Determination of the Optimum Amount of Superplasticizer Additive for Self-Compacting Concrete

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

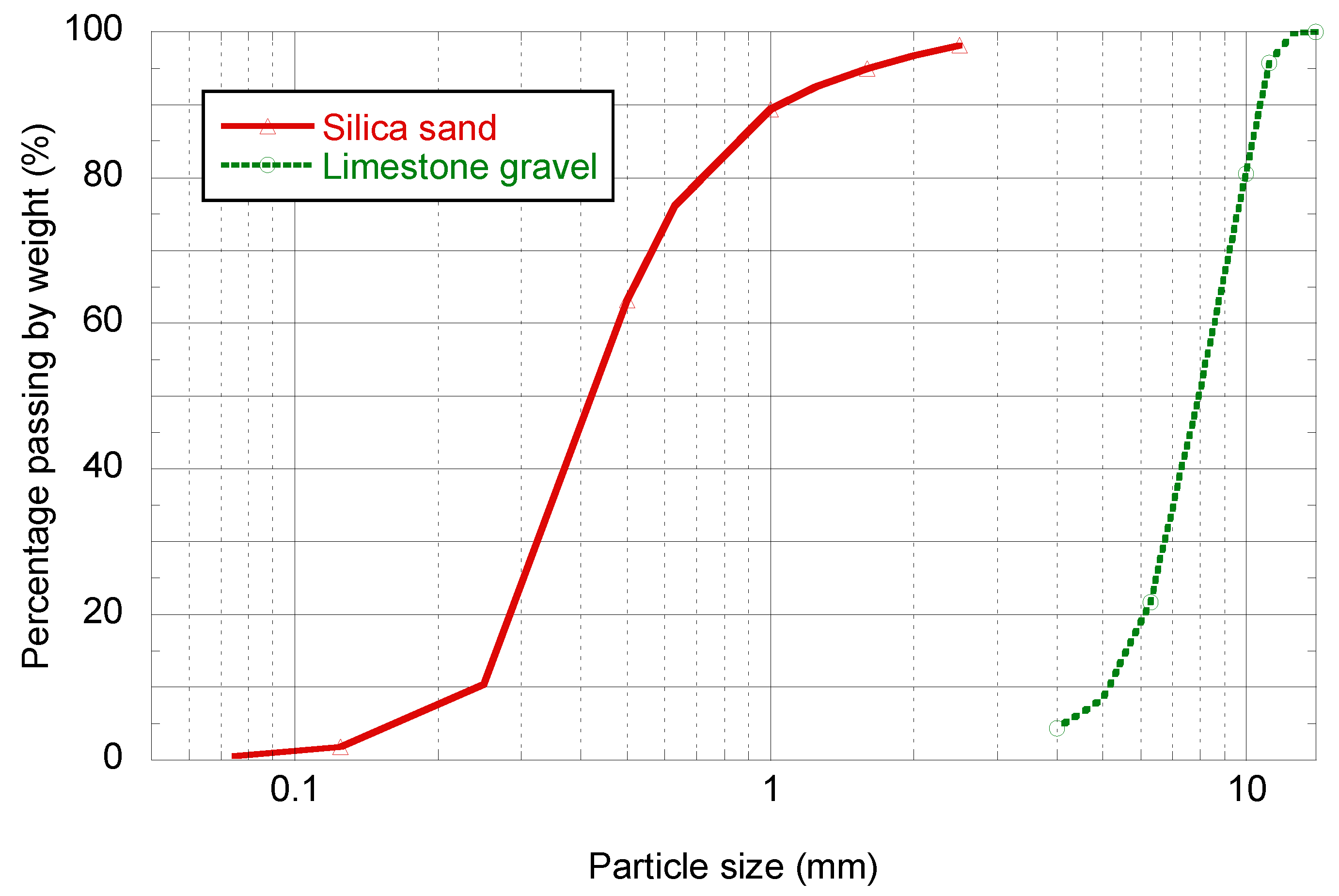

2.1. Materials

2.2. Mix Proportions

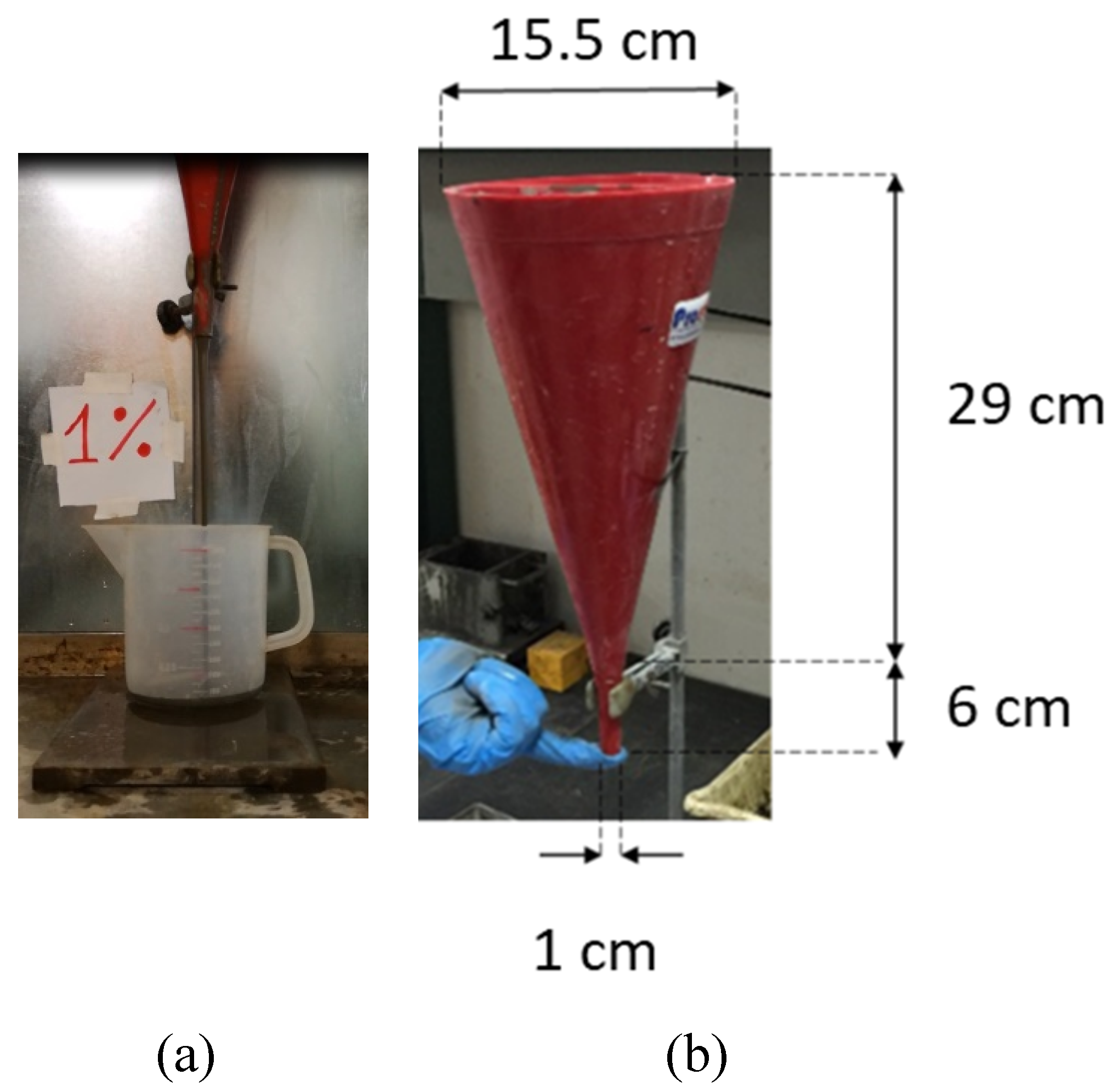

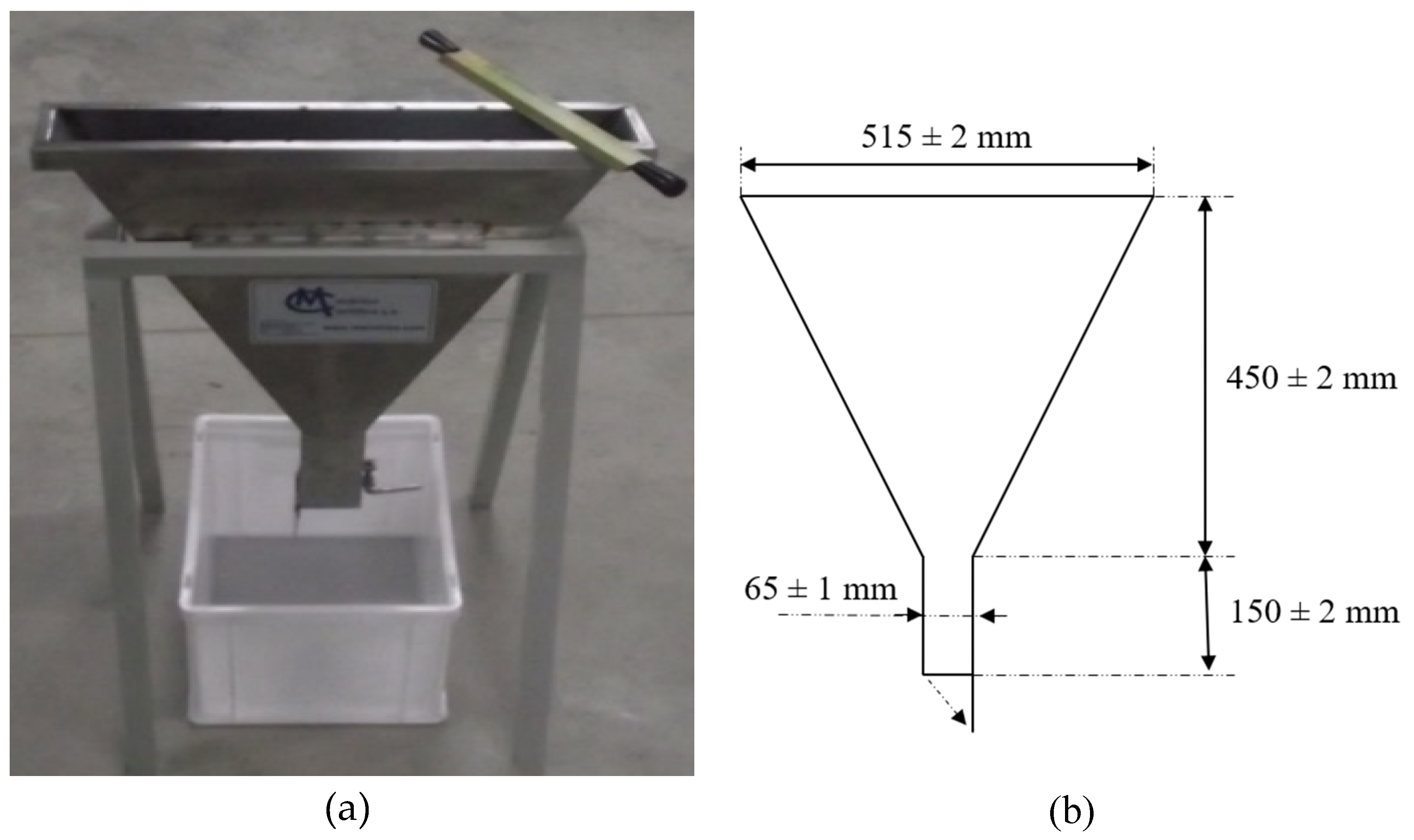

2.3. Cement Paste Flowability

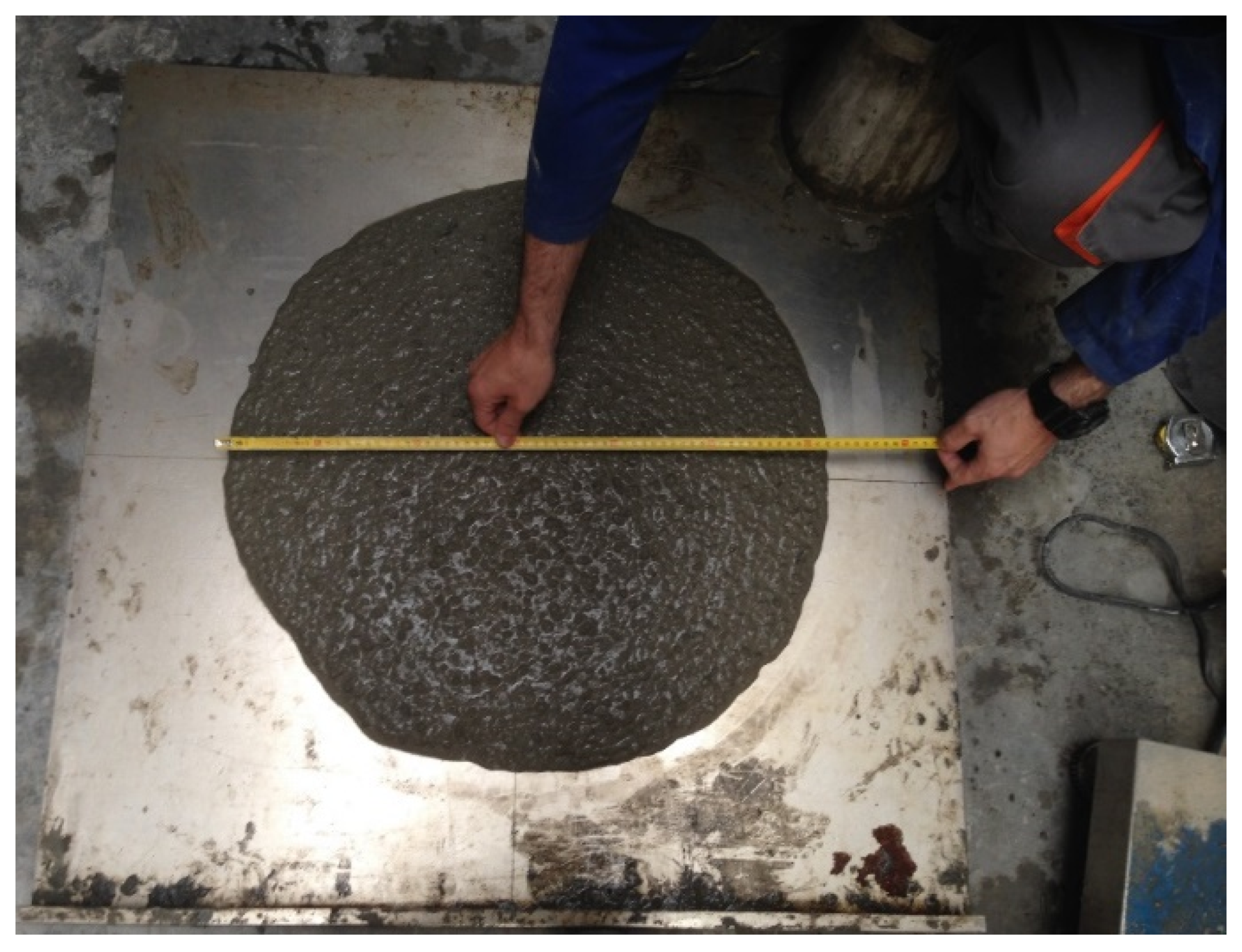

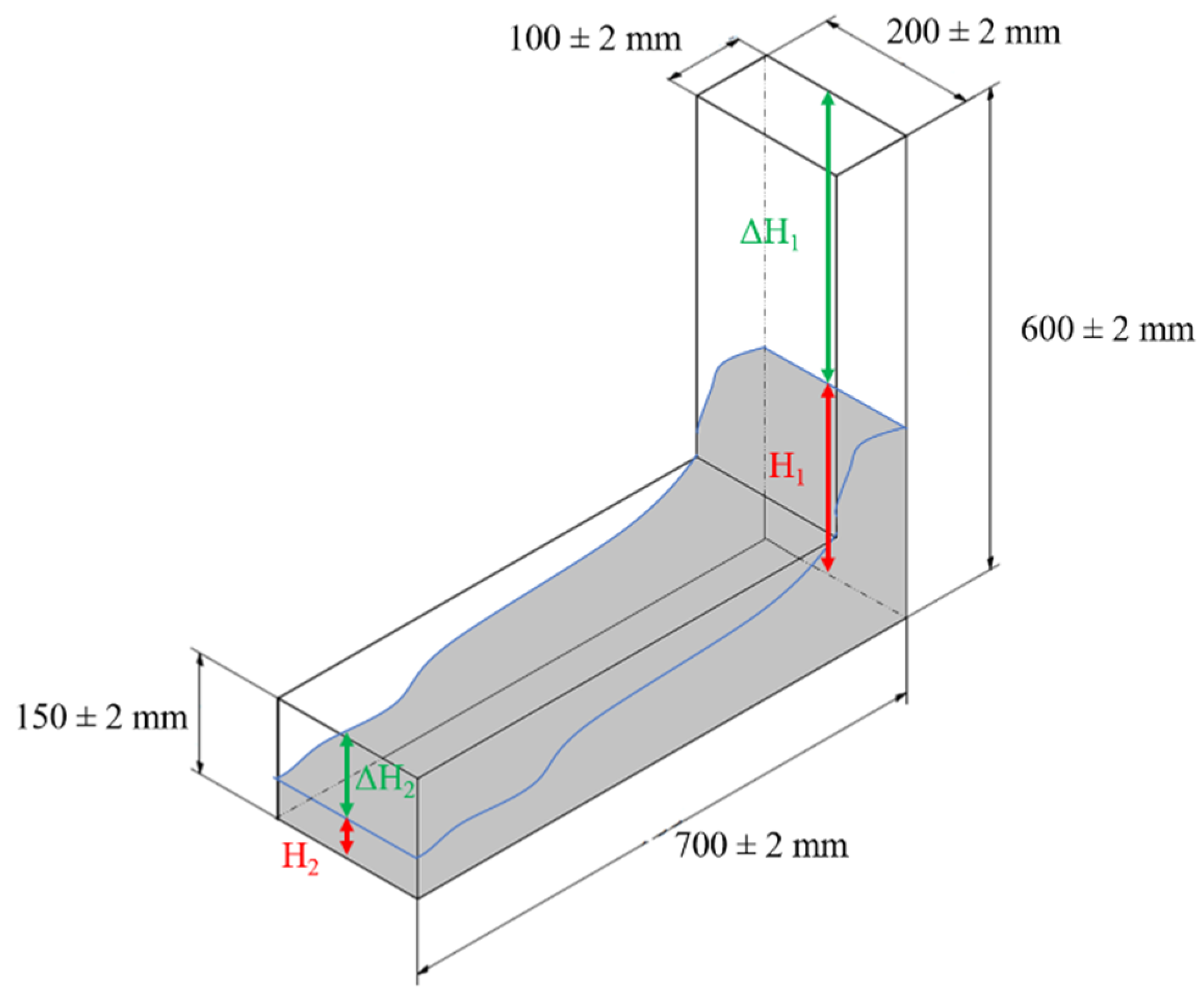

2.4. Concrete Flowability

2.5. Concrete Mixer Method

3. Results and Discussion

3.1. Cement Paste Flowability

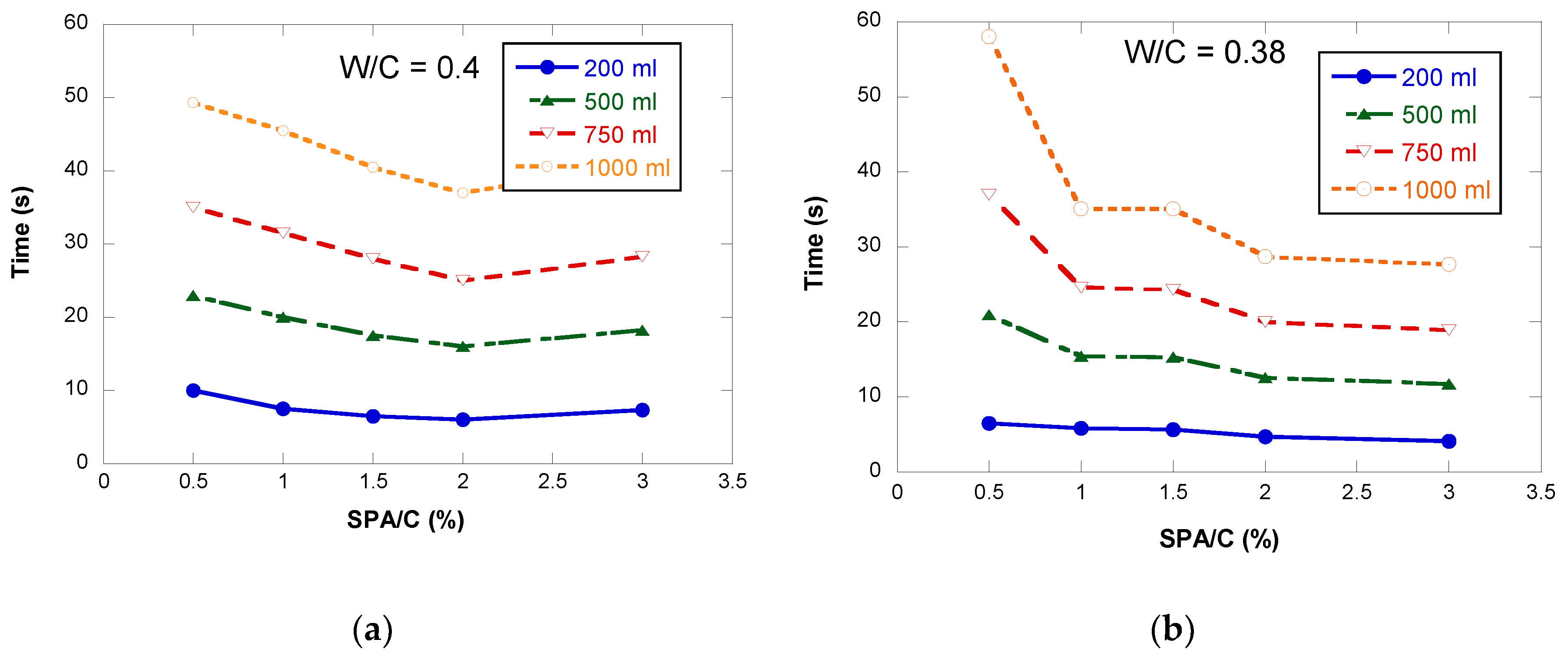

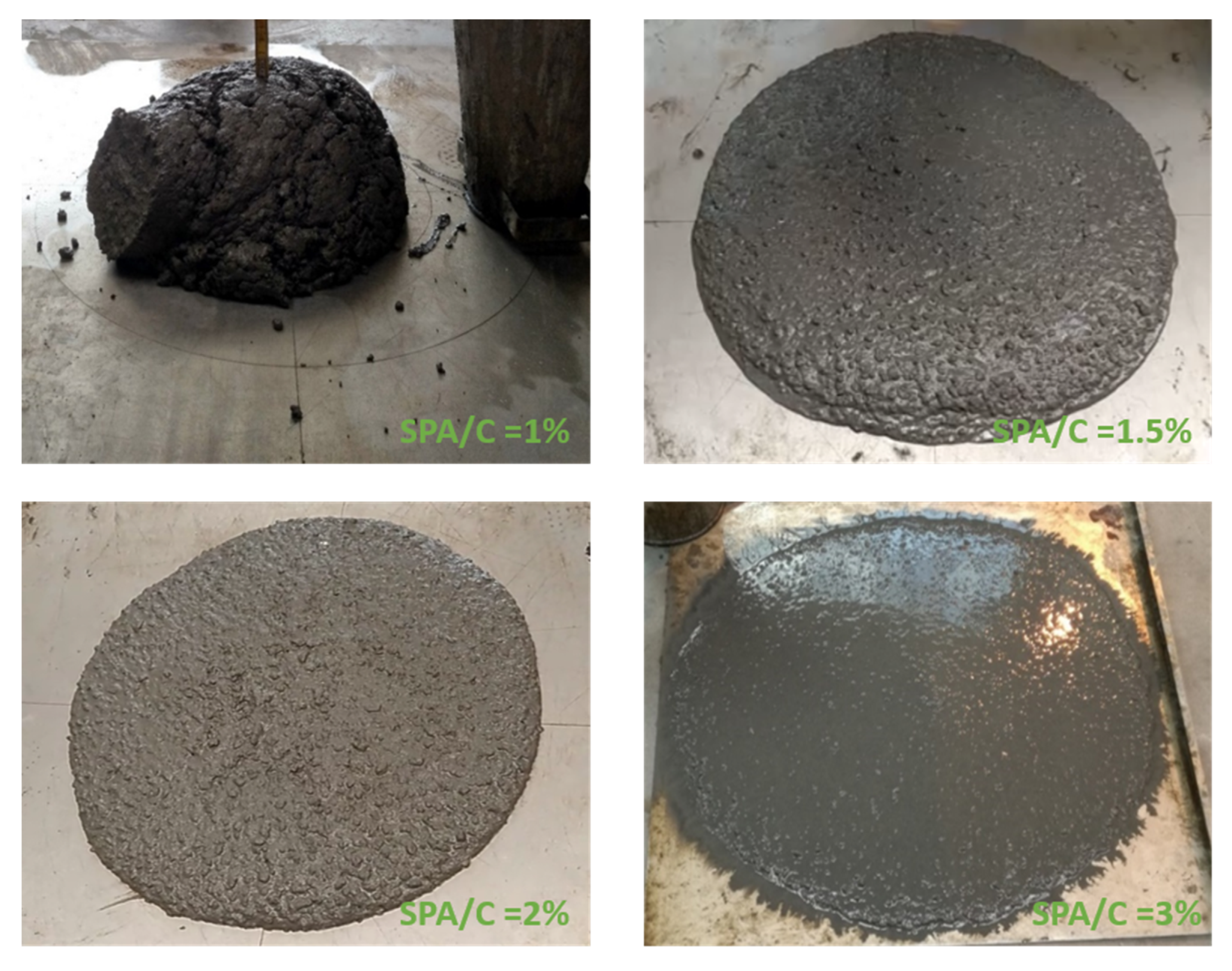

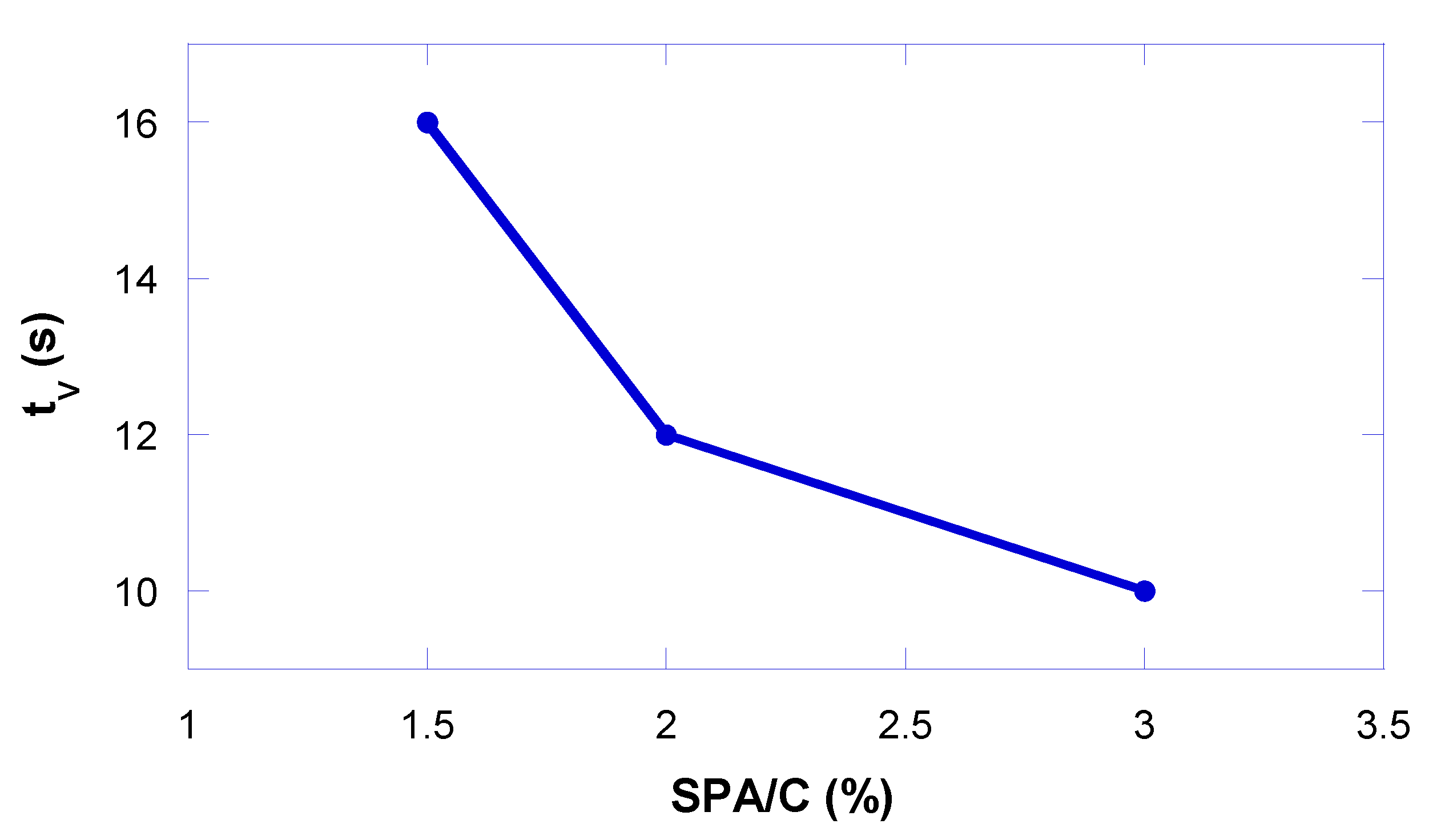

3.2. Concrete Flowability

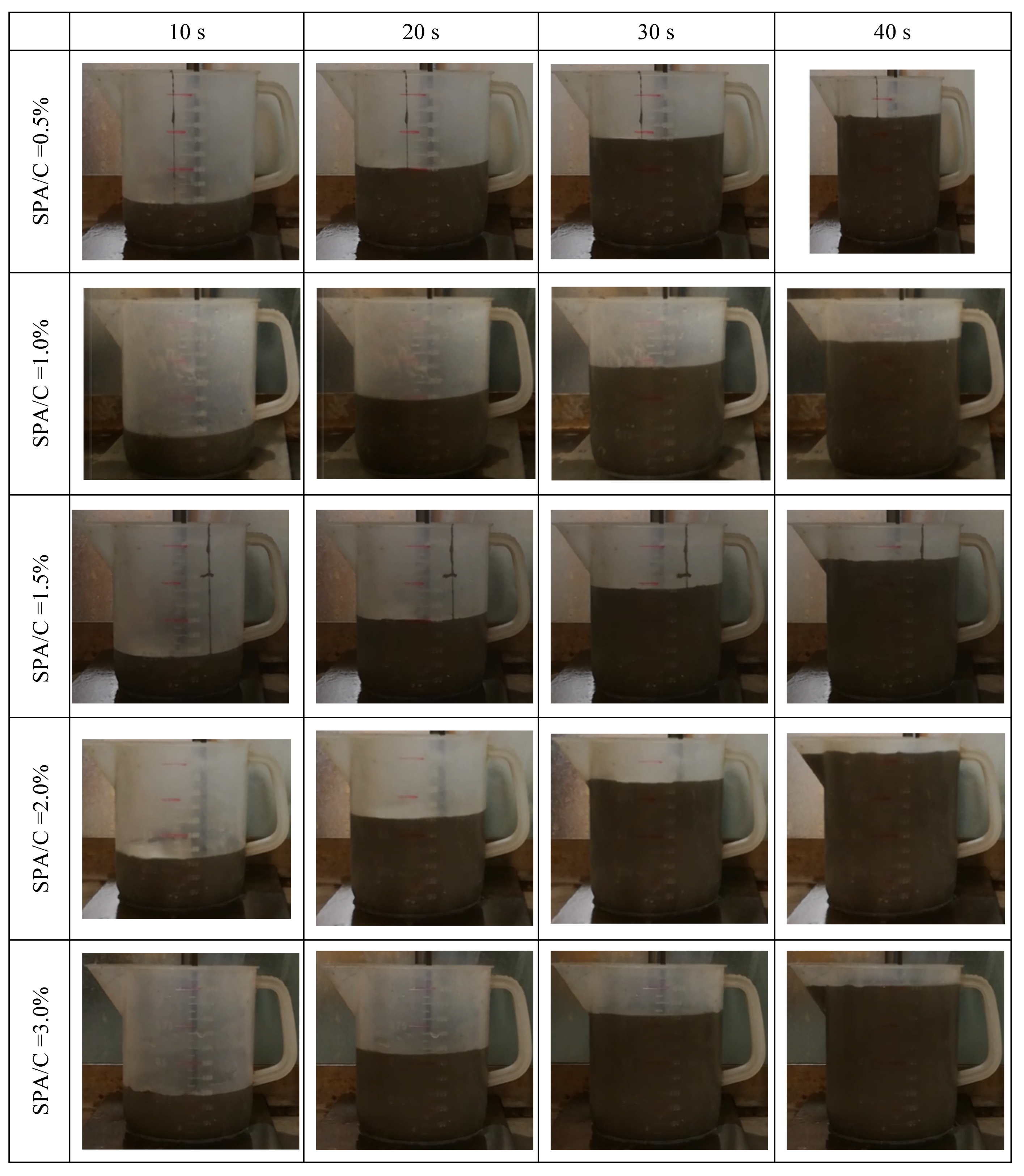

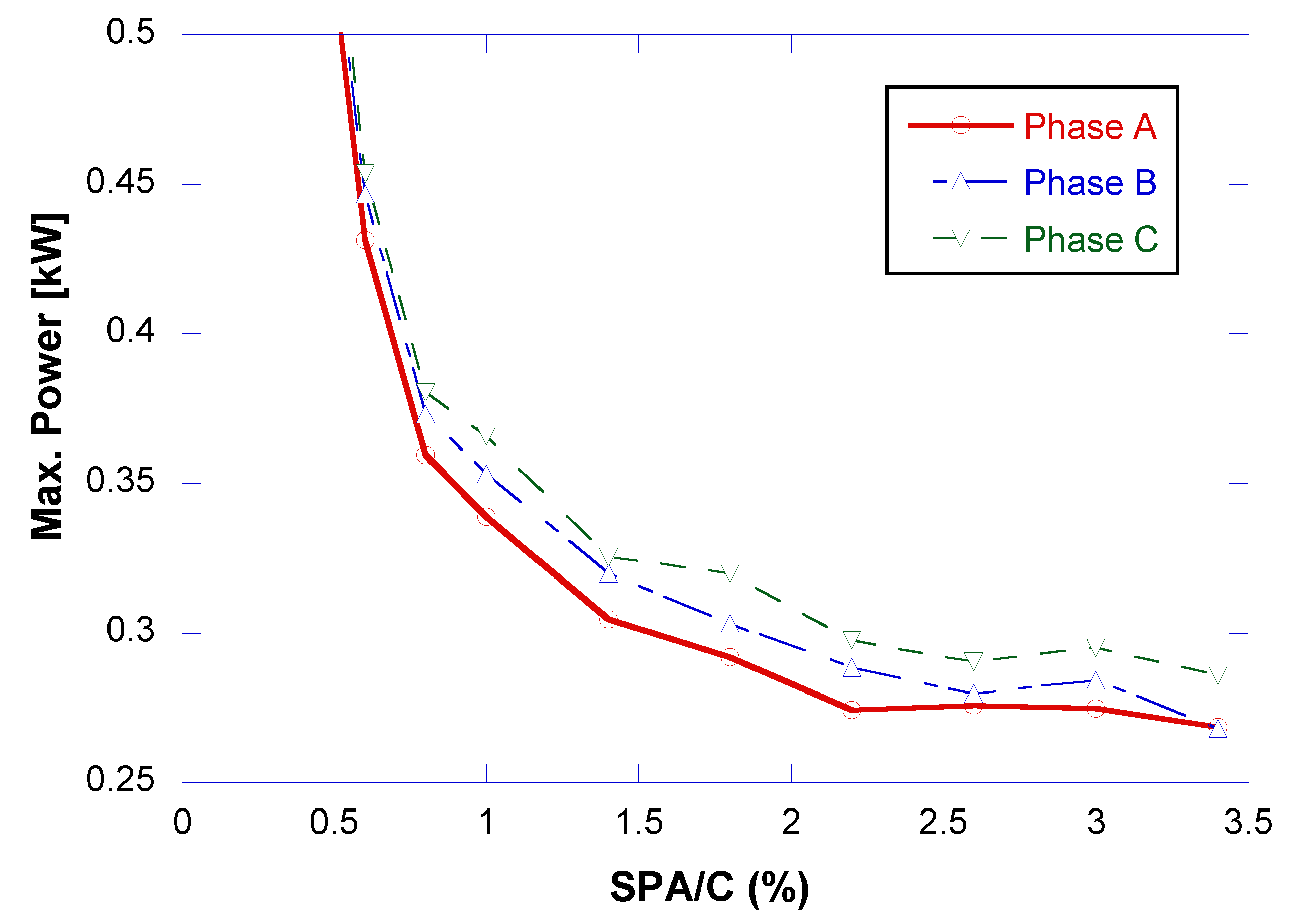

