A Novel Fault Feature Extraction Method for Bearing Rolling Elements Using Optimized Signal Processing Method

Abstract

:1. Introduction

2. VMD with Kurtosis Mean (KMVMD)

- Step 1: Determine the number of modes.

- Step 2: Decompose fault signals using VMD in order to obtain IMFs in different . ;

- Step 3: Calculate the kurtosis of each IMF, the set of kurtosis of IMF is obtained.;

- Step 4: In ,larger kurtosis is selected, so the set of larger kurtosis is obtained. . When , , When ;

- Step 5: Calculate the mean of larger kurtosis. ;

- Step 6: Finding the maximum value in {;

- Step 7: The mode number corresponding to is the number of modes for VMD, and the modes with larger kurtosis values are chosen to obtain the reconstructed signal.

3. MCMD with Power Spectral Entropy and Grid Search (PGMCKD)

3.1. MCKD

3.2. Parameter Optimization of MCKD

4. A Fault Feature Extraction Method

5. The Experiment and Analysis

5.1. Fault Data from CWRU

5.1.1. Experimental Analysis

5.1.2. Comparison Analysis

5.1.3. Experimental Results under Variable Condition

5.2. Fault Data from QPZZ-∏

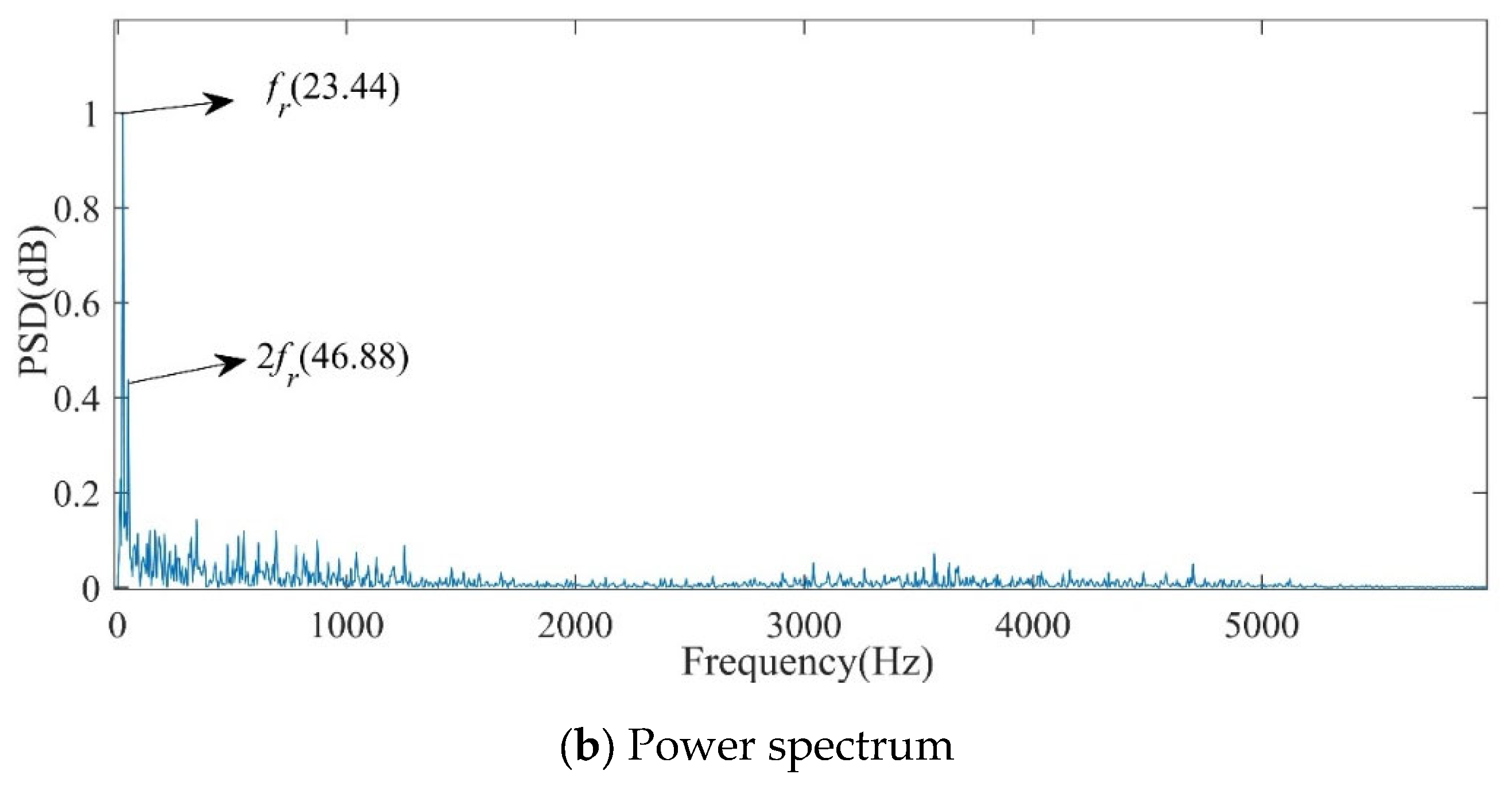

5.2.1. Experimental Analysis

5.2.2. Comparison Analysis

5.2.3. Experimental Results under Variable Working Condition

6. Conclusions

- (1).

