Application of the Improved Knothe Time Function Model in the Prediction of Ground Mining Subsidence: A Case Study from Heze City, Shandong Province, China

Abstract

1. Introduction

2. The Knothe Time Function Model

3. The Establishment of an Improved Knothe Time Function Model

4. Determination of Model Parameters

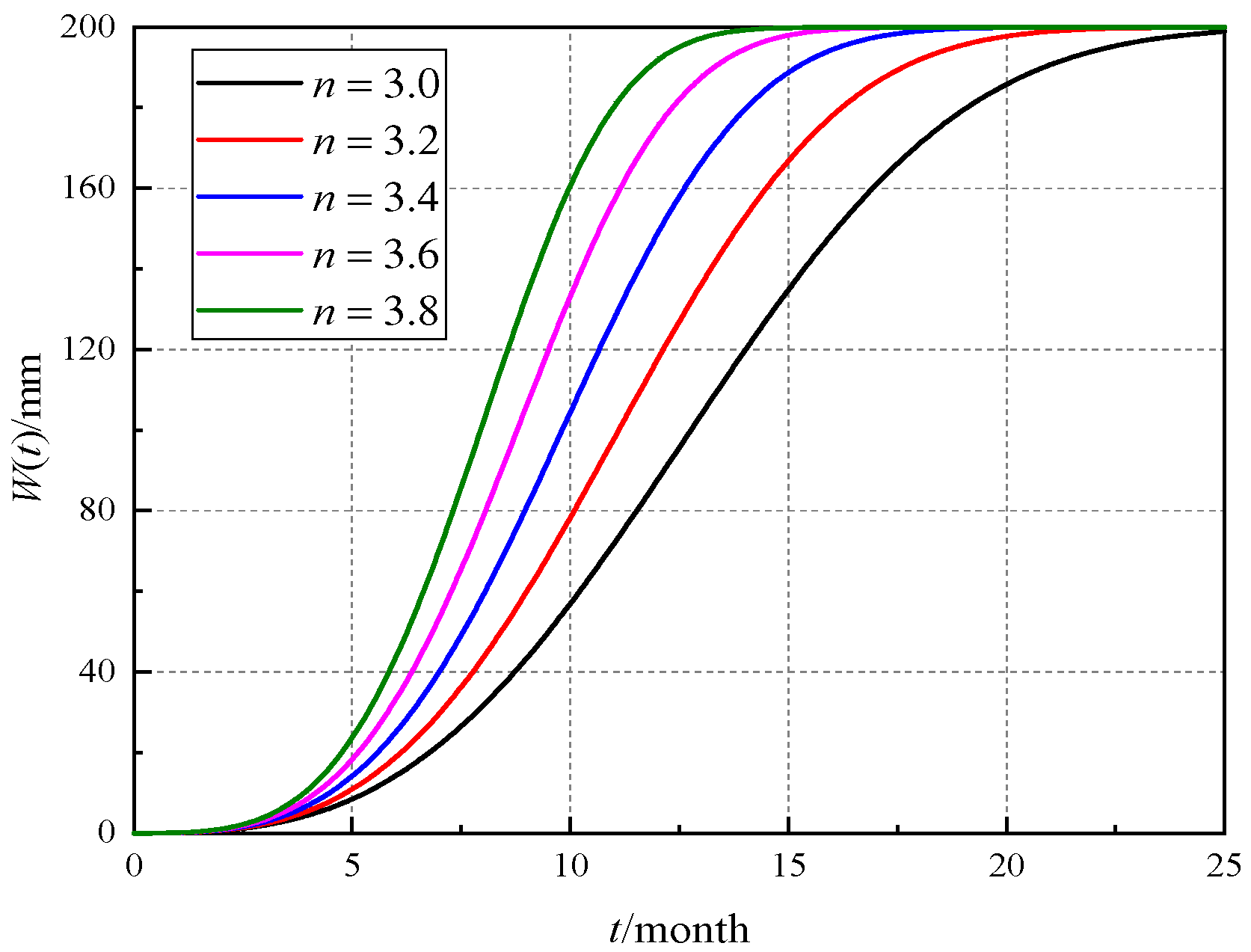

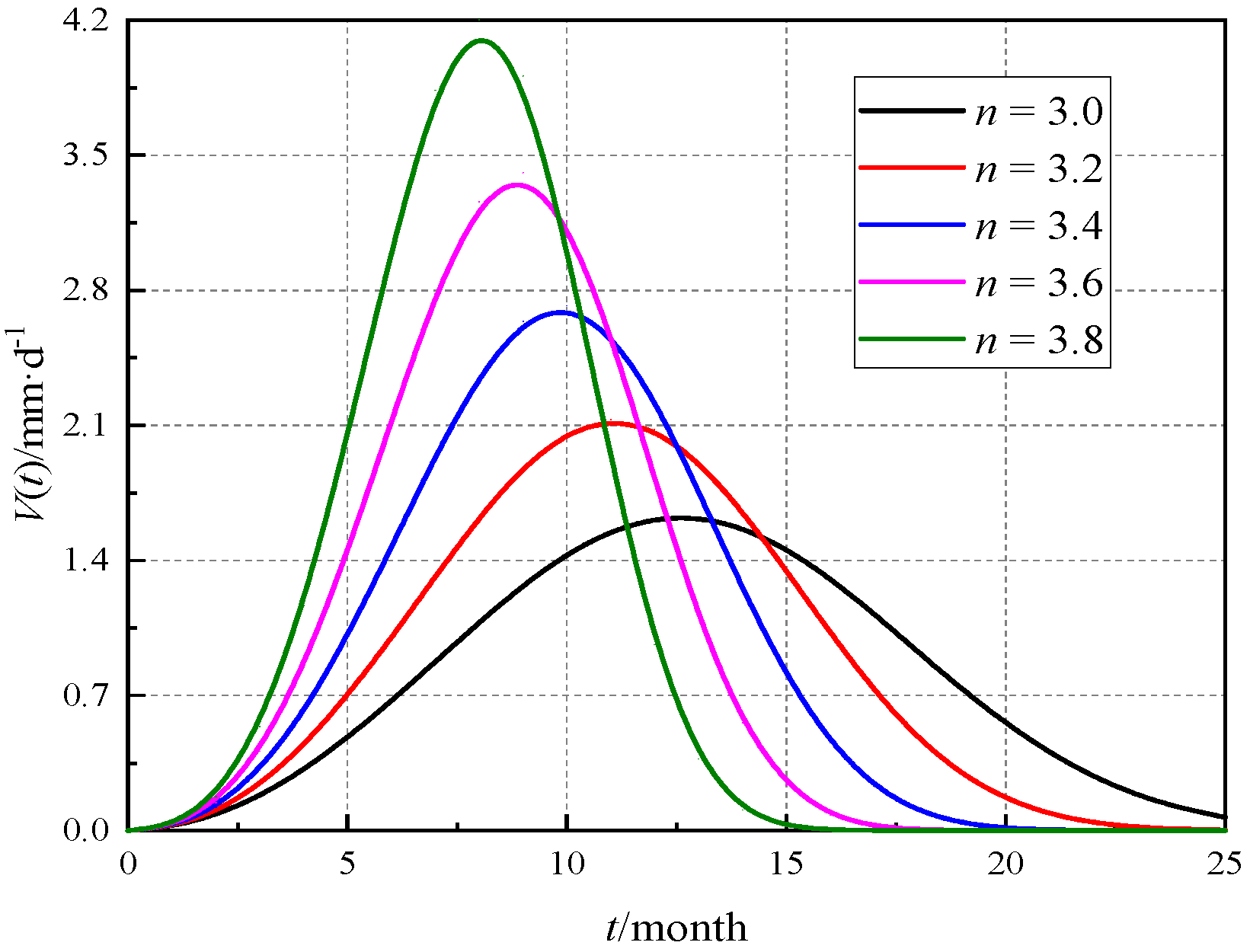

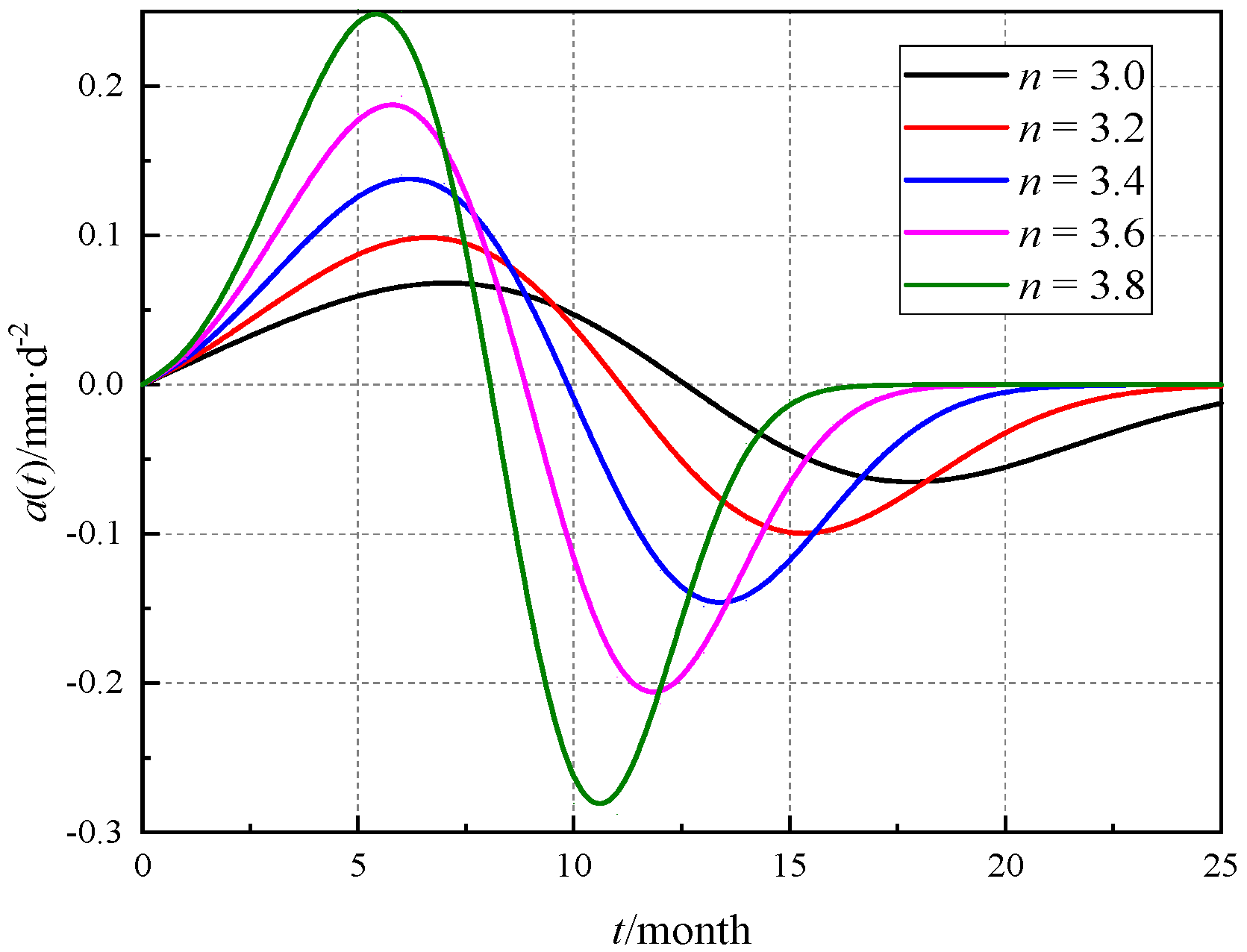

