Binary Mixes of Self-Compacting Concrete with Municipal Solid Waste Incinerator Bottom Ash

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cement, MIBA and Fly Ash

2.2. Aggregates

2.3. Water-Reducing Admixture and Water

2.4. Mix Design

2.5. Test Methods and Sample Preparation

3. Results and Discussion

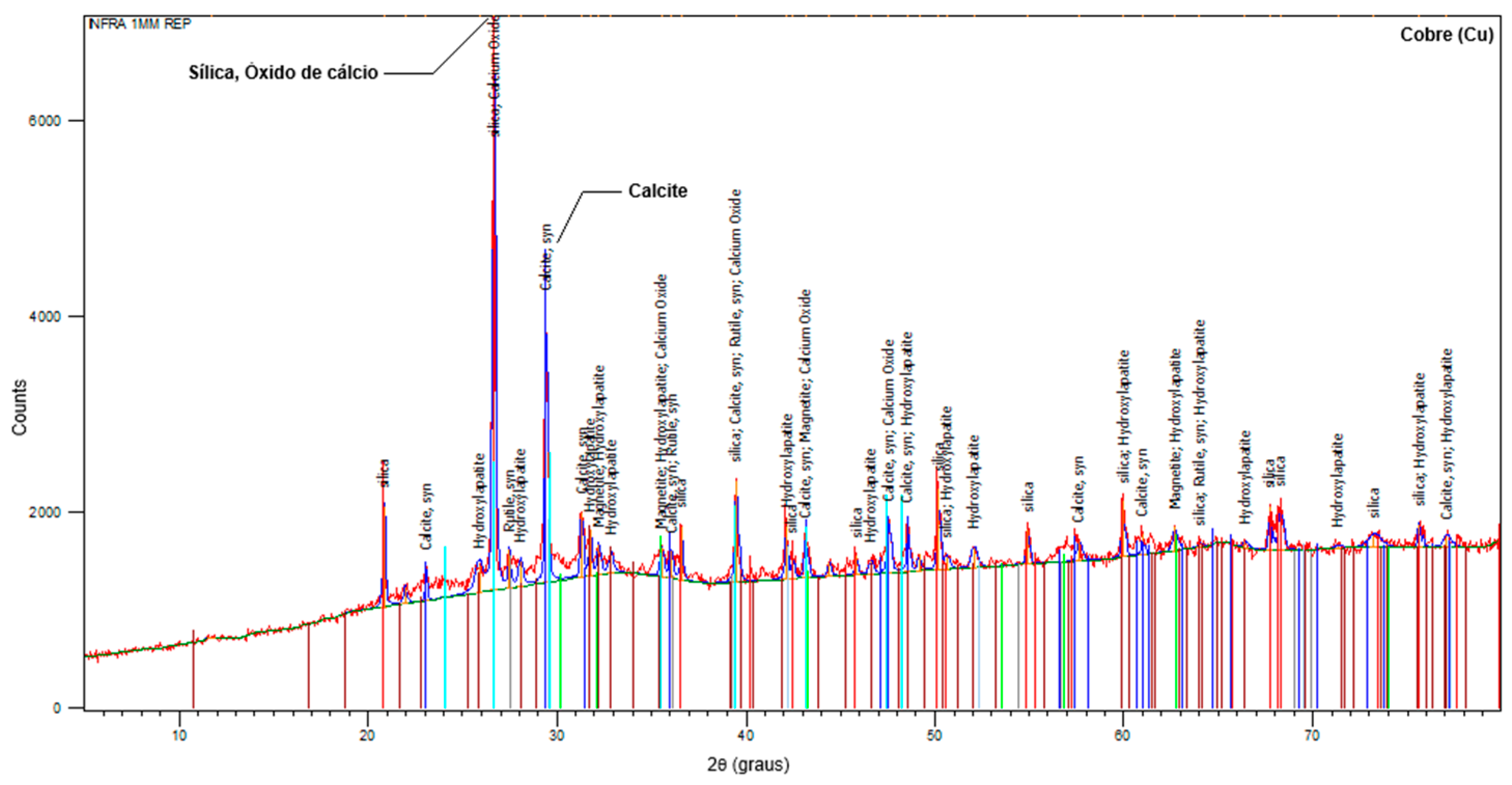

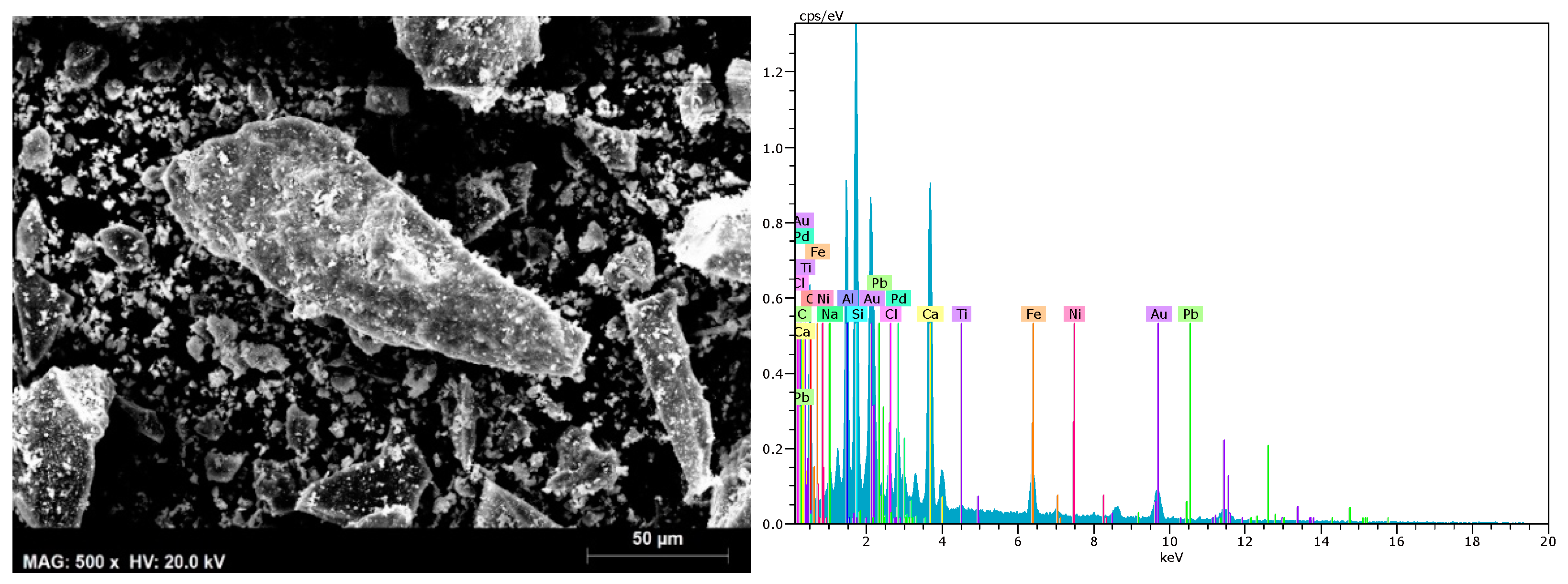

3.1. Characterization of the Materials

3.2. Properties of Aggregates

3.3. Fresh State Performance

3.4. Mechanical Performance

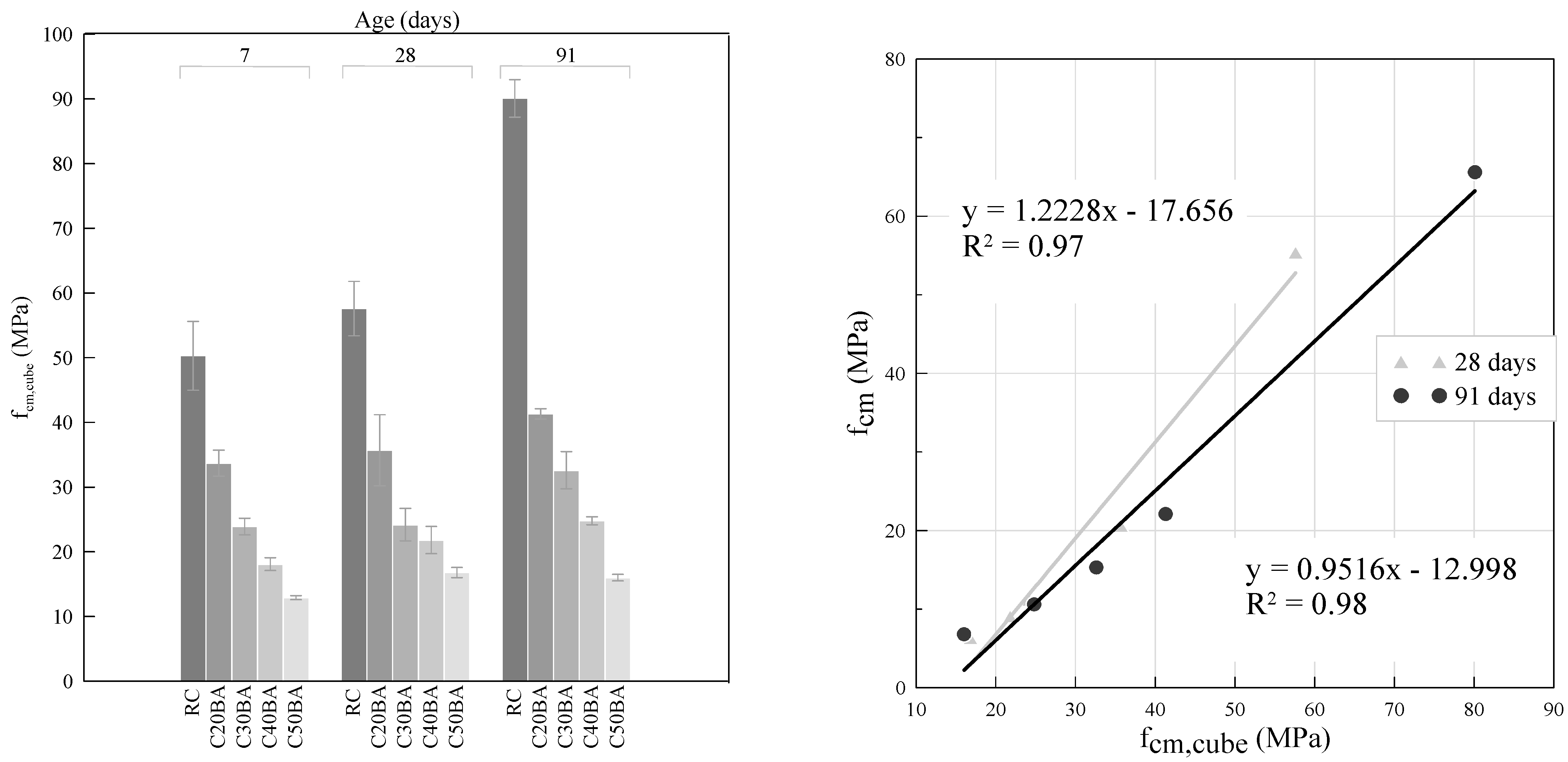

3.4.1. Compressive Strength

3.4.2. Splitting Tensile Strength

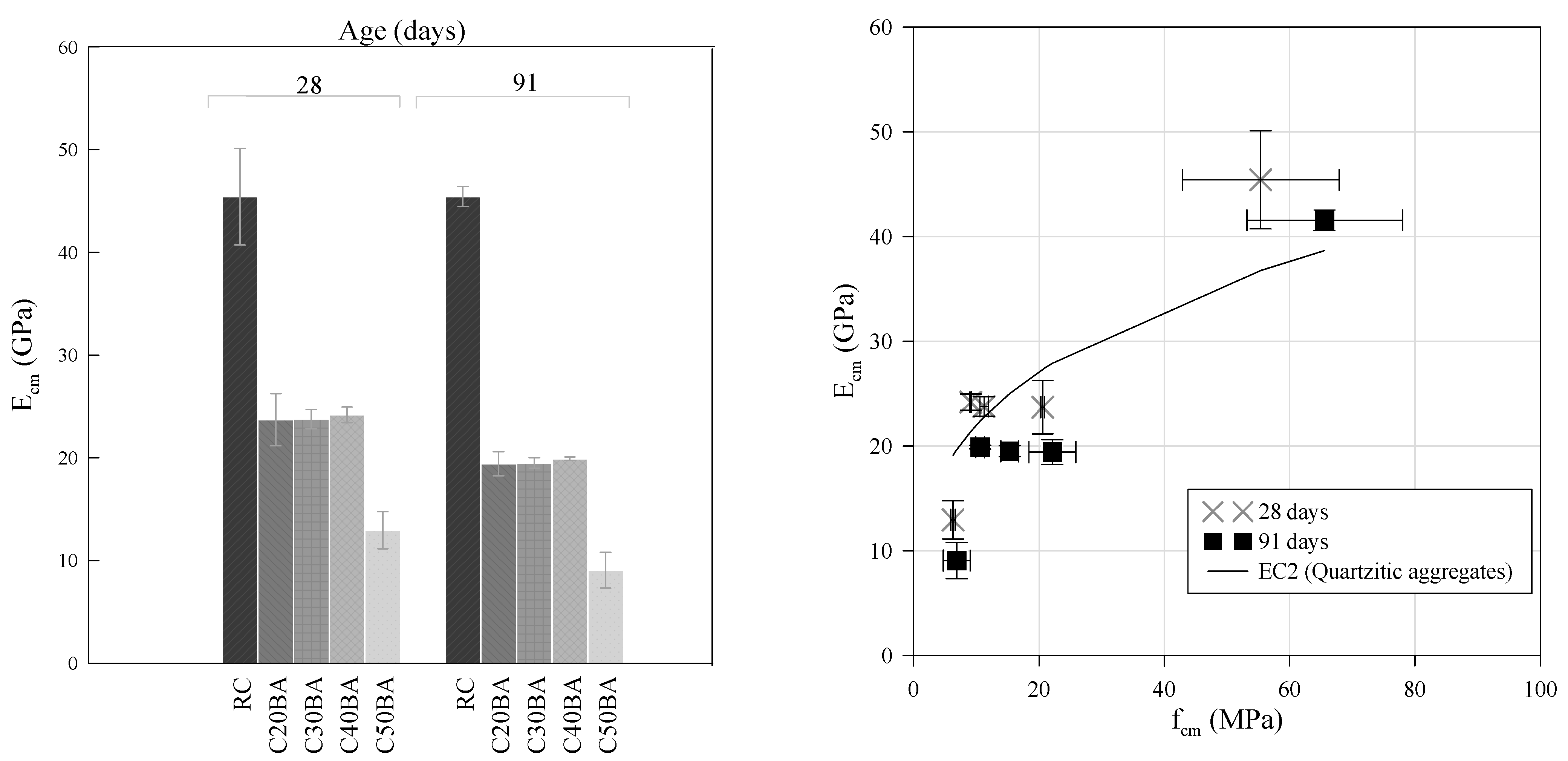

3.4.3. Secant Modulus of Elasticity

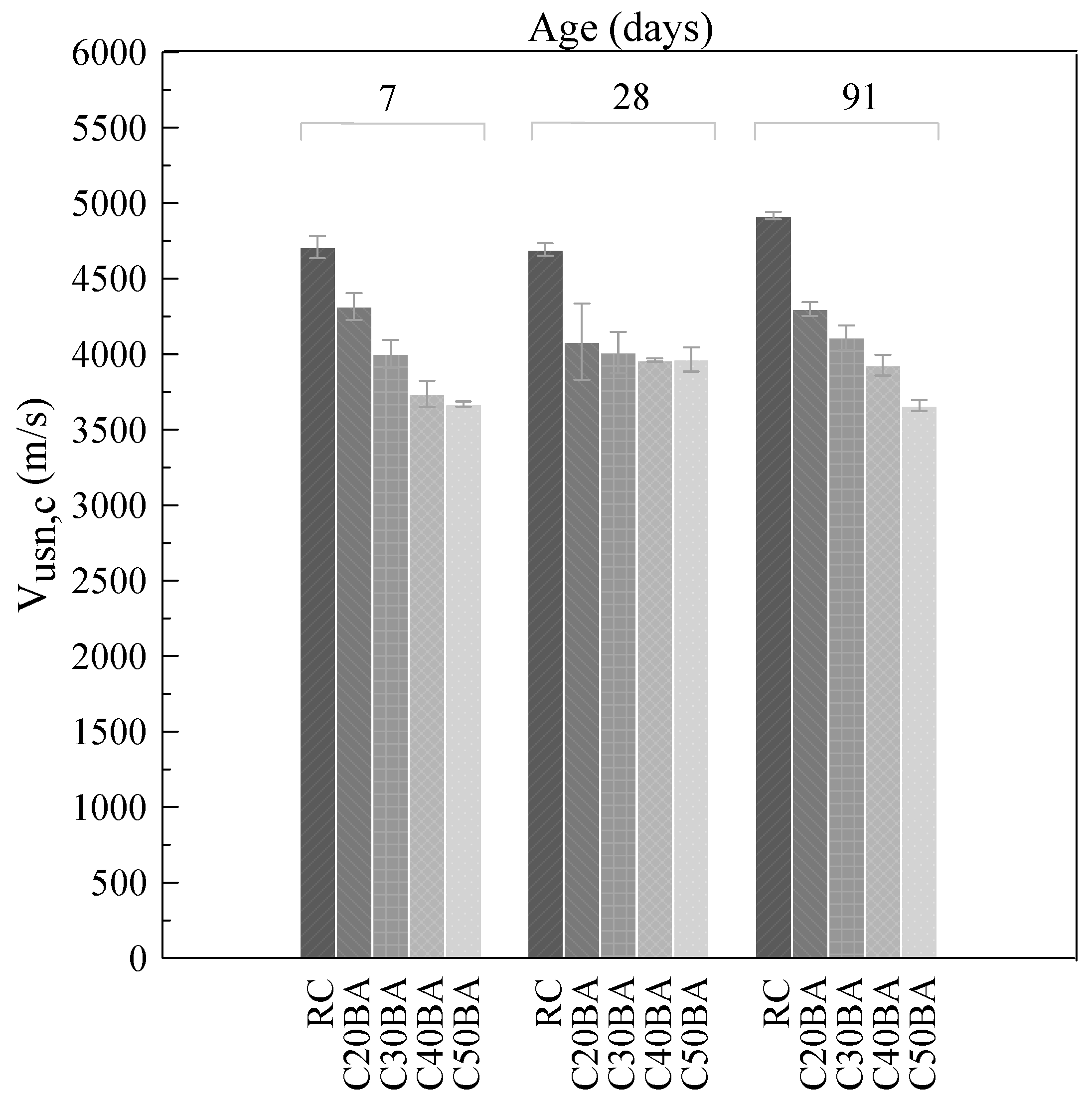

3.4.4. Ultrasonic Pulse Velocity

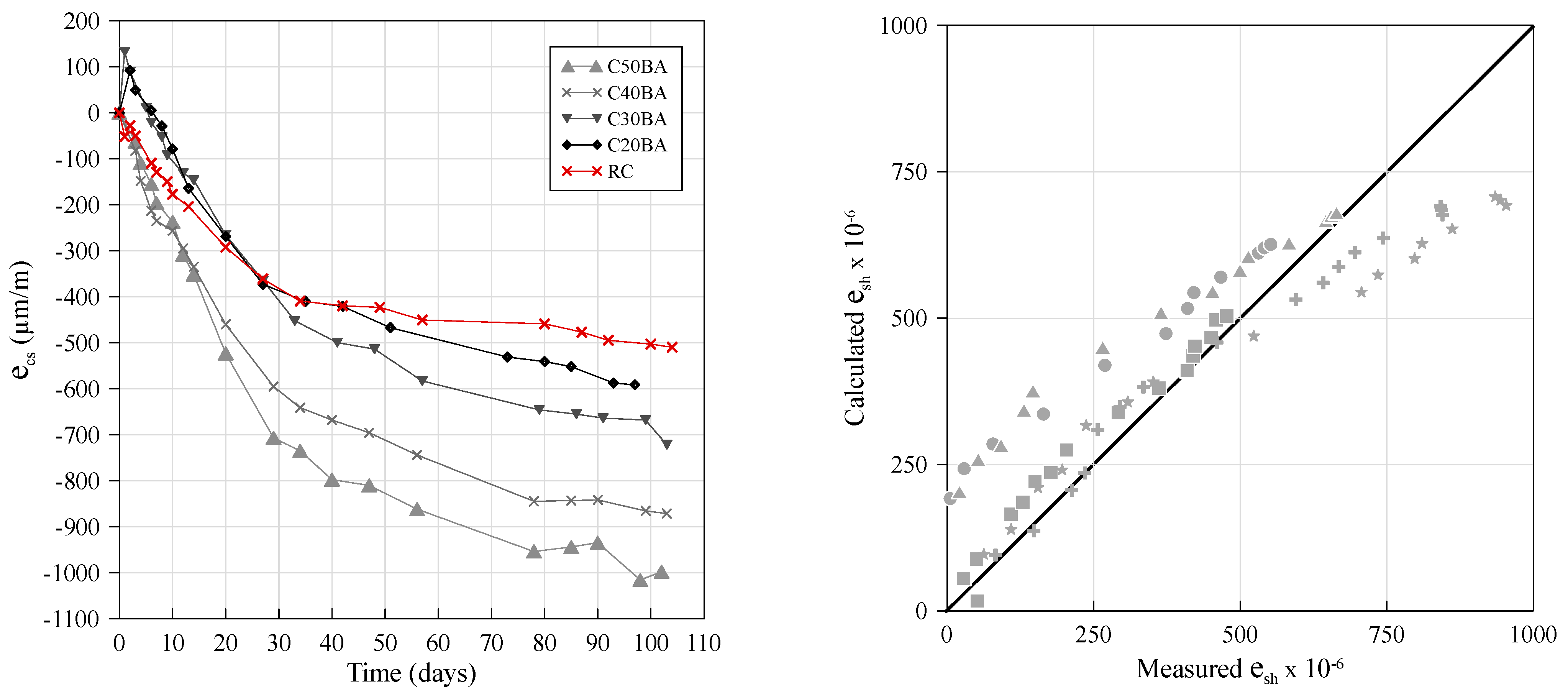

3.4.5. Shrinkage

3.5. Durability-Related Performance

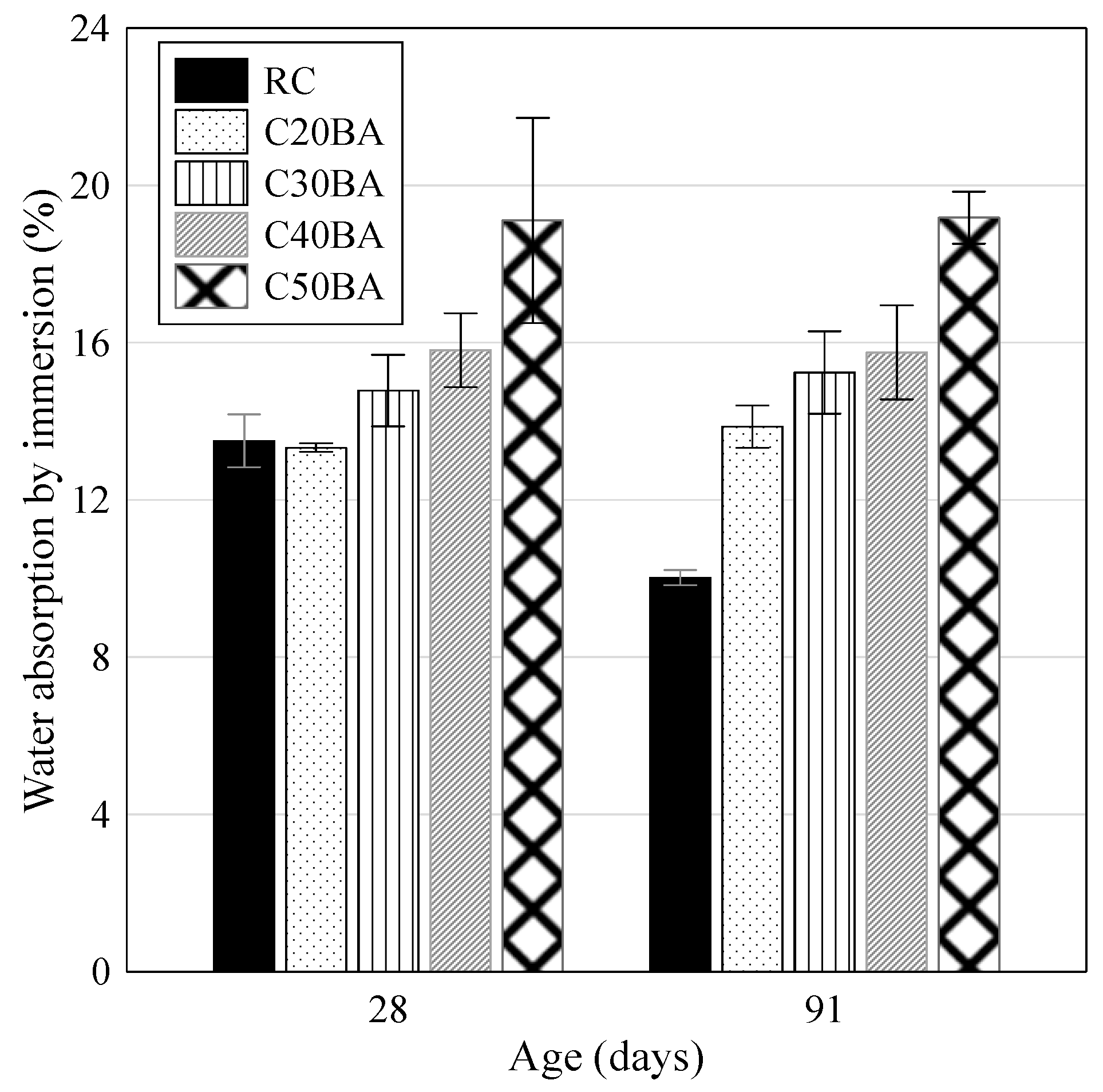

3.5.1. Water Absorption by Immersion