- The kurtosis mean has a suitable effect on the selection of mode number, which avoids the phenomenon of over decomposition or under decomposition and provides a suitable foundation for further processing;

- (2).

- The power spectrum entropy is used as the evaluation criterion for the selection of parameters in MCKD. The difference between the actual and theoretical conditions is considered. The L and the T are adaptively selected, which improves the effect of MCKD on the enhancement of weak fault features;

- (3).

- The combination of improved VMD and MCKD fully suppresses the noise interference on the fault features, highlights the periodic impact component, and solves difficult fault feature problems for bearing rolling elements. The effectiveness of the KMVMD-PGMCKD is also verified by experiments;

- (4).

- The signal processing effect of KMVMD-PGMCKD is not affected by the variable working condition. The experiment shows that KMVMD-PGMCKD has a strong generalization ability under the variable working condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.L.; Wu, Y.J.; Zhen, C.G. Rolling bearing fault diagnosis based on variational mode decomposition and fuzzy c-means clustering. Proc. Chin. Soc. Electr. Eng. 2015, 35, 3358–3365. [Google Scholar]

- Jin, T.; Xia, H.; Chen, H. Optimal control problem of the uncertain second-order circuit based on first hitting criteria. Math. Methods Appl. Sci. 2021, 44, 882–900. [Google Scholar] [CrossRef]

- Li, B.; Chow, M.Y.; Tipsuwan, Y.; Hung, J.C. Neural-network-based motor rolling bearing fault diagnosis. IEEE Trans. Ind. Electron. 2000, 47, 1060–1069. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Yuan, Y.; Zou, L.; Deng, W.; Guo, C.; Zhao, H.M. Study on a novel fault diagnosis method based on VMD and BLM. Symmetry 2019, 11, 747. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Zhang, X.; Du, Y.; Zheng, Y.; Cao, Z. Path planning of coastal ships based on optimized DQN reward function. J. Mar. Sci. Eng. 2021, 9, 210. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, H.; Luo, J.; Zhang, Q.; Jiao, S.; Zhang, X. Enhanced Moth-flame optimizer with mutation strategy for global optimization. Inf. Sci. 2019, 492, 181–203. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. Lond. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Tse, P.W.; Peng, Y.H.; Yam, R. Wavelet analysis and envelope detection for rolling element bearing fault diagnosis—Their effectiveness and flexibilities. J. Vib. Acoust. 2001, 123, 303–310. [Google Scholar] [CrossRef]

- Jin, T.; Xia, H.; Deng, W.; Li, Y.; Chen, H. Uncertain fractional-order multi-objective optimization based on reliability analysis and application to fractional-order circuit with Caputo type. Circuits Syst. Signal Process. 2021, 1–28. [Google Scholar] [CrossRef]

- Li, T.Y.; Shi, J.Y.; Zhang, D.H. Color image encryption based on joint permutation and diffusion. J. Electron. Imaging 2021, 30, 013008. [Google Scholar] [CrossRef]

- Rasolofondraibe, L.; Pottier, B.; Marconnet, P.; Perrin, E. Numerical model of the capacitive probe’s capacitance for measuring the external loads transmitted by the bearing’s rolling elements of rotating machines. IEEE Sens. J. 2013, 13, 3067–3072. [Google Scholar] [CrossRef]

- Nikolaou, N.G.; Antoniadis, I.A. Rolling element bearing fault diagnosis using wavelet packets. NDT&E Int. 2002, 35, 197–205. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.S. A roller bearing fault diagnosis method based on EMD energy entropy and ANN. J. Sound Vib. 2006, 294, 269–277. [Google Scholar]

- Eren, L.; Devaney, M.J. Bearing damage detection via wavelet packet decomposition of the stator current. IEEE Trans. Instrum. Meas. 2004, 53, 431–436. [Google Scholar] [CrossRef]

- Jin, T.; Ding, H.; Li, B.; Xia, H.; Xue, C. Valuation of interest rate ceiling and floor based on the uncertain fractional differential equation in Caputo sense. J. Intell. Fuzzy Syst. 2021, 40, 5197–5206. [Google Scholar] [CrossRef]