4.1. Determination of Model Order n

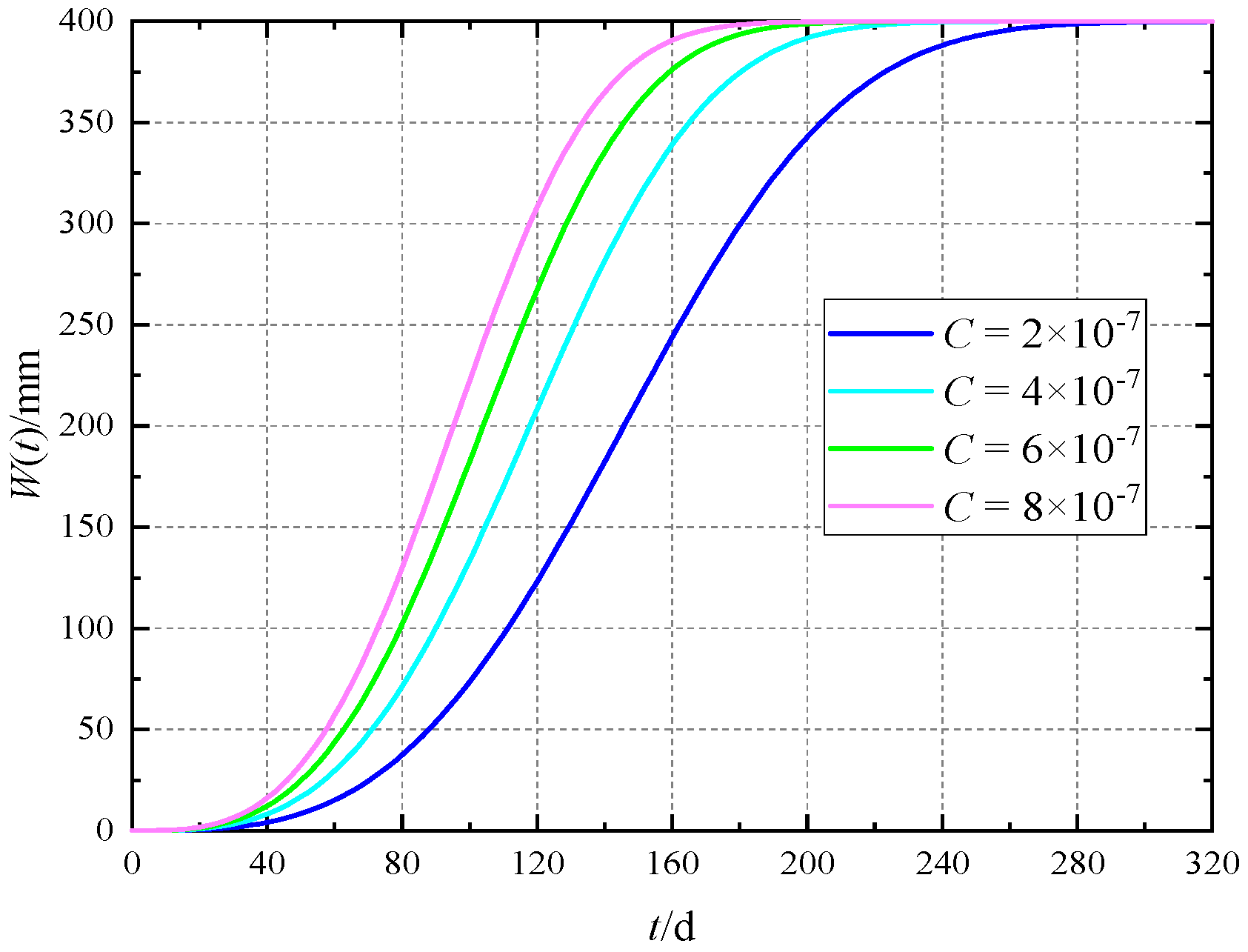

4.2. Determination of Time Influence Parameter C

- (1)

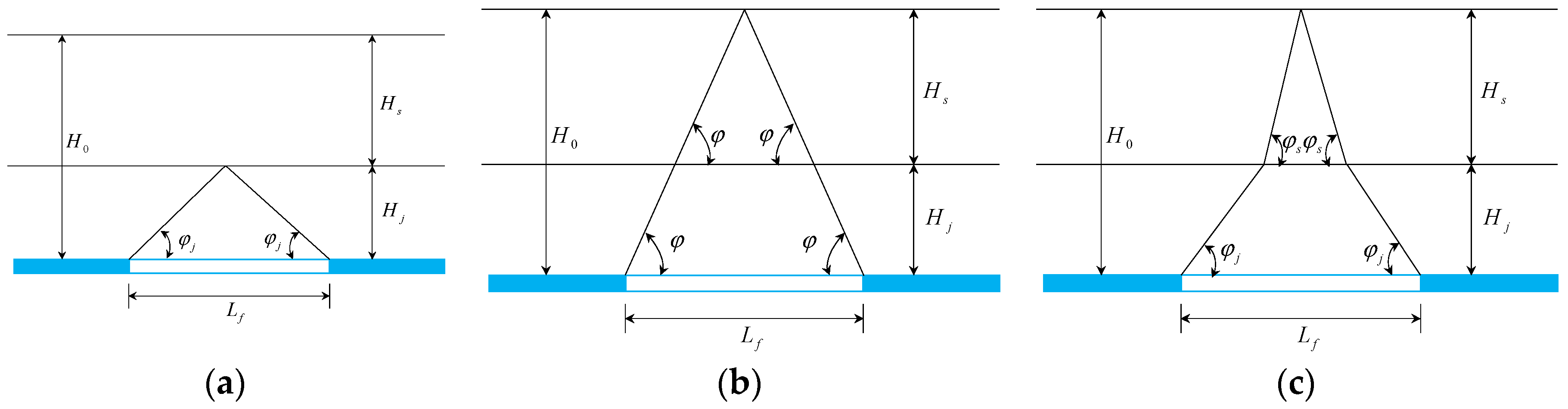

- Bedrock decision method: Determines final surface subsidence based only on the bedrock with no loose layer consideration. Obviously, the determined by this method is only suitable for a shallow loose layer, not applicable for mining areas with thick loose layers, such as those found in central and eastern China. This method’s calculation model is shown in Figure 6a and relating to the geometric relationship.

- (2)

- Comprehensive impact parameter method: Regards the loose layer and bedrock as a composite medium, so the bedrock and loose layers mining influence angle are equal. This method’s calculation model is seen in Figure 6b, with relating to the geometric relationship. This method ignores the mechanical properties difference between the loose layer and the bedrock, so errors exist. Generally speaking, the loose layer mining influence angle is larger than that of the bedrock.

- (3)

- Dual-medium method: The coal mining influence on the bedrock and loose layer deformation is considered comprehensively. The critical gob dimension obtained is close to the actual value. The calculation model is shown in Figure 6c. According to the geometric relationship, is determined as follows:

