A Low-Power, Low-Noise, Resistive-Bridge Microsensor Readout Circuit with Chopper-Stabilized Recycling Folded Cascode Instrumentation Amplifier

Abstract

:1. Introduction

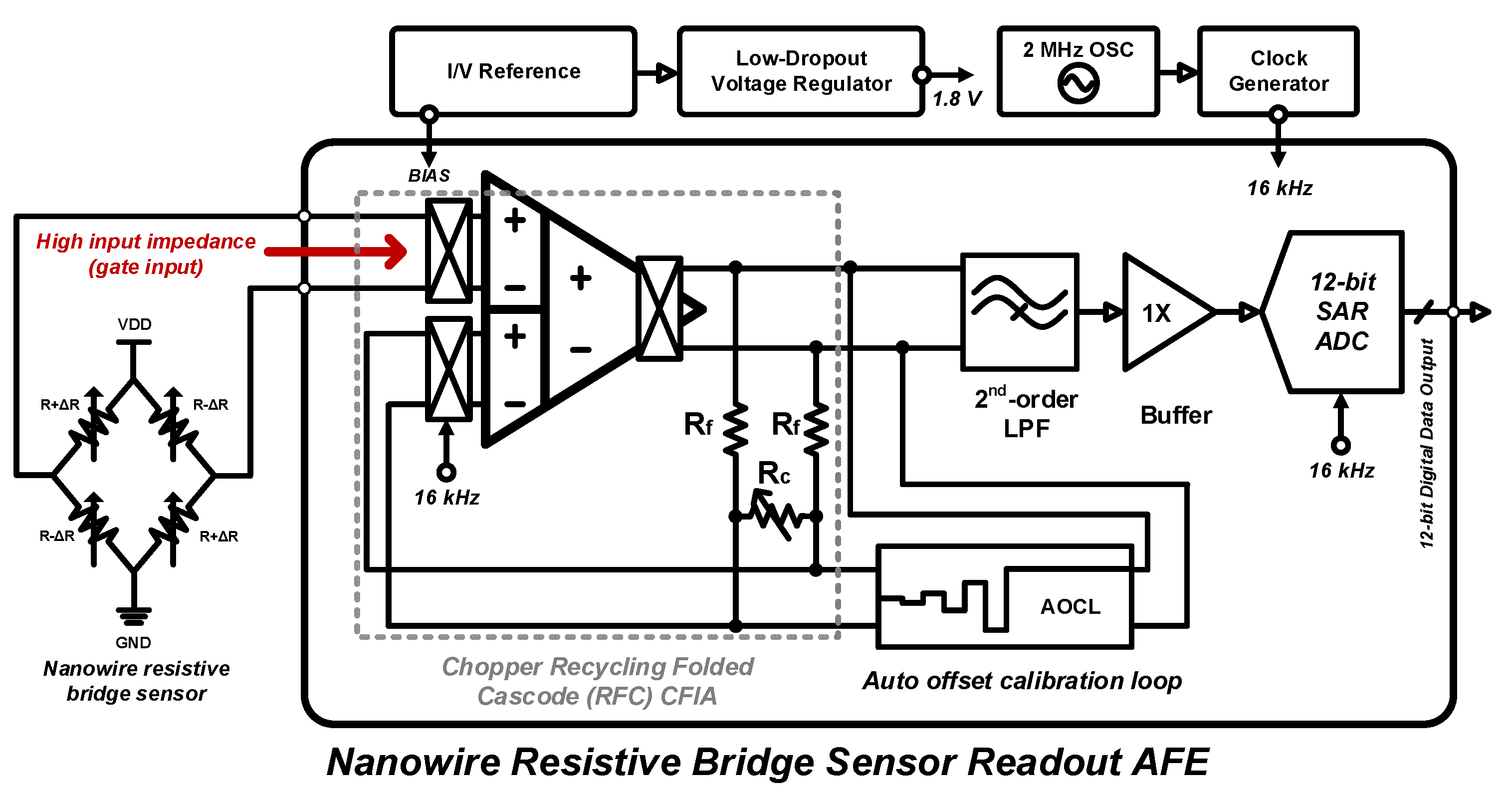

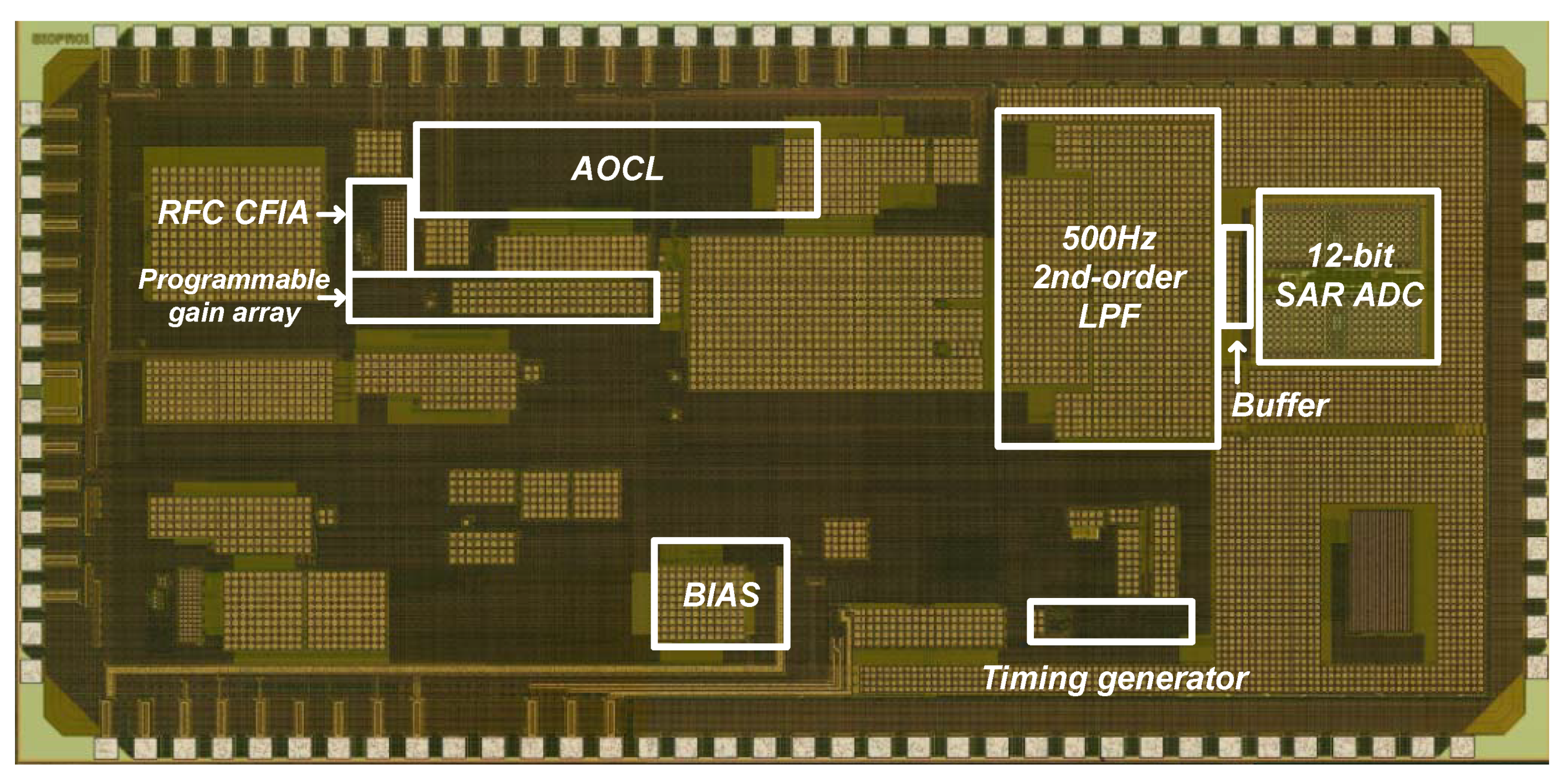

2. Proposed Resistive-Bridge Readout Integrated Circuit

2.1. Top Architecture of the Proposed Resistive-Bridge Microsensor ROIC

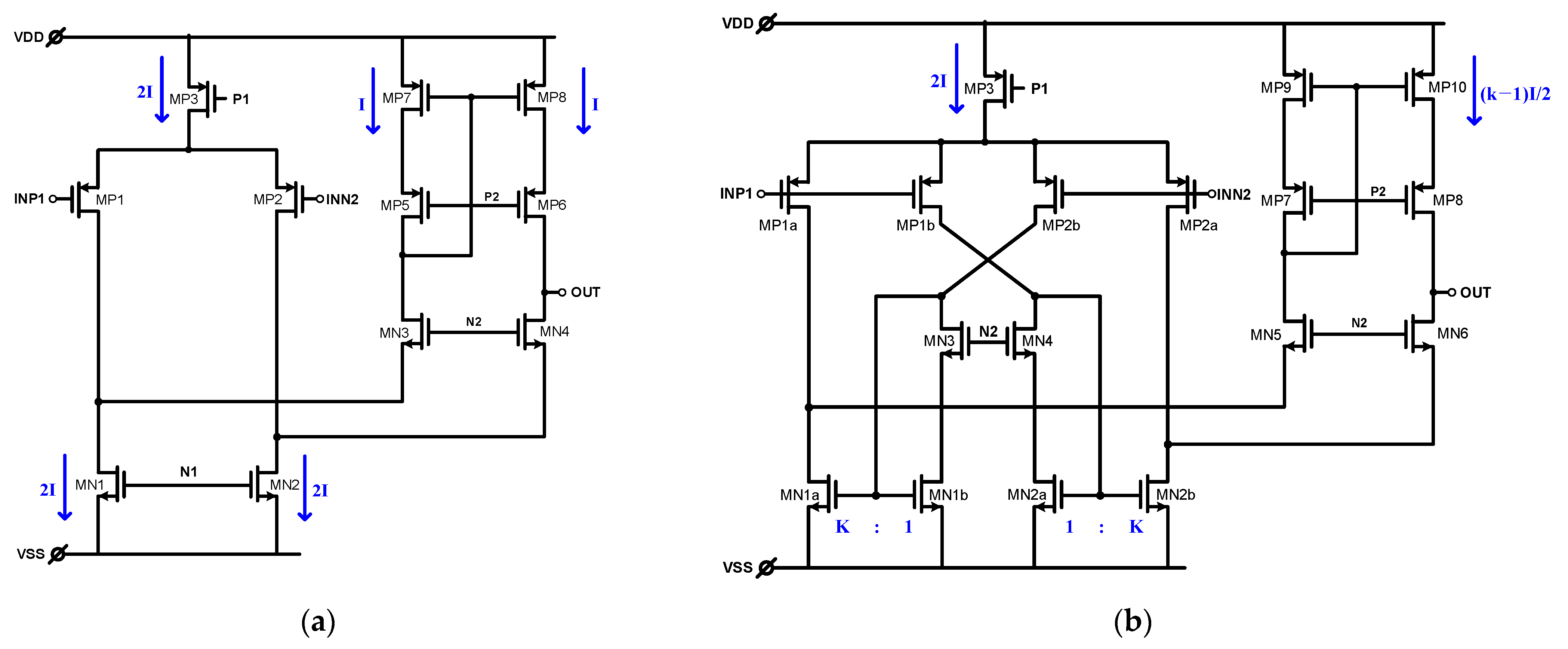

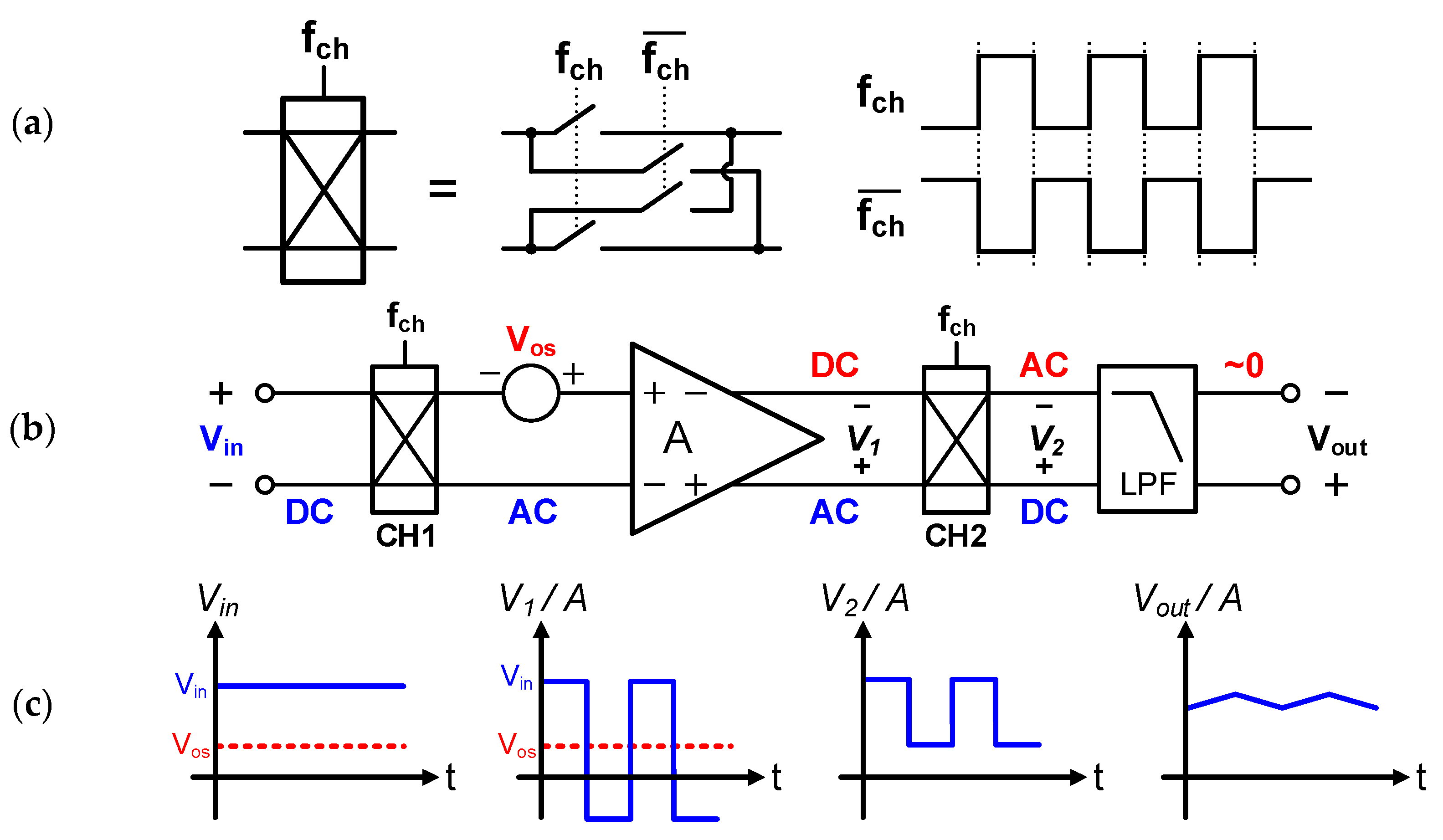

