Customized Approach to Greenhouse Gas Emissions Calculations in Railway Freight Transport

Abstract

:Featured Application

Abstract

1. Introduction

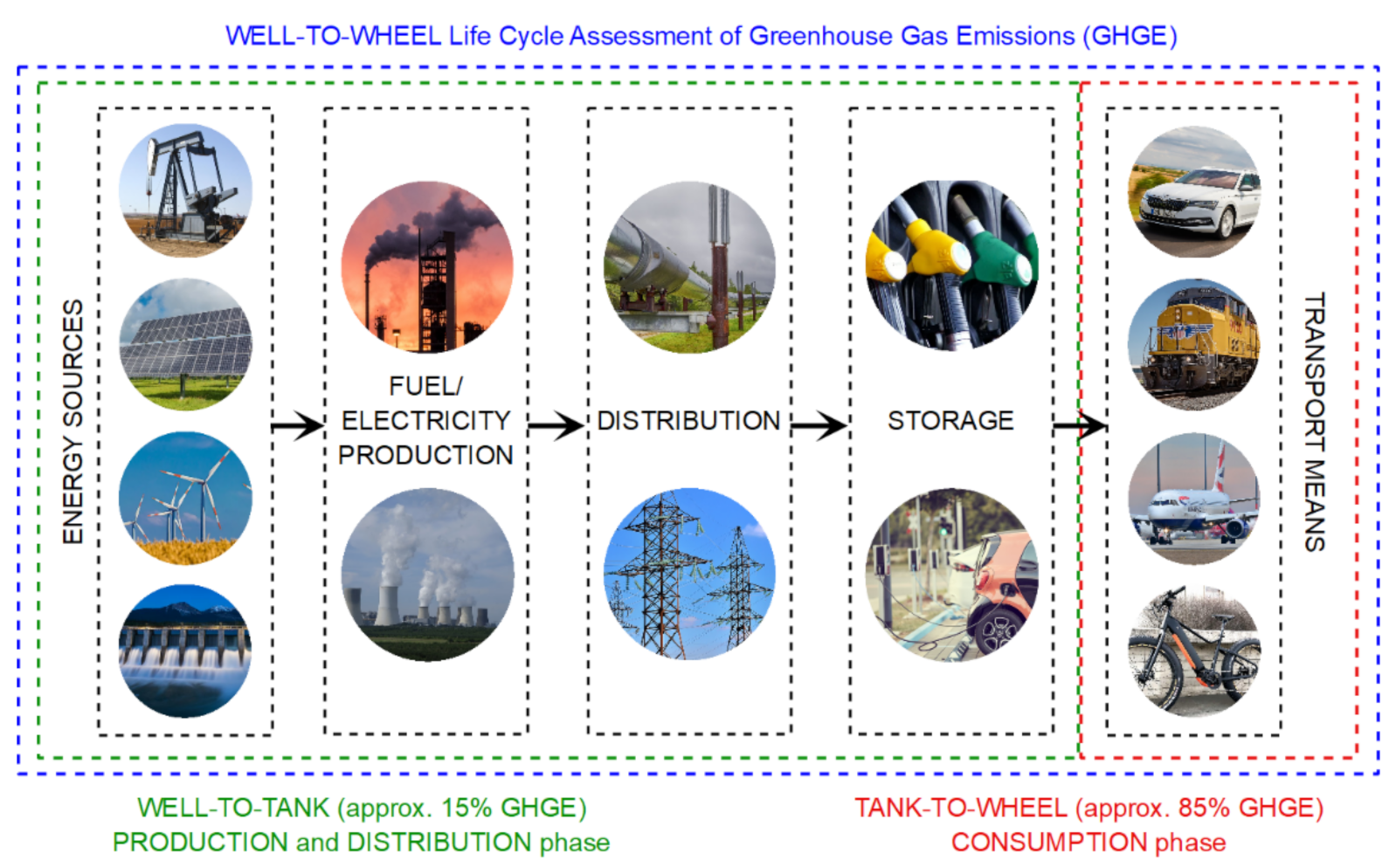

- Well-to-Wheel (the sum total of Well-to-Tank together with Tank-to-Wheel): an approach based on the monitoring of energy consumption and associated emissions production, which covers the whole process from the production of electricity or fuel, through supply to appropriate means of transport via the distribution network, to consumption associated with the operation of transport means. This approach is based on the sum of Tank-to-Wheel and Well-to-Tank values (Figure 1).

- Well-to-Tank: Energy consumption and emission production associated with energy or fuel production—this indicator covers all activities from mining of raw materials via energy or fuel production to delivery to relevant means of transport via the distribution network. This indicator does not include the mode of transport (Figure 1).

- Tank-to-Wheel: Consumption of energy and associated emissions production connected with transport means operations. This approach does not include the additional life cycle of the fuel and transport means (Figure 1).

2. Materials and Methods

2.1. Semi-Structured Interviews

2.2. Comparative Content Analysis

2.3. Interpretative Case Study

3. Mathematical Formulation

3.1. Identification and Synthesis of Assumptions for GHG Emission Calculations from RFT

- GHG emission calculations from RFT;

- GHG emission calculators or similar tool-use related to RFT;

- Cargo types related to RFT;

- Vehicle types and their specifications related to RFT;

- RFT restrictive assumptions;

- Requirements for GHG emission calculations related to RFT.

3.2. Analysis of Available Emission RFT Calculators

- No. 1—EcoPassenger [67];

- No. 2—Carbon Foot Print [68];

- No. 3—EcoTree [69];

- No. 4—The Engineering ToolBox [70];

- No. 5—EcoTransIT World [71];

- No. 6—CN [72];

- No. 7—CarbonCare [73];

- No. 8—World Land Trust [74];

- No. 9—ScotRail [75];

- No. 10—BNSF Railway Carbon Estimator [76];

- No. 11—Logward [77];

- No. 12—Trees for All [78].

