Mini-Crack Detection of Conveyor Belt Based on Laser Excited Thermography

Abstract

:1. Introduction

2. Mini-Crack Detection System Based on Laser Excited Thermography

2.1. Detection Theory

2.2. Detection System

3. Principle of the Proposed Method

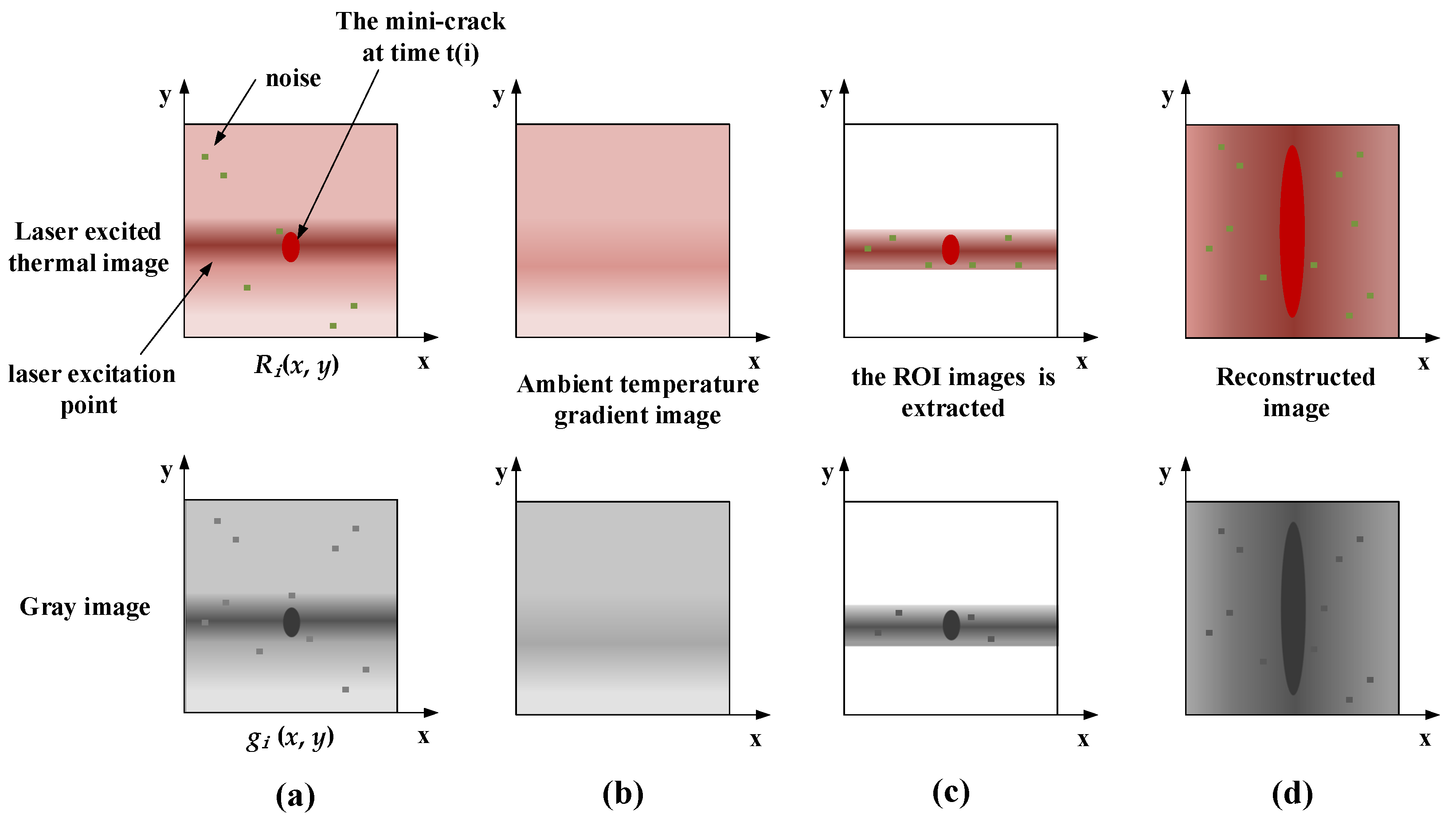

3.1. Mini-Crack Feature Extraction Based on Laser Excited Thermography

- Collect the thermal image by using the laser thermography system. Thermal response image Ri(x, y) is captured by an infrared camera, and then (x, y) will be defined as pixel coordinate. After obtaining all thermal response images Ri(x, y) in the current time T, they are converted into grayscale image gi(x, y) = Ri(x, y).

