1. Introduction

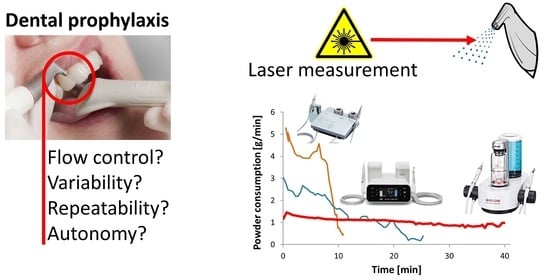

Bacteria play a major role in the development and progression of dental diseases, especially caries, gingivitis, and periodontitis [

1]. Most dental prophylaxes and therapeutic procedures, therefore, aim to—mostly nonspecifically—remove bacteria from the non-shedding surfaces of the mouth by mechanical or chemical means. For professional care, the projection of powders onto tooth surfaces with air-polishing devices has been shown to be very efficient [

2]. In the past, enamel was predominantly cleaned with sodium bicarbonate, which was effective but also quite aggressive in terms of the intrinsic abrasivity of the material. In response, new small-sized resorbable powders have found widespread clinical use, and have expanded the scope of air polishing from supra-gingival biofilm and stain removal to subgingival maintenance, as well as active therapy, because these surfaces require a gentler treatment based on selective removal. This approach has been proven to be very effective while being gentle to the treated substrates [

2,

3,

4]. The enlarged range of applications increases the performance expectations for the device. Indeed, more different types of tissues can now be treated, including exposed dentin and cementum, as well as prosthetic materials like composite resin, ceramics, and titanium. Among these materials, dentin is considered to be very critical because it has a low Vickers hardness (60 HV) [

5]. In the context of increasing life expectancy, roots become increasingly exposed in the oral cavity [

6]. Since exposed cervical roots may be sensitive to caries, erosion, and overall biofilm accumulation and related inflammatory reactions, they represent a delicate predilection site of specific interest. Although there is a need for meticulous cleaning, special care must be taken not to cause iatrogenic damage, including the unnecessary removal of cementum or the opening of tubules [

7], as dentinal hypersensitivity may additionally negatively affect this vulnerable area [

8].

With respect to these factors, air-polishing devices for the application of new small-sized powders are currently considered the most effective and least abrasive or invasive cleaning method for exposed dentine and other surfaces and materials [

9]. However, in order to more selectively clean contaminated areas, biofilm disclosing agents have also been recommended [

10]. These allow for a so-called ‘guided treatment approach’, which has been formalized in a global method called Guided Biofilm Therapy (GBT) [

11]. Nonetheless, the device itself plays a key role in this minimally-invasive approach because the mechanical interactions during application include many important aspects, such as the right choice of powder and its delivery quantity. For example, the more powder that is delivered in a given time interval, the more efficient the cleaning becomes. However, more abrasion can also occur on the surface, not only based on the amount but also on the powder’s characteristics [

12]. Therefore, mastering powder consumption has come into focus for material science, and is necessary to achieve the best and least invasive prophylactic treatment.

The development of a better understanding of the exact powder consumption for a given treatment is, therefore, important for any scientific in vitro or in vivo research using air-polishing systems. Ultimately, it is the effectively-used powder amount that determines the amount of abraded material and surface effects [

12]. The ability to determine a device’s powder consumption is also important for the correct interpretation of clinical outcomes.

Measuring powder consumption is a significant challenge, but it has not been considered in many studies yet, despite the important and early work of Petersilka et al. [

13], who characterized different air-polishing systems in terms of their powder consumption. The sampling rate in this study was two minutes, which provided information about general behavior, but no insights into shorter treatment cycles were provided. More recently, another study [

14] used powder mass data recovered from a weight scale in order to analyze the results. This study reported the use of short intervals, i.e., 5 s periods. However, due to continuous handpiece movement, the time spent during the prophylactic treatment is usually less than one second in a given spray area [

15]. Therefore, the question remains: what happens during very short application periods, and what is the actual amount of powder delivered? Only with an analysis of the working mode during a few seconds of treatment can the entire procedure be understood and improved further.