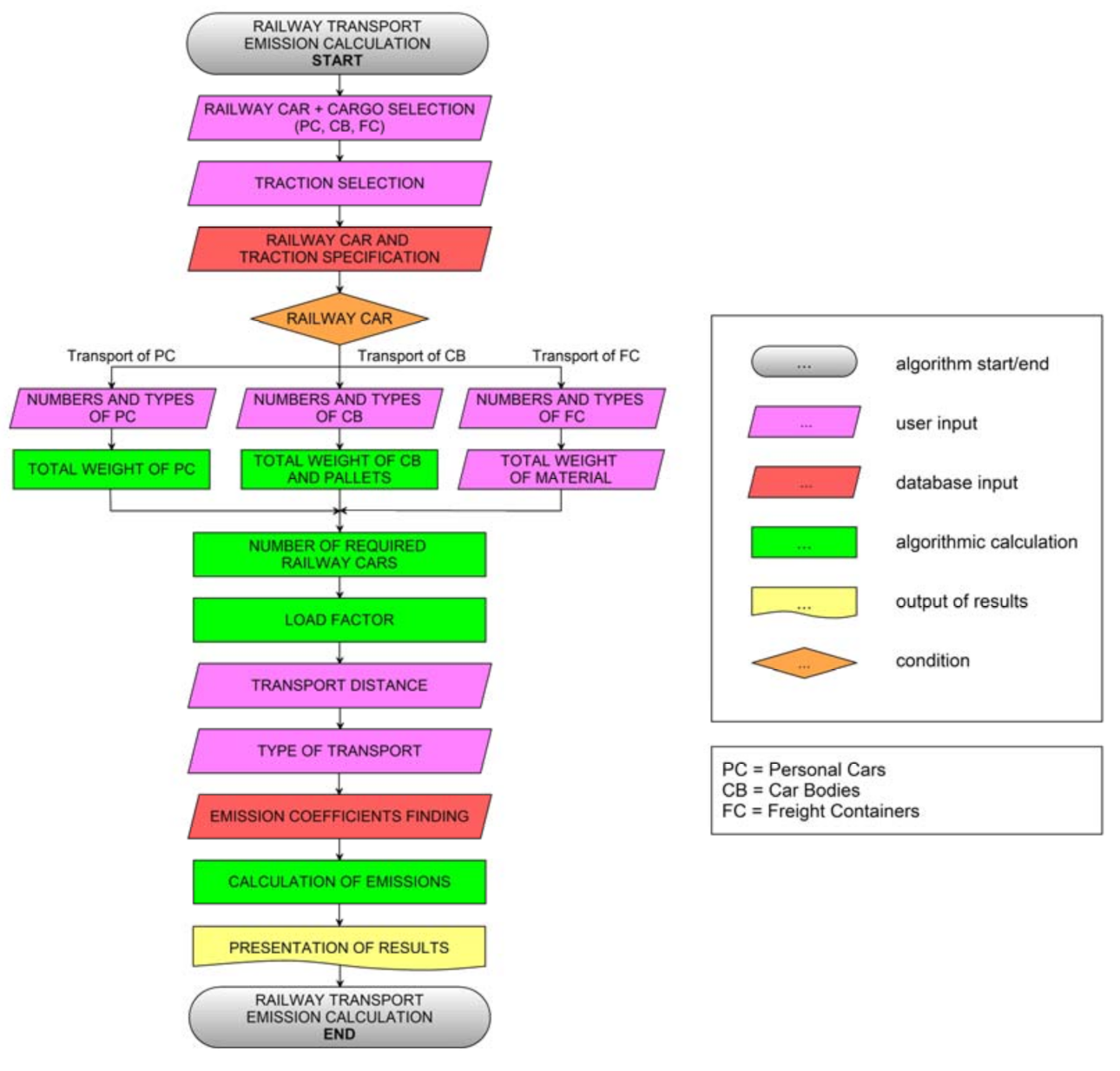

3.3. Proposal of a Customized Approach to GHG Emission Calculations in RFT for the AI

- In the case of PC transport, the user enters the number of individual types of transported PC;

- In the case of CB transport, the user enters the number of individual types of transported CB;

- In the case of FC transport, the user enters the number of individual types of transported FC and the total weight of transported material.

- In the case of PC transport, as the total weight of all transported PC;

- In the case of CB transport, as the total weight of all transported CB including all transported pallet weight;

- In the case of FC transport, as the total weight of all transported FC including all transported material weight.

for RC1 to RC25: LV [−] ≤ (nc [−] × LVmax [−]), nc ∈ N, LVmax = <10;11>,

for RC26 to RC29: LV [−] ≤ (nc [−] × LVmax [−]), nc ∈ N, LVmax = <8;10>,

for RC30 to RC32: LV [−] ≤ (nc [−] × LVmax [−]), nc ∈ N, LVmax = <1;4>,

IF transport of PC in RC1-25 from plant B THEN LVmax = 11,

IF transport of CB in RC26 OR RC28 THEN LVmax = 8,

IF transport of CB in RC27 OR RC29 THEN LVmax = 10,

IF transport of FC in RC30 OR RC31 THEN for FC2: LVmax = 1,

IF transport of FC in RC30 OR RC31 THEN for FC3: LVmax = 1,

IF transport of FC in RC32 THEN for FC1: LVmax = 4,

IF transport of FC in RC32 THEN for FC2: LVmax = 2,

IF transport of FC in RC32 THEN for FC3: LVmax = 2,

IF transport of FC in RC32 THEN for FC1 = 2 AND FC3 = 1,

IF transport of FC in RC32 THEN for FC2 = 1 AND FC3 = 1,

npck ∈ N, k ∈ <1;8>,

for CB: V = {(ncb1 × (VCB1 + VP1)) + (ncb2 × (VCB2 + VP2))} [t],

ncbl ∈ N, l ∈ <1;2>,

for FC: V = {(nfc1 × (VFC1 + VC1)) + (nfc2 × (VFC2 + VC2)) + (nfc3 × (VFC3 + VC3))} [t],

nfcm ∈ N, m ∈ <1;3>,

for CdWtTb, CdWtTf, CdTtWb, CdTtWf, CiWtTb, CiWtTf, CiTtWb and CiTtWf,

IF one-way transport THEN search emission coefficients values

for CdWtTb, CdWtTf, CdTtWb, CdTtWf, CiWtTb, CiWtTf, CiTtWb, CiTtWf, Cd0WtTb, Cd0WtTf,