- Extract feature regions from the n grayscale images gi(x, y). The laser region of each image is intercepted as the feature image as Fi(x, y), and the size of Fi(x, y) is (s, w), where s = vt, v is the operation speed of the conveyor belt, and t is the time difference between two frames of images. The w is width of conveyor belt.

- Perform further image processing of the feature image Fi(x, y). Firstly, the reference image Res(x, y) is made, that is, the thermal image without laser scanning; Then, the feature image is subtracted from the reference image Fi*(x, y) = Fi(x, y) − Res(x, y).

- Construct the final mini-crack feature image. After all grayscale feature images Fi*(x, y) are obtained in the above steps, matrix Mosaic and fusion are carried out to construct the final mini-crack feature image M(x, y).

3.2. Image Enhancement Based on Heat Signal

- Select a 3 × 3 template operator.

- Obtain the pixel point (i, j) with the highest gray value. The pixel point (i, j) with the highest gray value in the current line pixels of the mini-crack feature image M(x, y) is obtained, and is taken as the central reference pixel of the weighting function. The pixel in the center of the template is (i0, j0). The further the pixel in the template is from the (i, j), the smaller the weight should be assigned.

- Calculate the weighted function by Equation (2). The weight coefficient of each pixel in the 3 × 3 template is inversely proportional to the distance from the pixel to the center of the template.

- 4.

- Perform the weighted balance of the power function. The schematic of weighted template operator for image enhancement is shown in Figure 5. Based on Equation (2), the weighting coefficient of each pixel is determined by the distance between the template center and the pixel point. Then the template is moved horizontally or vertically according to a certain step size, and the weighted balance of power function is performed on all pixels in the template.

3.3. Threshold Segmentation

3.4. Determine Mini-Crack

- Suppose there exists a point (x, y) on the mini-crack line in Cartesian coordinate system, which can be expressed by polar coordinates as

- 2.

- For each group (r, θ) in polar coordinates corresponds to a line that passing through the point (x, y) in rectangular coordinates. For a given point (x, y), draw all the lines that passing through the point in polar coordinates, and obtain the sine curve;

- 3.

- Repeat the above steps for all points in the original image. Set the threshold and calculate the number of curves corresponding to each intersection point in the image. If the number of curves that intersecting at one point exceeds the threshold, the pair of parameters (r, θ) represented by the intersection point is considered a line in the original intersection point.

- 4.

- The equation of the line is obtained through Hough line detection, then the distance X between the two lines is calculated by the linear distance function. According to the camera calibration results, an appropriate threshold D is set to discriminate mini-crack and crack. When X = 0, the test result is normal; When X < D, the detected damage is considered as a mini-crack; When X > D, the damage is considered as crack.

4. Experimental Setup, Procedure, Results, and Analysis

4.1. Experiment Parameter

4.2. Experimental Procedure

4.3. Experimental Results

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, L.; Wang, J.; Jiang, H.; Feng, X. Prediction model of port throughput based on game theory and multimedia Bayesian regression. Multimed. Tools Appl. 2018, 78, 4397–4416. [Google Scholar] [CrossRef]

- He, D.; Pang, Y.; Lodewijks, G. Green operations of belt conveyors by means of speed control. Appl. Energy 2017, 188, 330–341. [Google Scholar] [CrossRef]

- Braun, T.; Hennig, A.; Lottermoser, B. The need for sustainable technology diffusion in mining: Achieving the use of belt conveyor systems in the German hard-rock quarrying industry. J. Sustain. Min. 2017, 16, 24–30. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, W.; Tang, C.; Wang, C. Study of multi-agent-based coal mine environmental monitoring system. Ecol. Indic. 2015, 51, 79–86. [Google Scholar] [CrossRef]