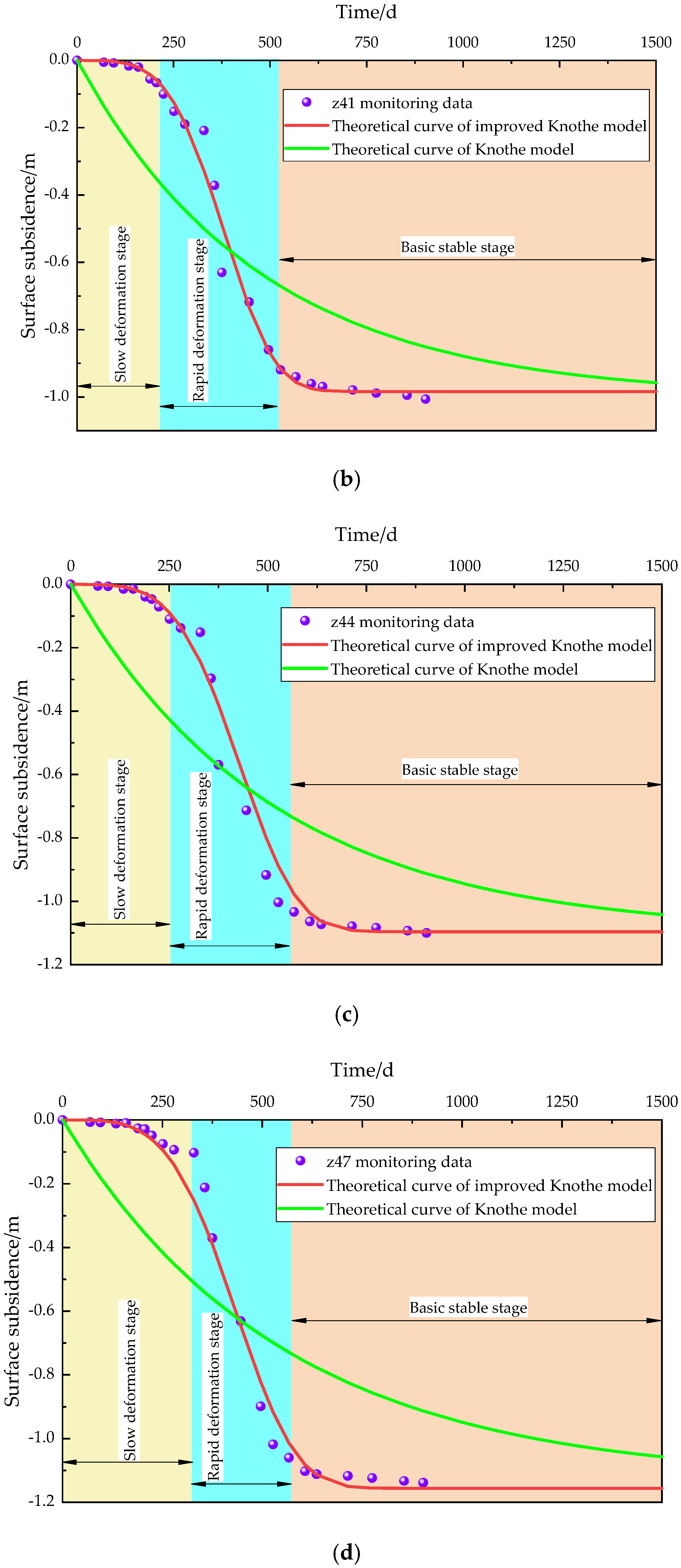

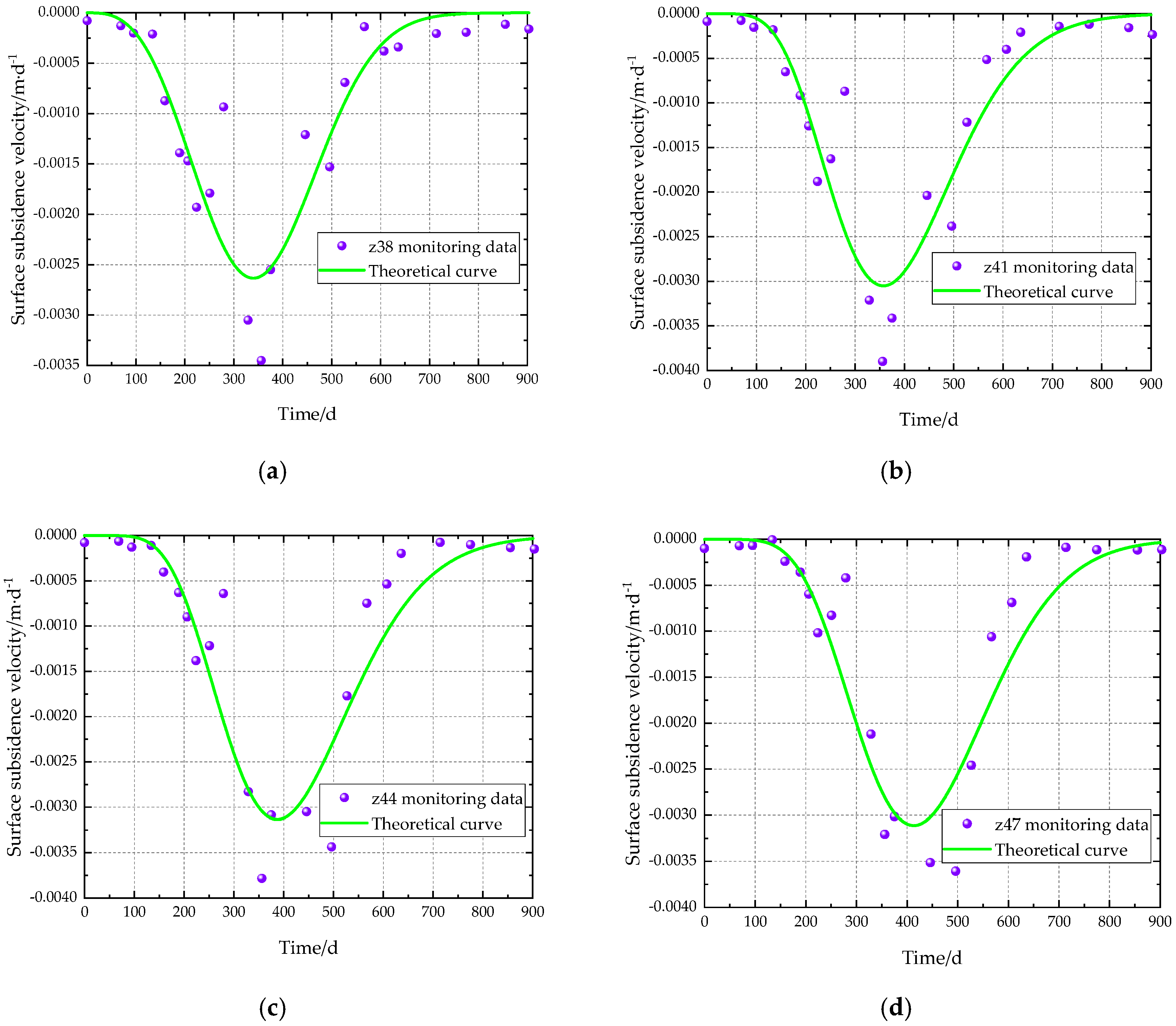

5. Model Validation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alam, M.S.; Kumar, D.; Chatterjee, R.S.; Upreti, V. Assessment of land surface subsidence due to underground metal mining using integrated spaceborne repeat-pass differential interferometric synthetic aperture radar (DInSAR) technique and ground based observations. J. Indian Soc. Remote Sens. 2018, 46, 1569–1580. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, S.S. Application of Artificial Neural Networks in Assessing Mining Subsidence Risk. Appl. Sci. 2020, 10, 1302. [Google Scholar] [CrossRef]

- Gueguen, Y.; Deffontaines, B.; Fruneau, B.; Al Heib, M.; De Michele, M.; Raucoules, D.; Guise, Y.; Planchenault, J. Monitoring residual mining subsidence of Nord/Pas-de-Calais coal basin from differential and Persistent Scatterer Interferometry (Northern France). J. Appl. Geophys. 2009, 69, 24–34. [Google Scholar] [CrossRef]

- Hejmanowski, R. Modeling of time dependent subsidence for coal and ore deposits. Int. J. Coal Sci. Technol. 2015, 2, 287–292. [Google Scholar] [CrossRef]

- Bai, E.; Guo, W.; Tan, Y.; Huang, G.; Guo, M.; Ma, Z. Roadway Backfill Mining with Super-High-Water Material to Protect Surface Buildings: A Case Study. Appl. Sci. 2019, 10, 107. [Google Scholar] [CrossRef]

