Opportunities and Barriers for Valorizing Waste Incineration Bottom Ash: Iberian Countries as a Case Study

Abstract

:1. Introduction

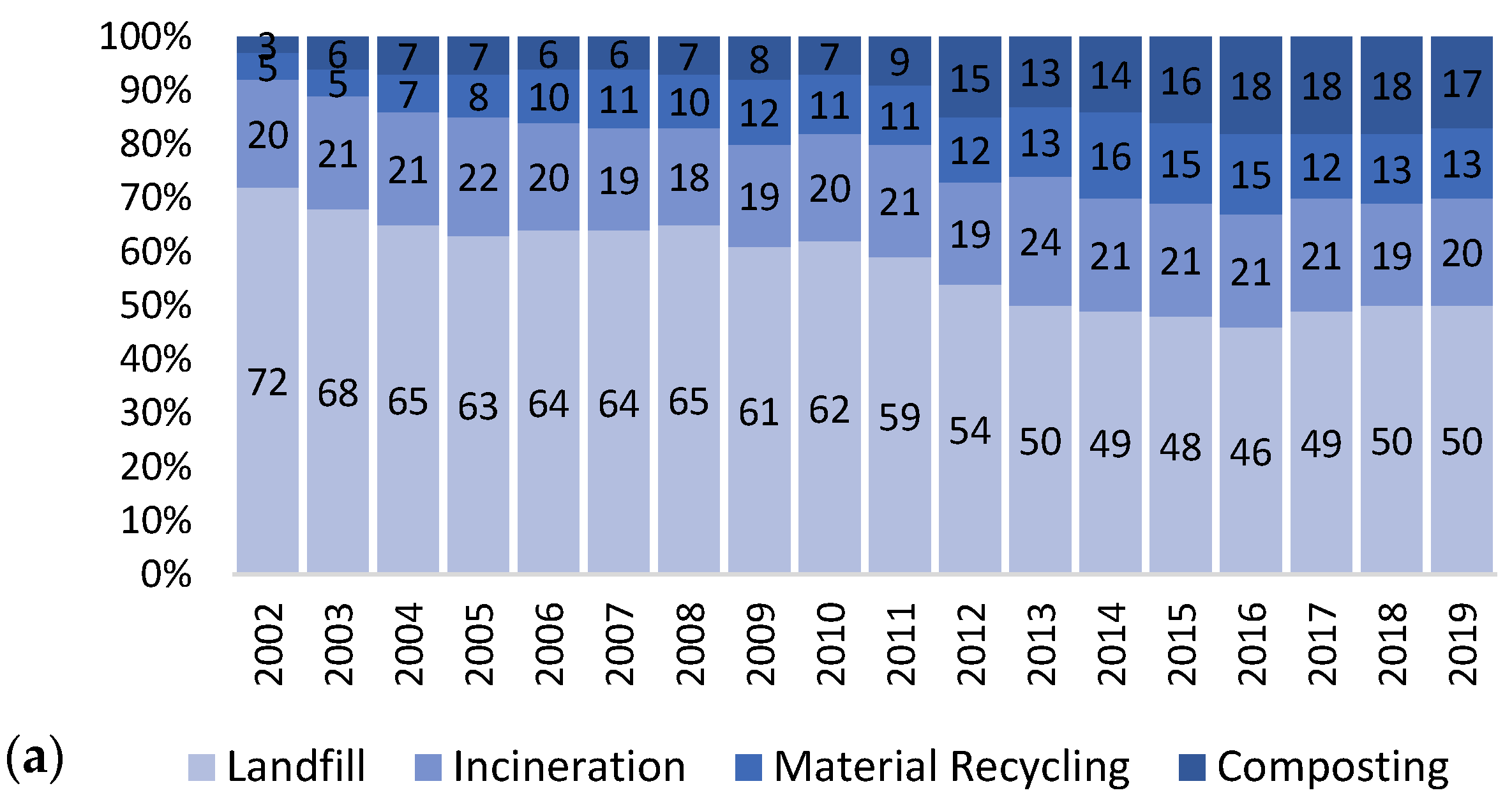