- Hakami, F.; Pramanik, A.; Ridgway, N.; Basak, A.K. Developments of rubber material wear in conveyer belt system. Tribol. Int. 2017, 111, 148–158. [Google Scholar] [CrossRef] [Green Version]

- Grincova, A.; Andrejiova, M.; Marasova, D.; Khouri, S. Measurement and determination of the absorbed impact energy for conveyor belts of various structures under impact loading. Measurement 2019, 131, 362–371. [Google Scholar] [CrossRef]

- Peng, X. A novel image-based method for conveyor belt rip detection. In Proceedings of the 2013 IEEE International Conference on Signal Processing, Communications and Computing (ICSPCC 2013), Kunming, China, 5–8 August 2013; pp. 1–4. [Google Scholar]

- Molnar, V.; Fedorko, G.; Andrejiova, M.; Grincova, A.; Tomaskova, M. Analysis of influence of conveyor belt overhang and cranking on pipe conveyor operational characteristics. Measurement 2015, 63, 168–175. [Google Scholar] [CrossRef]

- Błażej, R.; Jurdziak, L.; Kozłowski, T.; Kirjanów, A. The use of magnetic sensors in monitoring the condition of the core in steel cord conveyor belts—Tests of the measuring probe and the design of the DiagBelt system. Measurement 2018, 123, 48–53. [Google Scholar] [CrossRef]

- Yang, Y.; Miao, C.; Li, X.; Mei, X. On-line conveyor belts inspection based on machine vision. Optik 2014, 125, 5803–5807. [Google Scholar] [CrossRef]

- Li, J.; Miao, C. The conveyor belt longitudinal tear on-line detection based on improved SSR algorithm. Optik 2016, 127, 8002–8010. [Google Scholar] [CrossRef]

- Hao, X.-L.; Liang, H. A multi-class support vector machine real-time detection system for surface damage of conveyor belts based on visual saliency. Measurement 2019, 146, 125–132. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, L.; Sun, H.; Zhu, C. Longitudinal tear detection of conveyor belt under uneven light based on Haar-AdaBoost and Cascade algorithm. Measurement 2021, 168, 108341. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, H.; Zhang, Y.; Yu, Y.; Zhou, M. Deep learning-based damage detection of mining conveyor belt. Measurement 2021, 175, 109130. [Google Scholar] [CrossRef]

- Qiao, T.; Li, X.; Pang, Y.; Lü, Y.; Wang, F.; Jin, B. Research on conditional characteristics vision real-time detection system for conveyor belt longitudinal tear. IET Sci. Meas. Technol. 2017, 11, 955–960. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Shen, L.; Ming, Z.; Zhang, C.; Jiang, H. Laser-based on-line machine vision detection for longitudinal rip of conveyor belt. Optik 2018, 168, 360–369. [Google Scholar] [CrossRef]

- O’Malley, R.; Jones, E.; Glavin, M. Detection of pedestrians in far-infrared automotive night vision using region-growing and clothing distortion compensation. Infrared Phys. Technol. 2010, 53, 439–449. [Google Scholar] [CrossRef]

- Qiao, T.; Duan, Y.; Jin, B. Infrared spectra imaging mechanism and modelling of the transport of hazard belt. Mater. Res. Innov. 2015, 19 (Suppl. 6), 92–97. [Google Scholar] [CrossRef]

- Yang, Y.; Hou, C.; Qiao, T.; Zhang, H.; Ma, L. Longitudinal tear early-warning method for conveyor belt based on infrared vision. Measurement 2019, 147, 106817. [Google Scholar] [CrossRef]

- Yang, R.; Qiao, T.; Pang, Y.; Yang, Y.; Zhang, H.; Yan, G. Infrared spectrum analysis method for detection and early warning of longitudinal tear of mine conveyor belt. Measurement 2020, 165, 107856. [Google Scholar] [CrossRef]

- Qiao, T.; Chen, L.; Pang, Y.; Yan, G.; Miao, C. Integrative binocular vision detection method based on infrared and visible light fusion for conveyor belts longitudinal tear. Measurement 2017, 110, 192–201. [Google Scholar] [CrossRef]

- Yu, B.; Qiao, T.; Zhang, H.; Yan, G. Dual band infrared detection method based on mid-infrared and long infrared vision for conveyor belts longitudinal tear. Measurement 2018, 120, 140–149. [Google Scholar] [CrossRef]

