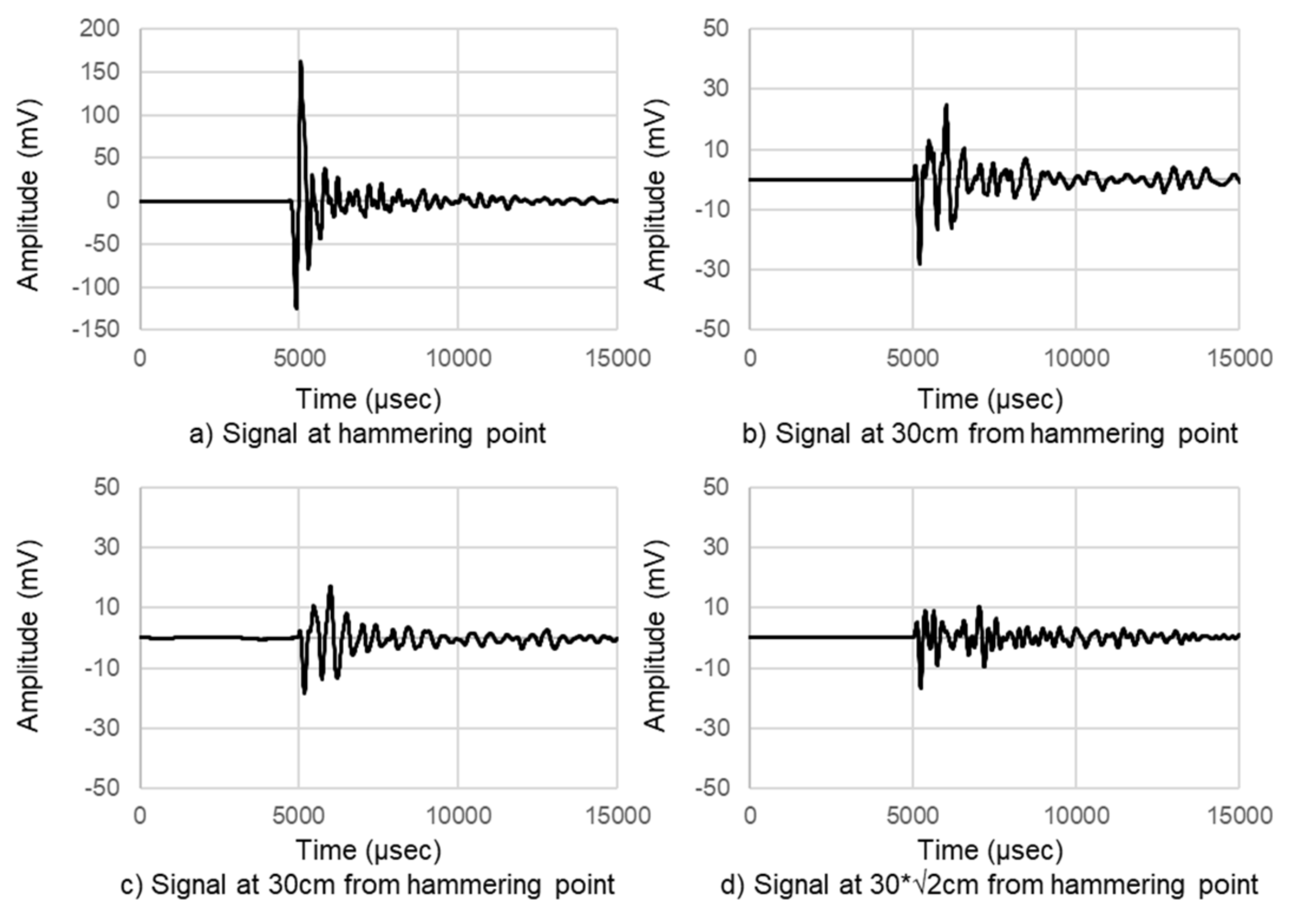

2.1. Sensor Array with Accelerometers and Laser Doppler Vibrometer

2.2. Computing Procedure for 3D SIBIE

- Place the sensor array on one surface of targeted concrete and hammer with steel sphere ball of 10 mm diameter near each sensor (n = 4) for 10 times respectively.