The aim of this study was, therefore, to build and test a new measurement instrument that allows for the measurement of the powder consumption of different air-polishing devices over a very short time period. The applied method was based on light dispersion measurements. The hypothesis was that powder delivery is constant during the very short time period under analysis, as well as for the longer periods already measured in the literature [

13].

2. Materials and Methods

2.1. Powder Consumption Measurement

The measurement method in this study was based on light dispersion, which occurs when a powder passes through a light beam (

Figure 1). Every particle crossing the incoming light beam will disperse light, and the intensity of the dispersed light is proportional to the number of particles in this beam. As bigger particles disperse more light than smaller ones, it was determined that the intensity of light is more directly proportional to the volume of the particles, rather than the number of particles. As a consequence, the measurement relies on the relationship of the light intensity with the amount of powder [

16]. This relationship was experimentally calibrated with the total powder consumption for every test.

The laser source used in this study was a 532 nm laser with a 30° line generator that created a light sheet sufficient to illuminate all of the powder (PGL-V-H-532-200mW, CNI Lasers, Changchun, China). The powder was sprayed without water in order to avoid light dispersion from the water itself. Indeed, the water was generally added at the nozzle end only, and so did not interact with the powder delivery of the device. In order to avoid dust deposition on the optical part, the powder was sprayed into a hollow cylinder 32 mm in diameter and 110 mm in length, with a side opening for the laser to cross the cylinder. At the end of this cylinder, an air evacuator was added to direct all of the powder towards the tube exit. The light measurement was obtained with a spectrometer (Avantes AvaSpec-UL2048CL-EVO-RS, s/n 1904311U1, Avantes, Apeldoorn, The Netherlands). This allowed for a specific measurement of the light’s integral signal between 530 and 535 nm. The measurement time varied according to the different conditions, and ranged between 0.1 and 5 milliseconds. These measurements were then averaged over the output measurement time, which was set to 0.1 s. The spectrometer measured the light emitted in the hollow cylinder through the use of an optical fiber fixed perpendicular to the laser beam. The total quantity of powder passing through the system was recorded by weighing the powder chamber of the device before and after the test using a precision scale (Mettler Toledo XP10002S, Greifensee, Switzerland).

This method was based on the proportionality of the light intensity (integral to the light intensity over time) with the quantity of powder. The calibration factor was determined via the integration of the total light measured divided by the total amount of powder used during the test. Therefore, the instantaneous powder consumption was simply given as the multiplication of the instantaneous light integral with the calibration factor. Using this method, a powder flowrate with a resolution of 0.1 s or less could be easily obtained.

2.2. Investigated Devices

In this investigation, different device types were evaluated, i.e., Table-top and Handy devices. The Table-top devices were measured in the sub-gingival mode (low pressure and gentle powder). These conditions were the most representative conditions for an advanced minimally-invasive treatment procedure. Three Table-top devices were used. Table-top E1 was an AIRFLOW® PROPHYLAXIS MASTER device (ref: FT-229, Electro Medical Systems SA, Nyon, Switzerland), operated at a pressure setting of 3/10 using AIRFLOW® PLUS powder (Erythritol, ref: DV-082, Electro Medical Systems SA, Nyon, Switzerland). This represents the recommended setting when exposed dentine is involved in the treatment. Table-top N2 was a VARIOS COMBI PRO device (ref: Y1002843, NSK-Nakanishi Inc, Kanuma Tochigi, Japan) used with the Perio kit (ref: Y1003042, NSK-Nakanishi Inc, Kanuma Tochigi, Japan), operated at a setting of 3/10 using PERIO MATE powder (Glycine, ref: Y900938, NSK-Nakanishi Inc, Kanuma Tochigi, Japan). Table-top M3 was a COMBI TOUCH device (ref: 04000103, Mectron s.p.a, Carasco, Italy) using the PERIO powder chamber and MECTRON SENSITIVE powder (Glycine, Mectron s.p.a, Carasco, Italy). This device has no pressure setting options.