- Hou, C.; Qiao, T.; Zhang, H.; Pang, Y.; Xiong, X. Multispectral visual detection method for conveyor belt longitudinal tear. Measurement 2019, 143, 246–257. [Google Scholar] [CrossRef]

- Chang, S.; Li, Z. Single-reference-based solution for two-point nonuniformity correction of infrared focal plane arrays. Infrared Phys. Technol. 2019, 101, 96–104. [Google Scholar] [CrossRef]

- Xu, C.; Xie, J.; Wu, C.; Gao, L.; Chen, G.; Song, G. Enhancing the Visibility of Delamination during Pulsed Thermography of Carbon Fiber-Reinforced Plates Using a Stacked Autoencoder. Sensors 2018, 18, 2809. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Robert, R.H.; Silva, P.; Mo, Y.L. Cyclic Crack Monitoring of a Reinforced Concrete Column under Simulated Pseudo-Dynamic Loading Using Piezoceramic-Based Smart Aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef] [Green Version]

- Vavilov, V.; Burleigh, D. Infrared Thermography and Thermal Nondestructive Testing; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Xu, C.; Xie, J.; Zhang, W.; Kong, Q.; Chen, G.; Song, G. Experimental Investigation on the Detection of Multiple Surface Cracks Using Vibrothermography with a Low-Power Piezoceramic Actuator. Sensors 2017, 17, 2705. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.; Zhou, N.; Xie, J.; Gong, X.; Chen, G.; Song, G. Investigation on eddy current pulsed thermography to detect hidden cracks on corroded metal surface. NDT E Int. 2016, 84, 27–35. [Google Scholar] [CrossRef]

- Parvasi, S.M.; Xu, C.; Kong, Q.; Song, G. Detection of multiple thin surface cracks using vibrothermography with low-power piezoceramic-based ultrasonic actuator—a numerical study with experimental verification. Smart Mater. Struct. 2016, 25, 55042. [Google Scholar] [CrossRef]

- Wang, F.; Song, G. Bolt early looseness monitoring using modified vibro-acoustic modulation by time-reversal. Mech. Syst. Signal Process. 2019, 130, 349–360. [Google Scholar] [CrossRef]

- Li, N.; Wang, F.; Song, G. New entropy-based vibro-acoustic modulation method for metal fatigue crack detection: An exploratory study. Measurement 2020, 150, 107075. [Google Scholar] [CrossRef]

- González, J.; Mendioroz, A.; Sommier, A.; Batsale, J.; Pradere, C.; Salazar, A. Fast sizing of the width of infinite vertical cracks using constant velocity Flying-Spot thermography. NDT E Int. 2019, 103, 166–172. [Google Scholar] [CrossRef]

- Ishikawa, M.; Ando, M.; Koyama, M.; Nishino, H. Active thermographic inspection of carbon fiber reinforced plastic laminates using laser scanning heating. Compos. Struct. 2019, 209, 515–522. [Google Scholar] [CrossRef]

- James, M.; Nik, R. Remote line scan thermography for the rapid inspection of composite impact damage. Compos. Struct. 2019, 208, 442–453. [Google Scholar] [CrossRef]

- Montinaro, N.; Cerniglia, D.; Pitarresi, G. A Numerical Study on Interlaminar Defects Characterization in Fibre Metal Laminates with Flying Laser Spot Thermography. J. Nondestruct. Eval. 2018, 37, 41. [Google Scholar] [CrossRef]

- Swiderski, W. Non-destructive testing of CFRP by laser excited thermography. Compos. Struct. 2018, 209, 710–714. [Google Scholar] [CrossRef]

- Salazar, A.; Mendioroz, A.; Oleaga, A. Flying spot thermography: Quantitative assessment of thermal diffusivity and crack width. J. Appl. Phys. 2020, 127, 131101. [Google Scholar] [CrossRef] [Green Version]

- Maierhofer, C.; Myrach, P.; Reischel, M.; Steinfurth, H.; Röllig, M.; Kunert, M. Characterizing damage in CFRP structures using flash thermography in reflection and transmission configurations. Compos. Part B Eng. 2014, 57, 35–46. [Google Scholar] [CrossRef]