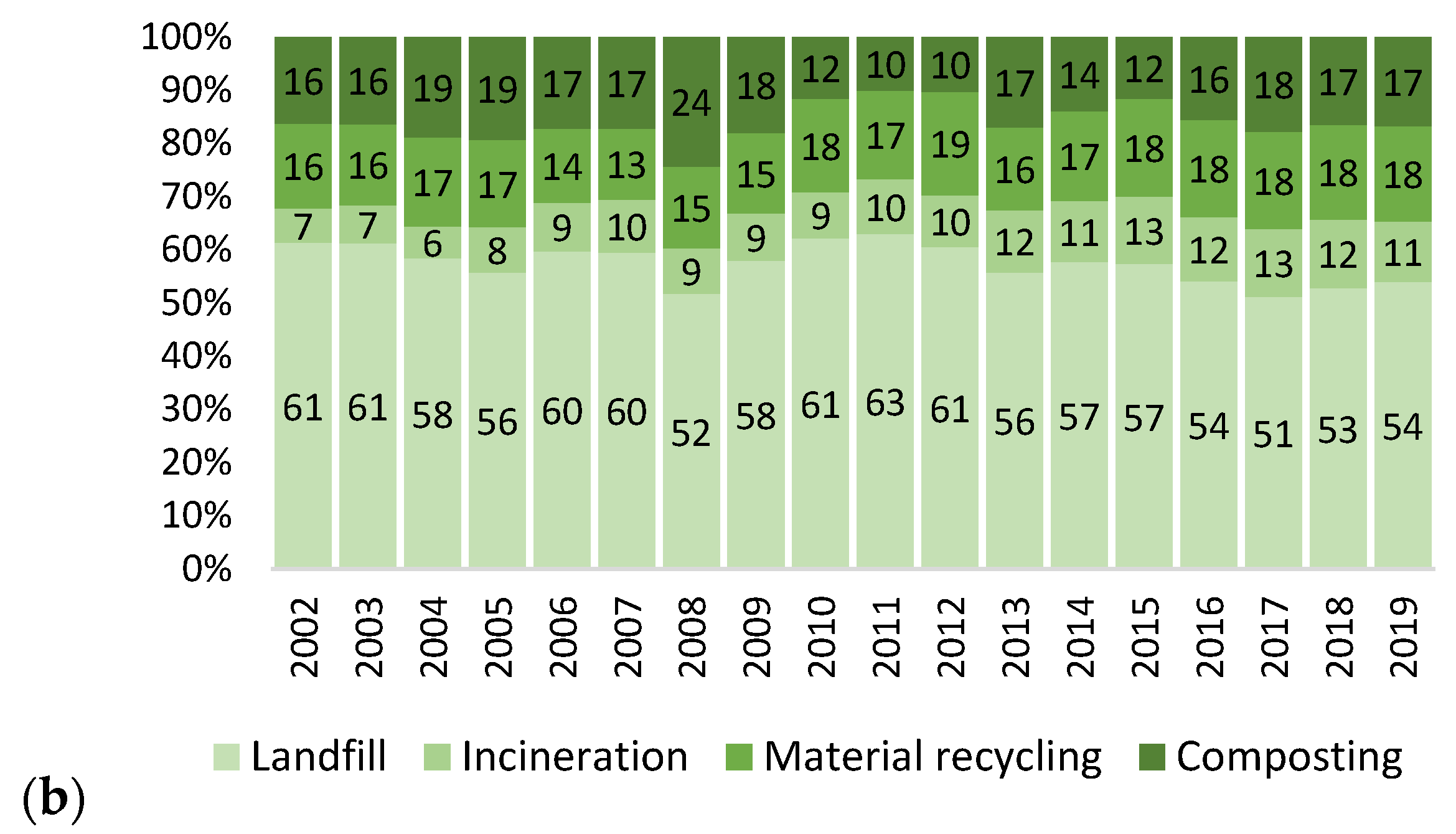

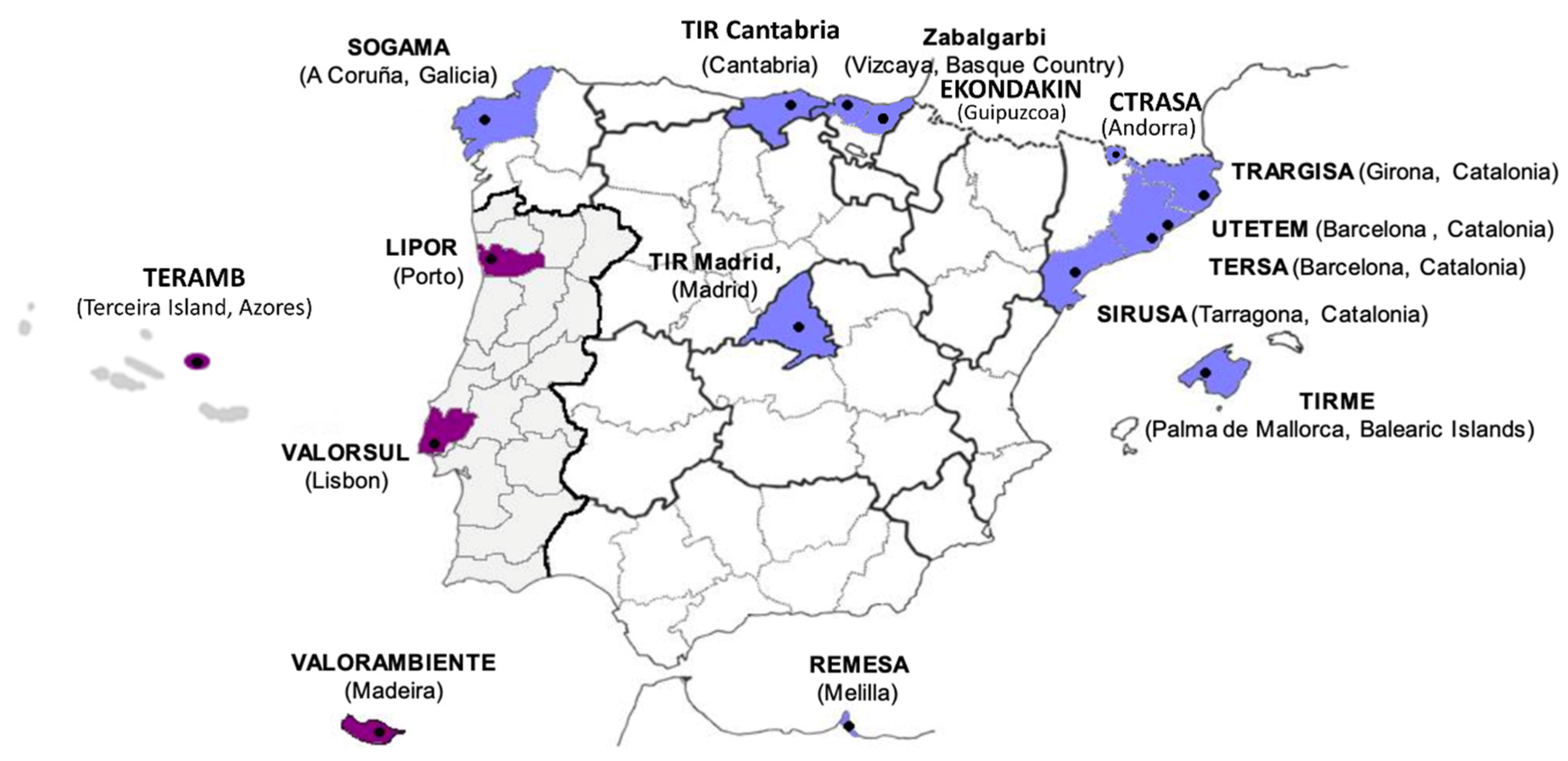

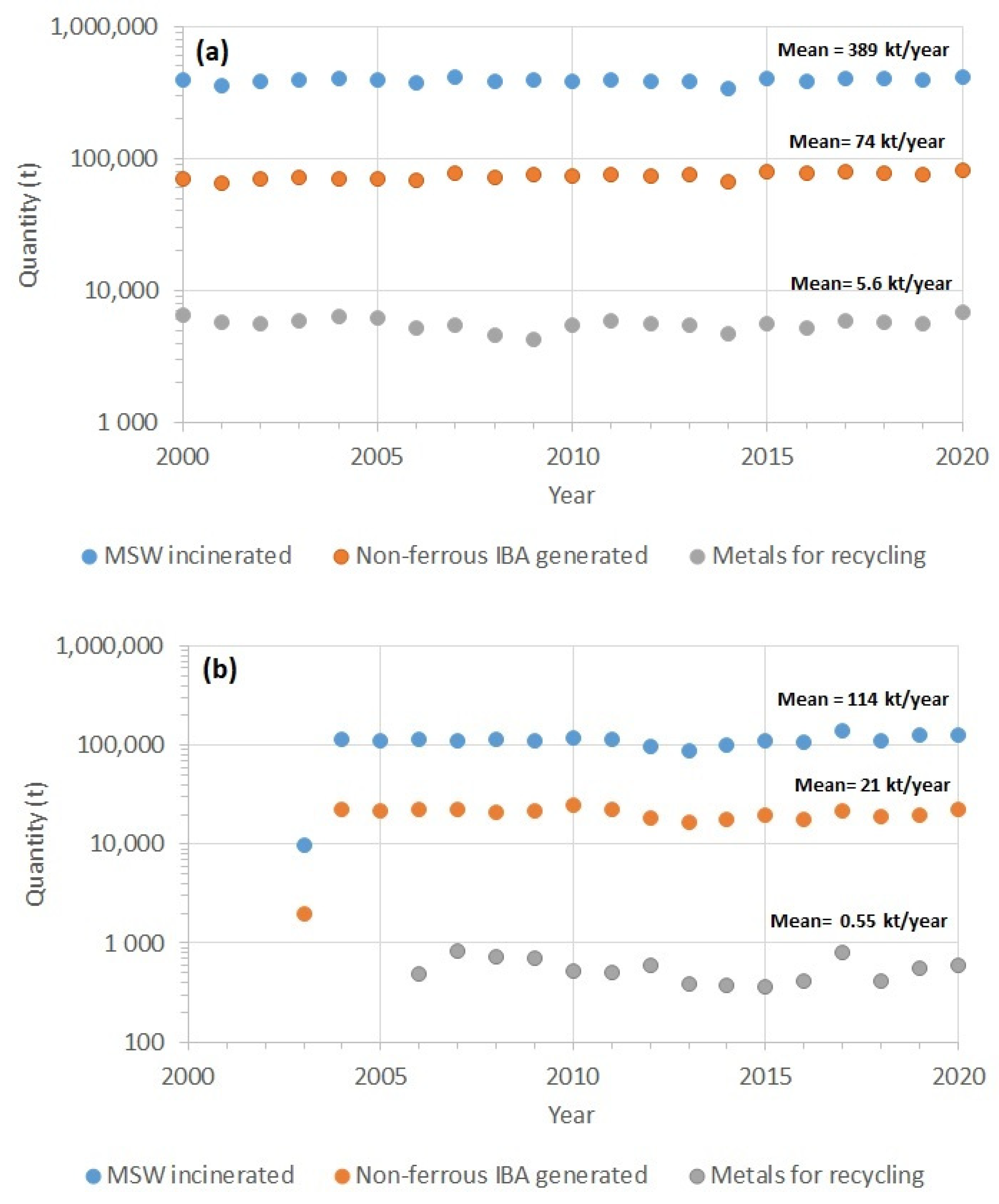

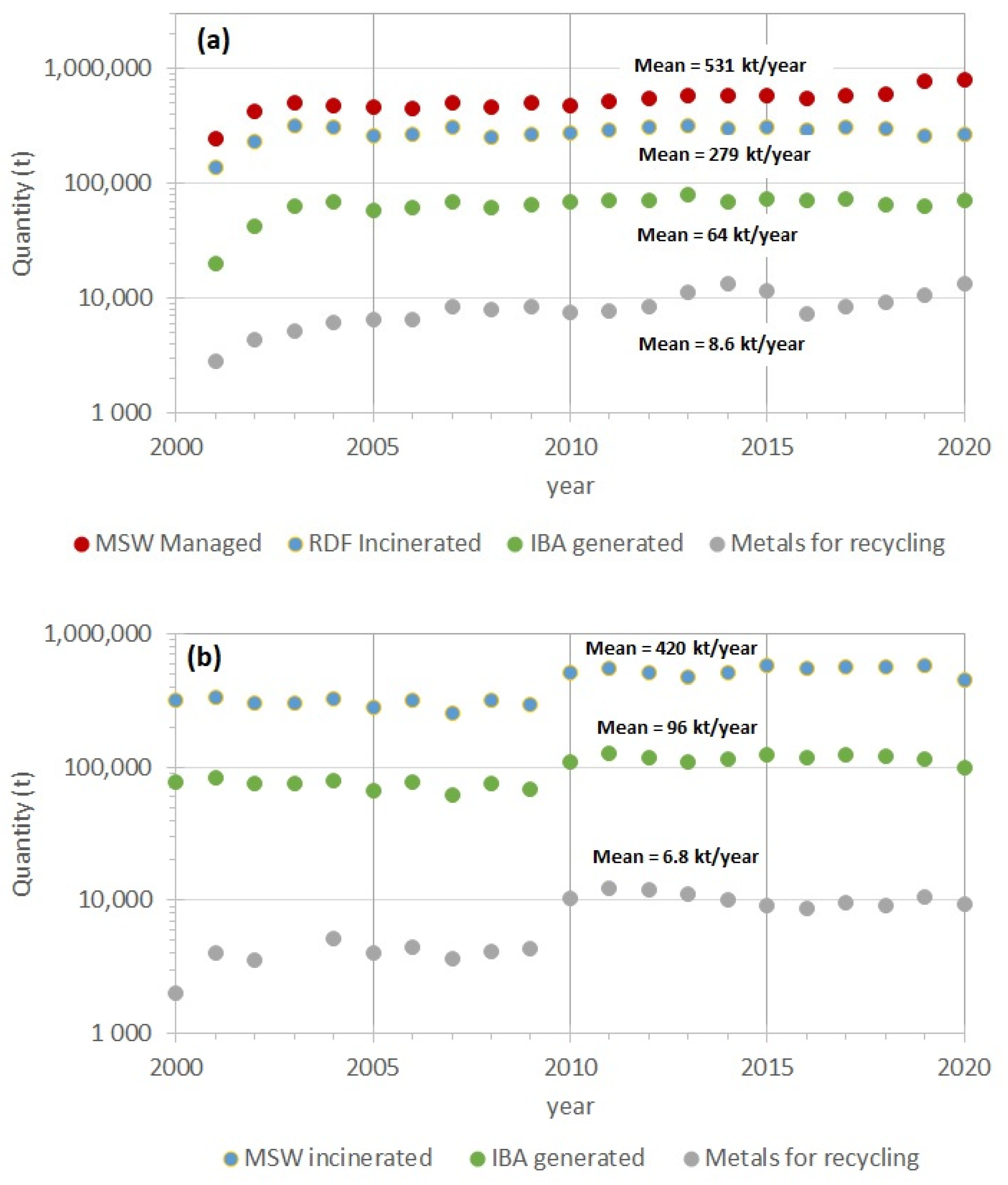

2. Incineration in the Iberian Countries