Cd0TtWb, Cd0TtWf, Ci0WtTb, Ci0WtTf, Ci0TtWb and Ci0TtWf,

+ Si1 [−] × CiWtTb [kgCO2e/SO2e/tkm]} × V [t] × L1 [km],

+ Si1 [−] × CiWtTf [kgCO2e/SO2e/tkm]} × V [t] × L1 [km],

+ Si1 [−] × CiTtWb [kgCO2e/SO2e/tkm]} × V [t] × L1 [km],

+ Si1 [−] × CiTtWf [kgCO2e/SO2e/tkm]} × V [t] × L1 [km],

L1d [km] + L1i [km] = L1 [km],

Si1 [−] = 0,

Si1 [−] = 1,

+ Si2 [−] × Ci0WtTb [kgCO2e/SO2e/tkm]} × V [t] × L2 [km],

+ Si2 [−] × Ci0WtTf [kgCO2e/SO2e/tkm]} × V [t] × L2 [km],

+ Si2 [−] × Ci0TtWb [kgCO2e/SO2e/tkm]} × V [t] × L2 [km],

+ Si2 [−] × Ci0TtWf [kgCO2e/SO2e/tkm]} × V [t] × L2 [km],

L2d [km] + L2i [km] = L2 [km],

Si2 [−] = 0,

Si2 [−] = 1,

3.4. Case Study Assumptions and Calculations

- Type of cargo: FC;

- Railway car: RC32 (Sggns S183);

- Traction: 62% dependent traction (Sd1 = 0.62), 38% independent traction (Si1 = 0.38);

- Numbers and types of FC: 24 FC2;

- Weight of the freight in one FC2 (VC2): 27.25 t;

- Total transport distance (L1): 472 km;

- Length of transport realized by RFT using dependent traction (L1d): 292.64 km;

- Length of transport realized by RFT using independent traction (L1i): 179.36 km;

- Type of transport: return.

for FC: V = {(0 + 745.2 + 0)} [t],

for FC: V = 745.2 [t],

for RC32: 745.2 [t] ≤ 810.0 [t],

for RC32: 24 [−] ≤ 24 [−],

LF = 0.92 [−],

- CdWtTb = 0.001802327 [kgCO2e/tkm];

- CdWtTf = 0.009762854 [kgCO2e/tkm];

- CdTtWb = 0.000000000 [kgCO2e/tkm];

- CdTtWf = 0.000000000 [kgCO2e/tkm];

- CiWtTb = 0.000109177 [kgCO2e/tkm];

- CiWtTf = 0.002784794 [kgCO2e/tkm];

- CiTtWb =0.001200000 [kgCO2e/tkm];

- CiTtWf = 0.015700000 [kgCO2e/tkm].

+ 0.38 [−] × 0.000109177 [kgCO2e/tkm]} × 745.2 [t] × 472 [km],

RWtTb [kgCO2e] = 407.635548192.

+ 0.38 [−] × 0.002784794 [kgCO2e/tkm]} × 745.2 [t] × 472 [km],

RWtTf [kgCO2e] = 2501.250570017.

+ 0.38 [−] × 0.001200000 [kgCO2e/tkm]} × 745.2 [t] × 472 [km],

RTtWb [kgCO2e] = 160.390886400.

+ 0.38 [−] × 0.015700000 [kgCO2e/tkm]} × 745.2 [t] × 472 [km],

RTtWf [kgCO2e] = 2098.447430400.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- Is the field of producing GHG emissions from RFT relevant for your company?

- Do you use any tool for calculating GHG emissions?

- Where do you analyze the GHG emissions produced by RFT?

- What emissions do you track in logistic processes connected with RFT?

- What kind of freight do you transport using RFT?

- Define restrictive conditions for RFT.

- What type of transport do you use?

- How do you want to present the resulting GHG emissions?

Appendix B

- 1.

- Is the field of producing GHG emissions from RFT relevant for your company?Yes, of course. This area is very popular for our company, because our company strives to minimize the negative impacts on the environment. The issue of GHG emission calculations is one of the tools to achieve the above goal.

- 2.

- Do you use any tool for calculating GHG emissions?Our company does not currently use any RFT emissions calculators or another similar tool. There is no appropriate GHG emissions calculator available to meet our assumptions and restrictive conditions. Our logistic processes related to the RFT are very comprehensive and specific with many unique conditions. There are currently no suitable RFT emission calculators or another similar tool that contains all required specifics of our company.

- 3.

- Where do you analyze the GHG emissions produced by RFT?We track produced GHG emissions by RFT in inbound and outbound logistics. The most important for us are transports within outbound logistics to foreign plants and to customers.

- 4.

- What emissions do you track in logistic processes connected with RFT?We track CO2 and SO2 emissions as part of logistic processes.

- 5.

- What kind of freight do you transport using RFT?We transport predominantly passenger cars (PC), car bodies (CB), and freight containers (FC). We have three kinds of vehicles there are: vehicles for the transportation of PC (see Appendix C, Table A1), vehicles for the transportation of CB (see Appendix D, Table A2), vehicles for the transportation of FC (see Appendix E, Table A3).

- 6.

- Define restrictive conditions for RFT.The fundamental restrictive conditions are the maximum freight weight of the vehicle, the maximum load volume of the vehicle and vehicle selection by type of transported freight. The following specific conditions are further applied to the transport of PC:

- Different PC (PC1–PC8) with different weights (WPC1–WPC8) are transported.

- The maximum number of PC is 10 PC for transport from plant A on one railway car.

- The maximum number of PC is 11 PC for transport from plant B on one railway car.