3.3. Concrete Mixer Method

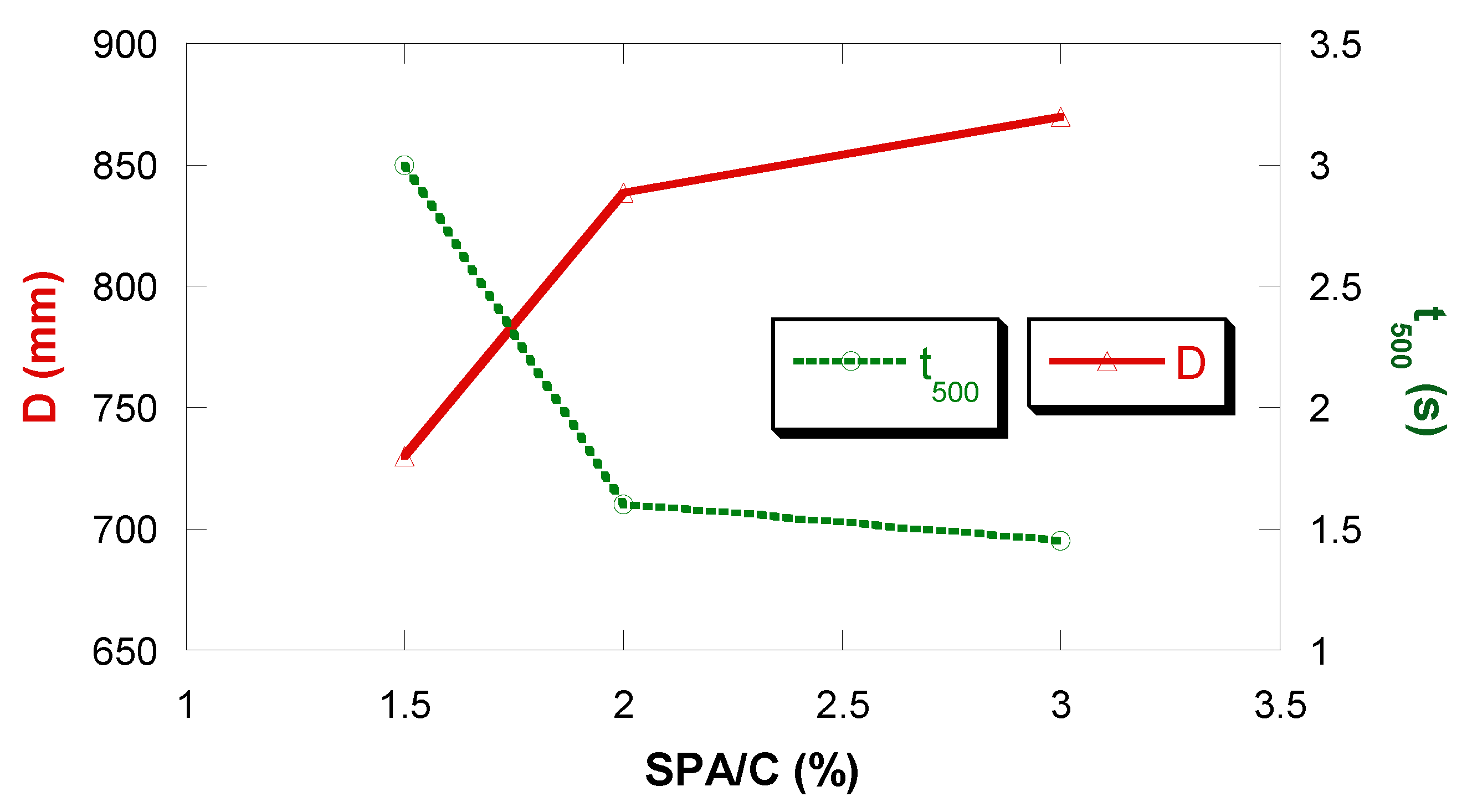

3.4. Correlation between the Results from the Marsh Cone, Concrete Workability and Concrete Mixer Methods

4. Conclusions

- After analyzing the results, it can be seen that the optimum quantity of SPA/C for the study case is 2%.

- Cement pastes and concretes with an SPA/C of 3% can show, in some cases, greater fluidity than for 2%, but the segregation of their elements is notable, and this is a situation to be avoided.

- Regarding the proposed concrete mixer test method, it has been revealed as a valid methodology to obtain the optimum amount of additive.

- This method is quicker than the current technique, since it allows results to be obtained from a single mix and also eliminates variables in the study when working on the real components of the concrete.

