Effects of Driving Frequency and Voltage on the Performances of Vibrating Mesh Nebulizers

Abstract

1. Introduction

2. Materials and Methods

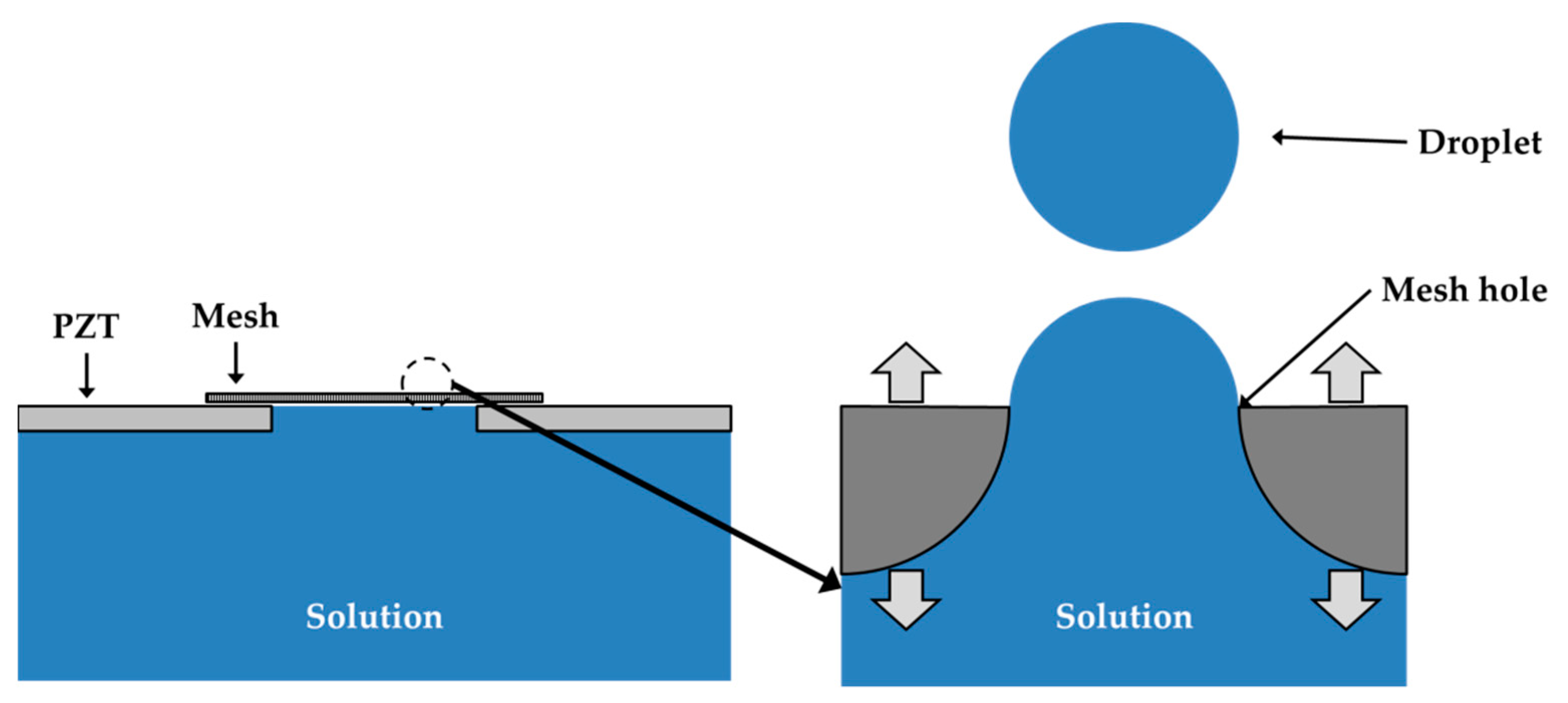

2.1. PZT for Nebulizer

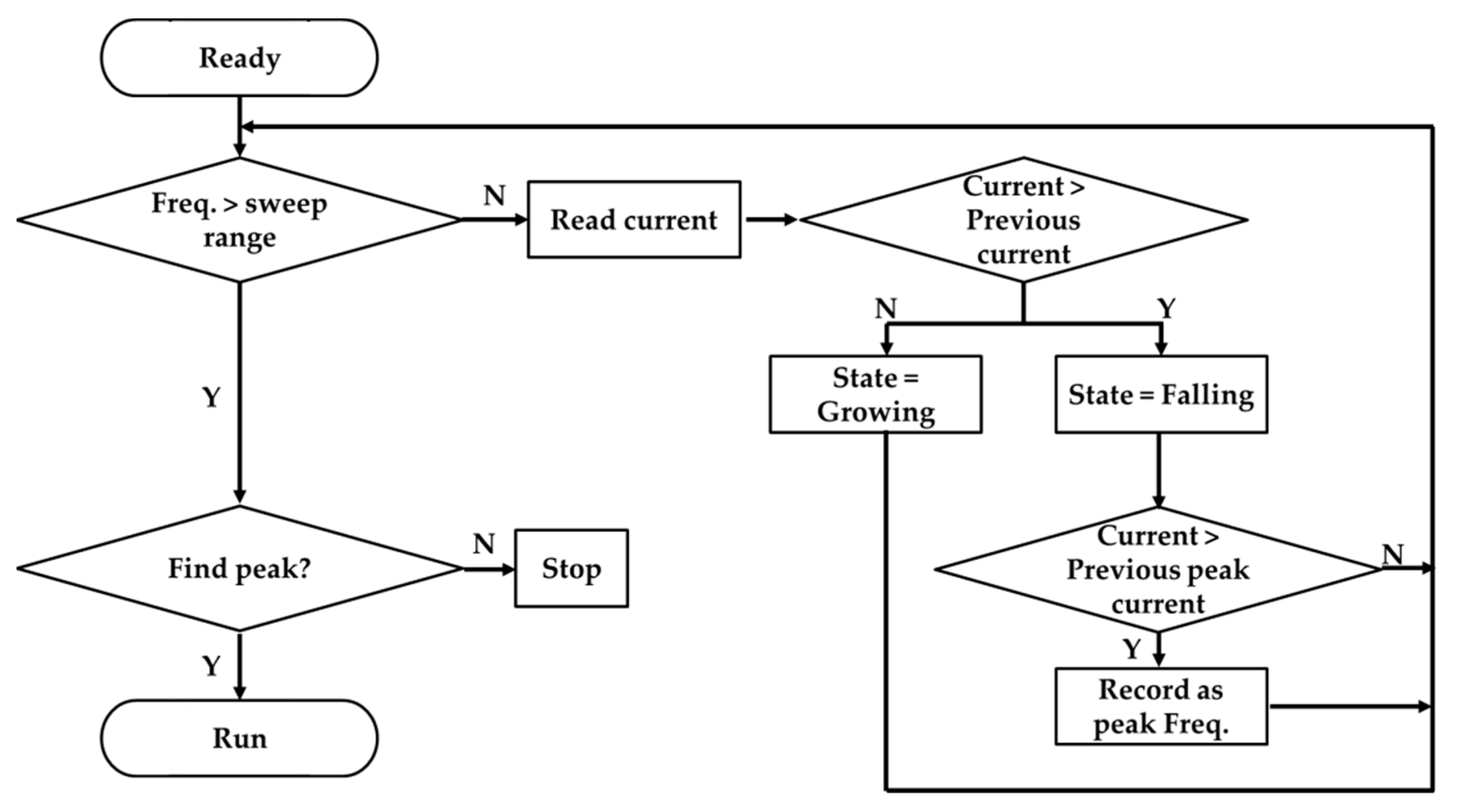

2.2. PZT Driving Circuit

2.3. Impedance Matching (IM)

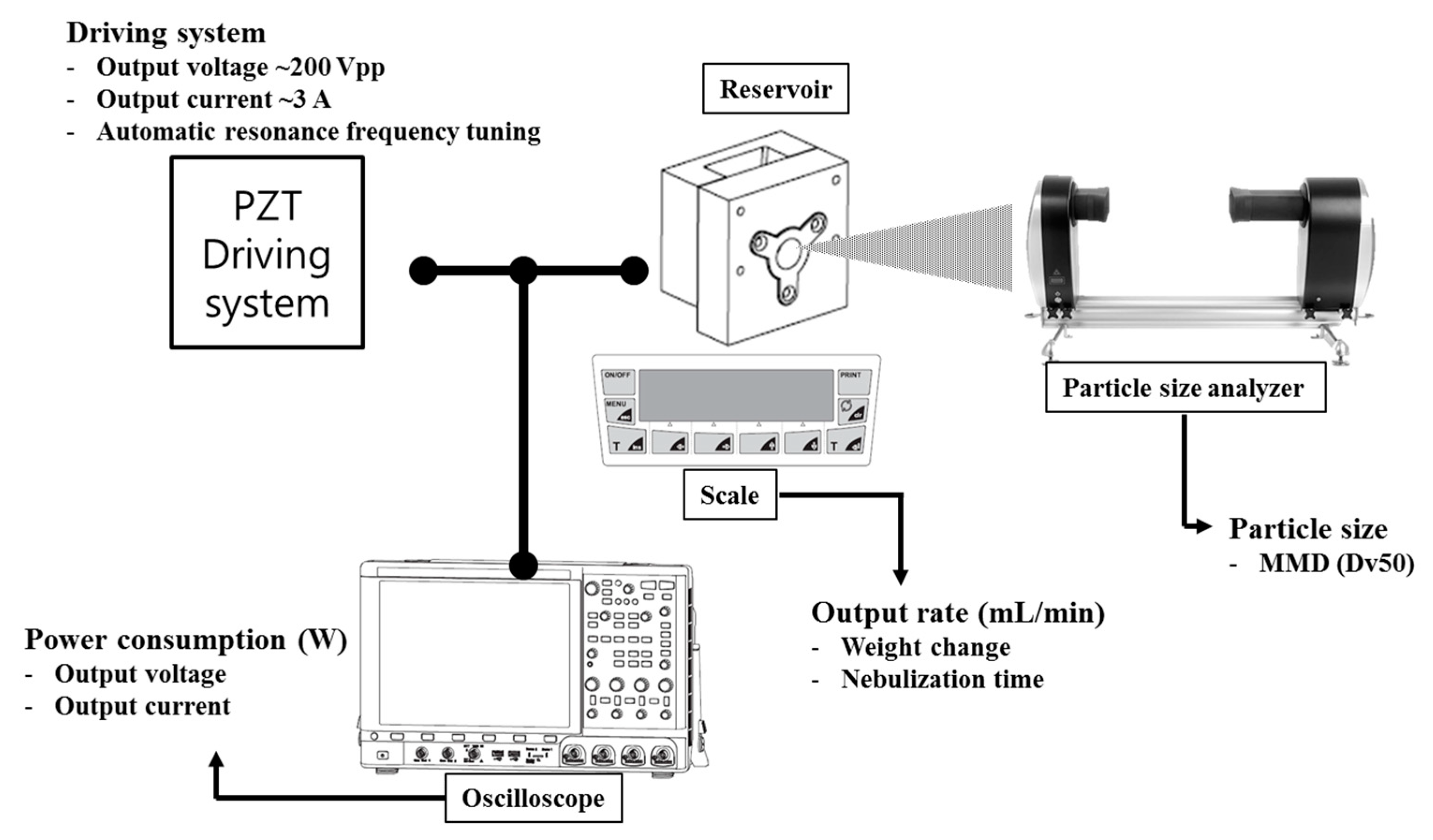

2.4. Output Rate