- Zhao, H.M.; Liu, H.D.; Jin, Y.; Xue, C.X. Feature extraction for data-driven remaining useful life prediction of rolling bearings. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Shao, H.D.; Zhong, X.; Cheng, J. Symplectic weighted sparse support matrix machine for gear fault diagnosis. Measurement 2021, 168, 108392. [Google Scholar] [CrossRef]

- Li, T.Y.; Zhou, M. ECG classification using wavelet packet entropy and random forests. Entropy 2016, 18, 285. [Google Scholar] [CrossRef]

- Deng, W.; Shang, S.F.; Cai, X.; Zhao, H.M.; Xu, J.J. An improved differential evolution algorithm and its application in optimization problem. Soft Comput. 2021, 7, 5277–5298. [Google Scholar] [CrossRef]

- Rai, V.K.; Mohanty, A.R. Bearing fault diagnosis using FFT of intrinsic mode functions in Hilbert–Huang transform. Mech. Syst. Signal Process. 2007, 21, 2607–2615. [Google Scholar] [CrossRef]

- Mandic, D.P.; Rehman, N.U.; Wu, Z.; Huang, N.E. Empirical mode decomposition-based time-frequency analysis of multivariate signals: The power of adaptive data analysis. IEEE Signal Process. Mag. 2013, 30, 74–86. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, Y.; Yang, Y. A rotating machinery fault diagnosis method based on local mean decomposition. Digit. Signal Process. 2012, 22, 356–366. [Google Scholar] [CrossRef]

- Guo, W.; Peter, W.T. A novel signal compression method based on optimal ensemble empirical mode decomposition for bearing vibration signals. J. Sound Vib. 2013, 332, 423–441. [Google Scholar] [CrossRef]

- Wu, Y.J.; Zhen, C.G.; Liu, C.L. Application of variational mode decomposition in wind power fault diagnosis. Mech. Transm 2015, 129–132. [Google Scholar]

- Deng, W.; Shang, S.; Cai, X.; Zhao, H.M.; Zhou, Y.Q.; Chen, H.Y.; Deng, W.Q. Quantum differential evolution with cooperative coevolution framework and hybrid mutation strategy for large scale optimization. Knowl.-Based Syst. 2021, 224, 107080. [Google Scholar] [CrossRef]

- Zhao, H.; Li, D.; Deng, W.; Yang, X. Research on vibration suppression method of alternating current motor based on fractional order control strategy. Proc. Inst. Mech. Eng. Part E J. Process. 2017, 231, 786–799. [Google Scholar] [CrossRef]

- Jin, T.; Ding, H.; Xia, H.; Bao, J. Reliability index and Asian barrier option pricing formulas of the uncertain fractional first-hitting time model with Caputo type. Chaos Solitons Fractals 2021, 142, 110409. [Google Scholar] [CrossRef]

- Wu, H.; Liang, S.; Zou, L. Method of evaluating aerodynamic damping of tall buildings based on wavelet analysis. J. Vib. Shock 2008, 4, 93–96. [Google Scholar]

- Jin, T.; Yang, X.; Xia, H.; Ding, H. Reliability index and option pricing formulas of the first hitting time model based on the uncertain fractional-order differential equation with Caputo type. Fractals 2021, 29, 2150012. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Q.; Luo, J.; Xu, Y.; Zhang, X. An enhanced Bacterial Foraging Optimization and its application for training kernel extreme learning machine. Appl. Soft Comput. 2020, 86, 105884. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Tran Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Z.; Feng, K. Research on variational mode decomposition in rolling bearings fault diagnosis of the multistage centrifugal pump. Mech. Syst. Signal Process. 2017, 93, 460–493. [Google Scholar] [CrossRef] [Green Version]

- Miao, Y.; Zhao, M.; Lin, J. Identification of mechanical compound-fault based on the improved parameter-adaptive variational mode decomposition. ISA Trans. 2019, 84, 82–95. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.L.; Jia, Y.F.; Wang, L.W.; Li, L.; Zheng, Y. Feature extraction and classification on partial discharge signals of power transformers based on improved variational mode decomposition and Hilbert transform. Trans. China Electrotech. Soc. 2017, 32, 221–235. [Google Scholar]

- Pu, Z.X.; Yin, H.; Zhang, N.; Yan, W.; Peng, Z. Bearing fault diagnosis using vmd and stationary wavelet method based on kurtosis criterion. Mach. Des. Res. 2017, 33, 67–71. [Google Scholar]

- Mcdonald, G.L.; Zhao, Q.; Zuo, M.J. Maximum correlated kurtosis deconvolution and application on gear tooth chip fault detection. Mech. Syst. Signal Process. 2012, 33, 237–255. [Google Scholar] [CrossRef]