Three Handy devices were also measured in a sub-gingival compatible mode (with a 3-bar dental chair pressure setting and gentle powder). Handy E1 was an AIRFLOW

® HANDY 3.0 PERIO device (ref: FT-221, Electro Medical Systems SA, Nyon, Switzerland) using AIRFLOW

® PLUS powder (Erythritol, DV-082, Electro Medical Systems SA, Nyon, Switzerland). Handy N2 was a PERIO MATE (ref: Y1002655, NSK-Nakanishi Inc, Kanuma Tochigi, Japan) operated using PERIO MATE powder (Glycine, ref: Y900938, NSK-Nakanishi Inc, Kanuma Tochigi, Japan). Handy M3 was a STARJET (ref: 05150075007, Mectron s.p.a, Carasco, Italy) using MECTRON SENSITIVE powder (Glycine, Mectron s.p.a, Carasco, Italy). In these tests, the handy devices were fixed perpendicularly to the ground, with the handpiece axis directed 30° down. A summary of all of the devices is provided in

Table 1.

All of the Table-top devices were operated with a regular pedal press of 25 s and a 5 s pedal release. The Handy devices, which are devoted to quick treatments, were operated with a regular pedal press of 12 s and a 6 s pedal release. This time setup was chosen to increase the number of pedal presses, as the test duration was very short, depending on the device.

2.3. Data Analysis

The raw data were obtained with a powder consumption resolution of 0.1 s. The results were then analyzed in three ways: (1) the precise powder consumption was measured during a pedal press; (2) the mean powder consumption value was calculated for every pedal press—each pedal press was combined, removing the release time, in order to determine the general behavior of the device during effective functioning; and (3) the device autonomy was calculated for every measurement, with a cut-off value of 0.5 g/min.

For the statistical analysis, powder consumption tests were repeated 10 times for each condition (see the Table-top example in

Figure 2). These repetitions were randomly distributed over a period of 3 weeks. For each powder consumption measurement, specific steps were followed:

The mean value for each pedal press, and the standard deviation (1 − σ), were calculated;

The overall mean powder consumption of each measurement, with the standard deviation, was calculated;

We considered the mean powder consumption of ten repetitions, with the standard deviation;

We reported the mean autonomy of the ten repetitions, with the standard deviation.

The differences in the results were analyzed using a Mann–Whitney test for the mean value compared to the device E1 in a given category as a reference, and an F-test to compare the variance based on the same reference. The level of significance was set at p < 0.05.

3. Results

The complete powder flowrate over the entire powder chamber was easily obtained for all of the test devices (

Figure 3).

The Table-top devices had longer autonomy due to their larger powder chambers and more regular flow rates than the handy devices. Table-top E1 had the most regular powder consumption, offering the slowest decreasing slope, and a level allowing the longest autonomy, thanks to its smaller mean powder consumption and larger powder reservoir. All of the Handies had a powder consumption that was strongly dependent on the usage time. Among the Handies, only Handy E1 presented a longer autonomy with a slower decreasing slope.

The overall statistical results in terms of the autonomy and mean powder consumption of the ten repetitions are presented in

Table 2.

For each category, the E1 devices had the longest autonomy. Table-top E1 had the lowest powder consumption that was statistically different compared to the other devices. Both Handy E1 and M3 had statistically similar mean powder consumptions.

The applied method allowed for a closer analysis of the powder consumption curve. It was possible to observe the details of the powder consumption during a single pedal press. For the Table-tops, this measurement was performed after 7 min of work, in order to ensure a stable device performance (

Figure 4).

For the Handy devices, the same zoom level for one pedal press was chosen after the sixth pedal press of the sixth repetition, in order to ensure stable device performance (

Figure 5).

Notably, because the Handy devices did not have regular powder flow rates, the mean value of one pedal press (

Figure 5) could be very different from the overall mean (

Table 2). Therefore, one defined pedal press was chosen arbitrarily. The most important function of this pedal press was to understand more precisely the working behavior within the handy powder chamber.