2.5. Power Consumption

2.6. Particle Size

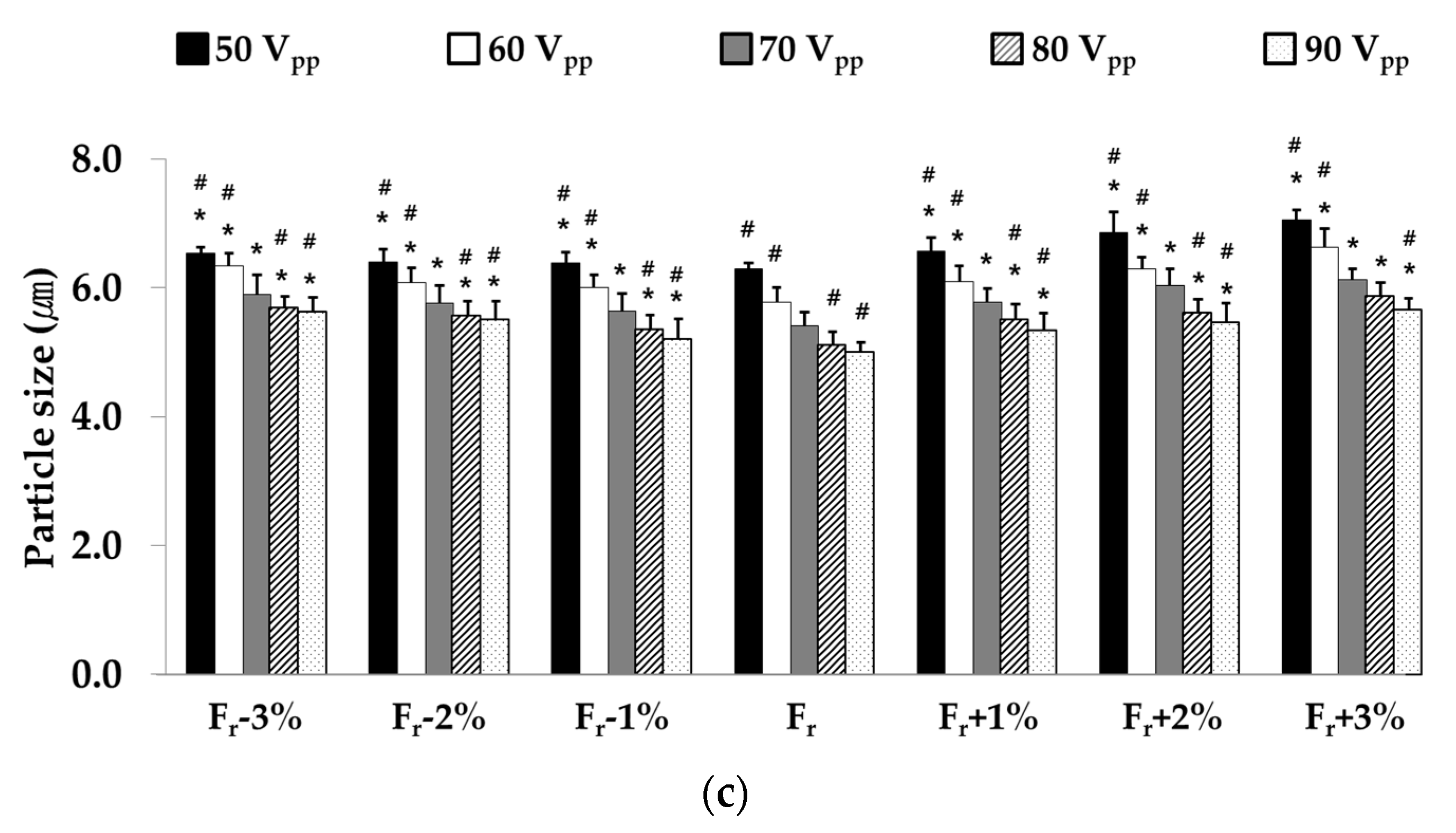

2.7. Nebulization Characteristics by Driving Frequency and Voltage

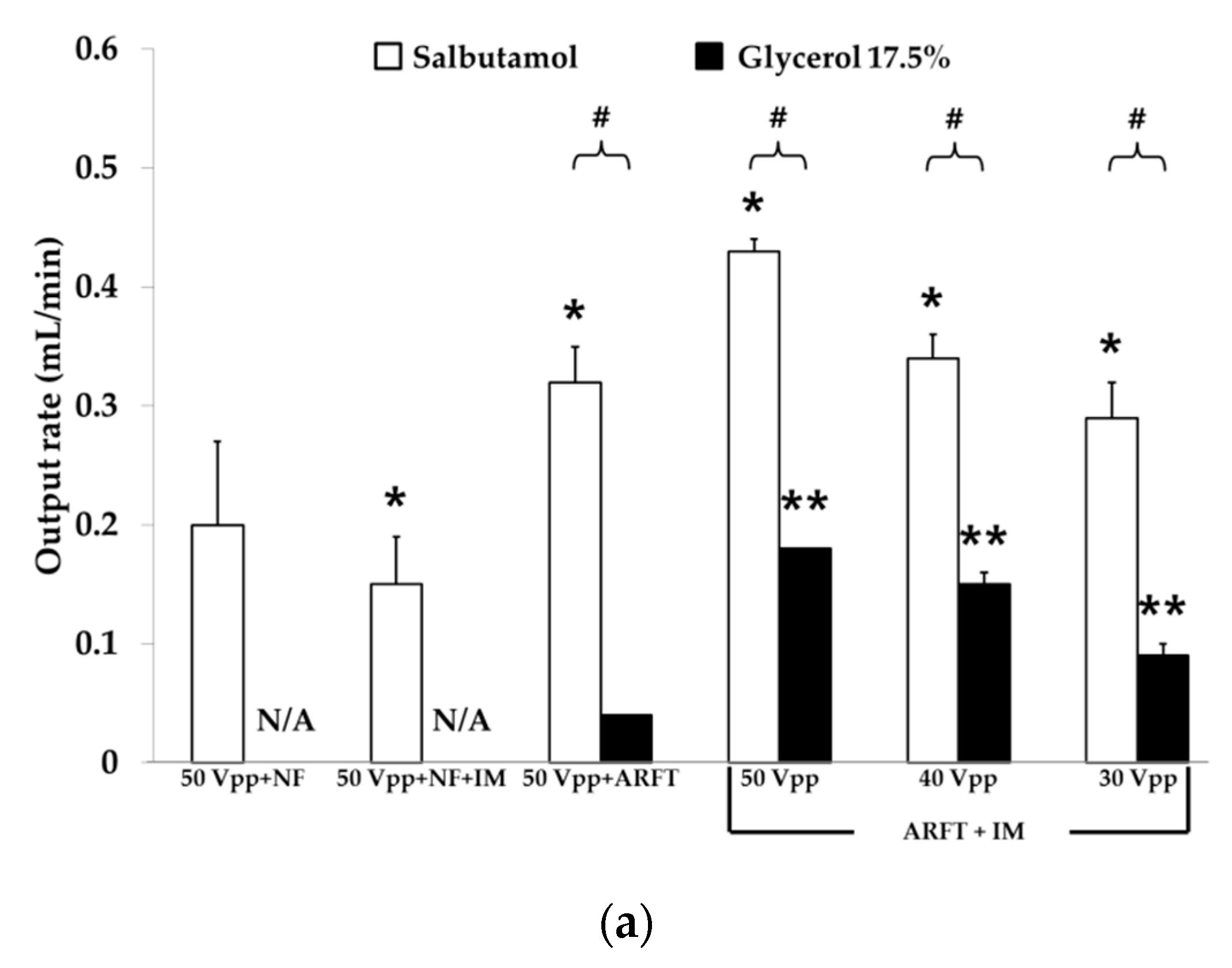

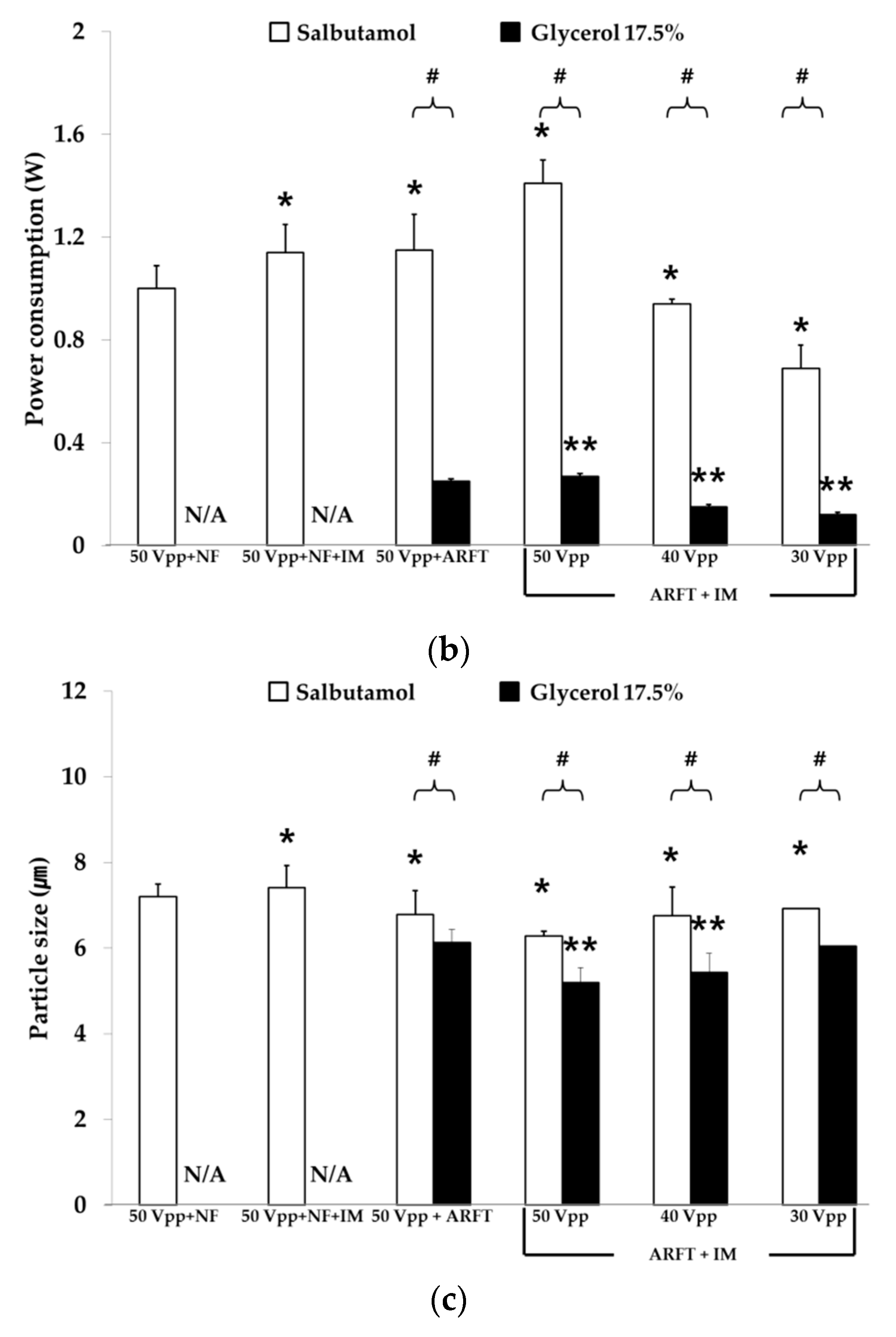

2.8. Nebulization Characteristics after ARFT and IM

2.9. Temperature Profile during Nebulization

2.10. Statistical Analysis