3.5.2. Water Absorption by Capillary Action

3.5.3. Carbonation

3.5.4. Chloride Ion Migration

3.5.5. Electrical Resistivity

4. Conclusions

- In the slump-flow and V-funnel tests, all mixes presented fluidity, flow rate and viscosity perfectly adjusted to that established in the normative requirements. As for the flow requirements in the L-box test, the mixes C20BA and C50BA presented the worst performance. Even so, the results were deemed as acceptable and, together with the visual analysis carried out during the execution of the test, it is possible to ensure that the produced SCCs present adequate fluidity and flow capacity.

- As for the mechanical performance, the C20BA mixture presents the most favourable overall results of mixes containing MIBA. The rest of the mixtures present considerably higher performance losses, particularly the mixtures C40BA and C50BA, which did not present enough compressive strength for a real structural situation.

- Regarding the durability-related performance, SCCs produced with MIBA present a promising behaviour. The C20BA mixture stood out as the most advantageous mixture with MIBA, presenting values very similar to those of the RC mixture for most of the studied properties. The C50BA mixture, on the other hand, presented the worst behaviour of all the mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lindsey, R. Climate Change: Atmospheric Carbon Dioxide. Available online: https://www.climate.gov/news-features/understanding-climate/climate-change-atmospheric-carbon-dioxide (accessed on 29 June 2021).

- Department of Trade and Industry. Our Energy Future—Creating a Low Carbon Economy; Department of Trade and Industry (DTI): London, UK, 2003; p. 144. [Google Scholar]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Rodgers, L. Climate Change: The Massive CO2 Emitter You May Not Know About. Available online: https://www.bbc.com/news/science-environment-46455844 (accessed on 29 June 2021).