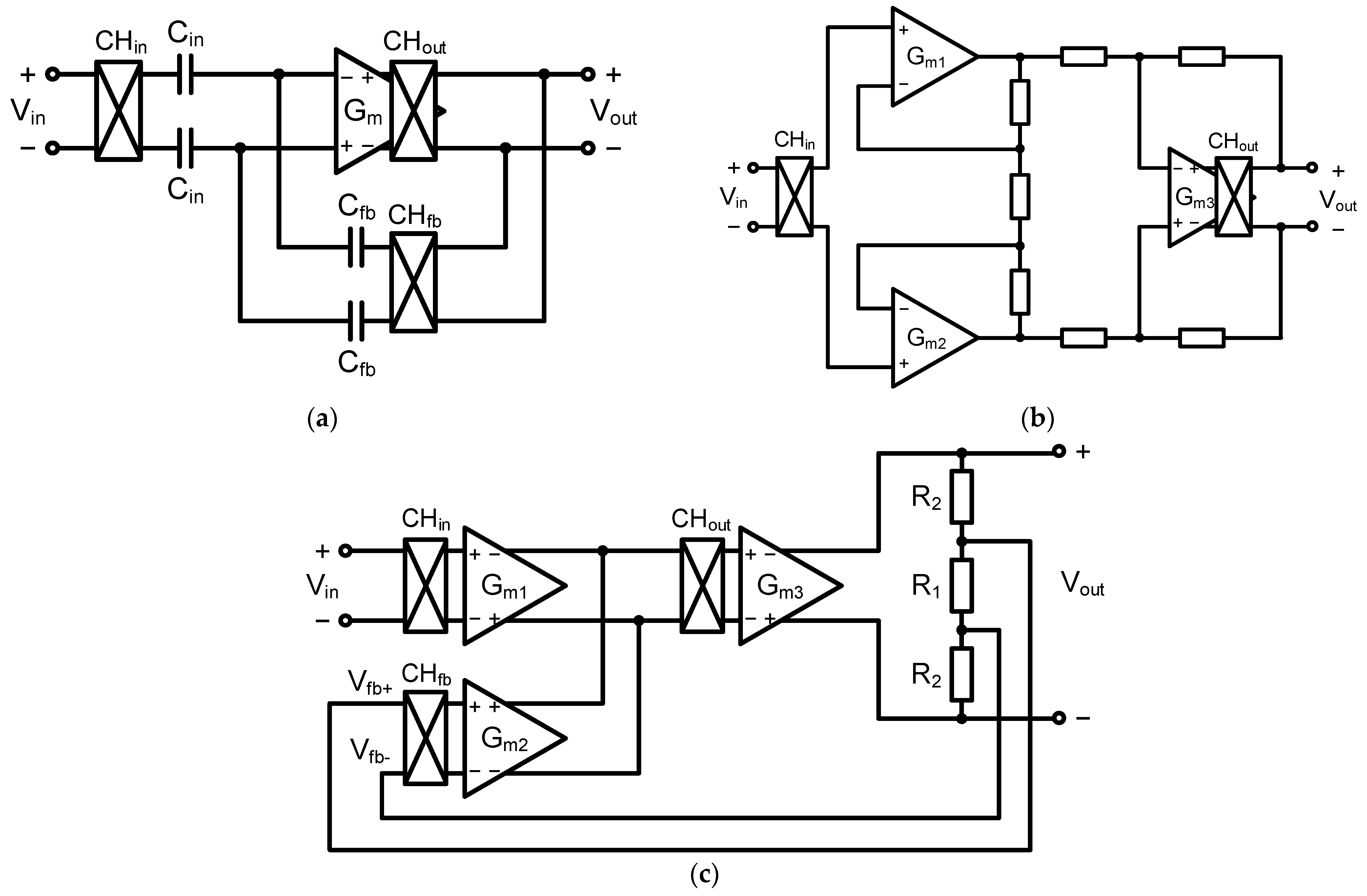

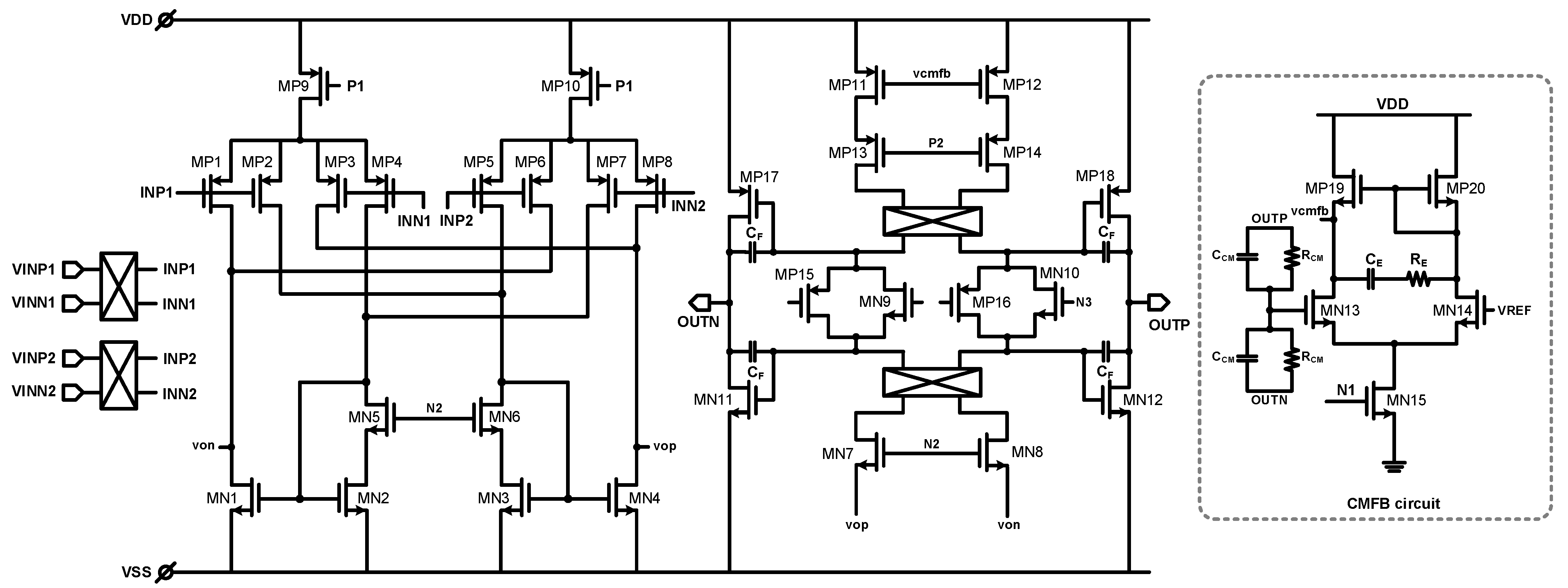

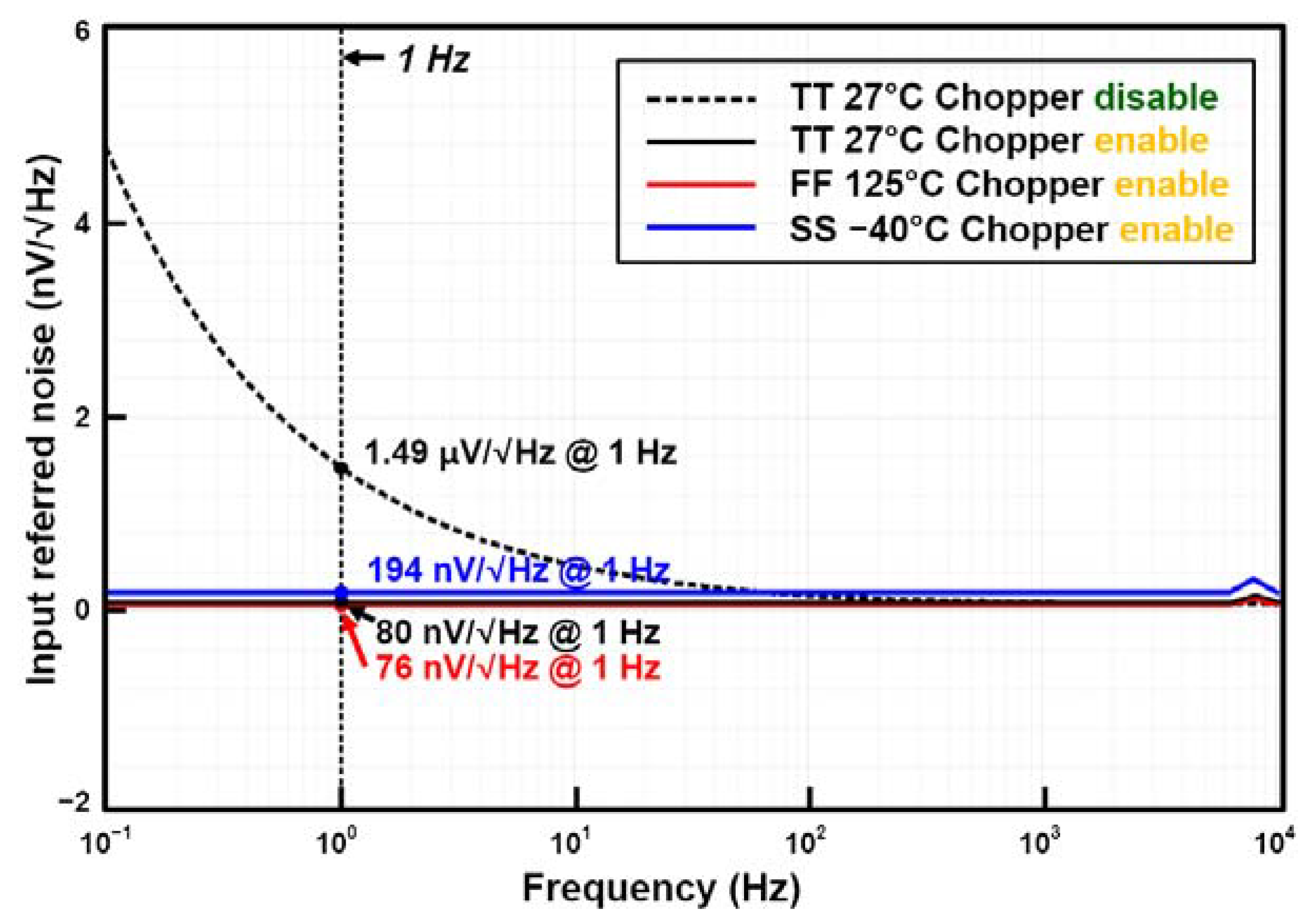

2.2. Circuit Implementation of a Chopper-Stabilized, Recycling Folded Cascode Instrumentaation Amplifier

2.3. AOCL, LPF, ADC Driving Buffer, and 12-Bit SAR ADC

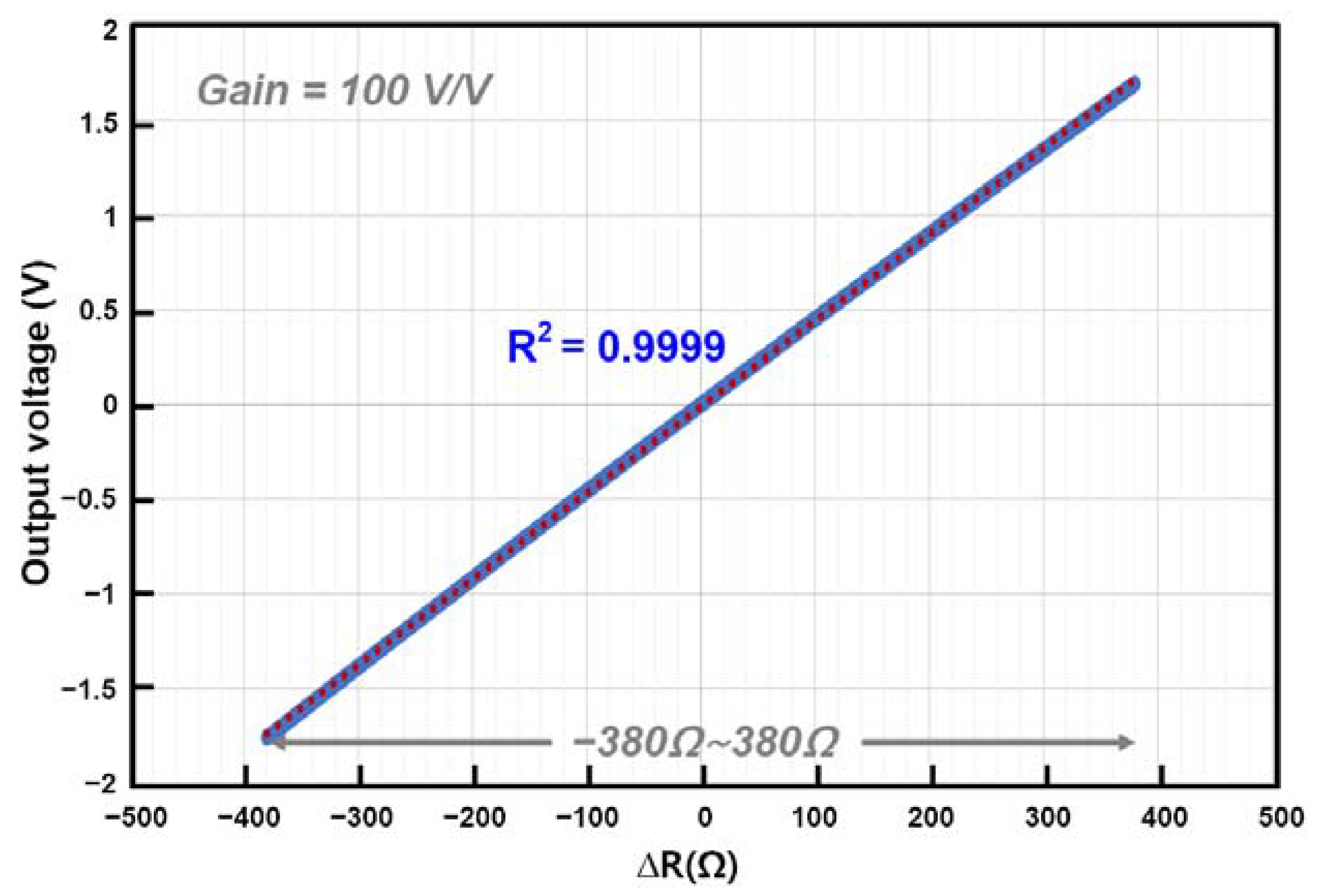

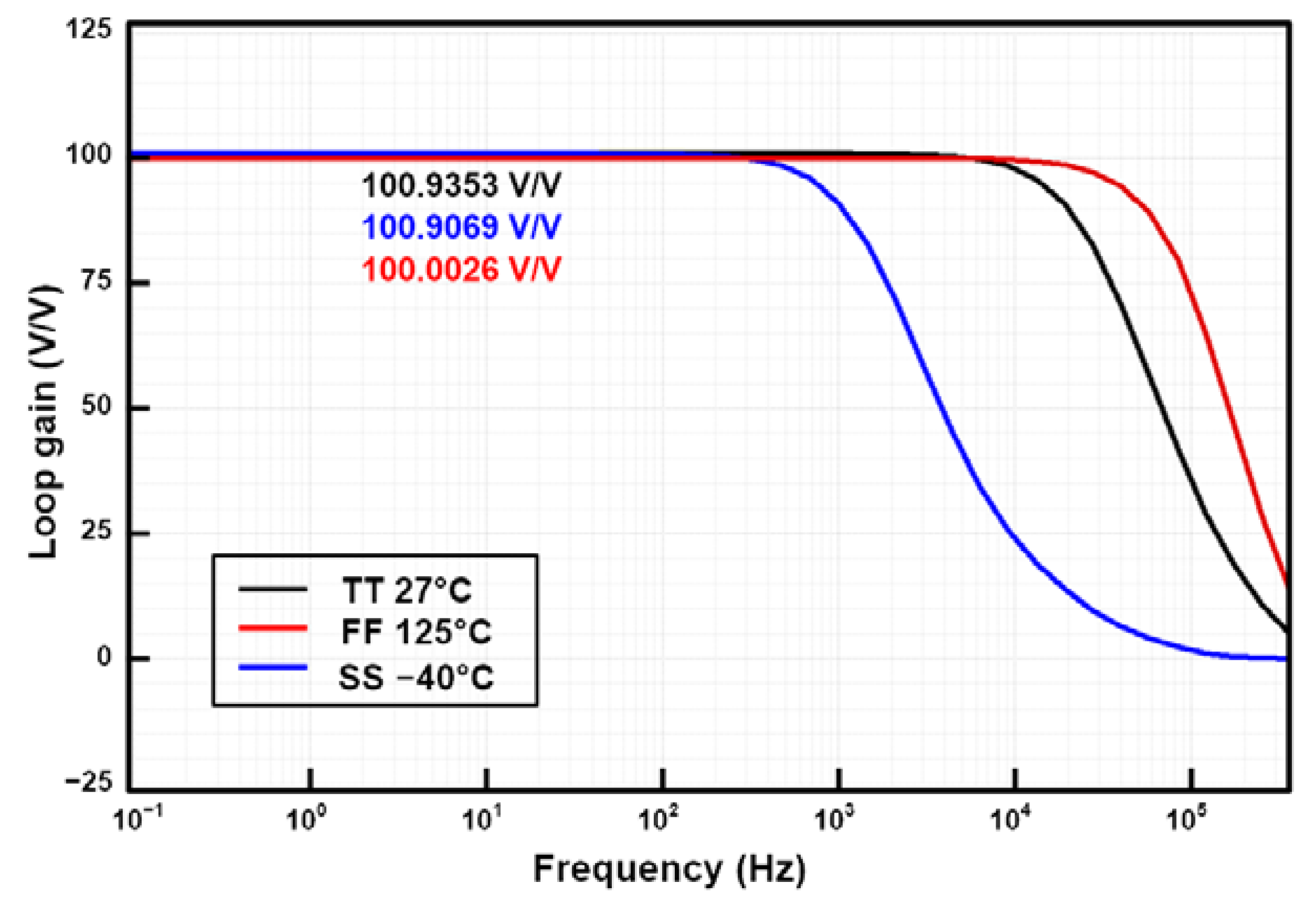

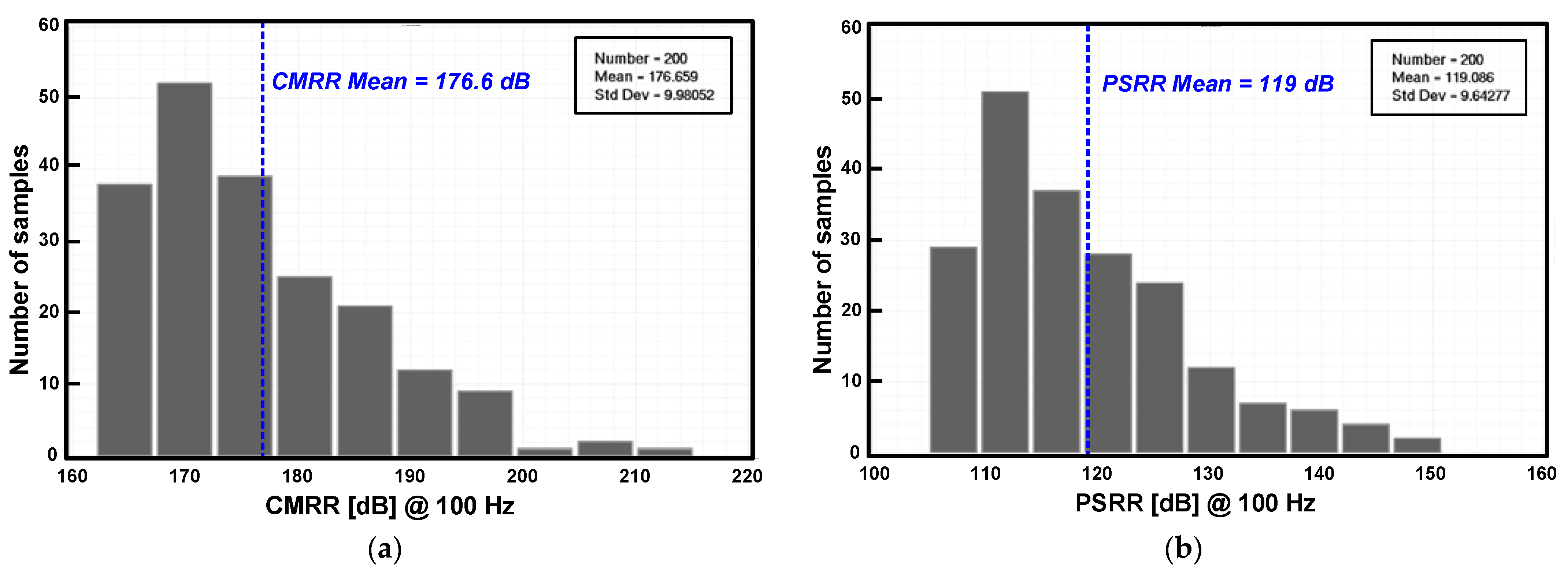