3. Results

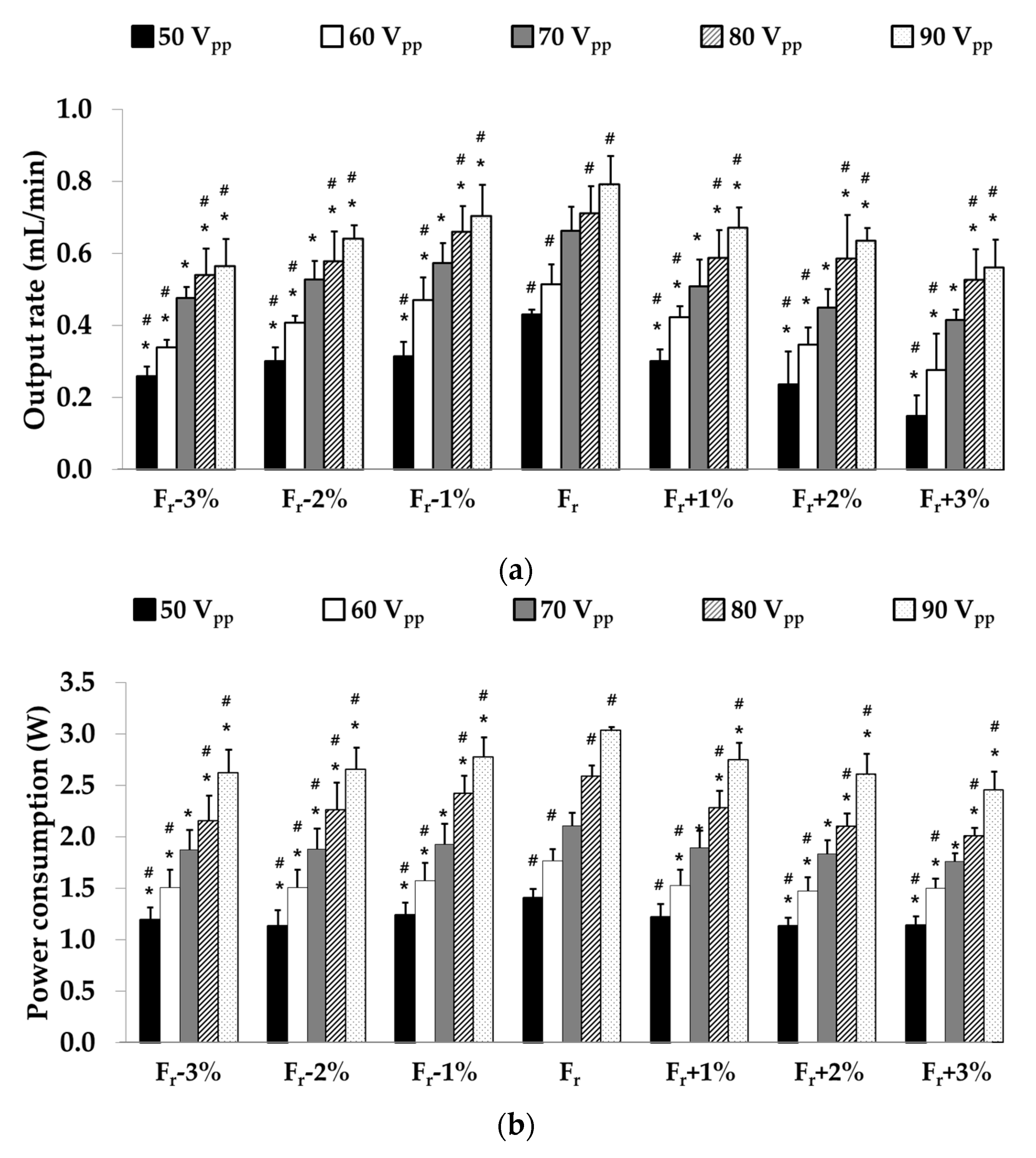

3.1. Nebulization Characteristics by Driving Frequency and Voltage

3.2. Resonance Frequency Changes by Impedance Matching

3.3. Dependence of Nebulization Characteristics on ARFT and IM

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ari, A. Jet, ultrasonic, and mesh nebulizers: An evaluation of nebulizers for better clinical outcomes. Eurasian J. Pulmonol. 2014, 16, 1–7. [Google Scholar] [CrossRef]

- Newman, S.P.; Clark, S.W. Therapeutic aerosols 1-physical and practical considerations. Thorax 1983, 38, 881–886. [Google Scholar] [CrossRef] [PubMed]

- Pitance, L.; Vecellio, L.; Leal, T.; Reychler, G.; Reychler, H.; Liistro, G. Delivery efficacy of a vibrating mesh nebulizer and a jet nebulizer under different configurations. J. Aerosol. Med. Pulm. Drug Deliv. 2010, 23, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Dolovich, M.B.; Dhand, R. Aerosol drug delivery: Developments in device design and clinical use. Lancet 2011, 377, 1032–1045. [Google Scholar] [CrossRef]

- Ghazanfari, T.; Elhissi, A.M.A.; Ding, Z.; Taylor, K.M.G. The influence of fluid physicochemical properties on vibrating-mesh nebulization. Int. J. Pharm. 2007, 339, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Hertel, S.P. Pulmonary Delivery of Pharmaceutical Proteins by Means of Vibrating Mesh Nebulization. Ph.D. Thesis, Ludwig Maximillian University of Munich, Munich, Germany, 7 July 2014. [Google Scholar]