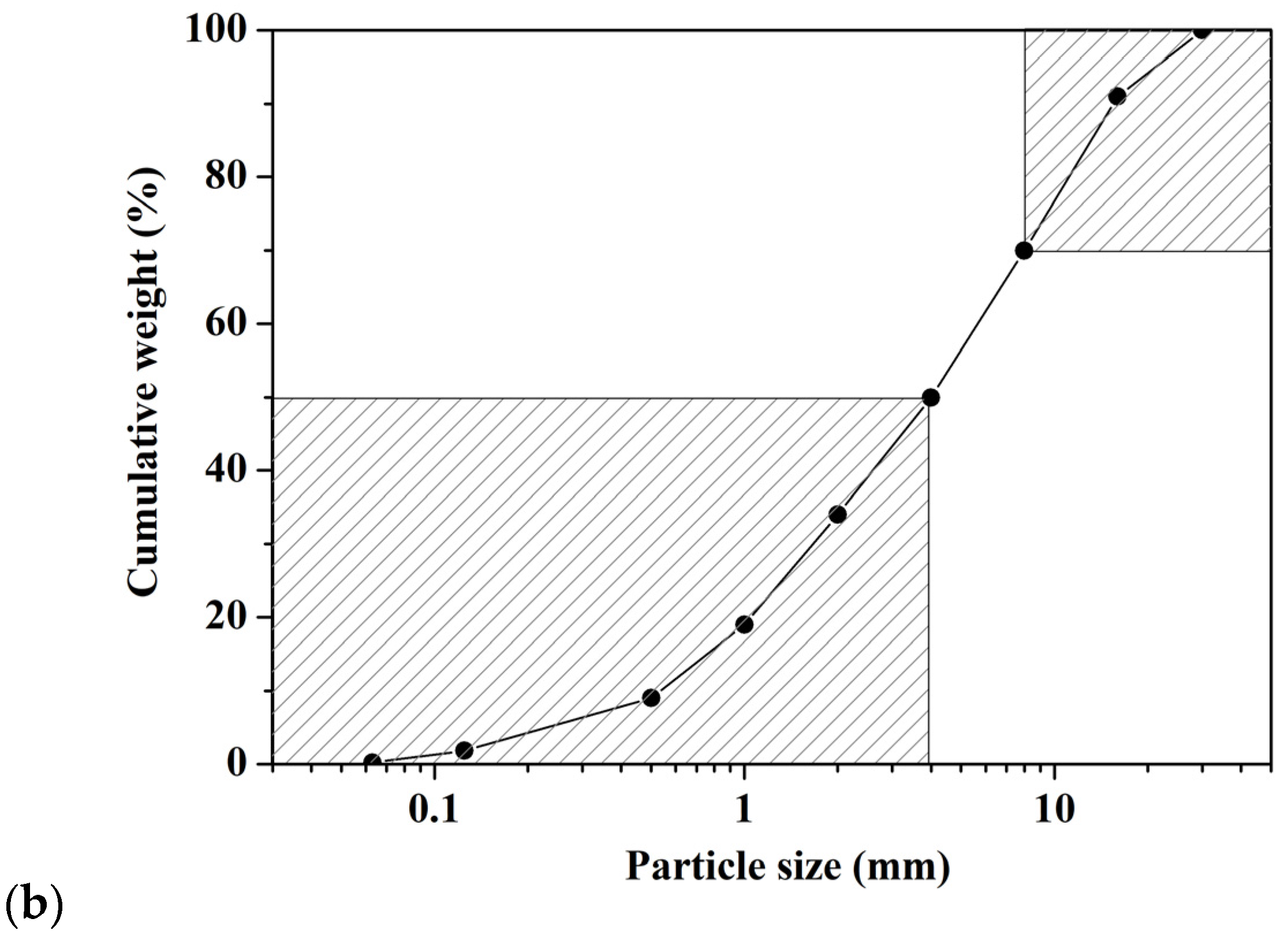

3. IBA Production and Characterization

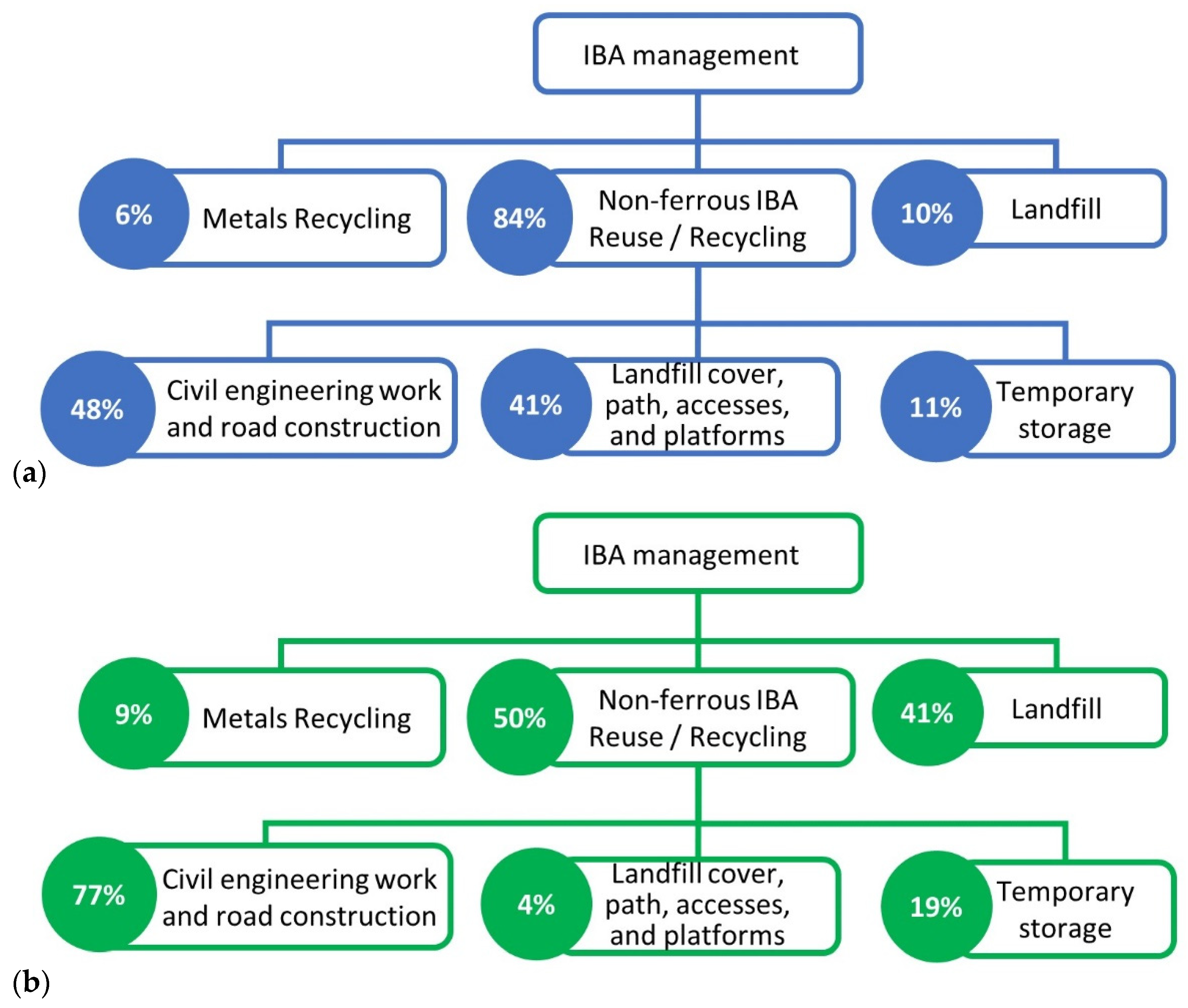

4. Current Management of IBA

- It will not be used in flood areas.