- Zhang, T.; Gao, P.; Gao, P.; Wei, J.; Yu, Q. Effectiveness of novel and traditional methods to incorporate industrial wastes in cementitious materials—An overview. Resour. Conserv. Recy. 2013, 74, 134–143. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Dhir, R.K.; De Brito, J.; Lynn, C.J.; Silva, R.V. Sustainable Construction Materials: Municipal Incinerator Bottom Ash; Woodhead Publishing: Duxford, UK, 2018. [Google Scholar]

- Hoornweg, D.; Bhada-Tata, P. What a waste: A global review of solid waste management. Urban. Dev. Ser. Knowl. Pap. 2012, 15, 1–98. [Google Scholar]

- DA_58. Aeiru—Agregados Artificiais de Escórias de Incineração de Resíduos Urbanos para Pavimentos Rodoviários; Laboratório Nacional de Engenharia Civil (LNEC): Lisboa, Protugal, 2015; p. 8. (In Portuguese) [Google Scholar]

- Amat, R.C.; Ismail, K.N.; Noor, N.M.; Ibrahim, N.M. The Effects of Bottom Ash from Mswi Used as Mineral Additions in Concrete. In Proceedings of the MATEC Web of Conferences, EDP Sciences, Ho Chi Minh City, Vietnam, 5–6 August 2016; p. 01053. [Google Scholar]

- Jurič, B.; Hanžič, L.; Ilić, R.; Samec, N. Utilization of municipal solid waste bottom ash and recycled aggregate in concrete. Waste Manag. 2006, 26, 1436–1442. [Google Scholar] [CrossRef]

- Lin, K.; Lin, D. Hydration characteristics of municipal solid waste incinerator bottom ash slag as a pozzolanic material for use in cement. Cem. Concr. Compos. 2006, 28, 817–823. [Google Scholar] [CrossRef]

- Cheng, A. Effect of incinerator bottom ash properties on mechanical and pore size of blended cement mortars. Mater. Des. 2012, 36, 859–864. [Google Scholar] [CrossRef]

- Simões, B.; da Silva, P.R.; Silva, R.V.; Avila, Y.; Forero, J.A. Ternary mixes of self-compacting concrete with fly ash and municipal solid waste incinerator bottom ash. Appl. Sci. 2021, 11, 107. [Google Scholar] [CrossRef]