- Choi, K.H.; Moon, S.H.; Park, S.K.; Cho, G.; Nam, K.C.; Park, B.J. Fabrication and Characterization of Medical Mesh-Nebulizer for Aerosol Drug Delivery. Appl. Sci. 2018, 8, 604. [Google Scholar] [CrossRef]

- Shen, S.C. A new cymbal-shaped high power microactuator for nebulizer application. Microelectron. Eng. 2010, 87, 89–97. [Google Scholar] [CrossRef]

- Olszewski, O.Z.; MacLoughlin, R.; Blake, A.; O’Neill, M.; Mathewsona, A.; Jacksona, N. A silicon-based MEMS vibrating mesh nebulizer for inhaled drug delivery. Procedia Eng. 2016, 168, 1521–1524. [Google Scholar] [CrossRef]

- Huang, J.; Chen, C. Microelectroforming of a nickel nozzle plate featured with anti-stiction for a piezoelectric atomizer. In Proceedings of the 8th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Suzhou, China, 7–10 April 2013; pp. 490–493. [Google Scholar]

- Lin, C.; Meng, H.; Fu, C. An ultrasonic aerosol therapy nebulizer using electroformed palladium–nickel alloy nozzle plates. Sens. Actuator A Phys. 2011, 169, 187–193. [Google Scholar] [CrossRef]

- Shen, S.; Wang, Y.; Chen, Y. Design and fabrication of medical micro-nebulizer. Sens. Actuator A Phys. 2008, 144, 135–143. [Google Scholar] [CrossRef]

- Zhang, G.; David, A.; Wiedmann, T.S. Performance of the vibrating membrane aerosol generation device: Aeroneb micropump nebulizer™. J. Aerosol. Med. 2007, 20, 408–416. [Google Scholar] [CrossRef] [PubMed]

- Yan, Q.; Wu, C.; Zhang, J. Effect of the dynamic cone angle on the atomization performance of a piezoceramic vibrating mesh atomizer. Appl. Sci. 2019, 9, 1836. [Google Scholar] [CrossRef]

- Kuo, Y.; Chan, W.; Lin, C.; Huang, S.; Chen, C. Characterization of Vibrating Mesh Aerosol Generators. Aerosol. Air Qual. Res. 2019, 19, 1678–1687. [Google Scholar] [CrossRef]

- Yan, Q.; Sun, W.; Zhang, J. Study on the Influencing Factors of the Atomization Rate in a Piezoceramic Vibrating Mesh Atomizer. Appl. Sci. 2020, 10, 2422. [Google Scholar] [CrossRef]

- Huynh, T.; Kim, J.T. Quantification of temperature effect on impedance monitoring via PZT interface for prestressed tendon anchorage. Smart Mater. Struct. 2017, 26, 1–19. [Google Scholar] [CrossRef]

- Wang, G.; Tan, C.; Li, F. A contact resonance viscometer based on the electromechanical impedance of a piezoelectric cantilever. Sens. Actuator A Phys. 2017, 267, 401–408. [Google Scholar] [CrossRef]

- Shih, W.Y.; Li, X.; Gu, H.; Shih, W.; Aksay, I.A. Simultaneous liquid viscosity and density determination with piezoelectric unimorph cantilevers. J. Appl. Phys. 2001, 89, 1497–1505. [Google Scholar] [CrossRef]

- Boontaklang, S.; Chompoo-Inwai, C. Automatic Resonance-Frequency Tuning and Tracking Technique for a 1MHz Ultrasonic-Piezoelectric-Transducer Driving Circuit in Medical Therapeutic Applications Using dsPIC Microcontroller and PLL Techniques. Int. J. Intell. Eng. Syst. 2019, 12, 14–24. [Google Scholar] [CrossRef]

- Hawkins, B.; Feng, Z. AN2265: Vibrating Mesh Nebulizer Reference Design. Available online: http://ww1.microchip.com/downloads/en/AppNotes/00002265B.pdf (accessed on 11 December 2020).

- Rathod, V.T. A Review of Electric Impedance Matching Techniques for Piezoelectric Sensors, Actuators and Transducers. Electronics 2019, 8, 169. [Google Scholar] [CrossRef]

- Garcia-Rodriguez, M.; Garcia-Alvarez, J.; Yanez, Y.; Garcia-Hernandez, M.J.; Salazar, J.; Turo, A.; Chavez, J.A. Low cost matching network for ultrasonic transducers. Phys. Procedia 2010, 3, 1025–1031. [Google Scholar] [CrossRef]

- Yang, K.C. Use Resonance with a High-Voltage Piezo Driver. Available online: https://www.electronicdesign.com/power-management/article/21808584/use-resonance-with-a-highvhighvo-piezo-driver (accessed on 11 December 2020).