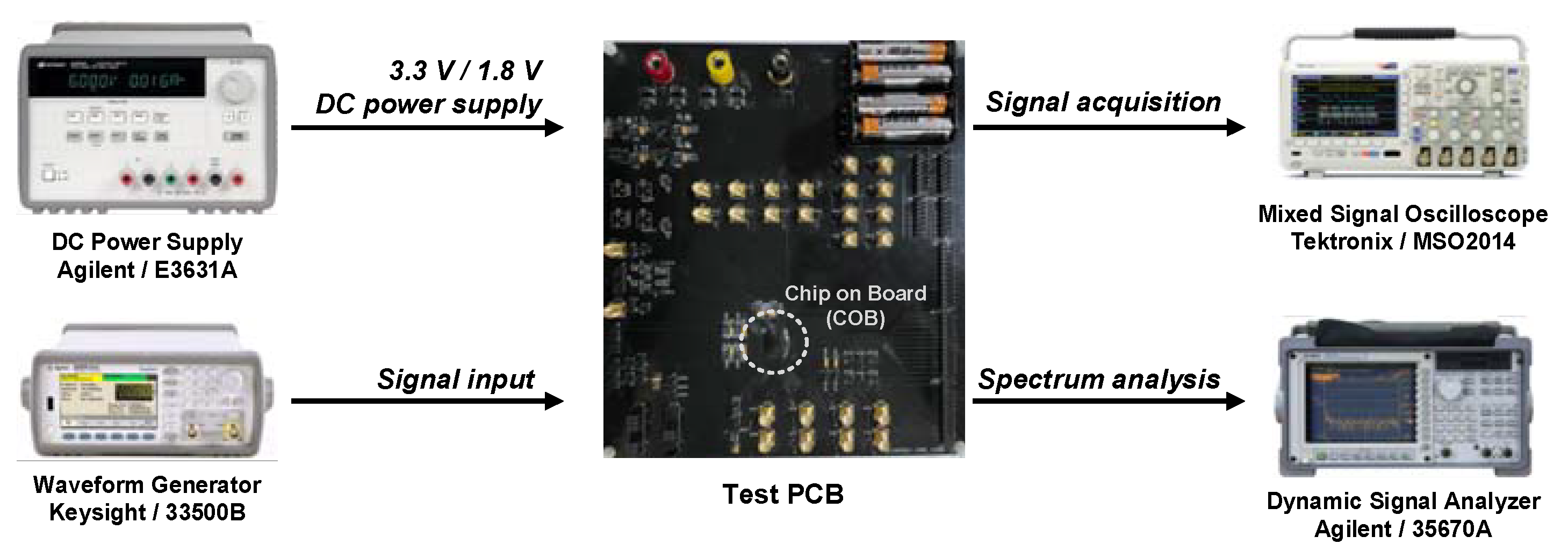

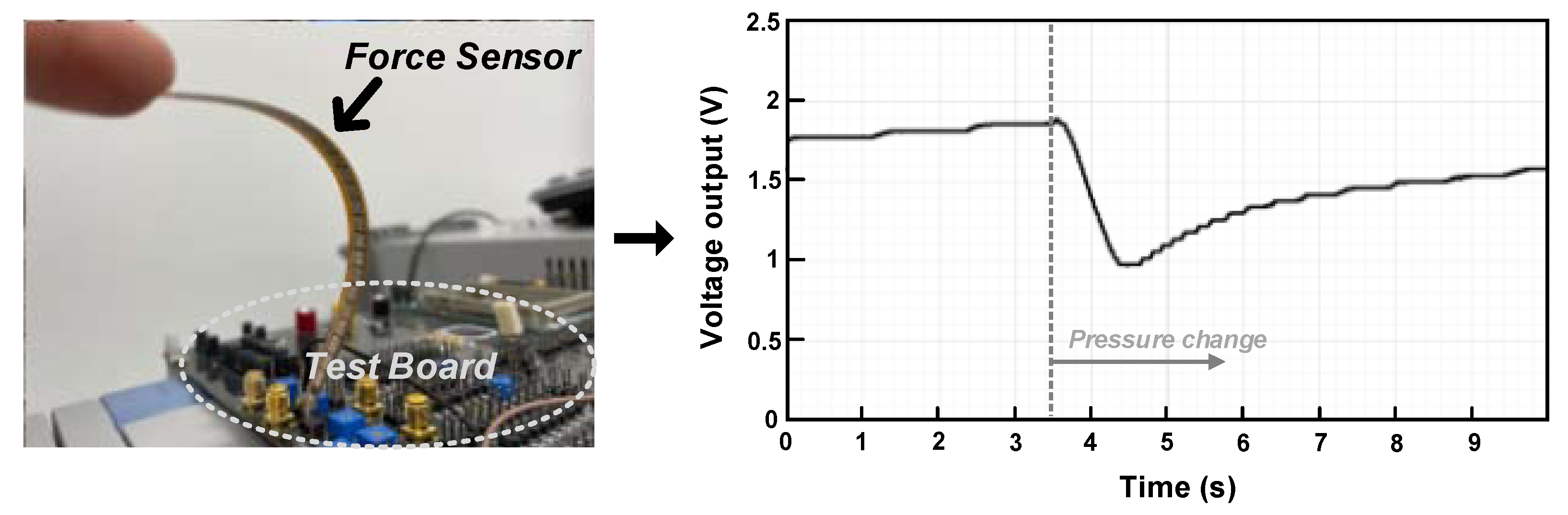

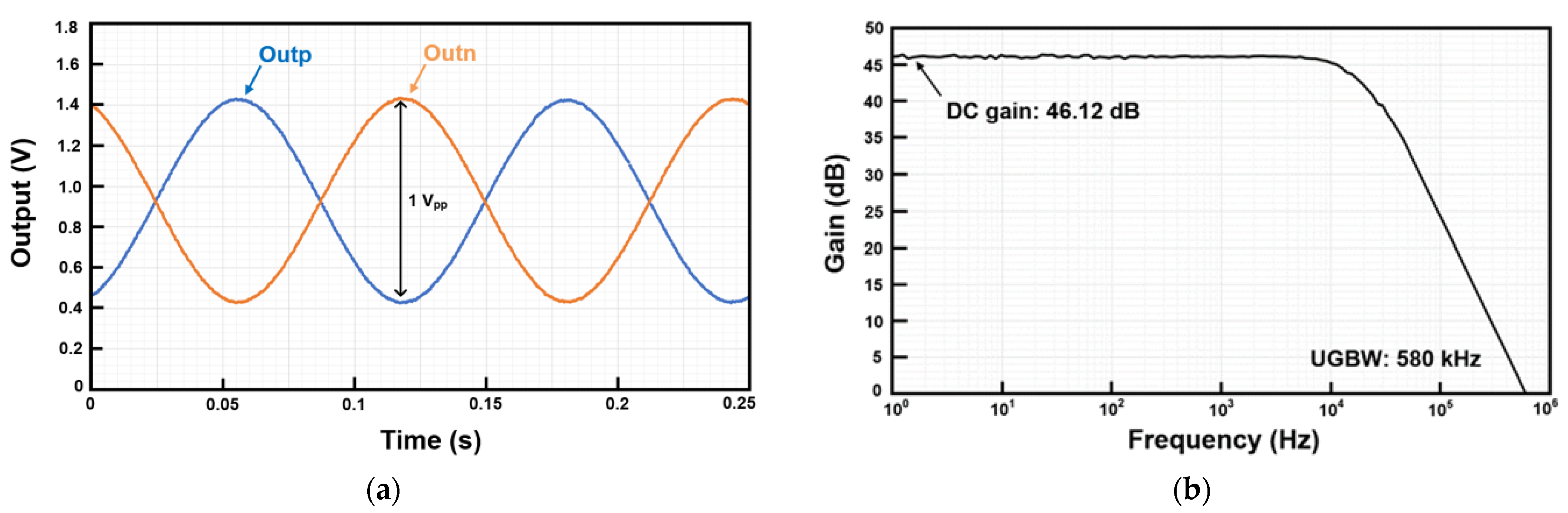

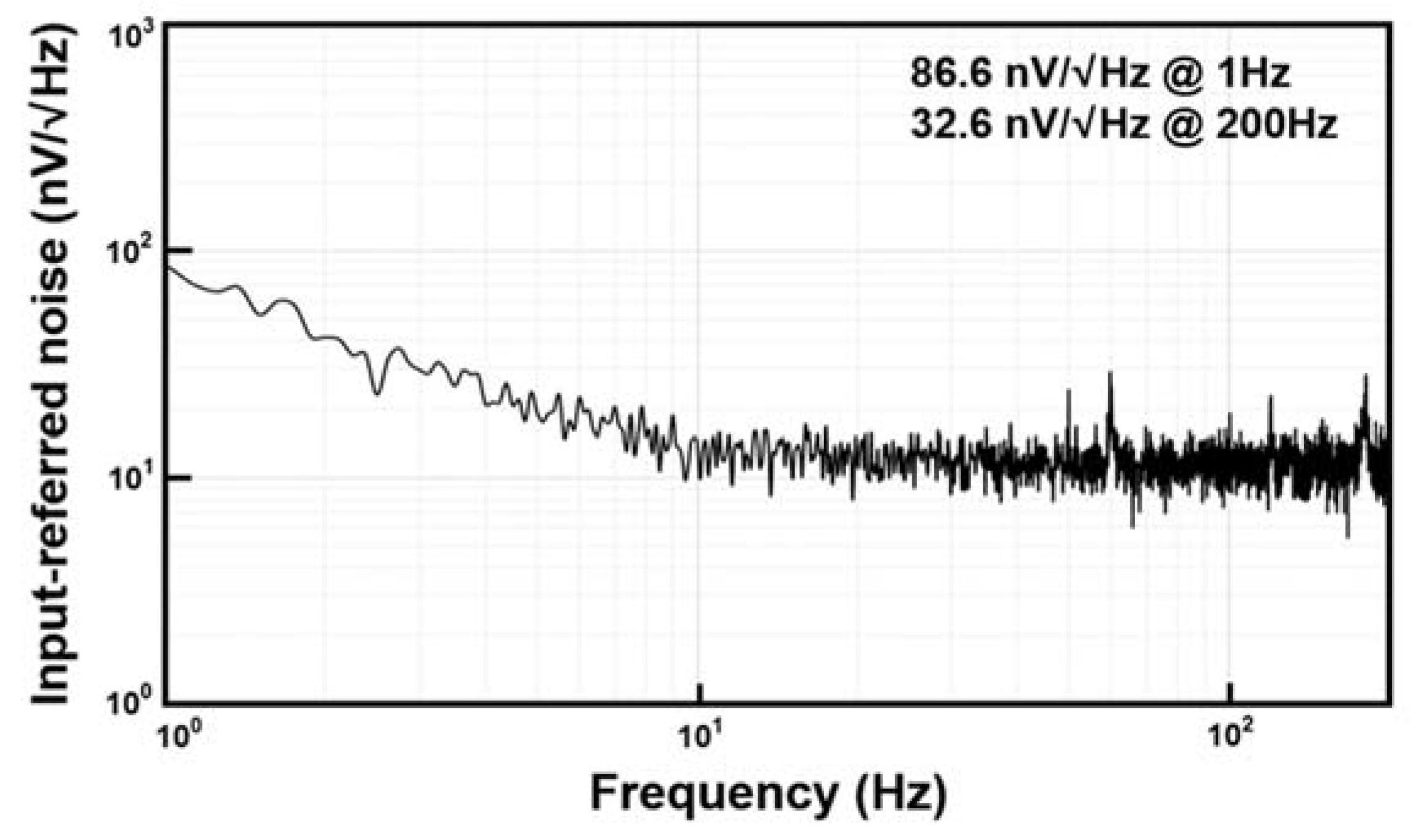

3. Experimental Results

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vetrivel, S.; Mathew, R.; Sankar, A.R. Design and optimization of a doubly clamped piezoresistive acceleration sensor with an integrated silicon nanowire piezoresistor. Microsyst. Technol. 2016, 23, 3525–3536. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Pang, B.; Yuan, L.; Ren, T. Tiny MEMS-based pressure sensors in the measurement of Intracranial Pressure. Tsinghua Sci. Technol. 2014, 19, 161–167. [Google Scholar] [CrossRef]

- Zhang, X.; Maddipatla, D.; Bose, A.K.; Hajian, S.; Narakathu, B.B.; Williams, J.D.; Mitchell, M.F.; Atashbar, M.Z. Printed Carbon Nanotubes-Based Flexible Resistive Humidity Sensor. IEEE Sens. J. 2020, 20, 12592–12601. [Google Scholar] [CrossRef]

- Lee, J.-H.; Yeh, S.-K.; Fang, W. Vertically Integrated Double-Bridge Design for CMOS-MEMS Tri-Axial Piezo-Resistive Force Sensor. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 693–696. [Google Scholar]

- Assaad, R.S.; Silva-Martinez, J. The Recycling Folded Cascode: A General Enhancement of the Folded Cascode Amplifier. IEEE J. Solid-State Circuits 2009, 44, 2535–2542. [Google Scholar] [CrossRef]

- Algueta-Miguel, J.M.; Lopez-Martin, A.; Garde, M.P.; De La Cruz, C.A.; Ramirez-Angulo, J. ±0.5 V 15 μ W Recycling Folded Cascode Amplifier With 34767 MHz·pF/mA FOM. IEEE Solid-State Circuits Lett. 2018, 1, 170–173. [Google Scholar] [CrossRef]

- Akbari, M.; Hashemipour, O.; Javid, A. An ultra-low voltage, ultra-low power fully recycling folded cascode amplifier. In Proceedings of the 2014 22nd Iranian Conference on Electrical Engineering (ICEE), Tehran, Iran, 20–22 May 2014; pp. 514–518. [Google Scholar]

- Sarkar, A.; Panda, S.S. Design of a power efficient, high slew rate and gain boosted improved recycling folded cascode amplifier with adaptive biasing technique. Microsyst. Technol. 2017, 23, 4255–4262. [Google Scholar] [CrossRef]

- Wu, R.; Huijsing, J.H.; Makinwa, K.A. Precision Instrumentation Amplifiers and Read-Out Integrated Circuits; Springer: New York, NY, USA, 2012; pp. 28–29. [Google Scholar]