- EN-197-1. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2011; p. 50. [Google Scholar]

- EN-450-1. Fly Ash for Concrete. Definition, Specifications and Conformity Criteria; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2012; p. 34. [Google Scholar]

- EN-12620:2002+A1:2008. Aggregates for Concrete; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2008; p. 56. [Google Scholar]

- EN-1008. Mixing Water for Concrete—Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2002; p. 22. [Google Scholar]

- EN-934-1. Admixtures for Concrete, Mortar and Grout. Common Requirements; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2008; p. 14. [Google Scholar]

- EN-934-2. Admixtures for Concrete, Mortar and Grout. Concrete Admixtures. Definitions, Requirements, Conformity, Marking and Labelling; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2012; p. 28. [Google Scholar]

- Nepomuceno, M.; Oliveira, L.; Lopes, S.M.R. Methodology for mix design of the mortar phase of self-compacting concrete using different mineral additions in binary blends of powders. Constr. Build. Mater. 2012, 26, 317–326. [Google Scholar] [CrossRef]

- Silva, P.; De Brito, J.; Costa, J. Viability of two new mixture design methodologies for self-consolidating concrete. ACI Mater. J. 2011, 108, 579–588. [Google Scholar]

- Ferraz, E.; Andrejkovičová, S.; Hajjaji, W.; Velosa, A.; Santos Silva, A.; Rocha, F. Pozzolanic activity of metakaolins by the french standard of the modified chapelle test: A direct methology. Acta Geodyn. Geomater. 2015, 12, 289–298. [Google Scholar] [CrossRef] [Green Version]

- NBR-15895. Materiais Pozolânicos—Determinação do teor de Hidróxido de Cálcio Fixado—Método de Chapelle Modificado; Brazilian Association for Technical Norms (Associação Brasileira de Normas Técnicas—ABNT): Rio de Janeiro, Brasil, 2010; p. 10. [Google Scholar]

- EN-12350-8. Testing Fresh Concrete. Self-Compacting Concrete. Slump-Flow Test; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2019; p. 14. [Google Scholar]

- EN-12350-9. Testing Fresh Concrete. Self-Compacting Concrete. V-Funnel Test; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2010; p. 12. [Google Scholar]

- EN-12350-10. Testing Fresh Concrete. Self-Compacting Concrete. L Box Test; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2010; p. 14. [Google Scholar]

- EN-12390-3. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2009; p. 22. [Google Scholar]

- EN-12390-6. Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2009; p. 14. [Google Scholar]

- LNEC-E397. Concrete: Determination of the Modulus of Elasticity under Compression; National Laboratory in Civil Engineering (Laboratório Nacional de Engenharia Civil—LNEC): Lisbon, Portugal, 1993; p. 2. (In Portuguese) [Google Scholar]

- EN-12504-4. Testing Concrete. Determination of Ultrasonic Pulse Velocity; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2004; p. 18. [Google Scholar]

- LNEC-E398. Concrete: Determination of Drying Shrinkage and Expansion; National Laboratory in Civil Engineering (Laboratório Nacional de Engenharia Civil—LNEC): Lisbon, Portugal, 1993; p. 2. (In Portuguese) [Google Scholar]

- LNEC-E391. Concrete: Determination of Carbonation Resistance; National Laboratory in Civil Engineering (Laboratório Nacional de Engenharia Civil—LNEC): Lisbon, Portugal, 1993; p. 2. (In Portuguese) [Google Scholar]

- LNEC-E394. Concrete: Determination of Water Absorption by Immersion—Testing at Atmospheric Pressure; National Laboratory in Civil Engineering (Laboratório Nacional de Engenharia Civil—LNEC): Lisbon, Portugal, 1993; p. 2. (In Portuguese) [Google Scholar]

- LNEC-E463. Concrete: Determination of the Chloride ion Diffusion Coefficient by Non-Steady State Migration; National Laboratory in Civil Engineering (Laboratório Nacional de Engenharia Civil—LNEC): Lisbon, Portugal, 2004; p. 8. (In Portuguese) [Google Scholar]

- Luping, T. Guidelines for Practical Use of Methods for Testing the Resistance of Concrete to Chloride Ingress; CHLORTEST—EU Funded Research Project under 5FP GROWTH Programme; Swedich National Testing and Research Institute: Karlskrona, Sweden, 2005; p. 271. [Google Scholar]

- Raverdy, M.; Brivot, F.; Paillere, A.M.; Dron, R. Appreciation of pozzolanic reactivity of secondary components. In Proceedings of the 7eme Congres International de la Chimie Des Ciments, Paris, France, 30 June–4 July 1980. (In French). [Google Scholar]

- ASTM-C618. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2019; p. 5. [Google Scholar]

- EN-206:2013+A1:2016. Concrete—Specification, Performance, Production and Conformity; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2016; p. 98. [Google Scholar]

- Zajac, M.; Rossberg, A.; Le Saout, G.; Lothenbach, B. Influence of limestone and anhydrite on the hydration of portland cements. Cem. Concr. Compos. 2014, 46, 99–108. [Google Scholar] [CrossRef]

- Kim, J.; An, J.; Nam, B.H.; Tasneem, K.M. Investigation on the side effects of municipal solid waste incineration ashes when used as mineral addition in cement-based material. Road Mater. Pavement Des. 2016, 17, 345–364. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S. Municipal incinerated bottom ash use as a cement component in concrete. Mag. Concr. Res. 2017, 69, 512–525. [Google Scholar] [CrossRef] [Green Version]

- Loginova, E.; Schollbach, K.; Proskurnin, M.; Brouwers, H.J.H. Municipal solid waste incineration bottom ash fines: Transformation into a minor additional constituent for cements. Resour. Conserv. Recycl. 2021, 166, 105354. [Google Scholar] [CrossRef]

- Pera, J.; Coutaz, L.; Ambroise, J.; Chababbet, M. Use of incinerator bottom ash in concrete. Cem. Concr. Res. 1997, 27, 1–5. [Google Scholar] [CrossRef]