- Rodal, J.J.A. Mach effect propulsion, an exact electroelasticity solution. In Proceedings of the Estes Park Advanced Propulsion Workshop, Mojave, NY, USA, 1–3 November 2017; pp. 127–136. [Google Scholar]

- Tandon, R.; McPeck, M.; Smaldone, G.C. Measuring Nebulizer Output Aerosol Production vs Gravimetric Analysis. Chest 1997, 111, 1361–1365. [Google Scholar] [CrossRef] [PubMed]

- Chang, K.H.; Moon, S.; Oh, J.Y.; Yoon, Y.; Gu, N.; Lim, C.; Park, B.J.; Nam, K.C. Comparison of Salbutamol Delivery Efficiency for Jet versus Mesh Nebulizer Using Mice. Pharmaceutics 2019, 11, 192. [Google Scholar] [CrossRef]

- Chang, K.H.; Moon, S.; Yoo, S.K.; Park, B.J.; Nam, K.C. Aerosol Delivery of Dornase Alfa Generated by Jet and Mesh Nebulizers. Pharmaceutics 2020, 12, 721. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Hu, J.; Zhan, S.; Zhang, R.; Tan, W. Effects of Temperature and Humidity on Laser Diffraction Measurements to Jet Nebulizer and Comparison with NGI. AAPS PharmSciTech 2016, 17, 380–388. [Google Scholar] [CrossRef] [PubMed]

- ISO 27427:2013. Anaesthetic and Respiratory Equipment—Nebulizing Systems and Components; International Organization for Standardization ISO Central Secretariat: Geneva, Switzerland, 2013. [Google Scholar]

- Kwong, W.T.; Ho, S.L.; Coates, A.L. Comparison of nebulized particle size distribution with Malvern laser diffraction analyzer versus Andersen cascade impactor and low-flow Marple personal cascade impactor. J. Aerosol. Med. 2000, 13, 303–314. [Google Scholar] [CrossRef]

- Cipollar, D.C.; Clark, A.R.; Chan, H.-K.; Gonda, I.; Shire, S.J. Assessment of aerosol delivery systems for recombinant human deoxyribonuclease. STP Pharma Sci. 1994, 4, 50–62. [Google Scholar]

- Zeles-Hahn, M.; Anchordoquy, T.J.; Lengsfeld, C.S. Observations on the impact of aerosolization on macromolecular therapeutics. In Proceedings of the European Conference on Liquid Atomization and Spray-Systems, Como lake, Italy, 8–10 September 2008; pp. 8–13. [Google Scholar]

| Voltage (Vpp) | Frequency | Impedance Matching |

|---|---|---|

| 50~90 (10 Vpp interval) | Resonance frequency (Fr) | Applied |

| Fr ± 3% (1% interval) |

| Experimental Condition | Purpose |

|---|---|

| 50 Vpp + Nominal resonance frequency (NF) | Control |

| 50 Vpp + NF + Impedance matching (IM) | IM effect |

| 50 Vpp + Automatic resonance frequency tuning (ARFT) | ARFT effect |

| 50 Vpp + ARFT + IM | ARFT + IM effect |

| 40 Vpp + ARFT + IM | ARFT + IM + driving voltage effect |

| 30 Vpp + ARFT + IM | ARFT + IM + driving voltage effect |

| PZT Sample | Resonance Frequency (kHz) | |

|---|---|---|

| Before Impedance Matching | After Impedance Matching | |

| #1 | 144.80 ± 0.49 | 141.30 ± 0.36 |

| #2 | 148.32 ± 0.26 | 144.10 ± 0.15 |

| #3 | 153.47 ± 0.01 | 149.00 ± 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, S.-H.; Chang, K.H.; Park, H.M.; Park, B.J.; Yoo, S.K.; Nam, K.C. Effects of Driving Frequency and Voltage on the Performances of Vibrating Mesh Nebulizers. Appl. Sci. 2021, 11, 1296. https://doi.org/10.3390/app11031296

Moon S-H, Chang KH, Park HM, Park BJ, Yoo SK, Nam KC. Effects of Driving Frequency and Voltage on the Performances of Vibrating Mesh Nebulizers. Applied Sciences. 2021; 11(3):1296. https://doi.org/10.3390/app11031296

Chicago/Turabian StyleMoon, Sang-Hyub, Kyung Hwa Chang, Hyun Mok Park, Bong Joo Park, Sun Kook Yoo, and Ki Chang Nam. 2021. "Effects of Driving Frequency and Voltage on the Performances of Vibrating Mesh Nebulizers" Applied Sciences 11, no. 3: 1296. https://doi.org/10.3390/app11031296

APA StyleMoon, S.-H., Chang, K. H., Park, H. M., Park, B. J., Yoo, S. K., & Nam, K. C. (2021). Effects of Driving Frequency and Voltage on the Performances of Vibrating Mesh Nebulizers. Applied Sciences, 11(3), 1296. https://doi.org/10.3390/app11031296