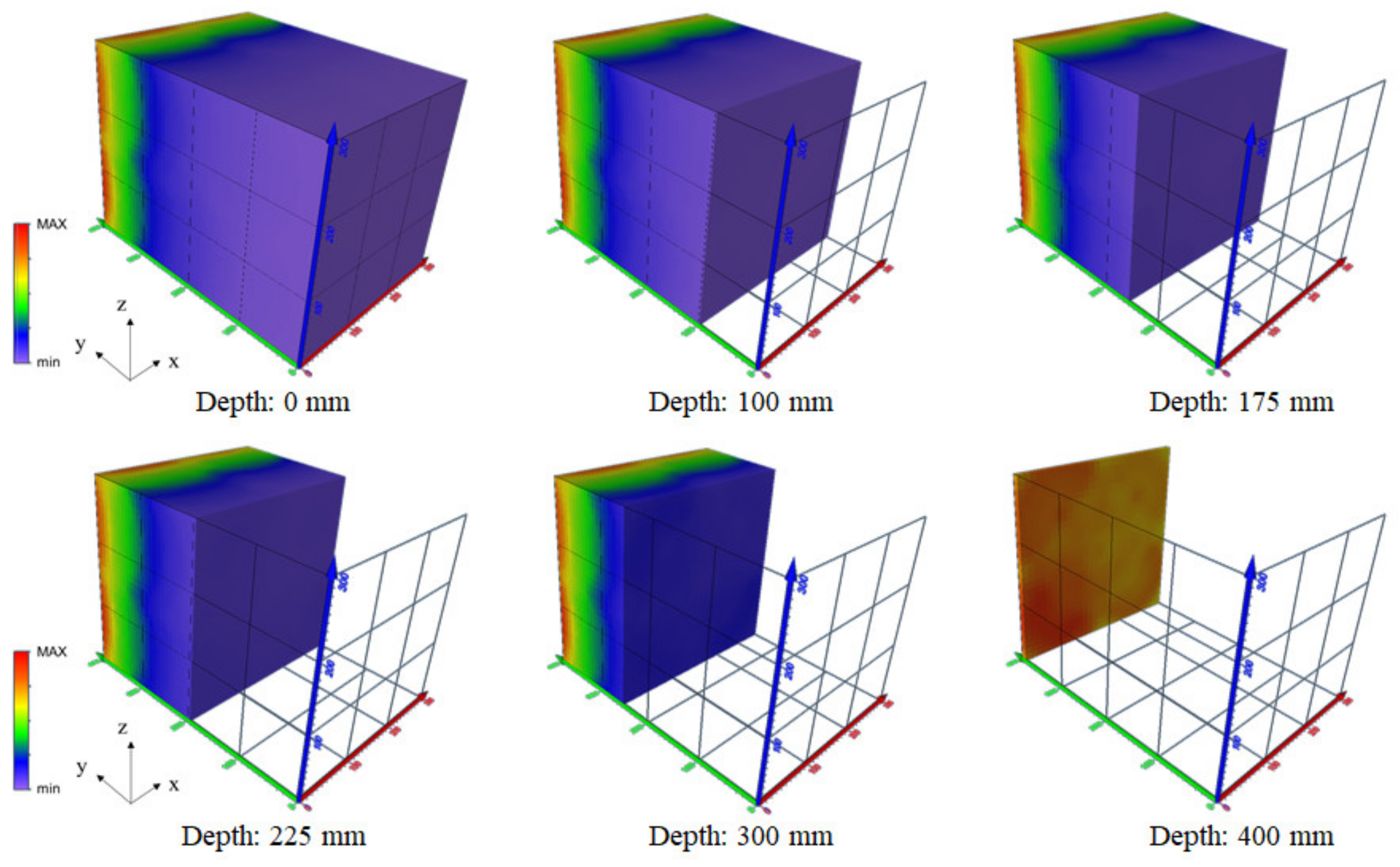

- Divide 300 (x-direction) × 300 mm (z-direction) in depth (y-direction) for volume of interest into 10 mm meshes.

- Employ the nodal points on the cross sections of x = 0, x = 300, z = 0, z = 300, x = z, x + z = 300 to mitigate computational load.

- Calculate R (travel length of elastic wave) from each nodal point to input and output points (R is the shortest linear path as explained).

- Search for fR frequencies due to reflection of propagating P-wave with velocity of Cp.