The following specific conditions are further applied to the transport of CB:- Different CB (CB1–CB2) with different weights (VCB1–VCB2) are transported.

- Each CB is transported together with a pallet of different pallet weights (VP1–VP2).

- The maximum number of transported CB including pallets is as follows: RC26—8 CB, RC27—10 CB, RC28—8 CB, RC29—10 CB.

The following specific conditions are further applied to the transport of FC:- Different FC (FC1–FC3) with different weights (VFC1–VFC3) are transported (VFC1 = 2.2 t, VFC2 = 3.8 t, VFC3 = 3.9 t).

- FC are preferably loaded on Sggns S183 railway cars (RC32).

- The options for loading railway cars are as follows: for Lgs 580 (RC30)—two FC1 or one FC2 or one FC3, for Lgns 583 (RC31)—two FC1 or one FC2 or one FC3, for Sggns S183 (RC32)—four FC1 or two FC2 or two FC3, two FC1 and one FC2, two FC1 and one FC3, one FC2 and one FC3.

- The aim is to maximize the load of railway cars during loading.

- 7.

- What type of transport do you use? We use one-way transport and return transport. When it is a one-way transport, our company uses multiplying of the produced emissions by specific coefficient.

- 8.

- How do you want to present the resulting GHG emissions? We would like to present the results in the form of: total GHG emissions, average GHG emissions per 1 km, average GHG emissions per 1 t and average GHG emissions per 1 tkm and according to the calculation approach and origin of GHG emissions (FO and BO).

Appendix C

| Railway Car | Type of Railway Car | Vmax |

|---|---|---|

| RC1 | Laaers 509.8 | 18,000 kg |

| RC2 | Laaeks 911 | 15,000 kg |

| RC3 | Leks 3125 | 18,000 kg |

| RC4 | Laekks 552 | 17,000 kg |

| RC5 | Laaeks 553 | 18,500 kg |

| RC6 | Laaes 556 | 24,000 kg |

| RC7 | Laes 559 | 20,000 kg |

| RC8 | Laaers 560 | 34,000 kg |

| RC9 | Laaers 1160-Touax | 34,000 kg |

| RC10 | Laaers 700–702 | 34,000 kg |

| RC11 | Laaers 800 | 34,000 kg |

| RC12 | Laeks 063C | 18,000 kg |

| RC13 | Laeks 063F | 18,000 kg |

| RC14 | Laeks 063A | 19,000 kg |

| RC15 | Laaeks 89 | 22,500 kg |

| RC16 | Laaers 142, 142A | 23,700 kg |

| RC17 | Laaers TAL 489M | 25,200 kg |

| RC18 | Laaefrs TAL 497 | 23,000 kg |

| RC19 | Laes TA 364M | 18,000 kg |

| RC20 | Laes TA 370M | 18,900 kg |

| RC21 | Laaers 5.837 | 21,000 kg |

| RC22 | Laaers 5.850 | 33,000 kg |

| RC23 | Laaers 224Sc | 24,000 kg |

| RC24 | Laaers 5.854 | 36,000 kg |

| RC25 | Laaers 6433CO | 24,000 kg |

Appendix D

| Railway Car | Type of Railway Car | Vmax |

|---|---|---|

| RC26 | Habiis 6 | 52,000 kg |

| RC27 | Habiis 8 | 51,500 kg |

| RC28 | Habiikks 10 | 43,000 kg |

| RC29 | Himrrs Doublwagon | 47,500 kg |

Appendix E

| Railway Car | Type of Railway Car | Vmax |

|---|---|---|

| RC30 | Lgs 580 | 27,000 kg |

| RC31 | Lgns 583 | 27,000 kg |

| RC32 | Sggns S183 | 67,500 kg |

Appendix F

- Cd0TtWb—appropriate emission coefficient for the empty load of CO2 or SO2 of BO calculated using the TtW approach for dependent traction [kgCO2e/SO2e/tkm]

- Cd0TtWf—appropriate emission coefficient for the empty load of CO2 or SO2 of FO calculated using the TtW approach for dependent traction [kgCO2e/SO2e/tkm]

- Cd0WtTb—appropriate emission coefficient for the empty load of CO2 or SO2 of BO calculated using the WtT approach for dependent traction [kgCO2e/SO2e/tkm]

- Cd0WtTf—appropriate emission coefficient for the empty load of CO2 or SO2 of FO calculated using the WtT approach for dependent traction [kgCO2e/SO2e/tkm]

- CdTtWb—appropriate emission coefficient of CO2 or SO2 of BO calculated using the TtW approach for dependent traction [kgCO2e/SO2e/tkm]

- CdTtWf—appropriate emission coefficient of CO2 or SO2 of FO calculated using the TtW approach for dependent traction [kgCO2e/SO2e/tkm]

- CdWtTb—appropriate emission coefficient of CO2 or SO2 of BO calculated using the WtT approach for dependent traction [kgCO2e/SO2e/tkm]

- CdWtTf—appropriate emission coefficient of CO2 or SO2 of FO calculated using the WtT approach for dependent traction [kgCO2e/SO2e/tkm]

- Ci0TtWb—appropriate emission coefficient for the empty load of CO2 or SO2 of BO calculated using the TtW approach for independent traction [kgCO2e/SO2e/tkm]

- Ci0TtWf—appropriate emission coefficient for the empty load of CO2 or SO2 of FO calculated using the TtW approach for independent traction [kgCO2e/SO2e/tkm]

- Ci0WtTb—appropriate emission coefficient for the empty load of CO2 or SO2 of BO calculated using the WtT approach for independent traction [kgCO2e/SO2e/tkm]

- Ci0WtTf—appropriate emission coefficient for the empty load of CO2 or SO2 of FO calculated using the WtT approach for independent traction [kgCO2e/SO2e/tkm]

- CiTtWb—appropriate emission coefficient of CO2 or SO2 of BO calculated using the TtW approach for independent traction [kgCO2e/SO2e/tkm]