- Marschalko, M.; Yilmaz, I.; Bednárik, M.; Kubecka, K. Influence of underground mining activities on the slope deformation genesis: Doubrava Vrchovec, Doubrava Ujala and Staric case studies from Czech Republic. Eng. Geol. 2012, 147, 37–51. [Google Scholar] [CrossRef]

- Williams, S.; Bock, Y.; Fang, P. Integrated satellite interferometry: Tropospheric noise, GPS estimates and implications for interferometric synthetic aperture radar products. J. Geophys. Res. Space Phys. 1998, 103, 27051–27067. [Google Scholar] [CrossRef]

- Kwinta, A.; Hejmanowski, R.; Sroka, A. A Time Function Analysis Used for the Prediction of Rock Mass Subsidence. In Proceedings of the International Symposium on Mining Science and Technology, Xuzhou, China, 16–18 October 1996; A.A. Balkema: Rotterdam, The Netherlands, 1996; pp. 419–424. [Google Scholar]

- Sheorey, P.; Loui, J.; Singh, K.; Singh, S. Ground subsidence observations and a modified influence function method for complete subsidence prediction. Int. J. Rock Mech. Min. Sci. 2000, 37, 801–818. [Google Scholar] [CrossRef]

- Lian, X.; Jarosz, A.; Saavedra-Rosas, J.; Dai, H.-Y. Extending dynamic models of mining subsidence. Trans. Nonferrous Met. Soc. China 2011, 21, s536–s542. [Google Scholar] [CrossRef]

- Tugrul, U.; Hakan, A.; Ozgur, Y. An integrated approach for the prediction of subsidence for coal mining basins. Eng. Geol. 2013, 166, 186–203. [Google Scholar]