- Sun, B.; Yuan, N.; Cao, C.; Hardeberg, J.Y. Design of four-band multispectral imaging system with one single-sensor. Futur. Gener. Comput. Syst. 2018, 86, 670–679. [Google Scholar] [CrossRef]

- Soonkyu, H.; An, Y.K.; Hoon, S. Continuous-wave line laser thermography for monitoring of rotating wind turbine blades. Struct. Health Monit. 2018, 18, 1010–1021. [Google Scholar] [CrossRef]

- Schlichting, J.; Maierhofer, C.; Kreutzbruck, M. Crack sizing by laser excited thermography. NDT E Int. 2012, 45, 133–140. [Google Scholar] [CrossRef]

- Du, H.; Chen, X.; Xi, J. An improved background segmentation algorithm for fringe projection profilometry based on Otsu method. Opt. Commun. 2019, 453, 124206. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.-H. Comparative analysis of image binarization methods for crack identification in concrete structures. Cem. Concr. Res. 2017, 99, 53–61. [Google Scholar] [CrossRef]

- Torrente, M.; Beltrametti, M.; Sendra, J. Perturbation of polynomials and applications to the Hough transform. J. Algebra 2017, 486, 328–359. [Google Scholar] [CrossRef]

| True Value/mm | Measured Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lengthobserved (50) | Lengthobserved (100) | Lengthobserved (150) | |||||||

| Lengthactual | Widthactual | Accuracy (%) | Lengthactual | Widthactual | Accuracy (%) | Lengthactual | Widthactual | Accuracy (%) | |

| Width(1) | 50.00 | 1.76 | 62.00 | 100.50 | 1.76 | 61.75 | 150.59 | 1.76 | 61.80 |

| Width(2) | 50.00 | 2.35 | 91.25 | 98.24 | 2.35 | 90.37 | 150.59 | 2.35 | 91.05 |

| Width(3) | 50.00 | 3.53 | 91.17 | 99.41 | 3.53 | 90.87 | 148.82 | 3.53 | 90.77 |

| Width(4) | 50.00 | 4.12 | 98.50 | 100.00 | 3.53 | 94.12 | 150.59 | 3.53 | 93.93 |

| Width(5) | 49.41 | 4.71 | 96.51 | 99.41 | 4.71 | 96.81 | 150.59 | 5.29 | 96.90 |

| Width(6) | 48.82 | 5.88 | 97.82 | 98.82 | 5.88 | 98.41 | 150.00 | 5.88 | 99.00 |

| Width(7) | 50.00 | 6.47 | 96.21 | 99.41 | 6.47 | 95.91 | 150.59 | 6.47 | 96.02 |

| Width(8) | 49.41 | 8.24 | 97.91 | 100.00 | 7.65 | 97.81 | 150.00 | 7.65 | 97.81 |

| Width(9) | 49.41 | 8.82 | 98.41 | 99.41 | 8.82 | 98.71 | 150.00 | 8.82 | 99.00 |

| Width(10) | 49.41 | 10.00 | 99.41 | 99.41 | 10.0 | 99.71 | 150.59 | 9.41 | 96.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, F.; Zhang, S.; Wang, T.; Wu, Q. Mini-Crack Detection of Conveyor Belt Based on Laser Excited Thermography. Appl. Sci. 2021, 11, 10766. https://doi.org/10.3390/app112210766

Zeng F, Zhang S, Wang T, Wu Q. Mini-Crack Detection of Conveyor Belt Based on Laser Excited Thermography. Applied Sciences. 2021; 11(22):10766. https://doi.org/10.3390/app112210766

Chicago/Turabian StyleZeng, Fei, Sheng Zhang, Tao Wang, and Qing Wu. 2021. "Mini-Crack Detection of Conveyor Belt Based on Laser Excited Thermography" Applied Sciences 11, no. 22: 10766. https://doi.org/10.3390/app112210766

APA StyleZeng, F., Zhang, S., Wang, T., & Wu, Q. (2021). Mini-Crack Detection of Conveyor Belt Based on Laser Excited Thermography. Applied Sciences, 11(22), 10766. https://doi.org/10.3390/app112210766