- CiTtWf—appropriate emission coefficient of CO2 or SO2 of FO calculated using the TtW approach for independent traction [kgCO2e/SO2e/tkm]

- CiWtTb—appropriate emission coefficient of CO2 or SO2 of BO calculated using the WtT approach for independent traction [kgCO2e/SO2e/tkm]

- CiWtTf—appropriate emission coefficient of CO2 or SO2 of FO calculated using the WtT approach for independent traction [kgCO2e/SO2e/tkm]

- FC1–3—different types of FC [−]

- k—type of transported PC [−]

- l—type of transported CB [−]

- l—internal coefficient defined by the company [−]

- L1—total transport distance [km]

- L1d—length of transport realized by RFT using dependent traction [km]

- L1i—length of transport realized by RFT using independent traction [km]

- L2—additional transport distance [km]

- L2d—additional length of transport realized by RFT using dependent traction [km]

- L2i—additional length of transport realized by RFT using independent traction [km]

- LF—railway car(s) load factor [−]

- LV—load volume of the load [−]

- LVmax—maximum load volume of the railway car required for transport [−]

- m—type of transported FC [−]

- nc—required number of railway cars for transport [−]

- ncbl—number of transported CB of type l [−]

- nfcm—number of transported FC of type m [−]

- npck—number of transported PC of type k [−]

- O—additional CO2 or SO2 emissions [kgCO2e/SO2e]

- OTtW—CO2 or SO2 emissions calculated using the TtW approach [kgCO2e/SO2e]

- OTtWb—CO2 or SO2 emissions of BO calculated using the TtW approach [kgCO2e/SO2e]

- OTtWf—CO2 or SO2 emissions of FO calculated using the TtW approach [kgCO2e/SO2e]

- OWtT—CO2 or SO2 emissions calculated using the WtT approach [kgCO2e/SO2e]

- OWtTb—CO2 or SO2 emissions of BO calculated using the WtT approach [kgCO2e/SO2e]

- OWtTf—CO2 or SO2 emissions of FO calculated using the WtT approach [kgCO2e/SO2e]

- R—total CO2 or SO2 emissions produced by the return transportation [kgCO2e/SO2e]

- RC1–32—different types of railway cars [−]

- RTtW—CO2 or SO2 emissions calculated using the TtW approach [kgCO2e/SO2e]

- RTtWb—CO2 or SO2 emissions of BO calculated using the TtW approach [kgCO2e/SO2e]

- RTtWf—CO2 or SO2 emissions of FO calculated using the TtW approach [kgCO2e/SO2e]

- RWtT—CO2 or SO2 emissions calculated using the WtT approach [kgCO2e/SO2e]

- RWtTb—CO2 or SO2 emissions of BO calculated using the WtT approach [kgCO2e/SO2e]

- RWtTf—CO2 or SO2 emissions of FO calculated using the WtT approach [kgCO2e/SO2e]

- Sd1—share of the total length of transport realized by RFT using dependent traction [−]

- Sd2—share of the additional length of transport realized by RFT using dependent traction [−]

- Si1—share of the total length of transport realized by RFT using independent traction [−]

- Si2—share of the additional length of transport realized by RFT using independent traction [−]

- T—total CO2 or SO2 emissions produced by transportation [kgCO2e/SO2e]

- V—weight of the freight [t]

- VCBl—weight of the CB of type l [t]

- VCm—weight of the freight in FC of type m [t]

- VFCm—weight of the FC of type m [t]

- Vmax—maximum freight weight of the railway cars required for transport [t]

- VPCk—weight of the PC of type k [t]

- VPl—weight of the pallet for CB of type l [t]

References

- Rungskunroch, P.; Shen, Z.J.; Kaewunruen, S. Benchmarking environmental and economic impacts from the HSR networks considering life cycle perspectives. Environ. Impact Assess. Rev. 2021, 90, 106608. [Google Scholar] [CrossRef]

- Cichozs, M.; Pluta-Zaremba, A. How to improve freight transport emissions’ management? LogForum 2019, 15, 93–105. [Google Scholar] [CrossRef]

- Lee, D.; Balachandran, S.; Pachon, J.; Shankaran, R.; Lee, S.; Mulholland, J.A.; Russell, A.G. Ensemble-trained PM2.5 source apportionment approach for health studies. Environ. Sci. Technol. 2009, 43, 7023–7031. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.W.; Zhang, M.; Zhou, M. Using LMDI method to analyze transport sector CO2 emissions in China. Energy 2011, 10, 5909–5915. [Google Scholar] [CrossRef]

- Lee, S.; Wang, Y.H.; Russell, A.G. Assessment of secondary organic carbon in the southeastern United States: A review. J. Air Waste Manag. Assoc. 2010, 60, 1282–1292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.; Russell, A.G.; Baumann, K. Source apportionment of fine particulate matter in the southeastern united states. J. Air Waste Manag. Assoc. 2007, 57, 1123–1135. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Liu, W.; Wang, Y.H.; Russell, A.G.; Edgerton, E.S. Source apportionment of PM2.5: Comparing PMF and CMB results for four ambient monitoriniz sites in the southeastern United States. Atmos. Environ. 2008, 42, 4126–4137. [Google Scholar] [CrossRef]

- Rungskunroch, P.; Shen, Z.J.; Kaewunruen, S. Getting it right on the policy prioritization for rail decarbonization: Evidence from whole-life CO2e emissions of railway systems. Front. Built Environ. 2021, 7, 638507. [Google Scholar] [CrossRef]

- Jung, J.; Lyu, Y.; Lee, M.; Hwang, T.; Lee, S.; Oh, S. Impact of Siberian forest fires on the atmosphere over the Korean Peninsula during summer 2014. Atmos. Chem. Phys. 2016, 16, 6757–6770. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Baumann, K.; Schauer, J.J.; Sheesley, R.J.; Naeher, L.P.; Meinardi, S.; Blake, D.R.; Edgerton, E.S.; Russell, A.G.; Clements, M. Gaseous and particulate emissions from prescribed burning in Georgia. Environ. Sci. Technol. 2005, 39, 9049–9056. [Google Scholar] [CrossRef]