- Hu, Q.; Deng, X.; Feng, R.; Li, C.; Wang, X.; Jiang, T. Model for calculating the parameter of the Knothe time function based on angle of full subsidence. Int. J. Rock Mech. Min. Sci. 2015, 78, 19–26. [Google Scholar] [CrossRef]

- Chen, B. Combining SAR interferometric phase and intensity information for monitoring of large gradient deformation in coal mining area. Eur. J. Remote. Sens. 2015, 48, 701–717. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Z.; Zhu, J.; Preusse, A.; Yi, H.; Hu, J.; Feng, G.; Papst, M. Retrieving 3-D Large Displacements of Mining Areas from a Single Amplitude Pair of SAR Using Offset Tracking. Remote Sens. 2017, 9, 338. [Google Scholar] [CrossRef]

- Rošer, J.; Potočnik, D.; Vulić, M. Analysis of Dynamic Surface Subsidence at the Underground Coal Mining Site in Velenje, Slovenia through Modified Sigmoidal Function. Minerals 2018, 8, 74. [Google Scholar] [CrossRef]

- Luo, H.; Li, Z.; Chen, J.; Pearson, C.; Wang, M.; Lv, W.; Ding, H. Integration of Range Split Spectrum Interferometry and conventional InSAR to monitor large gradient surface displacements. Int. J. Appl. Earth Obs. Geoinf. 2019, 74, 130–137. [Google Scholar] [CrossRef]

- Knothe, S. Effect of time on formation of basin subsidence. Arch. Min. Steel Ind. 1953, 1, 1–7. [Google Scholar]

- Gonzalez-Nicieza, C.; Alvarez-Fernandez, M.I.; Menéndez-Díaz, A.; Álvarez-Vigil, A.E. The influence of time on subsidence in the Central Asturian Coalfield. Bull. Int. Assoc. Eng. Geol. 2007, 66, 319–329. [Google Scholar] [CrossRef]

- Chen, Q.-J.; Hang, M. Dynamic Reclamation Methods for Subsidence Land in the Mining Area with High Underground Water Level. Open Geosci. 2018, 10, 639–646. [Google Scholar] [CrossRef]

- Kowalski, A. Surface subsidence and rate of its increaments based on measurements and theory. Arch. Min. Sci. 2001, 46, 391–406. [Google Scholar]

- Tang, J.; Wang, J.A.; Wang, L. Dynamic laws and characteristics of surface movement induced by mining under thin alluviumv. Rock Soil Mech. 2014, 35, 2958–2968. [Google Scholar]

- Nie, L.; Wang, H.; Xu, Y. Application of the arctangent function model in the prediction of ground mining subsidence deformation: A case study from Fushun City, Liaoning Province, China. Bull. Int. Assoc. Eng. Geol. 2016, 76, 1383–1398. [Google Scholar] [CrossRef]

- Xi, G.J.; Hong, X.; Shao, H.Q. Application of improved Logistic function model to prediction of surface subsidence. Coal Sci. Technol. 2013, 41, 114–117. [Google Scholar]

- Asadi, A.; Shakhriar, K.; Goshtasbi, K. Profiling Function for Surface Subsidence Prediction in Mining Inclined Coal Seams. J. Min. Sci. 2004, 40, 142–146. [Google Scholar] [CrossRef]

- Cai, Y.; Li, X.; Xiao, W.; Zhang, W. Simulation of Mining-Induced Ground Damage Using Orthogonal Experiments to Determine Key Parameters of Super-Large Coalface: A Case Study in Shendong Coalfield in China. Appl. Sci. 2020, 10, 2258. [Google Scholar] [CrossRef]

- Nie, L.; Wang, H.; Xu, Y.; Li, Z. A new prediction model for mining subsidence deformation: The arc tangent function model. Nat. Hazards 2014, 75, 2185–2198. [Google Scholar] [CrossRef]

- Iwanec, A.S.; Carter, J.; Hambleton, J. Geomechanics of subsidence above single and multi-seam coal mining. J. Rock Mech. Geotech. Eng. 2016, 8, 304–313. [Google Scholar] [CrossRef]

- Chang, Z.Q.; Wang, J.Z. Study on time function of surface subsidence—The improved Knothe time function. Chin. J. Rock Mech. Eng. 2003, 22, 1496. [Google Scholar]

- Cui, X.M.; Miao, X.X.; Zhao, Y.L.; Jin, R.P. Discussion on the time function of time dependent surface movement. J. China Coal Soc. 1999, 24, 454–456. [Google Scholar]

- Cui, X.; Wang, J.; Liu, Y. Prediction of progressive surface subsidence above longwall coal mining using a time function. Int. J. Rock Mech. Min. Sci. 2001, 38, 1057–1063. [Google Scholar] [CrossRef]