- It will not be used within 30 cm of rivers or streams.

- It will not be used on land that has its water paddock less than 5 m from the surface of the soil.

- It will not be used within 100 m of any operation of groundwater for the supply of drinking water to populations. If there are supply wells within its radius of influence that may be affected, a study of its power behavior must be studied for its authorization.

- It cannot be used in areas with significant thicknesses of the following materials:

- -

- Consolidated materials with high permeability due to intense cracking.

- -

- Non-consolidated porous materials such as current alluvial deposits and current coastal plains, terraces, and old alluvial deposits, which are not cemented.

- -

- Layers of surface alteration of materials originally permeable.

- It can only be used as a sub-base of roads when the slag layer used does not exceed a thickness of 50 cm and if the road has an asphalt surface layer on its surface.

- It may only be used for leveling of terrain and embankments if it is applied in layers of a thickness of 1 m on average for every 1000 m2 of extension without exceeding in any circumstances the layer of slag 2 m height and provided that the surface is then covered with densely compacted material.

- It may only be used for filling and restoration of degradable areas from extractive activities only if it is a filling on clay soils or restoration of clay extractions. In any case, it will be necessary to make a suitable sealing of the surface and drainage of rainwater.

5. Potential Drivers, Barriers, and Prospects for IBA Use

6. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brunner, P.H. Cycles, spirals and linear flows. Waste Manag. Res. 2013, 31, 1–2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quicker, P.; Consonni, S.; Grosso, M. The Zero Waste utopia and the role of waste-to-energy. Waste Manag. Res. 2020, 38, 481–484. [Google Scholar] [CrossRef]

- Eurostat. Municipal Waste by Waste Management Operations. Available online: http://appsso.eurostat.ec.europa.eu/nui/submitViewTableAction.do (accessed on 14 October 2020).

- PERSU. Plano Estratégico Para os Resíduos Urbanos 2014–2020, Portaria n.o 187-A/2014, Publicada em DR (I Série) n.o 179. Available online: https://dre.pt/pesquisa/-/search/56928479/details/maximized (accessed on 20 April 2021).

- APA. Relatório Anual Resíduos Urbanos 2019; Report by APA (Portuguese environmental agency); Agência Portuguesa do Ambiente—Departamento de Resíduos: Lisbon, Portugal, 2020. [Google Scholar]

- Ministerio para la Transición Ecológica y el Reto Demográfico (MITECO). Memoria Anual de Generación y Gestión de Residuos Residuos de Competencia Municipal 2018; Secretaría de Estado de Medio Ambiente: Madrid, Spain, 2020; Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/publicaciones/memoriaresiduosmunicipales2018_tcm30-521965.pdf (accessed on 10 February 2021).

- PEMAR. Plan Estatal Marco de Gestión de Residuos (PEMAR) 2016–2022. Ministerio de Agricultura, Alimentación y Medio Ambiente. Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/planes-y-estrategias/Programa de prevencion aprobado actualizado ANFABRA 11 02 2014_tcm30-192127.pdf (accessed on 10 February 2021).

- Eurostat. Municipal Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Municipal_waste_statistics#Municipal_waste_generation (accessed on 21 December 2020).

- Eurostat. Municipal Waste Landfilled, Incinerated, Recycled and Composted, EU-28, 1995–2019. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Municipal_waste_landfilled,_incinerated,_recycled_and_composted,_EU-27,_1995-2019.png (accessed on 21 December 2020).

- CEWEP—Confederation of European Waste-to-Energy Plants. What Is Waste-to-Energy—Incineration? Available online: https://www.cewep.eu/what-is-waste-to-energy/ (accessed on 18 April 2020).

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Environmental impacts of the use of bottom ashes from municipal solid waste incineration: A review. Resour. Conserv. Recycl. 2019, 140, 23–35. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Segarra, M.; Fernández, M.A.; Espiell, F. Characterization of the bottom ash in municipal solid waste incinerator. J. Hazard. Mater. 1999, 64, 211–222. [Google Scholar] [CrossRef]

- Dou, X.; Ren, F.; Nguyen, M.Q.; Ahamed, A.; Yin, K.; Chan, W.P.; Chang, V.W.C. Review of MSWI bottom ash utilization from perspectives of collective characterization, treatment and existing application. Renew. Sustain. Energy Rev. 2017, 79, 24–38. [Google Scholar] [CrossRef]

- CEWEP—Confederation of European Waste-to-Energy Plants. Bottom Ash Factsheet. Available online: http://www.cewep.eu/2017/09/08/bottom-ash-factsheet/ (accessed on 11 March 2020).

- Blasenbauer, D.; Huber, F.; Lederer, J.; Quina, M.J.; Blanc-Biscarat, D.; Bogush, A.; Bontempi, E.; Blondeau, J.; Chimenos, J.M.; Dahlbo, H.; et al. Legal situation and current practice of waste incineration bottom ash utilisation in Europe. Waste Manag. 2020, 102, 868–883. [Google Scholar] [CrossRef] [PubMed]

- Pordata—Base de Dados Portugal Contemporâneo. Resíduos Urbanos: Total e por Tipo de Operação de Destino. Available online: https://www.pordata.pt/Portugal/Resíduos+urbanos+total+e+por+tipo+de+operação+de+destino-1105 (accessed on 21 December 2020).

- AVALER. Contributo da AVALER—Associação de Entidades de Valorização Energética de Resíduos para o Plano de Recuperação Económica de Portugal 2020–2030. Available online: http://www.avaler.pt/media/12950/20200821_contributo-avaler-para-o-plano-recupera%C3%A7%C3%A3o-econ%C3%B3mica-2030.pdf (accessed on 20 April 2021).

- Park, Y.; Heo, J. Vitrification of fly ash from municipal solid waste incinerator. J. Hazard. Mater. 2002, 91, 83–93. [Google Scholar] [CrossRef]

- APA—Agência Portuguesa de Ambiente. ERSAR—Entidade Reguladora dos Serviços de Águas e Resíduos. Orientações e Recomendações Para a Gestão de Resíduos em Situação de Pandemia por SARS-CoV-2 (COVID-19); APA: Lisbon, Portugal, 2020. [Google Scholar]

- Margallo, M.; Aldaco, R.; Bala, A.; Fullana, P.; Irabien, Á. Best available techniques in municipal solid waste incineration: State of the art in Spain and Portugal. Chem. Eng. Trans. 2012, 29, 1345–1350. [Google Scholar] [CrossRef]

- EEA—European Environment Agency. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019 Technical Guidance to Prepare National Emission Inventories; EEA Report No 13/2019; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- BREF. Best Available Techniques (BAT) Reference Document for Waste Incineration—Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); European Commission: Luxembourg, 2019. [Google Scholar]

- Cheremisinoff, N.P. Handbook of Solid Waste Management and Waste Minimization Technologies; Butterworth-Heinemann: Burlington, MA, USA, 2003. [Google Scholar]

- Quina, M.J.; Bordado, J.C.M.; Quinta-Ferreira, R.M. Air Pollution Control of Municipal Solid Waste Incinerators. In The Impact of Air Pollution on Health, Economy, Environment and Agricultural Sources; Khallaf, M.K., Ed.; InTech.: Rijeka, Croatia, 2011; pp. 331–358. [Google Scholar]

- The International Bank for Reconstruction and Development/The World Bank. World Bank Technical Guidance Report—Municipal Solid Waste Incineration; The World Bank: Washington, DC, USA, 1999. [Google Scholar]

- AVALER—Associação de Entidades de Valorização Energética de Resíduos. Indicadores AVALER, Valorização Energética de Resíduos em Portugal. Available online: http://www.avaler.pt/informacao-tecnica/indicadores-avaler/ (accessed on 10 January 2021).

- ARM—Águas e Resíduos da Madeira. A IIRSU—Instalação de Incineração de Resíduos Sólidos Urbanos. Available online: http://www.aguasdamadeira.pt/Portals/0/Documentos/Instalações/ETRS-IIRSU.pdf (accessed on 22 December 2020).