- Jung, J.; Lee, S.; Kim, H.; Kim, D.; Lee, H.; Oh, S. Quantitative determination of the biomass-burning contribution to atmospheric carbonaceous aerosols in Daejeon, Korea, during the rice-harvest period. Atmos. Environ. 2014, 89, 642–650. [Google Scholar] [CrossRef]

- Balachandran, S.; Pachon, J.E.; Lee, S.; Oakes, M.M.; Rastogi, N.; Shi, W.Y.; Tagaris, E.; Yan, B.; Davis, A.; Zhang, X.L.; et al. Particulate and gas sampling of prescribed fires in South Georgia, USA. Atmos. Environ. 2013, 81, 125–135. [Google Scholar] [CrossRef]

- Liu, L.; Wang, K.; Wang, S.S.; Zhang, R.Q.; Tang, X.Y. Assessing energy consumption, CO2 and pollutant emissions and health benefits from China’s transport sector through 2050. Energy Policy 2018, 116, 382–396. [Google Scholar] [CrossRef]

- Georgatzi, V.V.; Stamboulis, Y.; Vetsikas, A. Examining the determinants of CO2 emissions caused by the transport sector: Empirical evidence from 12 European countries. Econ. Anal. Policy 2020, 65, 11–20. [Google Scholar] [CrossRef]

- Saboori, B.; Sapri, M.; Bin Baba, M. Economic growth, energy consumption and CO2 emissions in OECD (Organization for Economic Co-operation and Development)’s transport sector: A fully modified bi-directional relationship approach. Energy 2014, 66, 150–161. [Google Scholar] [CrossRef]

- Hao, H.; Geng, Y.; Li, W.; Bin, G. Energy consumption and GHG emissions from China’s freight transport sector: Scenarios through 2050. Energy Policy 2015, 85, 94–101. [Google Scholar] [CrossRef]

- Li, Y.; Du, Q.; Lu, X.R.; Wu, J.; Han, X. Relationship between the development and CO2 emissions of transport sector in China. Transp. Res. Part D Transp. Environ. 2019, 74, 1–14. [Google Scholar] [CrossRef]

- AutoSAP. Available online: https://autosap.cz/zakladni-prehledy-automotive/obecne-zakladni-prehledy (accessed on 20 May 2021).

- Inkinen, T.; Hämäläinen, E. Reviewing truck logistics: Solutions for achieving low emission road freight transport. Sustainability 2020, 12, 6714. [Google Scholar] [CrossRef]

- Matusiewicz, M. Towards sustainable urban logistics: Creating sustainable urban freight transport on the example of a limited accessibility zone in Gdansk. Sustainability 2019, 11, 3879. [Google Scholar] [CrossRef] [Green Version]

- EU Climate Action and the European Green Deal. EU Climate Action. Available online: https://ec.europa.eu/clima/policies/eu-climate-action_en (accessed on 21 May 2021).

- Nikas, A.; Elia, A.; Boitier, B.; Koasidis, K.; Doukas, H.; Cassetti, G.; Anger-Kraavi, A.; Bui, H.; Campagnolo, L.; Miglio, R.D.; et al. Where is the EU headed given its current climate policy? A stakeholder-driven model inter-comparison. Sci. Total Environ. 2021, 793, 148549. [Google Scholar] [CrossRef]

- Egli, F.; Stunzi, A. A dynamic climate finance allocation mechanism reflecting the Paris Agreement. Environ. Res. Lett. 2019, 14, 114024. [Google Scholar] [CrossRef]

- Chen, S.; Wu, J.; Zong, Y. The impact of the freight transport modal shift policy on China’s carbon emissions reduction. Sustainability 2020, 12, 583. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Xue, X.; Zhao, Z.; Wang, Y.; Zeng, Z. Finding the de-carbonization potentials in the transport sector: Application of scenario analysis with a hybrid prediction model. Environ. Sci. Pollut. Res. 2020, 27, 21762–21776. [Google Scholar] [CrossRef] [PubMed]

- Feng, F.; Liu, C.; Liu, H.; Ji, Z. Research on price of railway freight based on low-carbon economy. Math. Probl. Eng. 2016, 1–7. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Rungskunroch, P.; Jennings, D. A through-life evaluation of end-of-life rolling stocks considering asset recycling, energy recovering, and financial benefit. J. Clean. Prod. 2019, 212, 1008–1024. [Google Scholar] [CrossRef]

- Krezo, S.; Mirza, O.; He, Y.P.; Makim, P.; Kaewunruen, S. Field investigation and parametric study of greenhouse gas emissions from railway plain-line renewals. Transp. Res. Part D Transp. Environ. 2016, 42, 77–90. [Google Scholar] [CrossRef]

- Krezo, S.; Mirza, O.; Kaewunruen, S.; Sussman, J.M. Evaluation of CO2 emissions from railway resurfacing maintenance activities. Transp. Res. Part D Transp. Environ. 2018, 65, 458–465. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Yu, S.A. Global warming potentials due to railway tunnel construction and maintenance. Appl. Sci. 2020, 10, 6459. [Google Scholar] [CrossRef]

- Petro, F.; Konečný, V. Calculation of emissions from transport services and their use for the internalisation of external costs in road transport. Procedia Eng. 2017, 192, 677–682. [Google Scholar] [CrossRef]

- Eriksson, L.; Nielsen, L. Modelling and Control of Engines and Drivelines; John Wiley and Sons: Chennai, India, 2014. [Google Scholar]

- Skrúcaný, T.; Kendra, M.; Kalina, T.; Jurkovič, M. Environmental comparison of different transport modes. Naše More 2018, 65, 192–196. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Peng, J.Y. Life cycle cost, energy and carbon assessments of Beijing-Shanghai high-speed railway. Sustainability 2020, 12, 206. [Google Scholar] [CrossRef] [Green Version]