- Li, X.-G.; Lv, Y.; Ma, B.-G.; Chen, Q.-B.; Yin, X.-B.; Jian, S.-W. Utilization of municipal solid waste incineration bottom ash in blended cement. J. Clean. Prod. 2012, 32, 96–100. [Google Scholar] [CrossRef]

- EN-1992-1-1:2004+A1:2014. Eurocode 2—Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2014; p. 259. [Google Scholar]

- Dwivedi, A.; Jain, M.K. Fly ash—Waste management and overview: A review. Recent Res. Sci. Technol. 2014, 6, 30–35. [Google Scholar]

- Bertolini, L.; Carsana, M.; Cassago, D.; Curzio, A.Q.; Collepardi, M. Mswi ashes as mineral additions in concrete. Cem. Concr. Res. 2004, 34, 1899–1906. [Google Scholar] [CrossRef]

- Ravasan, F.M. Characterization and mechanical properties of concrete mixtures made with sedimentary lime and industrial incinerator ash. Malays. J. Civ. Eng. 2014, 26, 1–18. [Google Scholar]

- Pokorný, P.; Dobiáś, D.; Čítek, D. The influence of corrosion of zinc powder on mechanical properties of concrete. Ceram. Silikáty 2016, 60, 195–199. [Google Scholar] [CrossRef]

- Breysse, D. Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques: State-Of-The-Art Report of the Rilem Technical Committee 207-Inr; Springer Science & Business Media: Amsterdam, The Netherlands, 2012; p. 374. [Google Scholar]

- Whittaker, M.; Taylor, R.; Li, S.; Li, Q.; Black, L. The behaviour of finely ground bottom ash in portland cement. In Proceedings of the 29th Cement and Concrete Science Conference, Leeds, UK, 7–8 September 2009; pp. 70–73. [Google Scholar]

- Nithiya, A.; Saffarzadeh, A.; Shimaoka, T. Hydrogen gas generation from metal aluminum-water interaction in municipal solid waste incineration (mswi) bottom ash. Waste Manag. 2018, 73, 342–350. [Google Scholar] [CrossRef]

- Lin, K.L. The influence of municipal solid waste incinerator fly ash slag blended in cement pastes. Cem. Concr. Res. 2005, 35, 979–986. [Google Scholar] [CrossRef]

- Van Der Wegen, G.; Hofstra, U.; Speerstra, J. Upgraded mswi bottom ash as aggregate in concrete. Waste Biomass Valori. 2013, 4, 737–743. [Google Scholar] [CrossRef]

- Chinthakunta, R.; Ravella, D.P.; Sri Rama Chand, M.; Janardhan Yadav, M. Performance evaluation of self-compacting concrete containing fly ash, silica fume and nano titanium oxide. Mater. Today: Proc. 2021, 43, 2348–2354. [Google Scholar]

- Silva, P.; de Brito, J. Experimental study of the mechanical properties and shrinkage of self-compacting concrete with binary and ternary mixes of fly ash and limestone filler. Eur. J. Environ. Civ. Eng. 2017, 21, 430–453. [Google Scholar] [CrossRef]

- da Silva, P.R.; de Brito, J. Durability performance of self-compacting concrete (scc) with binary and ternary mixes of fly ash and limestone filler. Mater. Struct. 2016, 49, 2749–2766. [Google Scholar] [CrossRef]

| Mix Proportions | RC | C20BA | C30BA | C40BA | C50BA |

|---|---|---|---|---|---|

| (kg/m3) | |||||

| Cement | 482 | 496 | 452 | 387 | 323 |

| FA | 151 | - | - | - | - |

| MIBA | - | 99 | 154 | 206 | 257 |

| Sp | 4.8 | 5.9 | 6 | 5.9 | 5.8 |

| Water | 176 | 197 | 206 | 206 | 206 |

| Fine aggregate 0/2 | 354 | 318 | 332 | 332 | 332 |

| Fine aggregate 0/4 | 350 | 314 | 328 | 328 | 328 |

| Coarse aggregate 1 | 384 | 419 | 384 | 384 | 384 |

| Coarse aggregate 2 | 391 | 427 | 391 | 391 | 391 |

| Materials | Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | SiO2 | SO3 | Cl- | IR | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CEM I (%) | 5.24 | 62.7 | 3.17 | - | 2.23 | - | 19.6 | 3.13 | 0.01 | 1.37 | 2.94 |

| Fly ash (%) | 24.7 | 2.63 | 5.40 | 1.11 | 1.01 | 0.89 | 54.7 | 1.38 | <0.01 | - | 5.10 |

| MIBA (%) | 4.10 | 23.0 | 9.21 | 1.57 | 2.37 | 2.40 | 51.8 | 2.42 | 0.70 | - | 2.40 |

| Sive Size (mm) | Cumulative Pass Amount (%) | |||

|---|---|---|---|---|

| Fine Aggregate | Coarse Aggregate | |||

| Sand 0/2 | Sand 0/4 | Gravel 1 | Gravel 2 | |

| 22.4 | 100.0 | 100.0 | 100.0 | 100.0 |

| 16 | 100.0 | 100.0 | 100.0 | 83.4 |

| 11.2 | 100.0 | 100.0 | 80.1 | 30.0 |

| 8 | 100.0 | 100.0 | 39.2 | 4.4 |

| 5.6 | 100.0 | 99.5 | 5.7 | 2.6 |

| 4 | 100.0 | 98.2 | 1.2 | 1.6 |

| 2 | 99.9 | 89.1 | 0.7 | 1.3 |

| 1 | 99.4 | 59.4 | 0.5 | 0.9 |

| 0.5 | 80.7 | 21.5 | 0.5 | 0.5 |

| 0.25 | 16.1 | 3.5 | 0.4 | 0.3 |

| 0.125 | 0.3 | 0.3 | 0.2 | 0.1 |

| 0.063 | 0.0 | 0.0 | 0.0 | 0.0 |

| Fineness modulus | 2.04 | 3.28 | 6.57 | 7.08 |

| Mixes | Slump-Flow | V-Funnel | L Box | |

|---|---|---|---|---|

| t500 (s) | SF (mm) | Tv (s) | PL (H2/H1) | |

| RC | 2.7 | 680 | 5.6 | 0.9 |

| C20BA | 2.7 | 600 | 3.6 | 0.8 |

| C30BA | 2.9 | 645 | 2.7 | 0.9 |

| C40BA | 3.4 | 560 | 2.5 | 1.0 |

| C50BA | 3.7 | 550 | 2.2 | 0.8 |

| Mix | 7 days | 28 days | 91 days | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| fcm,cube | σfcm,cube | fcm,cube | σfcm,cube | fcm | σfcm | fcm,cube | σfcm,cube | fcm | σfcm | |