- Wang, B.; Xu, J.; Xuan, D. Time function model of dynamic surface subsidence assessment of grout-injected overburden of a coal mine. Int. J. Rock Mech. Min. Sci. 2018, 104, 1–8. [Google Scholar] [CrossRef]

| Observation Times | Observation Date | Relative Observation (Time/d) | z38 Settlement (Value/mm) | z41 Settlement (Value/mm) | z44 Settlement (Value/mm) | z47 Settlement (Value/mm) |

|---|---|---|---|---|---|---|

| 1 | 2010/10/18 | 0 | 0 | 0 | 0 | 0 |

| 2 | 2010/12/27 | 69 | −5.4 | −6.0 | −5.4 | −6.8 |

| 3 | 2011/1/23 | 95 | −10.0 | −7.7 | −6.6 | −7.9 |

| 4 | 2011/3/2 | 134 | −18.8 | −17.1 | −14.9 | −11.5 |

| 5 | 2011/3/27 | 159 | −23.7 | −20.1 | −15.0 | −9.5 |

| 6 | 2011/4/27 | 189 | −70.2 | −55.6 | −39.1 | −26.3 |

| 7 | 2011/5/14 | 206 | −91.2 | −66.7 | −46.9 | −28.9 |

| 8 | 2011/6/2 | 224 | −122.0 | −100.3 | −71.0 | −47.6 |

| 9 | 2011/6/29 | 251 | −180.2 | −151.5 | −109.5 | −74.5 |

| 10 | 2011/7/27 | 279 | −220.2 | −189.6 | −137.7 | −92.9 |

| 11 | 2011/9/17 | 329 | −242.2 | −208.5 | −151.4 | −102.1 |

| 12 | 2011/10/14 | 356 | −394.9 | −371.8 | −296.8 | −211.6 |

| 13 | 2011/11/3 | 375 | −604.3 | −630.0 | −569.4 | −370.4 |

| 14 | 2012/1/14 | 446 | −648.9 | −717.8 | −713.0 | −630.8 |

| 15 | 2012/3/4 | 496 | −738.2 | −859.9 | −916.9 | −898.7 |

| 16 | 2012/4/5 | 527 | −778.0 | −919.5 | −1003.5 | −1018.2 |

| 17 | 2012/5/15 | 567 | −782.0 | −940.1 | −1033.4 | −1060.6 |

| 18 | 2012/6/25 | 607 | −789.0 | −960.7 | −1063.4 | −1103.0 |

| 19 | 2012/7/24 | 636 | −806.0 | −969.0 | −1072.8 | −1112.1 |

| 20 | 2012/10/12 | 714 | −813.3 | −979.1 | −1078.3 | −1117.4 |

| 21 | 2012/12/13 | 775 | −832,7 | −988.7 | −1083.2 | −1123.9 |

| 22 | 2013/3/3 | 855 | −838.2 | −995.2 | −1092.7 | −1133.5 |

| 23 | 2013/4/21 | 903 | −845.9 | −1006.4 | −1099.8 | −1138.9 |

| Model Parameter | Monitoring Points | Average Value | |||

|---|---|---|---|---|---|

| z38 | z41 | z44 | z47 | ||

| C | 1.62 × 10−10 | 1.30 × 10−10 | 0.85 × 10−10 | 1.16 × 10−10 | 1.23 × 10−10 |

| n | 3.52 | 4.01 | 4.04 | 3.94 | 3.88 |

| Monitoring Points | Improved Knothe Time Function Model | Knothe Time Function Model | ||

|---|---|---|---|---|

| m/mm | f/% | m/mm | f/% | |

| z38 | 37.6 | 4.6 | 174.5 | 21.3 |

| z41 | 42.5 | 4.3 | 219.7 | 22.3 |

| z44 | 61.9 | 5.7 | 259.7 | 23.7 |

| z47 | 52.9 | 4.6 | 286.3 | 24.8 |

| Average value | 48.7 | 4.8 | 235.1 | 23 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Cheng, H.; Yao, Z.; Wang, X. Application of the Improved Knothe Time Function Model in the Prediction of Ground Mining Subsidence: A Case Study from Heze City, Shandong Province, China. Appl. Sci. 2020, 10, 3147. https://doi.org/10.3390/app10093147

Zhang L, Cheng H, Yao Z, Wang X. Application of the Improved Knothe Time Function Model in the Prediction of Ground Mining Subsidence: A Case Study from Heze City, Shandong Province, China. Applied Sciences. 2020; 10(9):3147. https://doi.org/10.3390/app10093147

Chicago/Turabian StyleZhang, Liangliang, Hua Cheng, Zhishu Yao, and Xiaojian Wang. 2020. "Application of the Improved Knothe Time Function Model in the Prediction of Ground Mining Subsidence: A Case Study from Heze City, Shandong Province, China" Applied Sciences 10, no. 9: 3147. https://doi.org/10.3390/app10093147

APA StyleZhang, L., Cheng, H., Yao, Z., & Wang, X. (2020). Application of the Improved Knothe Time Function Model in the Prediction of Ground Mining Subsidence: A Case Study from Heze City, Shandong Province, China. Applied Sciences, 10(9), 3147. https://doi.org/10.3390/app10093147