- DRA—Direção Regional do Ambiente da Região Autónoma dos Açores. Licença Ambiental LA n.o 3/2014/DRA, TERAMB—Empresa Municipal de Gestão e Valorização Ambiental da Ilha Terceira, EEM; Environmental License; DRA: Horta, Portugal, 2014. [Google Scholar]

- LIPOR. Valorização Energética. Available online: https://www.lipor.pt/pt/valorizar/valorizacao-energetica/ (accessed on 22 December 2020).

- Valorsul. Valorização Energética. Available online: http://www.valorsul.pt/pt/seccao/areas-de-negocio/valorizacao-energetica/ (accessed on 22 December 2020).

- AEVERSU. Estudio Sobre los Impactos Socio-Económicos y Ambientales de la Valorización Energética de los Residuos Urbanos en España y Andorra. 2015. Available online: http://www.sogama.gal/sites/default/files/users/1/AEVERSU_informefinal_3072015.pdf (accessed on 10 February 2021).

- GHK. Gipuzkoako Hondakinen Kudeaketa S.A.U. Available online: https://www.ghk.eus/inicio.htm (accessed on 10 February 2021).

- TERSA. Tractament i Selecció de Residus, S.A. Available online: https://www.tersa.cat/en (accessed on 10 February 2021).

- URBASER. Tratamiento de Residuos Municipales. Available online: https://www.urbaser.com/areas-de-actividad/tratamiento-de-residuos/tratamiento-de-residuos-municipales/ (accessed on 10 February 2021).

- Zabalgarbi, S.A. Available online: http://www.zabalgarbi.com/en/ (accessed on 10 February 2021).

- Siddiqi, M.M.; Naseer, M.N.; Wahab, Y.A.; Hamizi, N.A.; Badruddin, I.A.; Chowdhury, Z.Z.; Akbarzadeh, O.; Johan, M.R.; Khan, T.M.Y.; Kamangar, S. Evaluation of Municipal Solid Wastes Based Energy Potential in Urban Pakistan. Processes 2019, 7, 848. [Google Scholar] [CrossRef] [Green Version]

- Rendek, E.; Ducom, G.; Germain, P. Influence of waste input and combustion technology on MSWI bottom ash quality. Waste Manag. 2007, 27, 1403–1407. [Google Scholar] [CrossRef]

- Alhassan, H.M.; Tanko, A.M. Characterization of solid waste incinerator bottom ash and the potential for its use Characterization of Solid Waste Incinerator Bottom Ash and the Potential for its Use. Int. J. Eng. Res. Appl. 2012, 2, 516–522. [Google Scholar]

- Yin, K.; Chan, W.P.; Dou, X.; Ren, F.; Wei-Chung, C.V. Cr, Cu, Hg and Ni release from incineration bottom ash during utilization in land reclamation-based on lab-scale batch and column leaching experiments and a modeling study. Chemosphere 2018, 197, 741–748. [Google Scholar] [CrossRef]

- Joseph, A.M.; Snellings, R.; Van den Heede, P.; Matthys, S.; De Belie, N. The use of municipal solidwaste incineration ash in various building materials: A Belgian point of view. Materials 2018, 11, 141. [Google Scholar] [CrossRef] [Green Version]

- Seniunaite, J.; Vasarevicius, S. Leaching of copper, lead and zinc from municipal solid waste incineration bottom ash. Energy Procedia 2017, 113, 442–449. [Google Scholar] [CrossRef]

- Wiles, C.C. Municipal solid waste combustion ash: State-of-the-knowledge. J. Hazard. Mater. 1996, 47, 325–344. [Google Scholar] [CrossRef]

- AVALER. Indicadores AVALER—Valorização Energética de Resíduos em Portugal. Available online: http://www.avaler.pt/informacao-tecnica/indicadores-avaler/ (accessed on 27 April 2021).

- LIPOR. Relatório Integrado 2019; LIPOR: Porto, Portugal, 2019. [Google Scholar]

- Siaram. Direção Regional do Ambiente do Governo dos Açores. Valorização Energética dos Resíduos—Ilha Terceira. Available online: http://siaram.azores.gov.pt/residuos/Central-de-Valorizacao-Energetica/Valorizacao-Energetica-Residuos.pdf (accessed on 5 January 2021).

- Valorsul. Relatório e Contas 2019; ValorsuL: Lisbon, Portugal, 2019. [Google Scholar]

- AEVERSU. Asociación de Empresas de Valorización Energética de Residuos Urbanos. Available online: https://aeversu.org/ (accessed on 10 February 2021).

- TIRME. Parque de Tecnología Ambientales de Mallorca. Available online: https://www.tirme.com/es/index.html (accessed on 19 April 2021).

- Huber, F.; Blasenbauer, D.; Aschenbrenner, P.; Fellner, J. Complete determination of the material composition of municipal solid waste incineration bottom ash. Waste Manag. 2020, 102, 677–685. [Google Scholar] [CrossRef] [PubMed]

- Almeida, F.; Carneiro, J.R.; Lopes, M.D.L. Use of incinerator bottom ash as a recycled aggregate in contact with nonwoven geotextiles: Evaluation of mechanical damage upon installation. Sustainability 2020, 12, 9156. [Google Scholar] [CrossRef]

- Lopes, M.G. Reciclagem de Escórias de Incineração de RSU como Agregados para a Construção. Master’s Internship Report in Materials Engineering, University of Aveiro, Aveiro, Portugal, 2010. [Google Scholar]

- Reis-Barros, J.; Lopes, M.G.; Correia, A.G. Escórias de R.S.U.: Caracterização mecânica para fins rodoviários. In CONGRESSO NACIONAL DE GEOTECNIA, 10, Lisboa, Portugal, 2006—“Geotecnica multidisciplinar: Ambiente/sísmica”. [S.l.]; Sociedade Portuguesa de Geotecnia: Lisboa, Portugal, 2006; Volume 3, pp. 753–763. [Google Scholar]

- Izquierdo, M.; López-Soler, Á.; Vazquez, E.; Barra, M.; Querol, X. Characterisation of bottom ash from municipal solid waste incineration in Catalonia. J. Chem. Technol. Biotechnol. 2002, 77, 576–583. [Google Scholar] [CrossRef]

- del Valle-Zermeño, R.; Gómez-Manrique, J.; Giro-Paloma, J.; Formosa, J.; Chimenos, J.M. Material characterization of the MSWI bottom ash as a function of particle size. Effects of glass recycling over time. Sci. Total Environ. 2017, 581–582, 897–905. [Google Scholar] [CrossRef] [Green Version]

- Maldonado-Alameda, A.; Giro-Paloma, J.; Svobodova-Sedlackova, A.; Formosa, J.; Chimenos, J.M. Municipal solid waste incineration bottom ash as alkali-activated cement precursor depending on particle size. J. Clean. Prod. 2020, 242, 118443. [Google Scholar] [CrossRef]

- Luo, H.; Cheng, Y.; He, D.; Yang, E.H. Review of leaching behavior of municipal solid waste incineration (MSWI) ash. Sci. Total Environ. 2019, 668, 90–103. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Fernández, A.I.; Nadal, R.; Espiell, F. Short-term natural weathering of MSWI bottom ash. J. Hazard. Mater. 2000, 79, 287–299. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Fernández, A.I.; Miralles, L.; Segarra, M.; Espiell, F. Short-term natural weathering of MSWI bottom ash as a function of particle size. Waste Manag. 2003, 23, 887–895. [Google Scholar] [CrossRef]

- Monteiro, R.C.C.; Figueiredo, C.F.; Alendouro, M.S.; Ferro, M.C.; Davim, E.J.R.; Fernandes, M.H.V. Characterization of MSWI bottom ashes towards utilization as glass raw material. Waste Manag. 2008, 28, 1119–1125. [Google Scholar] [CrossRef] [PubMed]

- Cristelo, N.; Segadães, L.; Coelho, J.; Chaves, B.; Sousa, N.R.; Lopes, M.D.L. Recycling municipal solid waste incineration slag and fly ash as precursors in low-range alkaline cements. Waste Manag. 2020, 104, 60–73. [Google Scholar] [CrossRef] [PubMed]

- SOGAMA. Sociedade Galega do Medio Ambiente. Available online: http://www.sogama.gal/es (accessed on 10 February 2021).