Different overall working phases were observed:

Between 0 and 0.5 s, there was a powder burst. The intensity of this burst depended on the device’s construction. For example, Table-top M3 had a very high powder burst (>8 g/min) at its start-up, whereas Table-top E1 presented only a very small burst (<2 g/min). This burst has two potential drawbacks: first, it can lead to powder overconsumption if the powder consumption is too high; second, this overconsumption can create a powder residue on the surface, which can reduce the cleaning action over the following seconds of treatment. It was estimated that this burst comes from the residual powder inside the device’s tubing.

Between 0.5 and 5 s, the powder chamber started working, and the powder consumption reached a steady state. This powder consumption stabilization phase was shorter for the Handy than for the Table-top devices. For the Table-top devices, the step took approximately 2 s for Table-top E1 and Table-top M3, whereas it took approximately 5 s for Table-top N2. For Table-top E1 and Table-top M3, this transient phase represented only a powder consumption increase phase, whereas for Table-top N2, the transient phase was a high overflow phase. The shorter stabilization period for the Handy devices was estimated to be due to their shorter channel lines between the powder chamber and the nozzle. These variations suggest that if a user presses the pedal often during only about a 5 s period, he or she will consume much more powder with Table-top N2, and less powder with Table-top E1 and Table-top M3.

After 5 s, for all of the devices, steady-state behavior was established, leading to constant and regular mean powder consumption. This was only true for Table-top E1, Table-top M3, and Handy E1, whereas all of the other devices showed a decrease in mean powder consumption, with many brief high powder-consumption peaks.

After the pedal’s release, the powder delivery quickly (<1 s) stopped for the Table-tops, whereas it continued for about 3 s for the Handy devices.

The mean powder consumption values for this single pedal press period and its standard deviations are given in

Table 3.

The E1 devices had the most stable powder flowrate with the least deviation during a single pedal press.

4. Discussion

This study aimed to precisely determine the powder consumption of dental air-polishing systems in their standard working mode.

As stipulated, the precise measurement of powder consumption enables air polisher quality assessment. Considering a fraction of a second, slight variations are normal for most types of powder chambers, but large powder consumption variations can have detrimental effects on prophylactic treatments, both for the user and for the patient’s dental tissue. Unpredictable device behaviors causing powder consumption fluctuations lead to variability in efficiency. For dental tissue (e.g., dentine), consumption peaks lead to abrupt and uncontrolled abrasiveness increases [

12]. This becomes detrimental when critical regions, such as exposed dentine, are treated. In fact, a user usually adapts his hand movement according to the cleaning speed. Furthermore, in order to avoid overtreatment, the usage of a disclosing agent is also a tool to better guide his movement. Unfortunately, here, the use of a disclosing agent [

11] to avoid overtreatment is of no help, as the variability of the flowrate occurs over a very short period of time (<0.1 s), which is shorter than any possible user’s reaction time.

These variations in powder consumption also have two additional effects. First, it generates different dust amounts during the treatment time, which also makes it more difficult to remove properly. Second, the powder overconsumption is also powder wastage, which increases the treatment cost. Therefore, the most optimized device is the device with the most constant powder consumption during one pedal press.

The use of six different devices highlighted the impact of different technologies on general powder behavior. For example, whereas Table-top E1 used a ‘venturi’ powder chamber principle [

13], in which the powder is taken out of the chamber from the bottom of the chamber, the other Table-tops (i.e., N2 and M3) and the Handies used a standard ‘swirling’ generation with a picking-up mechanism above the powder level. This latter mechanism is less predictable than the first. This difference is underlined by the variations observed within the ten repetitions, which were significantly higher for the latter two Table-tops or the Handies. N2 and M3, as well as the Handies, were found to be powder-volume dependent, as we observed a decrease in powder consumption as a function of time. This was due to the decreasing powder volume in the powder chamber.

With regard to the stability of the powder delivery, it can be concluded that Table-top E1, the most predictable device, ensures the highest repeatability between two patients with minimal invasiveness. It has also the least instantaneous powder consumption variability, which also makes it the easiest to use, because the required treatment movement and dust removal are the most predictable. It is, consequently, more ergonomic than the two other Table-tops or Handies.

Considering the mean powder consumption of the Table-top, it should be highlighted that one device had an extremely high mean consumption (Table-top M3). This elevated consumption was mainly due to two factors:

This device does not have any power regulation settings; it always works at maximum consumption.