- Jiang, H.; Nihtianov, S.; Makinwa, K.A.A. An Energy-Efficient 3.7-nV/√Hz Hz Bridge Readout IC With a Stable Bridge Offset Compensation Scheme. IEEE J. Solid-State Circuits 2018, 54, 856–864. [Google Scholar] [CrossRef] [Green Version]

- Pham, X.T.; Duong, D.N.; Nguyen, N.T.; Van Truong, N.; Lee, J.-W. A 4.5 GΩ-Input Impedance Chopper Amplifier with Embedded DC-Servo and Ripple Reduction Loops for Impedance Boosting to Sub-Hz. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 116–120. [Google Scholar] [CrossRef]

- Witte, J.F.; Huijsing, J.H.; Makinwa, K.A.A. A Chopper and Auto-Zero Offset-Stabilized CMOS Instrumentation Amplifier. In Proceedings of the 2009 Symposium on VLSI Circuits, Kyoto, Japan, 16–18 June 2009; pp. 210–211. [Google Scholar]

- Dool, B.V.D.; Huijsing, J. Indirect current feedback instrumentation amplifier with a common-mode input range that includes the negative roll. IEEE J. Solid-State Circuits 1993, 28, 743–749. [Google Scholar] [CrossRef] [Green Version]

- Song, H.; Park, Y.; Kim, H.; Cho, D.-I.D.; Ko, H. Fully Integrated Low-Noise Readout Circuit with Automatic Offset Cancellation Loop for Capacitive Microsensors. Sensors 2015, 15, 26009–26017. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nam, K.; Kim, H.; Kwon, Y.; Choi, G.; Kim, T.; Kim, C.; Cho, D.; Lee, J.; Ko, H. A Four-Channel Low-Noise Readout IC for Air Flow Measurement Using Hot Wire Anemometer in 0.18 μm CMOS Technology. Sensors 2021, 21, 4694. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.; Kim, H.; Kim, J.; Han, K.; Cho, D.-I.D.; Ko, H. A low-power 33 pJ/conversion-step 12-bit SAR resistance-to-digital converter for microsensors. Microsyst. Technol. 2018, 25, 2093–2098. [Google Scholar] [CrossRef]

- Kwon, Y.; Kim, H.; Kim, J.; Han, K.; You, D.; Heo, H.; Cho, D.-I.; Ko, H. Fully Differential Chopper-Stabilized Multipath Current-Feedback Instrumentation Amplifier with R-2R DAC Offset Adjustment for Resistive Bridge Sensors. Appl. Sci. 2019, 10, 63. [Google Scholar] [CrossRef] [Green Version]

- Resistive Flex Sensors, Spectrasymbol. Available online: https://www.spectrasymbol.com/product/flex-sensors (accessed on 28 August 2021).

- Steyaert, M.S.J.; Sansen, W.M.C. A micropower low-noise monolithic instrumentation amplifier for medical purposes. IEEE J. Solid-State Circuits 1987, 22, 1163–1168. [Google Scholar] [CrossRef]

- Xie, P.; Duan, Q.; Meng, Z.; Huang, S.; Ding, Y.; Han, L. A Low-Noise, Low-Power, and Chopper-Stabilized, Cur-rent-Feedback Instrumentation Amplifier for Current Sensing Application. In Proceedings of the 2019 IEEE 4th International Conference on Integrated Circuits and Microsystems (ICICM), Beijing, China, 25–27 October 2019; pp. 162–165. [Google Scholar]

- Jun, J.; Rhee, C.; Kim, M.; Kang, J.; Kim, S. A 21.8 b Sub-100 μHz 1/f Corner 2.4μV-Offset Programmable-Gain Read-out IC for Bridge Measurement Systems. In Proceedings of the 2018 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 11–15 February 2018; pp. 330–332. [Google Scholar]

- Jiang, H.; Makinwa, K.A.A.; Nihitanov, S. An energy-efficient readout method for piezoresistive differential pressure sensors. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 4287–4291. [Google Scholar]

| Transistor | Size (W/L) (μm) | Transistor | Size (W/L) (μm) |

|---|---|---|---|

| MP1–MP8 | 32/4 | MN1, MN4 | 0.6/10 |

| MP9, MP10 | 2/1.5 | MN2, MN3 | 0.5/10 |

| MP11, MP12 | 4/10 | MN5, MN6 | 8/1 |

| MP13, MP14 | 4/10 | MN7, MN8 | 40/12 |

| MP15, MP16 | 1/10 | MN9, MN10 | 1/18 |

| MP17, MP18 | 2/10 | MN11, MN12 | 1/10 |

| MP19, MP20 | 2/2 | MN13, MN14 | 1/16 |

| - | - | MN15 | 0.5/12 |

| Component | Value |

|---|---|

| CF | 200 fF |

| CE | 16.6 pF |

| RE | 466 kΩ |

| CCM | 400 fF |

| RCM | 11 MΩ |

| This Work | [20] | [13] | [21] | [22] | |

|---|---|---|---|---|---|

| Architecture | CFIA (with RFC) + chopping | CFIA + chopping + RRL | CCIA + chopping | CCIA + chopping + CDS + RRL | RC + chopping |

| Technology (µm) | 0.18 | 0.18 | 0.18 | 0.13 | 0.35 |

| Supply voltage (V) | 1.8 | 3.3 | 1.8 | 3 | 5 |

| Total current consumption (µA) | 7.9 | 200 | 1200 | 326 | 860 |

| Gain of IA | 70–220 | 100 | 40 | 16–32 | - |

| Gain bandwidth (Hz) | 580 k | - | - | - | 2 k |

| Current consumption of IA (µA) | 2.23 | - | - | - | 700 |

| Input-referred noise (nV/√Hz) | 86.6 | 23 | 3.7 | 16 | 4.2 |

| NEF | 4.94 | 6.1 | 5.0 | 11.1 | 4.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, G.; Heo, H.; You, D.; Kim, H.; Nam, K.; Yoo, M.; Lee, S.; Ko, H. A Low-Power, Low-Noise, Resistive-Bridge Microsensor Readout Circuit with Chopper-Stabilized Recycling Folded Cascode Instrumentation Amplifier. Appl. Sci. 2021, 11, 7982. https://doi.org/10.3390/app11177982

Choi G, Heo H, You D, Kim H, Nam K, Yoo M, Lee S, Ko H. A Low-Power, Low-Noise, Resistive-Bridge Microsensor Readout Circuit with Chopper-Stabilized Recycling Folded Cascode Instrumentation Amplifier. Applied Sciences. 2021; 11(17):7982. https://doi.org/10.3390/app11177982

Chicago/Turabian StyleChoi, Gyuri, Hyunwoo Heo, Donggeun You, Hyungseup Kim, Kyeongsik Nam, Mookyoung Yoo, Sangmin Lee, and Hyoungho Ko. 2021. "A Low-Power, Low-Noise, Resistive-Bridge Microsensor Readout Circuit with Chopper-Stabilized Recycling Folded Cascode Instrumentation Amplifier" Applied Sciences 11, no. 17: 7982. https://doi.org/10.3390/app11177982

APA StyleChoi, G., Heo, H., You, D., Kim, H., Nam, K., Yoo, M., Lee, S., & Ko, H. (2021). A Low-Power, Low-Noise, Resistive-Bridge Microsensor Readout Circuit with Chopper-Stabilized Recycling Folded Cascode Instrumentation Amplifier. Applied Sciences, 11(17), 7982. https://doi.org/10.3390/app11177982