- Van Der Sloot, H.A.; Kosson, D.S.; Hjelmar, O. Characteristics, treatment and utilization of residues from municipal waste incineration. Waste Manag. 2001, 21, 753–765. [Google Scholar] [CrossRef]

- Weibel, G.; Eggenberger, U.; Kulik, D.A.; Hummel, W.; Schlumberger, S.; Klink, W.; Fisch, M.; Mäder, U.K. Extraction of heavy metals from MSWI fly ash using hydrochloric acid and sodium chloride solution. Waste Manag. 2018, 76, 457–471. [Google Scholar] [CrossRef] [PubMed]

- Crillesen, K.; Skaarup, J.; Bojsen, K. Management of Bottom Ash from WTE Plants—An Overview of Management Options and Treatment Methods; ISWA Working Group Thermal Treatment: Copenhagen, Denmark, 2006. [Google Scholar]

- del Valle-zermeño, R.; Chimenos, J.M.; Giró-paloma, J.; Formosa, J. Use of weathered and fresh bottom ash mix layers as a subbase in road constructions: Environmental behavior enhancement by means of a retaining barrier. Chemosphere 2014, 117, 402–409. [Google Scholar] [CrossRef] [Green Version]

- Fuchs, B.; Track, C.; Lang, S.; Gimmler, H. Salt effects of processed municipal solid waste incinerator bottom ash on vegetation and underground water. J. Appl. Bot. Food Qual. 1997, 71, 154–163. [Google Scholar]

- Shih, H.C.; Ma, H.W. Life cycle risk assessment of bottom ash reuse. J. Hazard. Mater. 2011, 190, 308–316. [Google Scholar] [CrossRef] [PubMed]

- Shih, H.C.; Ma, H.W. Assessing the health risk of reuse of bottom ash in road paving. Chemosphere 2011, 82, 1556–1562. [Google Scholar] [CrossRef] [PubMed]

- Alam, Q.; Schollbach, K.; Hoek, C.V.; Laan, S.V.D.; Wolf, T.D.; Brouwers, H.J.H. In-depth mineralogical quantification of MSWI bottom ash phases and their association with potentially toxic elements. Waste Manag. 2019, 87, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.H.; Chiou, I.J. Distribution of chloride ion in MSWI bottom ash and de-chlorination performance. J. Hazard. Mater. 2007, 148, 346–352. [Google Scholar] [CrossRef]

- Tang, J.; Steenari, B.M. Leaching optimization of municipal solid waste incineration ash for resource recovery: A case study of Cu, Zn, Pb and Cd. Waste Manag. 2016, 48, 315–322. [Google Scholar] [CrossRef]

- Xia, Y.; He, P.; Shao, L.; Zhang, H. Metal distribution characteristic of MSWI bottom ash in view of metal recovery. J. Environ. Sci. 2017, 52, 178–189. [Google Scholar] [CrossRef]

- BIO by Deloitte. Study to Assess the Impacts of Different Classification Approaches for Hazard Property “HP 14” on Selected Waste Streams—Final Report; Prepared for the European Commission (DG ENV), in collaboration with INERIS; BIO by Deloitte: London, UK, 2015. [Google Scholar]

- Stiernström, S.; Wik, O.; Bendz, D. Evaluation of frameworks for ecotoxicological hazard classification of waste. Waste Manag. 2016, 58, 14–24. [Google Scholar] [CrossRef]

- Oehmig, W.N.; Roessler, J.G.; Zhang, J.; Townsend, T.G. Effect of ferrous metal presence on lead leaching in municipal waste incineration bottom ashes. J. Hazard. Mater. 2015, 283, 500–506. [Google Scholar] [CrossRef]

- Neuwahl, F.; Cusano, G.; Benavides, J.G.; Holbrook, S.; Serge, R. Best Available Techniques (BAT) Reference Document for Waste Incineration. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention); Science for Policy report by the Joint Research Centre, European Commission: Luxembourg, 2019. [Google Scholar]

- Dhir, R.K.; De Brito, J.; Lynn, C.J.; Silva, R.V. Sustainable Construction Materials: Municipal Incinerator Bottom Ashes; Woodhead Publishing: Duxford, UK, 2018. [Google Scholar]

- Baciocchi, R.; Costa, G.; Lategano, E.; Marini, C.; Polettini, A.; Pomi, R.; Postorino, P.; Rocca, S. Accelerated carbonation of different size fractions of bottom ash from RDF incineration. Waste Manag. 2010, 30, 1310–1317. [Google Scholar] [CrossRef] [PubMed]

- Cornelis, G.; Gerven, T.V.; Vandecasteele, C. Antimony leaching from uncarbonated and carbonated MSWI bottom ash. J. Hazard. Mater. 2006, 137, 1284–1292. [Google Scholar] [CrossRef]

- Cornelis, G.; Gerven, T.V.; Vandecasteele, C. Antimony leaching from MSWI bottom ash: Modelling of the effect of pH and carbonation. Waste Manag. 2012, 32, 278–286. [Google Scholar] [CrossRef]

- Shimaoka, T.; Zhang, R.; Watanabe, K. Alterations of municipal solid waste incineration residues in a landfill. Waste Manag. 2007, 27, 1444–1451. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Saffarzadeh, A.; Shimaoka, T.; Zhao, C.; Peng, C.; Gao, J. Geoenvironmental weathering/deterioration of landfilled MSWI-BA glass. J. Hazard. Mater. 2014, 278, 610–619. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Shimaoka, T.; Saffarzadeh, A.; Takahashi, F. Alteration of municipal solid waste incineration bottom ash focusing on the evolution of iron-rich constituents. Waste Manag. 2011, 31, 1992–2000. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Shimaoka, T.; Saffarzadeh, A.; Takahashi, F. Mineralogical characterization of municipal solid waste incineration bottom ash with an emphasis on heavy metal-bearing phases. J. Hazard. Mater. 2011, 187, 534–543. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of municipal solid waste (MSW) ash in cement and mortar. Resour. Conserv. Recycl. 2010, 54, 1037–1047. [Google Scholar] [CrossRef]

- Jurič, B.; Hanžicč, L.; Ilić, R.; Samec, N. Utilization of municipal solid waste bottom ash and recycled aggregate in concrete. Waste Manag. 2006, 26, 1436–1442. [Google Scholar] [CrossRef]

- Ginés, O.; Chimenos, J.M.; Vizcarro, A.; Formosa, J.; Rosell, J.R. Combined use of MSWI bottom ash and fly ash as aggregate in concrete formulation: Environmental and mechanical considerations. J. Hazard. Mater. 2009, 169, 643–650. [Google Scholar] [CrossRef] [PubMed]

- Pecqueur, G.; Crignon, C.; Quénée, B. Behaviour of cement-treated MSWI bottom ash. Waste Manag. 2001, 229–233. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Use of municipal solid waste incineration bottom ashes in alkali-activated materials, ceramics and granular applications: A review. Waste Manag. 2017, 68, 207–220. [Google Scholar] [CrossRef]

- Maldonado-Alameda, À.; Giro-Paloma, J.; Alfocea-Roig, A.; Formosa, J.; Chimenos, J.M. Municipal solid waste incineration bottom ash as sole precursor in the alkali-activated binder formulation. Appl. Sci. 2020, 10, 4129. [Google Scholar] [CrossRef]

- ARM. Águas e Resíduos da Madeira. Relatorio e Contas 2019; Funchal: Madeira Island, Portugal, 2019. [Google Scholar]

- Teramb. Relatório de Gestão e Contas 2019; Teramb: Terceira Island, Portugal, 2019. [Google Scholar]

- Valorsul. Instalação de Tratamento e Valorização de Escórias. Available online: http://www.valorsul.pt/pt/seccao/areas-de-negocio/valorizacao-de-escorias/instalacao-de-tratamento-e-valorizacao-de-escorias. (accessed on 22 January 2021).

- LNEC—Laboratório Nacional de Engenharia Civil. Documento de Aplicação. AEIRU—Agregados Artificiais de Escórias de Incineração de Resíduos Urbanos para Pavimentos Rodoviários; Individual permit issued by LNEC (Portuguese National Civil Engineering Laboratory); LNEC: Lisboa, Portugal, 2015. [Google Scholar]

- Leder, J.; Syc, M.; Biganzoli, L.; Bogush, A.; Bontempi, E.; Braga, R.; Costa, G.; Funari, V.; Grosso, M.; Hyks, J.; et al. Recovery technologies for waste incineration residues (MINEA Deliverable). Mining the European Antroposphere (MINEA). 2018. Available online: http://www.minea-network.eu/upload/D31Report.pdf. (accessed on 24 May 2020).

- DOGC. Ordre de 15 de Febrer de 1996, Sobre Valorització D’escòries. Available online: http://residus.gencat.cat/web/.content/home/consultes_i_tramits/normativa/normativa_catalana_en_materia_de_residus/ordrePlease_15021996.pdf (accessed on 27 April 2021).

- BOC. Decreto 100/2018, de 20 de Diciembre, de Valorización de Escorias en la Comunidad Autónoma de Cantabria. Available online: https://boc.cantabria.es/boces/verAnuncioAction.do?idAnuBlob=333876 (accessed on 27 April 2021).

- OECD. Global Material Resources Outlook to 2060: Economic Drivers and Environmental Consequences; OECD Publishing: Paris, France, 2019; ISBN 9789264307452. [Google Scholar]

- Valorsul. Agregado para Construção Rodoviária. Available online: http://www.valorsul.pt/pt/seccao/areas-de-negocio/produtos/agregado-para-construcao-rodoviaria (accessed on 22 January 2021).