- On the other hand, it has been proven that obtaining the saturation point of the Marsh cone test is more precise when using a higher volume than that recommended by current standards.

- The measurement of the power of the three electrical phases has proved to be similar, so the methodology could be simplified by using only one of the phases of the concrete mixer.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Salhi, M.; Ghrici, M.; Bilir, T.; Uysal, M. Combined effect of temperature and time on the flow properties of self-compacting concrete. Constr. Build. Mater. 2020, 240, 117914. [Google Scholar] [CrossRef]

- Okamura, H.; Ozawa, K. Self-compacting high performance concrete. Struct. Eng. Int. J. Int. Assoc. Bridg. Struct. Eng. 1996. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M.; Ozawa, K. Self-compacting concrete. Struct. Concr. 2000. [Google Scholar] [CrossRef] [Green Version]

- Heirman, G.; Vandewalle, L. The influence of fillers on the properties of self-compacting concrete in fresh and hardened state. In Proceedings of the 3rd International RILEM Symposium on Self-Compacting Concrete (SCC2003), Reykjavik, Iceland, 17–20 August 2003; RILEM Publications SARL: Paris, France, 2003; pp. 606–618. [Google Scholar]

- Kanellopoulos, A.; Savva, P.; Petrou, M.F.; Ioannou, I.; Pantazopoulou, S. Assessing the quality of concrete—Reinforcement interface in Self Compacting Concrete. Constr. Build. Mater. 2020, 240, 117933. [Google Scholar] [CrossRef]