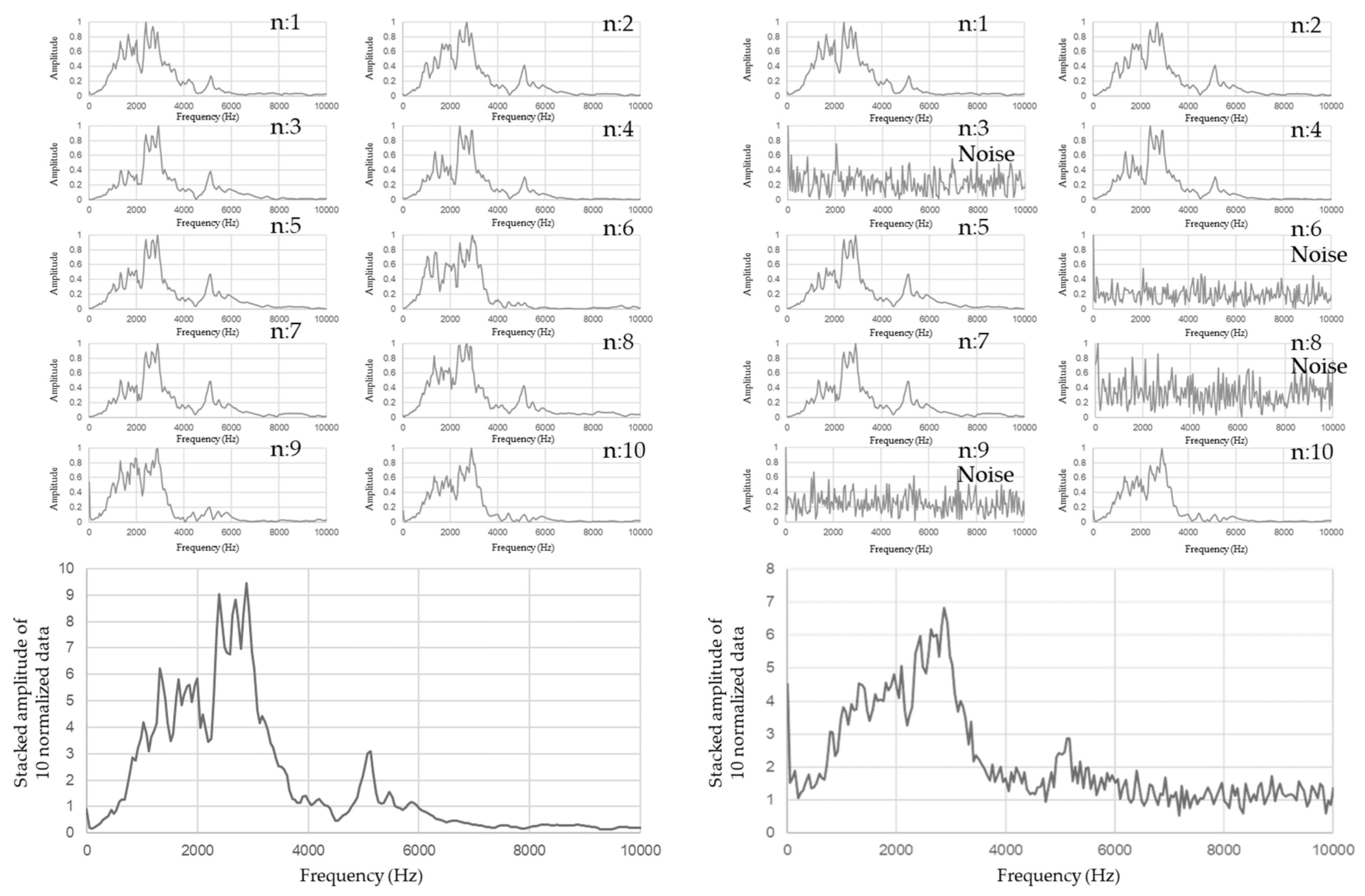

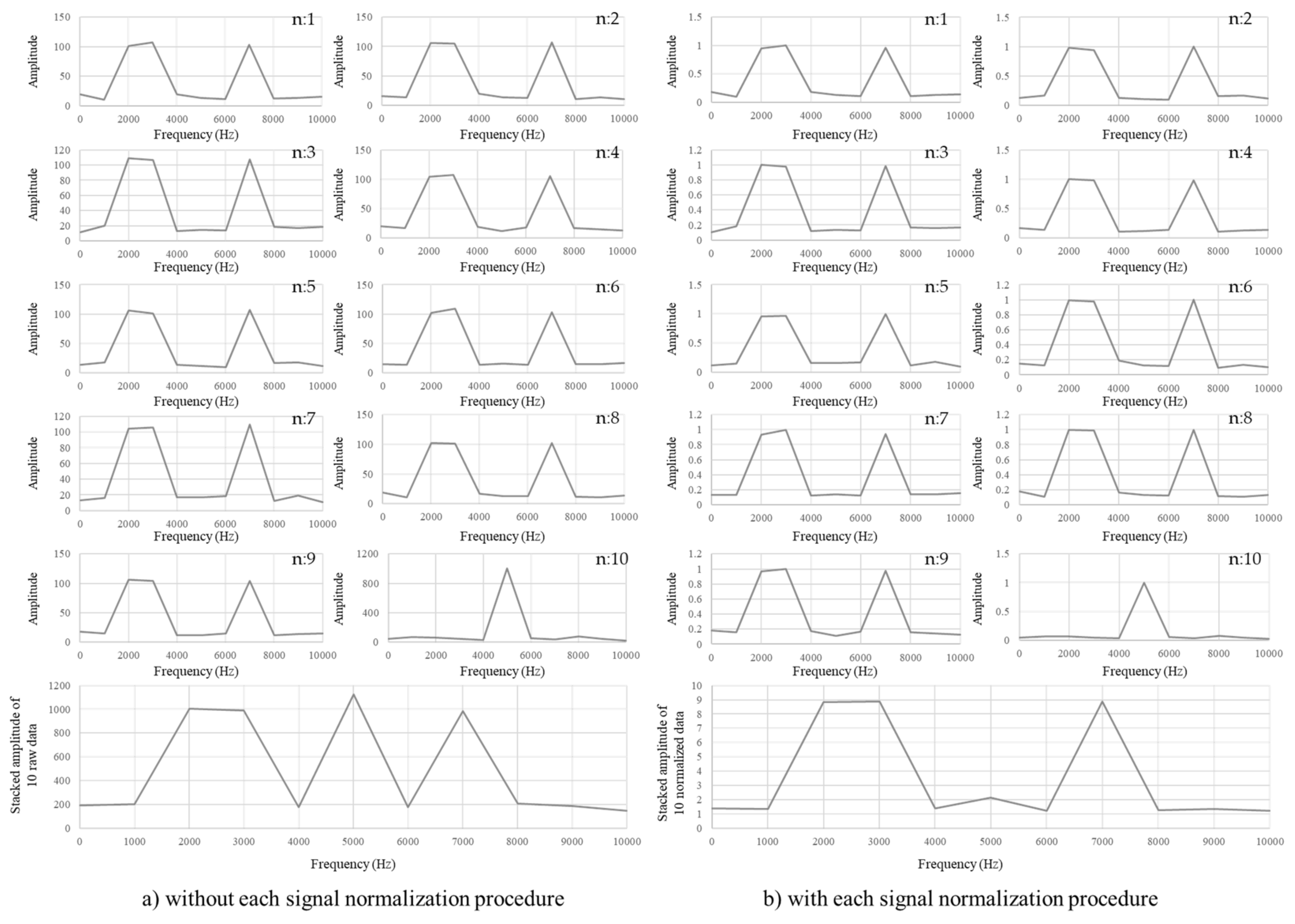

- Normalize the amplitude from 0 to 1 based on the highest peak value in the frequency spectrum to cancel the variability of each manual hammering impact.

- Stack amplitudes according to fR and quantify reflection intensity values at each nodal point.

- Visualize 3D geometry with the stacking data based on local polynomial regression method.