- European Commission. Environment Action Programme to 2020. Available online: https://ec.europa.eu/environment/action-programme/ (accessed on 24 May 2020).

- European Commission. A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en#latest (accessed on 24 May 2020).

- Pandard, P.; Devillers, J.; Charissou, A.M.; Poulsen, V.; Jourdain, M.J.; Férard, J.F.; Grand, C.; Bispo, A. Selecting a battery of bioassays for ecotoxicological characterization of wastes. Sci. Total Environ. 2006, 363, 114–125. [Google Scholar] [CrossRef]

- Verbinnen, B.; Billen, P.; Van Caneghem, J.; Vandecasteele, C. Recycling of MSWI Bottom Ash: A Review of Chemical Barriers, Engineering Applications and Treatment Technologies. Waste Biomass Valorization 2017, 8, 1453–1466. [Google Scholar] [CrossRef]

- Velzeboer, I.; Van Zomeren, A. End of Waste Criteria for Inert Aggregates in Member States; ECN (Energy Research Centre of The Netherlands): Petten, The Netherlands, 2017; Available online: https://publicaties.ecn.nl/PdfFetch.aspx?nr=ECN-E--17-010 (accessed on 20 May 2021).

- Klymko, T.; Dijkstra, J.J.; van Zomeren, A. Guidance Document on Hazard Classification of MSWI Bottom Ash; ECN (Energy Research Centre of The Netherlands): Petten, The Netherlands, 2017. Available online: https://publicaties.ecn.nl/PdfFetch.aspx?nr=ECN-E--17-024 (accessed on 20 May 2021).

- Freire, A.C.; Antunes, M.L.; Dinis de Sousa, C. Application of Municipal Solid Waste Incineration Bottom Ash in Road Construction. A Case Study. In Proceedings of the 4th International SIIV Congress Advances in Transport Infrastructures and Stakeholders Expectations, Palermo, Italy, 12–14 September 2007. [Google Scholar]

- Hennebert, P. Proposal of concentration limits for determining the hazard property HP 14 for waste using ecotoxicological tests. Waste Manag. 2018, 74, 74–85. [Google Scholar] [CrossRef]

- Wahlström, M.; Laine-Ylijok, J.; Wik, O.; Oberender, A.; Hjelmar, O. Hazardous Waste Classification: Amendments to the European Waste Classification Regulation—What do They Mean and What Are the Consequences? Report for the Nordic Council of Ministers; TemaNord: Copenhagen, Denmark, 2016. [Google Scholar]

- WRc. Assessment of Hazard Classification of UK IBA; Report for the January–June 2011 IBA Dataset, Report for Environmental Services Association, WRc Reference: UC8540.06; WRc: Wiltshire, UK, 2012. [Google Scholar]

- Hjelmar, O.; Van Der Sloot, H.A.; Van Zomeren, A. Hazard Property Classification of High Temperature Waste Materials. Proceedings Sardinia 2013, Fourteenth International Waste Management and Landfill Symposium, S. Margherita di Pula, Cagliari, Italy, 30 September–4 October 2013; CISA Publisher: Cagliari, Italy, 2013. [Google Scholar]

- Ferrari, B.; Radetski, C.M.; Veber, A.M.; Ferard, J.F. Ecotoxicological assessment of solid wastes: A combined liquid- and solid-phase testing approach using a battery of bioassays and biomarkers. Environ. Toxicol. Chem. 1999, 18, 1195–1202. [Google Scholar] [CrossRef]

- Lapa, N.; Barbosa, R.; Morais, J.; Mendes, B.; Méhu, J.; Santos Oliveira, J.F. Ecotoxicological assessment of leachates from MSWI bottom ashes. Waste Manag. 2002, 22, 583–593. [Google Scholar] [CrossRef]

- Moser, H.; Römbke, J. Ecotoxicological Characterization of Waste—Results and Experiences of a European Ring Test; Springer Ltd.: New York, NY, USA, 2009; ISBN 9780387889580. [Google Scholar]

- Römbke, J.; Moser, T.; Moser, H. Ecotoxicological characterisation of 12 incineration ashes using 6 laboratory tests. Waste Manag. 2009, 29, 2475–2482. [Google Scholar] [CrossRef]

- Pandard, P.; Römbke, J. Proposal for a “Harmonized” strategy for the assessment of the HP 14 property. Integr. Environ. Assess. Manag. 2013, 9, 665–672. [Google Scholar] [CrossRef] [PubMed]

- Ribé, V.; Nehrenheim, E.; Odlare, M. Assessment of mobility and bioavailability of contaminants in MSW incineration ash with aquatic and terrestrial bioassays. Waste Manag. 2014, 34, 1871–1876. [Google Scholar] [CrossRef]

- APA—Agência Portuguesa de Ambiente. Guia de Classificação de Resíduos; APA: Lisbon, Portugal, 2020. [Google Scholar]

- Margallo, M.; Aldaco, R.; Irabien, Á. Environmental management of bottom ash from municipal solid waste incineration based on a life cycle assessment approach. Clean Technol. Environ. Policy 2014, 16, 1319–1328. [Google Scholar] [CrossRef]

- Margallo, M.; Aldaco, R.; Bala, A.; Fullana, P.; Irabien, A. Contribution to closing the loop on waste materials: Valorization of bottom ash from waste-to-energy plants under a life cycle approach. J. Mater. Cycles Waste Manag. 2018, 20, 1507–1515. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Mañosa, J.; Giro-Paloma, J.; Formosa, J.; Chimenos, J.M. Alkali-Activated Binders Using Bottom Ash from Waste-to-Energy Plants and Aluminium Recycling Waste. Appl. Sci. 2021, 11, 3840. [Google Scholar] [CrossRef]

| Country | Plant Location | Plant Name | Startup (Year) | Nominal Capacity (t/Year) | Incinerator Technology | Energy Production (MWh) |

|---|---|---|---|---|---|---|

| Portugal | Lisbon | Valorsul | 2000 | 662,000 | Moving grate | 361,151 a |

| Porto | LIPOR | 2000 | 380,000 | Moving grate | 188,808 a | |

| Madeira Island | ARM | 2003 | 126,000 | Moving grate | 53,206 a | |

| Terceira Island (Azores) | Teramb | 2015 | 40,000 | Moving grate | 16,035 a | |

| Spain | Barcelona | TERSA | 1975 | 360,000 | Moving grate | 194,742 a |

| Barcelona | UTETEM | 1994 | 160,000 | Moving grate | 85,435 a | |

| Girona | TRARGISA | 1984 | 37,600 | Moving grate | 4202 b | |

| Tarragona | SIRUSA | 1991 | 144,000 | Moving grate | 49,649 a | |

| Cantabria | TIR Cantabria | 2006 | 96,000 | Moving grate | 87,245 a | |

| Vizcaya | Zabalgarbi | 2005 | 230,000 | Moving grate | 666,233 c | |

| Guipuzcoa | Ekondakin | 2020 | 200,000 | Moving grate | 160,000 a | |

| Coruña | SOGAMA | 2002 | 600,000 | Fluidized bed | 334,461 a | |

| Madrid | TIR Madrid | 1997 | 315,000 | Fluidized bed | 228,262 a | |

| Melilla | REMESA | 1996 | 48,000 | Moving grate | 14,703 a | |

| Mallorca Island | TIRME | 1997 | 690,000 | Moving grate | 346,905 a | |

| Andorra | Andorra | CTRASA | 2007 | 55,000 | Moving grate | 24,855 a |

| Country | Plant | MSW Incinerated (t) | IBA | |

|---|---|---|---|---|

| Metals for Recycling (t) | Non-Ferrous IBA Generated (t) | |||

| Portugal c | Valorsul | 645,943 | 8318 | 122,242 |

| LIPOR | 389,291 | 5582 | 76,280 | |

| ARM | 128,155 | 559 | 19,794 | |

| Teramb | 33,250 | 143 | 7637 | |

| Spain | TERSA c | 351,308 | 4477 | 69,163 |

| UTEEM c | 165,756 | 222 | 30,993 | |

| TRARGISA d | 22,003 | 610 | 5853 | |

| SIRUSA c | 140,775 | 3154 | 27,471 | |

| TIR Cantabria c | 119,813 | 2825 | 16,522 | |

| Zabalgarbi | 224,591 | 2530 | 45,334 | |

| Ekondakin e | 144,810 | n.d. | 32,804 | |

| SOGAMA | 769,674 f | 14,660 g | 70,349 | |

| TIR Madrid c | 330,290 | 5535 | 17,199 | |

| REMESA | 42,673 | 592 | 9793 | |

| TIRME c | 454,734 | 9370 | 100,247 | |

| CTRASA | 50,902 | 715 | 8088 | |

| Properties (wt.%) | [59] a | [60] b | [51] c | [55] d | SOGAMA (2019) e,c | TIRME (2020) f | |