- Diego Carro-López, B.G.-F. Dosificación, propiedades en estado fresco y reología de hormigón autocompactante con áridos reciclados finos. Hormigón Y Acero 2018, 69, 286. [Google Scholar]

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Alyamac, K.E.; Ghafari, E.; Ince, R. Development of eco-efficient self-compacting concrete with waste marble powder using the response surface method. J. Clean. Prod. 2017, 144, 192–202. [Google Scholar] [CrossRef]

- Yepes, V.; Martí, J.V.; García-Segura, T. Cost and CO2 emission optimization of precast-prestressed concrete U-beam road bridges by a hybrid glowworm swarm algorithm. Autom. Constr. 2015, 49, 123–134. [Google Scholar] [CrossRef]

- Sonebi, M.; Rooney, M.; Bartos, P.J.M. Evaluation of the segregation resistance of fresh self-compacting concrete using different test methods. In Proceedings of the SCC’2005-China: 1st International Symposium on Design, Performance and Use of Self-Consolidating Concrete, Changsha, China, 26–28 May 2005; RILEM Publications SARL: Paris, France, 2005; pp. 301–308. [Google Scholar]

- Sonebi, M.; Grünewald, S.; Walraven, J. Filling ability and passing ability of self-consolidating concrete. ACI Mater. J. 2007, 104, 162–170. [Google Scholar]

- Sainz-Aja, J.A. Slab Track Manufacture Using Out of Service Railways Wastes. Ph.D. Thesis, University of Cantabria, Santander, Spain, 2019. [Google Scholar]

- ACHE—Asociación Científico Técnica del Hormigón Estructural. M-16: Manual de Tecnología de Aditivos para Hormigón; ACHE: Madrid, Spain, 2010. [Google Scholar]

- Kou, S.C.C.; Poon, C.S.S. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Sainz-Aja, J.; Thomas, C.; Polanco, J.A.; Carrascal, I. High-Frequency Fatigue Testing of Recycled Aggregate Concrete. Appl. Sci. 2019, 10, 10. [Google Scholar] [CrossRef] [Green Version]

- Pereira-De-Oliveira, L.A.; Nepomuceno, M.C.S.; Castro-Gomes, J.P.; Vila, M.F.C. Permeability properties of self-Compacting concrete with coarse recycled aggregates. Constr. Build. Mater. 2014, 51, 113–120. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Manso, J.M.; Ortega-López, V. Self-compacting concrete manufactured with recycled concrete aggregate: An overview. J. Clean. Prod. 2020, 262, 121362. [Google Scholar] [CrossRef]