- Kaewunruen, S.; Peng, J.Y.; Phil-Ebosie, O. Digital twin aided sustainability and vulnerability audit for subway stations. Sustainability 2020, 12, 7873. [Google Scholar] [CrossRef]

- Pan, S.; Ballot, E.; Fontane, F. The reduction of greenhouse gas emissions from freight transport by pooling supply chains. Int. J. Prod. Econ. 2013, 143, 86–94. [Google Scholar] [CrossRef]

- Rouquet, A.; Vauché, L. A typology of logistics pooling in supply chains. Supply Chain Forum Int. J. 2015, 16, 2–12. [Google Scholar] [CrossRef]

- Senkel, M.-P.; Durand, B.; Vo, T.l.H. La mutualisation logistique: Entre théories et pratiques. Logistique Manag. 2013, 21, 19–30. [Google Scholar] [CrossRef]

- Lee, S.; Choi, Y.; Woo, J.; Kang, W.; Jung, J. Estimating and comparing greenhouse gas emissions with their uncertainties using different methods: A case study for an energy supply utility. J. Air Waste Manag. Assoc. 2014, 64, 1164–1173. [Google Scholar] [CrossRef] [Green Version]

- Padgett, J.P.; Steinemann, A.C.; Clarke, J.H.; Vandenbergh, M.P. A comparison of carbon calculators. Environ. Impact Assess. Rev. 2008, 28, 106–115. [Google Scholar] [CrossRef]

- Weigel, B.A.; Southworth, F.; Meyer, M.D. Calculators to estimate greenhouse gas emissions from public transit vehicles. Transp. Res. Rec. 2010, 2143, 125–133. [Google Scholar] [CrossRef]

- Rabionet, S.E. How I learned to design and conduct semi-structured interviews: An ongoing and continuous journey. Qual. Rep. 2009, 35, 203–206. [Google Scholar]

- Crist, K.; Bolling, K.; Schipperijn, J.; Hurst, S.; Takemoto, M.; Sallis, J.F.; Badland, H.; Kerr, J. Collaboration between physical activity researchers and transport planners: A qualitative study of attitudes to data driven approaches. J. Transp. Health 2018, 8, 157–168. [Google Scholar] [CrossRef]

- Hilgarter, K.; Granig, P. Public perception of autonomous vehicles: A qualitative study based on interviews after riding an autonomous shuttle. Transp. Res. Part F Traffic Psychol. Behav. 2020, 72, 226–243. [Google Scholar] [CrossRef]

- Qu, S.Q.; Dumay, J. The qualitative research interview. Qual. Res. Account. Manag. 2011, 8, 238–264. [Google Scholar] [CrossRef]

- Aljohani, K.; Thompson, R.G. An examination of last mile delivery practices of freight carriers servicing business receivers in inner-city areas. Sustainability 2020, 12, 2837. [Google Scholar] [CrossRef] [Green Version]

- Karolemeas, C.; Tsigdinos, S.; Tzouras, P.G.; Nikitas, A.; Bakogiannis, E. Determining electric vehicle charging station location suitability: A qualitative study of greek stakeholders employing thematic analysis and analytical hierarchy process. Sustainability 2021, 13, 2298. [Google Scholar] [CrossRef]

- Kaupa, F.; Naude, M.J. Critical success factors in the supply chain management of essential medicines in the public health-care system in Malawi. J. Glob. Oper. Strat. Sour. 2021, 1, 4. [Google Scholar] [CrossRef]

- Schlegel, A.; Birkel, H.S.; Hartmann, E. Enabling integrated business planning through big data analytics: A case study on sales and operations planning. Int. J. Phys. Distr. Logist. Manag. 2020, 11, 156. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Content Analysis: Theoretical Foundation, Basic Procedures and Software Solution; Leibniz-Institut für Sozialwissenschaften: Klagenfurt, Austria, 2014; Available online: https://www.psychopen.eu/fileadmin/user_upload/books/mayring/ssoar-2014-mayring-Qualitative_content_analysis_theoretical_foundation.pdf (accessed on 18 December 2020).

- Lutz, C.; Collins, J. Reading National Geographic; University of Chicago Press: Chicago, IL, USA, 1993. [Google Scholar]

- Bryman, A. Social Research Methods; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Schreier, M. Ways of doing qualitative content analysis: Disentangling terms and terminologies. Forum Qual. Soc. Res. 2014, 15, 1–27. [Google Scholar] [CrossRef]

- Sousa, S. Local planning attitudes: Comparative content analysis of municipal director plans of Portuguese shrinking cities. Bull. Geogr. 2019, 44, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Fischhendler, I.; Tenenboim-Weinblatt, K. The peace dividend as an intangible benefit in mega-project justification: A comparative content analysis of the Dead Sea-Red Sea Canal. Geoforum 2019, 101, 141–149. [Google Scholar] [CrossRef]

- Kim, R.C. Can Creating Shared Value (CSV) and the United Nations Sustainable Development Goals (UN SDGs) collaborate for a better world? Insights from East Asia. Sustainability 2018, 11, 4128. [Google Scholar] [CrossRef] [Green Version]

- Ponelis, S.R. Using interpretive qualitative case studies for exploratory research in doctoral studies: A case of Information Systems research in small and medium enterprises. Int. J. Dr. Stud. 2015, 10, 535–550. [Google Scholar] [CrossRef] [Green Version]

- Bygrave, W.D. The entrepreneurship paradigm (I): A philosophical look at its research methodologies. Entrep. Theory Pract. 1989, 14, 7–26. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Frishammar, J.; Cenamor, J.; Cavalli-Bjorkman, H.; Hernell, E.; Carlsson, J. Digital strategies for two-sided markets: A case study of shopping malls. Decis. Supp. Syst. 2018, 108, 34–44. [Google Scholar] [CrossRef]

- Alvarez, C.B.; Adhikari, P.; Mejia, A.G. Management accounting practices and efficiency in a Colombian multi-utility conglomerate. J. Accoun. Emerg. Econ. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Diab, A.A.A. Interplay between labour dynamics, accounting and accountability practices during the rise of a political logic: An Egyptian case study. Qualit. Res. Accoun. Manag. 2020, 17, 675–702. [Google Scholar] [CrossRef]

- Respondent 1; (Leading company in the automotive industry, Czech Republic). Personal communication, 2021.