3. Examination of 3D SIBIE Procedure

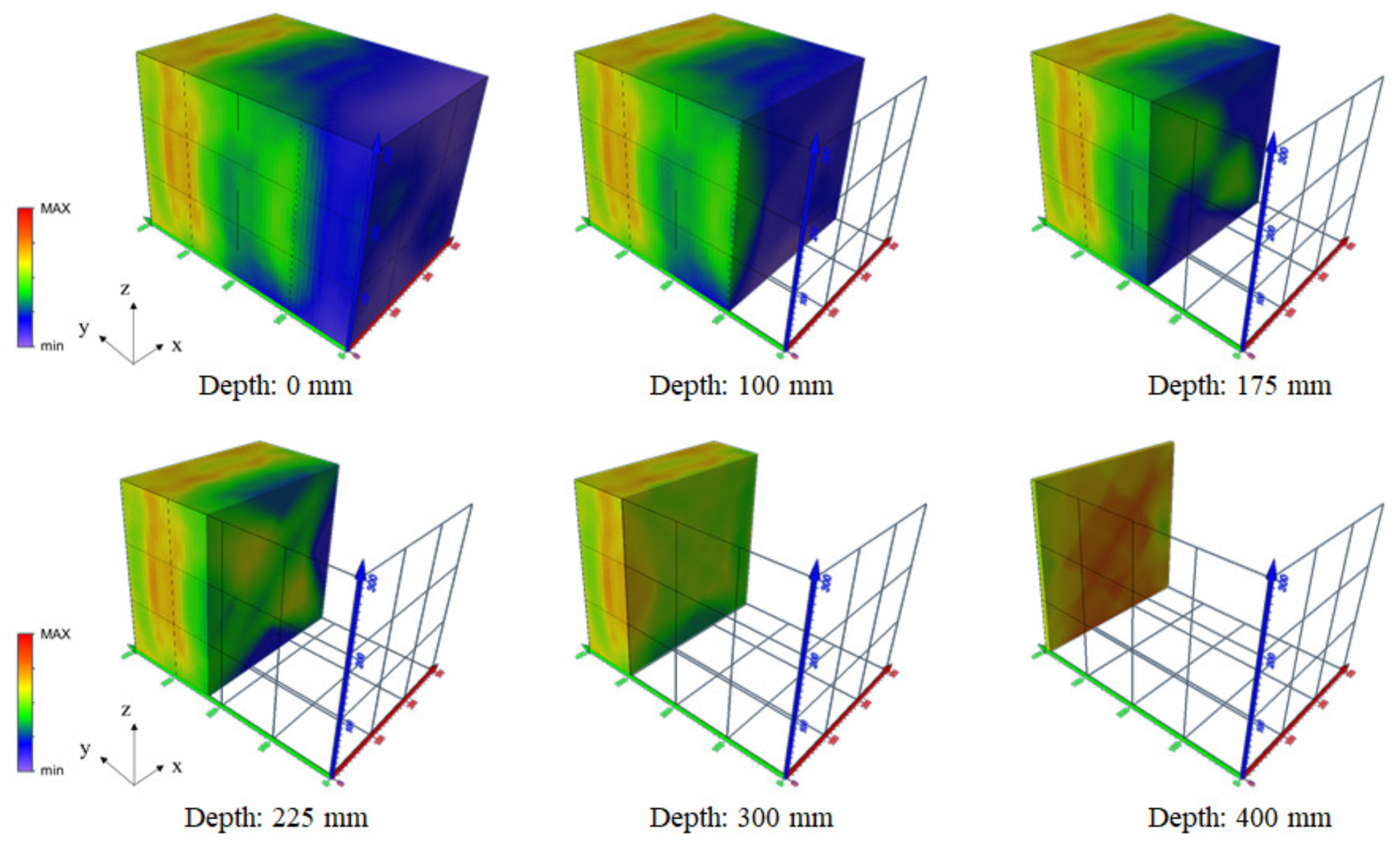

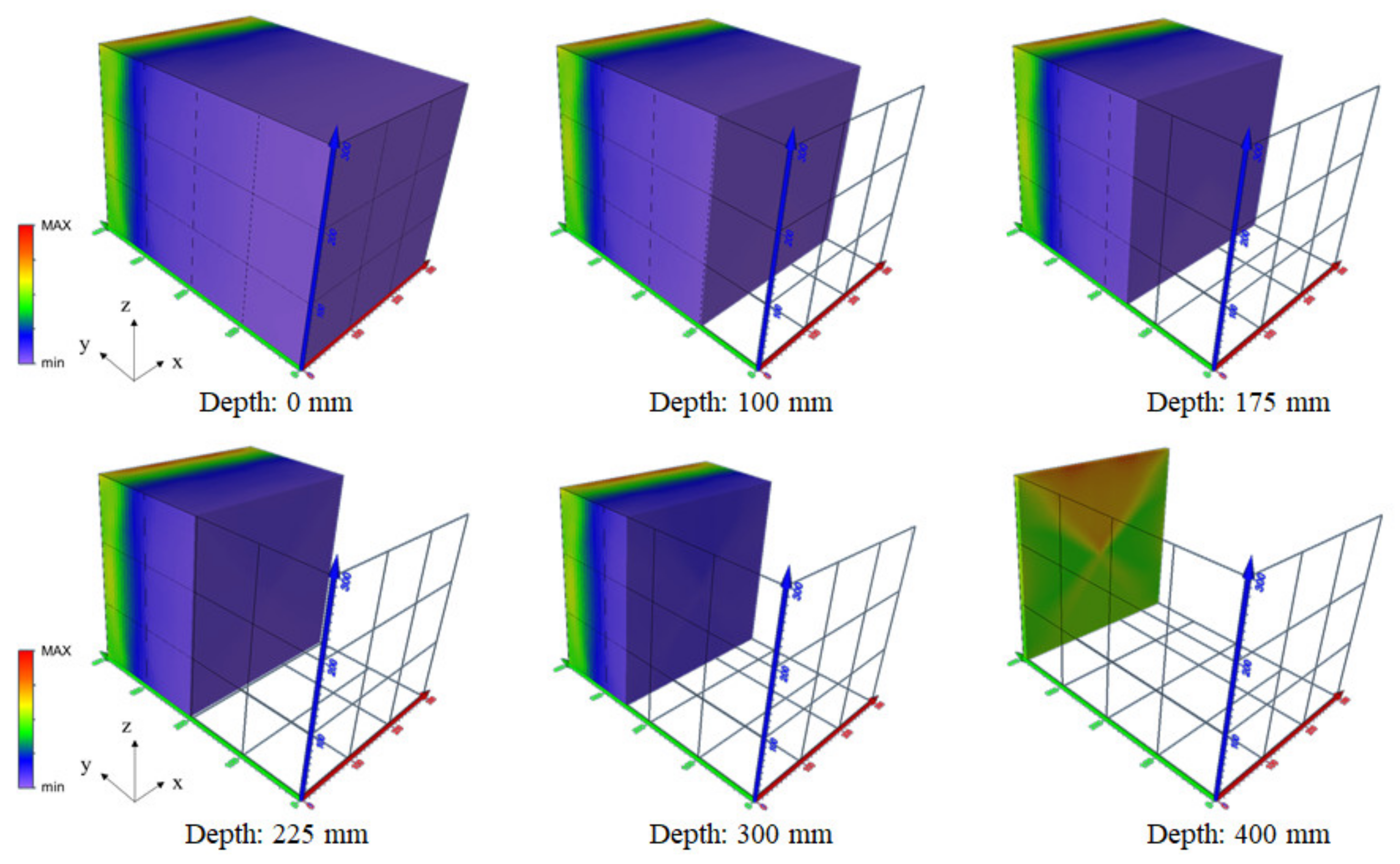