- Torrents, J.M.; Roncero, J.; Gettu, R. Utilization of impedance spectroscopy for studying the retarding effect of a superplasticizer on the setting of cement. Cem. Concr. Res. 1998, 28, 1325–1333. [Google Scholar] [CrossRef]

- Roncero, J.; Gettu, R.; Agulló, L.; Vázquez, E. Flow behaviour of superplasticised cement pastes: Influence of silica fume. Indian Concr. J. 2002, 76, 31–35. [Google Scholar]

- Roncero, J.; Valls, S.; Gettu, R. Study of the influence of superplasticizers on the hydration of cement paste using nuclear magnetic resonance and X-ray diffraction techniques. Cem. Concr. Res. 2002, 32, 103–108. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Melo, K.A.; Repette, W.L. Optimization of Superplasticizer Content in Self-Compacting Concrete Bt—Measuring, Monitoring and Modeling Concrete Properties; Konsta-Gdoutos, M.S., Ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 469–477. [Google Scholar]

- Kwan, A.K.H.; Ng, I.Y.T. Optimum superplasticiser dosage and aggregate proportions for SCC. Mag. Concr. Res. 2009, 61, 281–292. [Google Scholar] [CrossRef] [Green Version]

- Brouwers, H.J.H.; Radix, H.J. Self-Compacting Concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. An overview on mixture design of self-compacting concrete. Struct. Concr. 2019, 20, 371–395. [Google Scholar] [CrossRef] [Green Version]

- Asociación Española del Hormigón Estructural, A.C.T. M-13: Hormigón Autocompactante: Diseño Y Aplicación; ACHE: Madrid, Spain, 2008. [Google Scholar]

- Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1; European Committee for Standardization: Brussels, Belgium, 2011.

- Alfa, C. CEM IV/B (V) 32,5 N. Available online: http://www.valderrivas.es/recursos/doc/Productos/Cemento/Productos/Hontoria/214926555_2112011132543.pdf. (accessed on 28 April 2020).

- Test Methods of Cements. Physical Analysis. Actual Density Determination; UNE 80103:2013; Asociacion Espanola de Normalizacion: Madrid, Spain, 2013.

- Methods of Testing Cement—Part 6: Determination of Fineness; SS-EN 196-6:2010; Swedish Institute for Standards: Stockholm, Sweden, 2010.

- Basf MasterGlenium® ACE 450. Available online: https://assets.master-builders-solutions.basf.com/en-tr/eng_masterglenium-ace450-tds.pdf (accessed on 5 February 2020).

- Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; BS EN 933-1:2012; European Committee for Standardization: Brussels, Belgium, 2012.

- ASTM International. ASTM C 939-97 Flow of Grout for Preplaced-Aggregate Concrete (Flow ConeMethod); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Sainz-Aja, J.; Carrascal, I.; Polanco, J.A.; Thomas, C.; Sosa, I.; Casado, J.; Diego, S. Self-compacting recycled aggregate concrete using out-of-service railway superstructure wastes. J. Clean. Prod. 2019, 230. [Google Scholar] [CrossRef]

- Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump-Flow Test; I.S. EN 12350-8:2010; National Standards Authority of Ireland: Dublin, Ireland, 2011.

- Testing Fresh Concrete—Part 2: Slump-Test; I.S. EN 12350-2:2009; National Standards Authority of Ireland: Dublin, Ireland, 2009.

- Testing Fresh Concrete—Part 10: Self-Compacting Concrete—L Box Test; I.S. EN 12350-10:2010; National Standards Authority of Ireland: Dublin, Ireland, 2015.

- Testing Fresh Concrete—Part 9: Self-Compacting Concrete—V-Funnel Test; I.S. EN 12350-9:2010; National Standards Authority of Ireland: Dublin, Ireland, 2011.

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | SO3 | Ignition Loss | |

|---|---|---|---|---|---|---|---|---|

| CEMENT | 35.5 | 41.2 | 13.3 | 4.4 | 1.2 | 1.4 | 1.3 | 1.7 |

| Material | Density (kg/dm3) |

|---|---|

| Silica sand | 2.64 |

| Limestone gravel | 2.54 |

| Material | Mass (kg/m3) |

|---|---|

| Cement | 500 |

| Water | 200 |

| Silica sand (0–5) | 1000 |

| Limestone gravel (5–12): | 650 |

| Water/cement | 0.4 |

| Step | t0 (min) | t (min) | SPA (mL) | SPAa (mL) | SPA/C (%) |

|---|---|---|---|---|---|

| 0 | 0 | 3 | 0 | 0 | 0 |

| 1 | 3 | 3 | 50 | 50 | 0.2 |

| 2 | 6 | 3 | 50 | 100 | 0.4 |

| 3 | 9 | 3 | 50 | 150 | 0.6 |

| 4 | 12 | 3 | 50 | 200 | 0.8 |

| 5 | 15 | 3 | 50 | 250 | 1.0 |

| 6 | 18 | 3 | 100 | 350 | 1.4 |

| 7 | 21 | 3 | 100 | 450 | 1.8 |

| 8 | 24 | 3 | 100 | 550 | 2.2 |

| 9 | 27 | 3 | 100 | 650 | 2.6 |

| 10 | 30 | 3 | 100 | 750 | 3.0 |

| 11 | 33 | 3 | 100 | 850 | 3.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sainz-Aja, J.A.; Carrascal, I.A.; Polanco, J.A.; Sosa, I.; Thomas, C.; Casado, J.; Diego, S. Determination of the Optimum Amount of Superplasticizer Additive for Self-Compacting Concrete. Appl. Sci. 2020, 10, 3096. https://doi.org/10.3390/app10093096

Sainz-Aja JA, Carrascal IA, Polanco JA, Sosa I, Thomas C, Casado J, Diego S. Determination of the Optimum Amount of Superplasticizer Additive for Self-Compacting Concrete. Applied Sciences. 2020; 10(9):3096. https://doi.org/10.3390/app10093096

Chicago/Turabian StyleSainz-Aja, Jose A., Isidro A. Carrascal, Juan A. Polanco, Israel Sosa, Carlos Thomas, Jose Casado, and Soraya Diego. 2020. "Determination of the Optimum Amount of Superplasticizer Additive for Self-Compacting Concrete" Applied Sciences 10, no. 9: 3096. https://doi.org/10.3390/app10093096

APA StyleSainz-Aja, J. A., Carrascal, I. A., Polanco, J. A., Sosa, I., Thomas, C., Casado, J., & Diego, S. (2020). Determination of the Optimum Amount of Superplasticizer Additive for Self-Compacting Concrete. Applied Sciences, 10(9), 3096. https://doi.org/10.3390/app10093096