- Respondent 2; (Leading company in the automotive industry, Czech Republic). Personal communication, 2021.

- Respondent 3; (Leading company in the automotive industry, Czech Republic). Personal communication, 2021.

- Respondent 4; (Leading company in the automotive industry, Czech Republic). Personal communication, 2021.

- EcoPassenger. Available online: http://ecopassenger.org/bin/query.exe/en?L=vs_uic (accessed on 6 February 2021).

- Public Transport Carbon Footprint Calculator. Carbon Foot Print. Available online: https://calculator.carbonfootprint.com/calculator.aspx?tab=6 (accessed on 6 February 2021).

- Calculate and Reduce the CO2 Emissions of Your Train Journey. EcoTree. Available online: https://ecotree.green/en/calculate-train-co2 (accessed on 6 February 2021).

- CO2 Calculator—Emissions from Trains. The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/CO2-emissions-transport-car-plane-train-bus-d_2000.html (accessed on 6 February 2021).

- Emission Calculator for Greenhouse Gases and Exhaust Emissions. EcoTransIT World. Available online: https://www.ecotransit.org/en/emissioncalculator/ (accessed on 6 February 2021).

- Carbon Calculator. CN. Available online: https://www.cn.ca/en/delivering-responsibly/environment/emissions/carbon-calculator/ (accessed on 7 February 2021).

- CO2 Emissions Calculator. CarbonCare. Available online: https://www.carboncare.org/en/co2-emissions-calculator.html (accessed on 7 February 2021).

- World Land Trust. Available online: https://www.worldlandtrust.org/carbon-calculator/individual/transport/transport-calculator/ (accessed on 7 February 2021).

- Travelling by Train Is One of the Lowest Carbon Modes of Transport, Other than Using Your Own Two Feet of Course. ScotRail. Available online: https://www.scotrail.co.uk/carbon-calculator (accessed on 8 February 2021).

- BNSF Railway Carbon Estimator. Available online: https://domino.bnsf.com/website/carbon.nsf/ce?open (accessed on 8 February 2021).

- CO2 Calculator. Logward. Available online: https://www.logward.com/co2-calculator?gclid=EAIaIQobChMIlsrTtPv47wIVGKd3Ch2AggkbEAMYAyAAEgK60fD_BwE (accessed on 8 February 2021).

- Trees for All. Available online: https://treesforall.nl/en/calculate-emission/ (accessed on 8 February 2021).

- Logistic Emissions Calculator. Available online: https://kalogemis.upce.cz/ (accessed on 16 May 2021).

| No. | Source | Railway Transport | Transport of PC, CB, and FC | Own Vehicle Option | Restrictive Condition Implementation | One-Way and Return Transport | CO2e and SO2e Outputs | Total and Average Emission Outputs | WtW, WtT and TtW Calculation Approach |

|---|---|---|---|---|---|---|---|---|---|

| 1 | [67] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| 2 | [68] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| 3 | [69] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| 4 | [70] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| 5 | [71] | RFT | NA | Y | NA | Y | Y | Only total emissions | Y |

| 6 | [72] | RFT | NA | NA | NA | NA | Only CO2e | Only total emissions | NA |

| 7 | [73] | RFT | NA | NA | NA | NA | Only CO2e | Only total emissions | Y |

| 8 | [74] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| 9 | [75] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| 10 | [76] | RFT | NA | NA | NA | NA | Only CO2e | Only total emissions | NA |

| 11 | [77] | RFT | NA | NA | NA | NA | Only CO2e | Only total emissions | NA |

| 12 | [78] | RPT | NFA | NFA | NFA | NFA | NFA | NFA | NFA |

| CO2 Emissions | WtT Biogenic Origin [kgCO2e] | WtT Fossil Origin [kgCO2e] | TtW Biogenic Origin [kgCO2e] | TtW Fossil Origin [kgCO2e] |

|---|---|---|---|---|

| Total by origin | 407.635548192 | 2501.250570017 | 160.390886400 | 2098.447430400 |

| Average per 1 km | 0.863634636 | 5.299259682 | 0.339811200 | 4.445863200 |

| Average per 1 t | 0.547014960 | 3.356482246 | 0.215232000 | 2.815952000 |

| Average per 1 tkm | 0.001158930 | 0.007111191 | 0.000456000 | 0.005966000 |

| Total WtT | 2908.886118209 | NC | ||

| Total TtW | NC | 2258.838316800 | ||

| Total WtW | 5167.724435009 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chocholac, J.; Hruska, R.; Machalik, S.; Sommerauerova, D.; Krupka, J. Customized Approach to Greenhouse Gas Emissions Calculations in Railway Freight Transport. Appl. Sci. 2021, 11, 9077. https://doi.org/10.3390/app11199077

Chocholac J, Hruska R, Machalik S, Sommerauerova D, Krupka J. Customized Approach to Greenhouse Gas Emissions Calculations in Railway Freight Transport. Applied Sciences. 2021; 11(19):9077. https://doi.org/10.3390/app11199077

Chicago/Turabian StyleChocholac, Jan, Roman Hruska, Stanislav Machalik, Dana Sommerauerova, and Jiri Krupka. 2021. "Customized Approach to Greenhouse Gas Emissions Calculations in Railway Freight Transport" Applied Sciences 11, no. 19: 9077. https://doi.org/10.3390/app11199077

APA StyleChocholac, J., Hruska, R., Machalik, S., Sommerauerova, D., & Krupka, J. (2021). Customized Approach to Greenhouse Gas Emissions Calculations in Railway Freight Transport. Applied Sciences, 11(19), 9077. https://doi.org/10.3390/app11199077