- Tang, G.J.; Wang, X.L. Weak feature extraction of gear fault based on maximum correlated kurtosis deconvolution and sparse code shrinkage. J. Vib. Eng. 2015, 28, 478–486. [Google Scholar]

- Zhongliang, L.; Tang, B.; Zhou, Y.; Meng, J. Rolling bearing early fault diagnosis based on maximum correlated kurtosis deconvolution optimized with grid search algorithm. J. Vib. Shock 2016, 35, 29–34. [Google Scholar]

- Zhao, H.M.; Sun, M.; Deng, W.; Yang, X. A new feature extraction method based on EEMD and multi-scale fuzzy entropy for motor bearing. Entropy 2016, 19, 14. [Google Scholar] [CrossRef] [Green Version]

- Deng, W.; Liu, H.; Zhang, S.; Liu, H.; Zhao, H.; Wu, J. Research on an adaptive variational mode decomposition with double thresholds for feature extraction. Symmetry 2018, 10, 684. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; He, G.; Du, W.; Zhou, J.; Kou, Y. Application of parameter optimized variational mode decomposition method in fault diagnosis of gearbox. IEEE Access 2019, 7, 44871–44882. [Google Scholar] [CrossRef]

- Shao, H.D.; Lin, J.; Zhang, L.W.; Galar, D.; Kumar, U. A novel approach of multisensory fusion to collaborative fault diagnosis in maintenance. Inf. Fusion 2021, 74, 65–76. [Google Scholar] [CrossRef]

- Wrzochal, M.; Adamczak, S. The problems of mathematical modelling of rolling bearing vibrations. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 1363–1372. [Google Scholar]

- Luo, C.; Jia, M.; Wen, Y. The diagnosis approach for rolling bearing fault based on Kurtosis criterion EMD and Hilbert envelope spectrum. In Proceedings of the2017 IEEE 3rd Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 3–5 October 2017; pp. 843–847. [Google Scholar]

- Available online: https://csegroups.case.edu/bearingdatacenter/pages/welcome-case-western-reserve-university-bearing-data-center-website (accessed on 10 May 2021).

| Kurtosis | IMF1 | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | Kurtosis Mean | |

|---|---|---|---|---|---|---|---|---|---|

| k | |||||||||

| 2 | 3.0346 | 3.0406 | 3.0406 | ||||||

| 3 | 3.0427 | 3.1279 | 3.0361 | 3.0853 | |||||

| 4 | 2.5209 | 2.118 | 3.1205 | 3.0365 | 3.0785 | ||||

| 5 | 2.519 | 2.1155 | 3.0974 | 3.4117 | 2.7499 | 3.0863 | |||

| 6 | 2.3611 | 2.9584 | 3.1004 | 3.4003 | 2.7476 | 3.1516 | 3.2174 | ||

| 7 | 2.3452 | 3.0009 | 1.9672 | 3.0901 | 3.4083 | 2.7464 | 3.1055 | 3.2013 | |

| Kurtosis | IMF1 | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | Kurtosis Mean | |

|---|---|---|---|---|---|---|---|---|---|

| k | |||||||||

| 2 | 4.3737 | 4.2419 | 4.3737 | ||||||

| 3 | 4.3696 | 4.2406 | 4.8543 | 4.6119 | |||||

| 4 | 4.2420 | 4.3257 | 5.7181 | 4.8536 | 5.2850 | ||||

| 5 | 3.6537 | 3.5656 | 4.4510 | 5.4256 | 4.8390 | 4.9052 | |||

| 6 | 3.3937 | 3.5400 | 4.4029 | 5.7447 | 5.3062 | 4.8391 | 5.2960 | ||

| 7 | 3.3374 | 4.3578 | 4.3320 | 5.7153 | 5.6530 | 5.2321 | 3.4010 | 5.5334 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Li, Y.; Yu, L.; Ma, J.; Zhu, L.; Li, L.; Chen, H.; Deng, W. A Novel Fault Feature Extraction Method for Bearing Rolling Elements Using Optimized Signal Processing Method. Appl. Sci. 2021, 11, 9095. https://doi.org/10.3390/app11199095

Li W, Li Y, Yu L, Ma J, Zhu L, Li L, Chen H, Deng W. A Novel Fault Feature Extraction Method for Bearing Rolling Elements Using Optimized Signal Processing Method. Applied Sciences. 2021; 11(19):9095. https://doi.org/10.3390/app11199095

Chicago/Turabian StyleLi, Weihan, Yang Li, Ling Yu, Jian Ma, Lei Zhu, Lingfeng Li, Huayue Chen, and Wu Deng. 2021. "A Novel Fault Feature Extraction Method for Bearing Rolling Elements Using Optimized Signal Processing Method" Applied Sciences 11, no. 19: 9095. https://doi.org/10.3390/app11199095