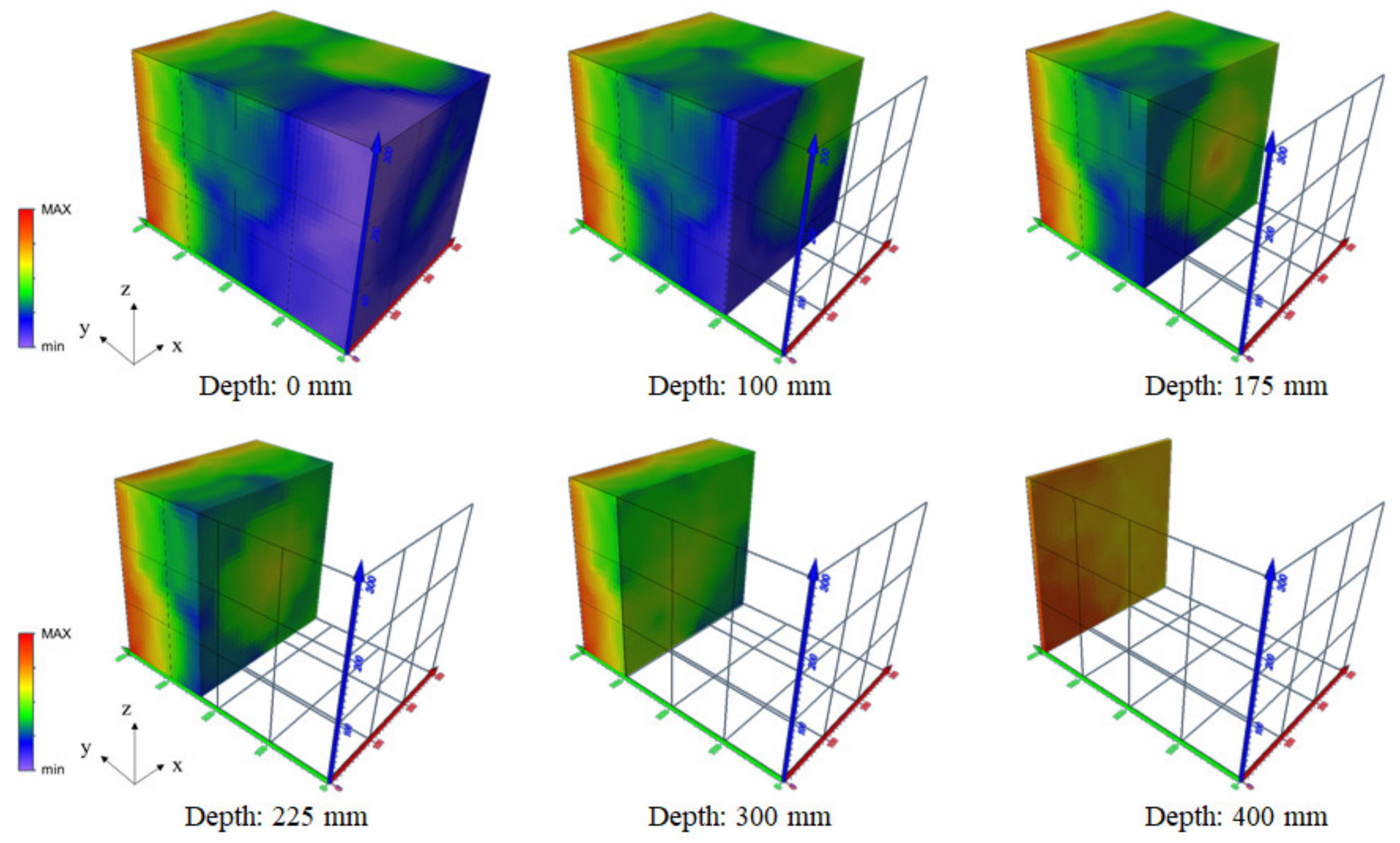

3.1. Application of Accelerometer Array for Detecting Signals

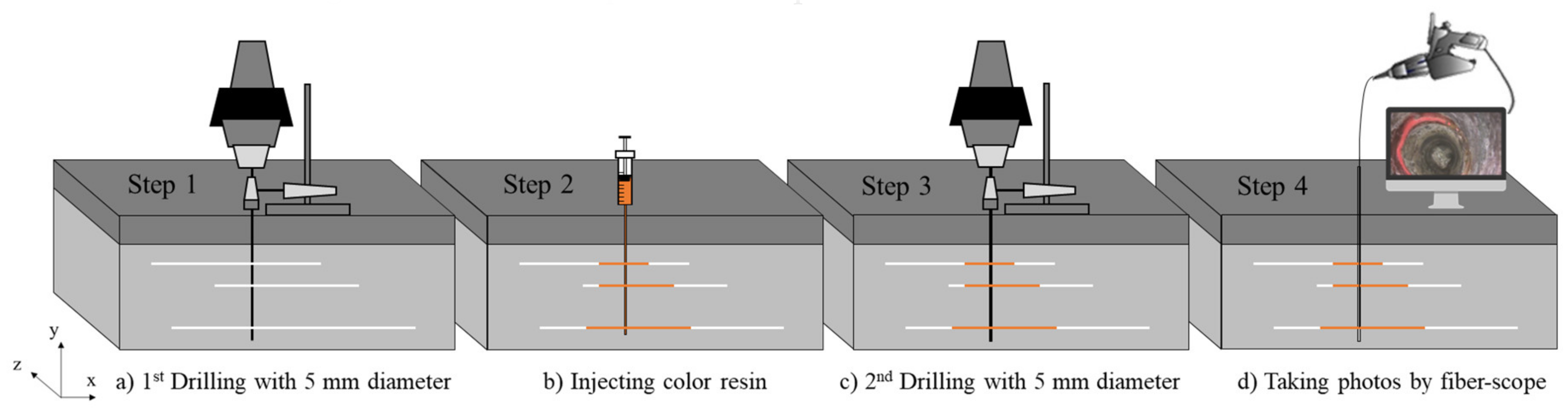

3.1.1. Reinforced Concrete Bridge Deck

- Drilling a 5 mm diameter hole into the concrete deck from the surface of asphalt pavement