This device uses a ‘swirling’ picking-up mechanism, so the powder consumption cannot be regulated.

Consequently, this device will likely over-consume powder, as the user is not able to compensate for the faster powder delivery with this device by sufficiently speeding up the treatment. After nearly nine minutes of treatment with this device, the powder consumption reduced drastically; this is barely enough time to treat the full mouth of one patient. Therefore, Table-top M3 needs to be refilled after each treatment. In addition, the device likely generates more dust, which is more difficult to master with a high-speed suction unit.

The case of Table-top N2 was slightly different. The powder picking-up mechanism of this device used the powder–air interface and the empty volume above the powder limit. As the empty powder volume increased with the powder consumption, it was also observed that the powder consumption decreased accordingly [

13]. During the emptying of the powder chamber, the user will, therefore, experience a change in the cleaning capacity at a factor higher than two, if we assume that the cleaning capacity is proportional to the consumed powder amount [

12]. Supposing that the device could last for two full mouth treatments of 10 min each, both treatments would be very different in terms of functionality.

For Table-top E1, the results were completely different. The reduction in the powder consumption over time was quite low (max 20%), such that—under intensive usage—the user has to refill the powder chamber after four full-mouth treatments (assuming a 10 min treatment for a full-mouth), which represents nearly half a day of work. This powder consumption consistency was mainly due to the working mechanism of the powder chamber, which picks up the powder from the chamber bottom. As a result, the powder volume does not impact the resulting powder consumption. These findings were corroborated by the results of the study of Petersilka et al. [

13].

The working behavior of the Handy devices is far less controlled than that of the Table-tops:

The autonomy of the Handy devices is much shorter;

The powder consumption is less controlled;

They have a lack of reactivity due to additional powder delivery after the pedal is released.

It should be highlighted that, during a longer powder delivery after the pedal’s release, the device is not more active. Therefore, this consumed powder is pure powder waste for the system. Considering a 12 s pedal press, a 3 s stop–delay represents about 25% overconsumption due only to this working mode. Therefore, the Handy devices consume more powder than the Table-top devices, consequently entailing a greater running cost.

Clinical Considerations

The first clinical application that may benefit from these precise flowrate evaluations is the cleaning of sensitive areas like exposed dentine or soft composite. In these cases, even if the powder is quite soft and gentle and the least damaging method is used, overtreatment should be avoided in order to be as minimally invasive as possible. Since the surface-cleaning effect and further overtreatment effects depend on the amount of abrasive material sprayed on the surface [

12], it becomes very important to minimize the powder consumption variability as much as possible.

Figure 4 shows that Table-top N2, for example, has powder consumption peaks ranging from 1 g/min to 3 g/min over a period of less than 1 s (

Figure 4, with a 10 s working time). This instantaneous variability may lead to an instantaneous abrasivity increase by as much as a factor of three. The user would never be able to adapt his or her movements to this sudden abrasivity increase, which would most likely result in overtreatment. Thus, the most reliable device with the most consistent powder consumption is Table-top E1, which was the most minimally invasive device tested in this study. The same considerations apply for the cleaning of implants with powders. The implant surfaces to be cleaned could be damaged by powder consumption peaks, even if those peaks are only of a short duration.

The second clinical implication of these observations is the powder usage in deep subgingival pockets. Most manufacturer’s recommendations are currently set at five seconds, which corresponds to the starting phase. The above-mentioned considerations also have a strong clinical impact. During, for example, the first important powder burst of Table-top M3, the pocket could be overlaid with powder before enough rinsing water is used to remove that powder. This powder layer could then be responsible for less efficient cleaning, reducing the clinical effectiveness of the method. This could also occur through powder overuse with Table-top N2 during the transient phase. Only Table-top E1 showed regular behavior. Nevertheless, with this device, it could be beneficial to increase the application time by 2 s in order to obtain a full 5 s of efficient cleaning. From this observation, it is clear that one device is not equal to another, and that the clinical data obtained with one device (e.g., Table-top E1) cannot be transferred to another device without conducting the type of analysis performed here.