|---|---|---|---|---|---|---|---|

| Valorsul | LIPOR | LIPOR | ARM | SIRUSA | SOGAMA | TIRME | |

| SiO2 | 52 | 52.2 | 43.75 | 41.75 | 45.44 | 59.21 | 22.53 |

| CaO | 14 | 13.6 | 22.77 | 21.85 | 17.55 | 13.60 | 26.05 |

| Fe2O3 | 6.8 | 6.8 | 2.03 | 7.26 | 6.08 | 1.24 | 6.68 |

| Na2O | 6 | 3.6 | 7 | 6.01 | 5.04 | 6.83 | 2.65 |

| Al2O3 | 5.9 | 7.7 | 6.81 | 7.94 | 10.38 | 7.49 | 21.76 |

| P2O5 | 5.5 | 2.9 | 3.91 | 6.27 | 1.55 | 3.51 | 1.69 |

| MgO | 2 | 3 | 5.11 | 2.59 | 2.66 | 1.79 | 2.84 |

| K2O | 2 | 2.2 | 3.12 | 1.33 | 1.54 | 2.10 | 0.76 |

| TiO2 | 0.5 | 0.7 | - | 1.29 | 0.65 | 0.42 | 0.54 |

| SO3 | - | - | 2.43 | 1.55 | 2.57 | 1.20 | 3.59 |

| BaO | - | - | - | 0.12 | - | 0.12 | 0.08 |

| CuO | - | - | - | 0.2 | 0.13 | 0.16 | 0.27 |

| Cr2O3 | - | - | - | 0.11 | - | 0.04 | 0.07 |

| PbO | 0.35 | - | - | 0.16 | 0.11 | 0.07 | - |

| NiO | - | - | - | 0.02 | - | 0.01 | 0.01 |

| ZnO | 0.3 | - | 0.65 | 0.33 | 0.51 | 0.20 | - |

| MnO | 0.1 | 0.1 | - | 0.09 | 0.03 | 0.04 | 0.08 |

| SrO | - | - | - | 0.05 | 0.07 | 0.07 | 0.05 |

| SnO2 | - | - | - | 0.04 | 0.02 | - | 0.02 |

| ZrO2 | - | - | - | 0.03 | 0.03 | 0.03 | 0.02 |

| Cl | - | - | 2.42 | 1.05 | 1.42 | 0.18 | 0.50 |

| Loss on ignition (1000 °C) | 5.5 | 7.2 | - | - | 5.8 | 1.5 | 14.8 |

| Country | Use Authorized | Use Rate Outside Landfills (wt.%) | National Use Rate Outside Landfills (wt.%) | Document Regulating Use Outside Landfills | Permitted Application Outside Landfills | Specific Criteria for IBA | Requirements on the Total Content | Requirements on Leaching Content | Other Requirements |

|---|---|---|---|---|---|---|---|---|---|

| PT | Valorsul plant | 73 a | 40 b | Individual permit issued by an independent national body c (LNEC d) | Aggregates for unbound and hydraulically bound materials for civil engineering work and road construction. | No | No | As, Ba, Cd, Cr (total), Cu, Hg, Mo, Ni, Pb, Sb, Se, Zn, chloride, fluoride, sulfate, dissolved organic carbon, total dissolved solids e | Compliance with NP EN 13242:2002 + A1:2010 |

| ES | Catalonia and Cantabria (autonomous communities) | 88 f | 38 g,h | Legislation i: Ordre de 15 de febrer de 1996, sobre valorització d’escóries, (Catalonia) | Road subbase, leveling of terrain and embankments, filling, and restoration of degradable areas from extractive activities, others. | Yes | Loss on ignition, unburnt material | As, Cd, Cr (VI), Cu, Pb, Zn, total dissolved solids | No |

| Legislation j: Decreto 100/2018, de 20 de diciembre, de valorización de escorias (Cantabria) | Cantabria: road construction and formulation of concrete. | Yes | No | As, Ba, Cd, Cu, Cr (total), Hg, Ni, Pb, Zn, Mo, Se, chloride, fluoride, sulfate, dissolved organic carbon, total dissolved solids | Compliance with Pliego de Prescipciones Técnicas Generales para obras de carreteras y puentes, PG-3 |

| Parameters | Leaching Content | Limit Values for Landfills of Non-Hazardous Waste |

|---|---|---|

| Total Moisture (%) | 12 | - |

| pH | 9.9 | - |

| TDS (mg/kg) | 12,293 | 60,000 |

| DOC (mg/kg) a | 869 | 1000 b |

| Chlorides (mg/kg) c | 3082 | 50,000 |

| Fluorides (mg/kg) | 20 | 250 |

| Sulphates (mg/kg) c | 2172 | 20,000 |

| As (mg/kg) | <0.02 | 5.0 |

| Ba (mg/kg) | 1.04 | 100 |

| Cd (mg/kg) | <0.02 | 2.0 |

| Cr (mg/kg) | <0.08 | 20 |

| Cu (mg/kg) | 7.8 | 50 |

| Hg (mg/kg) | <0.01 | 0.5 |

| Mo (mg(kg) | 0.67 | 10 |

| Ni (mg/kg) | 0.15 | 10 |

| Pb (mg/kg) | <0.13 | 10 |

| Sb (mg/kg) | 0.39 | 0.7 |

| Se (mg/kg) | <0.04 | 0.5 |

| Zn (mg/kg) | 0.49 | 50 |

| Parameters | Typical Content a | Limit Values for Valorizing IBA (Catalonia) b | Limit Values for Valorizing IBA (Cantabria) | |

|---|---|---|---|---|

| Solid IBA (s.m.t.q.) c | Soluble fraction (%) | 0.8–1.15 | 3 | - |

| Loss on ignition between 500 and 105 °C (%) | 3.9–5.9 | 5 | - | |

| Unburned matter (%) | 1.6–2.5 | 5 | - | |

| Leachate a | ||||

| As (mg/kg) | <0.02–0.03 | 1 | 0.5 | |

| Ba (mg/kg) | 0.42–0.6 | - | 20 | |

| Cd (mg/kg) | <0.01–0.04 | 1 | 0.04 | |

| Cu (mg/kg) | 1.9–5.2 | 20 | 2 | |

| Cr VI (mg/kg) | 0.05–0.2 | 1 | ||

| Cr total (mg/kg) | 0.1–0.4 | - | 0.5 | |

| Hg (mg/kg) | <0.05 | - | 0.01 | |

| Ni (mg/kg) | 0.1–0.03 | - | 0.4 | |

| Pb (mg/kg) | 0.08–0.5 | 5 | 0.5 | |

| Zn (mg/kg) | 0.9–1.7 | 20 | 4 | |

| Mo (mg/kg) | 0.3–0.7 | - | 0.5 | |

| Se (mg/kg) | <0.05 | - | 0.1 | |

| Sb (mg/kg) | 0.05–0.4 | - | 0.06 | |

| Chlorides (mg/kg) | 120–18,000 | - | 800 | |

| Fluorides (mg/kg) | 0.2–2.0 | - | 10 | |

| Sulphates (mg/kg) | 250–2000 | - | 1000 | |

| TDS (mg/kg) | 4000–6000 | - | 4000 | |

| DOC (mg/kg) | 20–50 | - | 500 | |

| Phenol index | <0.01 | - | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandarra, B.S.; Pereira, J.L.; Martins, R.C.; Maldonado-Alameda, A.; Chimenos, J.M.; Quina, M.J. Opportunities and Barriers for Valorizing Waste Incineration Bottom Ash: Iberian Countries as a Case Study. Appl. Sci. 2021, 11, 9690. https://doi.org/10.3390/app11209690

Bandarra BS, Pereira JL, Martins RC, Maldonado-Alameda A, Chimenos JM, Quina MJ. Opportunities and Barriers for Valorizing Waste Incineration Bottom Ash: Iberian Countries as a Case Study. Applied Sciences. 2021; 11(20):9690. https://doi.org/10.3390/app11209690

Chicago/Turabian StyleBandarra, Beatriz S., Joana L. Pereira, Rui C. Martins, Alex Maldonado-Alameda, Josep M. Chimenos, and Margarida J. Quina. 2021. "Opportunities and Barriers for Valorizing Waste Incineration Bottom Ash: Iberian Countries as a Case Study" Applied Sciences 11, no. 20: 9690. https://doi.org/10.3390/app11209690

APA StyleBandarra, B. S., Pereira, J. L., Martins, R. C., Maldonado-Alameda, A., Chimenos, J. M., & Quina, M. J. (2021). Opportunities and Barriers for Valorizing Waste Incineration Bottom Ash: Iberian Countries as a Case Study. Applied Sciences, 11(20), 9690. https://doi.org/10.3390/app11209690