- Injecting epoxy resin (in orange-colored to clearly see the crack)

- Re-Drilling a 10 mm diameter hole at the same location after the resin is hardened

- Inserting a flexible fiber optic borescope into concrete to take photos

3.1.2. Concrete Specimen with Simulated Defect

3.2. Application of Laser Doppler Vibrometer for Detecting Signals

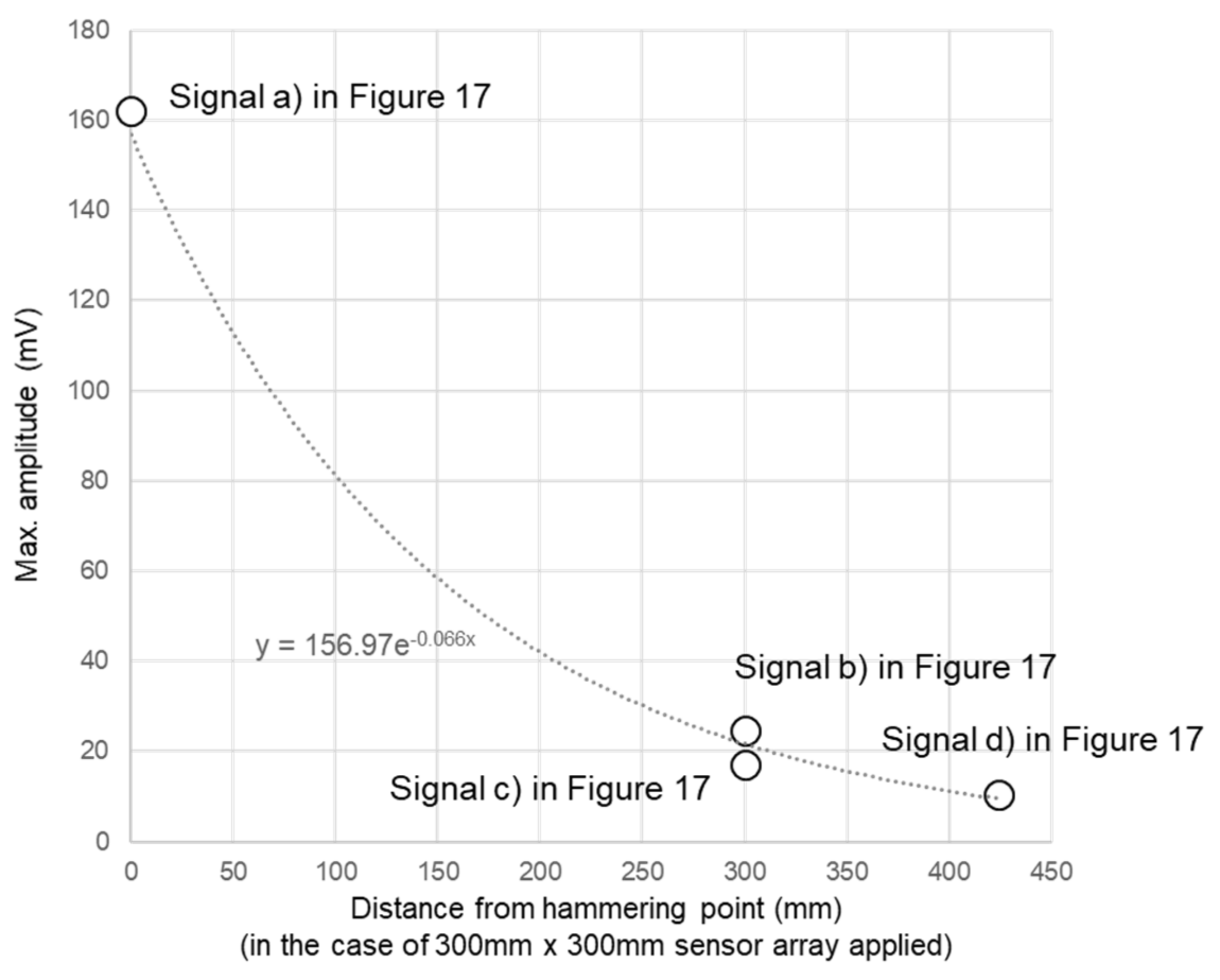

3.3. 3D SIBIE Procedure Improved with Signal Amplification

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ACI Committee 215. Consideration for design of concrete subjected to fatigue loading. ACI J. 1974, 71, 97–121. [Google Scholar]

- Zhang, J.; Peng, H.; Cai, C.S. Field study of overload behavior of an existing reinforced concrete bridge under simulated vehicle loads. J. Bridge Eng. 2010, 16, 226–237. [Google Scholar] [CrossRef]

- Fujiyama, C.; Maekawa, K. A computational simulation for the damage mechanism of steel-concrete composite slabs under high cycle fatigue loads. J. Adv. Concr. Technol. 2011, 9, 193–204. [Google Scholar] [CrossRef] [Green Version]