| RC | 50.3 | 5.3 | 57.6 | 4.2 | 55.4 | 12.5 | 80.1 | 2.9 | 65.6 | 12.4 |

| C20BA | 33.7 | 2.0 | 35.7 | 5.5 | 20.6 | 0.3 | 41.3 | 0.8 | 22.1 | 3.7 |

| C30BA | 23.9 | 1.3 | 24.2 | 2.5 | 11.2 | 0.7 | 32.6 | 2.9 | 15.3 | 1.4 |

| C40BA | 18.1 | 1.0 | 21.8 | 2.1 | 9.1 | 0.1 | 24.8 | 0.6 | 10.6 | 0.7 |

| C50BA | 12.9 | 0.3 | 16.8 | 0.8 | 6.3 | 0.4 | 16.0 | 0.5 | 6.8 | 2.1 |

| Mix | fcm,28 (MPa) | fctm,28 (MPa) | fcm,91 (MPa) | fctm,91 (MPa) | ||

|---|---|---|---|---|---|---|

| EC2 | Measured | EC2 | Measured | |||

| RC | 55.4 | 3.98 | 5.03 | 65.6 | 4.29 | 4.88 |

| C20BA | 20.6 | 2.37 | 3.09 | 22.1 | 2.48 | 3.40 |

| C30BA | 11.2 | 1.60 | 2.32 | 15.3 | 1.97 | 2.36 |

| C40BA | 9.10 | 1.37 | 2.19 | 10.6 | 1.53 | 2.24 |

| C50BA | 6.28 | 1.03 | 1.96 | 6.85 | 1.11 | 1.87 |

| Mix | fcm,28 (MPa) | Ecm,28 (GPa) | fcm,91 (MPa) | Ecm,91 (GPa) | ||

|---|---|---|---|---|---|---|

| EC2 | Measured | EC2 | Measured | |||

| RC | 55.4 | 36.7 | 45.4 | 65.6 | 38.7 | 41.6 |

| C20BA | 20.8 | 27.3 | 23.7 | 22.1 | 27.9 | 19.4 |

| C30BA | 11.2 | 22.8 | 23.8 | 15.3 | 25.0 | 19.5 |

| C40BA | 9.10 | 21.4 | 24.2 | 10.6 | 22.4 | 19.9 |

| C50BA | 6.28 | 19.1 | 12.9 | 6.85 | 19.6 | 9.07 |

| Mix | Age (Days) | Water Absorption (kg/m2) | Capillary Absorption | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| t 3 h | t 6 h | t 24 h | t 72 h | Coefficient (mm/min0.5) | |||||||

| Absm | S.D. | Absm | S.D. | Absm | S.D. | Absm | S.D. | Coefabs | R2 | ||

| RC | 28 | 1.43 | 0.28 | 1.83 | 0.33 | 2.57 | 0.46 | 2.96 | 0.42 | 0.095 | 0.98 |

| 91 | 0.93 | 0.20 | 1.04 | 0.23 | 1.34 | 0.27 | 1.72 | 0.39 | 0.052 | 0.86 | |

| C20BA | 28 | 1.48 | 0.11 | 1.87 | 0.10 | 2.75 | 0.24 | 3.45 | 0.26 | 0.095 | 0.96 |

| 91 | 0.80 | 0.23 | 0.94 | 0.28 | 1.34 | 0.28 | 1.85 | 0.29 | 0.047 | 0.91 | |

| C30BA | 28 | 1.83 | 0.17 | 2.40 | 0.24 | 3.79 | 0.44 | 4.89 | 0.55 | 0.125 | 0.99 |

| 91 | 0.97 | 0.04 | 1.15 | 0.07 | 1.68 | 0.09 | 2.34 | 0.23 | 0.058 | 0.92 | |

| C40BA | 28 | 1.67 | 0.33 | 2.23 | 0.39 | 3.73 | 0.60 | 5.26 | 0.85 | 0.116 | 0.99 |

| 91 | 0.93 | 0.11 | 1.08 | 0.11 | 1.51 | 0.17 | 2.00 | 0.17 | 0.054 | 0.89 | |

| C50BA | 28 | 1.84 | 0.03 | 2.45 | 0.09 | 3.96 | 0.20 | 5.21 | 0.23 | 0.126 | 0.99 |

| 91 | 1.07 | 0.12 | 1.21 | 0.14 | 1.70 | 0.17 | 2.34 | 0.20 | 0.059 | 0.85 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simões, J.R.; Silva, P.R.d.; Silva, R.V. Binary Mixes of Self-Compacting Concrete with Municipal Solid Waste Incinerator Bottom Ash. Appl. Sci. 2021, 11, 6396. https://doi.org/10.3390/app11146396

Simões JR, Silva PRd, Silva RV. Binary Mixes of Self-Compacting Concrete with Municipal Solid Waste Incinerator Bottom Ash. Applied Sciences. 2021; 11(14):6396. https://doi.org/10.3390/app11146396

Chicago/Turabian StyleSimões, Joel R., Pedro R. da Silva, and Rui V. Silva. 2021. "Binary Mixes of Self-Compacting Concrete with Municipal Solid Waste Incinerator Bottom Ash" Applied Sciences 11, no. 14: 6396. https://doi.org/10.3390/app11146396

APA StyleSimões, J. R., Silva, P. R. d., & Silva, R. V. (2021). Binary Mixes of Self-Compacting Concrete with Municipal Solid Waste Incinerator Bottom Ash. Applied Sciences, 11(14), 6396. https://doi.org/10.3390/app11146396