- Fathalla, E.; Tanaka, Y.; Maekawa, K. Effect of crack orientation on fatigue life of reinforced concrete bridge decks. Appl. Sci. 2019, 9, 1644. [Google Scholar] [CrossRef] [Green Version]

- Toutlemonde, F.; Ranc, G. Fatigue tests of cracked reinforced concrete slabs for estimating the service life of composite bridge decks. Revue Française de Génie Civil 2001, 5, 483–494. [Google Scholar] [CrossRef]

- Hashimoto, K.; Shiotani, T.; Nishida, T.; Miyagawa, T. Application of elastic-wave tomography to repair inspection in deteriorated concrete structures. J. Disaster Res. 2017, 12, 2017. [Google Scholar] [CrossRef]

- Chai, H.K.; Momoki, S.; Kobayashi, Y.; Aggelis, D.G.; Shiotani, T. Tomographic reconstruction for concrete using attenuation of ultrasound. NDT E Int. 2011, 44, 206–211. [Google Scholar] [CrossRef]

- Chai, H.K.; Aggelis, D.G.; Momoki, S.; Kobayashi, Y.; Shiotani, T. Single-side access tomography for evaluating interior defect of concrete. Constr. Build. Mater. 2010, 24, 2411–2418. [Google Scholar] [CrossRef]

- Carino, N.J.; Sansalone, M. Detecting voids in metal tendon ducts using the impact-echo method. Mater. J. Am. Concr. Inst. 1992, 89, 296–303. [Google Scholar]

- Sansalone, M.; Lin, J.M.; Streett, W.B. A New Procedure for determining the thickness of concrete highway pavements using surface wave speed measurements and the impact-echo method. In Innovations of Nondestructive Testing; Pessiki, S., Olson, L., Eds.; American Concrete Institute: Farmington Hills, MI, USA, 1997; p. 167. [Google Scholar]

- Ohtsu, M.; Watanabe, T. Stack Imaging of Spectral Amplitudes based on Impact-Echo for Flaw Detection. NDT E Int. 2002, 35, 189–196. [Google Scholar] [CrossRef]

- Ohtsu, M.; Yamada, M. and Sonoda, T. Quantitative evaluation of SIBIE procedure and case studies. Constr. Build. Mater. 2013, 48, 1248–1254. [Google Scholar] [CrossRef]

- Akamatsu, R.; Sugimoto, T.; Utagawa, N.; Katakura, K. Proposal of non-contact inspection method for concrete structures using high-power directional sound source and scanning laser doppler vibrometer. Jpn. J. Appl. Phys. 2013, 52, 07HC12. [Google Scholar] [CrossRef]

- Kurahashi, S.; Mikami, K.; Kitamura, T.; Hasegawa, N.; Okada, H.; Kondo, S.; Nishikino, M.; Kawauchi, T.; Shimada, Y. Demonstration of 25-Hz-inspection speed laser remote sensing for internal concrete defects. J. Appl. Remote Sens. 2018, 12, 015009. [Google Scholar] [CrossRef] [Green Version]

- Furusawa, A.; Takenaka, Y.; Nishimura, A. Proposal of laser-induced ultrasonic guided wave for corrosion detection of reinforced concrete structures in Fukushima daiichi nuclear power plant decommissioning site. Appl. Sci. 2019, 9, 3544. [Google Scholar] [CrossRef] [Green Version]

- Rausche, F.; Kung, S.R.; Linkins, G. Comparison of pulse echo and transient response pile integrity test methods. Transp. Res. Rec. 1991, 1331, 21–27. [Google Scholar]

- Rausche, F.; Linkins, G.; Kung, S.R. Pile integrity testing and analysis. In Proceedings of the International Conference on the Application of Stress-Wave Theory to Piles, The Hague, The Netherlands, 21–24 September 1992; pp. 613–617. [Google Scholar]

- Ni, S.H.; Lehmann, L.; Charng, J.J.; Lo, K.F. Low-strain integrity testing of drilled piles with high slenderness ratio. Comput. Geotech. 2006, 33, 283–293. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashimoto, K.; Shiotani, T.; Ohtsu, M. Application of Impact-Echo Method to 3D SIBIE Procedure for Damage Detection in Concrete. Appl. Sci. 2020, 10, 2729. https://doi.org/10.3390/app10082729

Hashimoto K, Shiotani T, Ohtsu M. Application of Impact-Echo Method to 3D SIBIE Procedure for Damage Detection in Concrete. Applied Sciences. 2020; 10(8):2729. https://doi.org/10.3390/app10082729

Chicago/Turabian StyleHashimoto, Katsufumi, Tomoki Shiotani, and Masayasu Ohtsu. 2020. "Application of Impact-Echo Method to 3D SIBIE Procedure for Damage Detection in Concrete" Applied Sciences 10, no. 8: 2729. https://doi.org/10.3390/app10082729

APA StyleHashimoto, K., Shiotani, T., & Ohtsu, M. (2020). Application of Impact-Echo Method to 3D SIBIE Procedure for Damage Detection in Concrete. Applied Sciences, 10(8), 2729. https://doi.org/10.3390/app10082729